Patents

Literature

62results about "Gasifier electrodes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

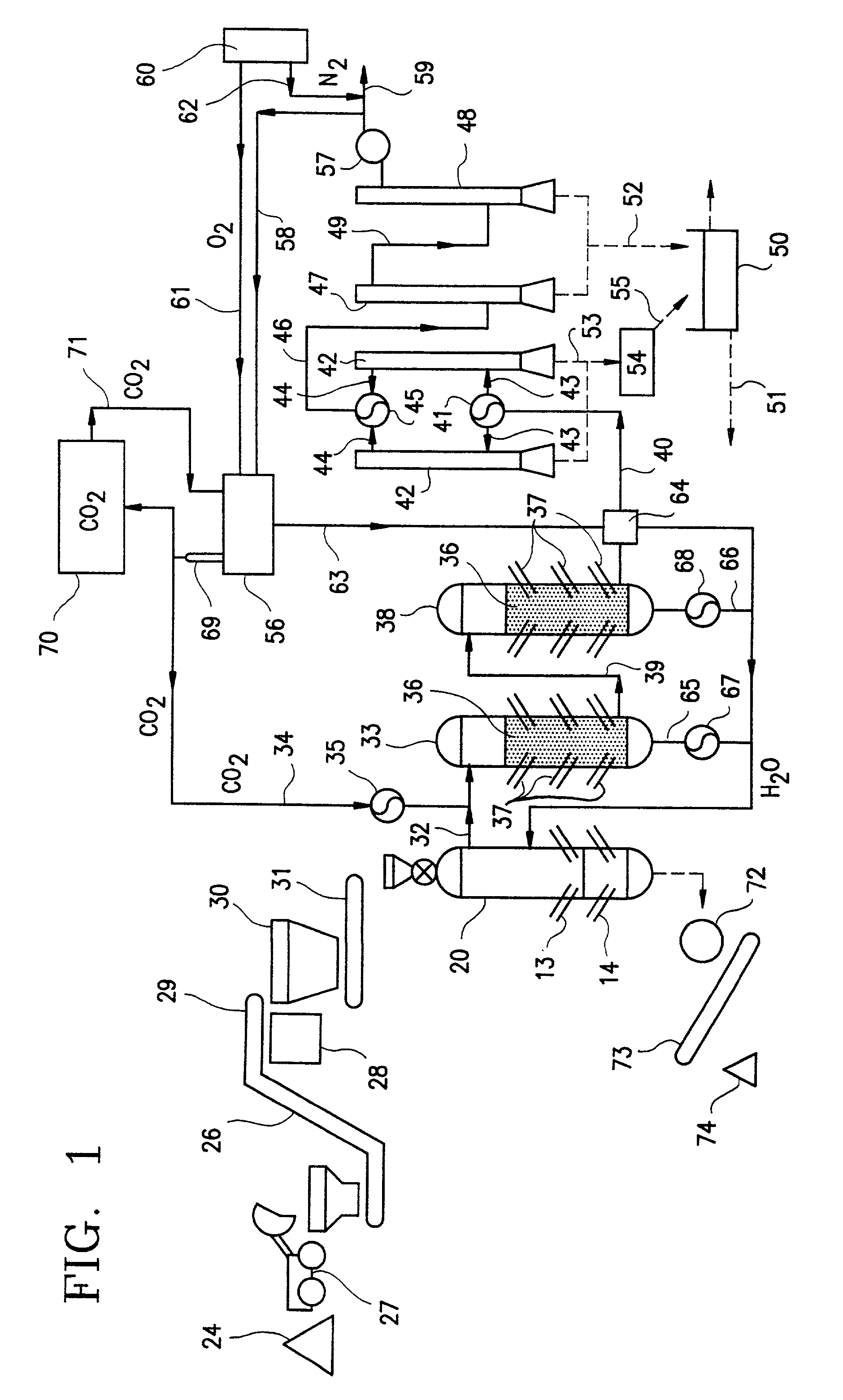

Synthesis gas production and power generation with zero emissions

InactiveUS6333015B1Avoid water pollutionEliminate needElectrical coke oven heatingGasifier electrodesClosed loopProduct gas

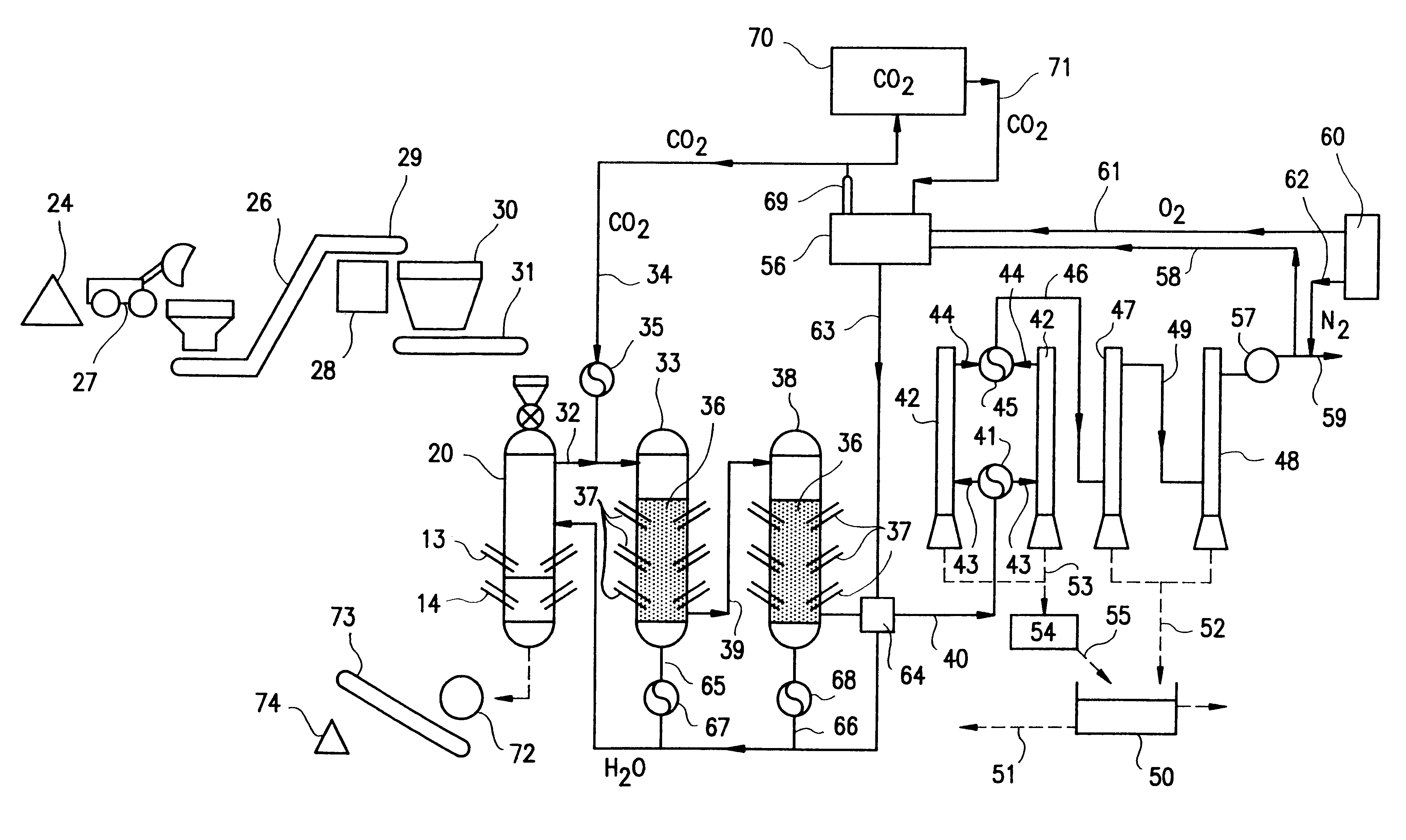

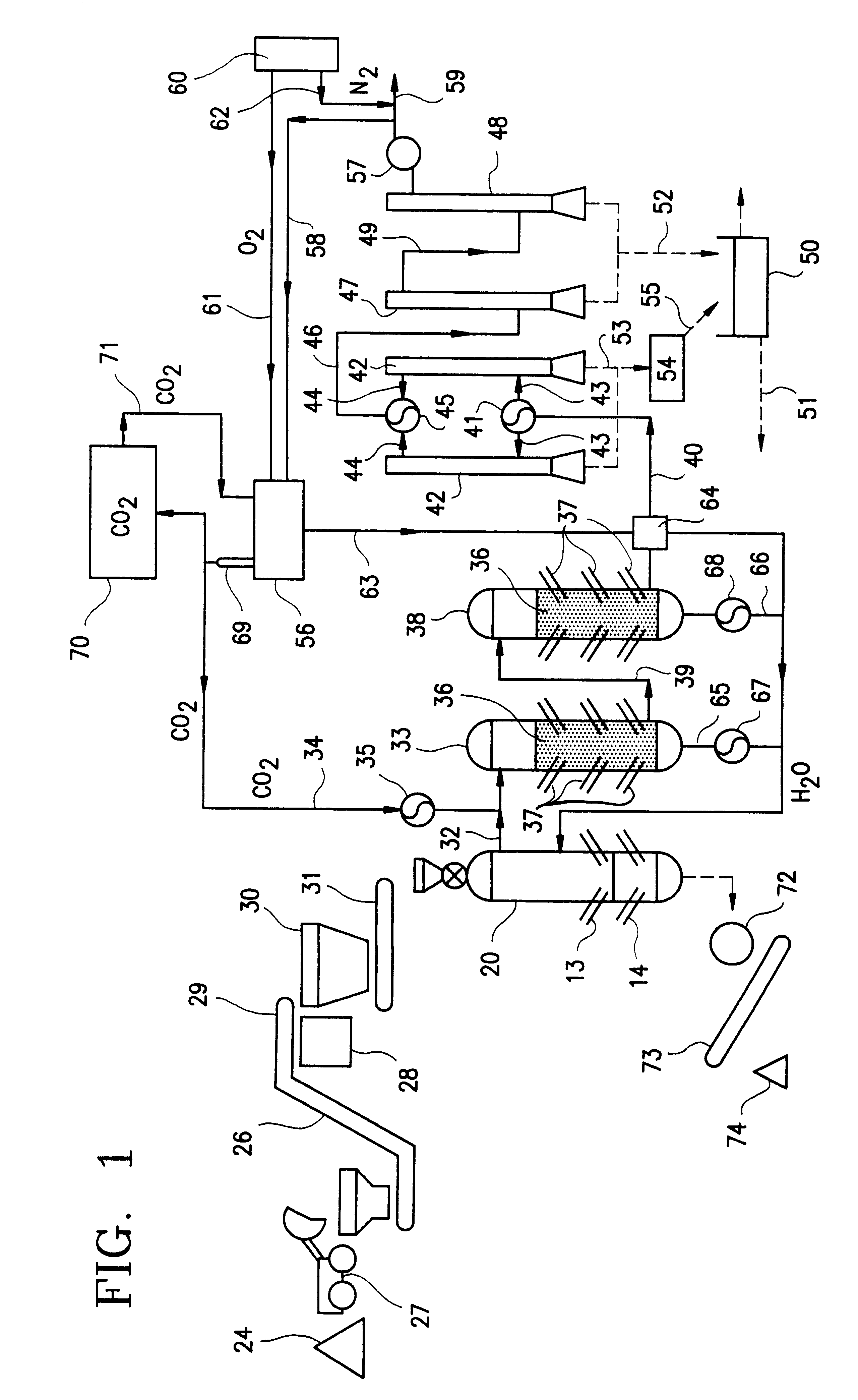

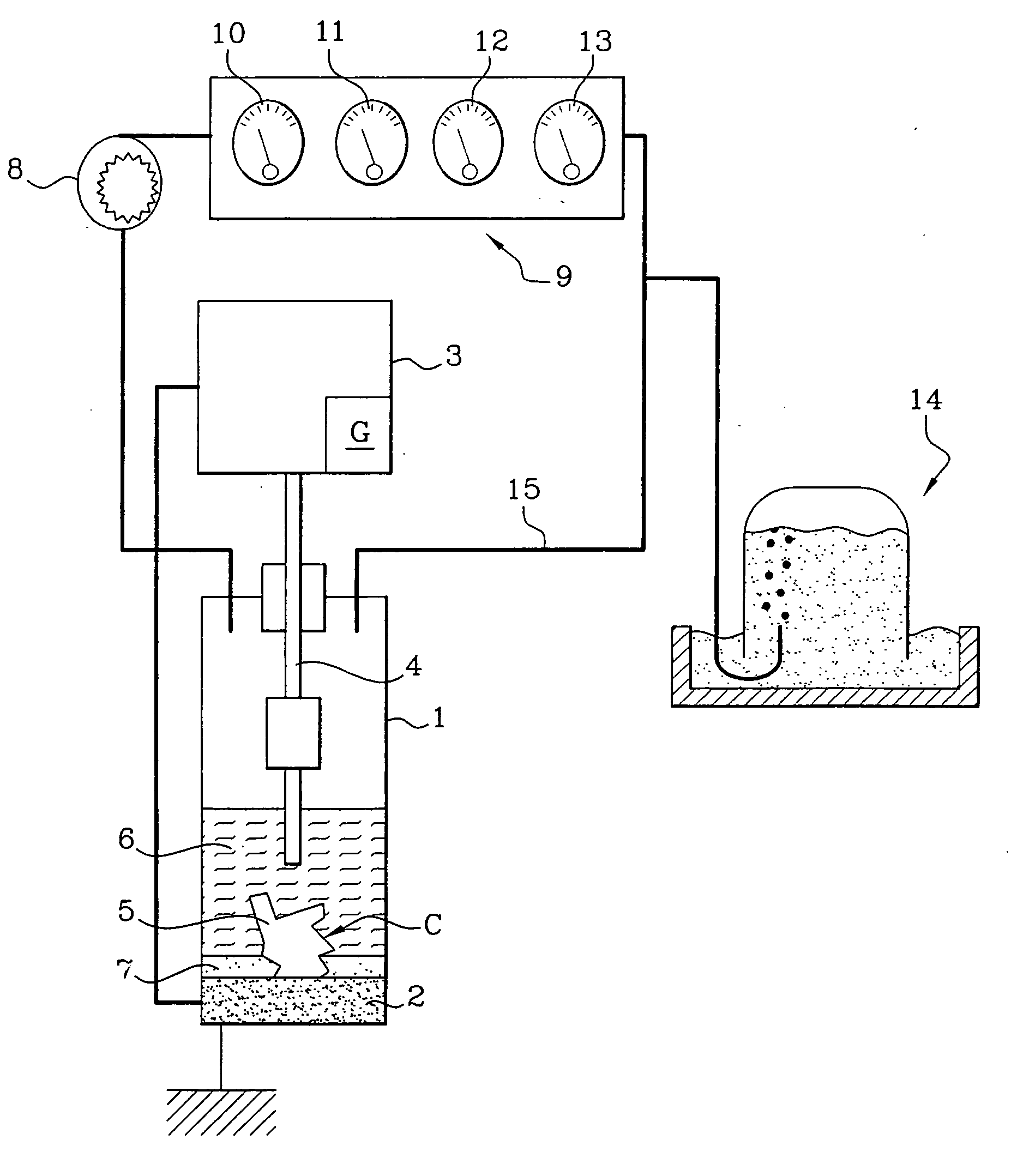

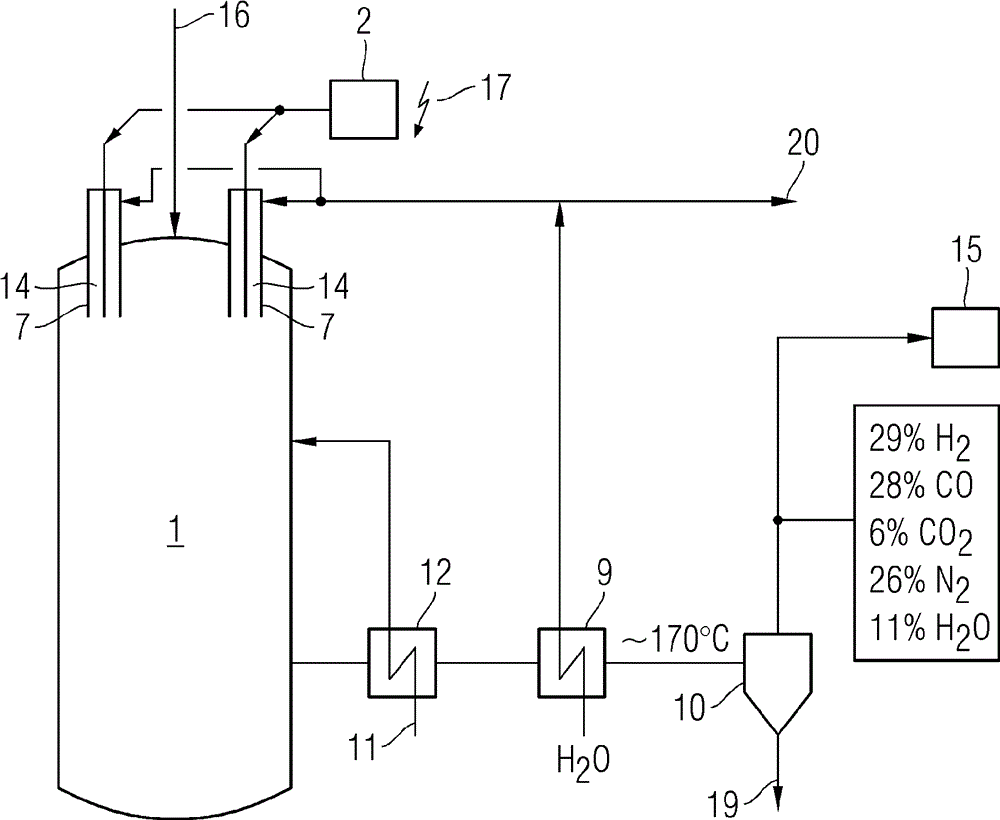

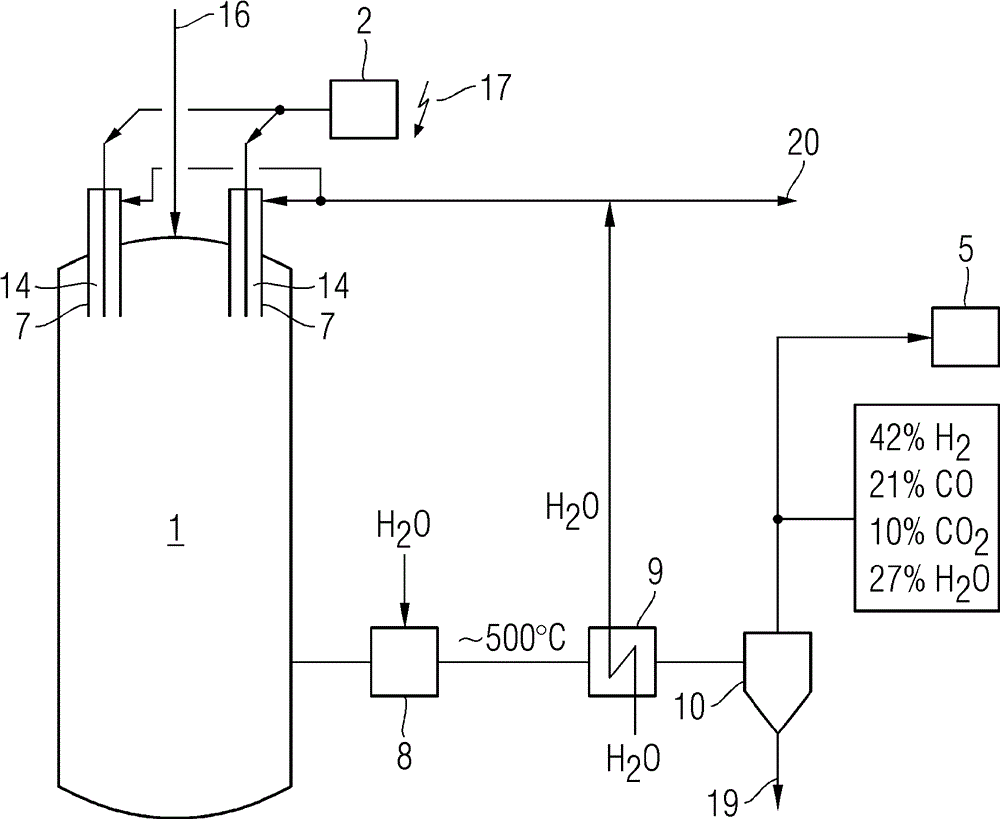

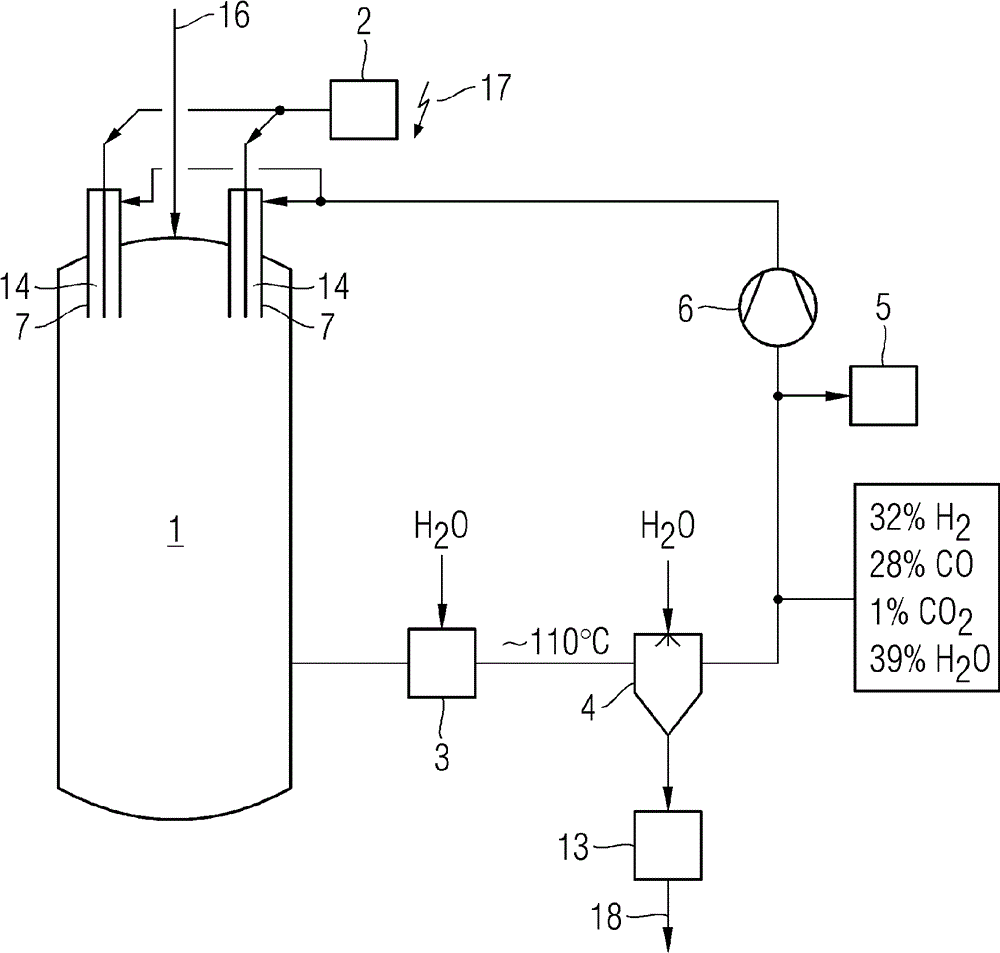

A process and apparatus for producing and burning synthesis gas. Carbonaceous waste material is pyrolytically decomposed in a primary reactor in the presence of steam to produce raw product gas containing H2 and CO. The raw product gas and CO2 is then introduced into a coke containing secondary reactor under pyrolyzing conditions, so that the CO2 and coke react to produce combustible gas having an increased CO content. The combustible gas is mixed with oxygen and CO2 to produce a combustible mixture which is burned as a fuel to produce heat, CO2 and H2O. A portion of the produced CO2 is recovered and used as the source of CO2 gas in the combustible mixture and as a source of CO2 gas for the secondary reactor. Preferably filters and scrubbers are used in a closed loop system to avoid undesirable emissions into the environment.

