Patents

Literature

111results about "Molten salts/metals gasification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

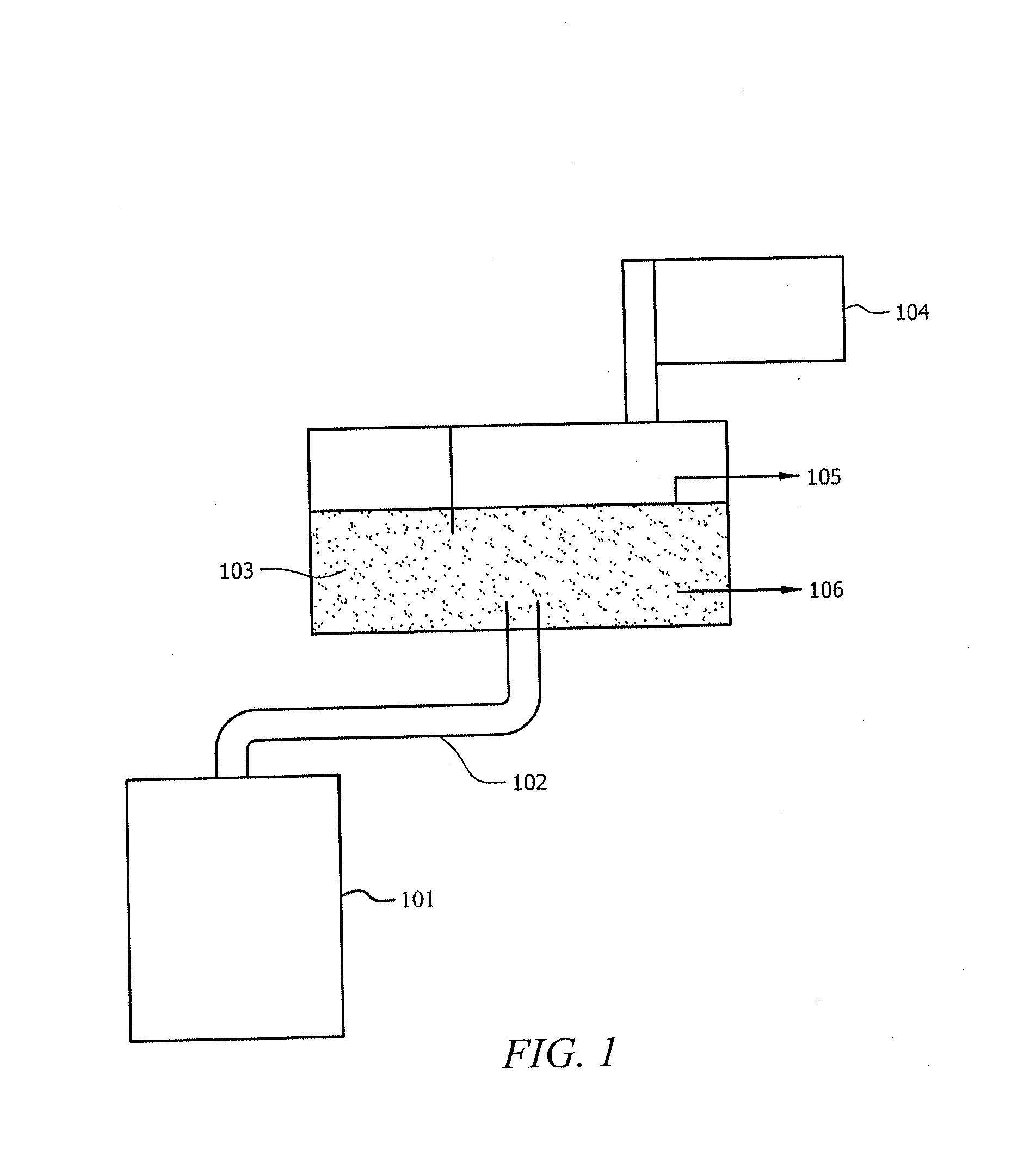

Method and apparatus to protect synthesis gas via flash pyrolysis and gasification in a molten liquid

InactiveUS20080307703A1Improve efficiencyLittle heating lossWaste based fuelRetortsSyngasThermodynamics

