Two-stage plasma process for converting waste into fuel gas and apparatus therefor

a plasma process and waste gas technology, applied in the direction of combustible gas production, molten salt/metal gasification, soldering apparatus, etc., can solve the problems of high energy consumption of electrical energy, significant electrical energy must be used for dissociation,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]The process of the present invention can be used to process various types of industrial, hazardous or domestic waste in the form of liquids or solids. The solid wastes can be hospital waste, mixed plastics waste, municipal solid waste, automobile shredder residue or the like. The liquid wastes can be spent solvents, used oils, petroleum sludge, municipal water treatment sludge, de-inking sludge or similar liquids. Normally, the waste will comprise organic and inorganic constituents and in most cases, it will be rich in organic materials. When the waste comprises a combination of solids and liquids, the liquid portion should normally not exceed about 30% by weight of the total.

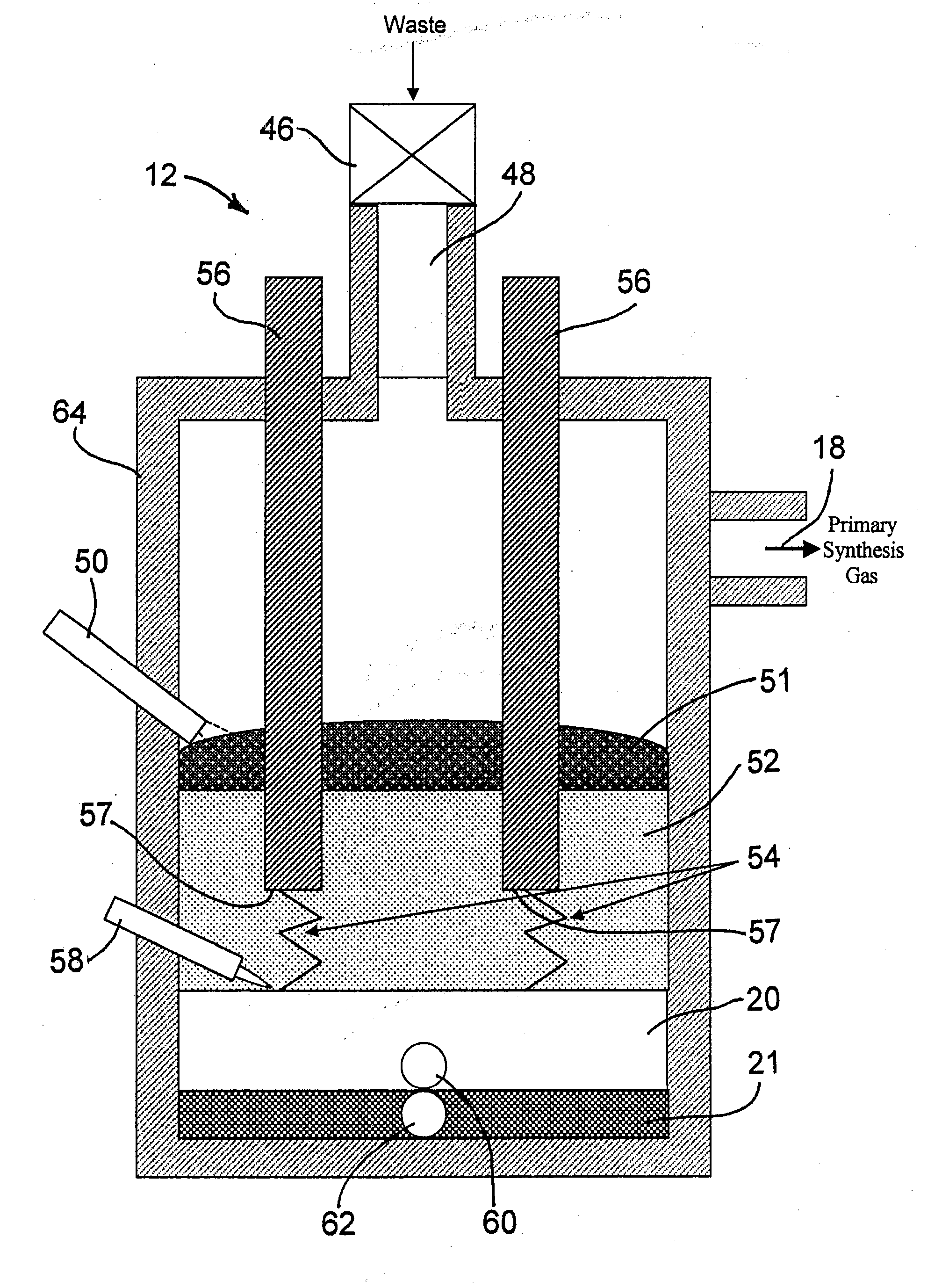

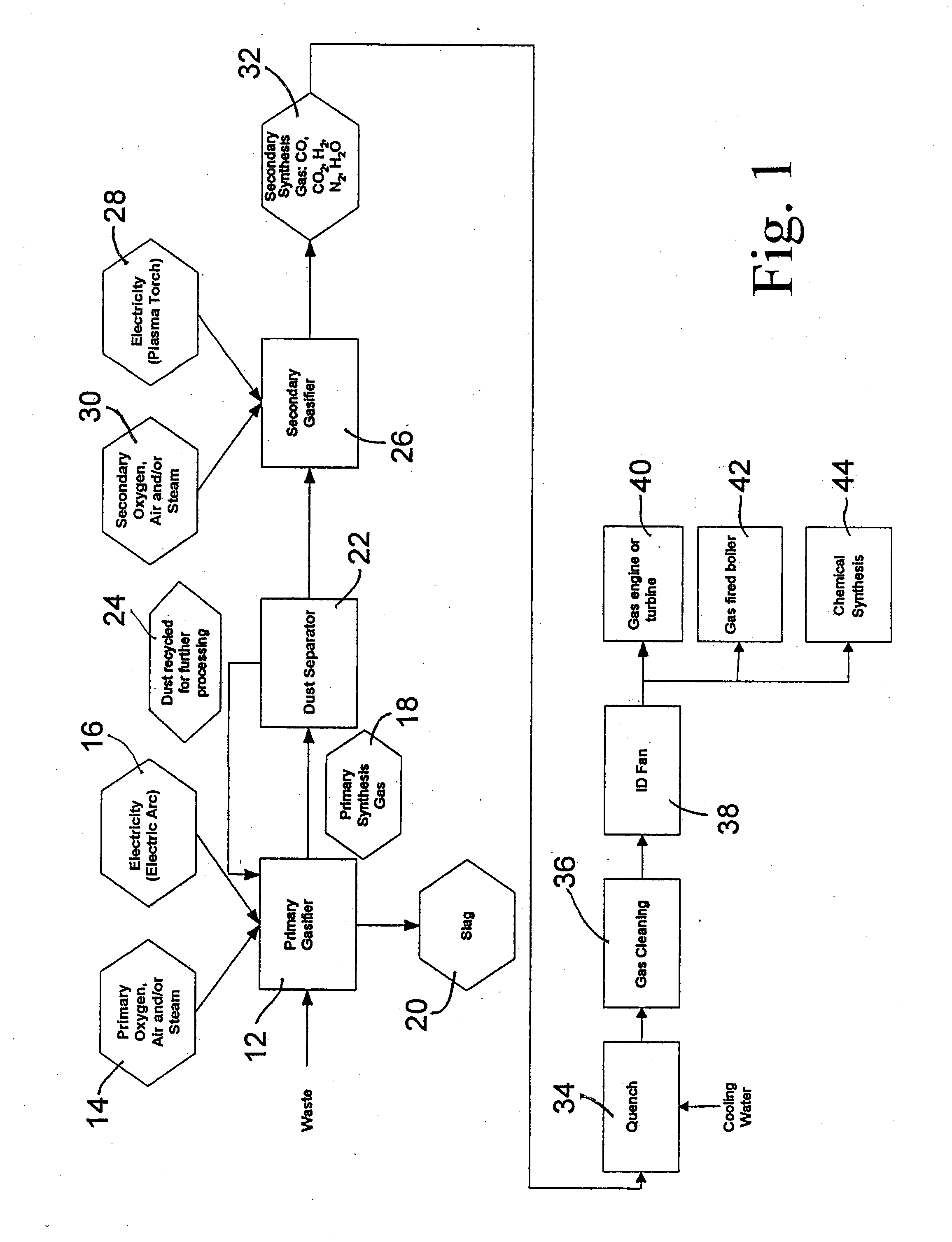

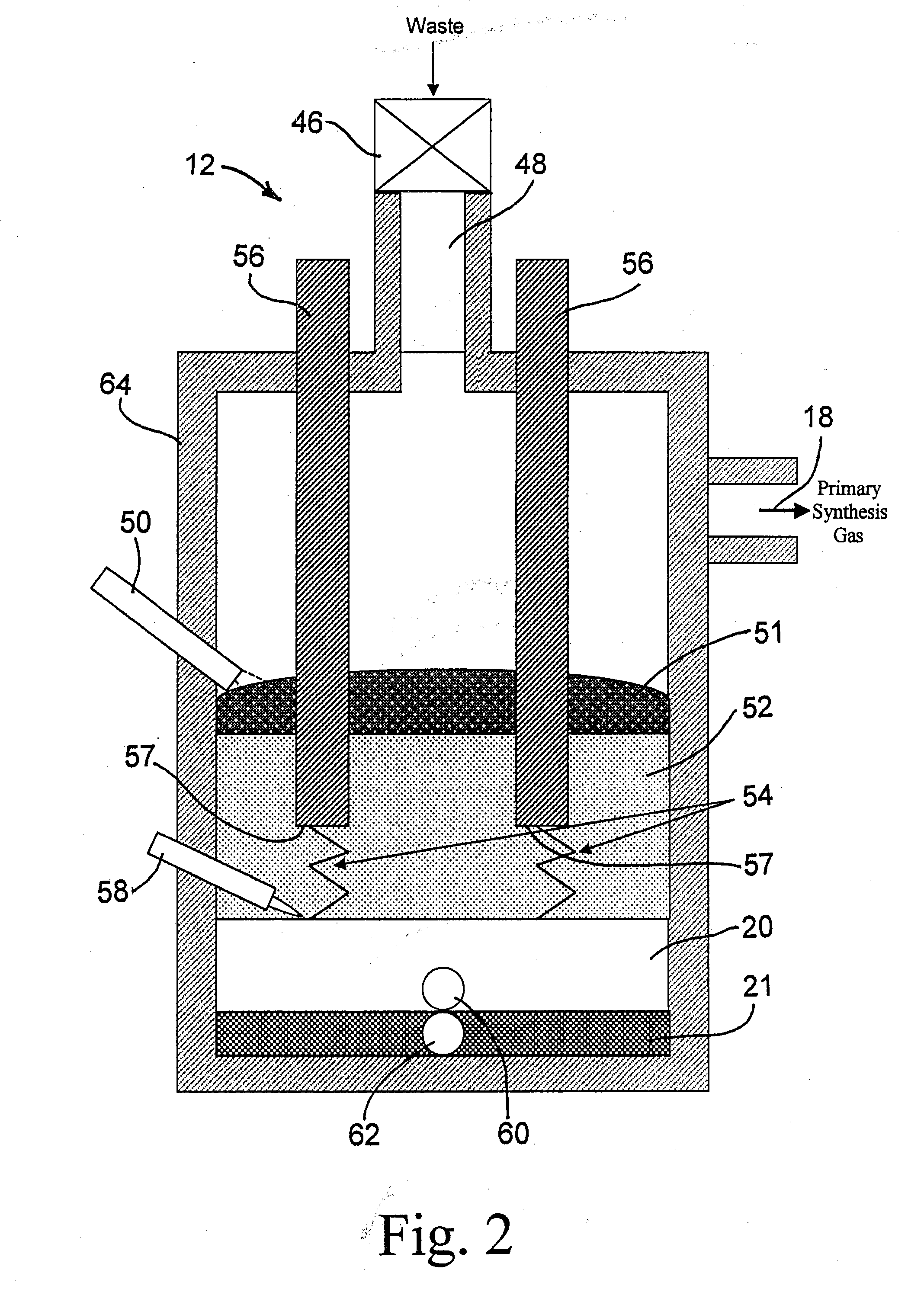

[0040]As shown in FIG. 1, the waste is first introduced into a primary gasifier (12) which is a plasma furnace. This plasma furnace is normally a refractory lined, enclosed, graphite arc furnace, where the plasma is generated by one or several direct current electrodes forming an electric arc, generally a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com