Owner:LEWIS GLORIA B

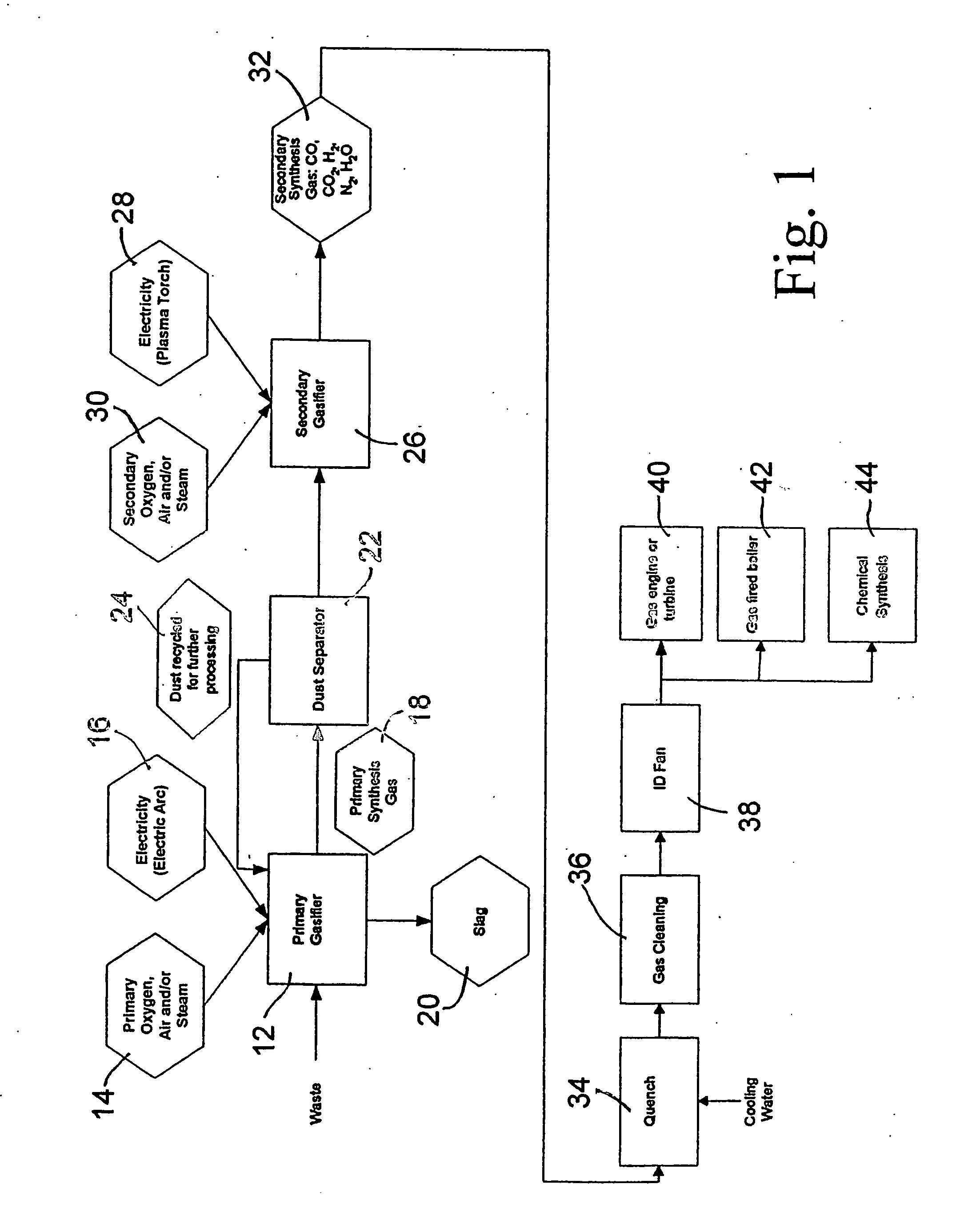

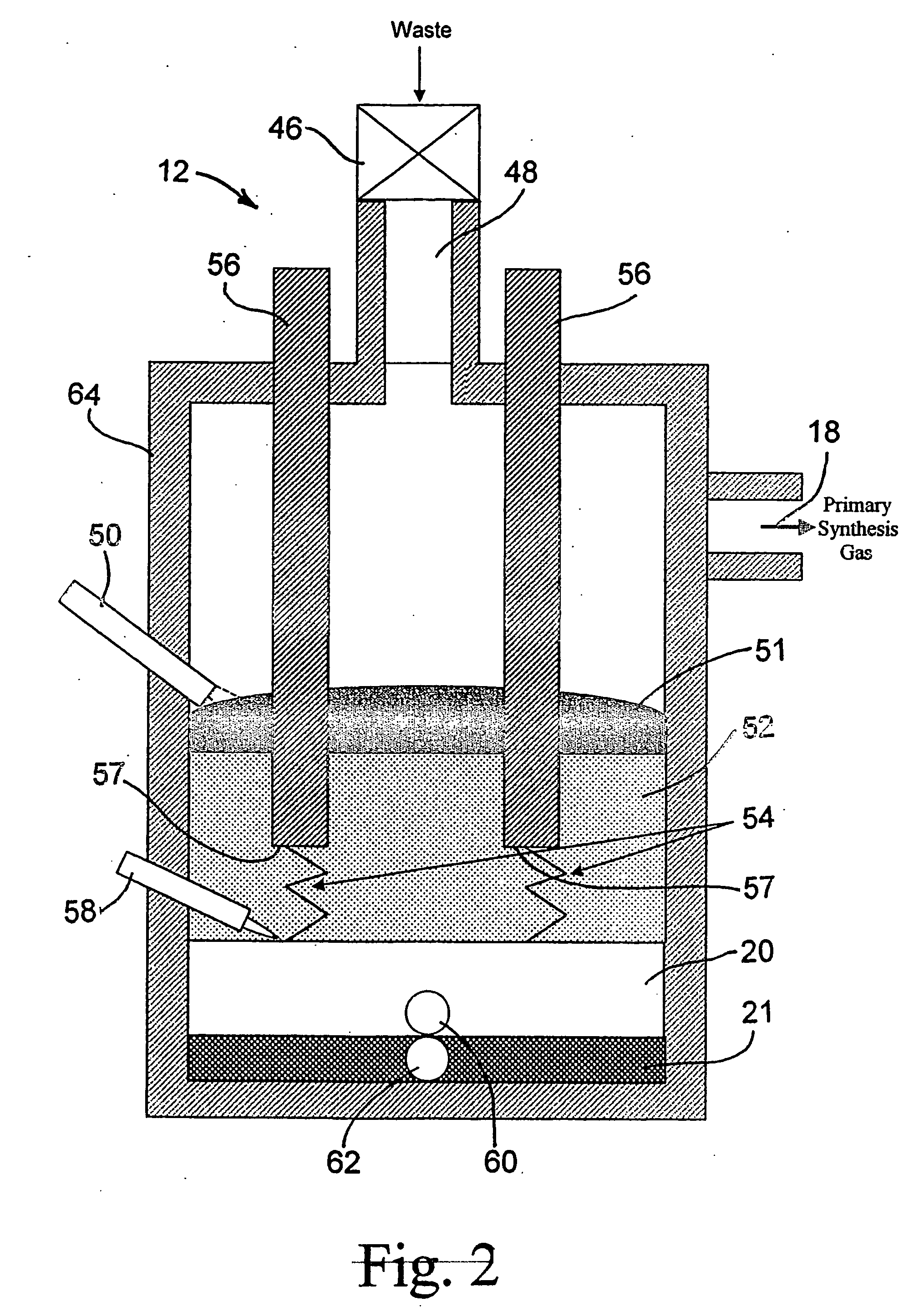

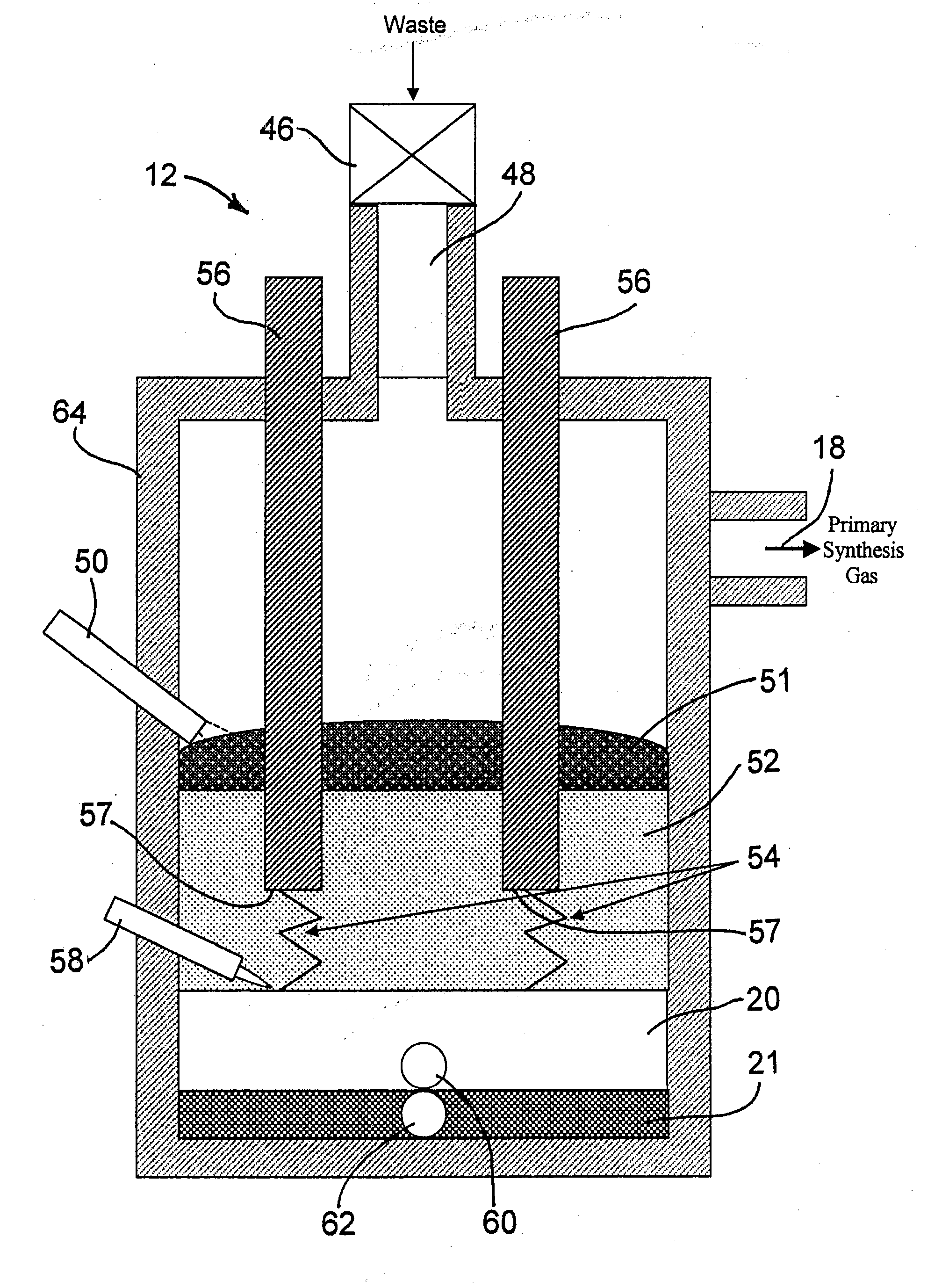

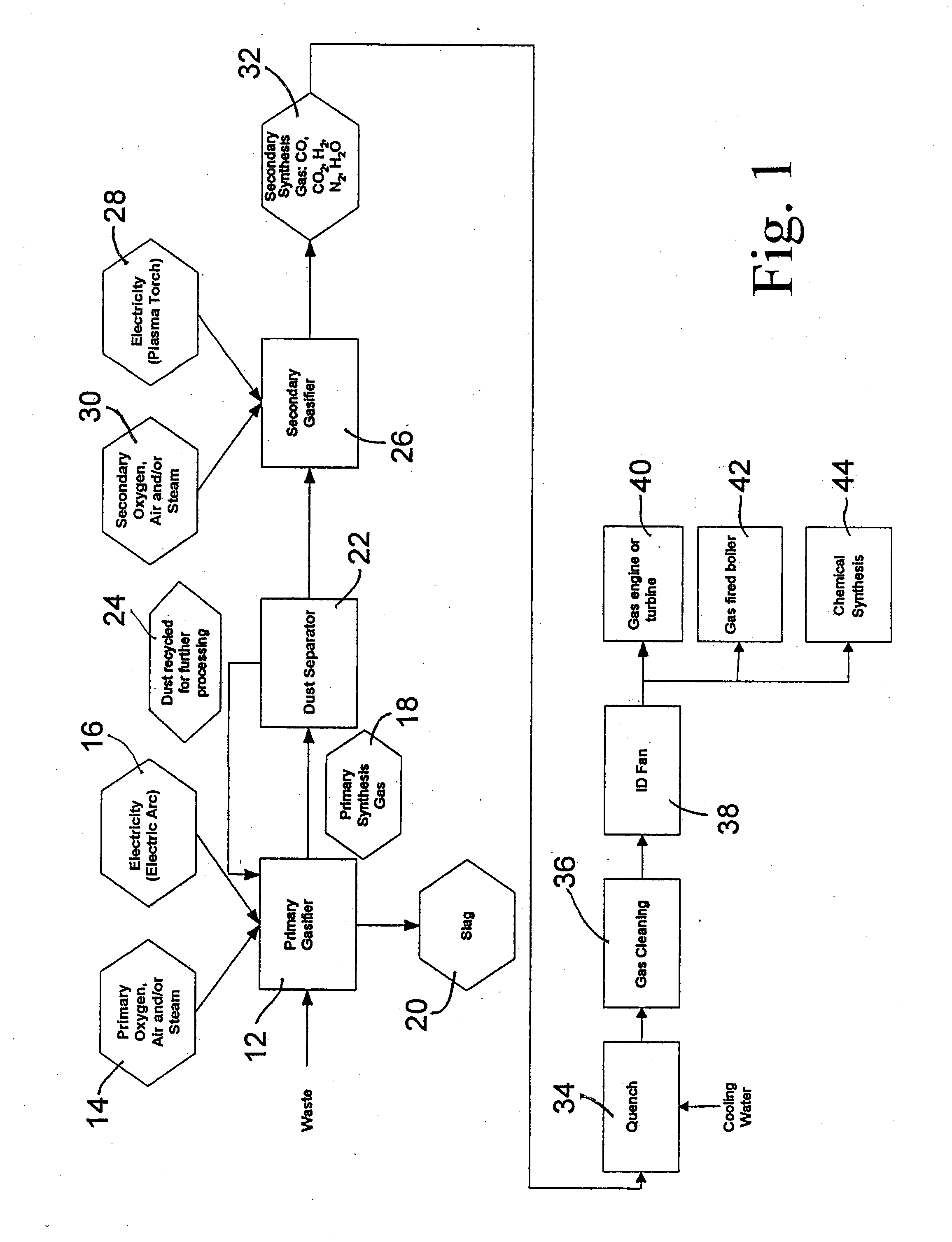

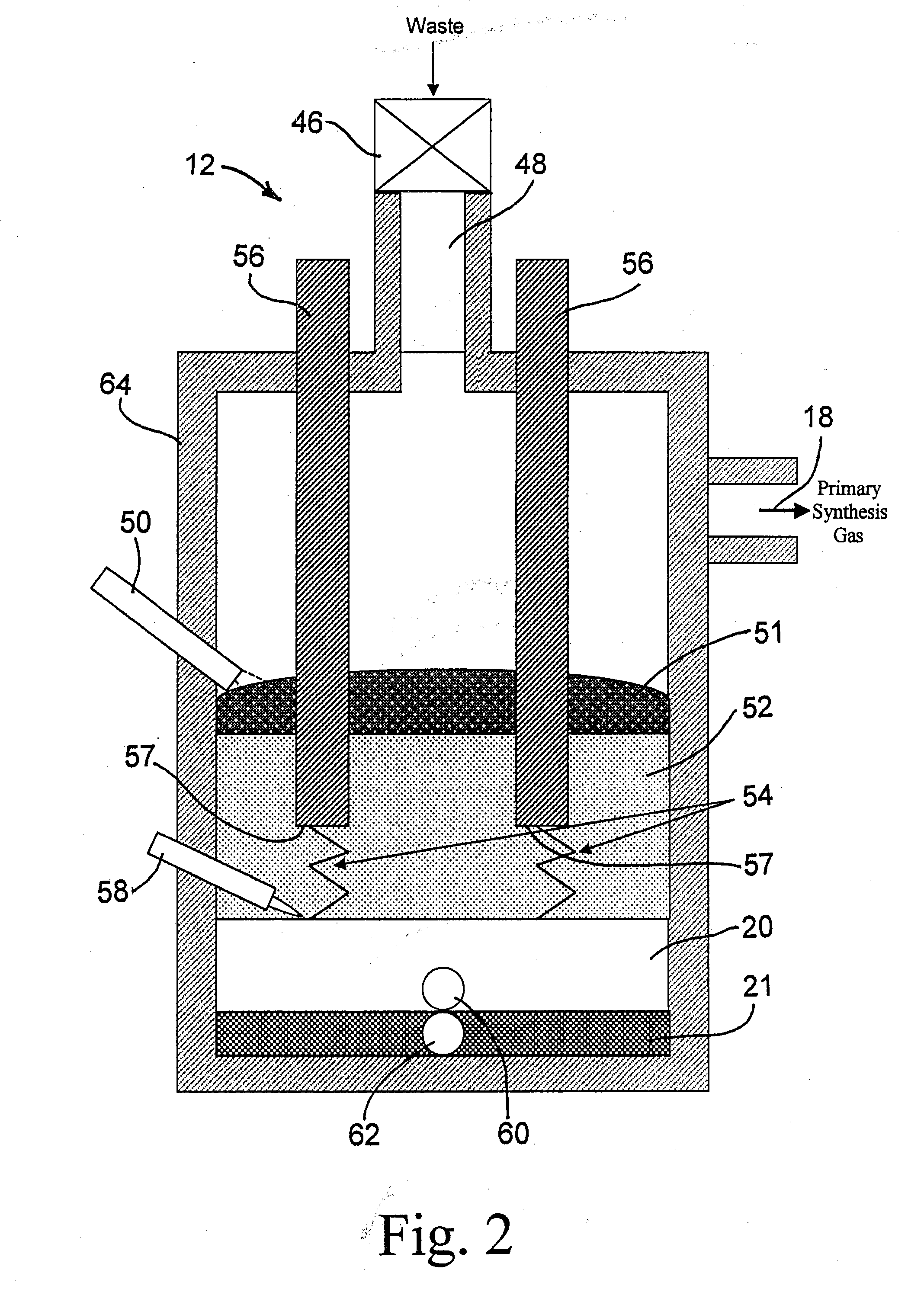

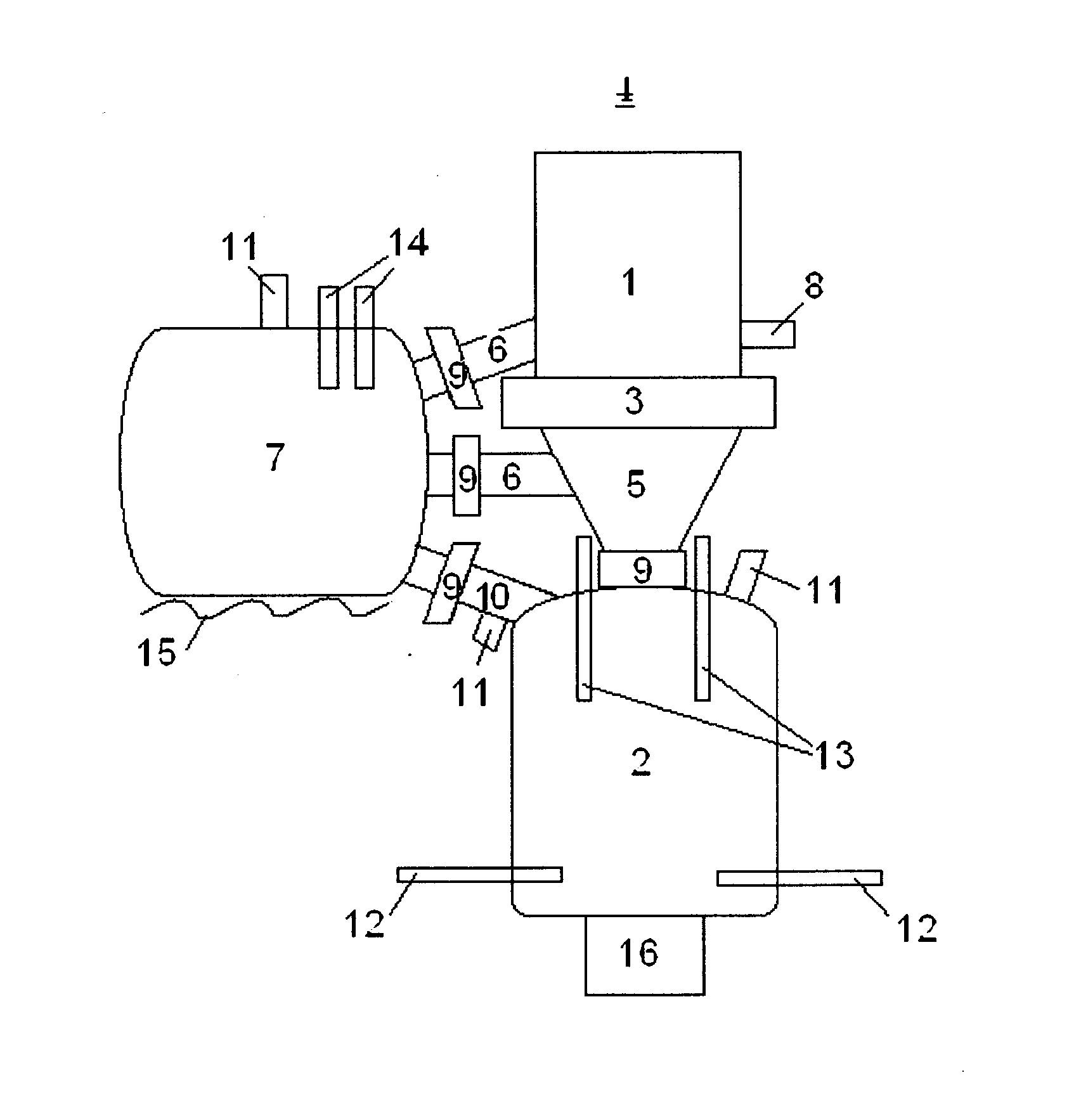

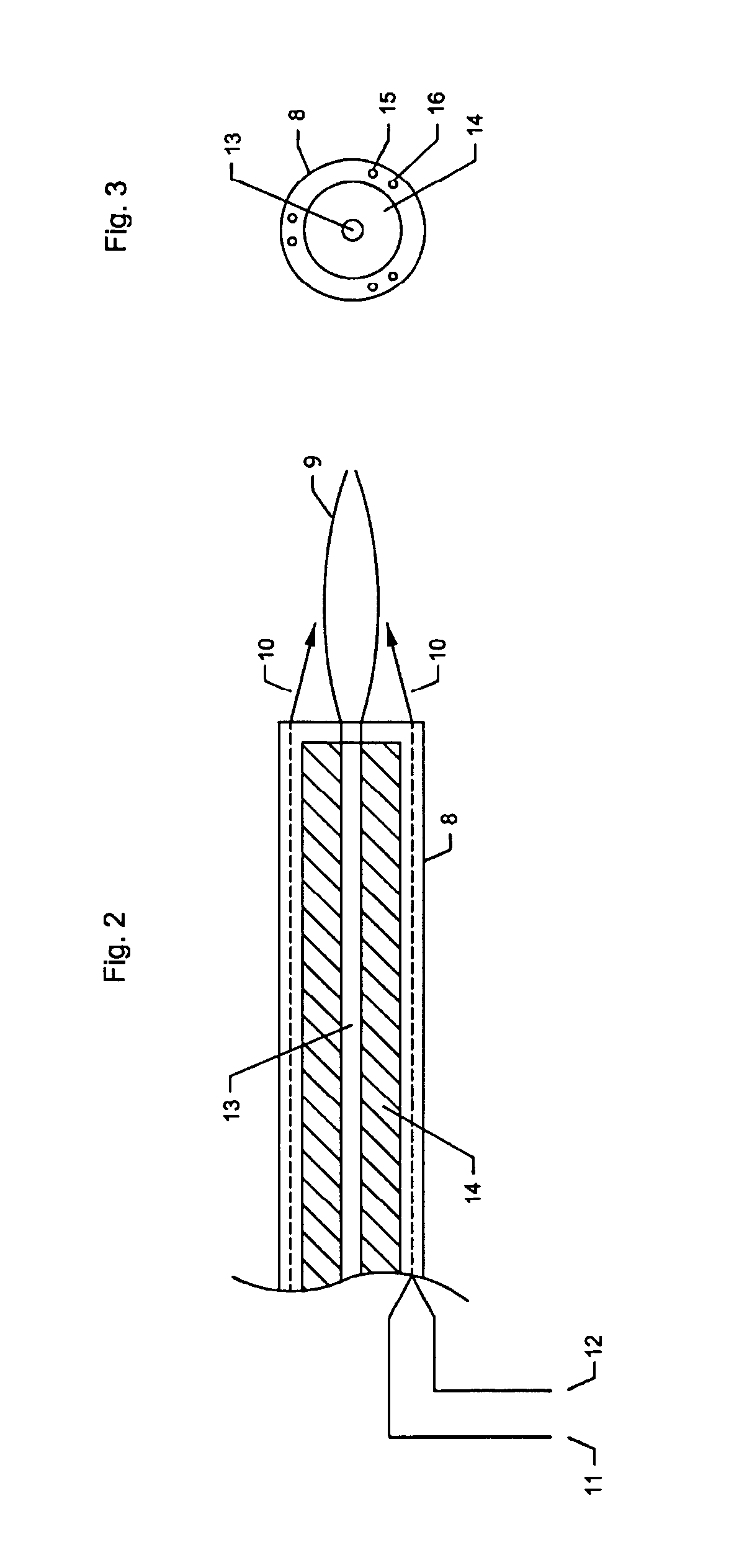

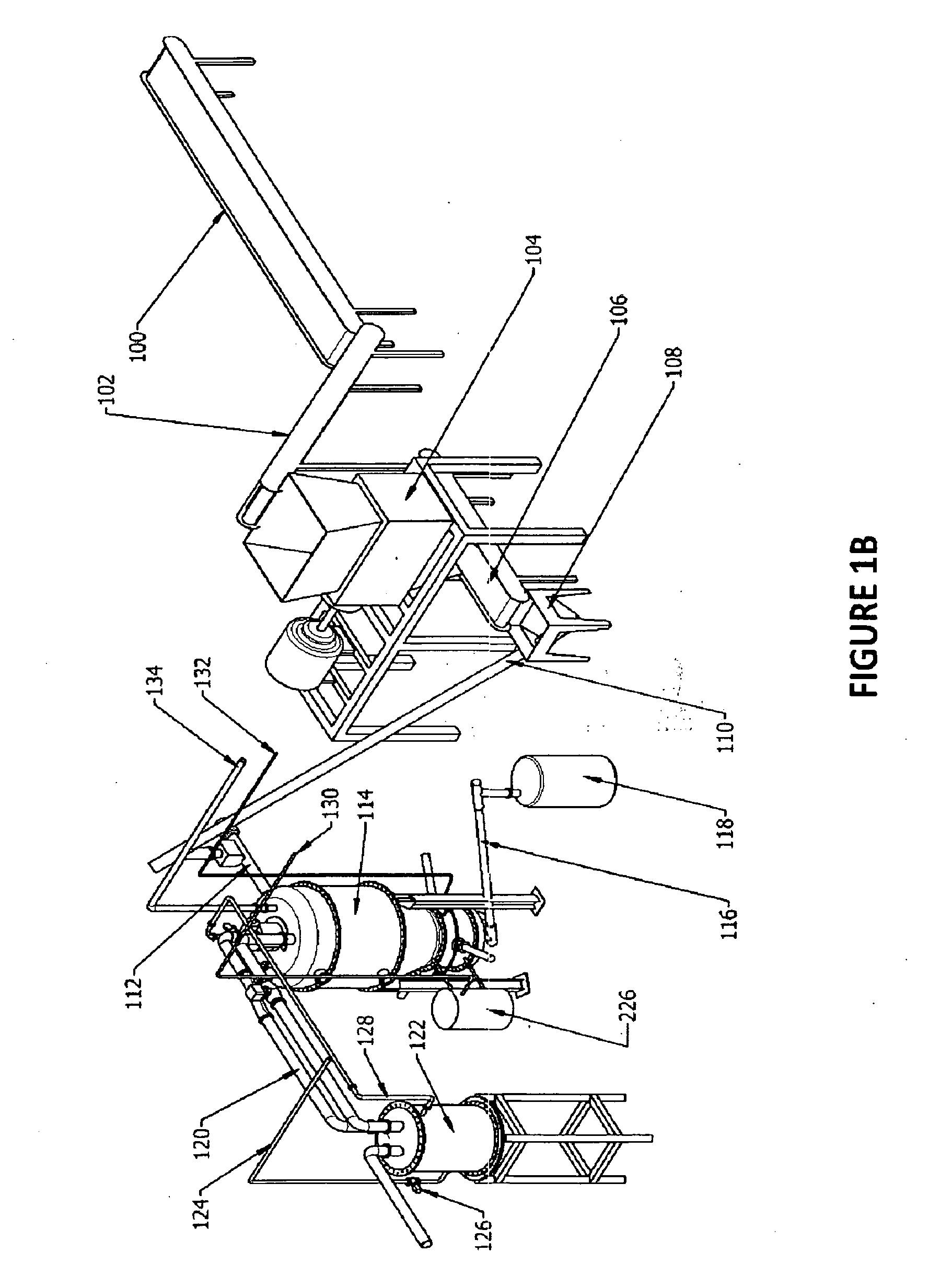

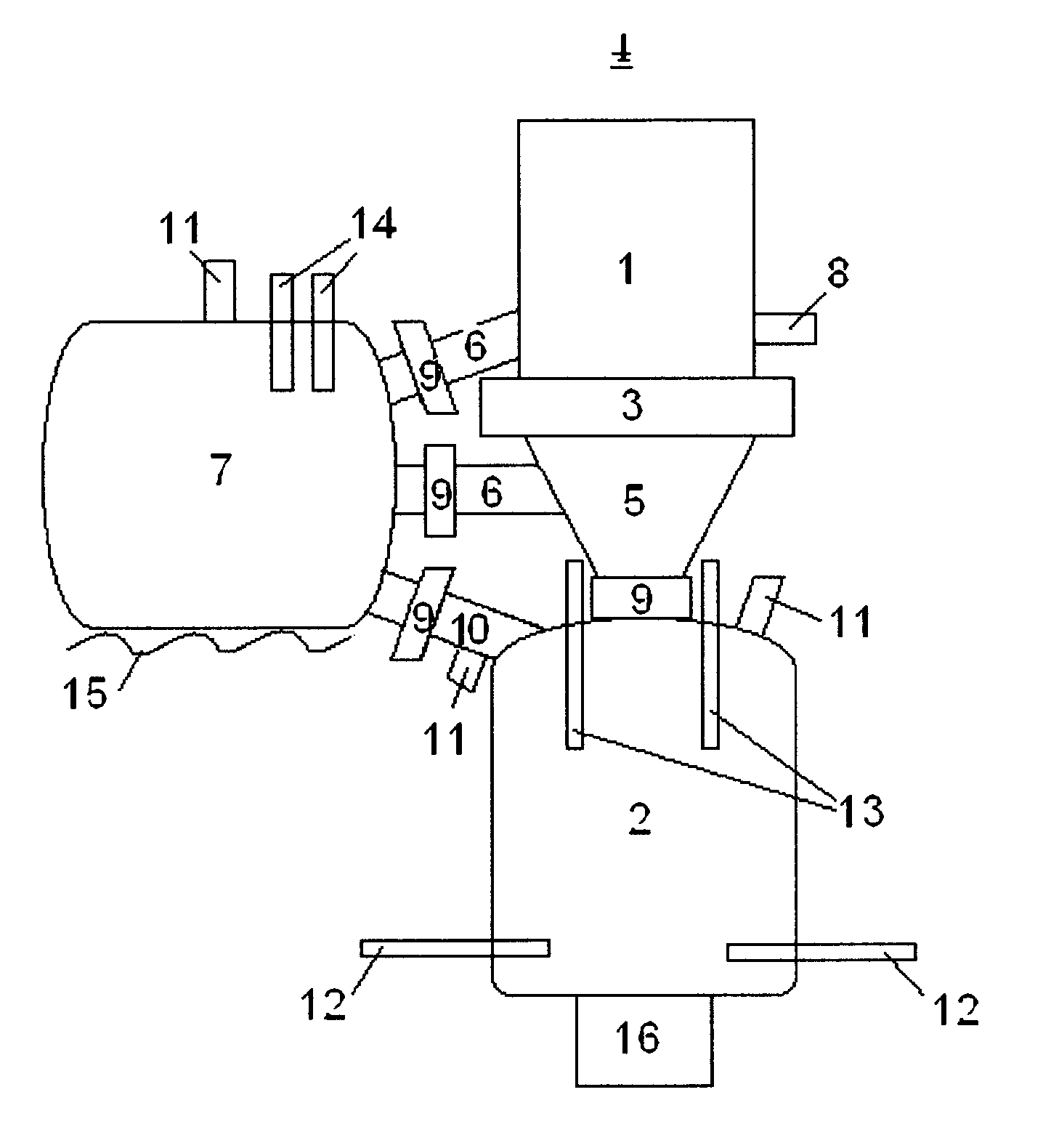

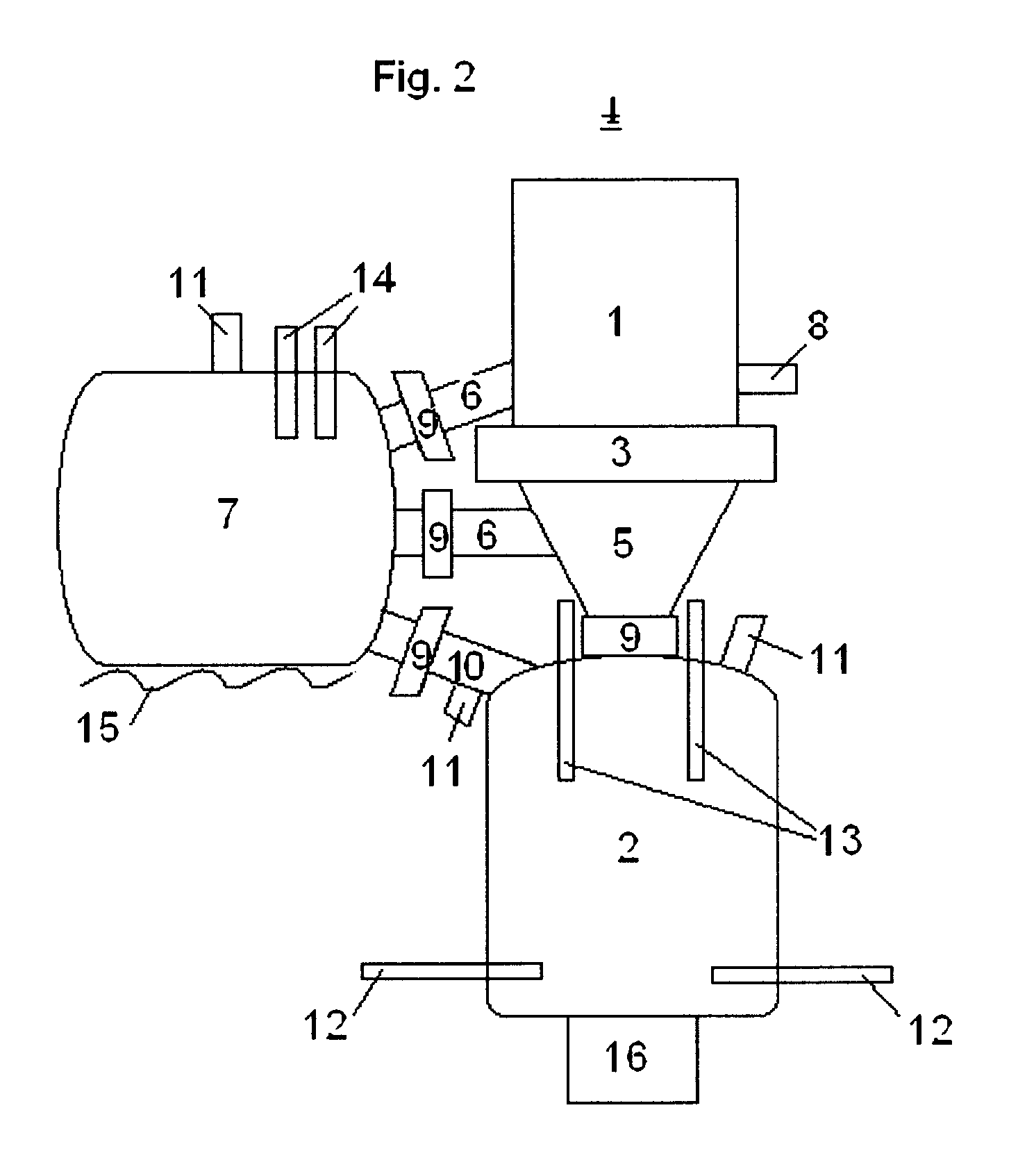

Two-Stage Plasma Process For Converting Waste Into Fuel Gas And Apparatus Therefor

InactiveUS20070272131A1Limited amountImprove energy efficiencyGasifier electrodesGasification processes detailsPlasma jetCyclone

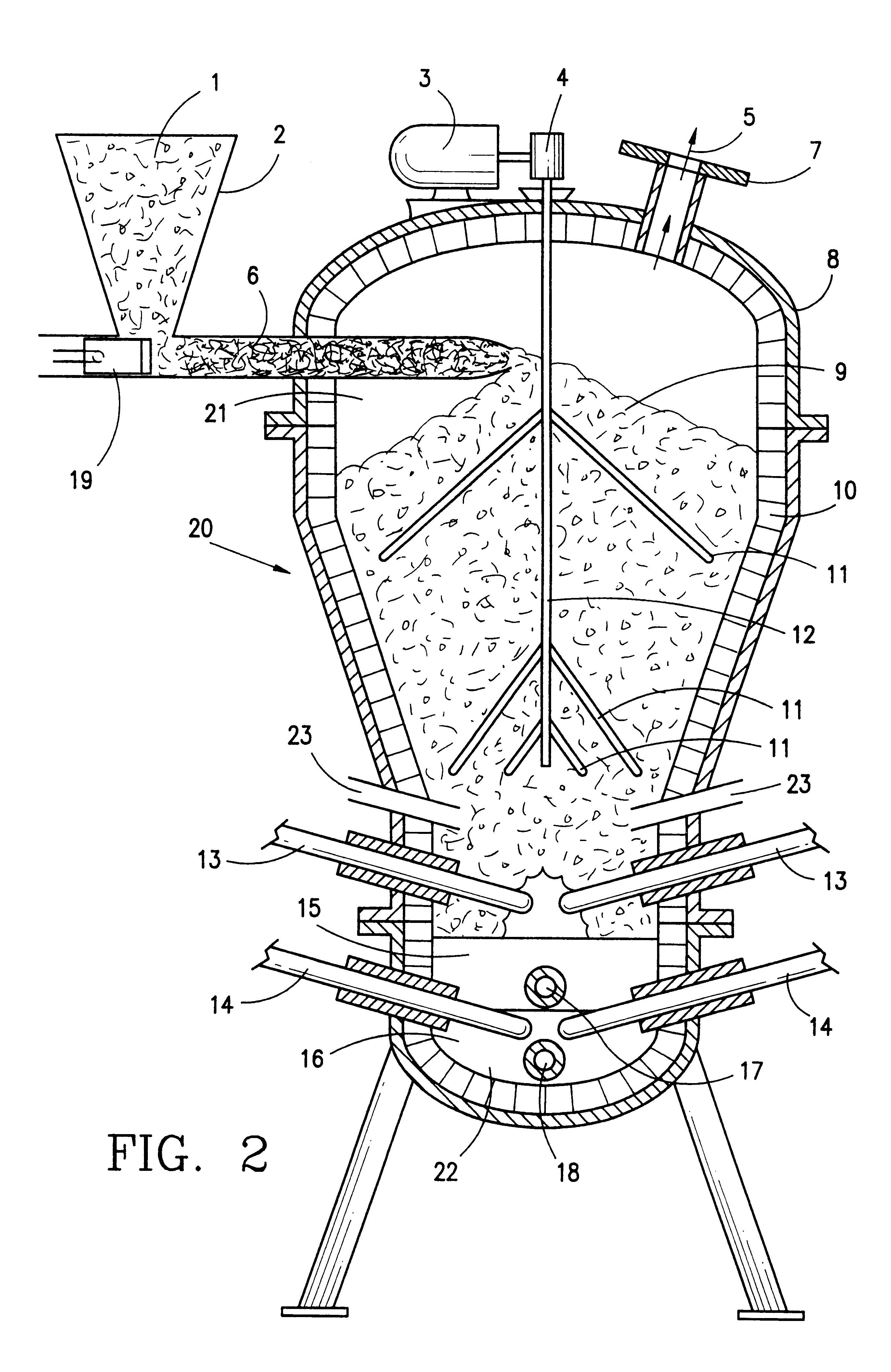

A two-step gasification process and apparatus for the conversion of solid or liquid organic waste into clean fuel, suitable for use in a gas engine or a gas burner, is described. The waste is fed initially into a primary gasifier, which is a graphite arc furnace. Within the primary gasifier, the organic components of the waste are mixed with a predetermined amount of air, oxygen or steam, and converted into volatiles and soot. The volatiles consist mainly of carbon monoxide and hydrogen, and may include a variety of other hydrocarbons and some fly ash. The gas exiting the primary gasifier first passes through a hot cyclone, where some of the soot and most of the fly ash is collected and returned to the primary gasifier. The remaining soot along with the volatile organic compounds is further treated in a secondary gasifier where the soot and the volatile compounds mix with a high temperature plasma jet and a metered amount of air, oxygen or steam, and are converted into a synthesis gas consisting primarily of carbon monoxide and hydrogen. The synthesis gas is then quenched and cleaned to form a clean fuel gas suitable for use in a gas engine or a gas burner. This offers higher thermal efficiency than conventional technology and produces a cleaner fuel than other known alternatives.

Owner:PHOENIX HAUTE TECH

Synthesis gas production and power generation with zero emissions

InactiveUS20020048545A1Avoid water pollutionEliminating any build-up of this productElectrical coke oven heatingGasifier electrodesClosed loopProduct gas

A process and apparatus for producing and burning synthesis gas. Carbonaceous waste material is pyrolytically decomposed in a primary reactor in the presence of steam to produce raw product gas containing H2 and CO. The raw product gas and CO2 is then introduced into a coke containing secondary reactor under pyrolyzing conditions, so that the CO2 and coke react to produce combustible gas having an increased CO content. The combustible gas is mixed with oxygen and CO2 to produce a combustible mixture which is burned as a fuel to produce heat, CO2 and H2O. A portion of the produced CO2 is recovered and used as the source of CO2 gas in the combustible mixture and as a source of CO2 gas for the secondary reactor. Preferably filters and scrubbers are used in a closed loop system to avoid undesirable emissions into the environment.

Owner:LEWIS ARLIN C

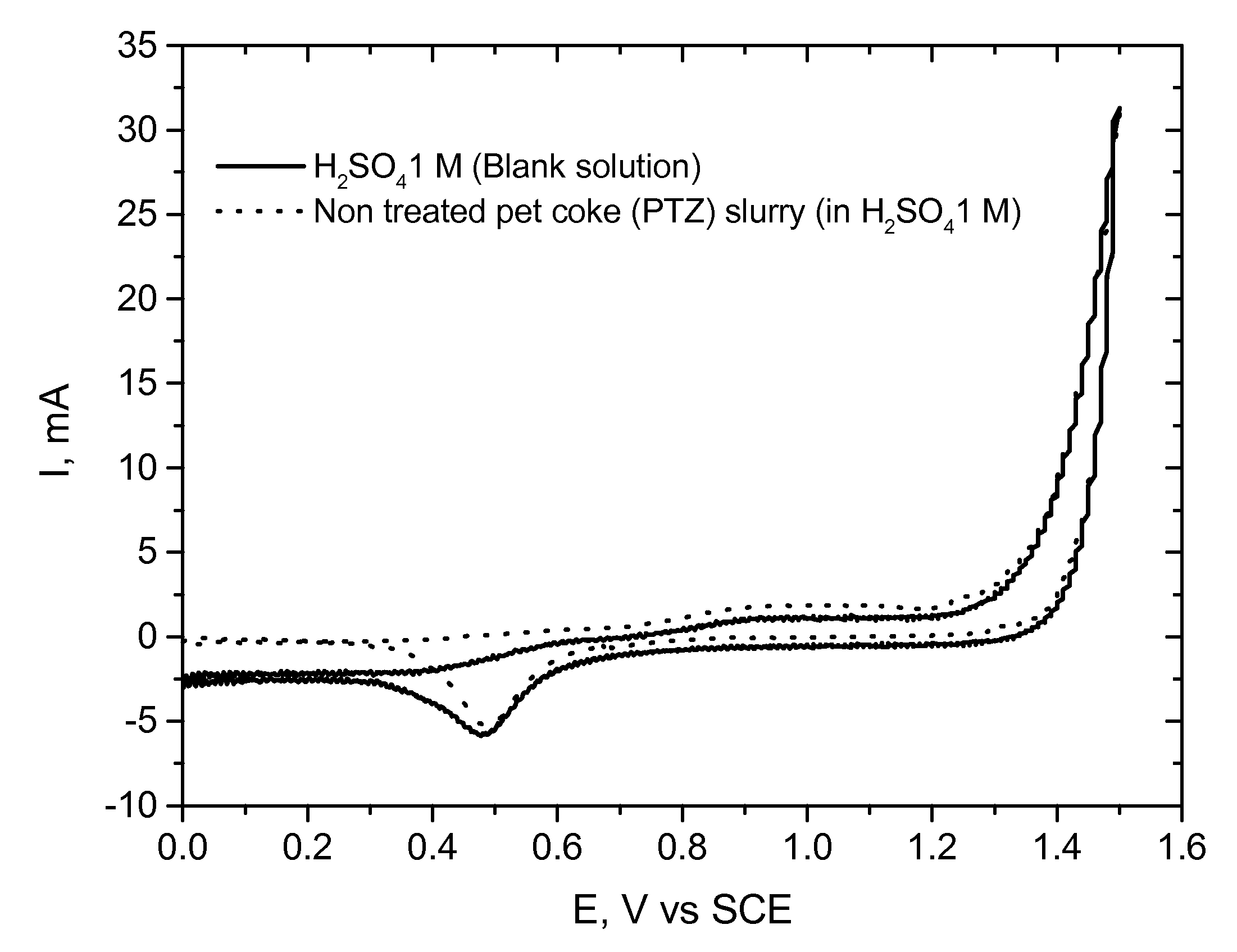

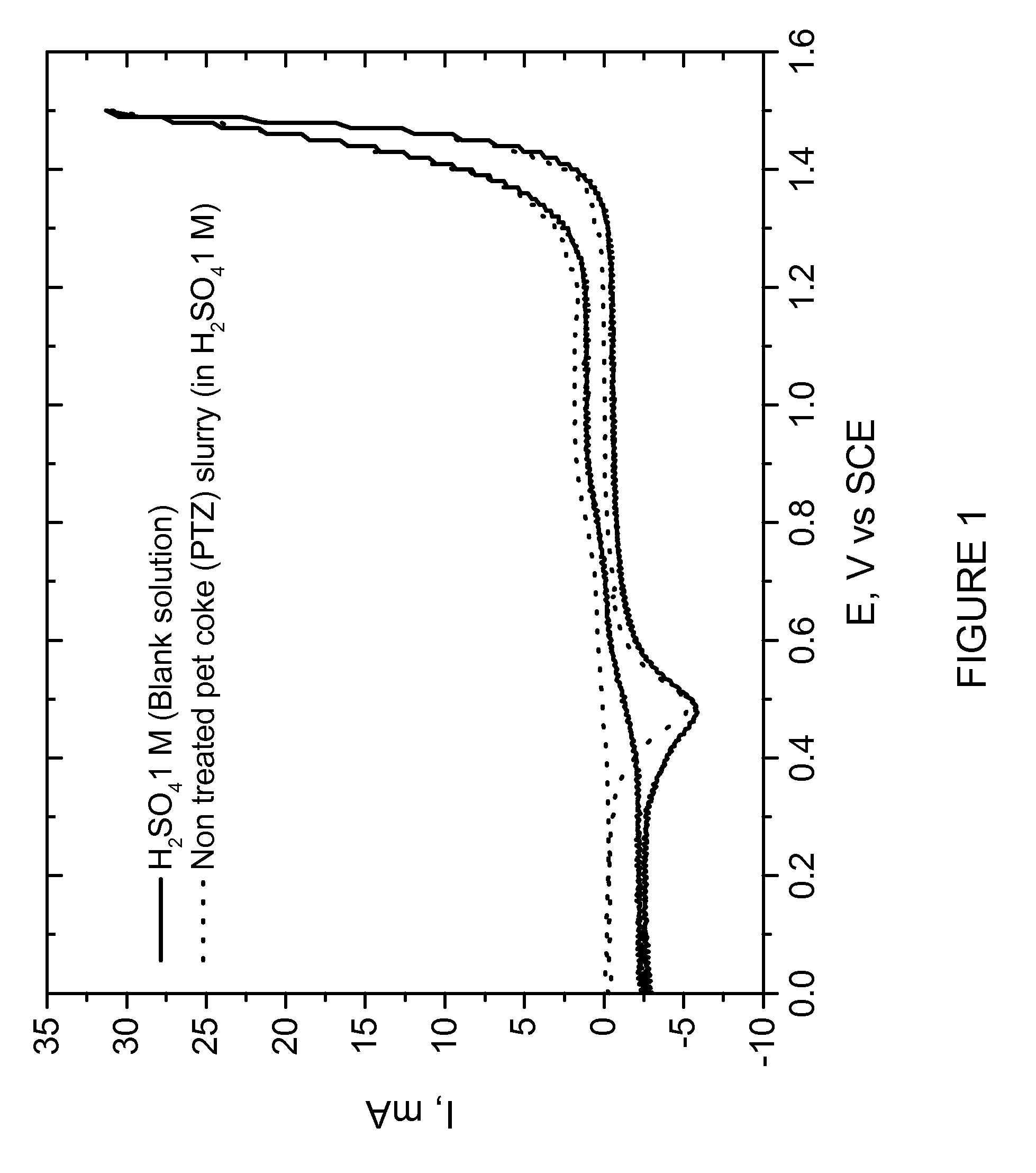

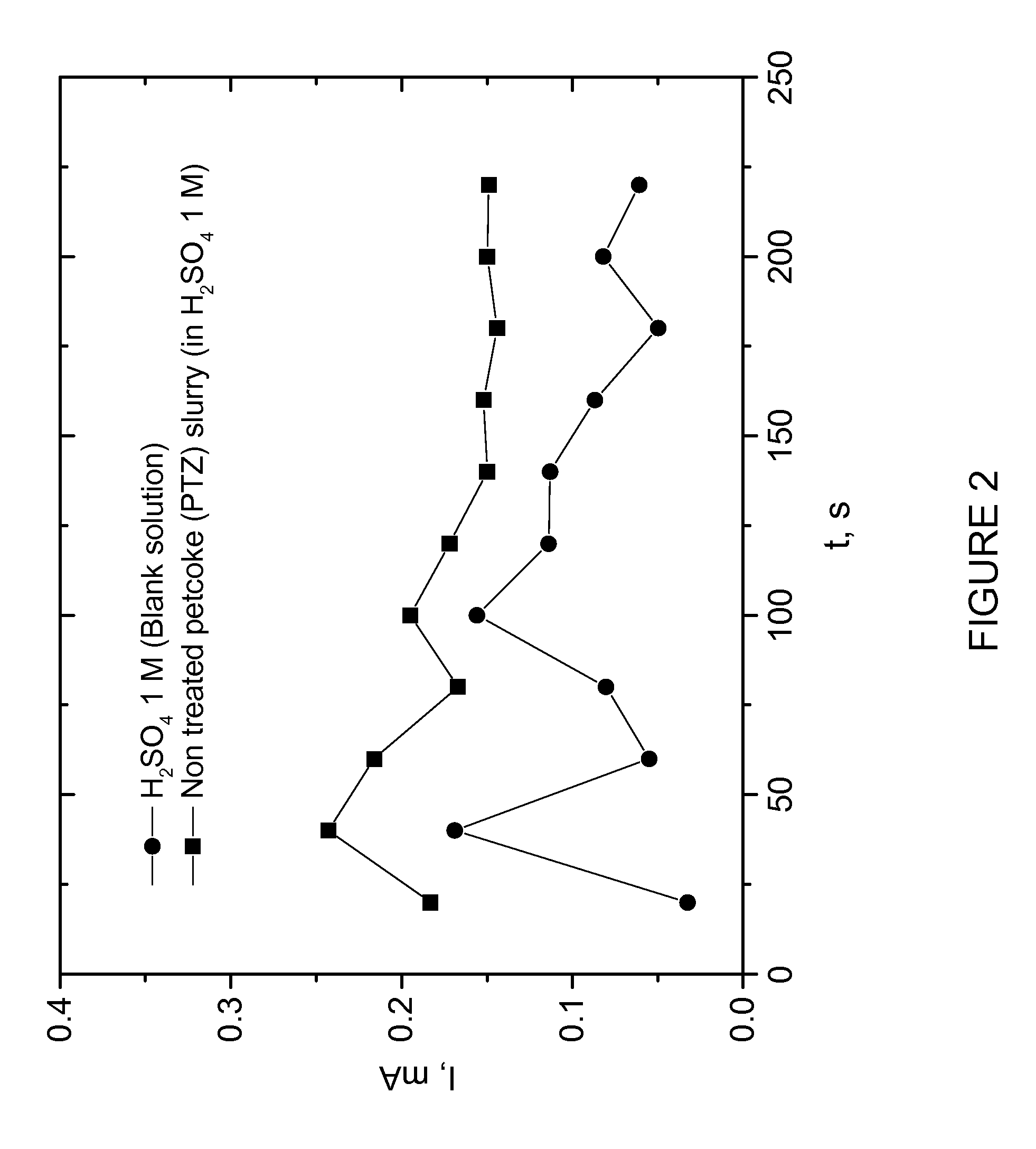

Electro-gasification process using pre-treated pet-coke

A method is provided for electro-gasification of pet-coke, including the steps of providing a pet-coke material; treating the pet-coke material to obtain a treated pet-coke material having an average particle size of between about 20 and about 106 μm; and exposing the treated pet-coke material to electro-gasification conditions to produce synthesis gas and / or hydrogen. Extraction of metals from the pet-coke is facilitated.