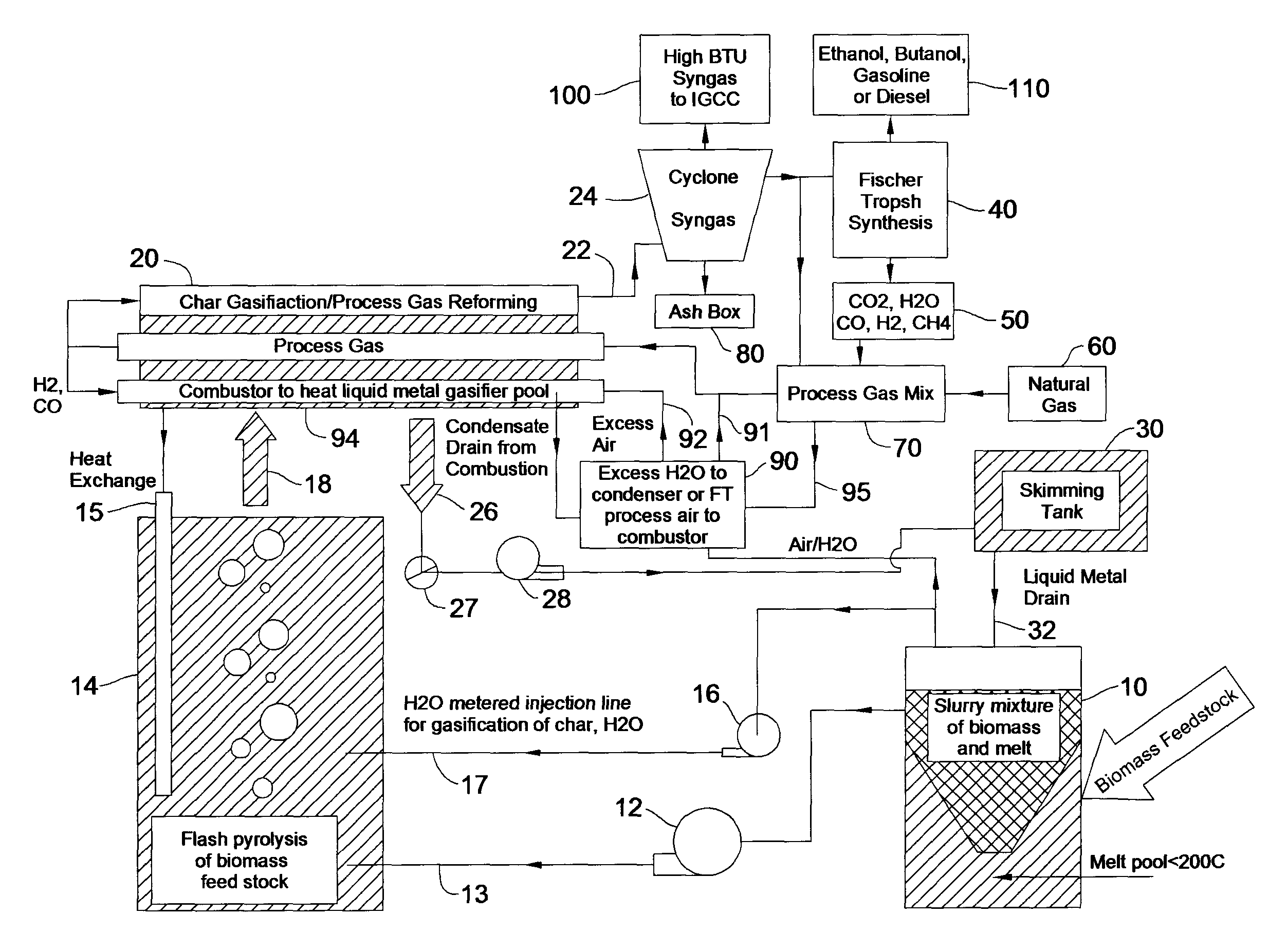

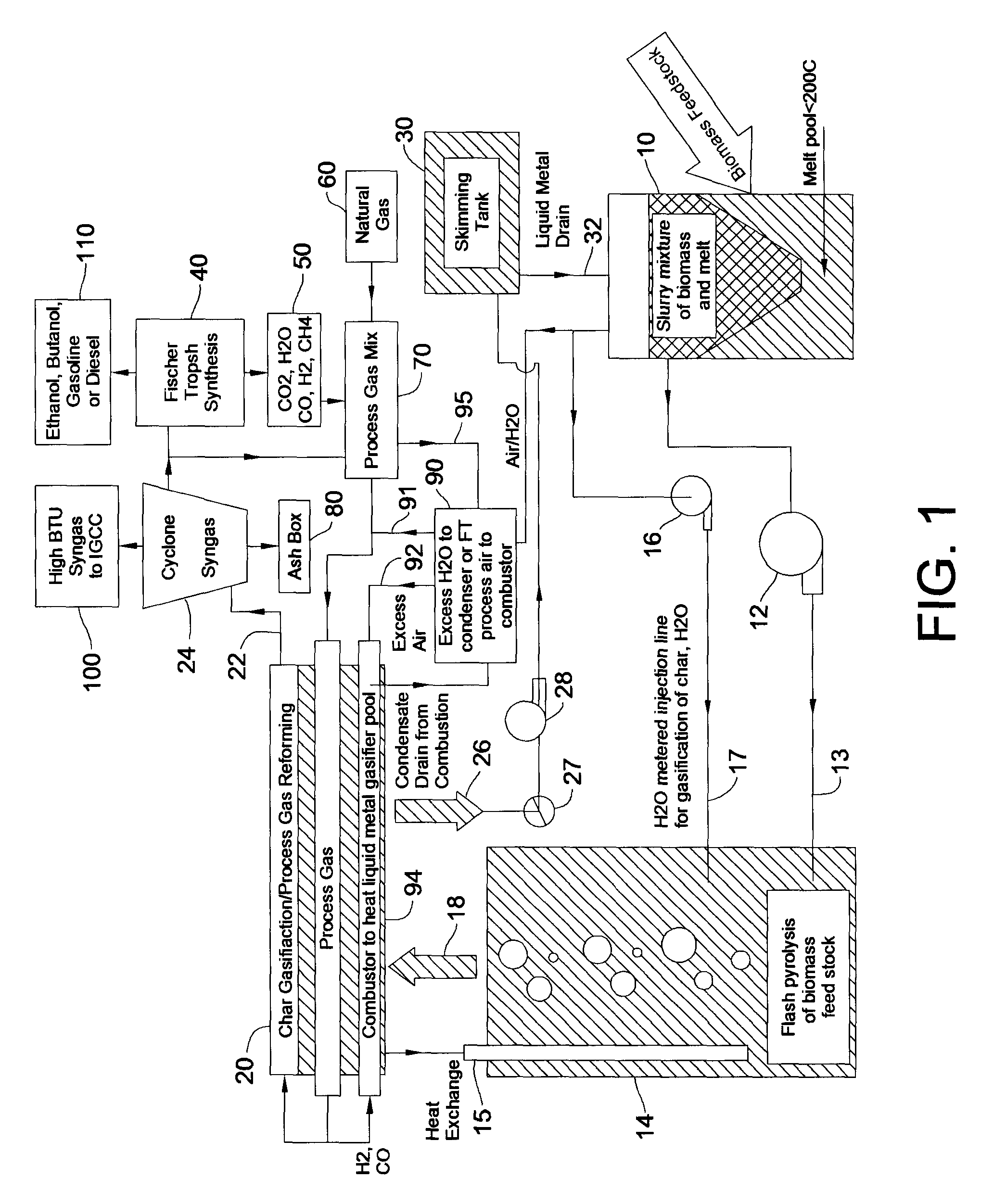

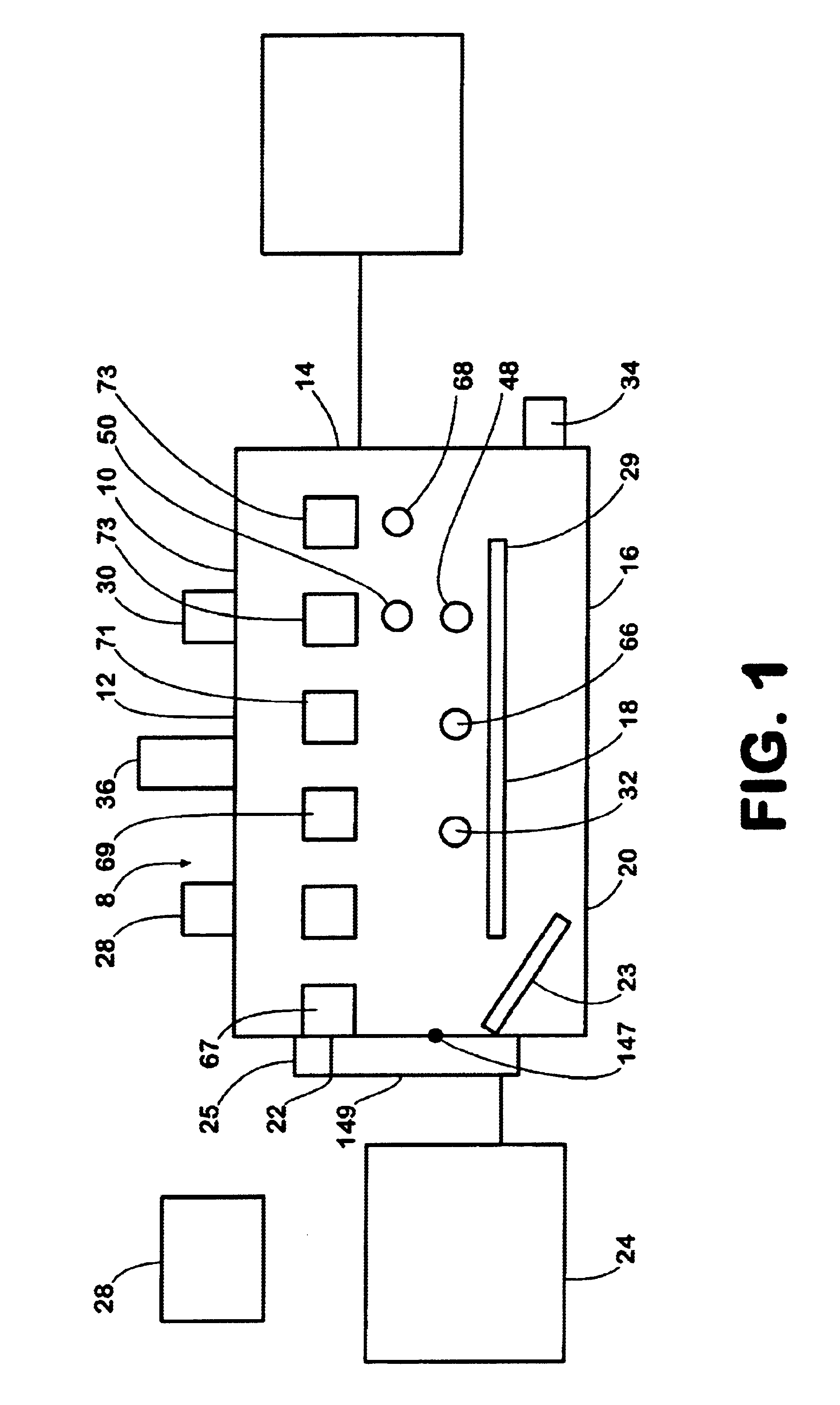

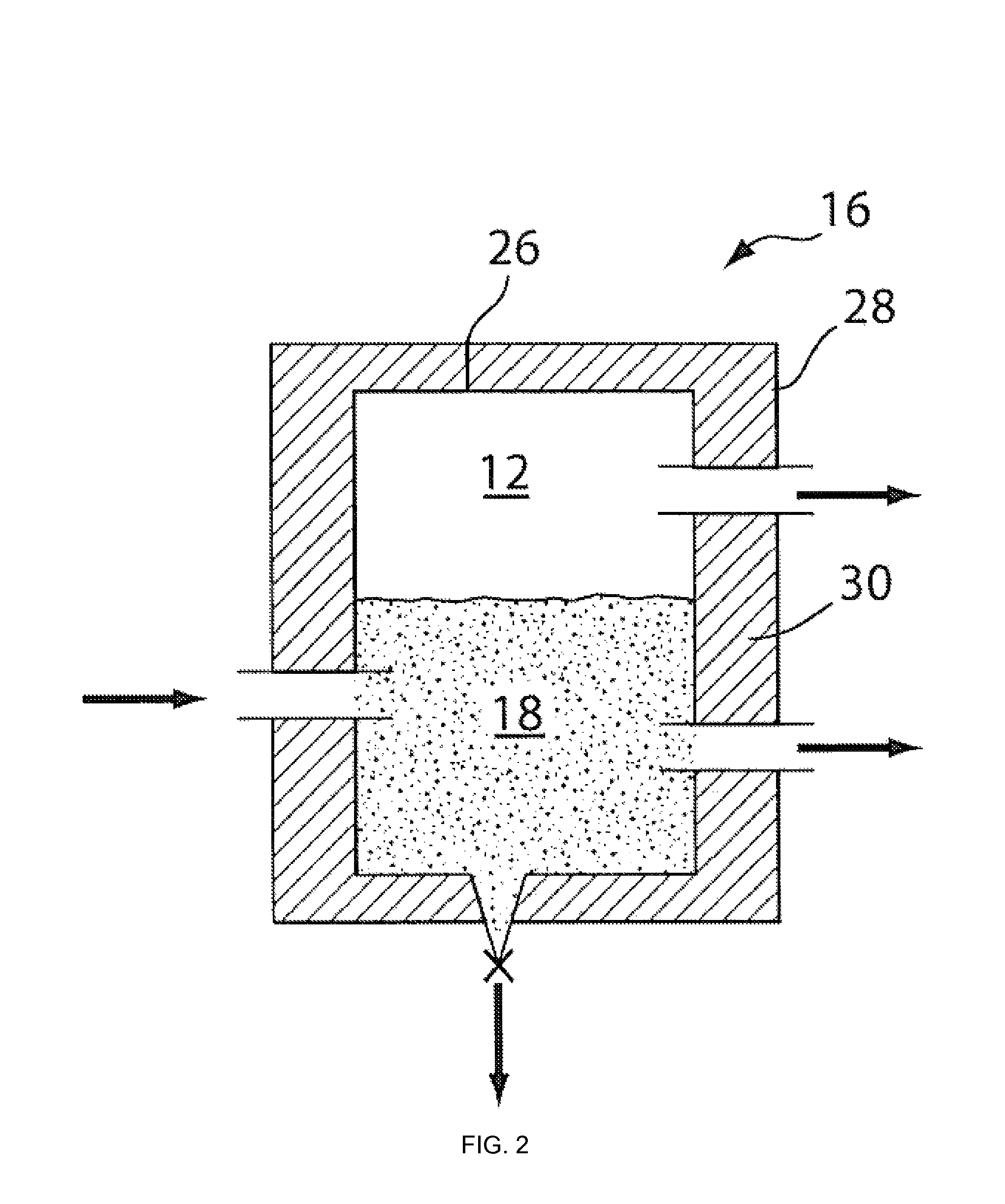

Disclosed are a method and a corresponding apparatus for converting a biomass reactant into synthesis gas. The method includes the steps of (1) heating biomass in a first molten liquid bath at a first temperature, wherein the first temperature is at least about 100° C., but less than the decomposition temperature of the biomass, wherein gas comprising water is evaporated and air is pressed from the biomass, thereby yielding dried biomass with minimal air content. (2) Recapturing the moisture evaporated from the biomass in step 1 for use in the process gas. (3) Heating the dried biomass in a second molten liquid bath at a second temperature, wherein the second temperature is sufficiently high to cause flash pyrolysis of the dried biomass, thereby yielding product gases, tar, and char. (4) Inserting recaptured steam into the process gas, which may optionally include external natural gas or hydrogen gas or recycled syngas for mixing and reforming with tar and non-condensable gases. (5) Further reacting the product gases, tar, and char with the process gas within a third molten liquid bath at a third temperature which is equal to or greater than the second temperature within the second molten liquid bath, thereby yielding high quality and relatively clean synthesis gas after a relatively long residence time needed for char gasification. A portion of the synthesis gas so formed is combusted to heat the first, second, and third molten liquid baths, unless external natural or hydrogen gas is available for this use.

Owner:US SEC AGRI +1

Waste to liquid hydrocarbon refinery system

InactiveUS20110158858A1Eliminate concernsReduce dependenceDirect heating destructive distillationCombustible gas catalytic treatmentLiquid wasteCogeneration

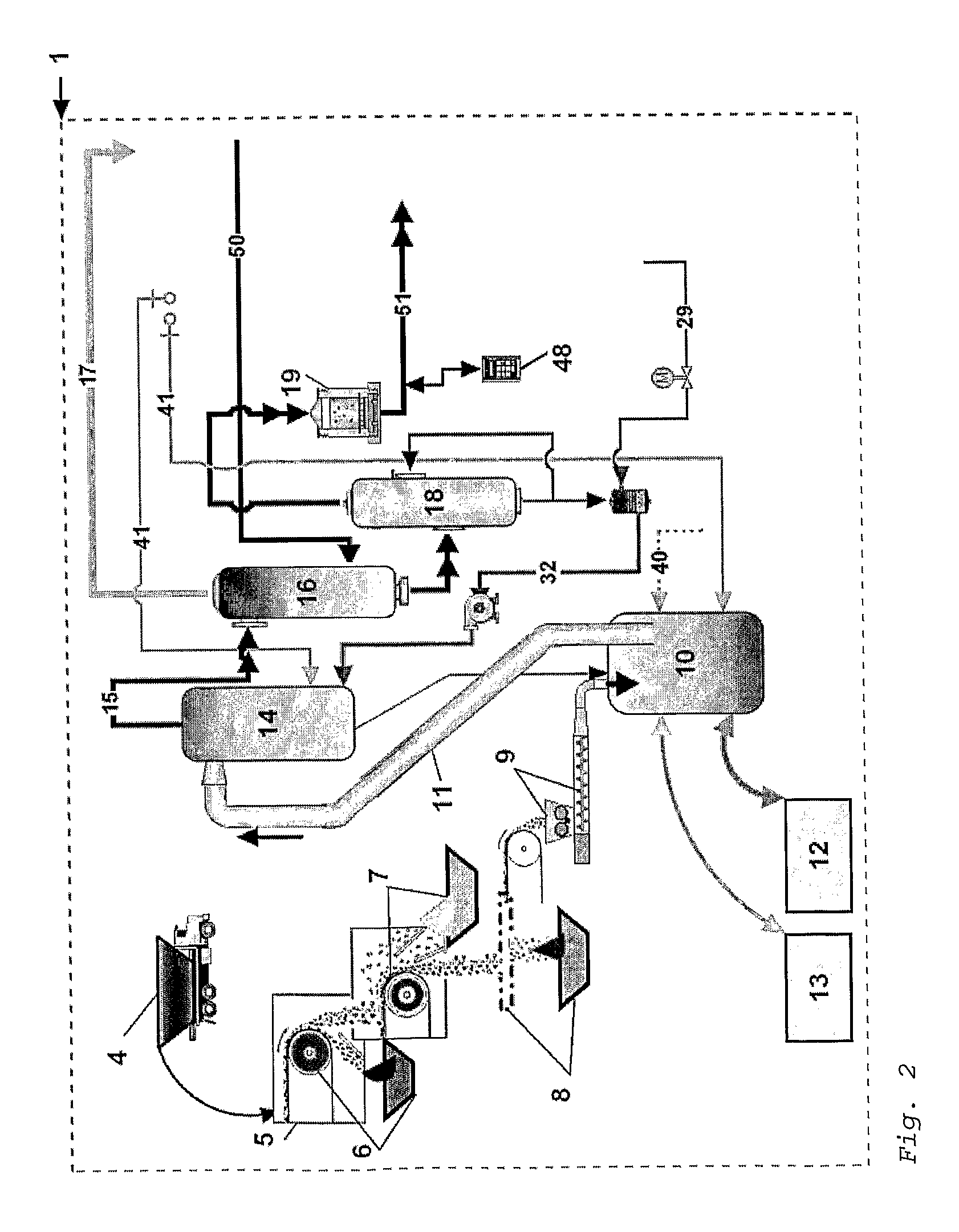

A Waste to Liquid Hydrocarbon Refinery System that transforms any municipal solid wastes and hazardous industrial wastes, Biomass or any carbon containing feedstock into synthetic hydrocarbon, particularly, but not exclusively, diesel and gasoline and / or electricity and co-generated heat, comprising three major subsystems: i) the Pyro-Electric Thermal Converter (PETC) (10) and Plasma Arc (PA) waste and biomass gasification subsystem (1); ii) the hydrocarbon synthesis subsystem (2); and iii) the electricity generation and heat co-generation subsystem (3).

Owner:ALVES RAMALHO GOMES MARIO LUIS

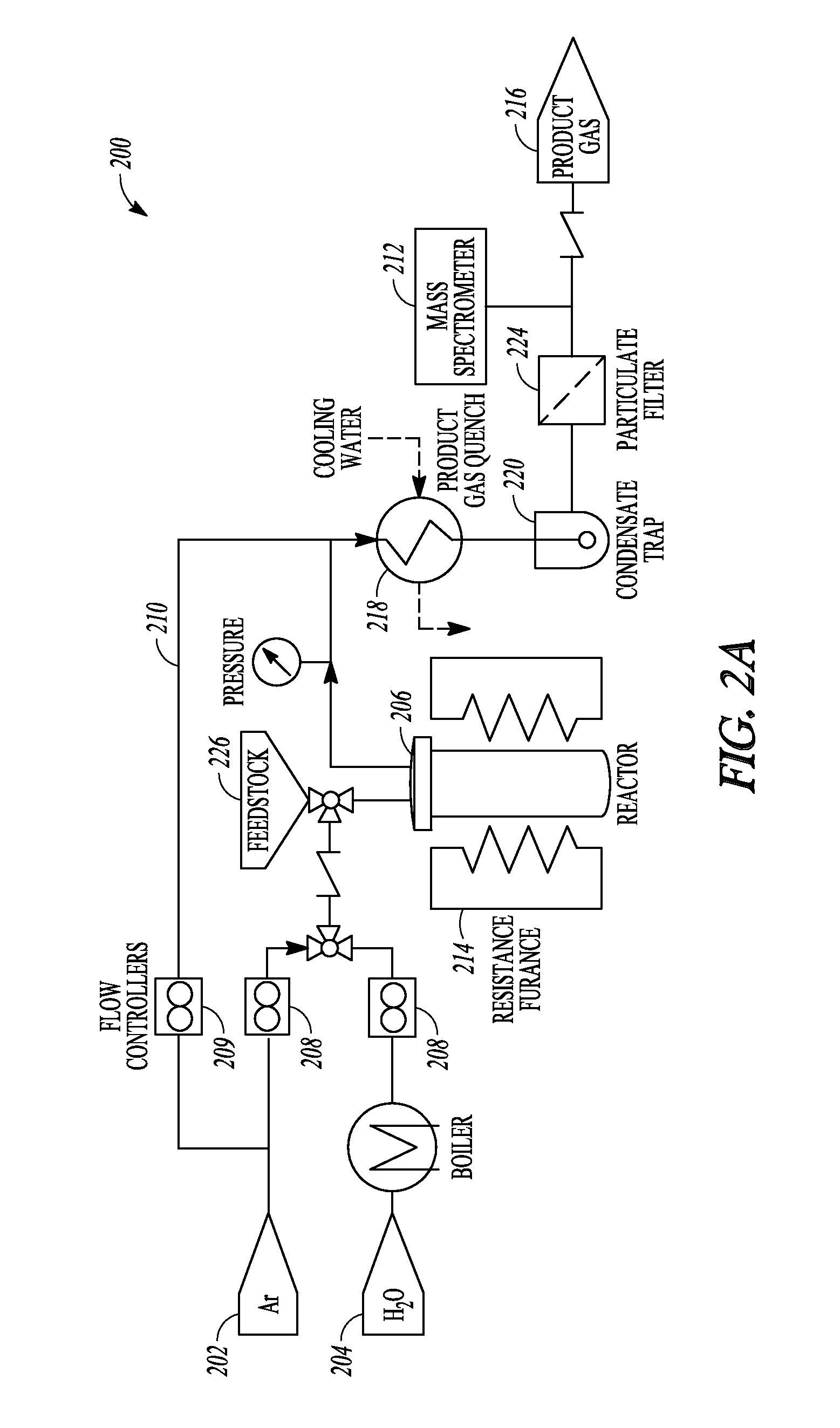

Process and apparatus using a molten metal bath

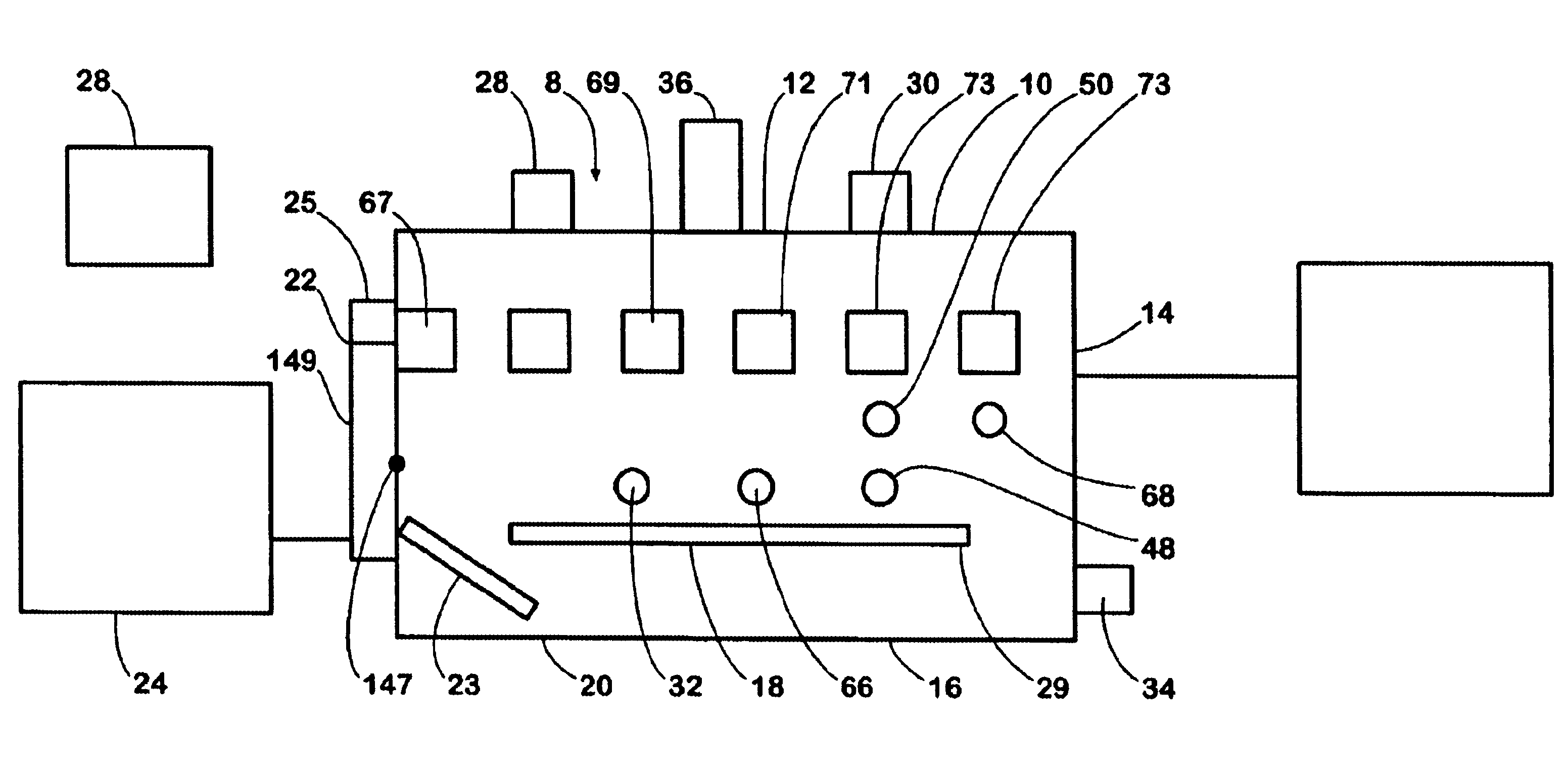

Processes and apparatus for treating organic and inorganic materials in a metal bath contained in a high temperature reactor to produce synthesis gas are provided. The feed materials are prepared and analyzed for heat value prior to injection and the composition of materials in and exiting the reactor are monitored. Based upon the results of the analysis and monitoring, oxygen, steam, and / or other feed materials are also injected into the reactor, to control processing and synthesis gas quality.