Owner:INTREVEP SA

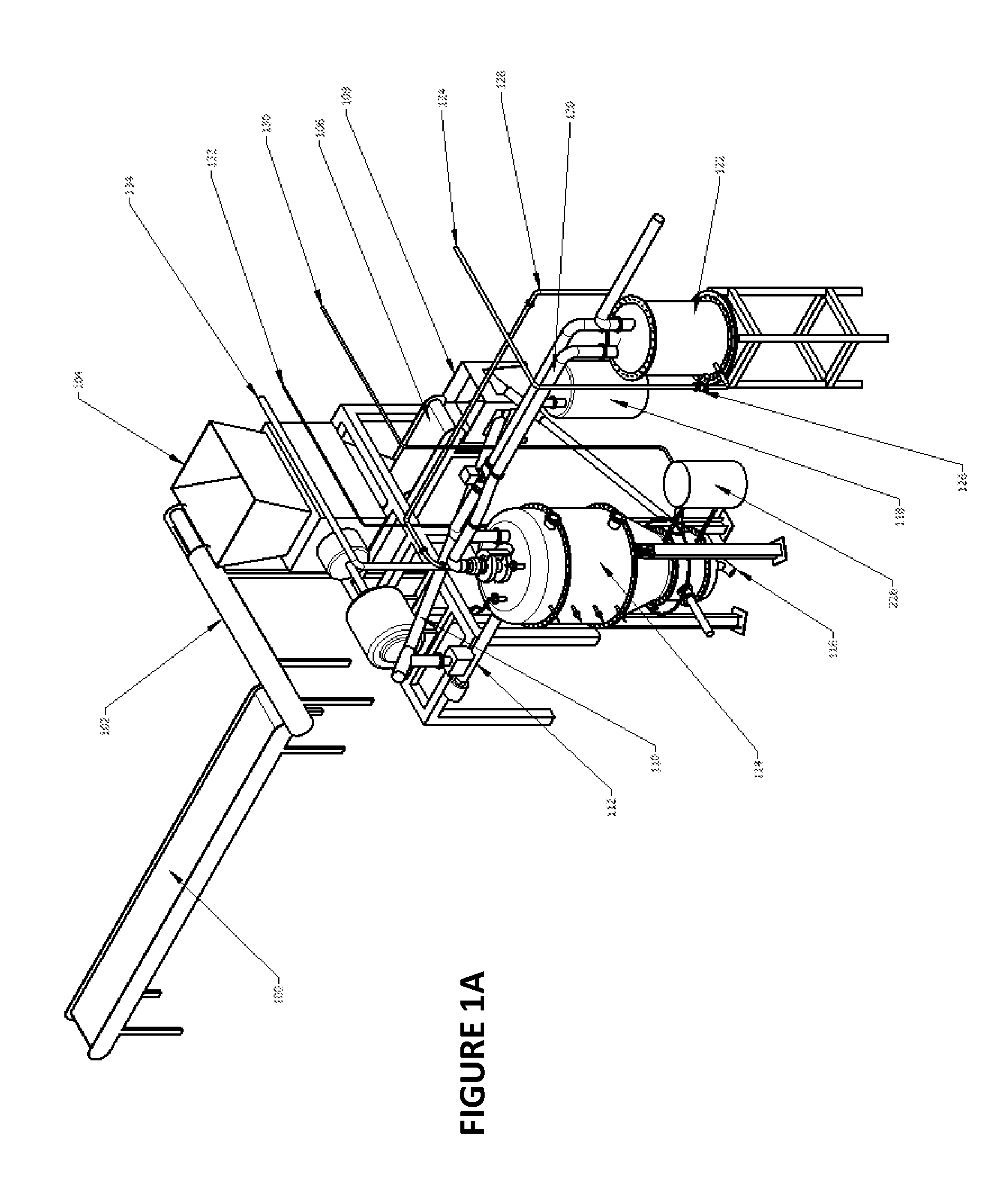

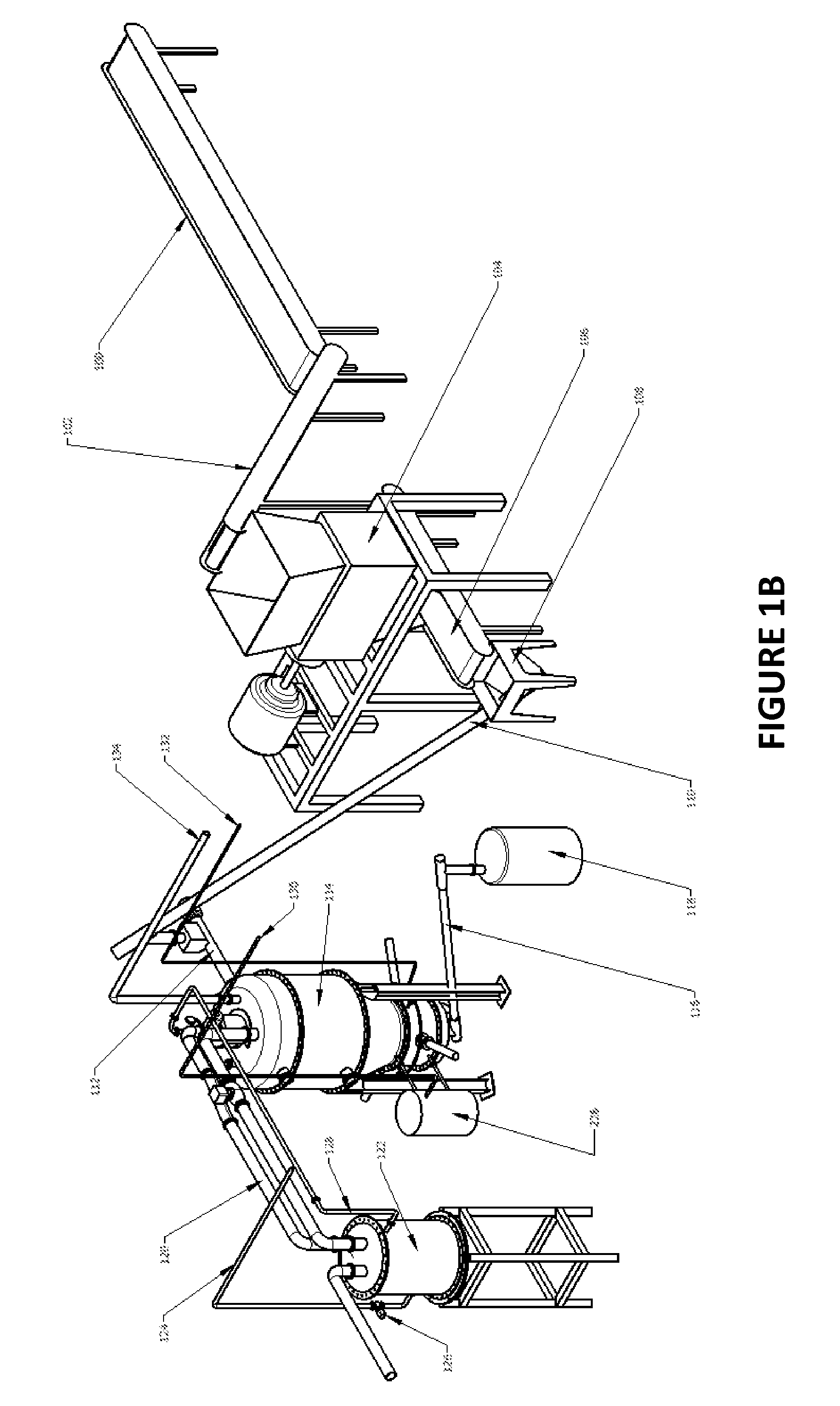

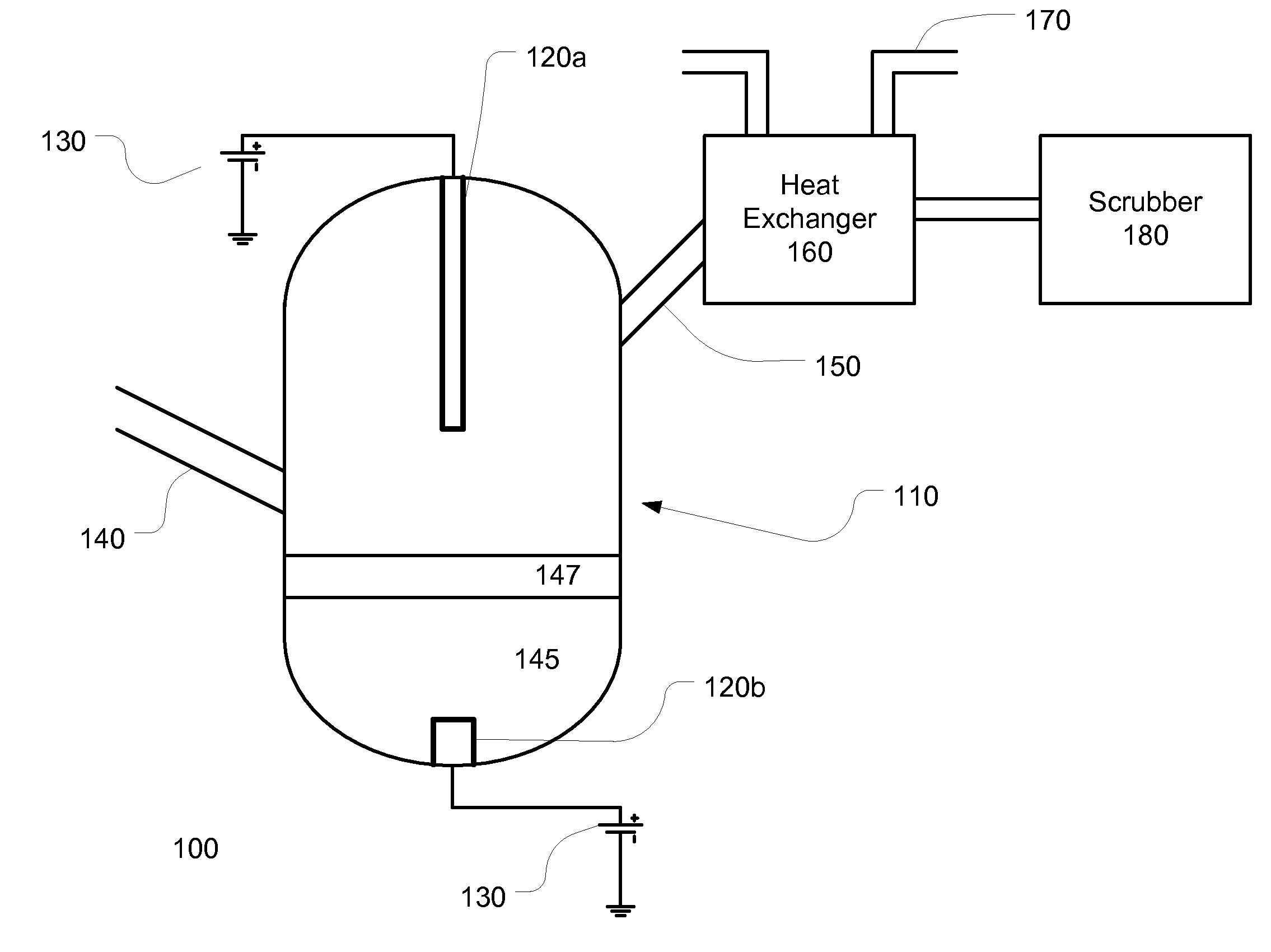

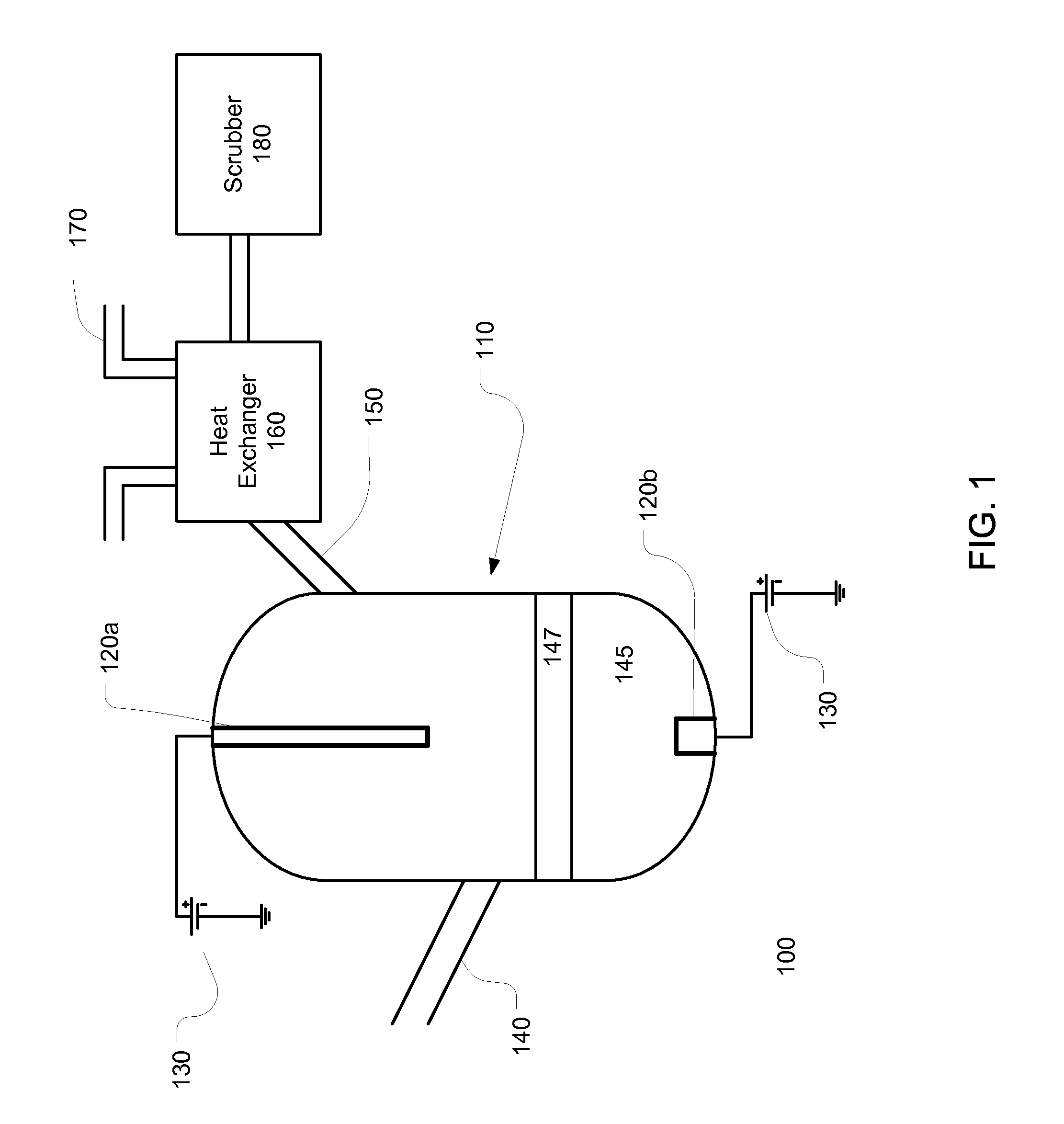

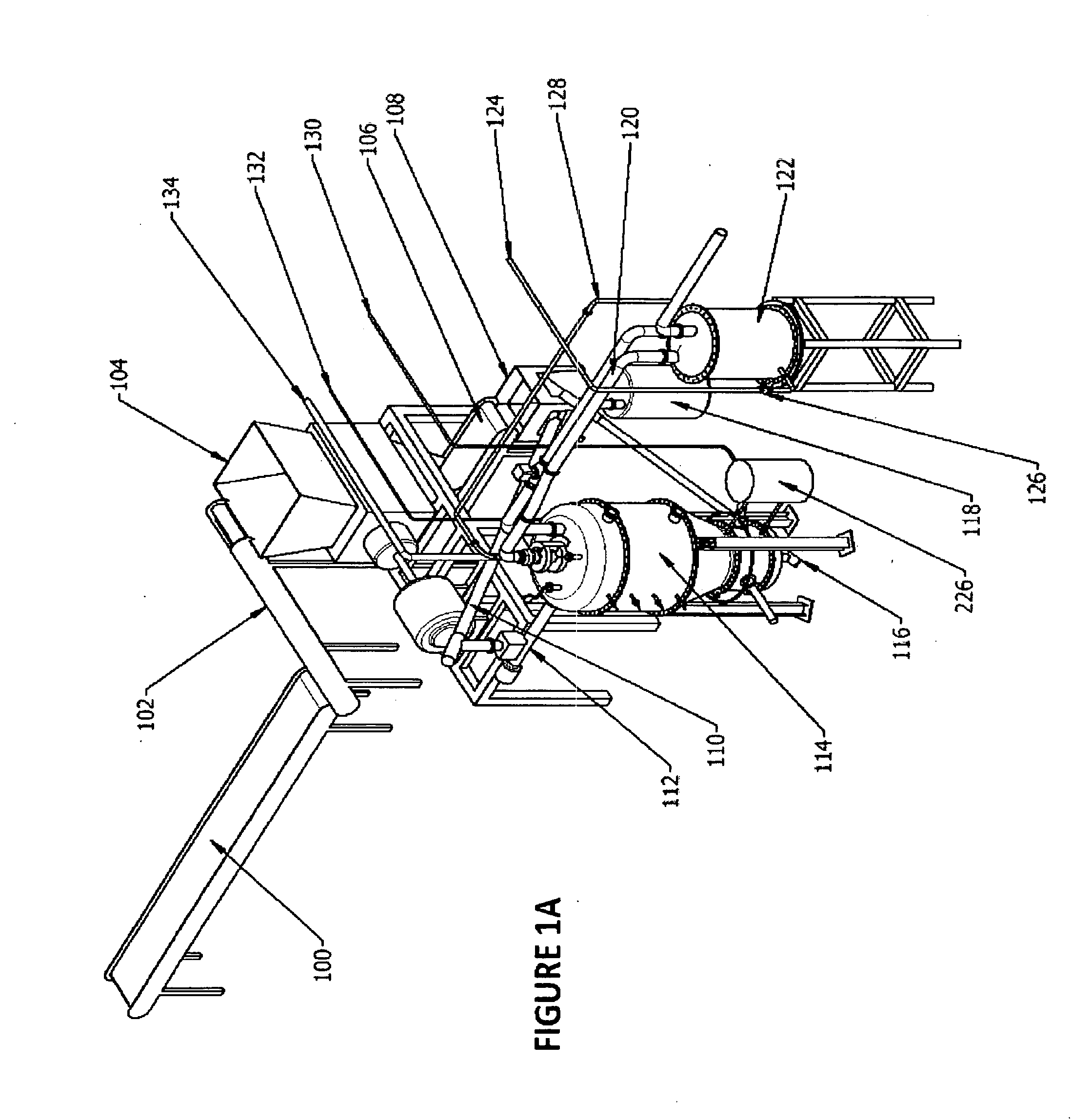

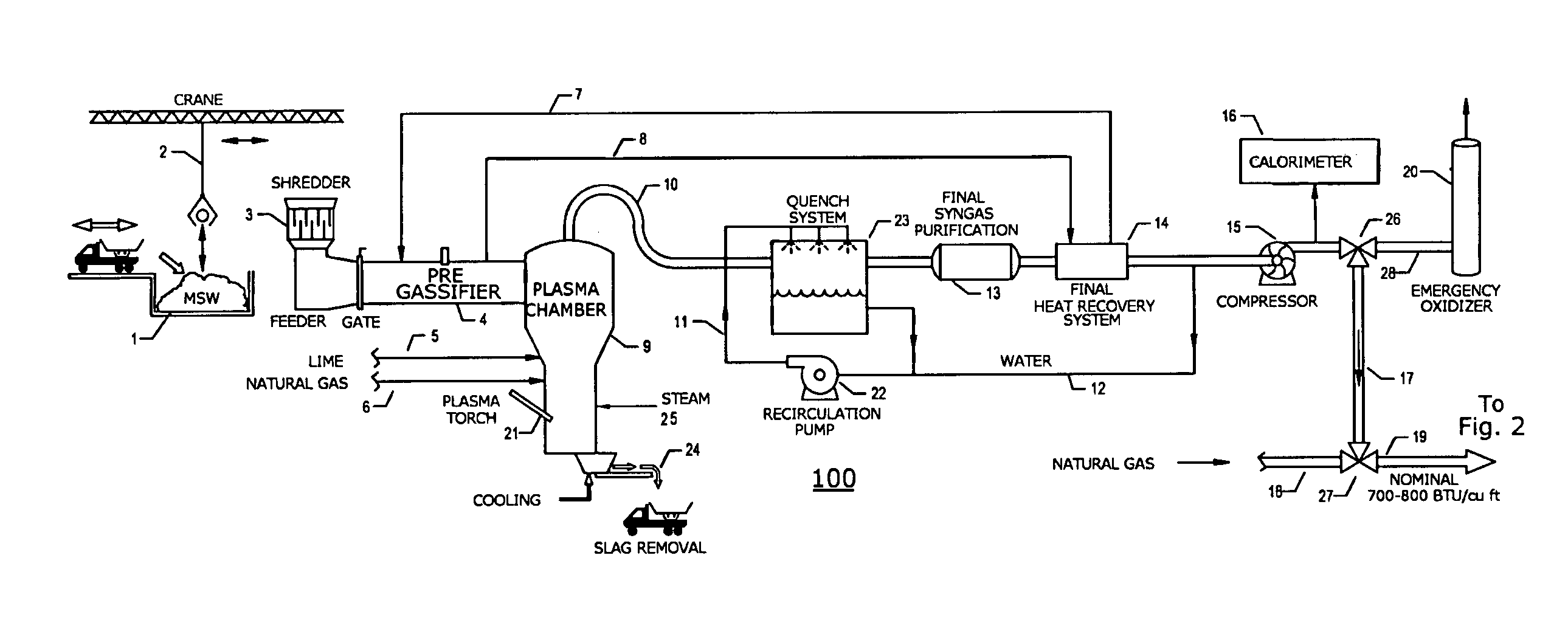

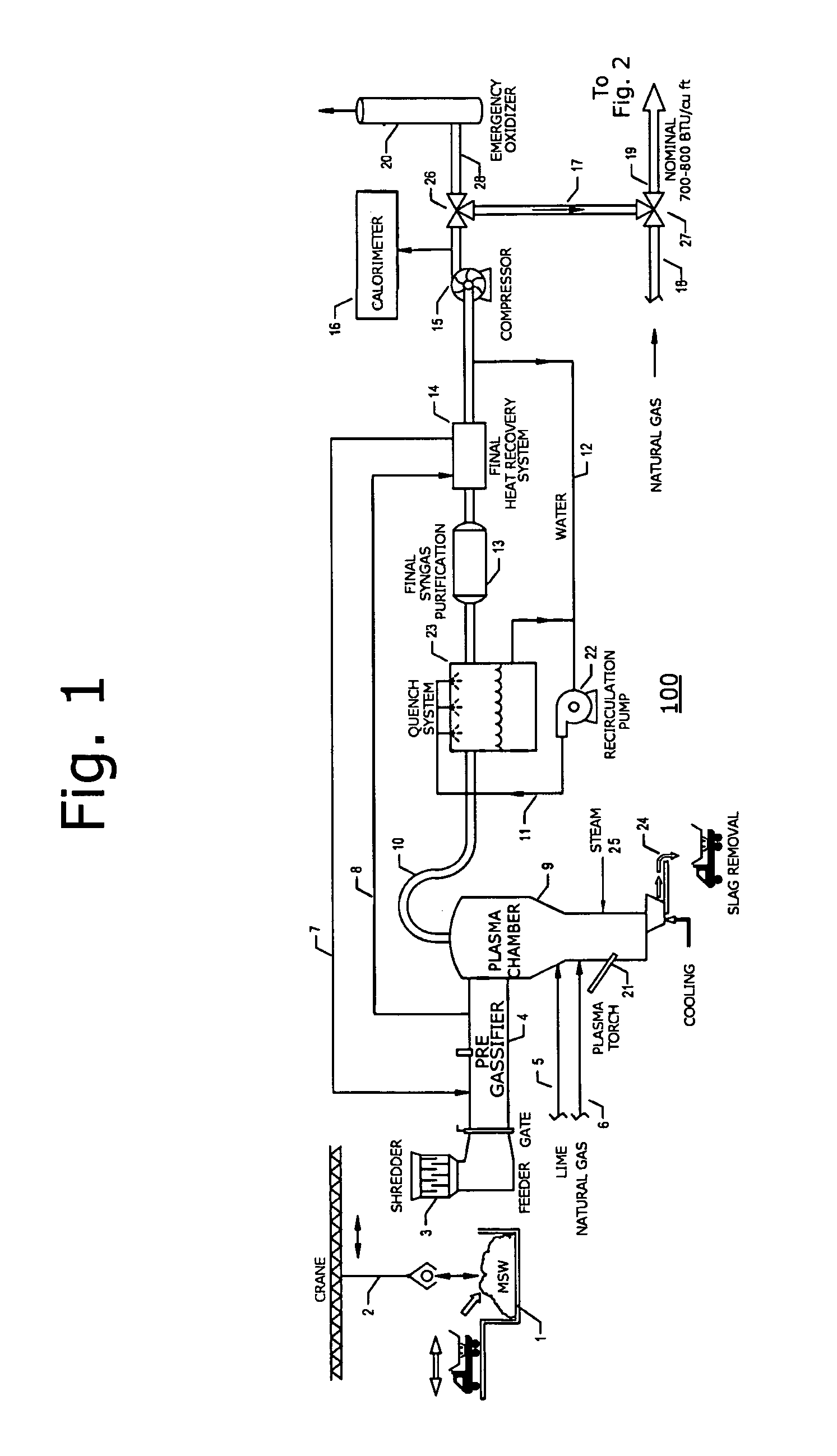

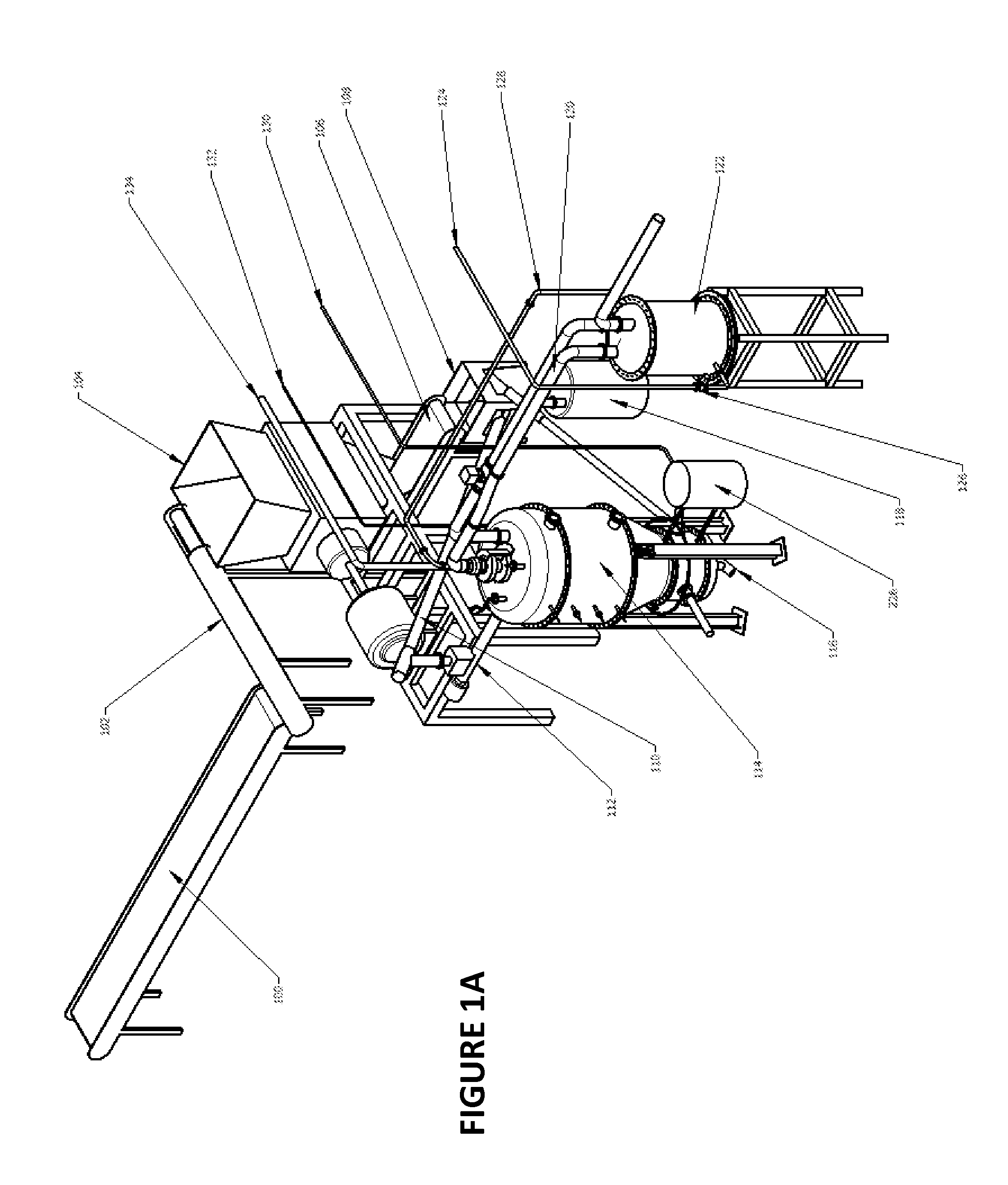

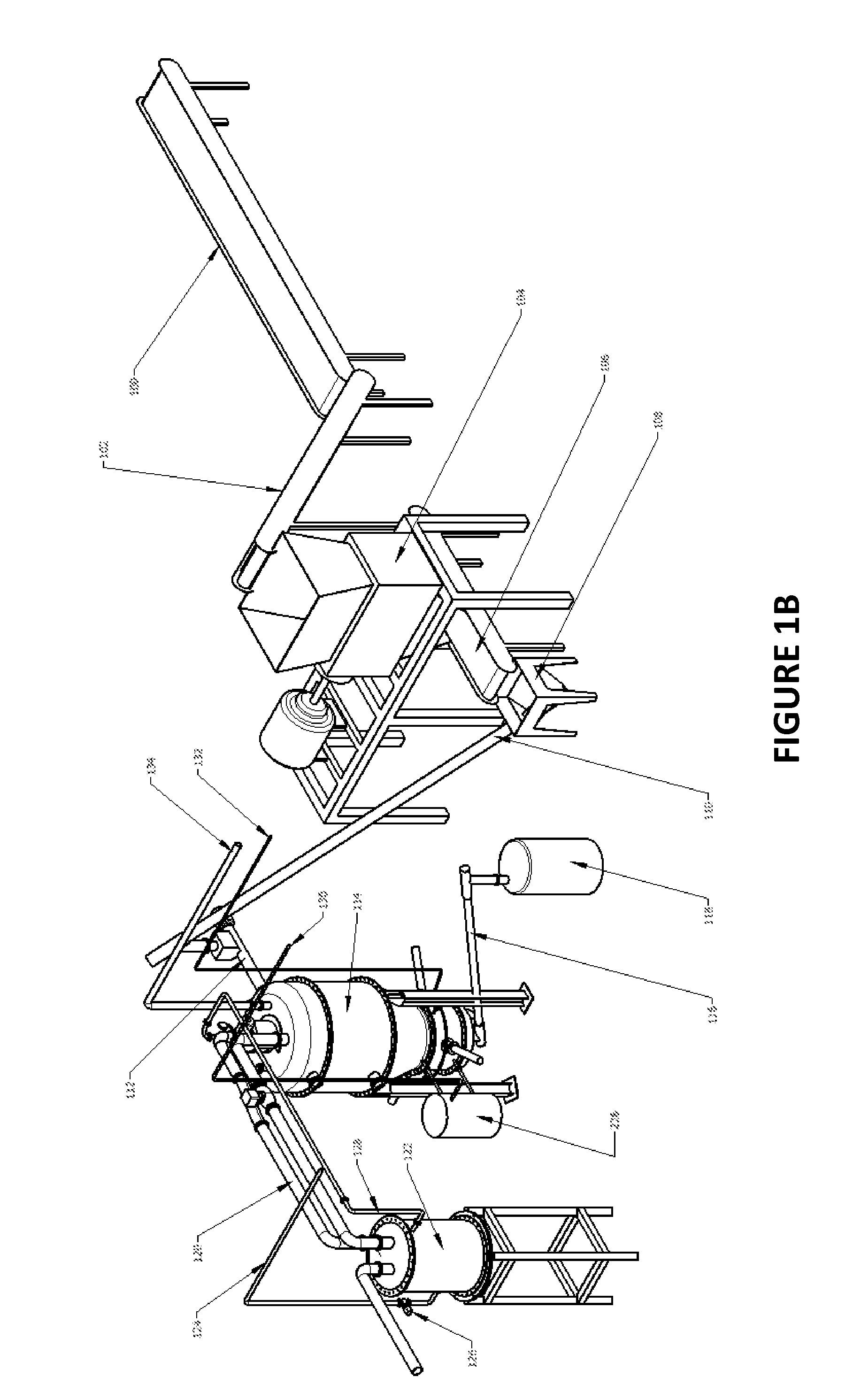

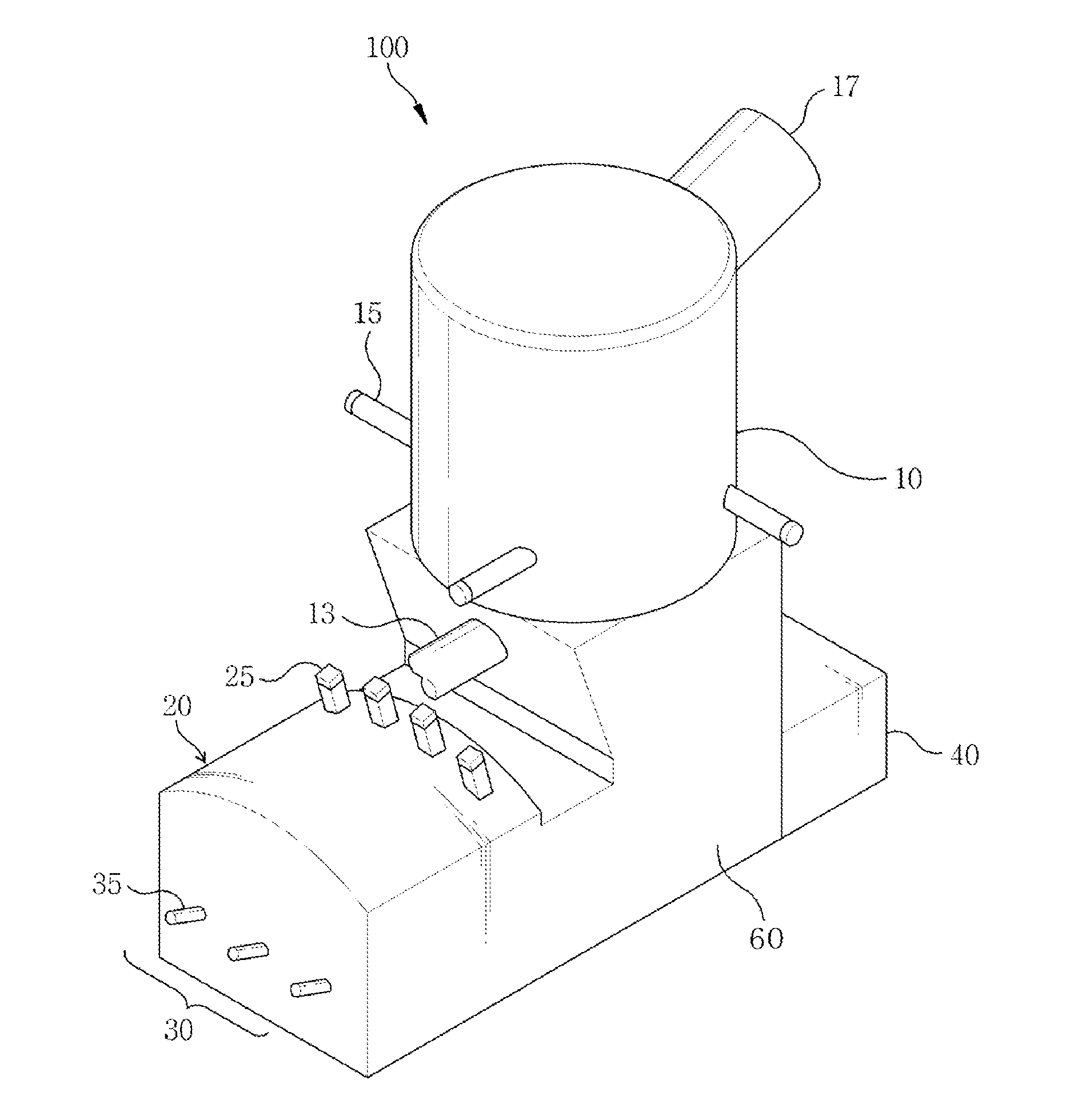

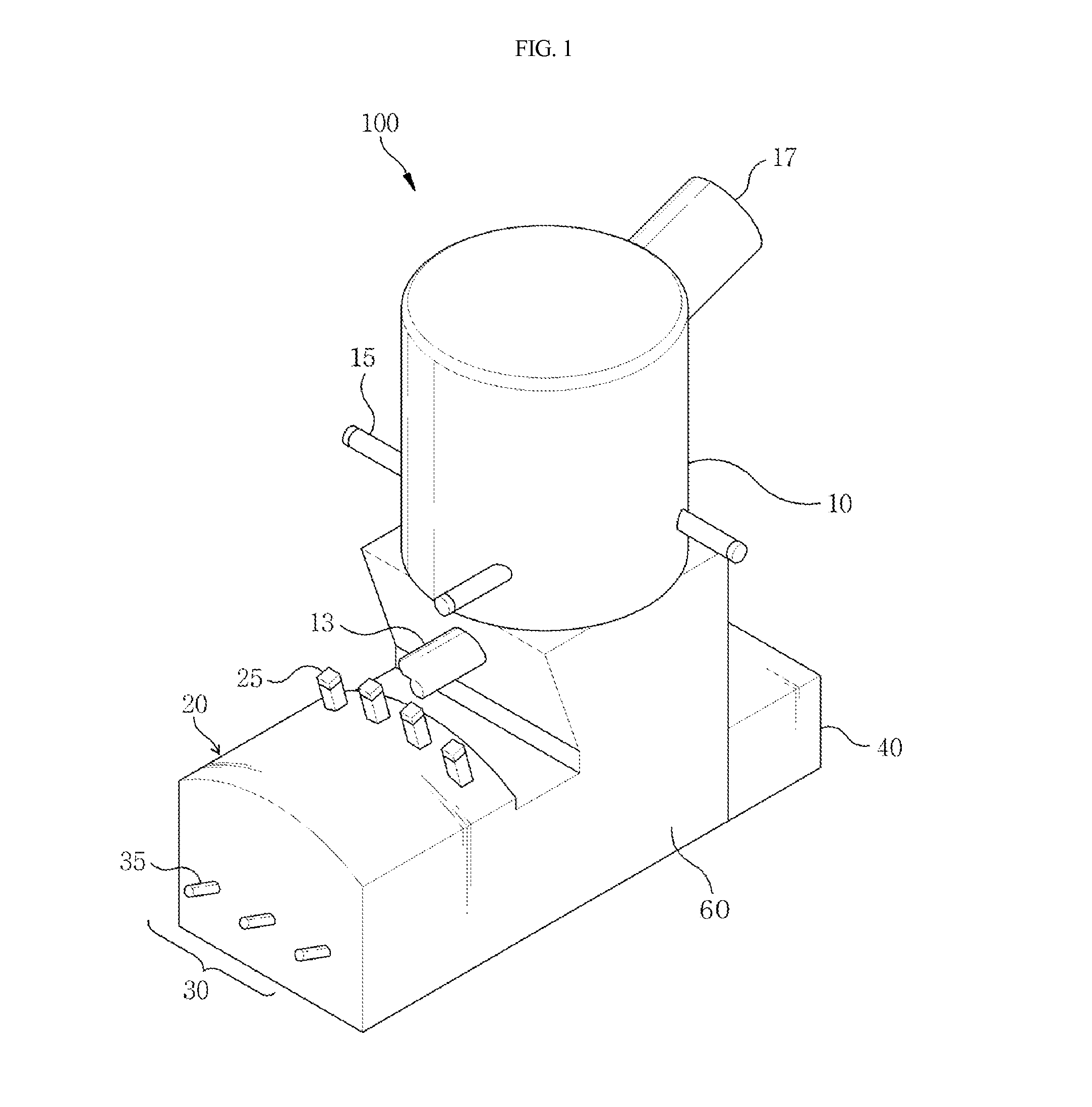

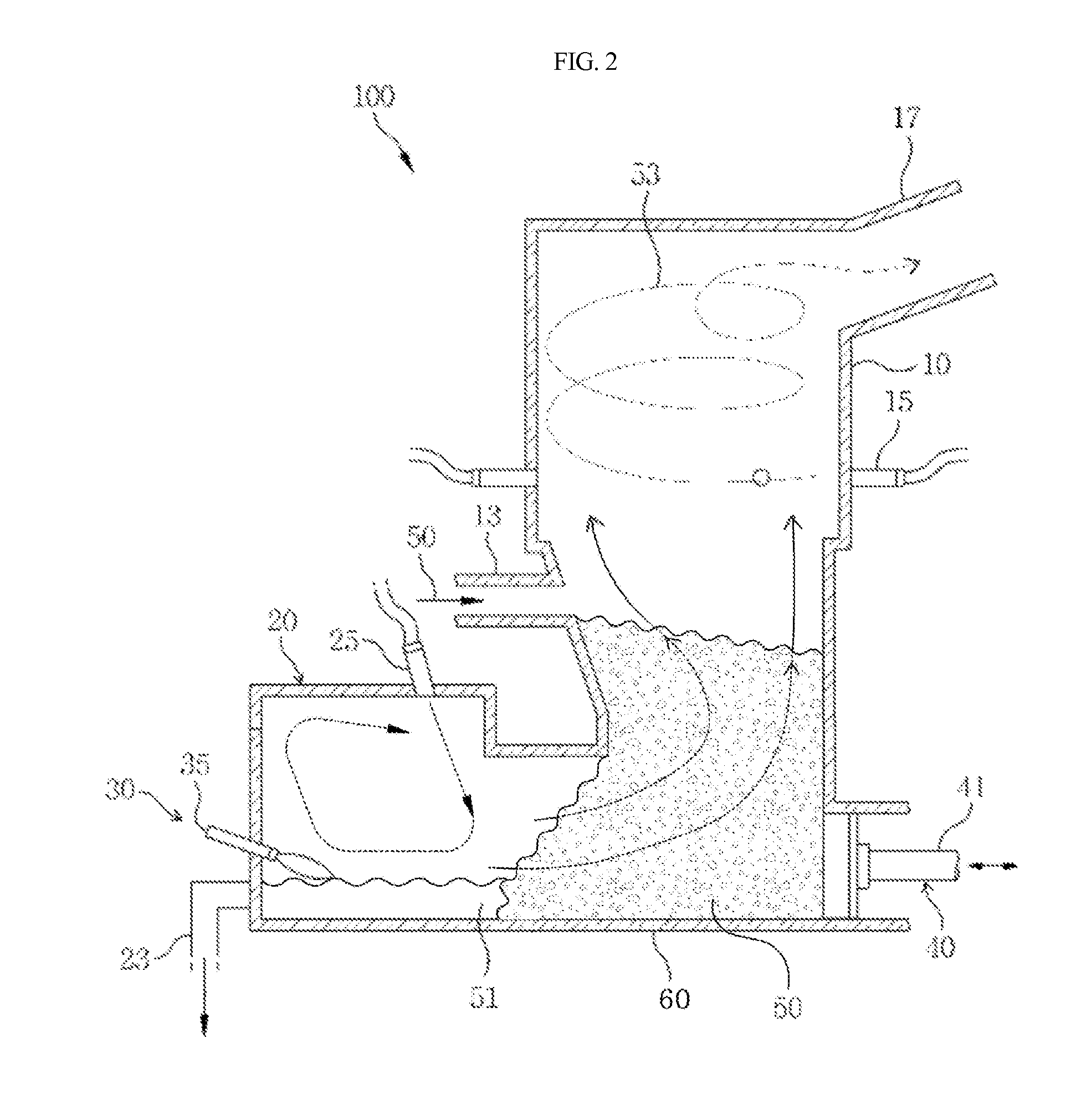

System and method for processing material to generate syngas

ActiveUS8574325B2Prevent escapeGasifier electrodesGas purification by non-gaseous materials condensationSyngasElectricity