Owner:ZE-GEN

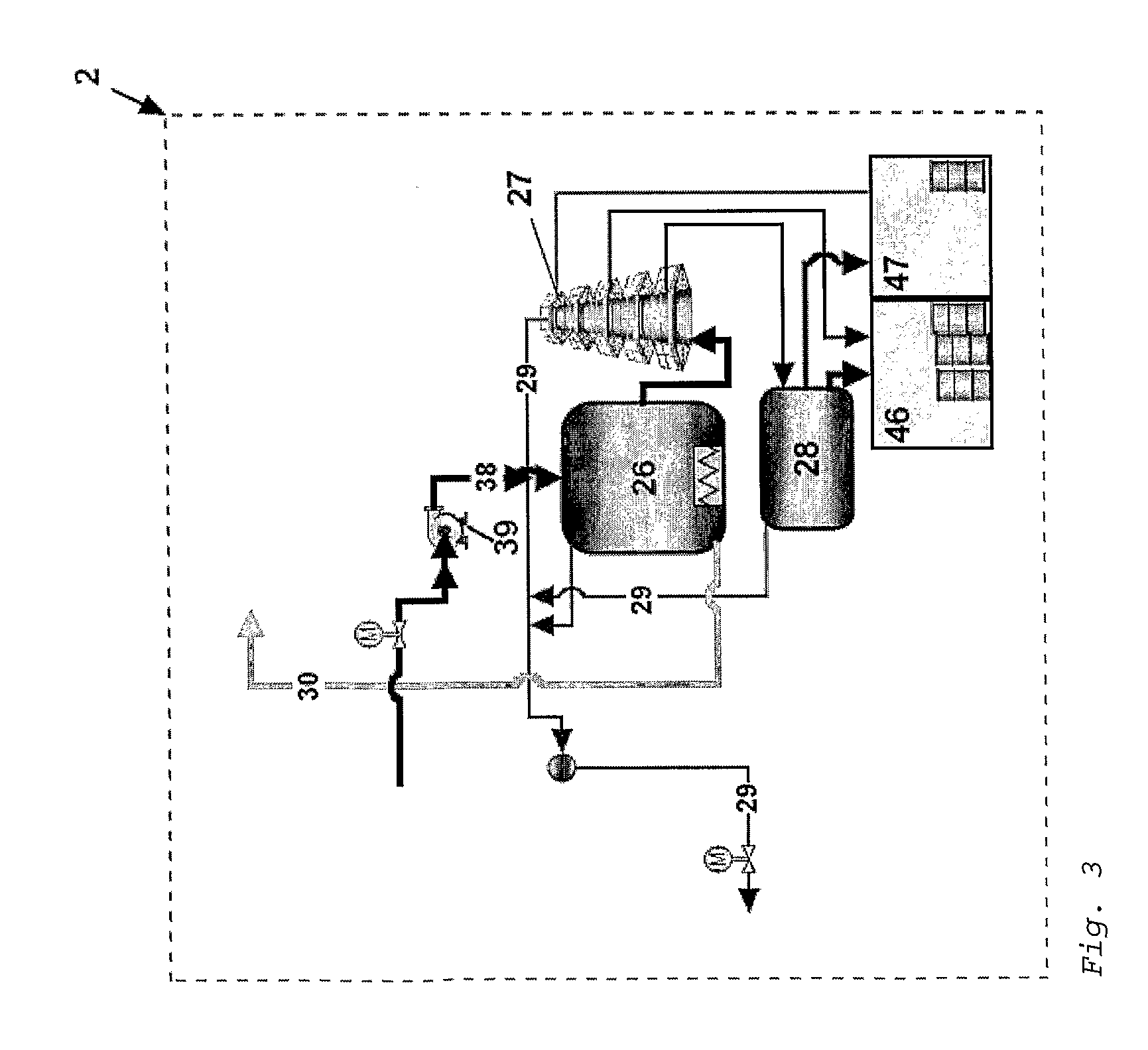

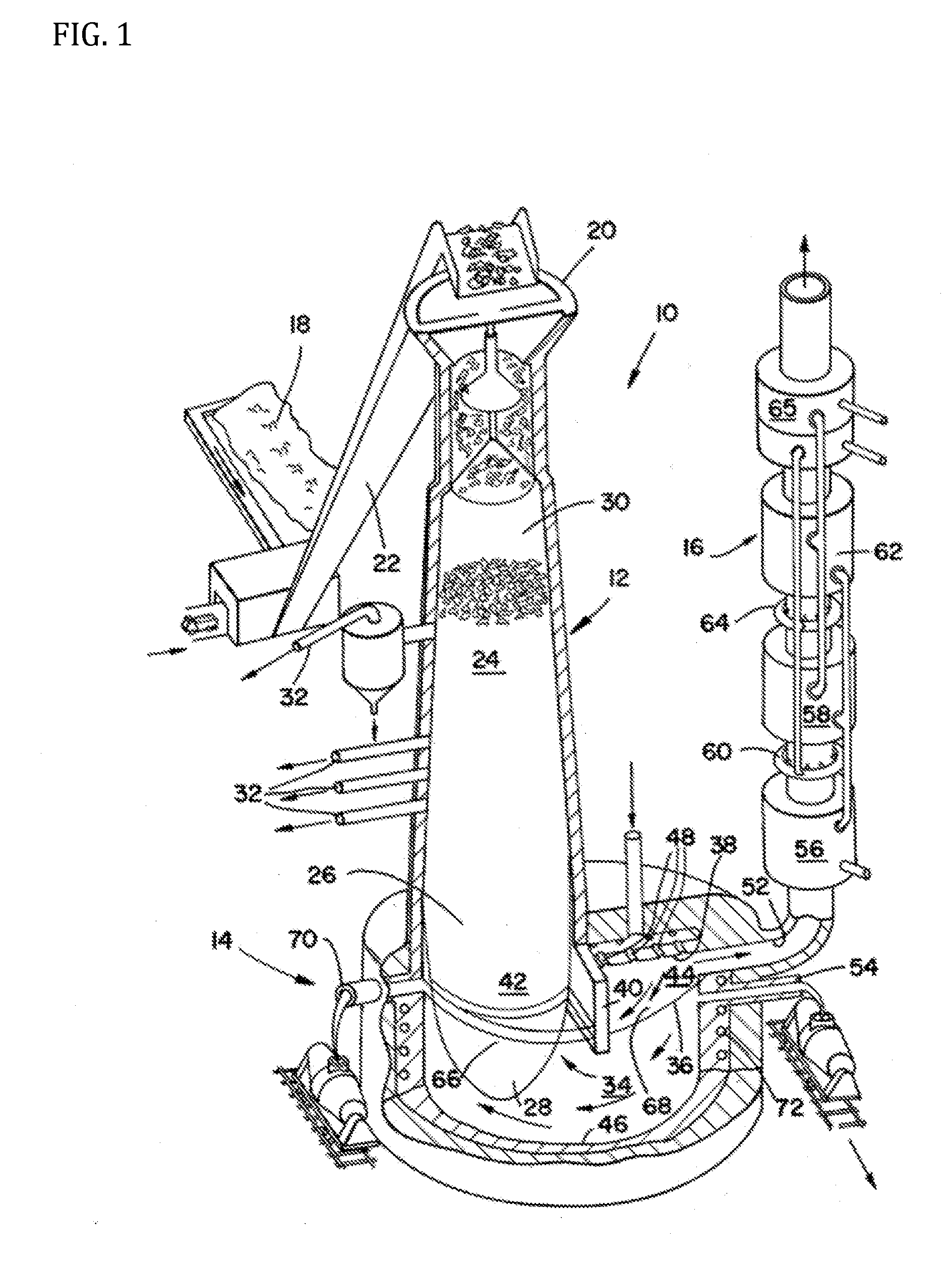

Two-Stage Plasma Process For Converting Waste Into Fuel Gas And Apparatus Therefor