Owner:RESPONSIBLE ENERGY

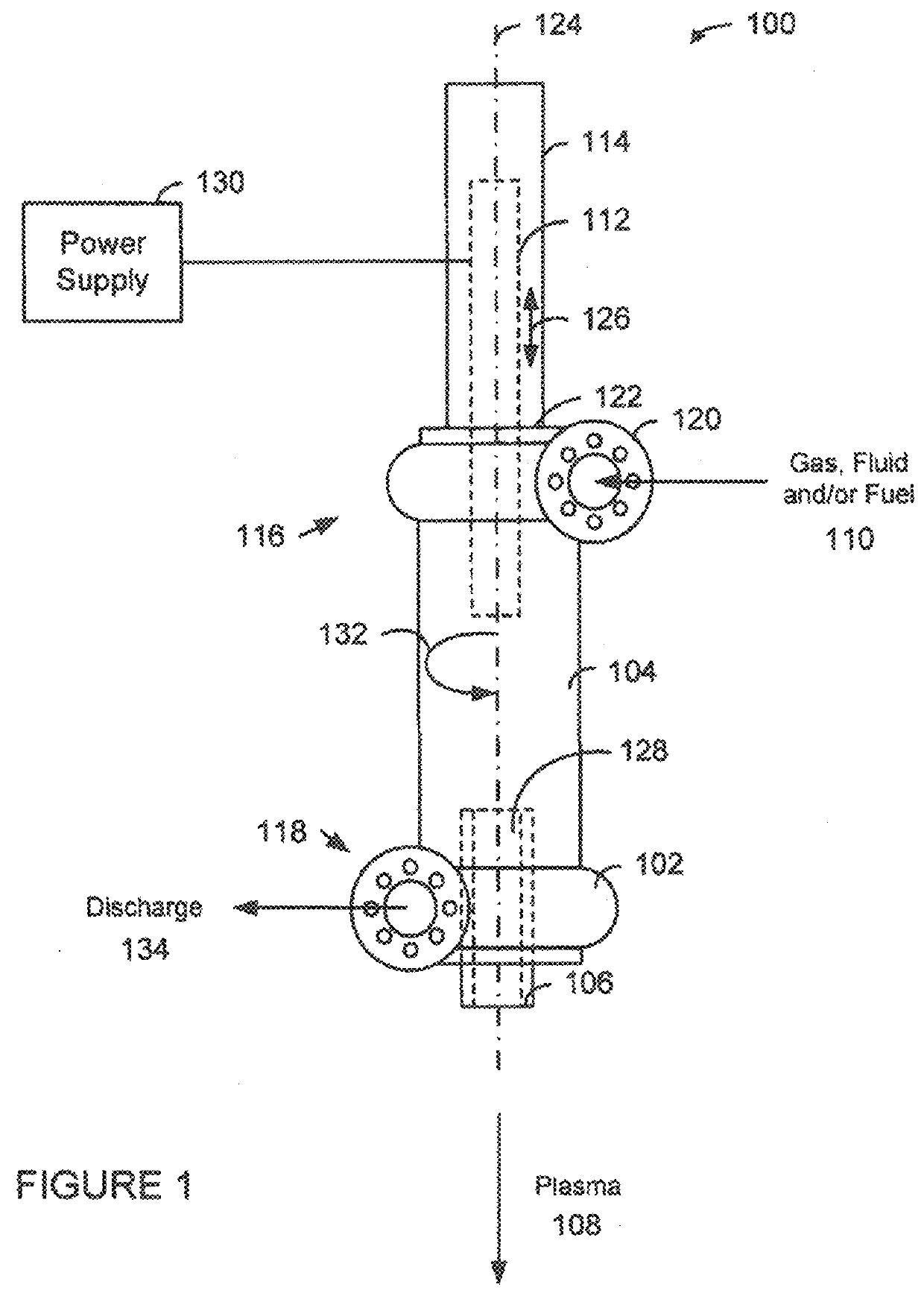

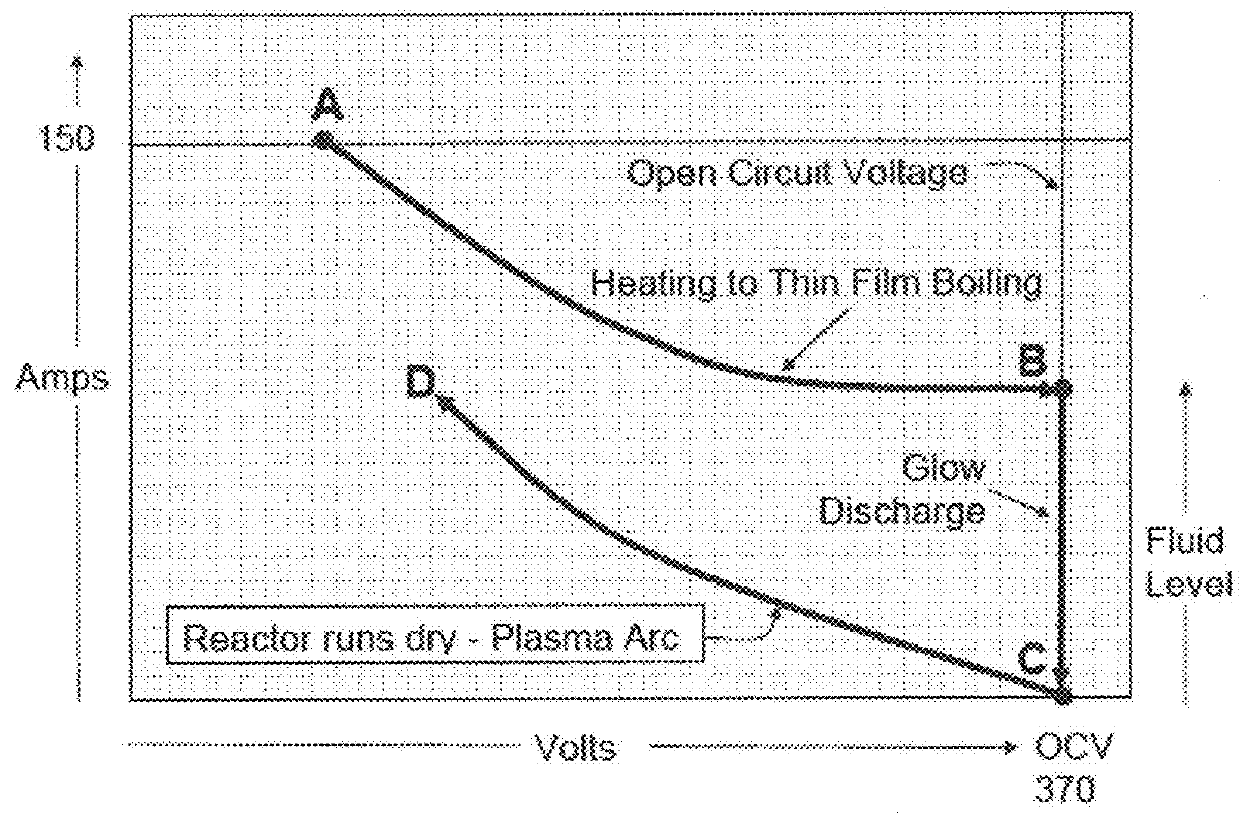

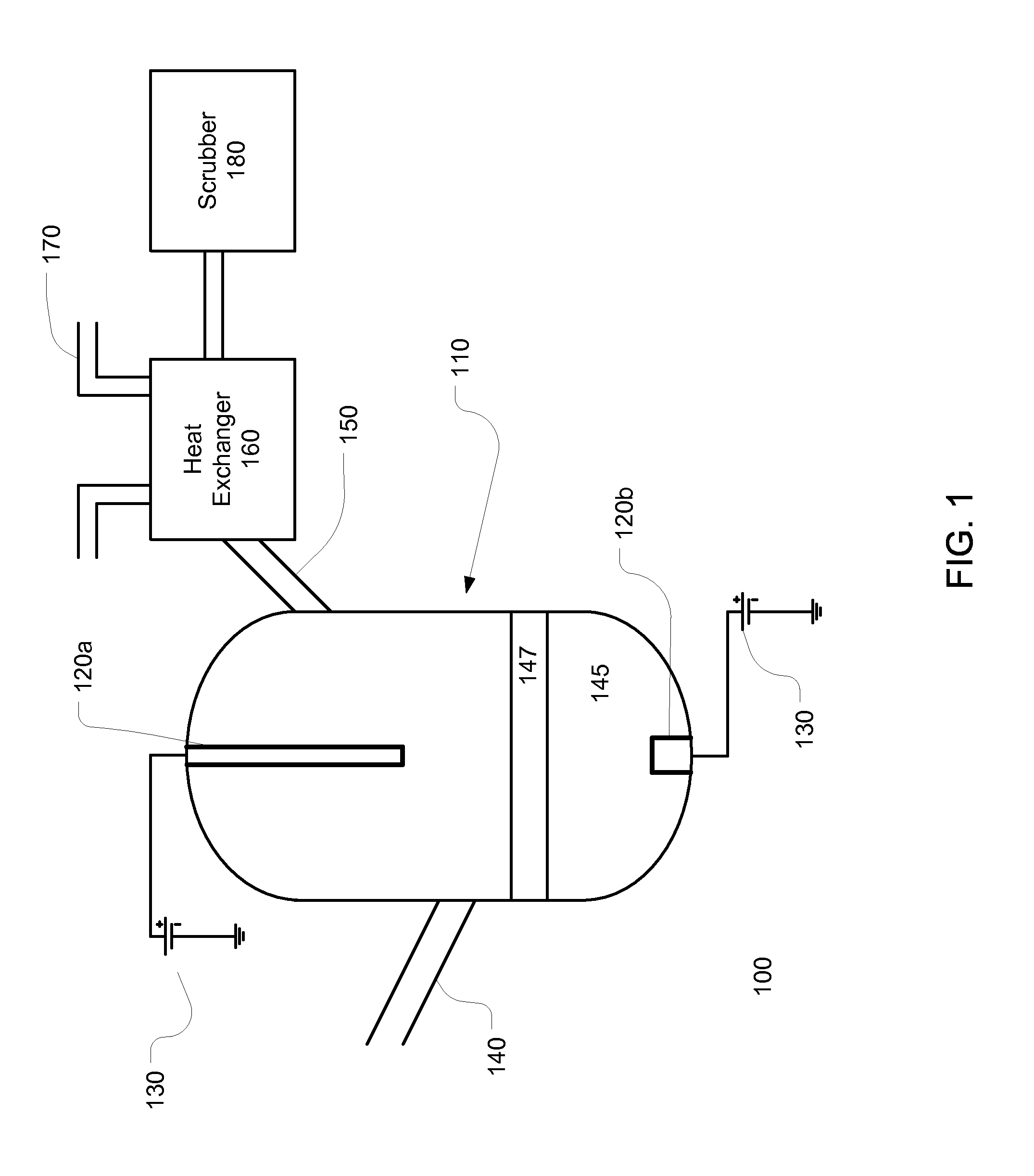

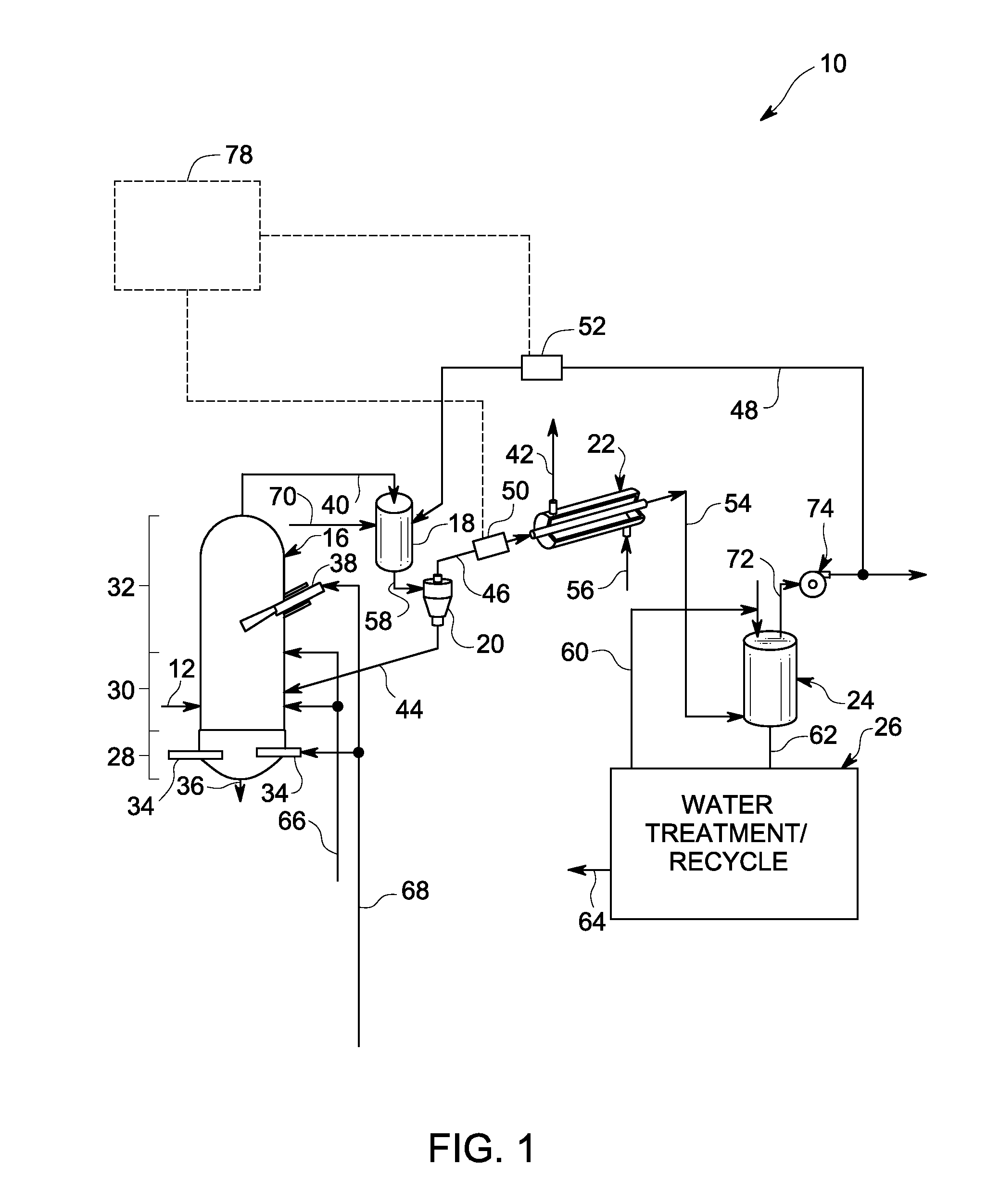

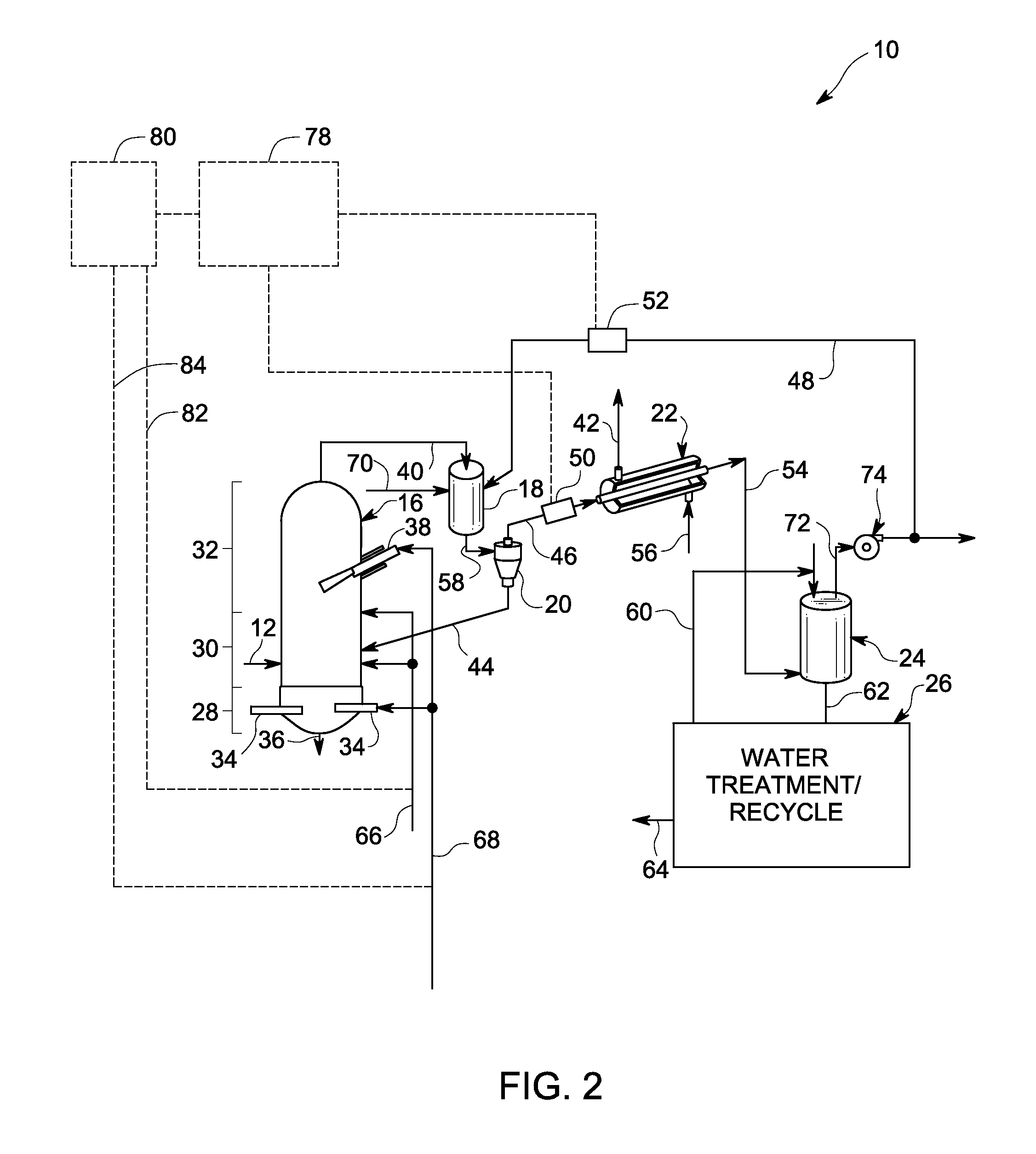

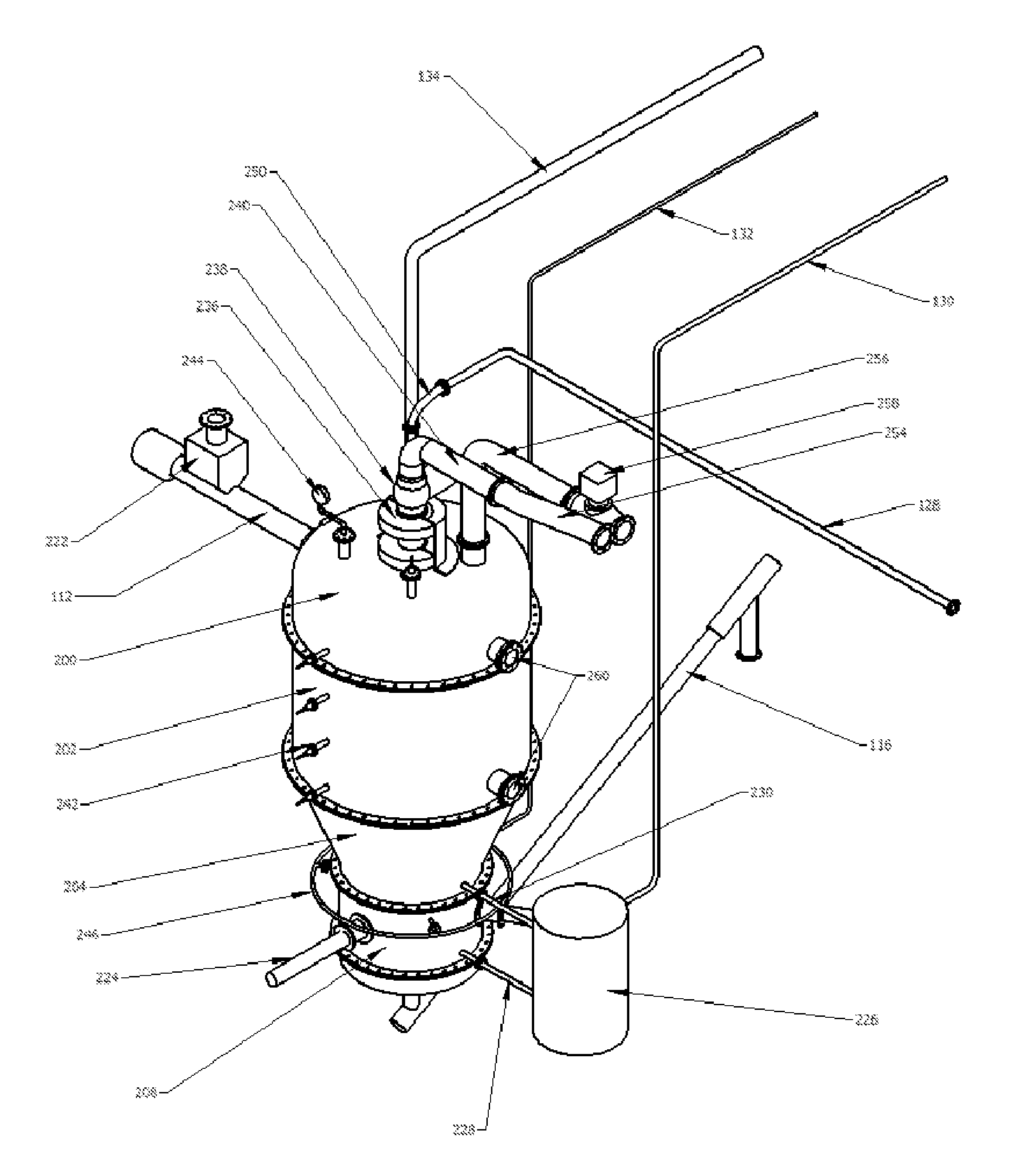

Water/wastewater recycle and reuse with plasma, activated carbon and energy system

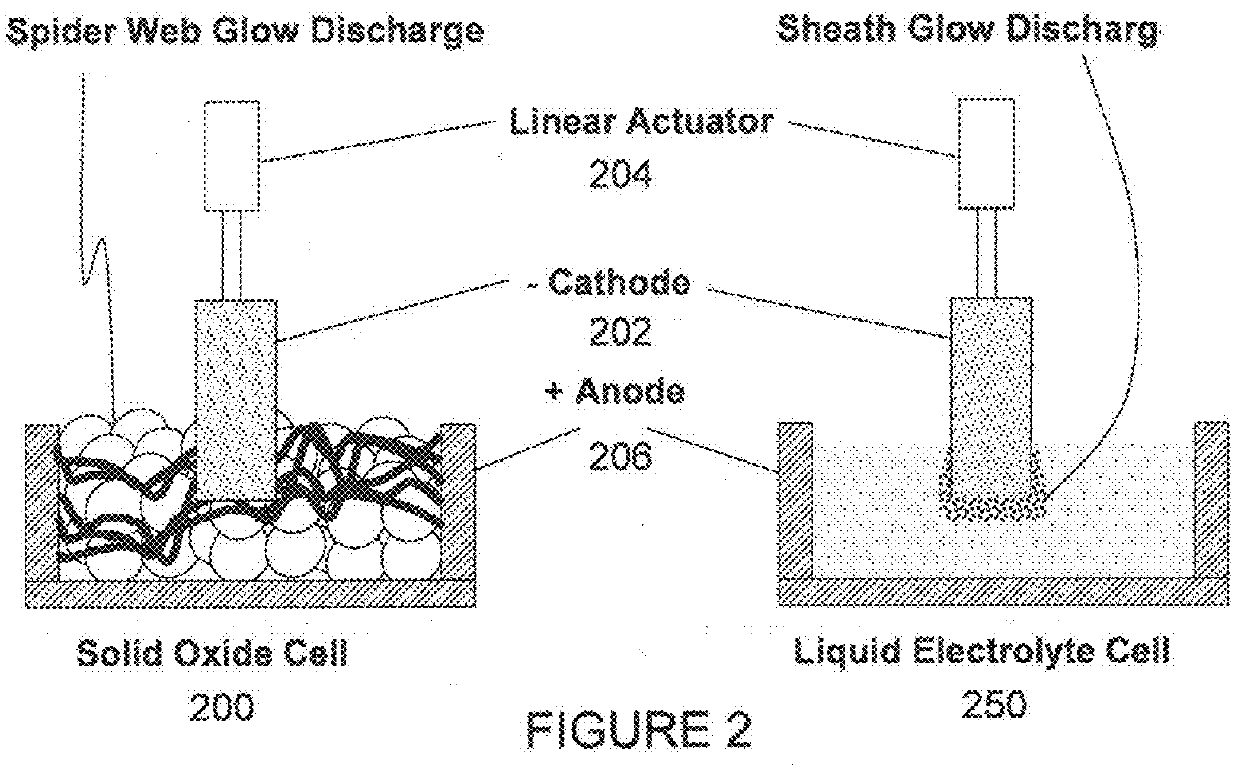

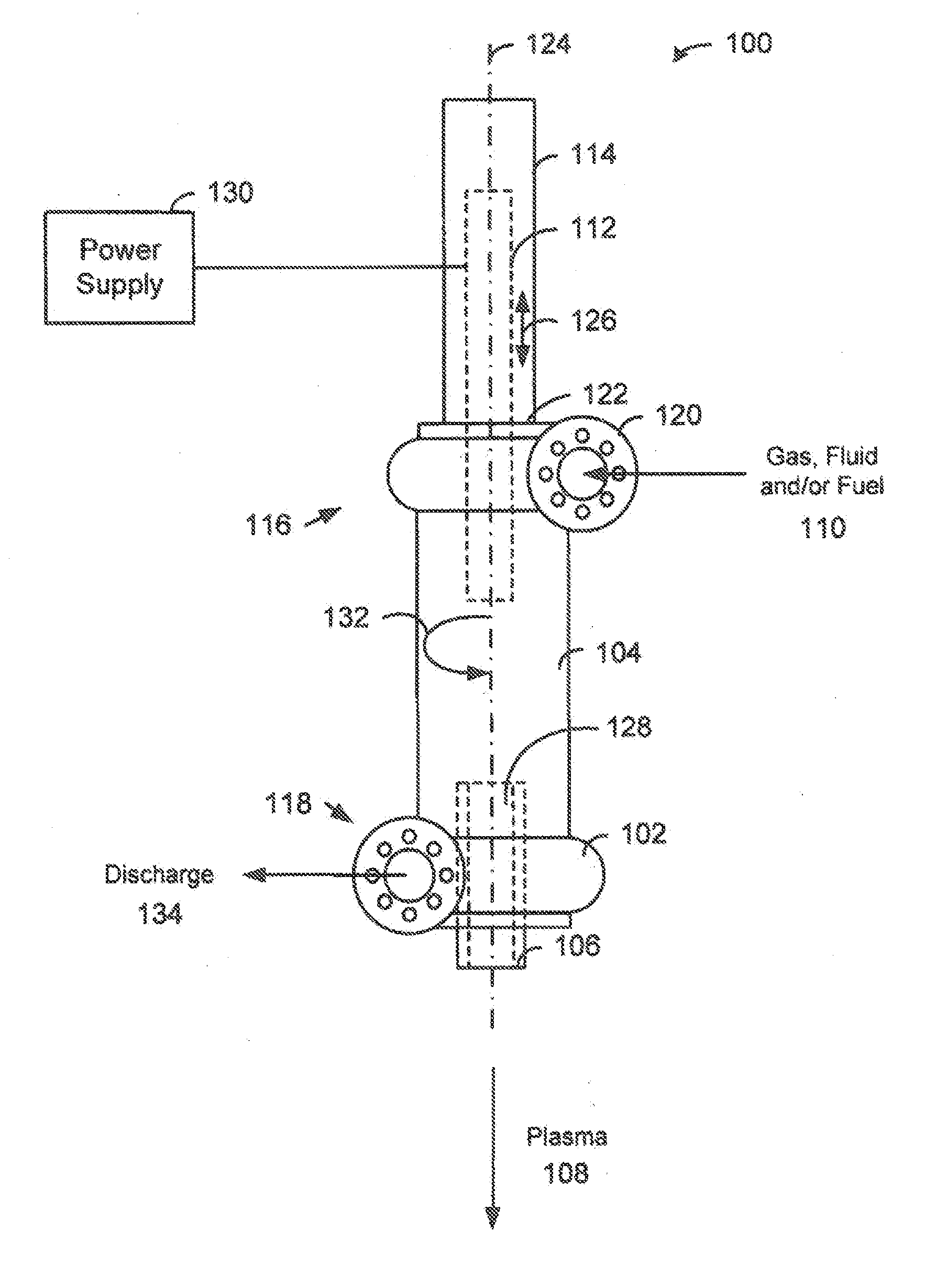

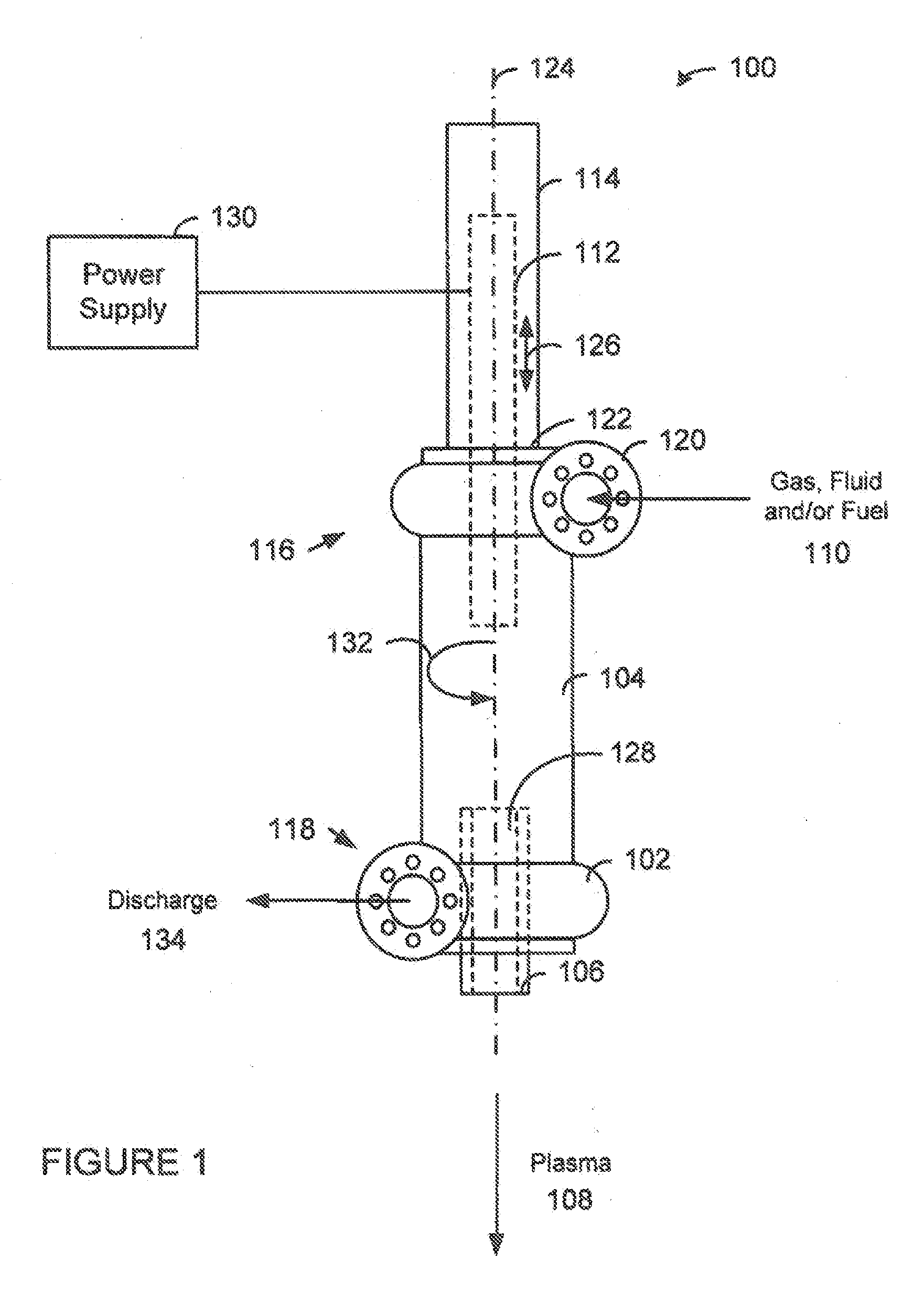

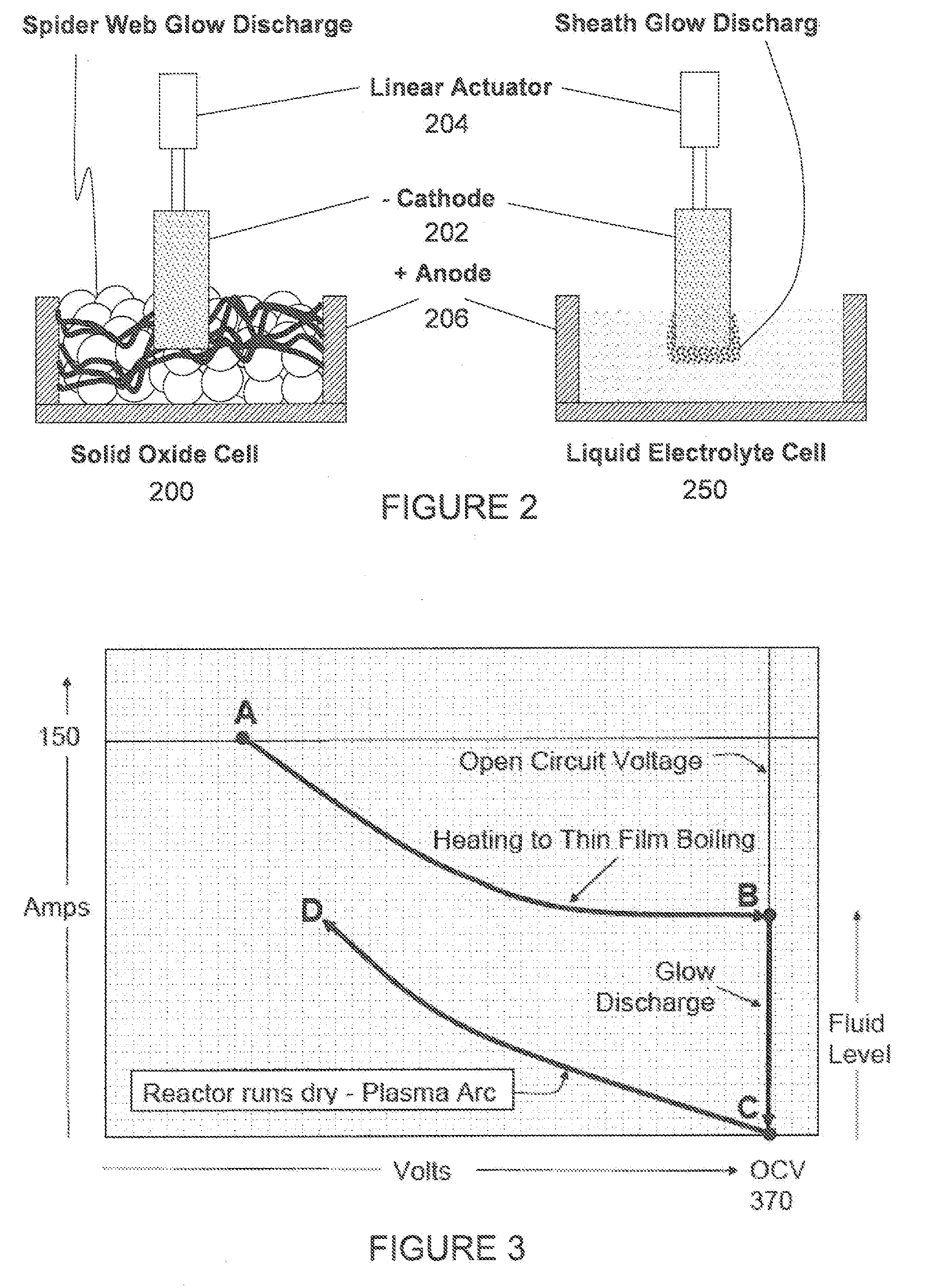

ActiveUS9230777B2Emission reductionFree chlorine residualGasifier electrodesThermionic cathodesActivated carbonTorch

The present invention provides a system that includes a glow discharge cell and a plasma arc torch. A first valve is connected to a wastewater source. An eductor has a first inlet, a second inlet and an outlet, wherein the first inlet is connected to the outlet of the electrically conductive cylindrical vessel, the second inlet is connected to the first valve, and the outlet is connected to the tangential inlet of the plasma arc torch. A second valve is connected between the tangential outlet of the plasma arc torch and the inlet of the glow discharge cell, such that the plasma arc torch provides the electrically conductive fluid to the glow discharge cell and the glow discharge cell provides a treated water via the outlet centered in the closed second end.

Owner:FORET PLASMA LABS

Water/wastewater recycle and reuse with plasma, activated carbon and energy system

ActiveUS20140210344A1Produce energySafe recyclingGasifier electrodesEnergy based wastewater treatmentActivated carbonEngineering

The present invention provides a system that includes a glow discharge cell and a plasma arc torch. A first valve is connected to a wastewater source. An eductor has a first inlet, a second inlet and an outlet, wherein the first inlet is connected to the outlet of the electrically conductive cylindrical vessel, the second inlet is connected to the first valve, and the outlet is connected to the tangential inlet of the plasma arc torch. A second valve is connected between the tangential outlet of the plasma arc torch and the inlet of the glow discharge cell, such that the plasma arc torch provides the electrically conductive fluid to the glow discharge cell and the glow discharge cell provides a treated water via the outlet centered in the closed second end.

Owner:FORET PLASMA LABS

Two-stage plasma process for converting waste into fuel gas and apparatus therefor

InactiveUS20110107669A1Limited amountImprove energy efficiencyGasifier electrodesGaseous fuelsCyclonePlasma jet

A two-step gasification process and apparatus for the conversion of solid or liquid organic waste into clean fuel, suitable for use in a gas engine or a gas burner, is described. The waste is fed initially into a primary gasifier, which is a graphite arc furnace. Within the primary gasifier, the organic components of the waste are mixed with a predetermined amount of air, oxygen or steam, and converted into volatiles and soot. The volatiles consist mainly of carbon monoxide and hydrogen, and may include a variety of other hydrocarbons and some fly ash. The gas exiting the primary gasifier first passes through a hot cyclone, where some of the soot and most of the fly ash is collected and returned to the primary gasifier. The remaining soot along with the volatile organic compounds is further treated in a secondary gasifier where the soot and the volatile compounds mix with a high temperature plasma jet and a metered amount of air, oxygen or steam, and are converted into a synthesis gas consisting primarily of carbon monoxide and hydrogen. The synthesis gas is then quenched and cleaned to form a clean fuel gas suitable for use in a gas engine or a gas burner. This offers higher thermal efficiency than conventional technology and produces a cleaner fuel than other known alternatives.

Owner:PYROGENESIS CANADA INC

High pressure gasifier system using electrically assisted heating

ActiveUS20110126461A1Good and more complete processingIncrease temperatureGasifier electrodesEngine sealsElectricityMicrowave

The problems of the prior art are overcome by the apparatus and method disclosed herein. The reactor vessel of a plasma gasifier is operated at high pressure. To compensate for the negative effects of high pressure, various modifications to the plasma gasifier are disclosed. For example, by moving the slag, more material is exposed to the plasma, allowing better and more complete processing thereof. In some embodiments, magnetic fields are used to cause movement of the slag and molten metal within the vessel. An additional embodiment is to add microwave heating of the slag and / or the incoming material. Microwave heating can also be used as an alternative to plasma heating in a high pressure gasification system.

Owner:INENTEC

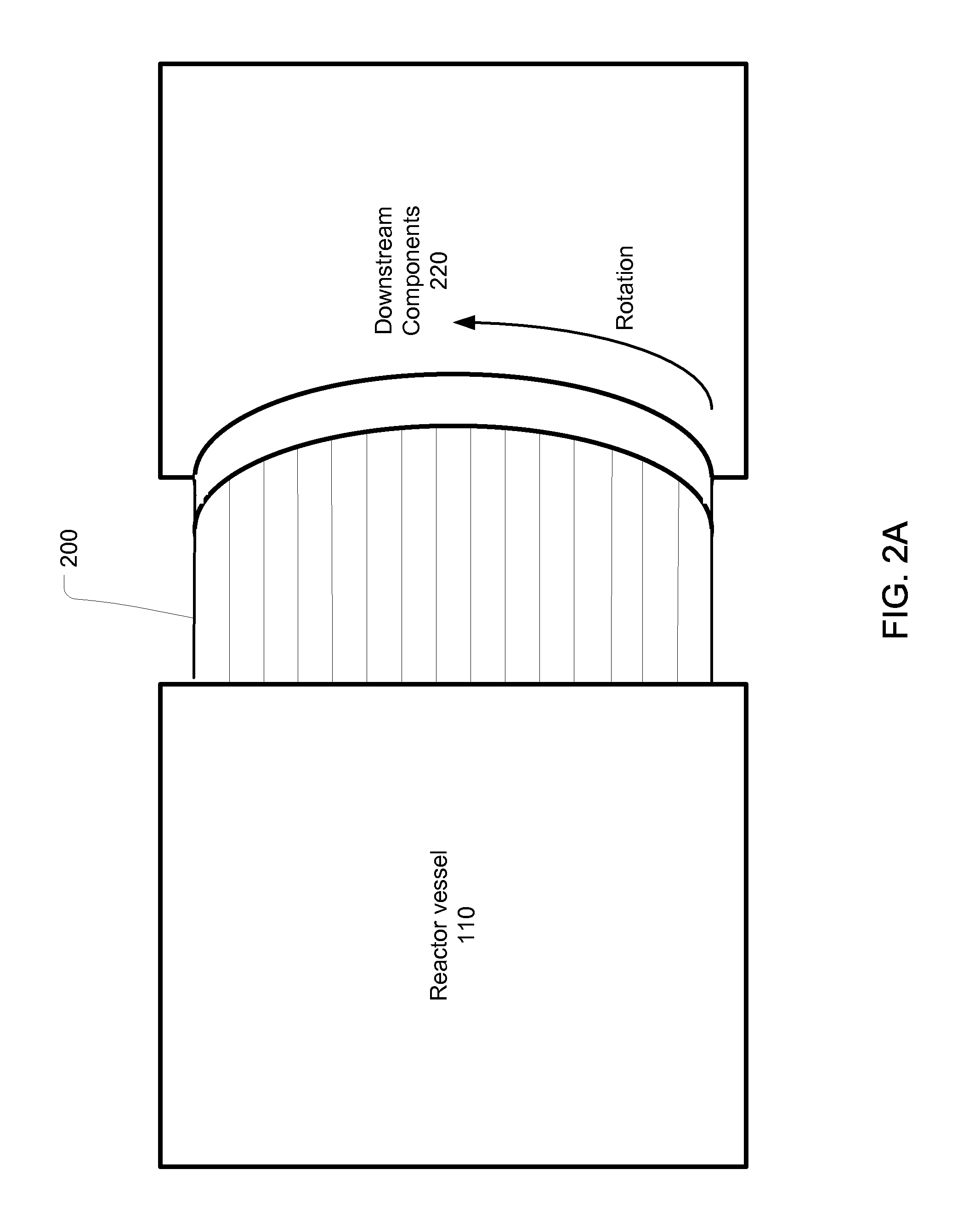

Regenerator for syngas cleanup and energy recovery in gasifier systems

ActiveUS20110126460A1Reduce heatReduce the amount requiredGasifier electrodesGasifier mechanical detailsSyngasParticulates

A rotating heat regenerator is used to recover heat from the syngas at it exits the reactor vessel of a waste or biomass gasifier. In some embodiments, three or more streams are passed through the heat exchanger. One stream is the dirty syngas, which heats the rotating material. A second stream is a cold stream that is heated as it passes through the material. A third stream is a cleaning stream, which serves to remove particulates that are collected on the rotating material as the dirty syngas passes through it. This apparatus can also be used as an auto-heat exchanger, or it can exchange heat between separate flows in the gasifier process. The apparatus can also be used to reduce the heating requirement for the thermal residence chamber (TRC) used downstream from the gasification system.

Owner:INENTEC

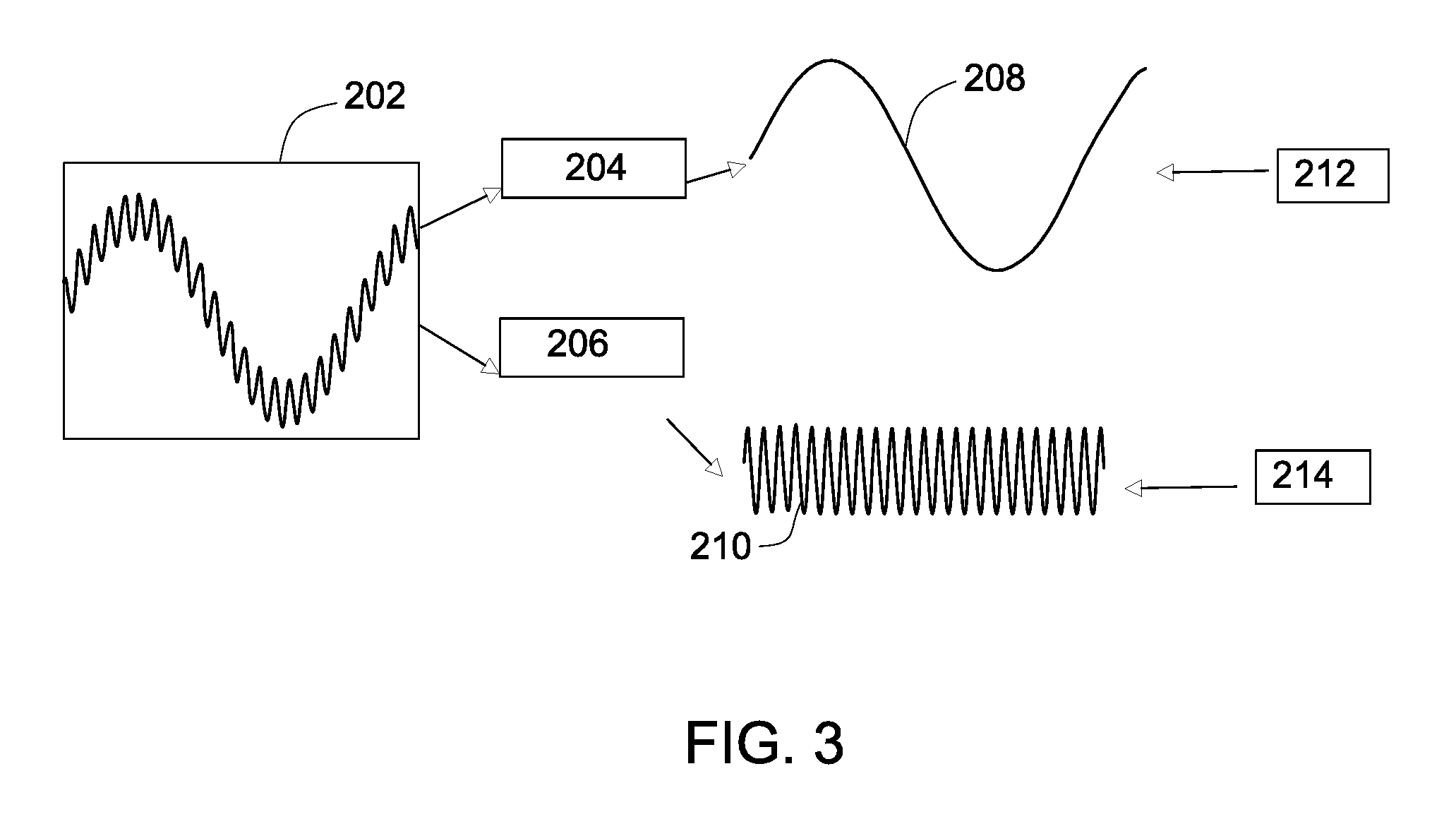

Sensing and control for plasma-assisted waste gasification

A plasma-assisted waste gasification system including a sensing mechanism and process for converting waste stream reaction residues into a clean synthesis gas (syngas) is disclosed. The gasification system includes a first sensor located between a gas quench unit and a heat recovery unit to measure a first temperature and first flow rate of the synthesis gas exiting the gas quench unit; a second sensor to measure a second temperature and a second flow rate of a low temperature synthesis gas entering the gas quench unit; wherein the first sensor and the second sensor are connected to an inferential sensing mechanism. The inferential sensing mechanism is capable of estimating the temperature of the synthesis gas in the reactor, based on the measured first temperature and first flow rate, and the measured second temperature and second flow rate, using a mass-energy balance relationship that is based on the measurements of the two sensors. Another aspect of the invention relates to a control unit to control the temperature of the reactor to a required operating temperature range.

Owner:GENERAL ELECTRIC CO

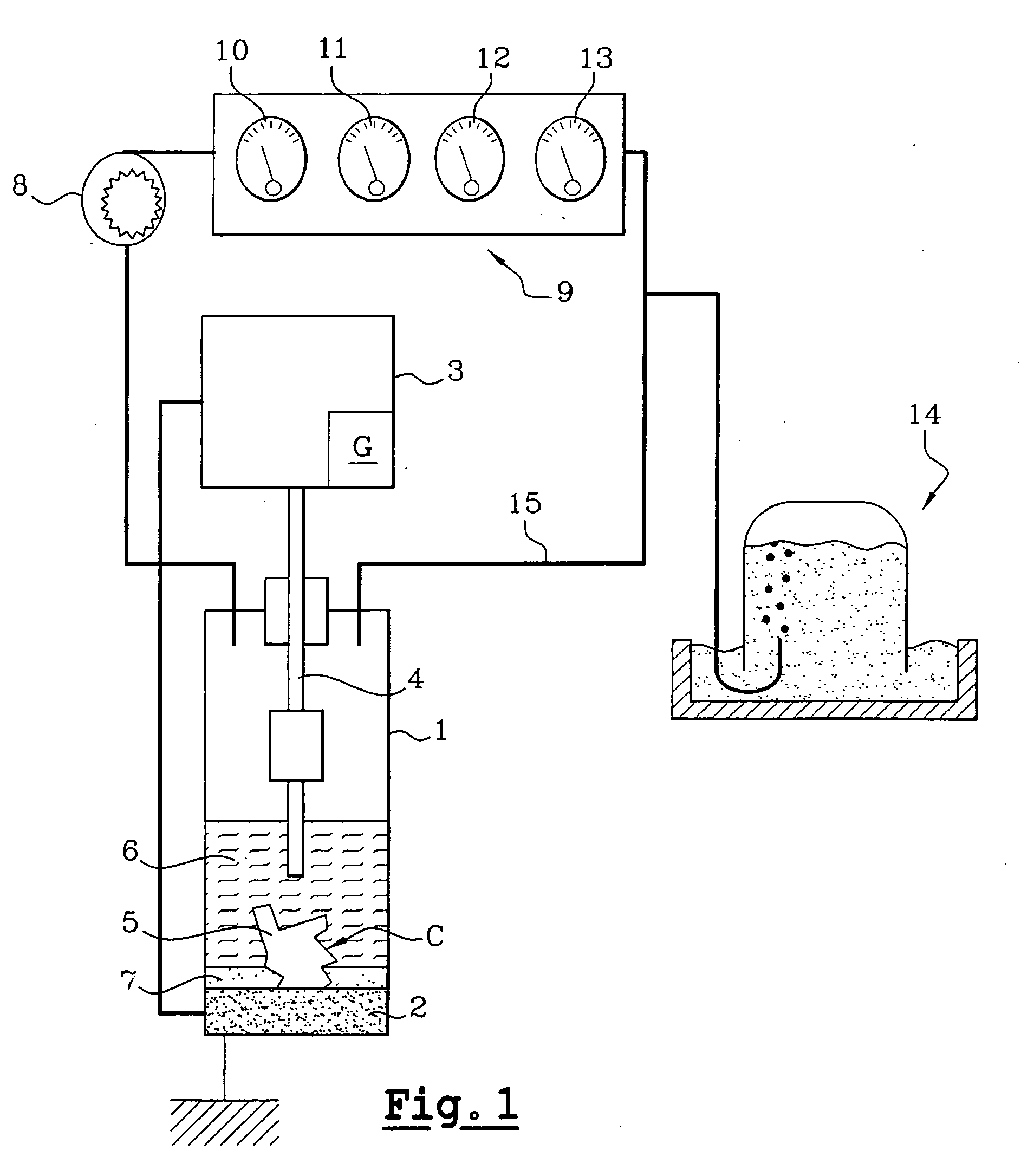

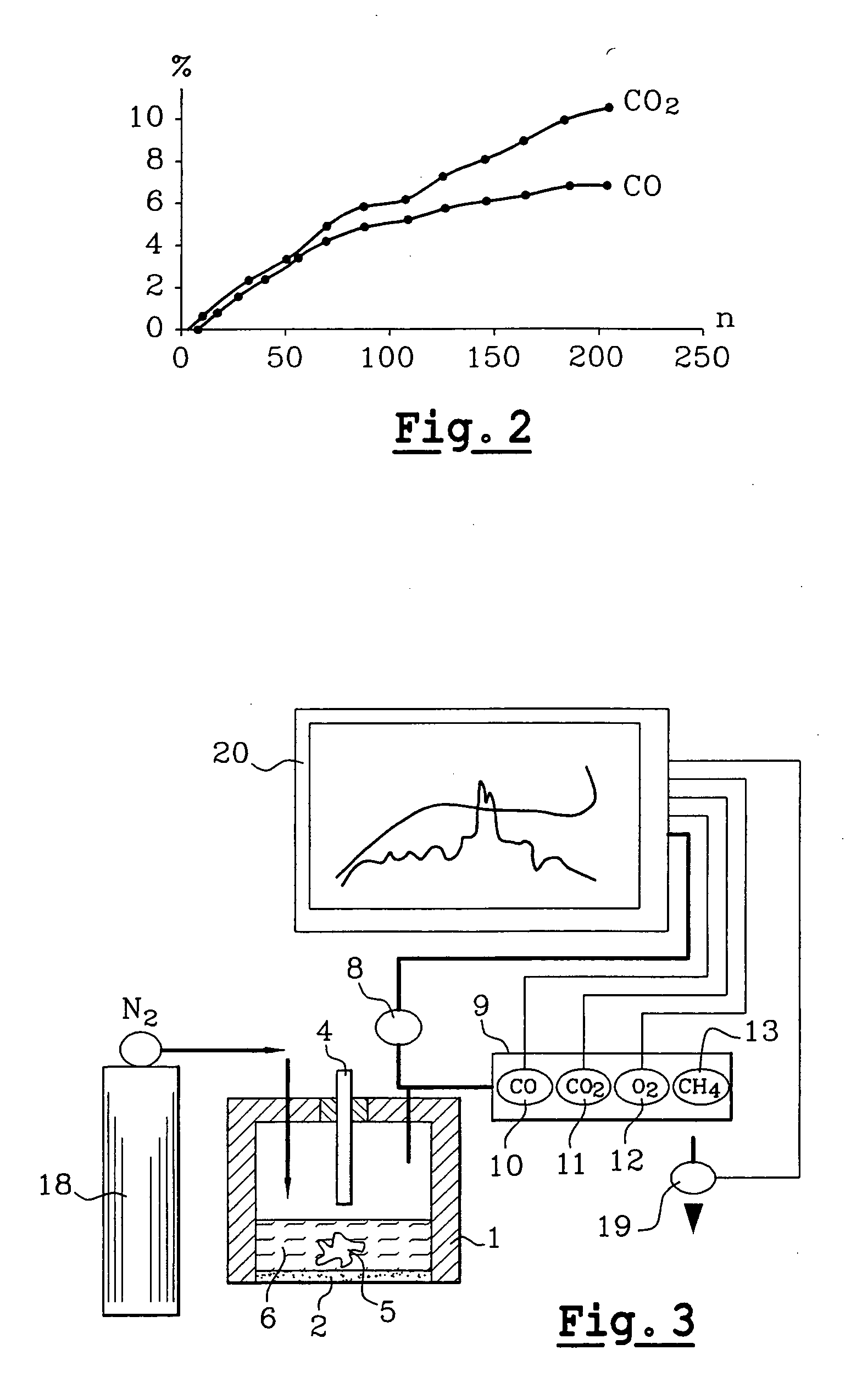

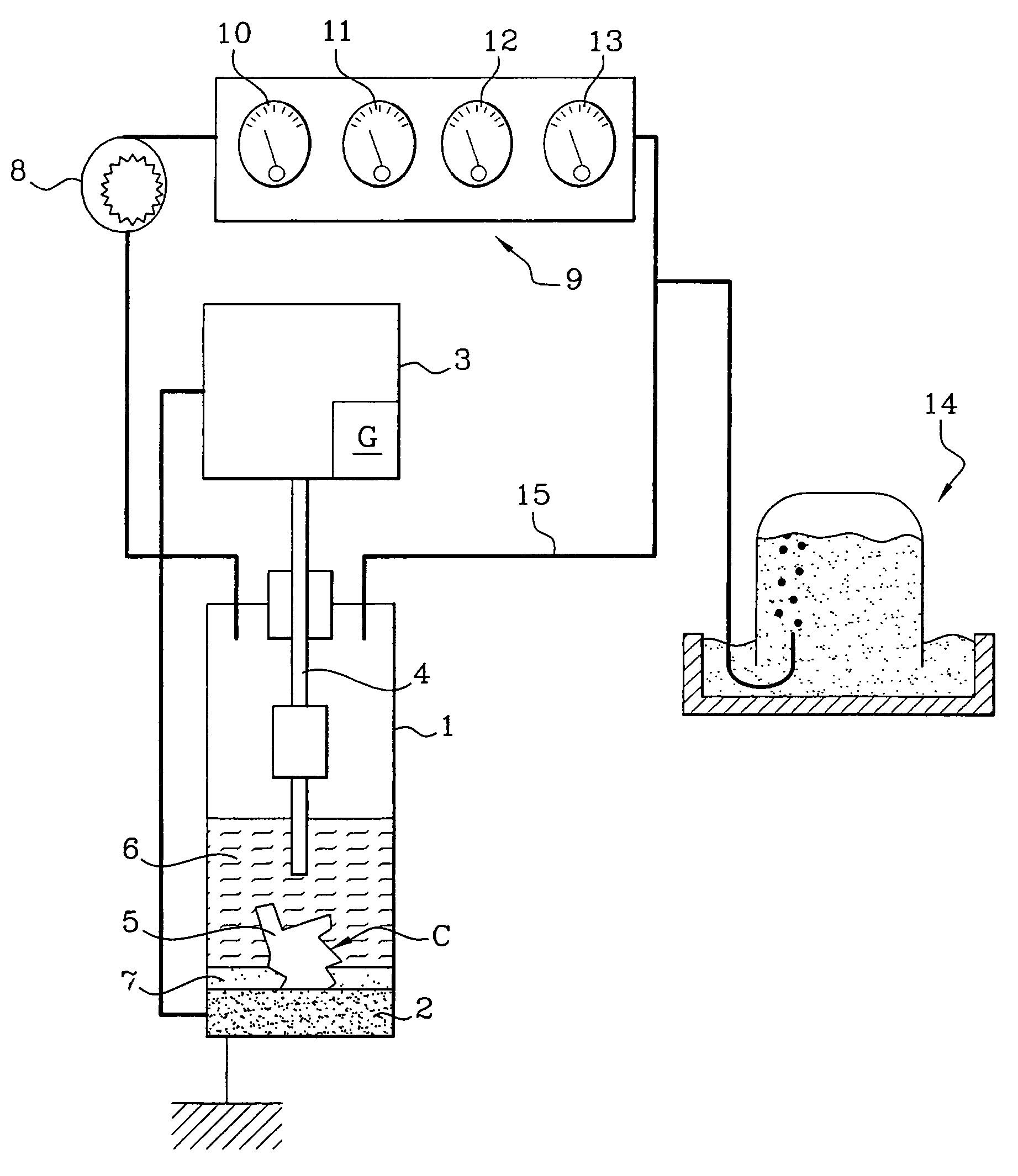

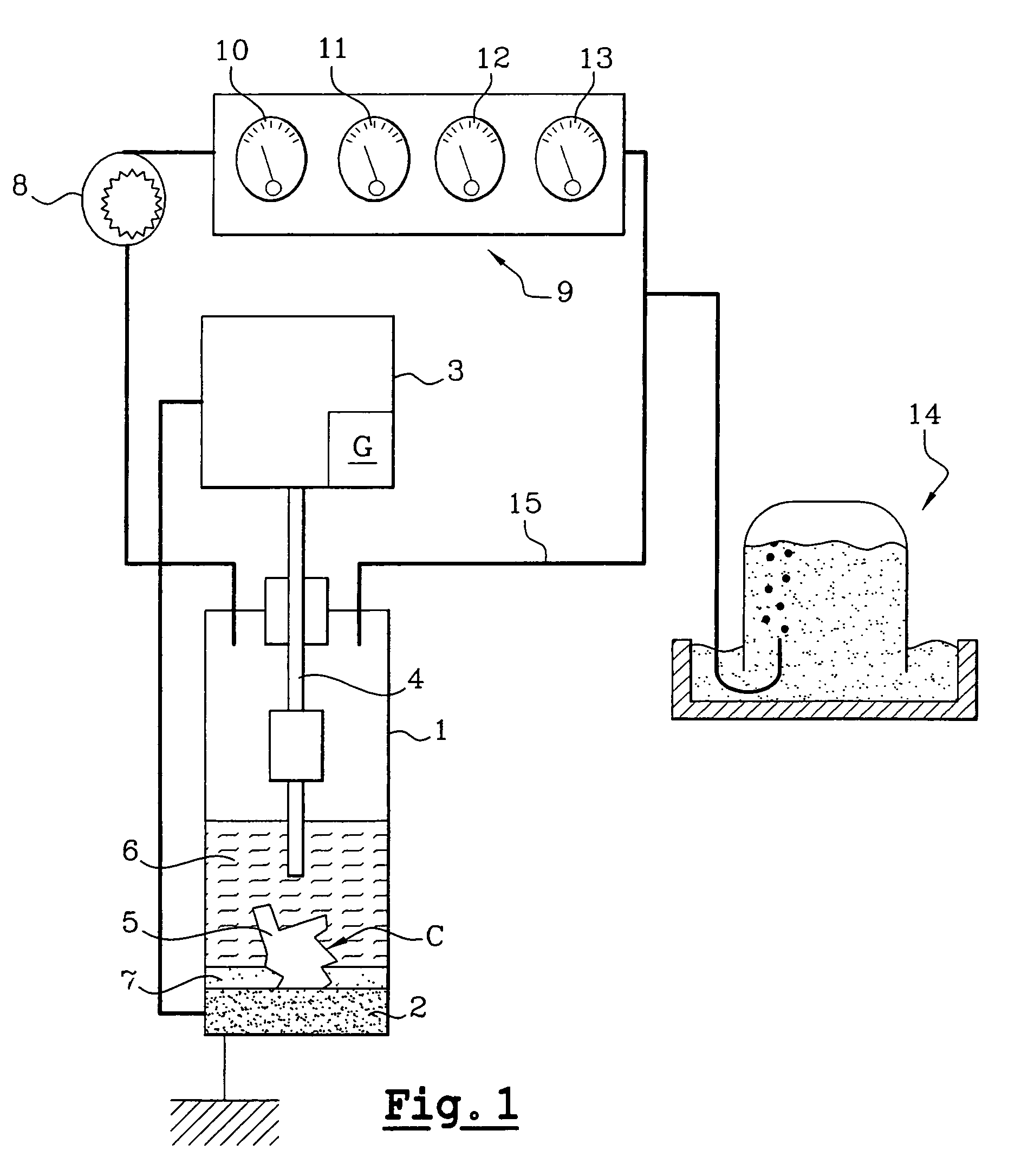

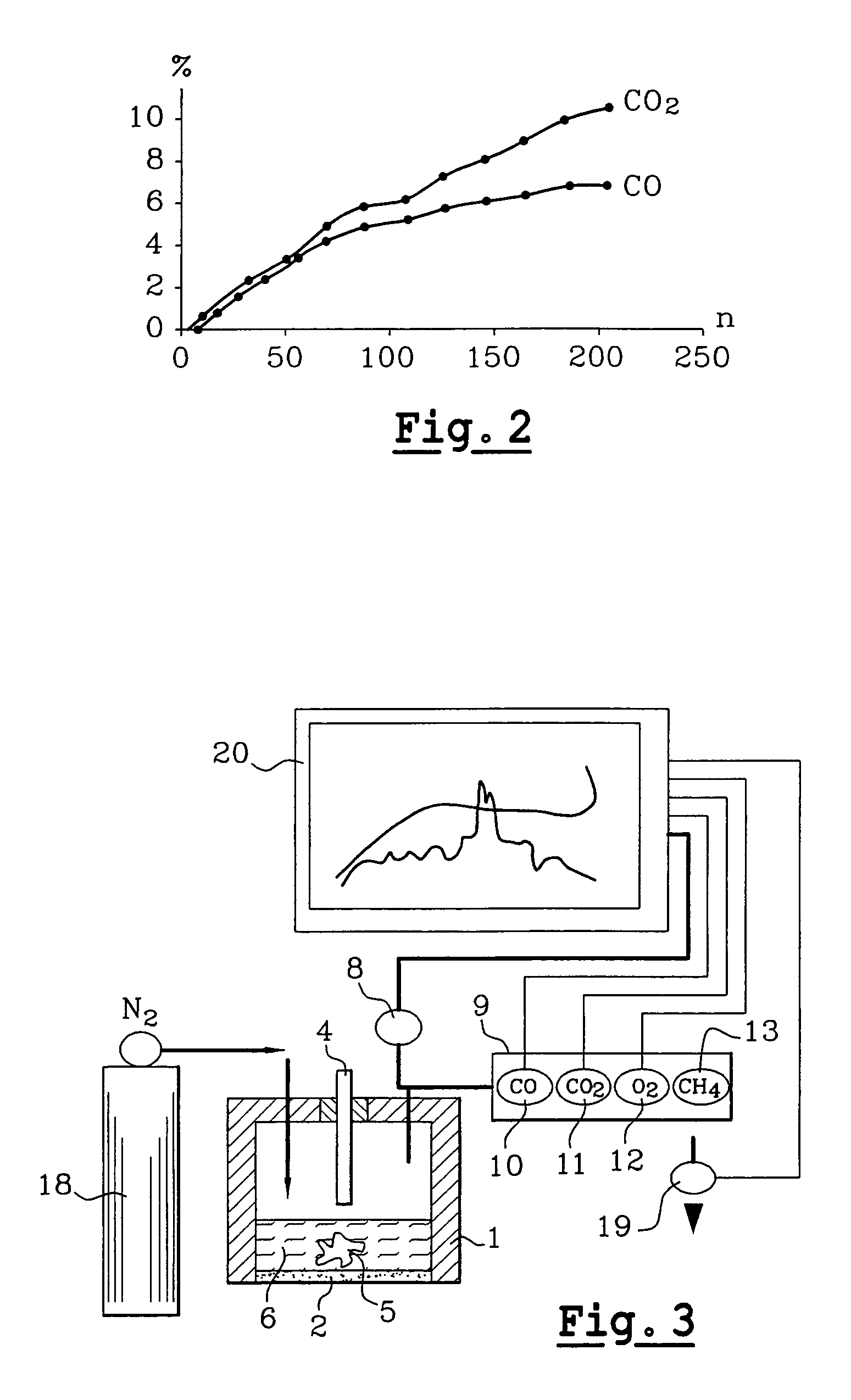

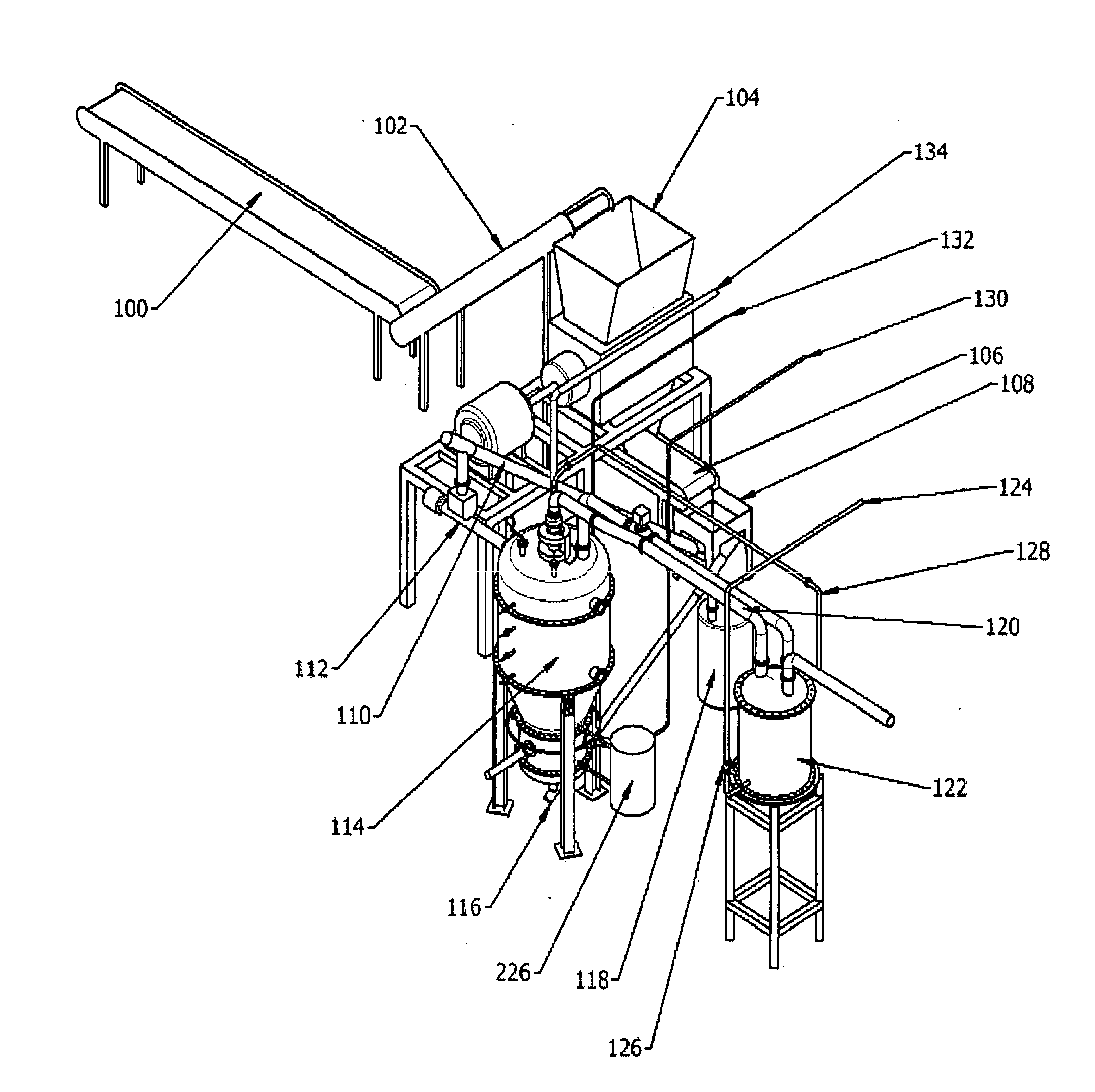

Method for destroying a nuclear graphite by gasification in aqueous medium

A process for the treatment of a nuclear graphite contaminated with radioelements includes subjecting the graphite, immersed in a medium containing water, to high-voltage pulses. The pulses have sufficient energy for electric arcs to be initiated and to break the constituent bonds of the water molecules and the carbon-carbon bonds of the graphite. The number of high-voltage pulses is determined so as to convert the graphite into gas.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Gasification System

ActiveUS20120090237A1Reduce materialMaximize effectivenessGasifier electrodesHydrogenProcess engineeringSolid material

Owner:INENTEC

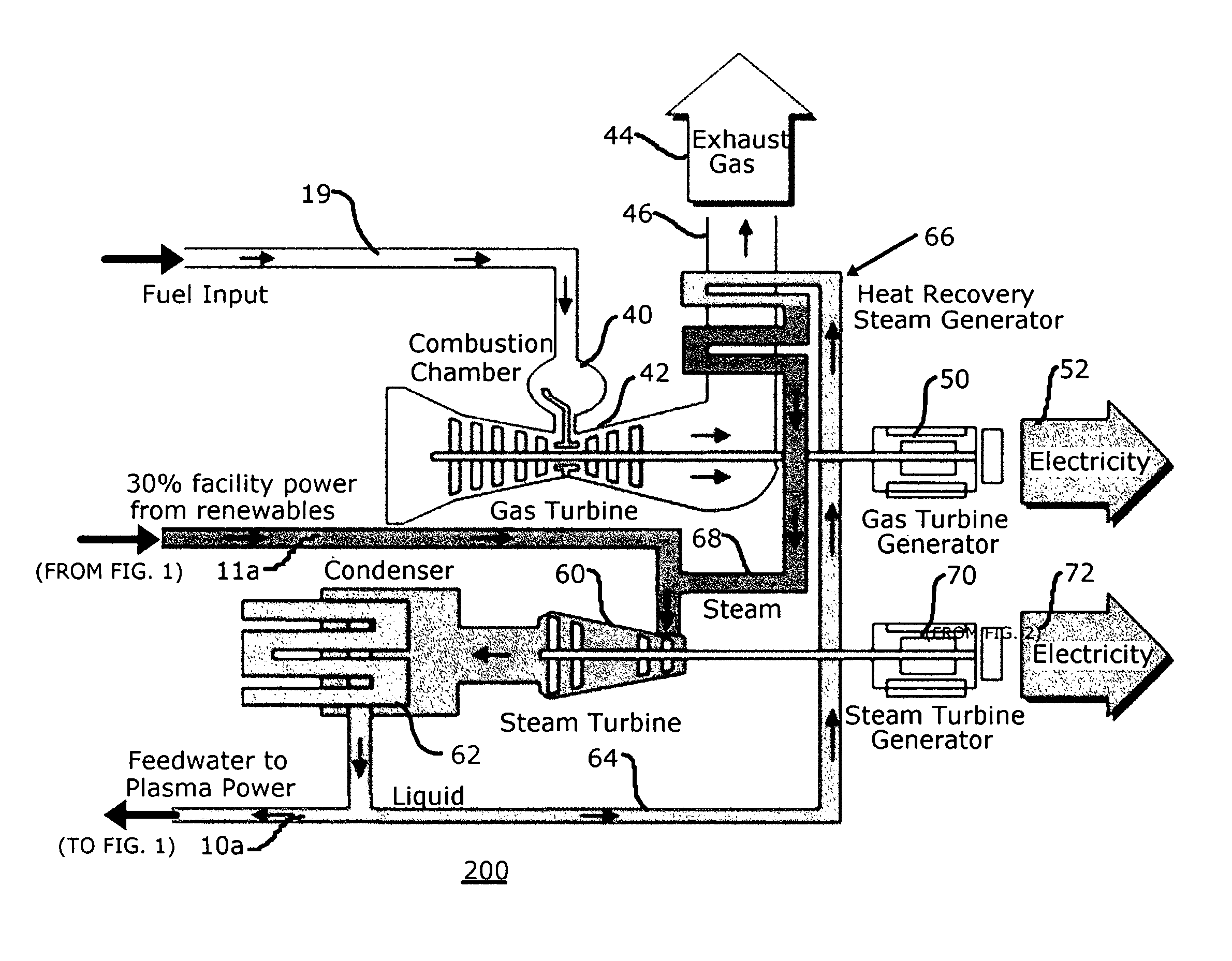

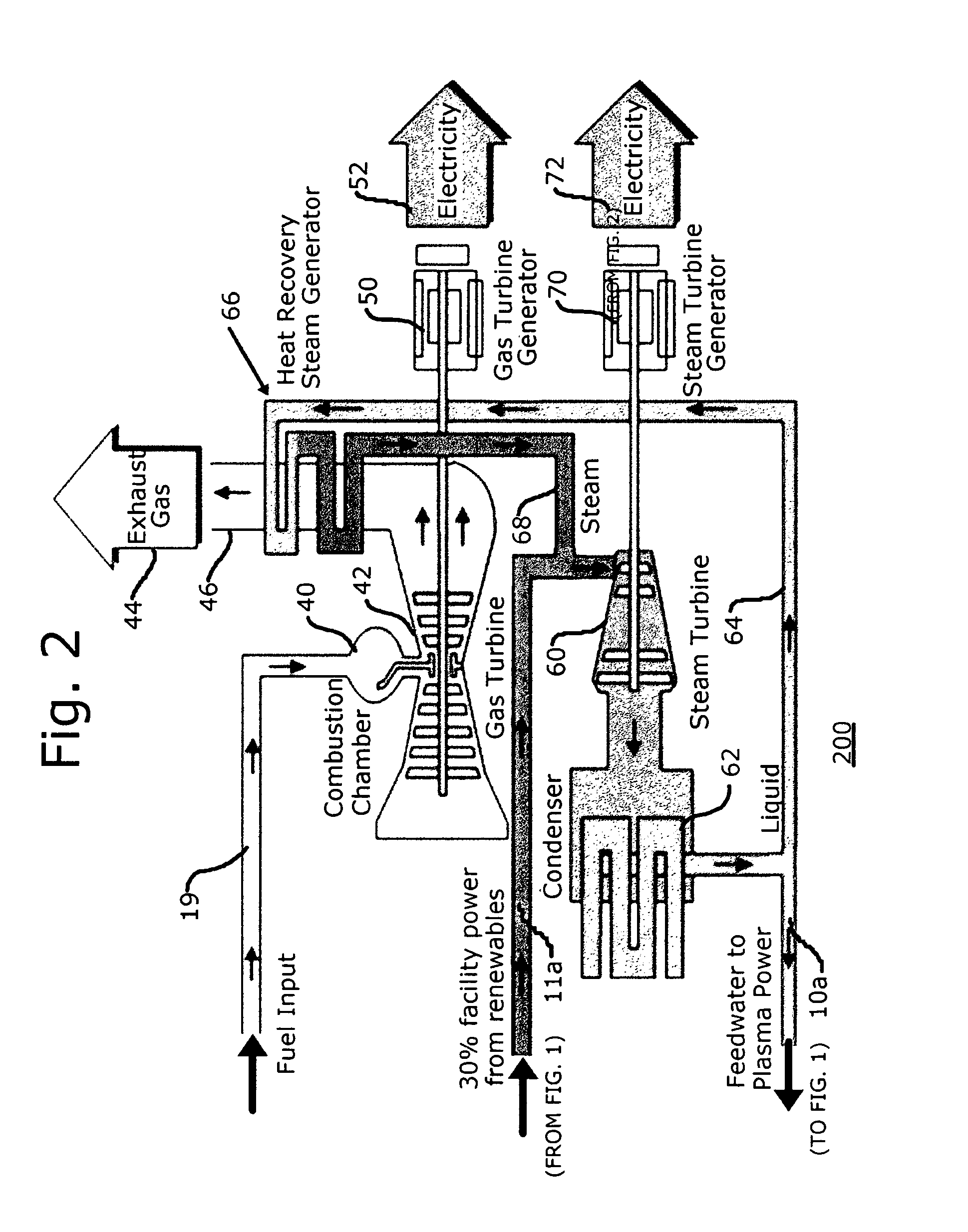

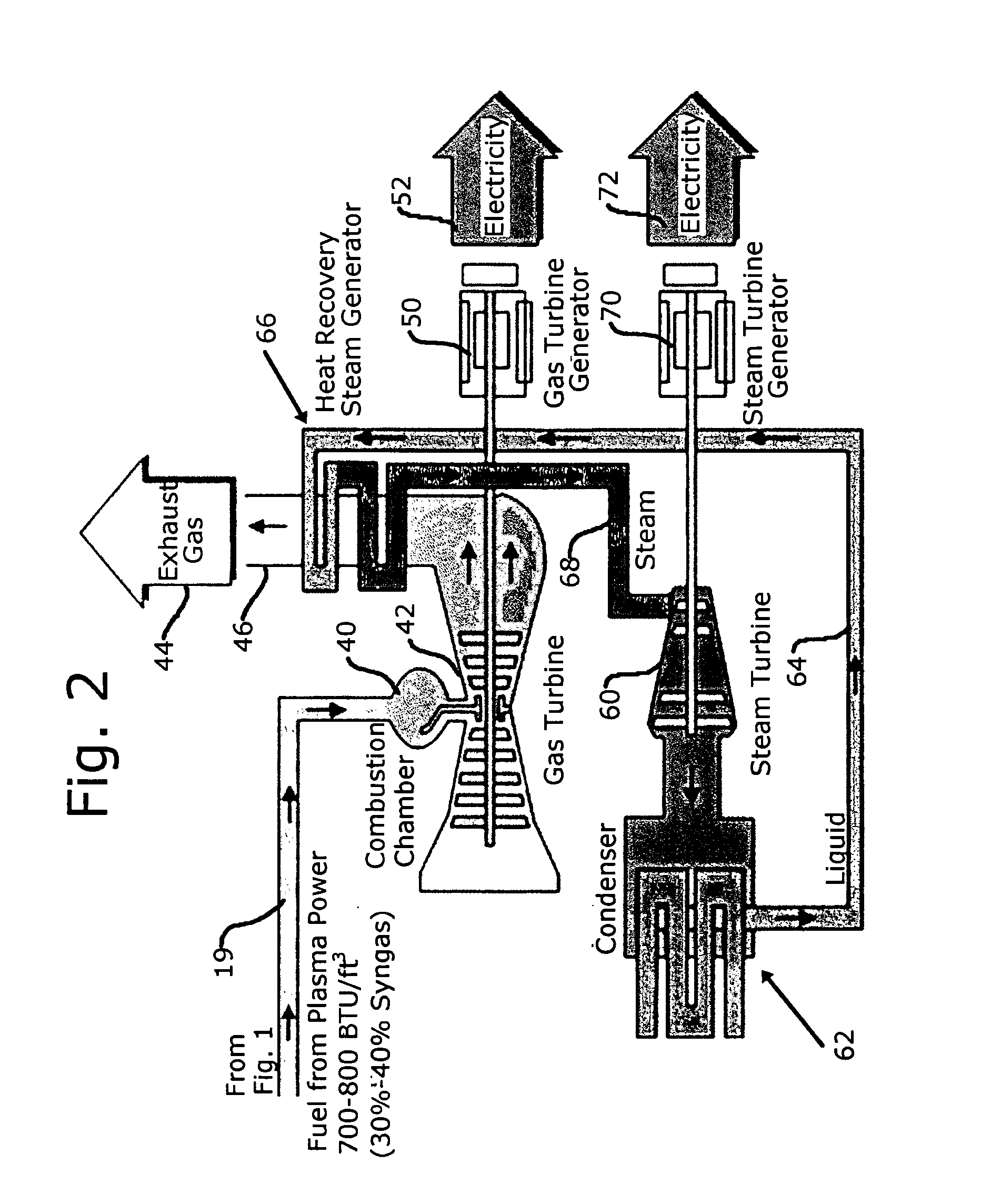

Renewable Combined Cycle Low Turbine Boost

ActiveUS20130312424A1Emission reductionSupplement extractedGasifier electrodesBiofuelsSyngasEnergy transfer

A method and system for cost effectively converting a feedstock using thermal plasma, or other styles of gassifiers, into to a feedwater energy transfer system. The feedstock can be any organic material, or fossil fuel. The energy transferred in the feedwater is converted into steam which is then injected into the low turbine of a combined cycle power plant. Heat is extracted from gas product issued by a gassifier and delivered to a power plant via its feedwater system. The gassifier is a plasma gassifier and the gas product is syngas. In a further embodiment, prior to performing the step of extracting heat energy, there is provided the further step of combusting the syngas in an afterburner. An air flow, and / or EGR flow is provided to the afterburner at a rate that is varied in response to an operating characteristic of the afterburner. The air flow to the afterburner is heated.