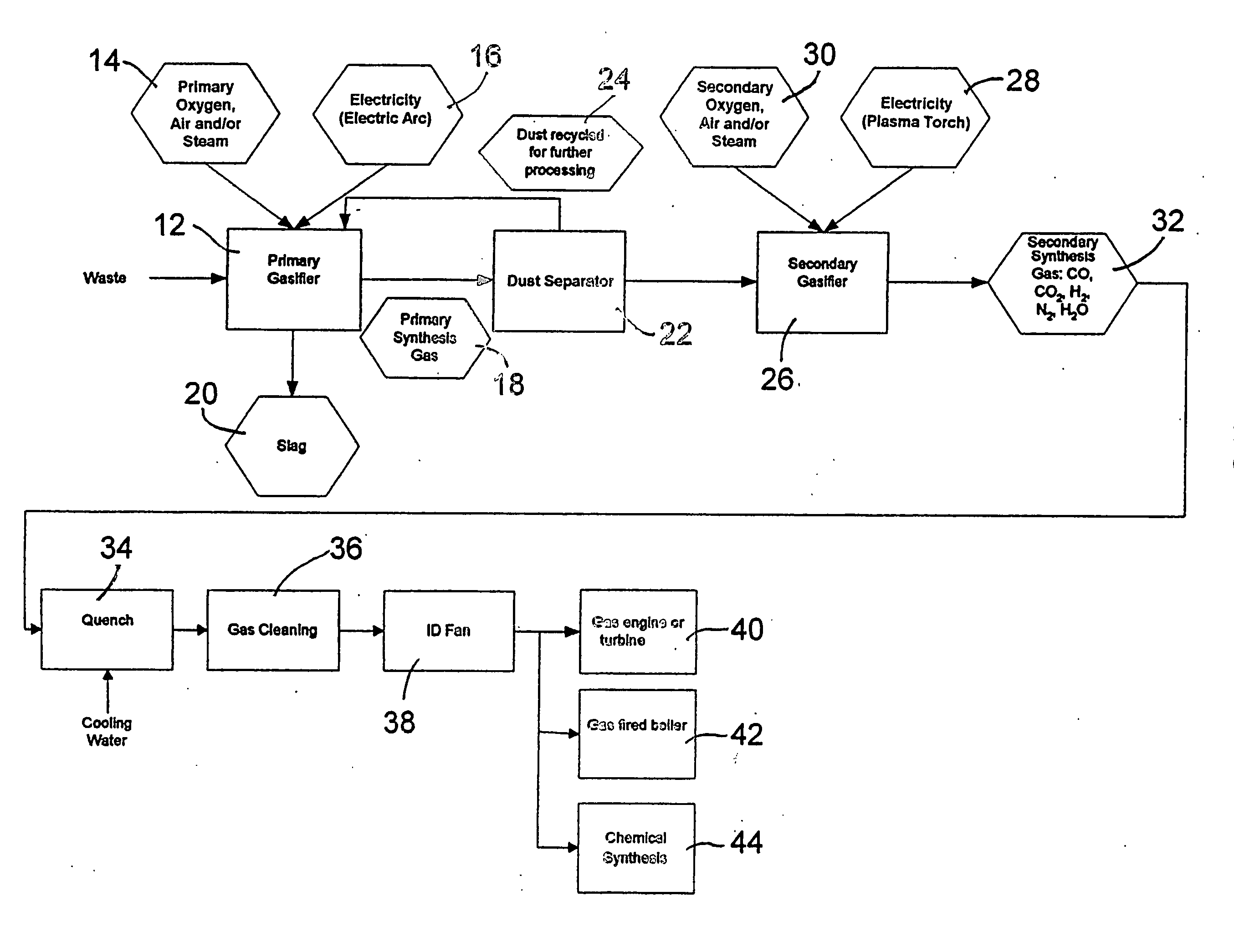

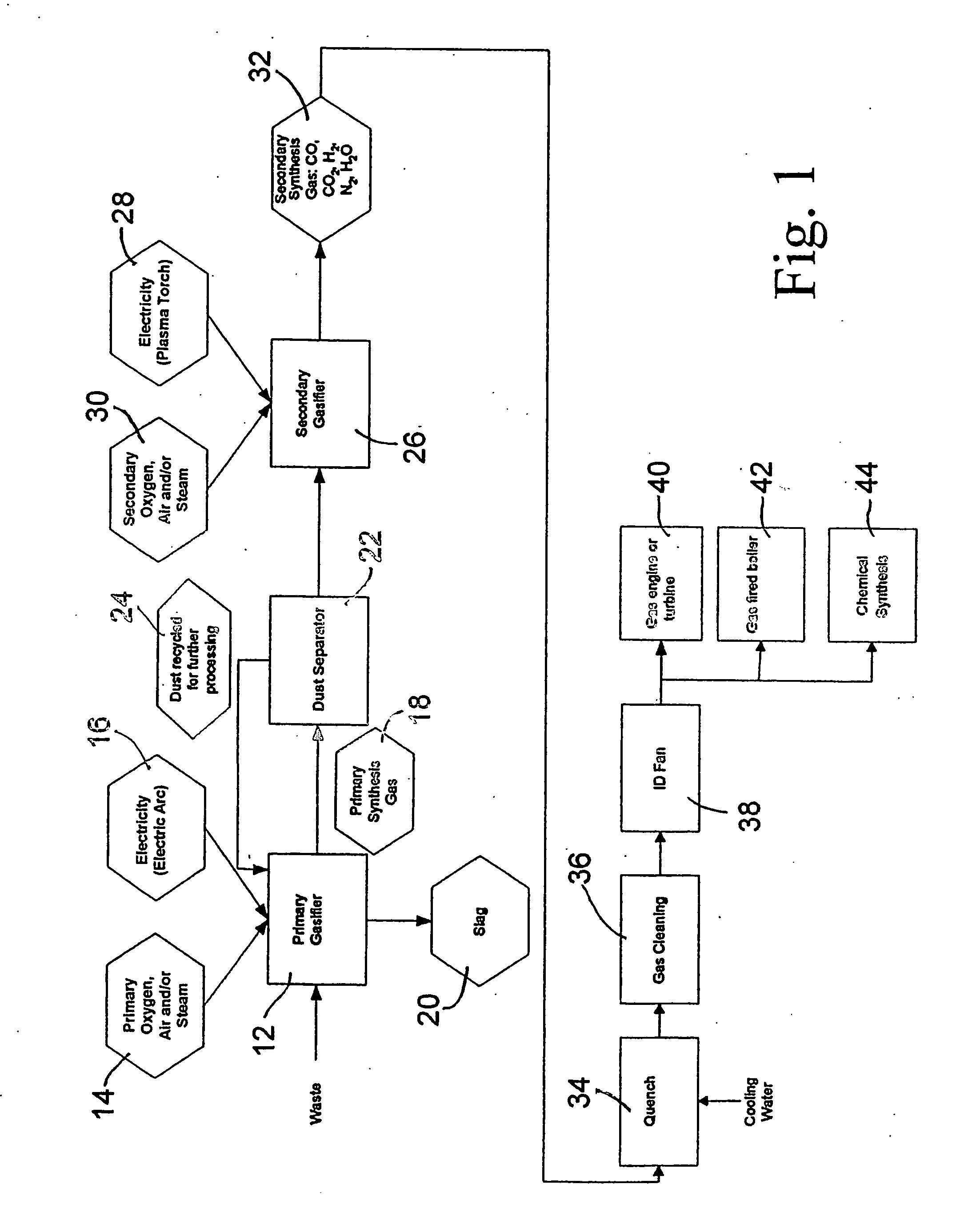

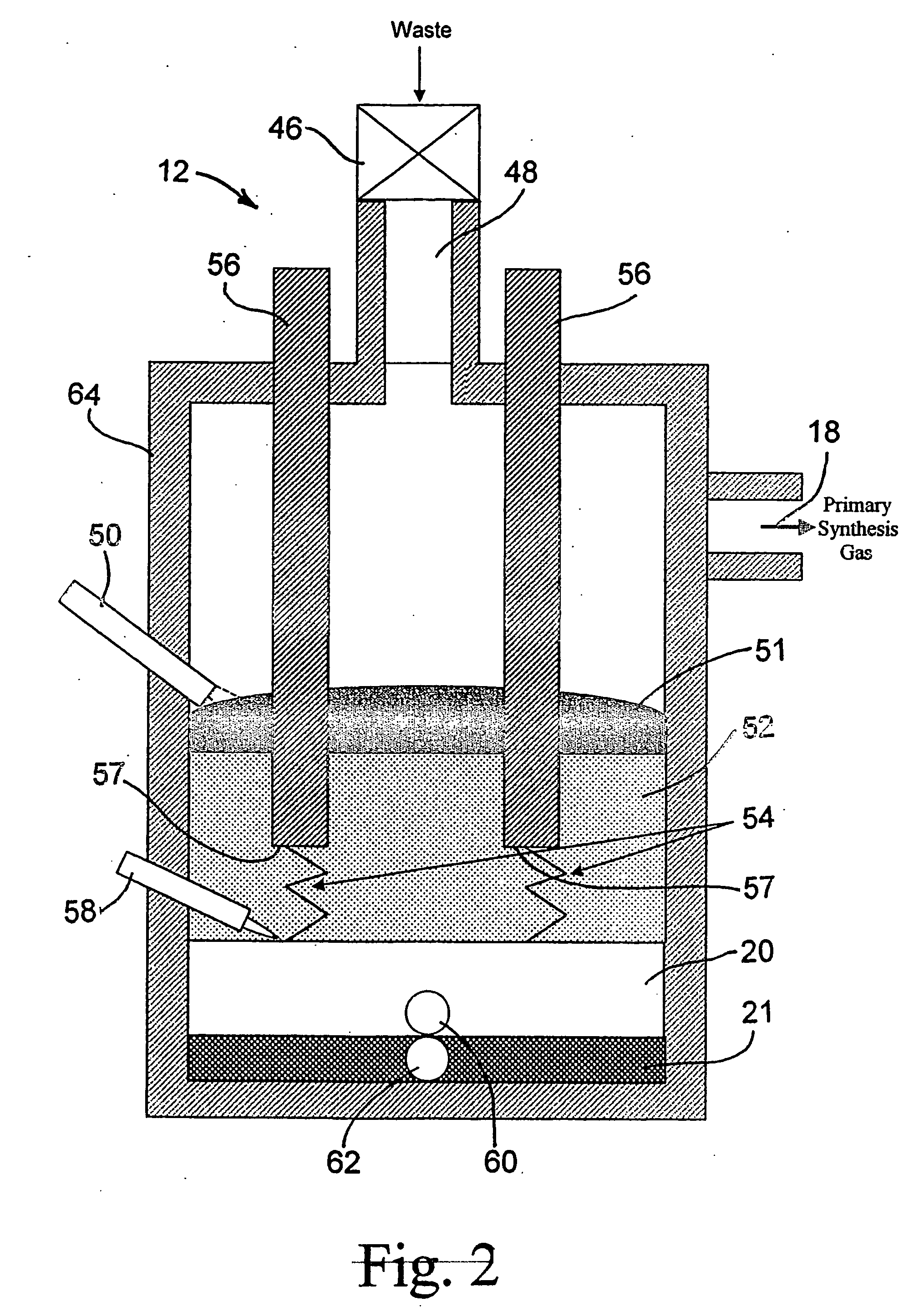

InactiveUS20070272131A1Limited amountImprove energy efficiencyGasifier electrodesGasification processes detailsPlasma jetCyclone