Owner:PLASMA TECH HLDG LLC

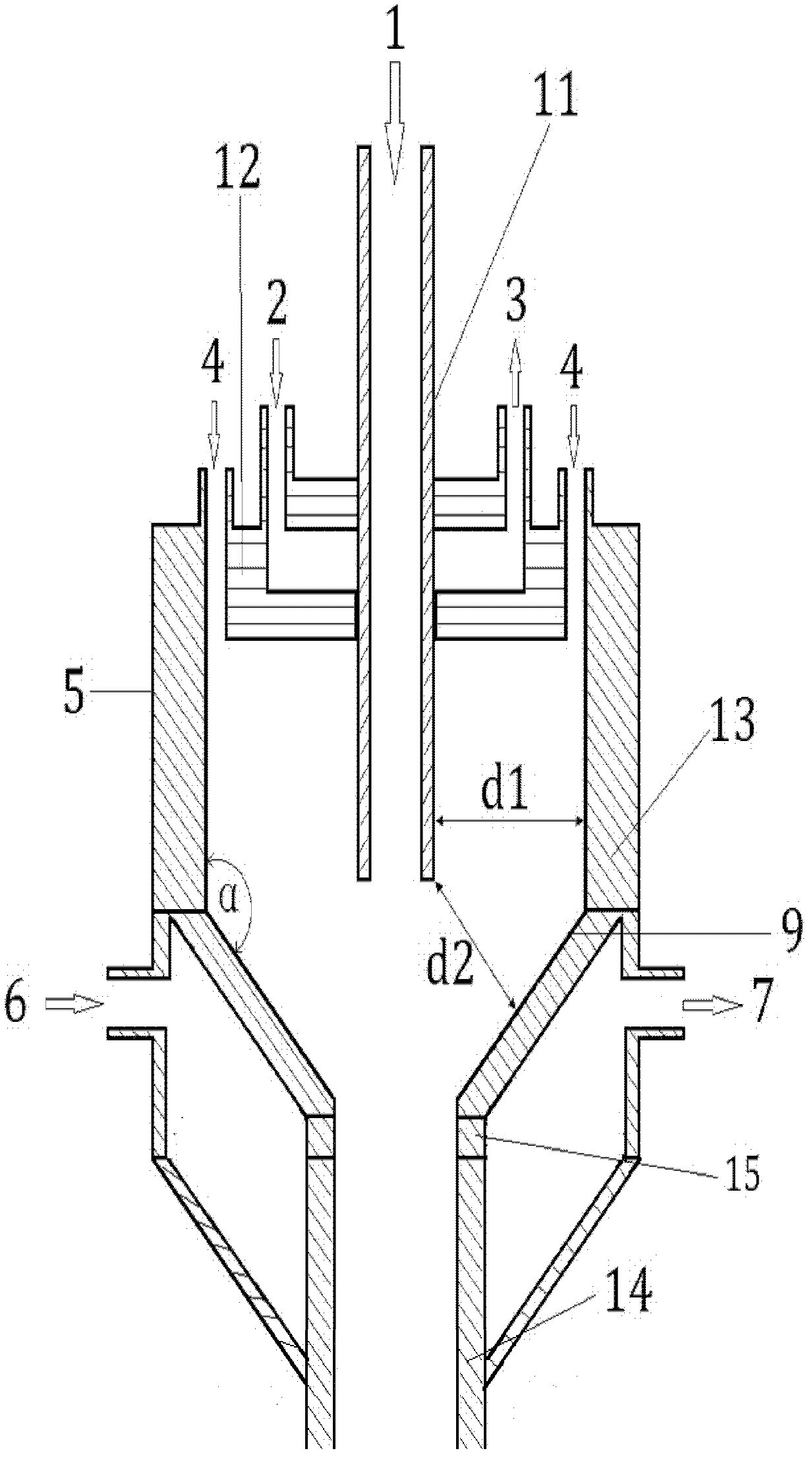

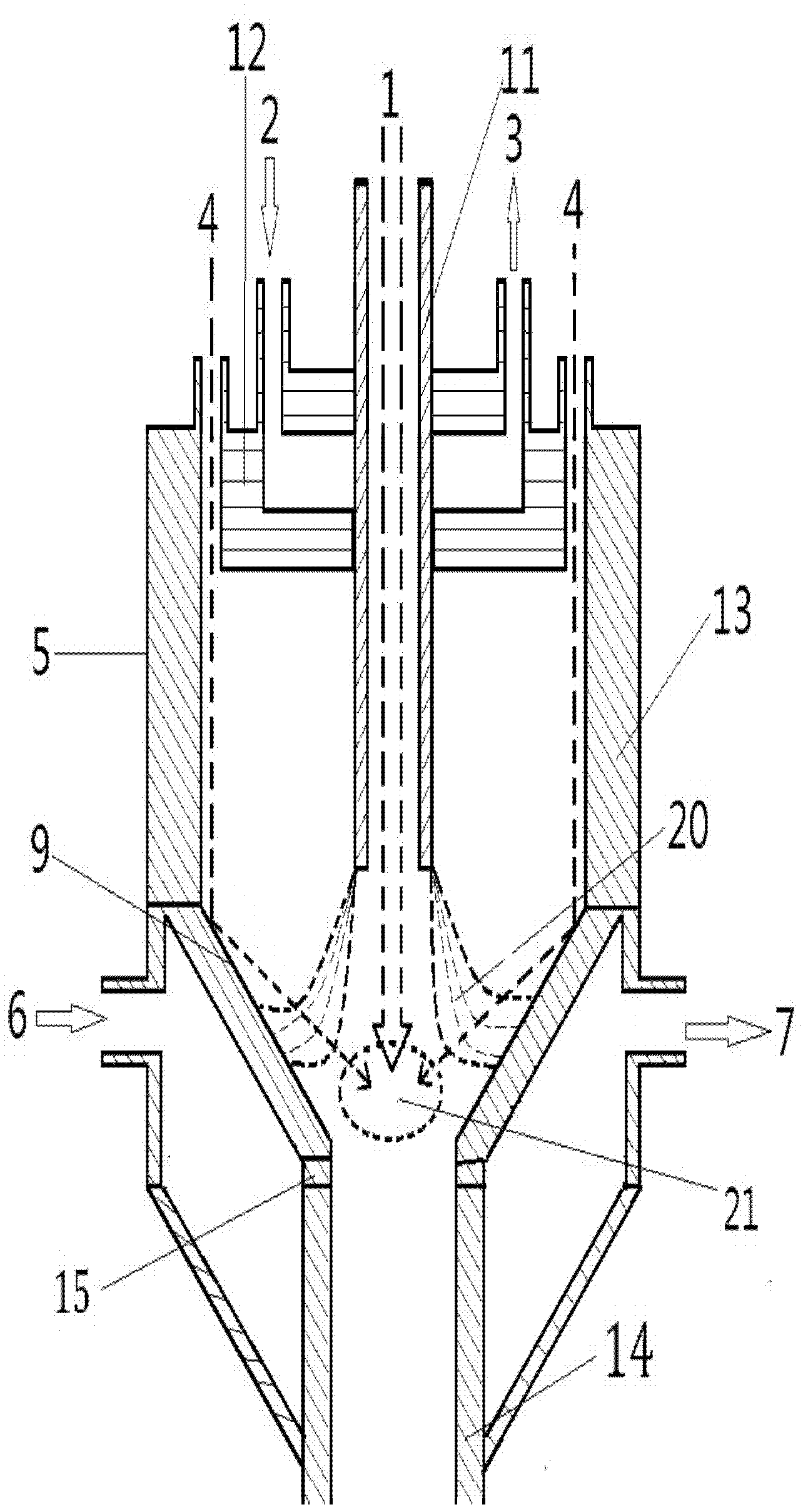

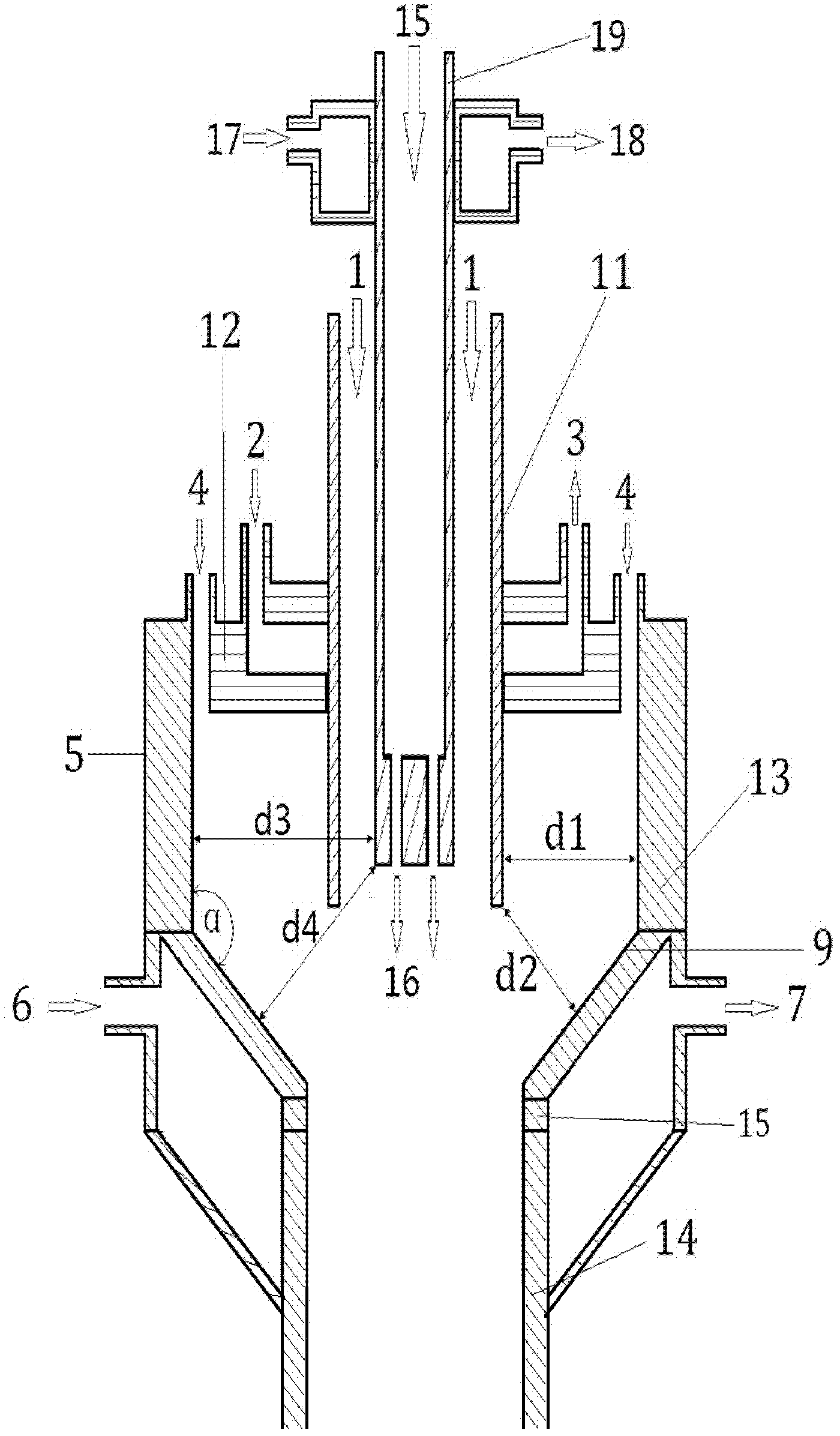

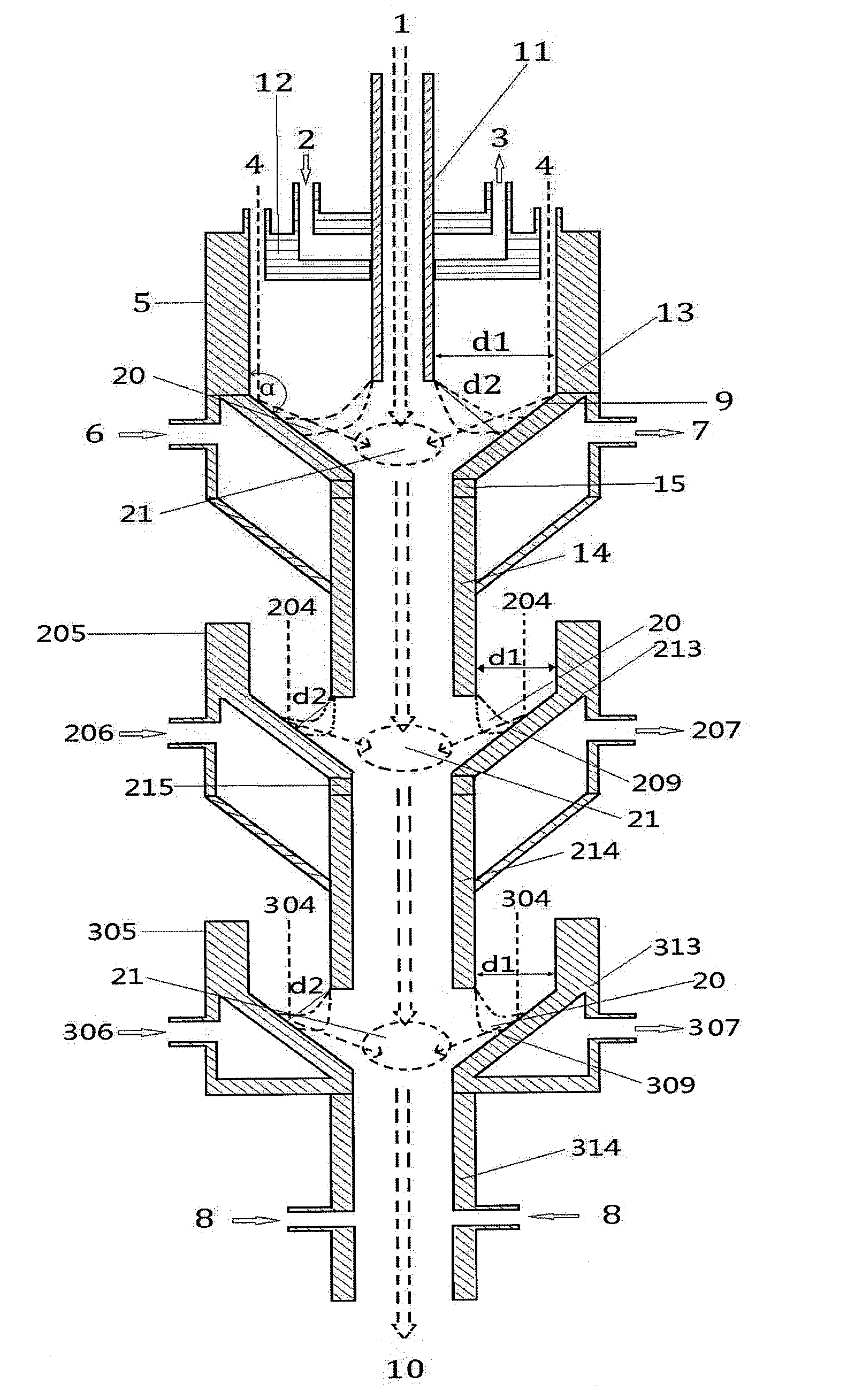

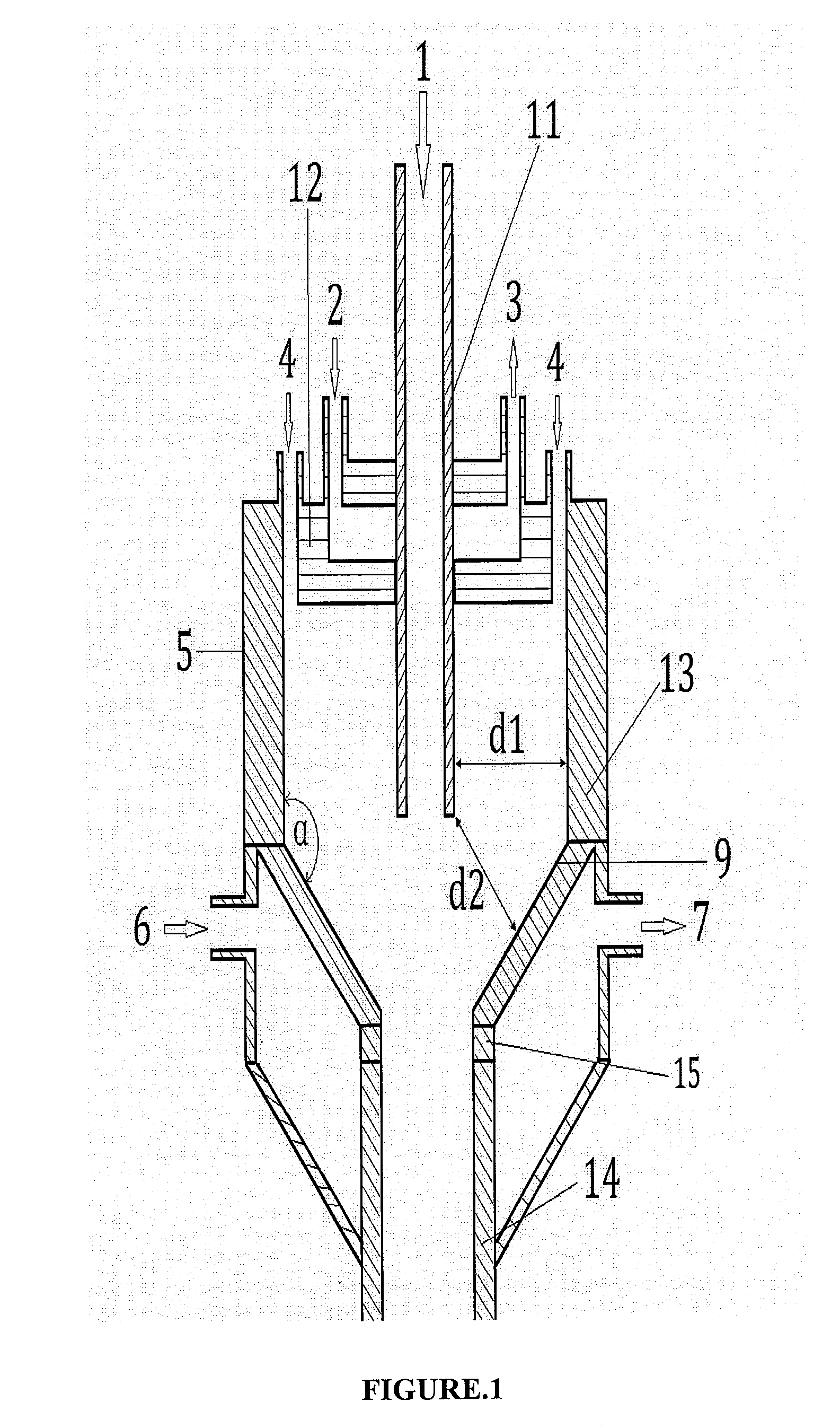

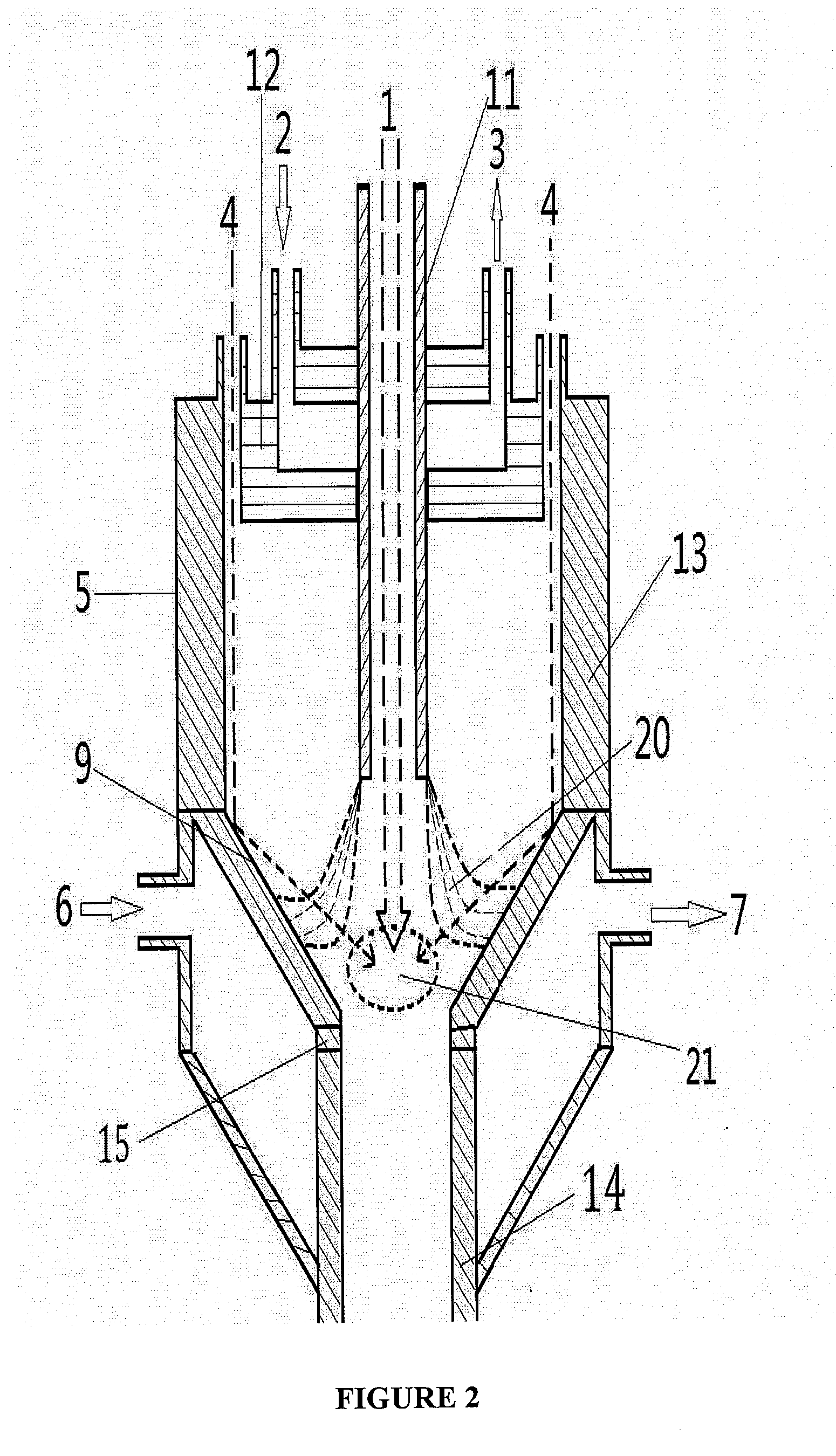

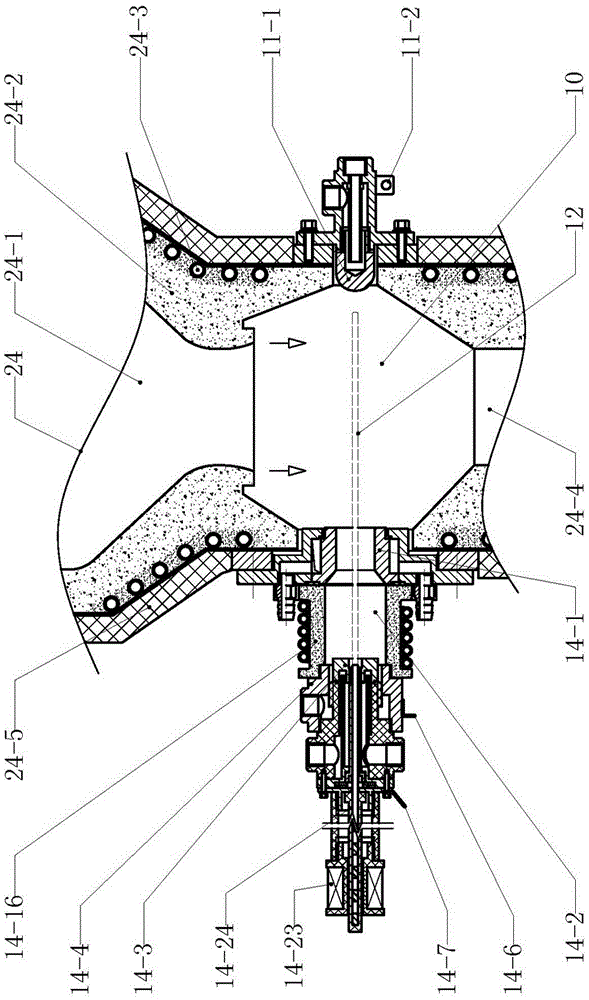

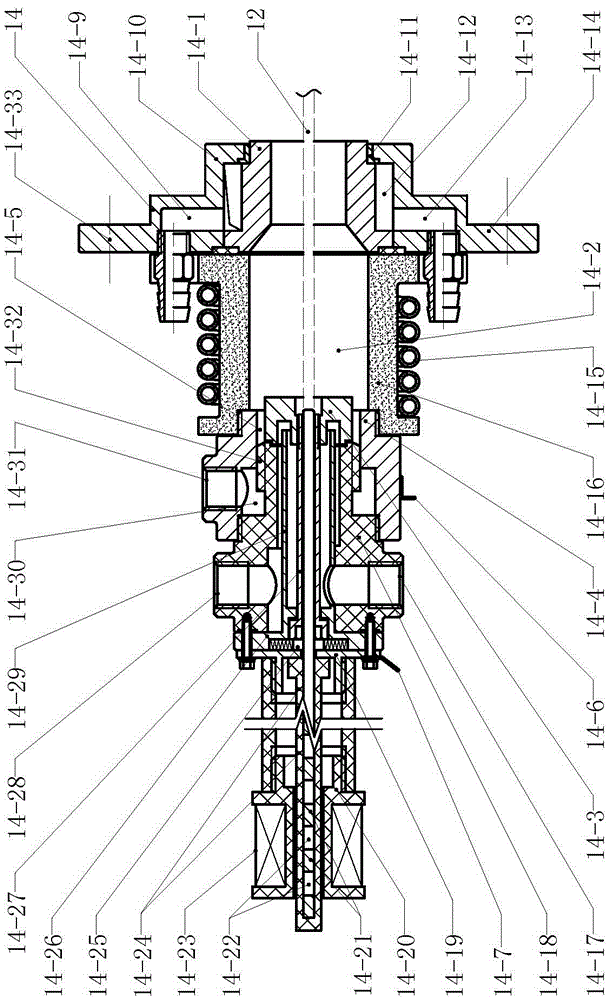

Multi-segment plasma cracking carbonaceous material reactor system with hollow cathodes

The invention discloses a multi-segment plasma cracking carbonaceous material reactor system with hollow cathodes. Each segment of the system comprises a hollow cathode, a hollow anode, a working gas inlet, a carbonaceous material and carrier gas feeding inlet and reaction tubes, and further comprises at least one chilling medium inlet and at least one outlet of chilling products and gases, wherein the hollow cathode and the hollow anode are circularly cooled by cooling media, the reaction tubes are connected with the cathode and the anode, the chilling medium inlet is located on the lower portion of the last reaction tube, and the outlet of the chilling products and the gases is located at the bottom of the last reaction tube or the lower portion of the last reaction tube. A cavity generating plasmas and / or voltaic arcs is formed between hollow cathodes of the first segment and hollow cathodes and anodes of any segment being used as a reaction tube. On the highest-temperature regions of the cavity or around highest-temperature regions of the cavity, plasma air current makes full contact with the carbonaceous material and carrier gas feedings and / or pyrolysis volatiles and is fully mixed with the carbonaceous material and the carrier gas feedings and / or the pyrolysis volatiles, and pyrolysis and / or gas-phase reactions are conducted. The multi-segment plasma cracking carbonaceous material reactor system with the hollow cathodes is perfect in thermal efficiency and high in cracking product productivity.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

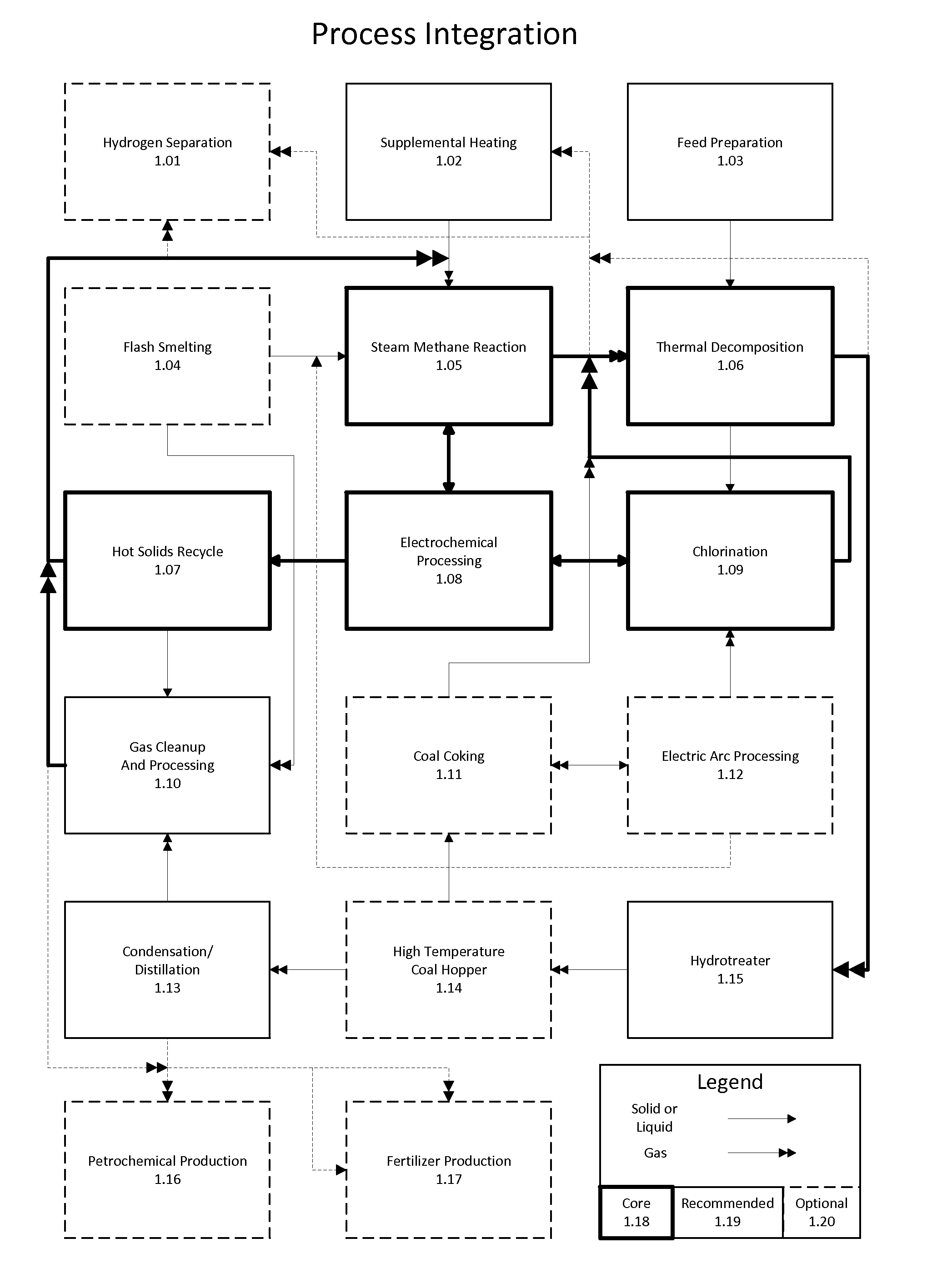

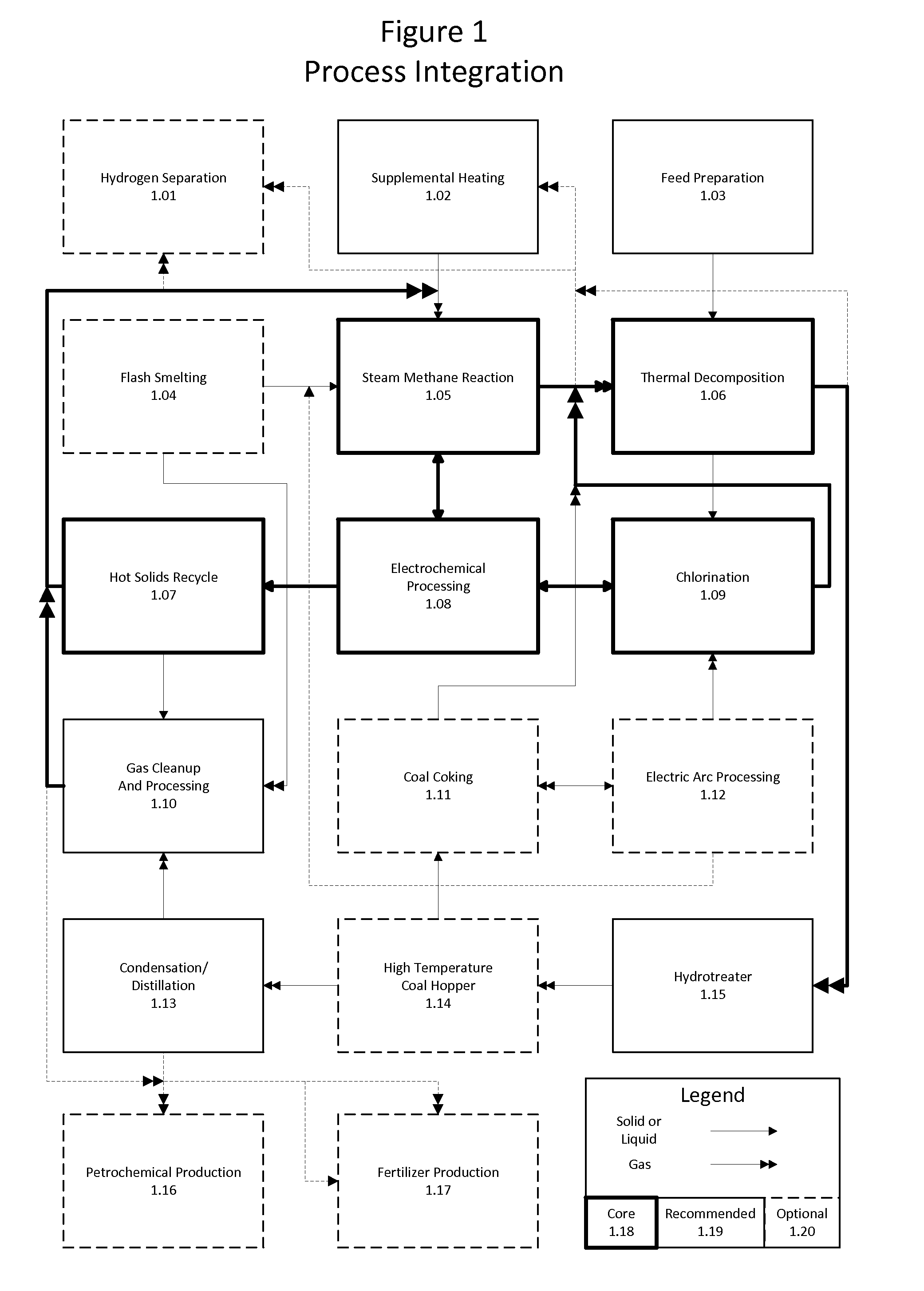

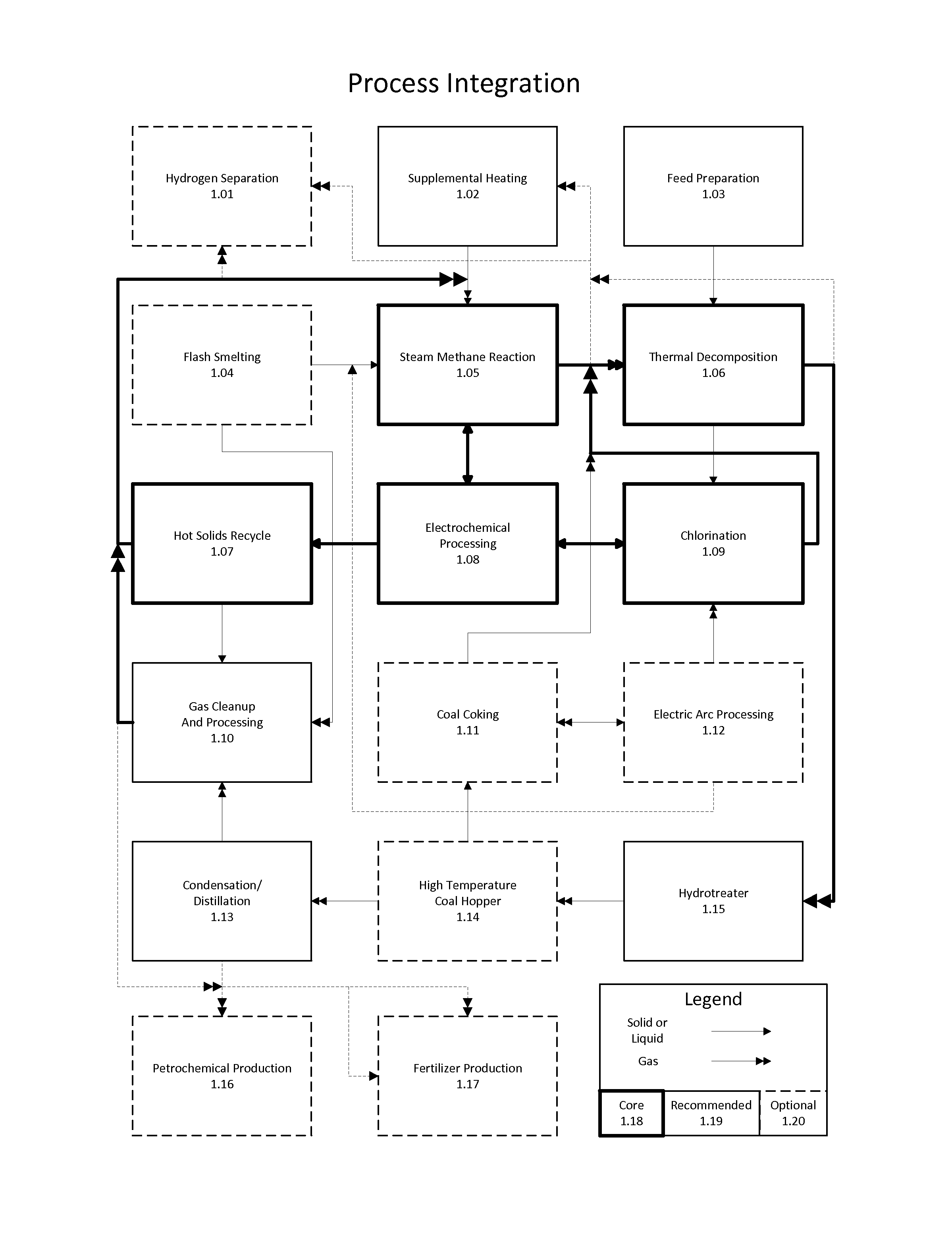

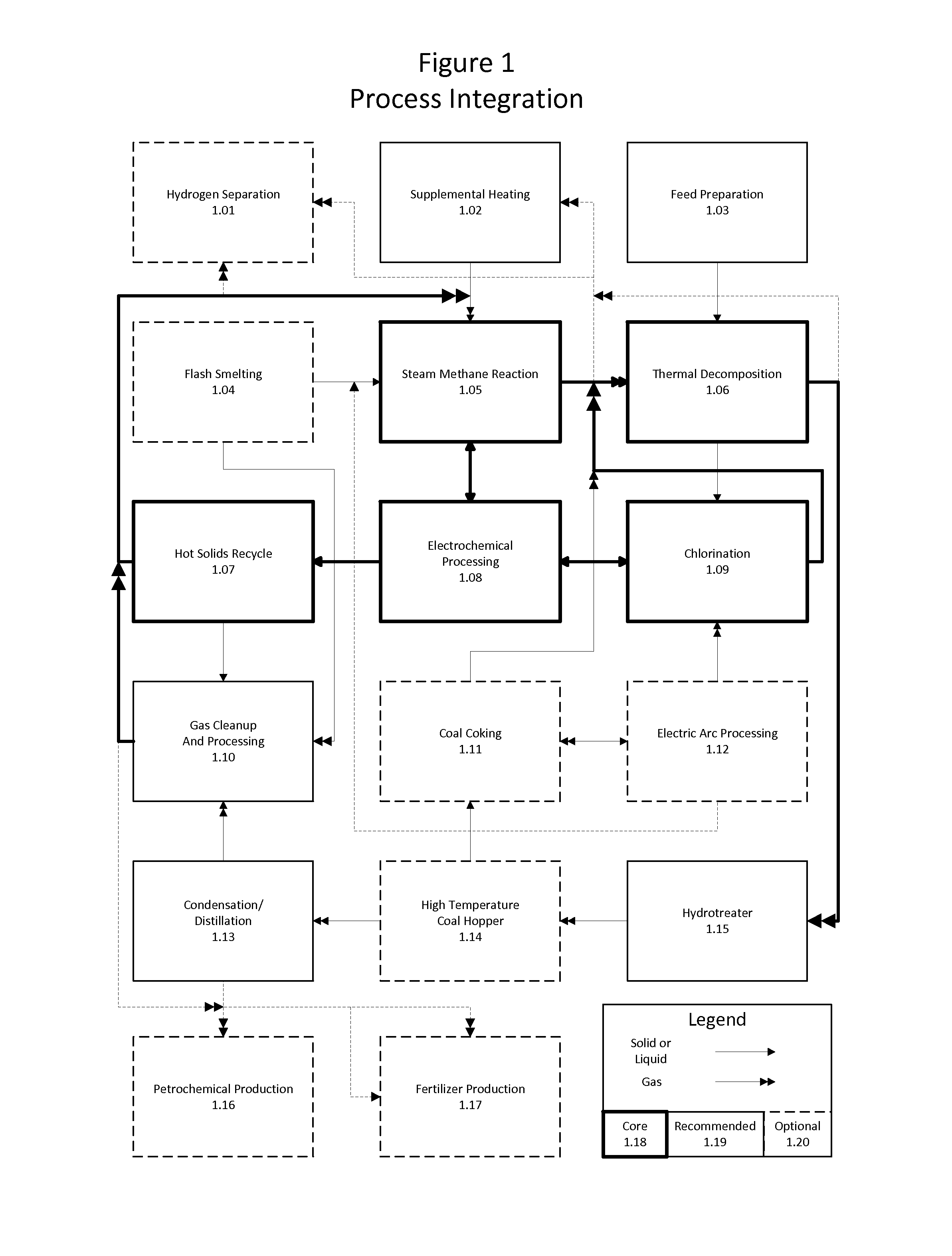

Method for the integration of carbochlorination into a staged reforming operation as an alternative to direct residue oxidation for the recovery of valuable metals

Method of combining industrial processes having inherent carbon capture and conversion capabilities offering maximum flexibility, efficiency, and economics while enabling environmentally and sustainably sound practices. Maximum chemical energy is retained throughout feedstock processing. A hybrid thermochemical cycle couples staged reforming with hydrogen production and chlorination. Hydrogen generated is used to upgrade feedstocks including bitumen, shale, coal, and biomass. Residues of upgrading are chlorinated, metals of interest are removed, and the remainder is reacted with ammonia solution and carbon dioxide to form carbonate minerals. The combination provides emissions free production of synthetic crude oil and derivatives, as well as various metals and fertilizers. Sand and carbonate minerals are potentially the only waste streams. Through this novel processing, major carbon dioxide reduction is afforded byminimizing direct oxidation. Supplemental heat to run the reactions is obtained through external means such as concentrated solar, geothermal, or nuclear.