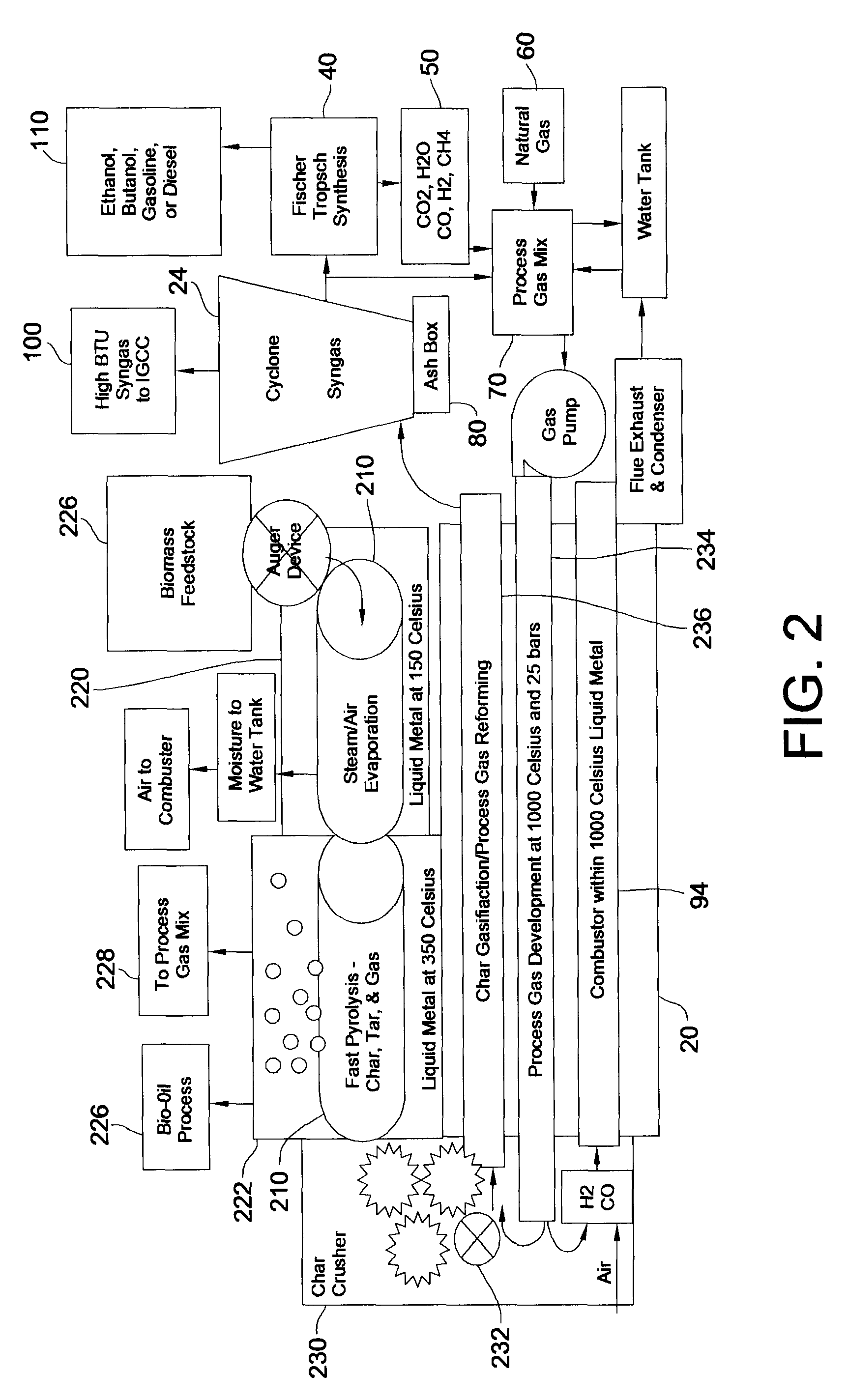

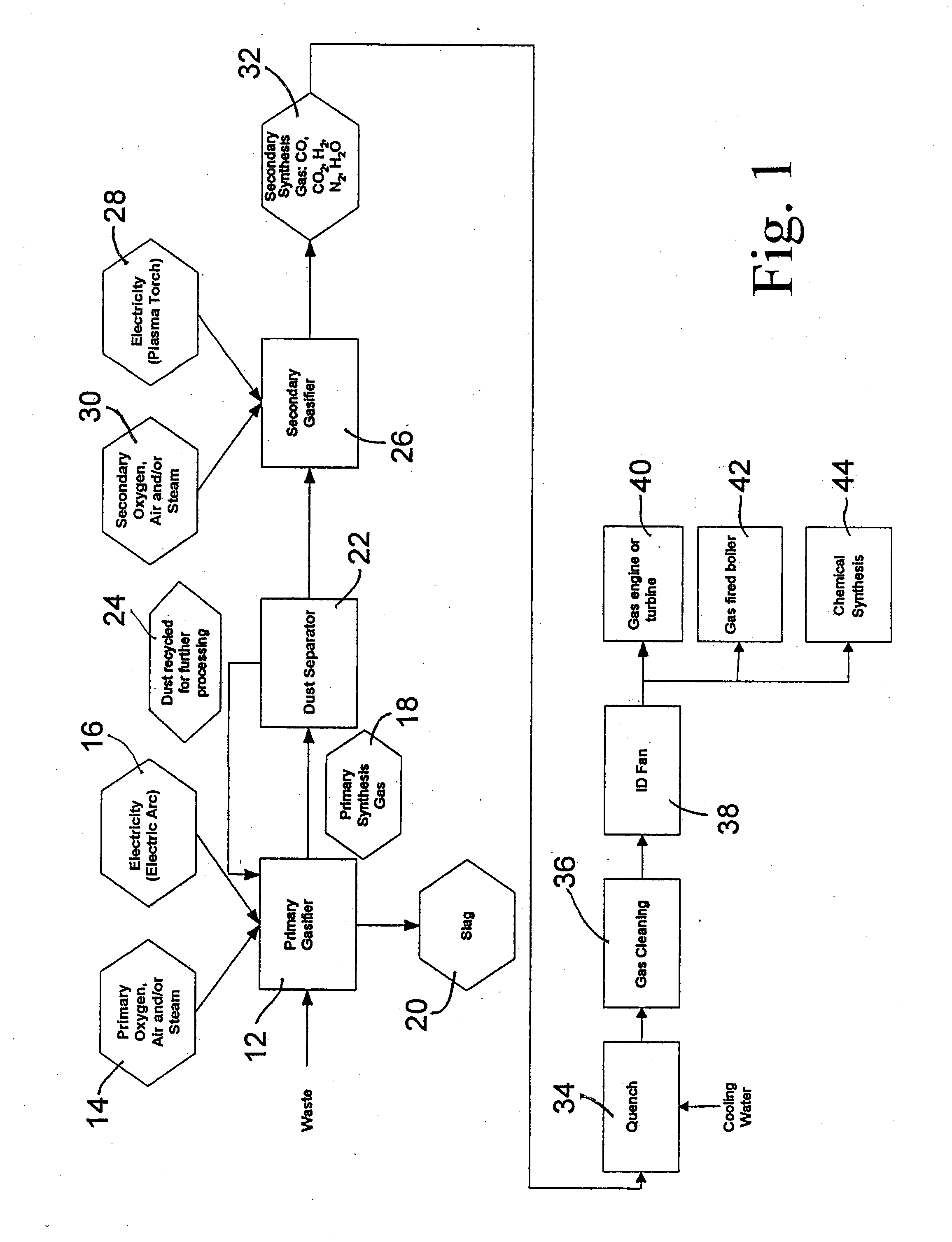

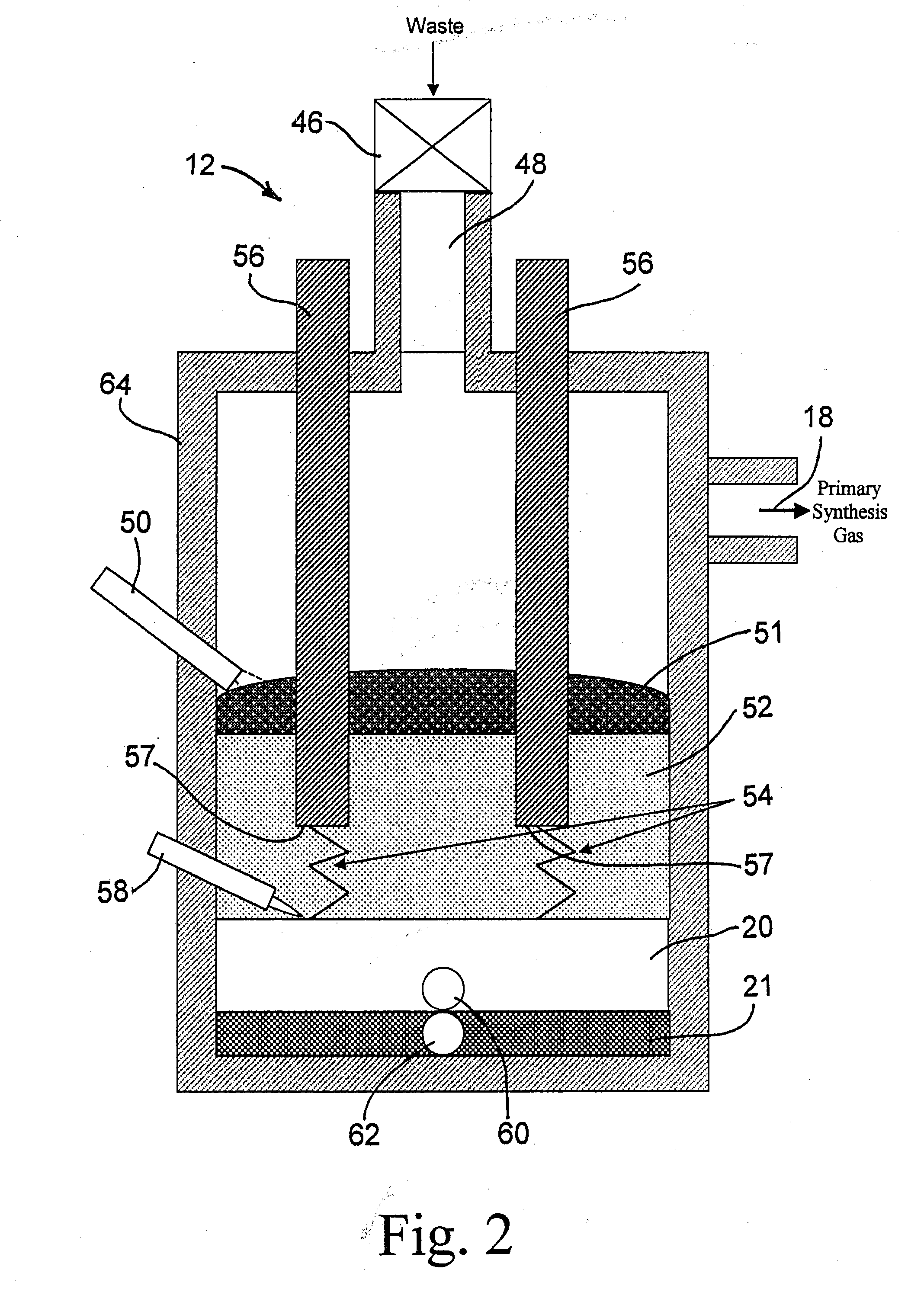

A two-step gasification process and apparatus for the conversion of solid or liquid organic waste into clean fuel, suitable for use in a gas engine or a gas burner, is described. The waste is fed initially into a primary gasifier, which is a graphite arc furnace. Within the primary gasifier, the organic components of the waste are mixed with a predetermined amount of air, oxygen or steam, and converted into volatiles and soot. The volatiles consist mainly of carbon monoxide and hydrogen, and may include a variety of other hydrocarbons and some fly ash. The gas exiting the primary gasifier first passes through a hot cyclone, where some of the soot and most of the fly ash is collected and returned to the primary gasifier. The remaining soot along with the volatile organic compounds is further treated in a secondary gasifier where the soot and the volatile compounds mix with a high temperature plasma jet and a metered amount of air, oxygen or steam, and are converted into a synthesis gas consisting primarily of carbon monoxide and hydrogen. The synthesis gas is then quenched and cleaned to form a clean fuel gas suitable for use in a gas engine or a gas burner. This offers higher thermal efficiency than conventional technology and produces a cleaner fuel than other known alternatives.