Owner:BLUE SKIES RES INC

Multi-stage plasma reactor system with hollow cathodes for cracking carbonaceous material

Disclosed is a multi-stage plasma reactor system with hollow cathodes for cracking carbonaceous material with each stage comprising: hollow cathodes and hollow anodes cooled by recycling cooling medium or refrigerant; working gas inlet(s); inlet(s) of carbonaceous material and carrier gas as feedstock; reaction tubes in connection with the anode or cathode, in addition, the reactor system also comprises: at least one inlet(s) of quench medium located lower portion of last one of the reaction tubes; and at least one outlet(s) of quenched products and gases located on bottom or lower portion of last one of the reaction tubes, wherein chambers are formed between the first hollow cathode or the hollow cathode used as the reaction tube of any stage and the anode so as to generate plasma gas and / or electric arc therein, generated plasma gas jet fully contacts and efficiently mixes with the carbonaceous material and carrier gas as feedstock and / or volatiles caused by pyrolysis within or nearby highest temperature region of the chambers, and pyrolysis of the carbonaceous material and / or gas-phase reaction of volatiles are occurred. The present reactor system has excellent energy efficiency and higher cracked products yield.

Owner:CHNA ENERGY INVESTMENT CORP LTD

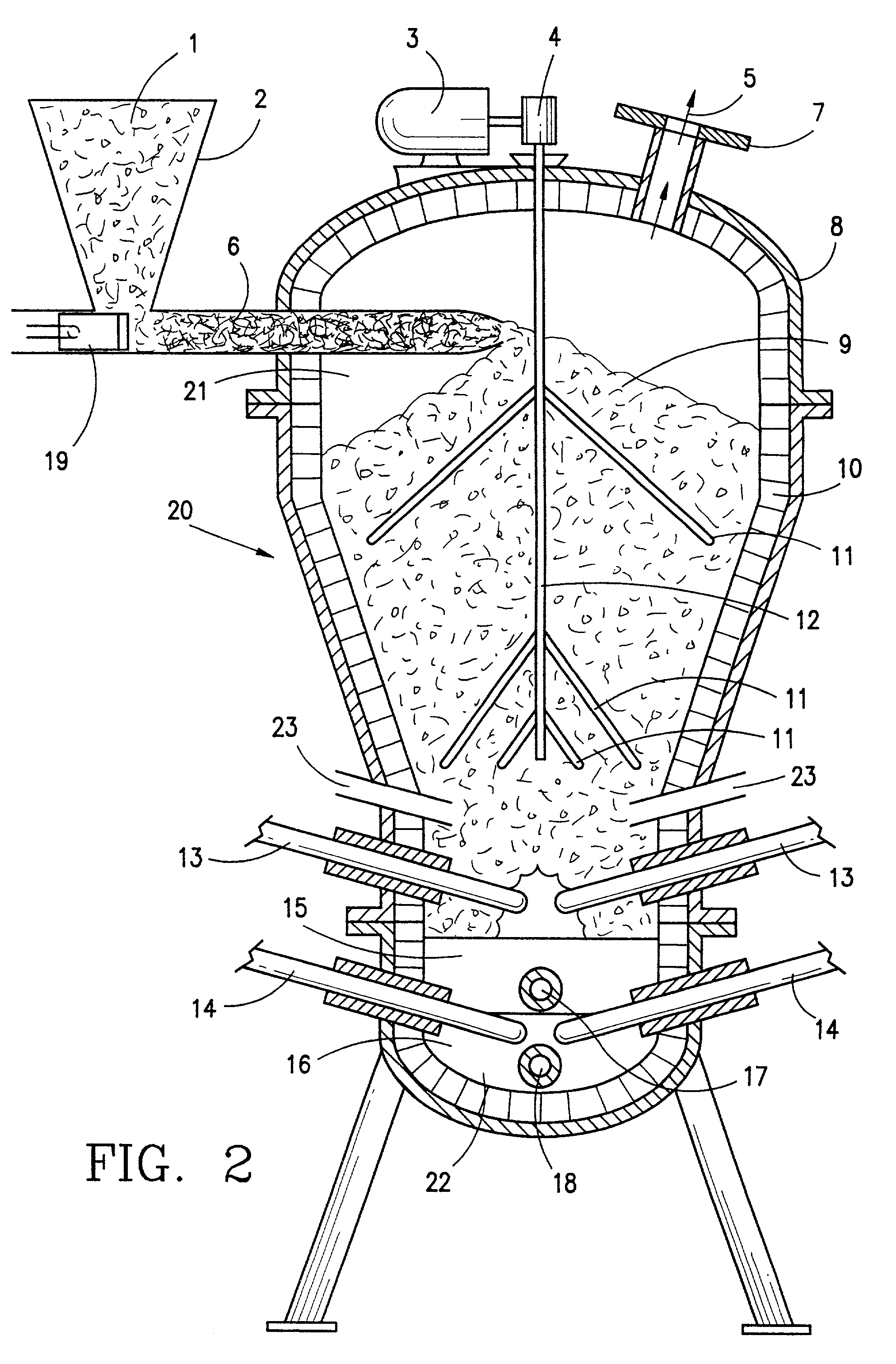

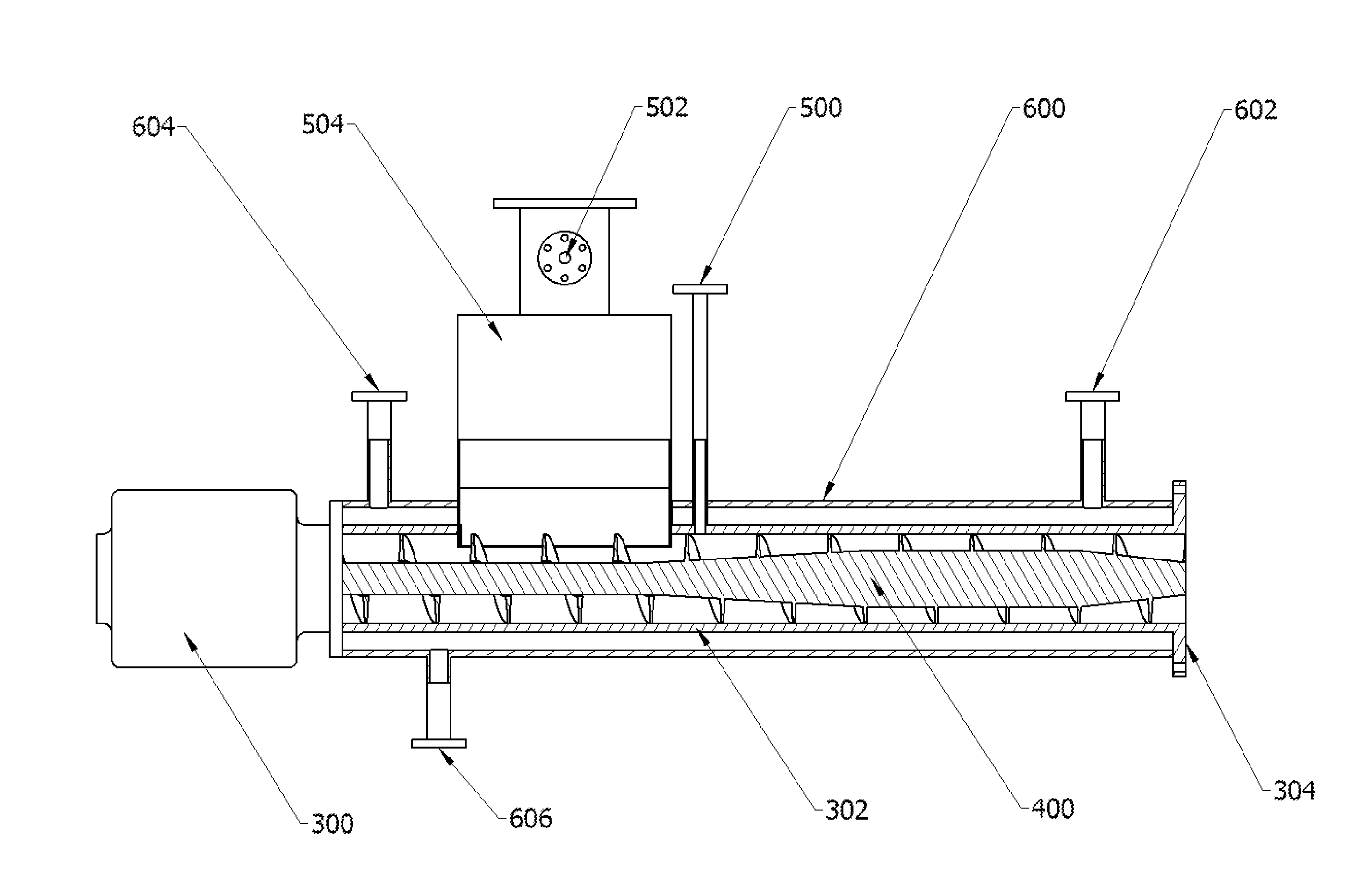

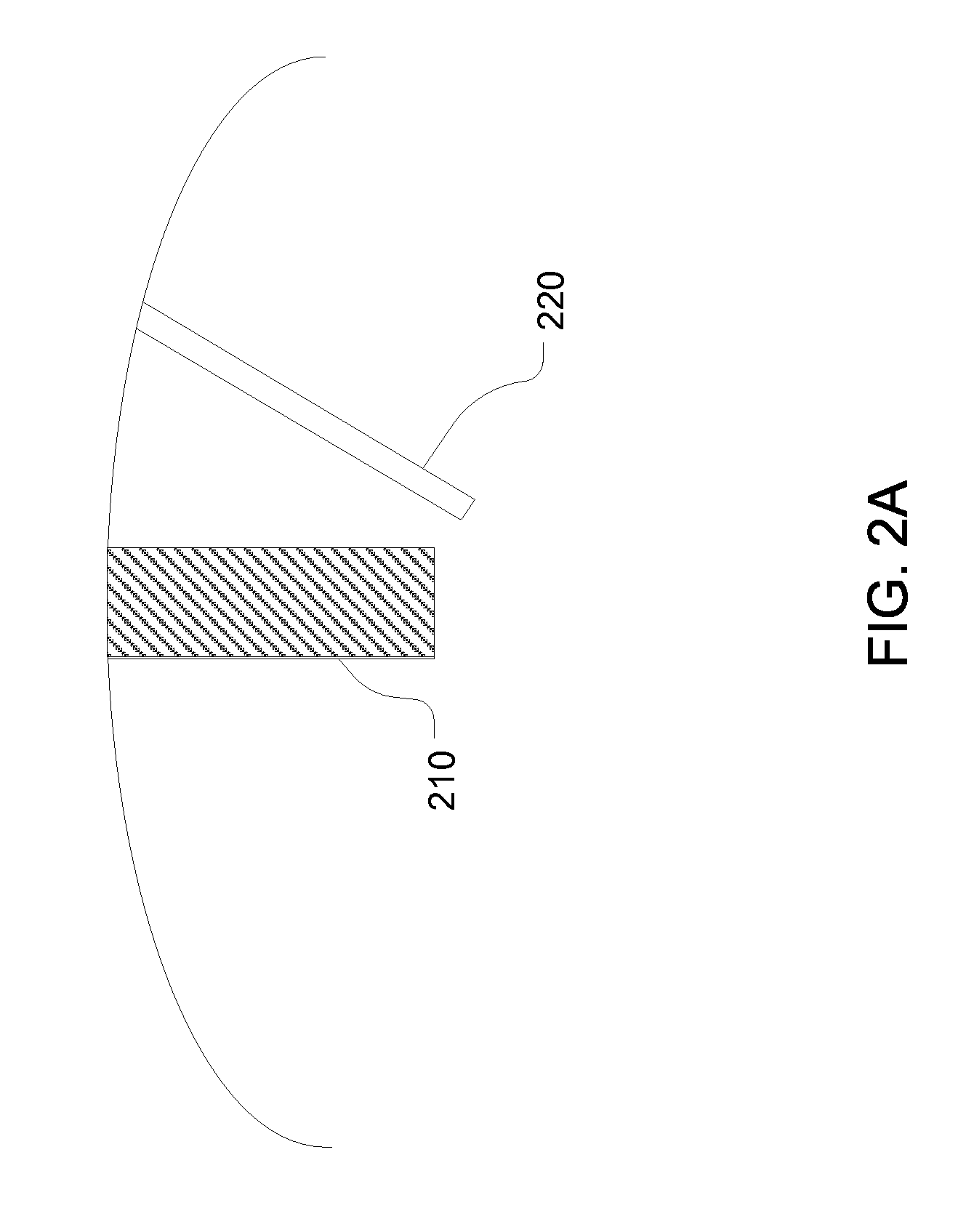

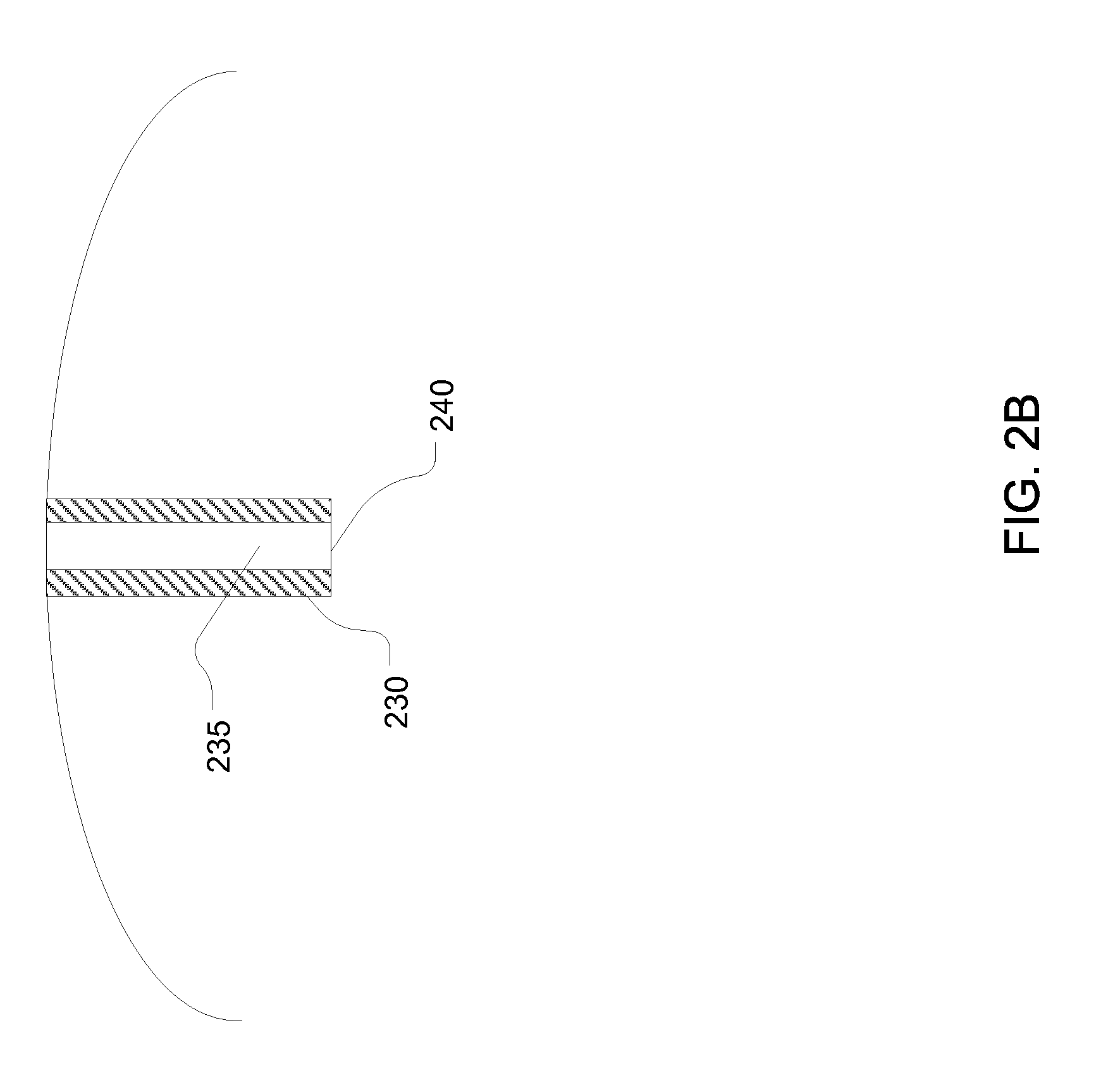

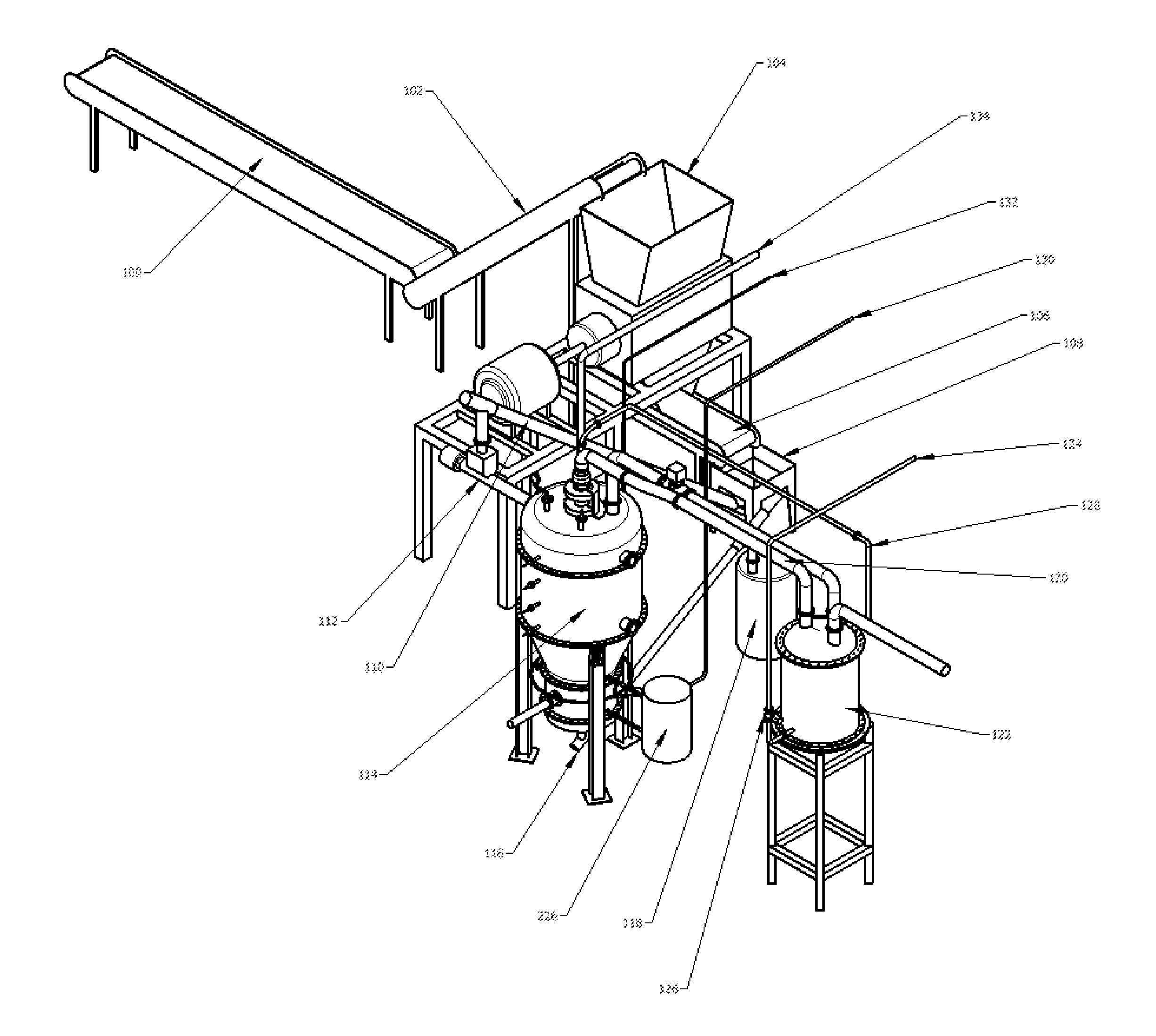

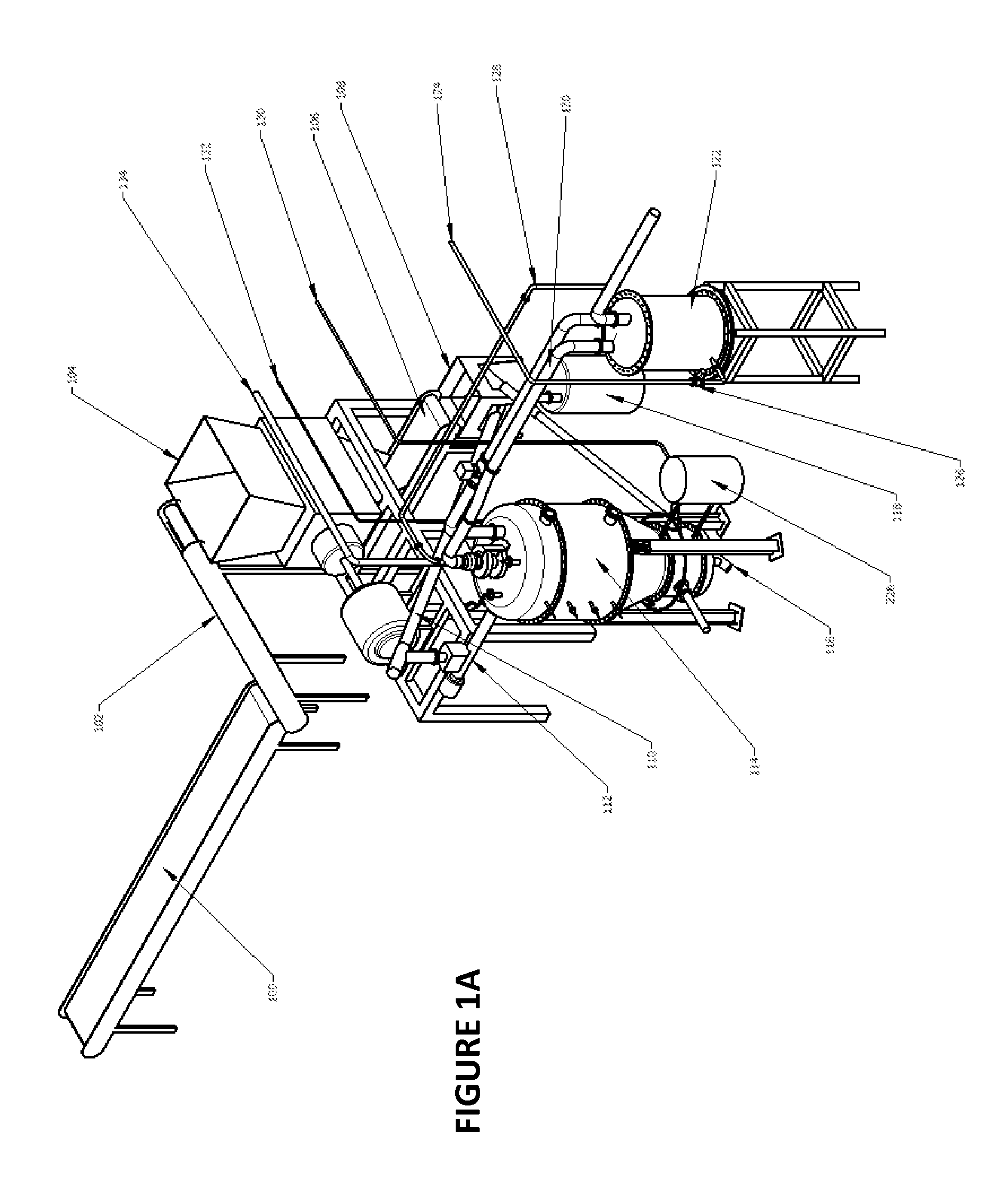

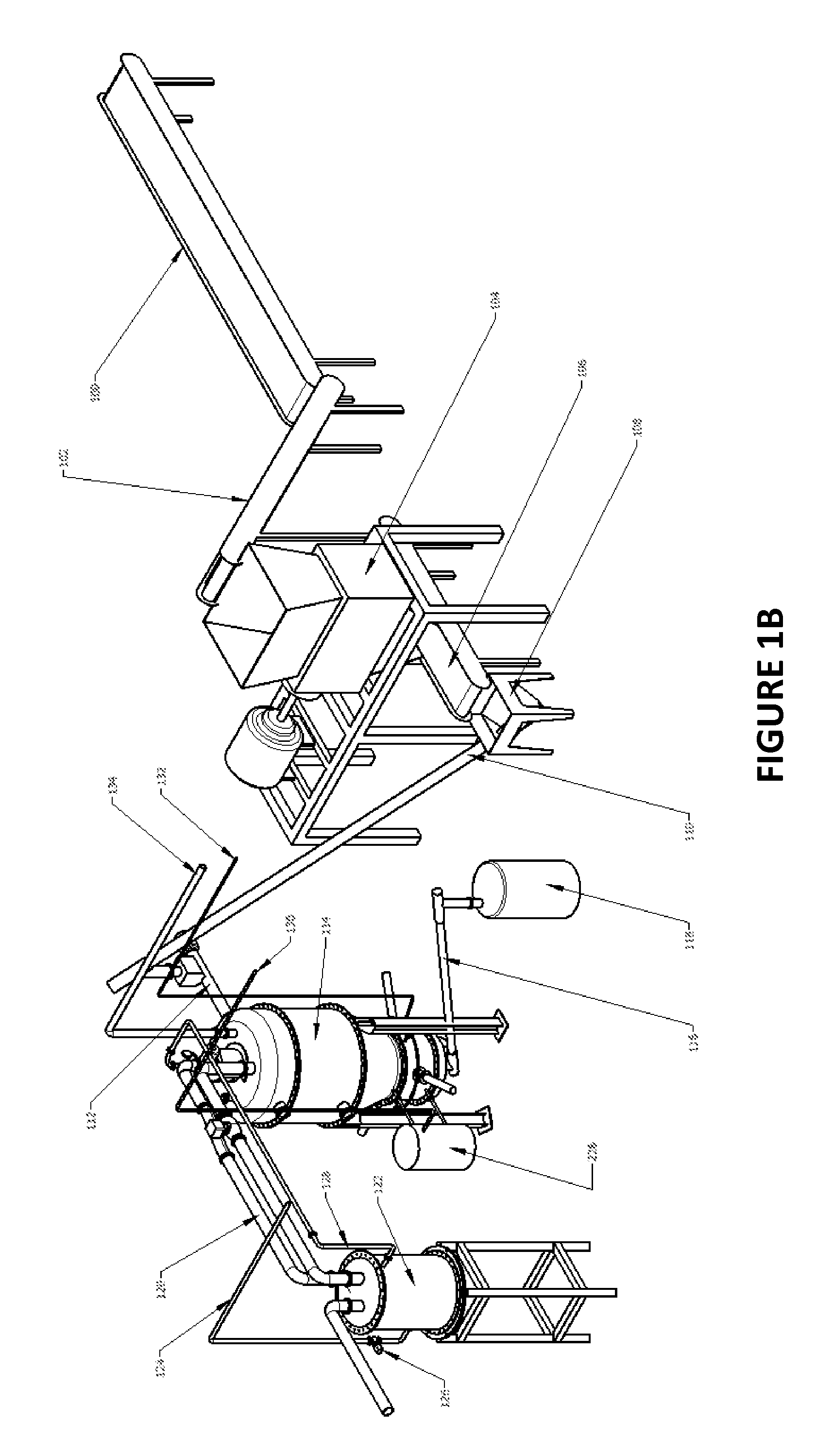

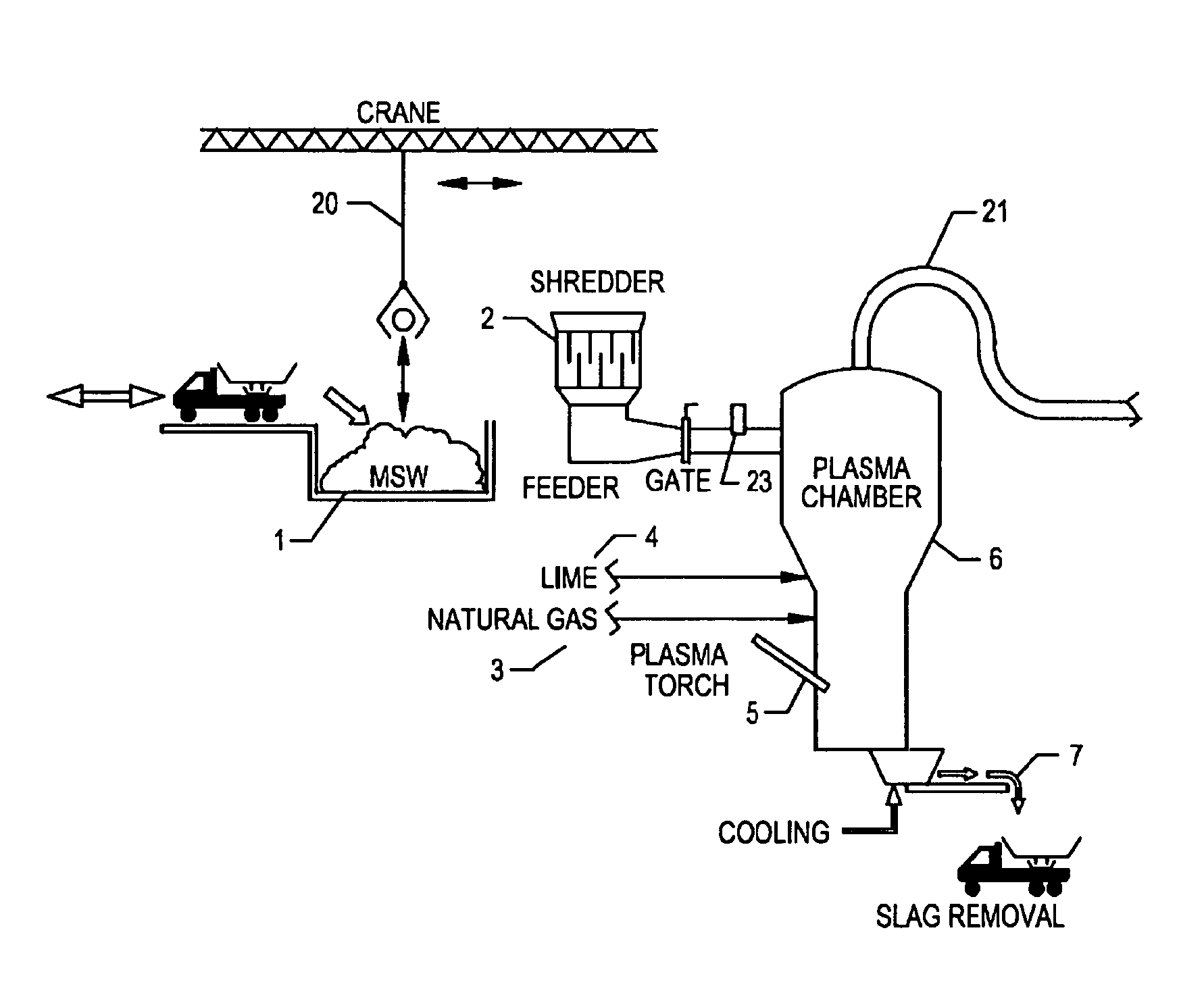

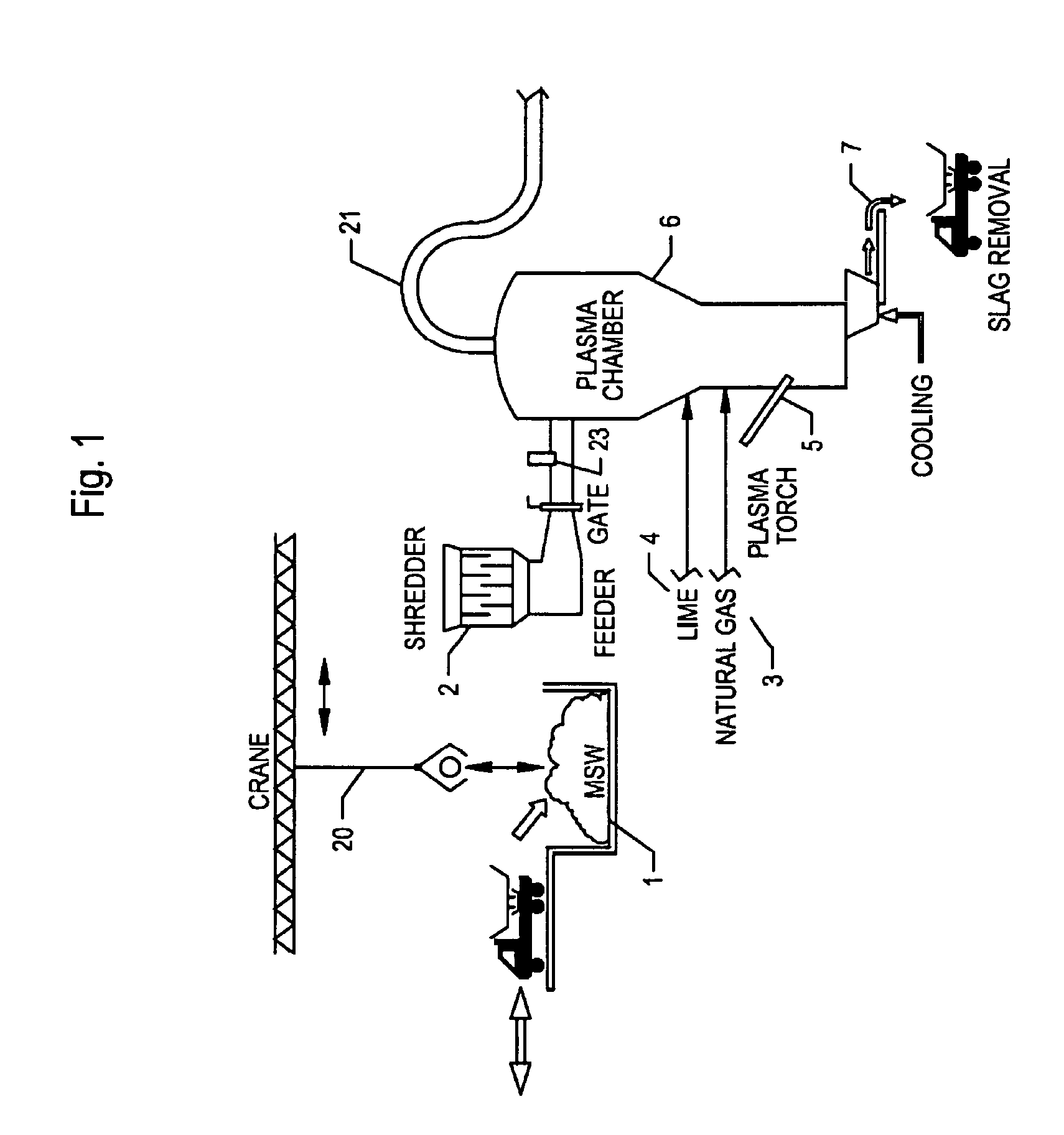

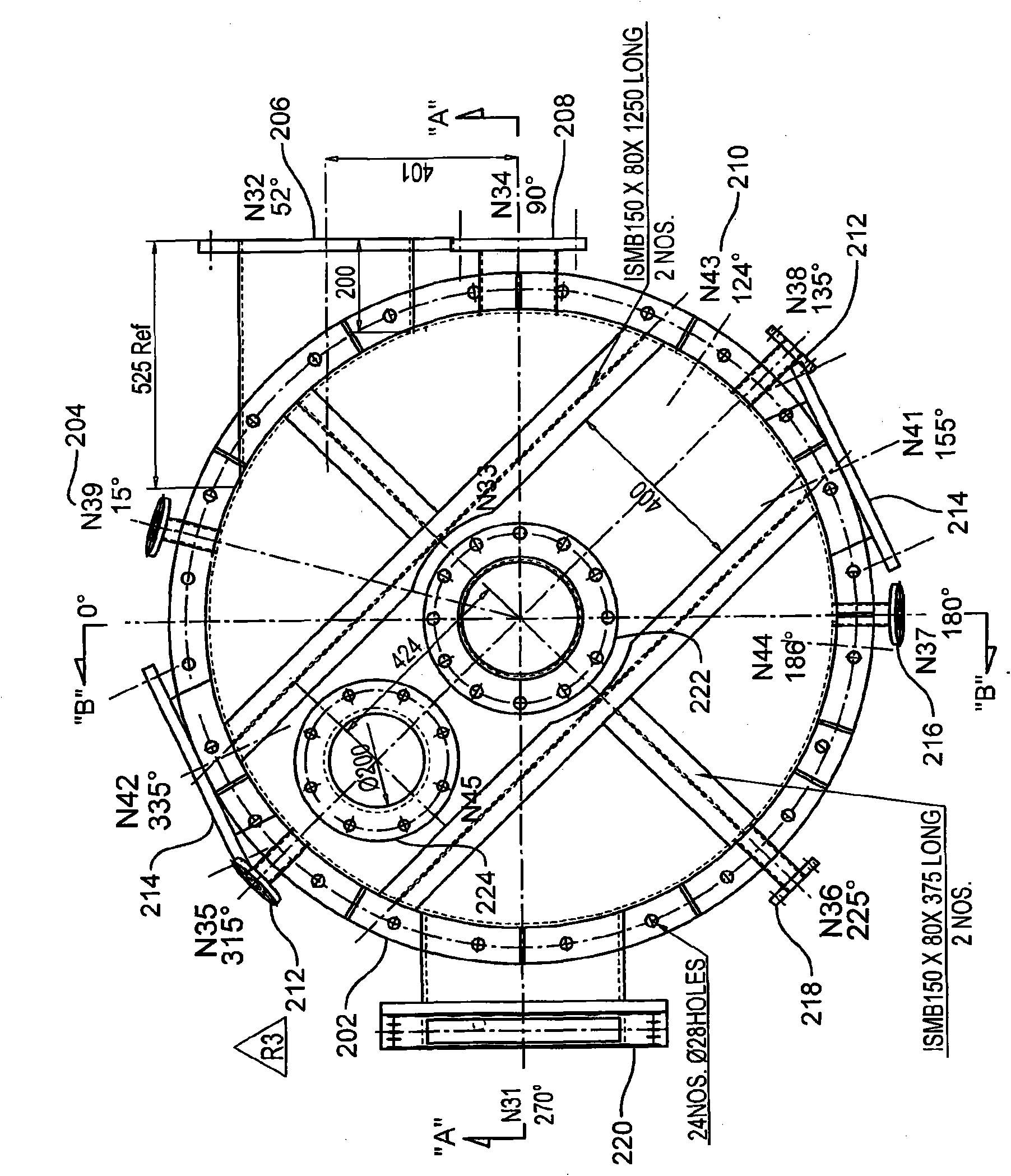

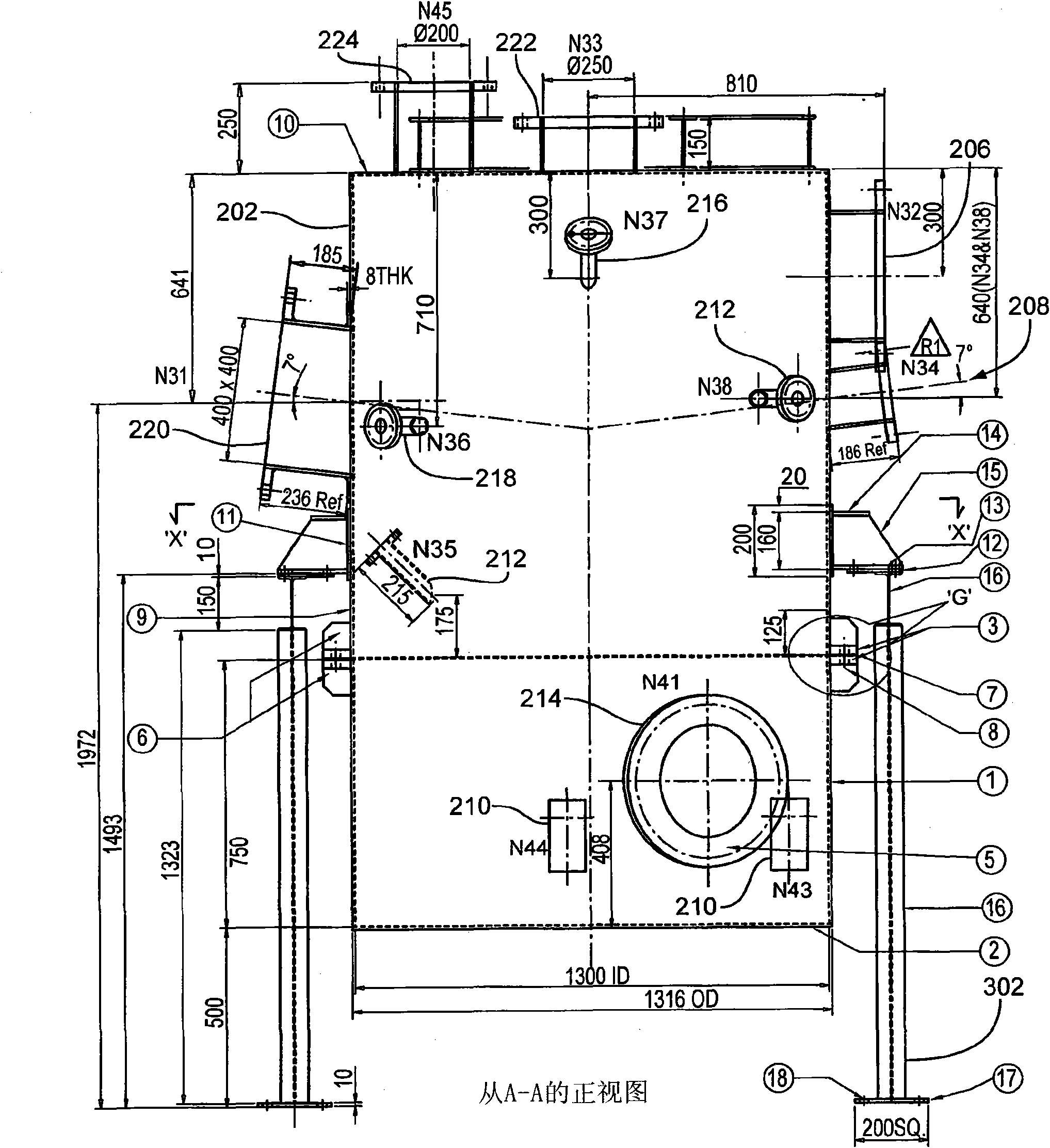

System and method for processing material to generate syngas using plurality of gas removal locations

The present invention is directed to system and method for processing material to generate syngas. A reactor chamber is implemented with a plurality of electrodes that can generate an arc within the chamber when electricity is applied to them. The arc can be used to create free radicals which along with the heat and light of the arc breakdown material comprising carbonaceous material, such as Municipal Solid Waste (MSW), into gas components that form syngas. The syngas can be extracted from the reactor chamber and be used for various commercial purposes. The reactor chamber may comprise a material feed system operable to move material from a material input opening in the reactor chamber towards the electrodes at a controlled rate. Further, the reactor chamber may comprise a water injection system within the reactor chamber operable to inject water into the reactor chamber while electricity is applied to the electrodes. Yet further, the reactor chamber may comprise a gas removal system within the reactor chamber operable to extract gas generated from breakdown of the material from a plurality of gas removal locations. The gas removal system may be integrated within the material feed system.

Owner:RESPONSIBLE ENERGY

Method for the integration of carbochlorination into a staged reforming operation as an alternative to direct residue oxidation for the recovery of valuable metals

Method of combining industrial processes having inherent carbon capture and conversion capabilities offering maximum flexibility, efficiency, and economics while enabling environmentally and sustainably sound practices. Maximum chemical energy is retained throughout feedstock processing. A hybrid thermochemical cycle couples staged reforming with hydrogen production and chlorination. Hydrogen generated is used to upgrade feedstocks including bitumen, shale, coal, and biomass. Residues of upgrading are chlorinated, metals of interest are removed, and the remainder is reacted with ammonia solution and carbon dioxide to form carbonate minerals. The combination provides emissions free production of synthetic crude oil and derivatives, as well as various metals and fertilizers. Sand and carbonate minerals are potentially the only waste streams. Through this novel processing, major carbon dioxide reduction is afforded byminimizing direct oxidation. Supplemental heat to run the reactions is obtained through external means such as concentrated solar, geothermal, or nuclear.

Owner:BLUE SKIES RES INC

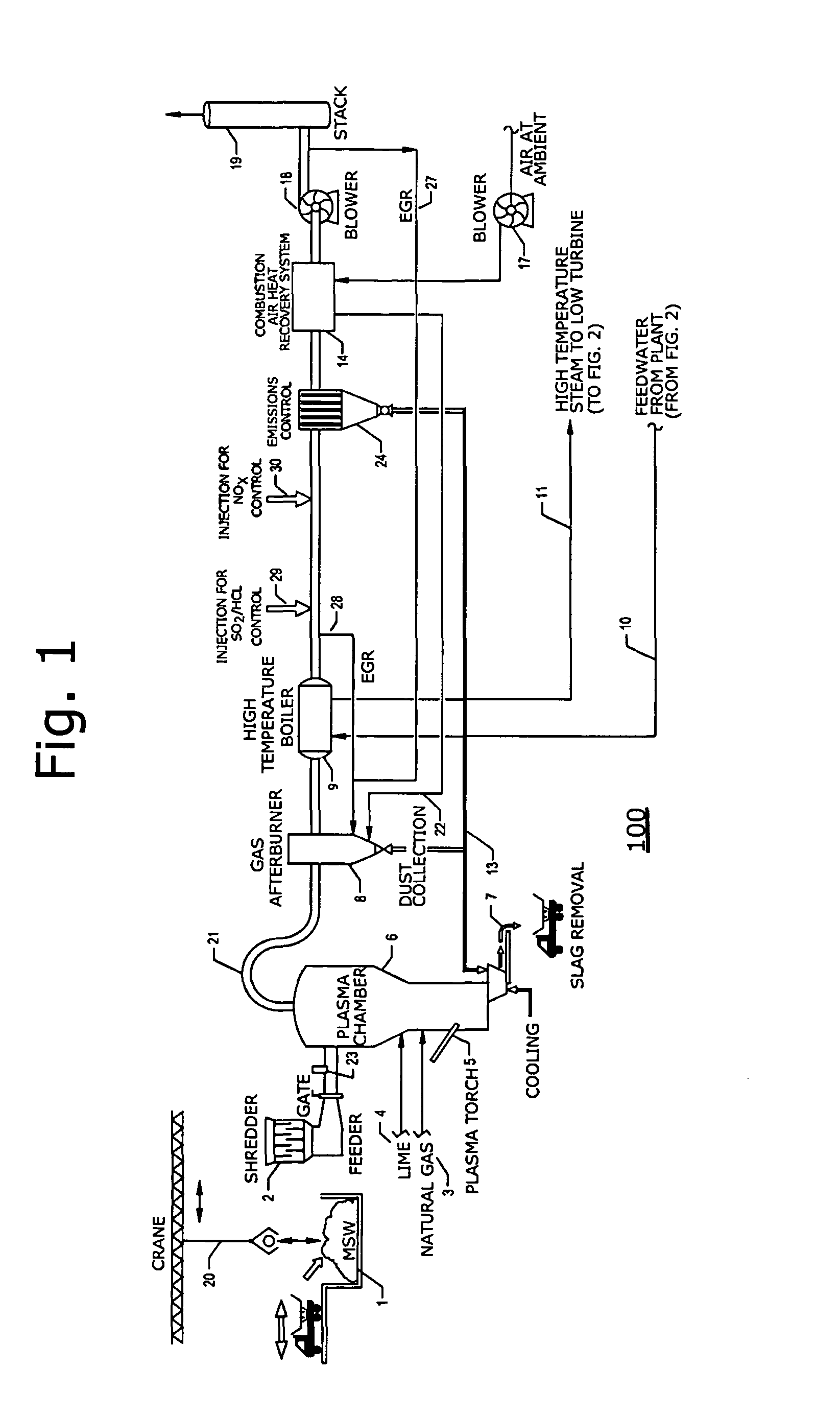

Renewable blended natural gas and rock wool production from a plasma-based system

InactiveUS20130323132A1Increase temperatureEasy to controlGasifier electrodesGasification processes detailsEngineeringHeat energy

A method and system for augmenting the heat energy of a plasma torch in a gassifier using chemical energy, including the steps of injecting a fuel in the proximity of a plasma torch inside the gassifier chamber; and injecting an oxidant in the proximity of a plasma torch inside the gassifier chamber. As apparatus, an enhanced plasma gassifier arrangement is of the type that has a gassifier chamber having an electrically operated plasma torch for issuing a plasma discharge into the gassifier chamber. A fuel injection arrangement is disposed to surround the electrically operated plasma torch for injecting a fuel and an oxidant into the gassifier chamber. A natural gas inlet delivers natural gas into the gassifier chamber, thereby enhancing the temperature within the gassifier chamber.

Owner:JURANITCH JAMES C +2

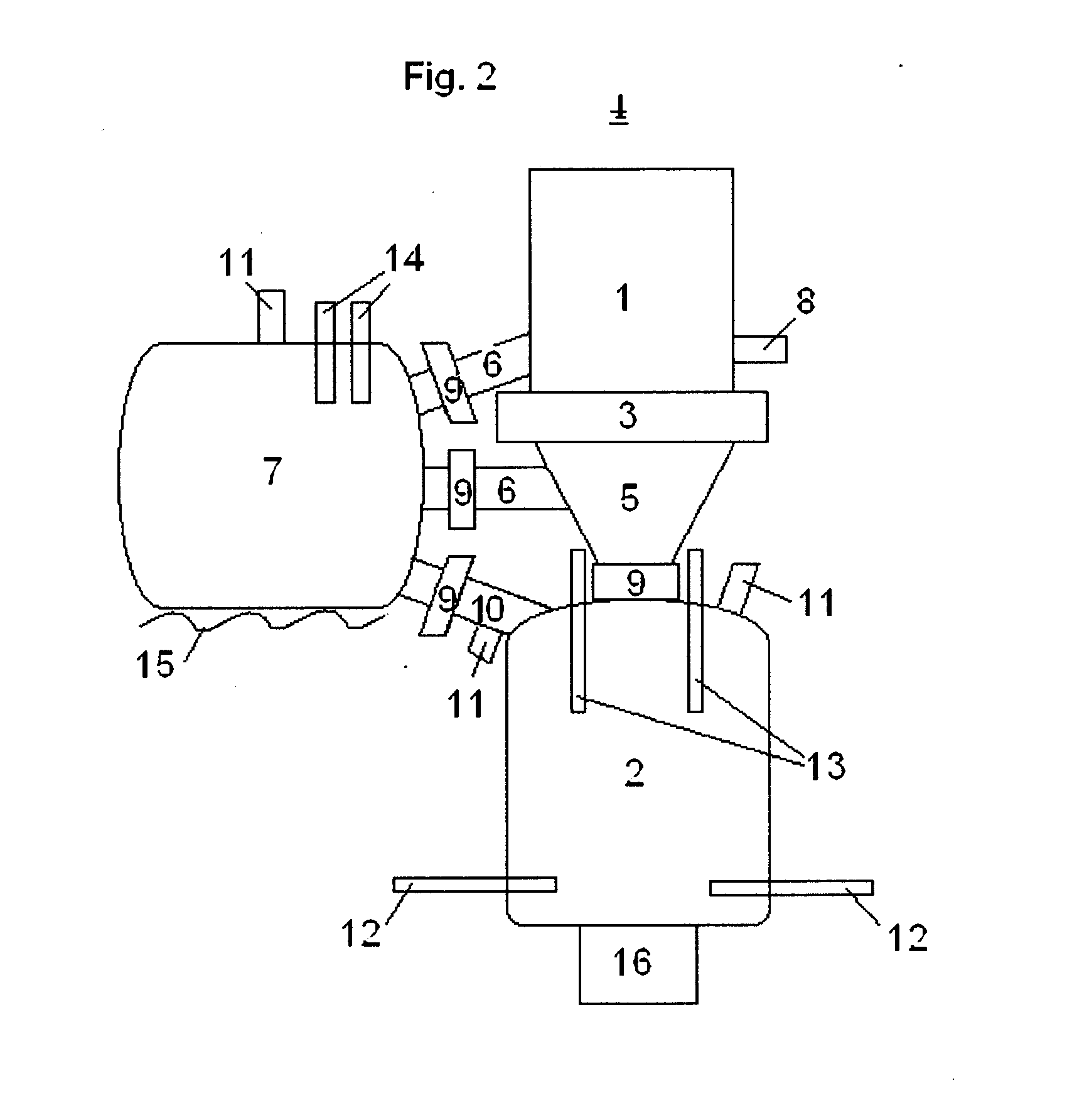

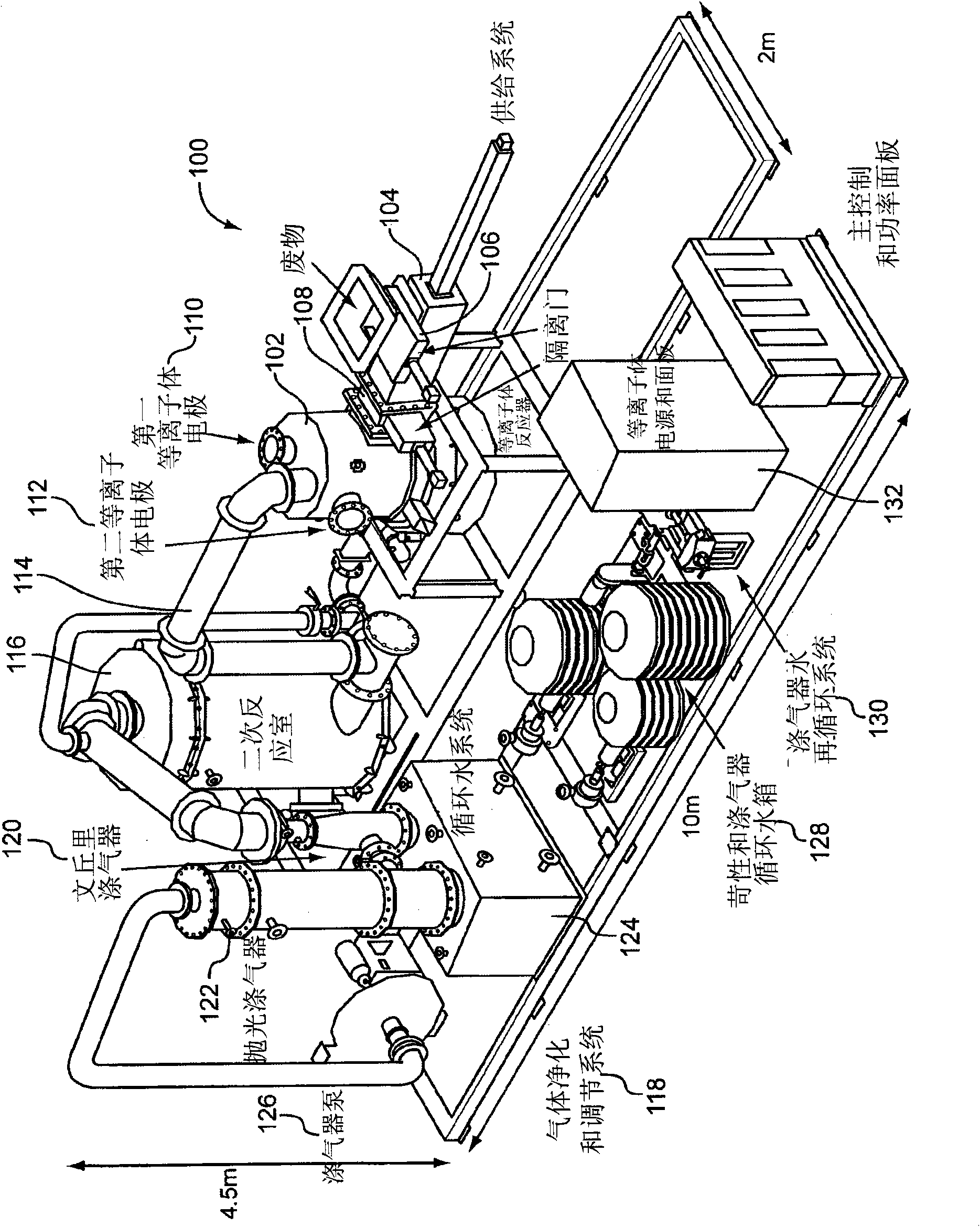

Method and apparatus of treating waste

InactiveCN101983087AGasifier electrodesWater treatment parameter controlControl systemMovement control

A waste treatment system processes waste upon the application of energy. The system includes a vessel that has an open space that receives waste feedstock. At least two plasma electrodes are mounted to the vessel. An electrode movement control system may position the plasma electrodes to facilitate a pryolysis process to treat the waste feedstock.

Owner:PEAT INT INC

Entrained bed gasifier with integrated medium temperature plasma

A process for gasifying solid or liquid gasification materials, in particular biomass, at pressures in the range from atmospheric pressure to 10 MPa and at gasification temperatures in the range from 800° C. to 1500° C. to form a highly calorific synthesis gas. An endothermic steam gasification process proceeds in a gasification space of an entrained flow gasifier, and a plasma of intermediate temperature (typically <3500° C., preferably <2000° C.) introduces heat of reaction into the gasification space in such a quantity that the gasification temperature is kept below the ash softening temperature of 1500° C. Endothermic reactions, in particular reactions having a high activation energy, proceed at high rates at far lower gas temperatures than in the case of a thermal process. The gasification process, which does not require an oxygen plant, gives a crude gas which is free of hydrocarbons.

Owner:SIEMENS AG

Method for destroying a nuclear graphite by gasification in aqueous medium

A process for the treatment of a nuclear graphite contaminated with radioelements includes subjecting the graphite, immersed in a medium containing water, to high-voltage pulses. The pulses have sufficient energy for electric arcs to be initiated and to break the constituent bonds of the water molecules and the carbon-carbon bonds of the graphite. The number of high-voltage pulses is determined so as to convert the graphite into gas.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

System and method for processing material to generate syngas using water injection

The present invention is directed to system and method for processing material to generate syngas. A reactor chamber is implemented with a plurality of electrodes that can generate an arc within the chamber when electricity is applied to them. The arc can be used to create free radicals which along with the heat and light of the arc breakdown material comprising carbonaceous material, such as Municipal Solid Waste (MSW), into gas components that form syngas. The syngas can be extracted from the reactor chamber and be used for various commercial purposes. The reactor chamber may comprise a material feed system operable to move material from a material input opening in the reactor chamber towards the electrodes at a controlled rate. Further, the reactor chamber may comprise a water injection system within the reactor chamber operable to inject water into the reactor chamber while electricity is applied to the electrodes. Yet further, the reactor chamber may comprise a gas removal system within the reactor chamber operable to extract gas generated from breakdown of the material from a plurality of gas removal locations. The gas removal system may be integrated within the material feed system.

Owner:RESPONSIBLE ENERGY

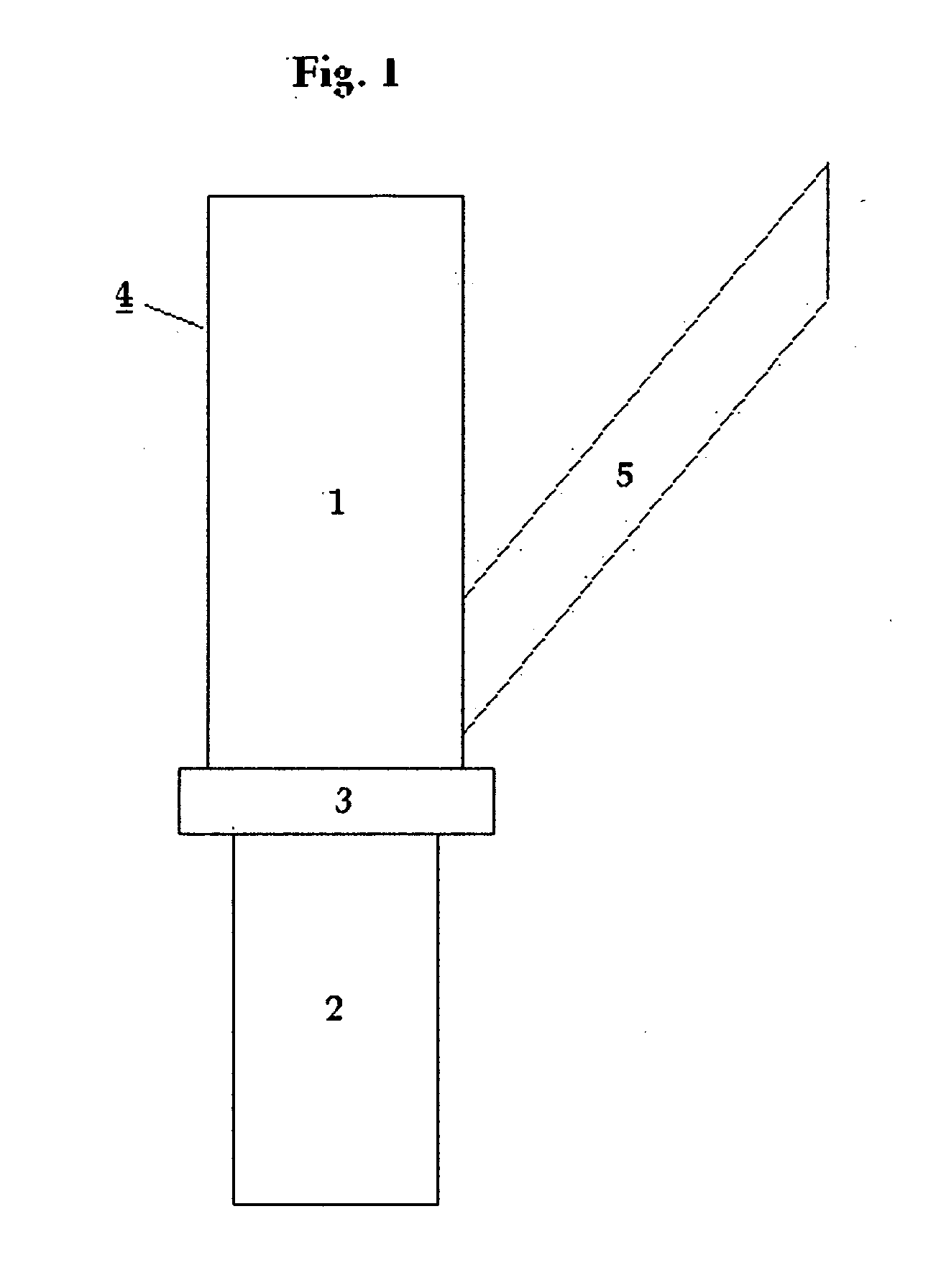

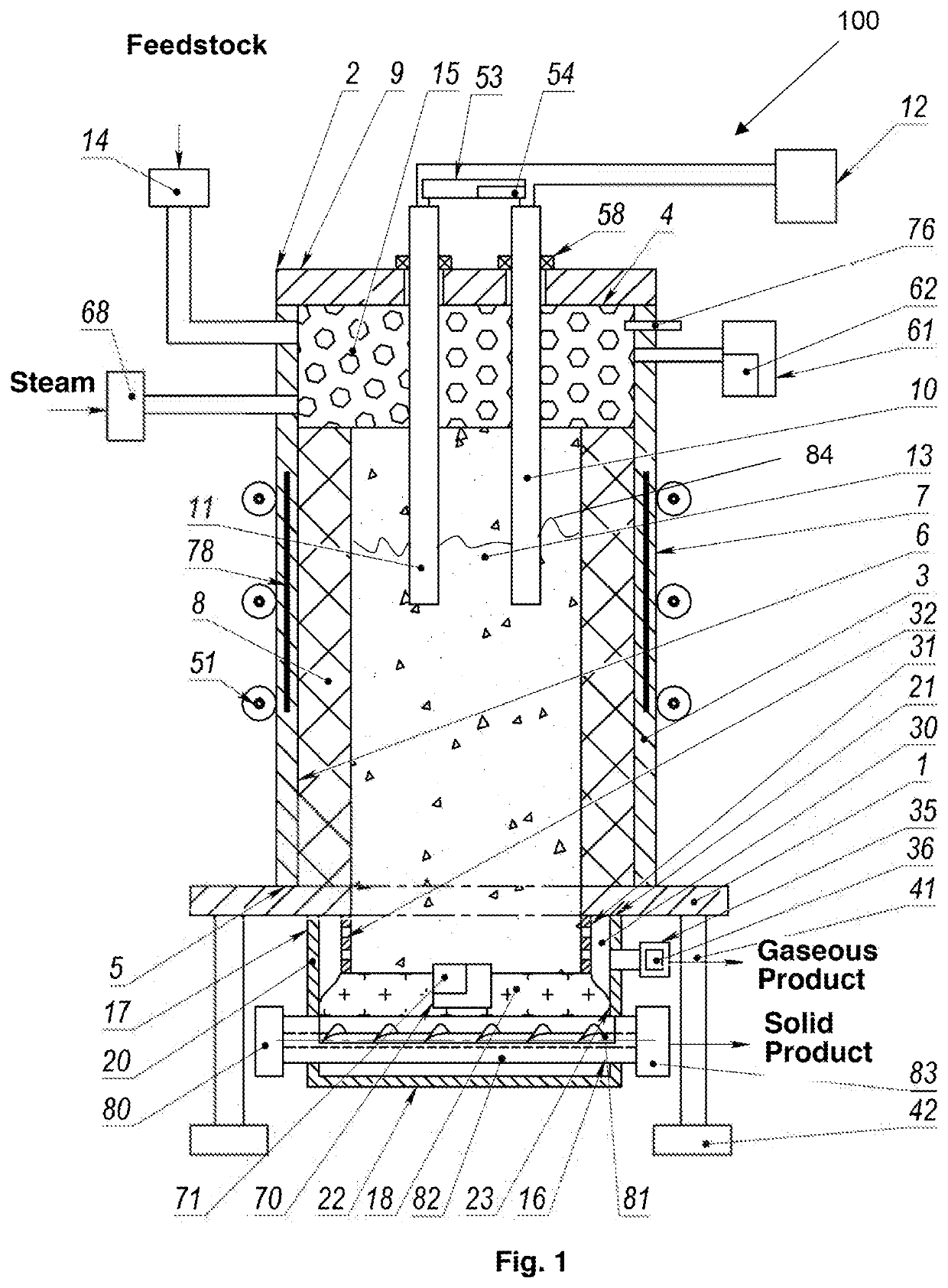

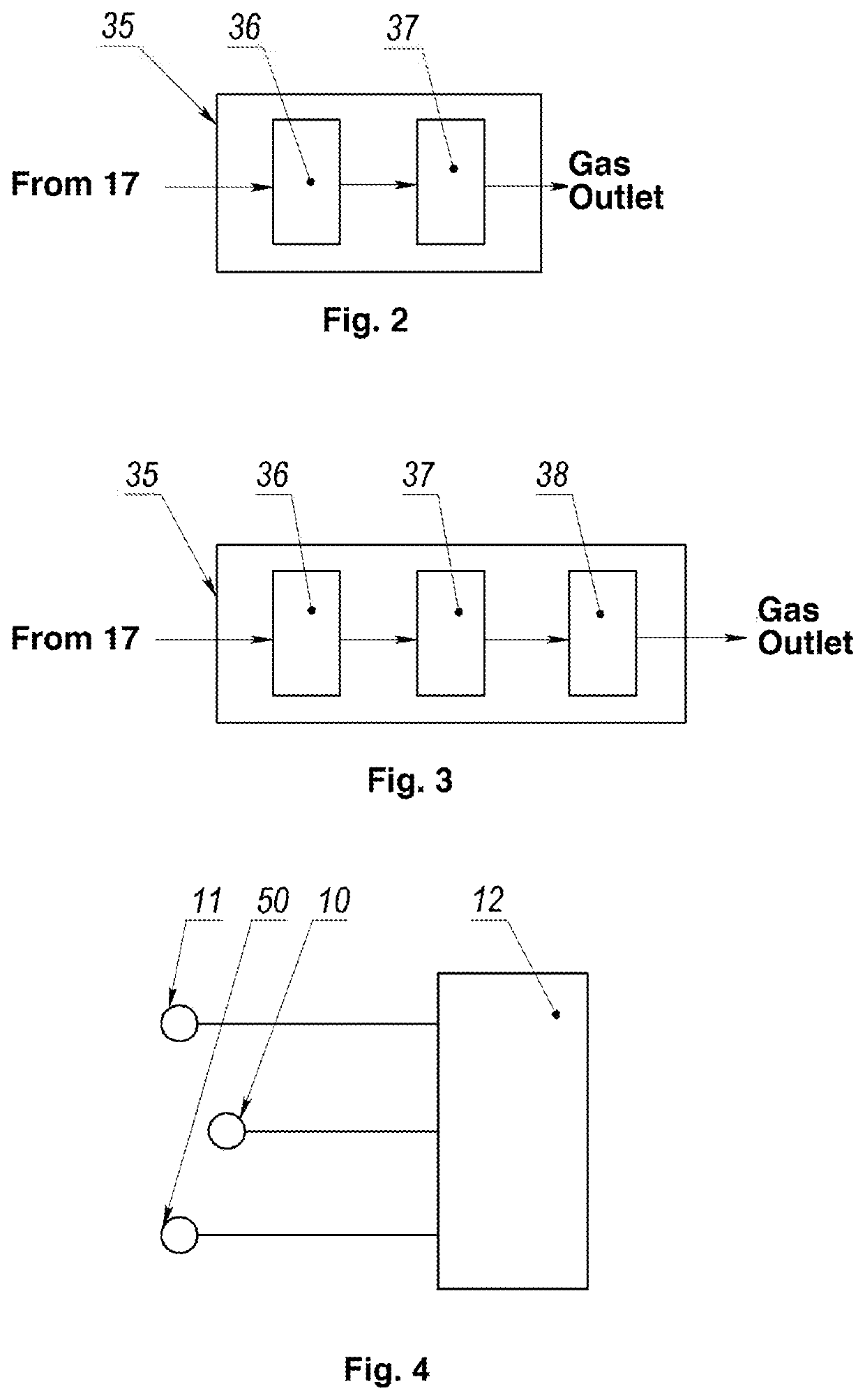

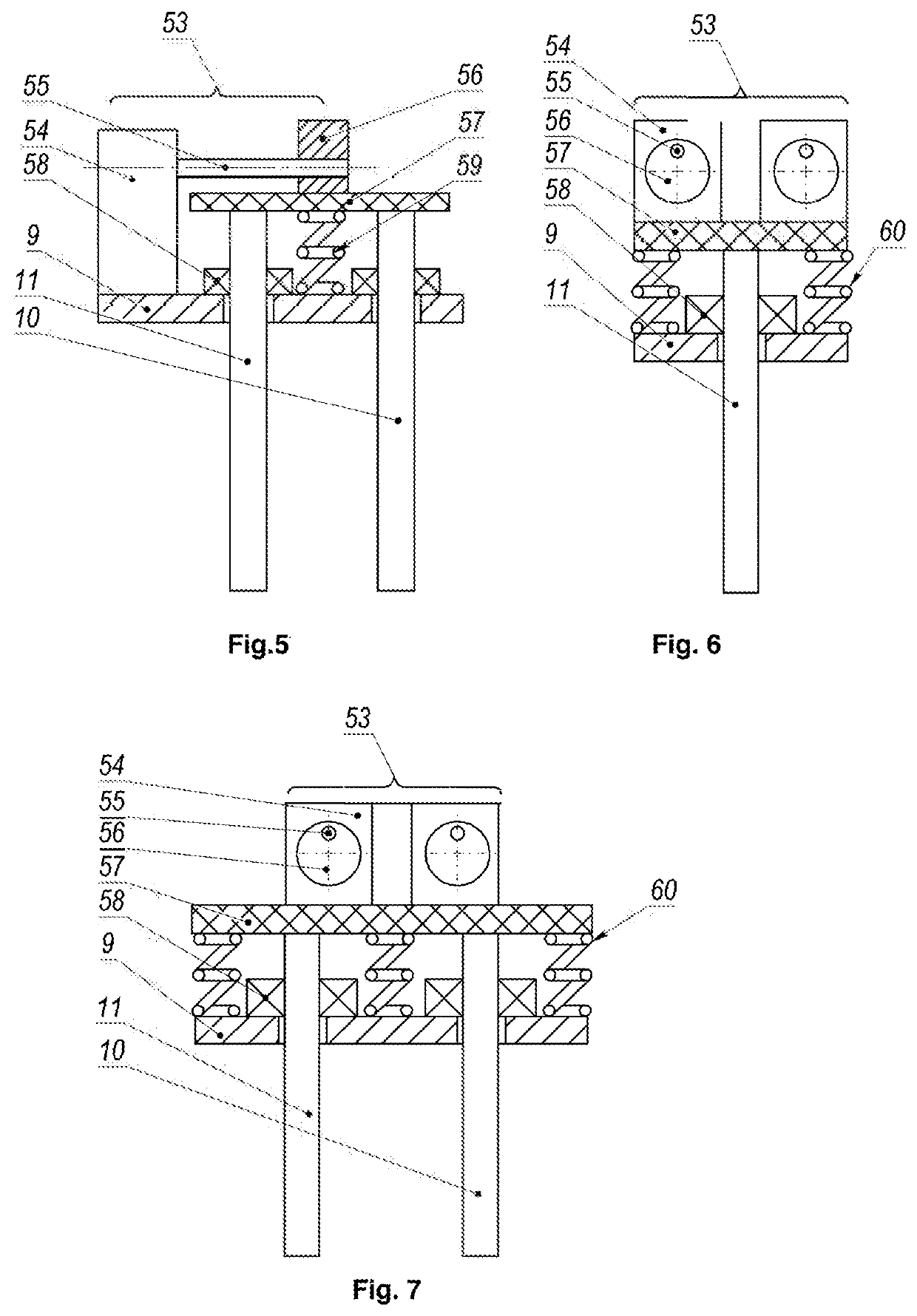

Device for pyrolysis of carbonaceous materials and method

ActiveUS20220282160A1Improve permeabilityEfficient responseGasifier electrodesElectrical coke oven heatingEngineeringGraphite

The device for pyrolysis of carbonaceous materials comprises a working chamber comprising a non-magnetic wall comprising an inner graphite lining; one or more electrodes adapted to be inserted within a carbon-based bedding; a solenoid coiled around the device exterior, the solenoid adapted to create a magnetic field within the working chamber such that when the solenoid is energized, the carbon-based bedding is caused to move; a lower solids outlet comprising an airlock, the solids outlet adapted to permit solids to exit the device; and a lower gas outlet adapted to permit gaseous substances to exit after having traveled through the carbon-based bedding. The method comprises the steps of loading carbon-containing materials into the working chamber; using the first and second electrodes to heat the carbon-containing materials by passing electric current through the carbon-containing materials without air access; collecting, cleaning and releasing gaseous pyrolysis products produced by the heating.

Owner:EXTIEL AP LLC

Renewable Blended Syngas from a Plasma-Based System

ActiveUS20130320679A1Quality improvementLow costGasifier electrodesGas modification by gas mixingEnergy transferSyngas

A method and system for cost-effectively converting a feedstock using thermal plasma, or other styles of gassifiers, into an energy transfer system using a blended syngas. The feedstock is any organic material or fossil fuel to generate a syngas. The syngas is blended with any fuel of a higher thermal content (BTU) level, such as natural gas. The blended syngas high thermal content fuel can be used in any energy transfer device such as a boiler for simple cycle Rankine systems, an internal combustion engine generator, or a combined cycle turbine generator system. The quality of the high thermal content fuel is monitored using a thermal content monitoring feedback system and a quenching arrangement.

Owner:PLASMA TECH HLDG LLC

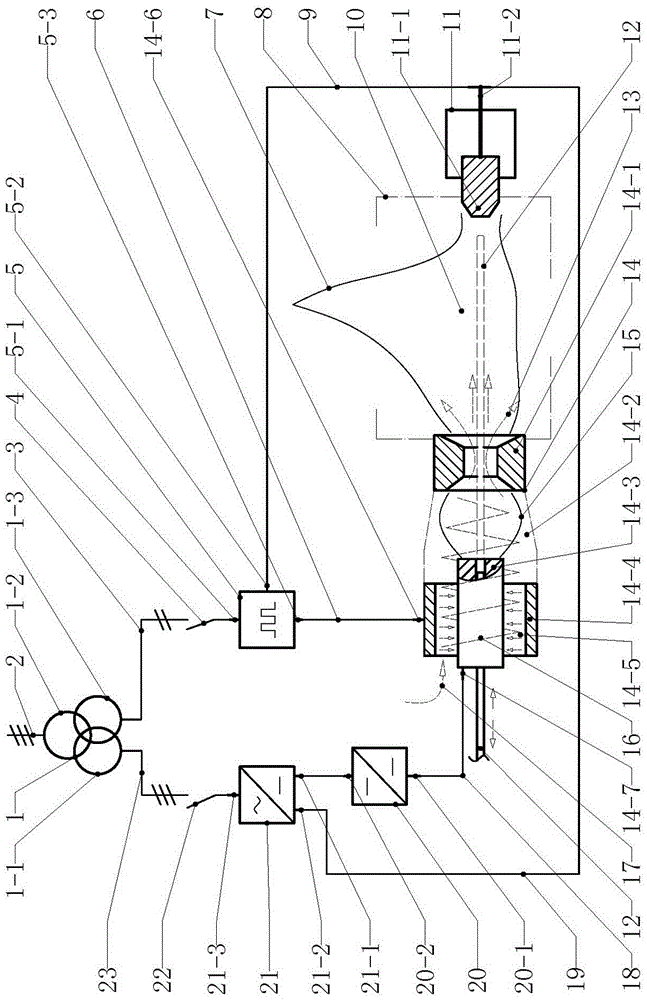

Plasma pyrolysis system

ActiveCN105567328AHigh energyIncrease space distanceGasifier electrodesGasification processes detailsIsolatorMaterials science

A plasma pyrolysis system relates to a plasma device and comprises a triphase rectifier, a high frequency power source and a plasma device; a triphase alternating current circuit is connected to a triphase alternating current input interface of the triphase rectifier; a monophase alternating current circuit is connected to a working frequency input interface of a high frequency power source; an isolator is arranged in the system; a direct current output interface of the triphase rectifier is connected to a direct current input end of the isolator; the plasma device consists of a first discharging component and a second discharging component; a first electrode, a second electrode, a third electrode are arranged in the first discharging component; a fourth electrode is arranged in the second discharging component; a high frequency output interface of the high frequency power source is connected to the first electrode; the direct current output end of the isolator is connected to the second electrode; a direct current loop interface of the triphase rectifier is connected to the fourth electrode. A plasma gasifying manner is adopted to perform ionization activation and then perform pyrolysis treatment through a second-class hyperthermia plasma arc on water vapor to dissolve the water vapor into active substances of hydrogen and oxygen to be used as a gasifying agent.

Owner:JINING XINRUIDA INFORMATION TECH CO LTD

Gasification system

ActiveUS9206364B2Reduce materialMaximize effectivenessGasifier electrodesProductsPartial oxidationProduct gas

A gasification system method and apparatus to convert a feed stream containing at least some organic material into synthesis gas having a first region, a second region, a gas solid separator, and a means for controlling the flow of material from the first region to the second region. The feed stream is introduced into the system, and the feed stream is partially oxidized in the first region thereby creating a solid material and a gas material. The method further includes the steps of separating at least a portion of the solid material from the gas material with the gas solid separator, controlling the flow of the solid material into the second region from the first region, and heating the solid material in the second region with an electrical means.

Owner:INENTEC

System and method for processing material to generate syngas

ActiveUS20120017509A1Prevent escapeGasifier electrodesGas purification by non-gaseous materials condensationElectricitySyngas

The present invention is directed to system and method for processing material to generate syngas. A reactor chamber is implemented with a plurality of electrodes that can generate an arc within the chamber when electricity is applied to them. The arc can be used to create free radicals which along with the heat and light of the arc breakdown material comprising carbonaceous material, such as Municipal Solid Waste (MSW), into gas components that form syngas. The syngas can be extracted from the reactor chamber and be used for various commercial purposes. The reactor chamber may comprise a material feed system operable to move material from a material input opening in the reactor chamber towards the electrodes at a controlled rate. Further, the reactor chamber may comprise a water injection system within the reactor chamber operable to inject water into the reactor chamber while electricity is applied to the electrodes. Yet further, the reactor chamber may comprise a gas removal system within the reactor chamber operable to extract gas generated from breakdown of the material from a plurality of gas removal locations. The gas removal system may be integrated within the material feed system.

Owner:RESPONSIBLE ENERGY

Gasification melting furnace and method for treating combustible material using the same

InactiveUS20130294474A1Efficiently treating great amount of wasteWeaken energyGasifier electrodesElectric discharge heatingForming gasHazardous substance

A gasification melting furnace includes a gasification part into which the combustible material inputs, a sedimentary part communicating with a lower part of the gasification part, and a melting part communicating with a lateral face of the sedimentary part and having a heater, wherein the sedimentary part is filled with the combustible material and a gas generated in the melting part passes through the combustible material and inputs into the gasification part, thereby stably and rapidly treating the combustible material, reducing energy consumption of the heater, and providing a synthetic gas containing decreased hazardous substances.

Owner:GS PLATECH

Popular searches

Carburetting by solid carbonaceous material pyrolysis Special form destructive distillation Combustible gas production Incinerator apparatus Combined combustion mitigation Molten salts/metals gasification Granular/pulverulent flues gasification Furnace types Hydrogen production Indirect heat exchangers

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com