Owner:PHOENIX HAUTE TECH

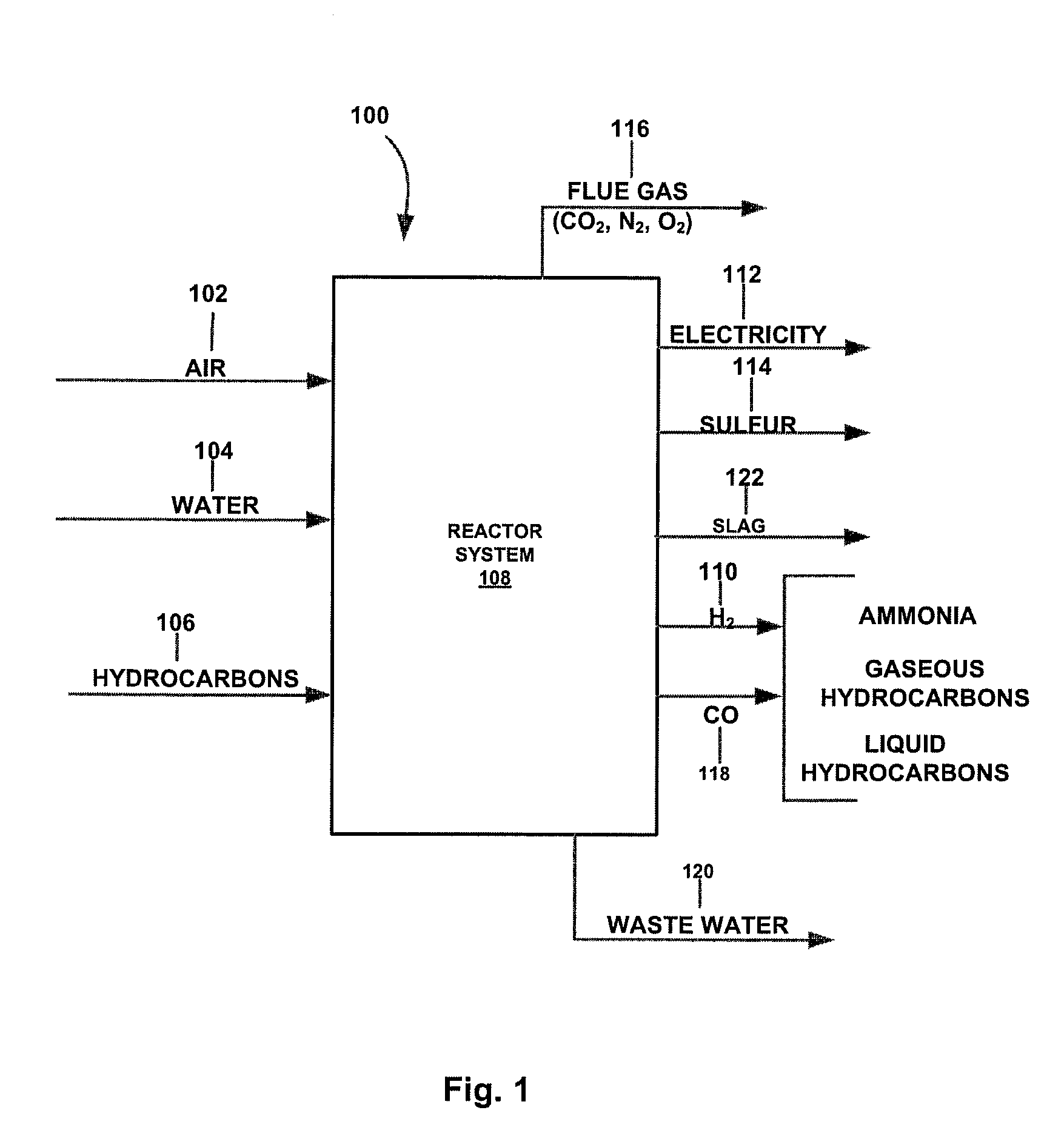

Method for the gasification of hydrocarbon feedstocks

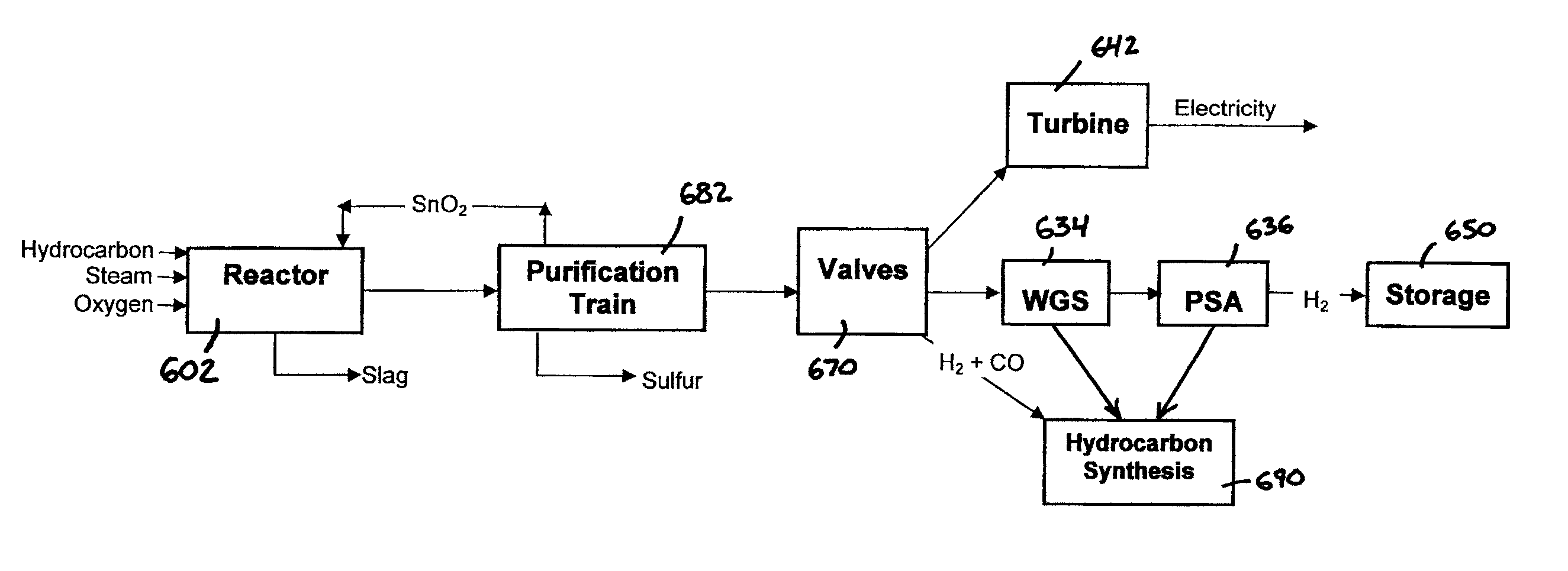

InactiveUS20070256361A1Lower cost of capitalReduce productionBioreactor/fermenter combinationsBiological substance pretreatmentsSyngasAmmonia

A method for the gasification of a hydrocarbon-bearing feedstock to produce useful co-products such as high-value hydrocarbon fuels, pure H2, electricity, and / or ammonia. The method advantageously gasifies the carbon in the feedstock to carbon monoxide (CO) without producing large quantities of carbon dioxide (CO2). Supplemental hydrogen (H2) is also produced by reacting steam (H2O) with a metal. The method can advantageously produce two separate syngas streams, one that is CO-rich and one that is H2-rich.

Owner:ALCHEMIX CORP

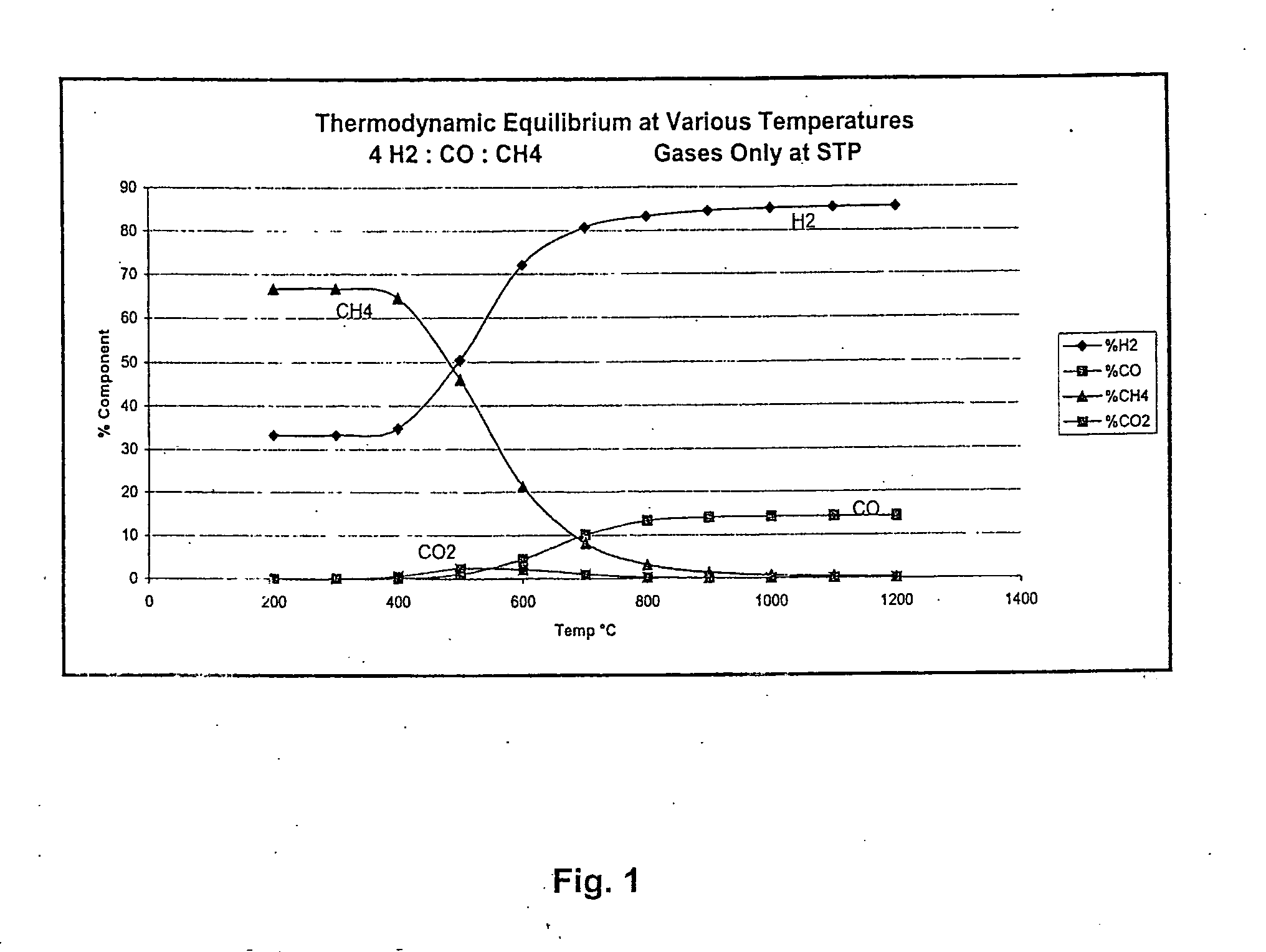

Method for the production of hydrogen-containing gaseous mixtures

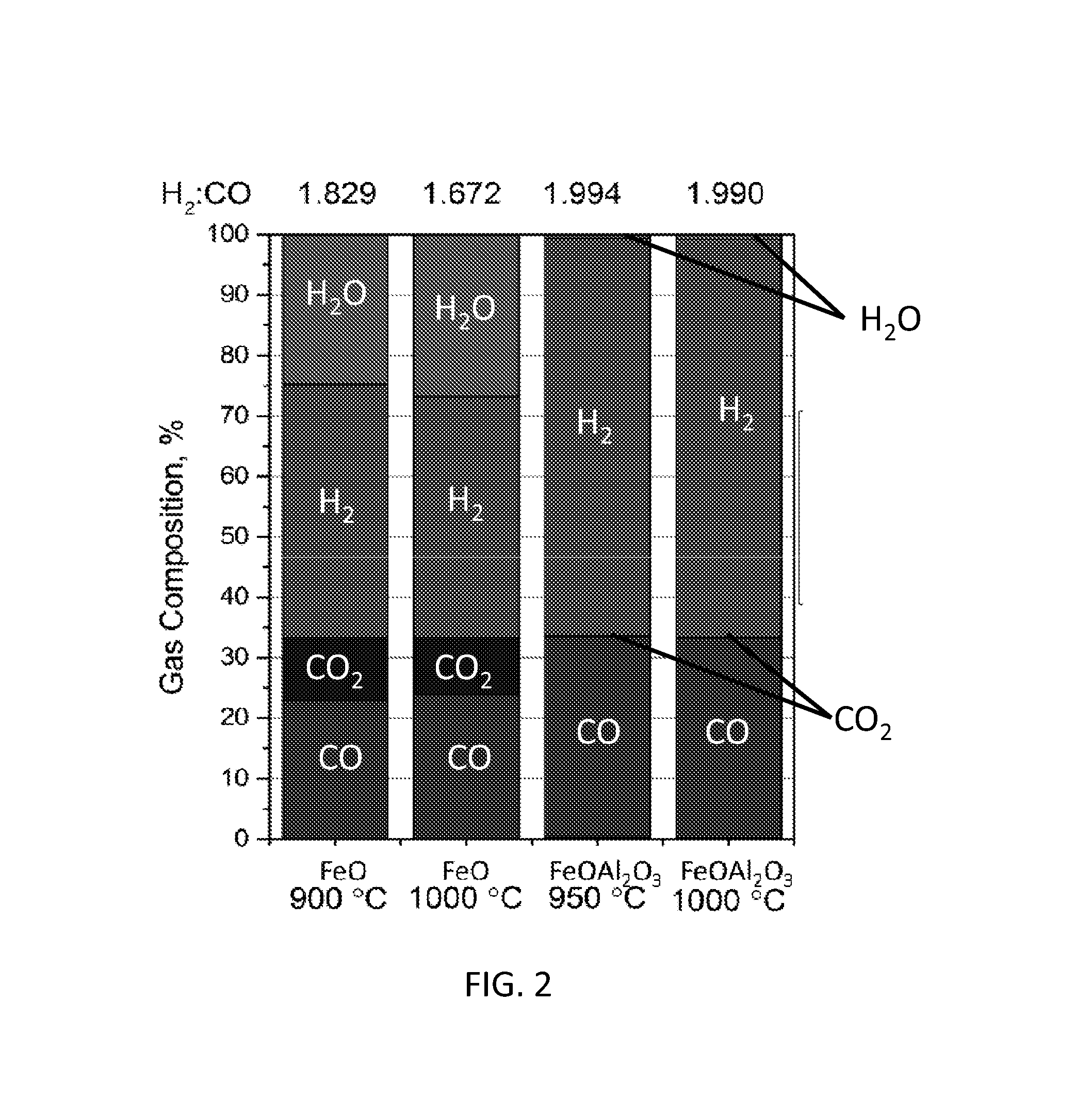

InactiveUS20050042166A1Cheap productionDirect heating destructive distillationWaste based fuelSyngasGas composition

A method for the production of a hydrogen-containing gas composition, such as a synthesis gas including hydrogen and carbon monoxide. The molar ratio of hydrogen to carbon monoxide (H2:CO) in the synthesis gas can be well-controlled to yield a ratio that is adequate for the synthesis of useful products such as methane or methanol, without the need to remove carbon oxides from the gas stream to adjust the ratio.

Owner:ALCHEMIX CORP

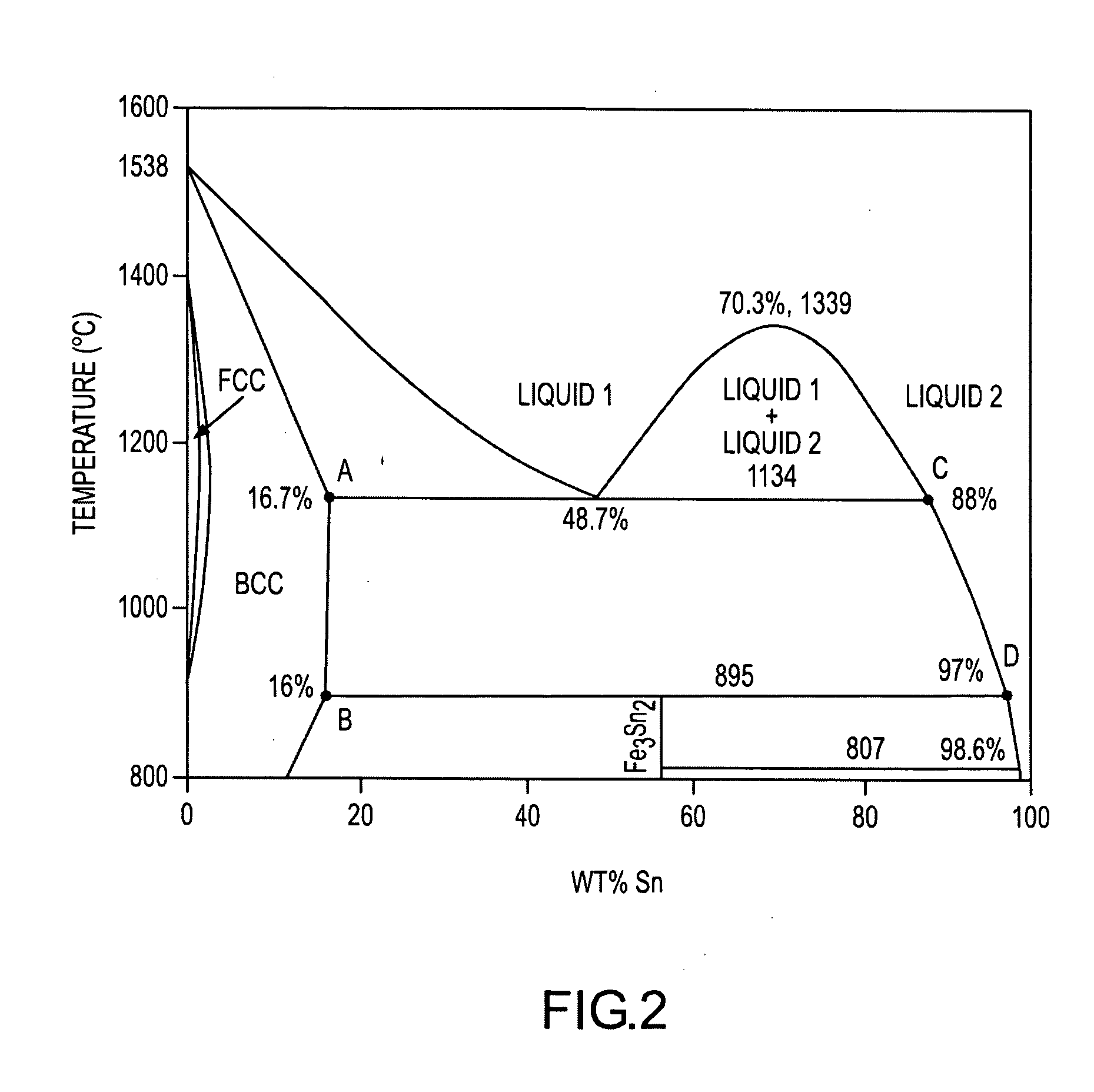

Process for producing molten iron

InactiveUS20110154951A1Efficient productionIncrease productionGasification processes detailsManufacturing convertersChemical compositionCarbon source

The object of the present invention is to provide a process for producing molten iron through the efficient reduction of iron oxide having various chemical compositions and various shapes, or through the efficient melting of scrap iron or reduced iron having various shapes and various chemical compositions, the process being used in cases where the amount of iron necessary per furnace is not so large as in blast furnace processes. Specifically, the present invention provides a process for producing molten iron comprising the steps of: supplying carbon-containing molten iron to a holding container, heating the molten iron using heat of a combustion reaction of a gas mixture containing a fuel gas and a combustion-supporting gas, thereby storing the heat therein, and adding a carbon source and an iron-containing material that contains iron oxide and / or scrap iron to the heated and heat-stored molten iron, thereby converting the iron-containing material to molten iron.

Owner:ISTC

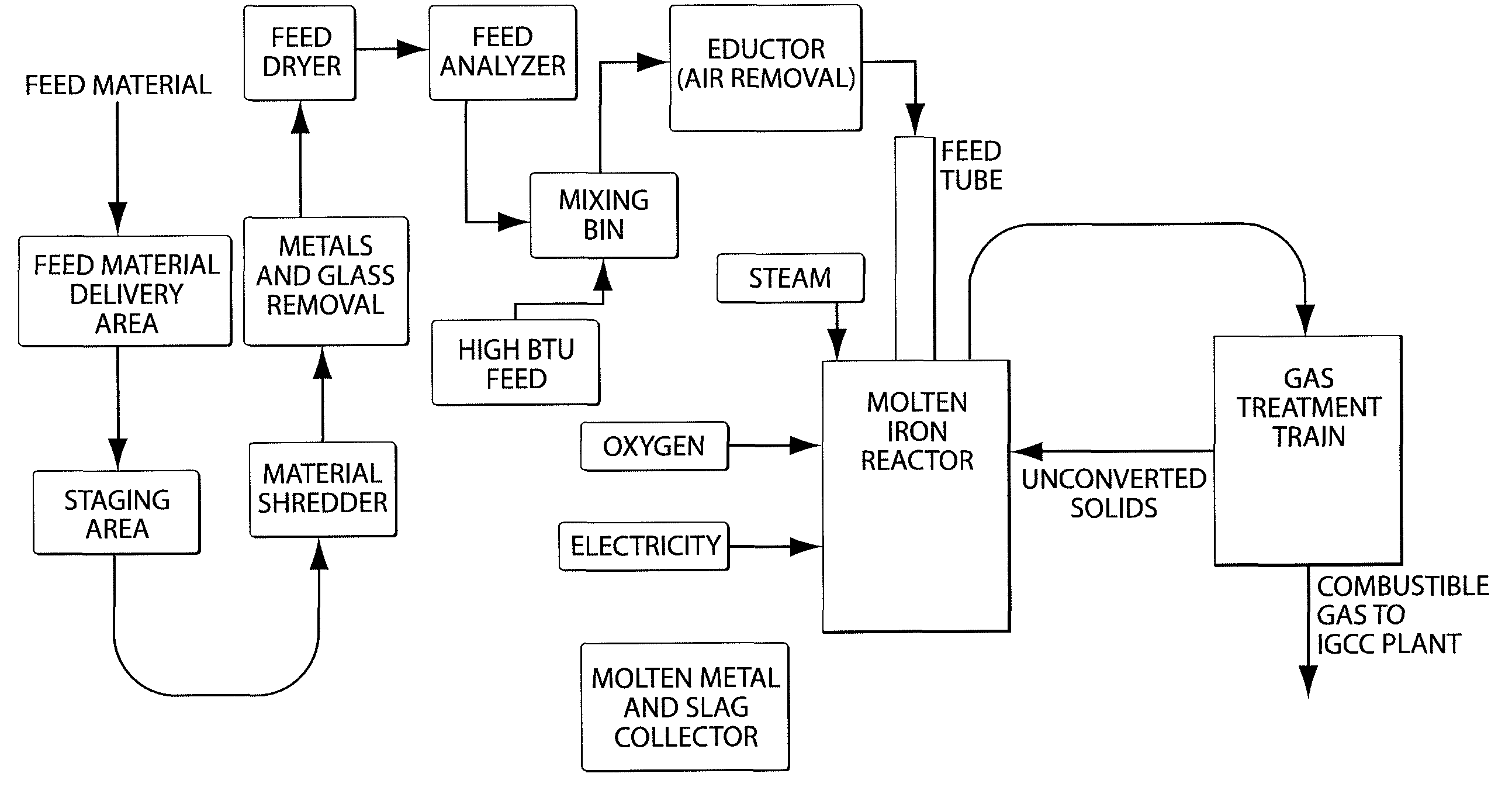

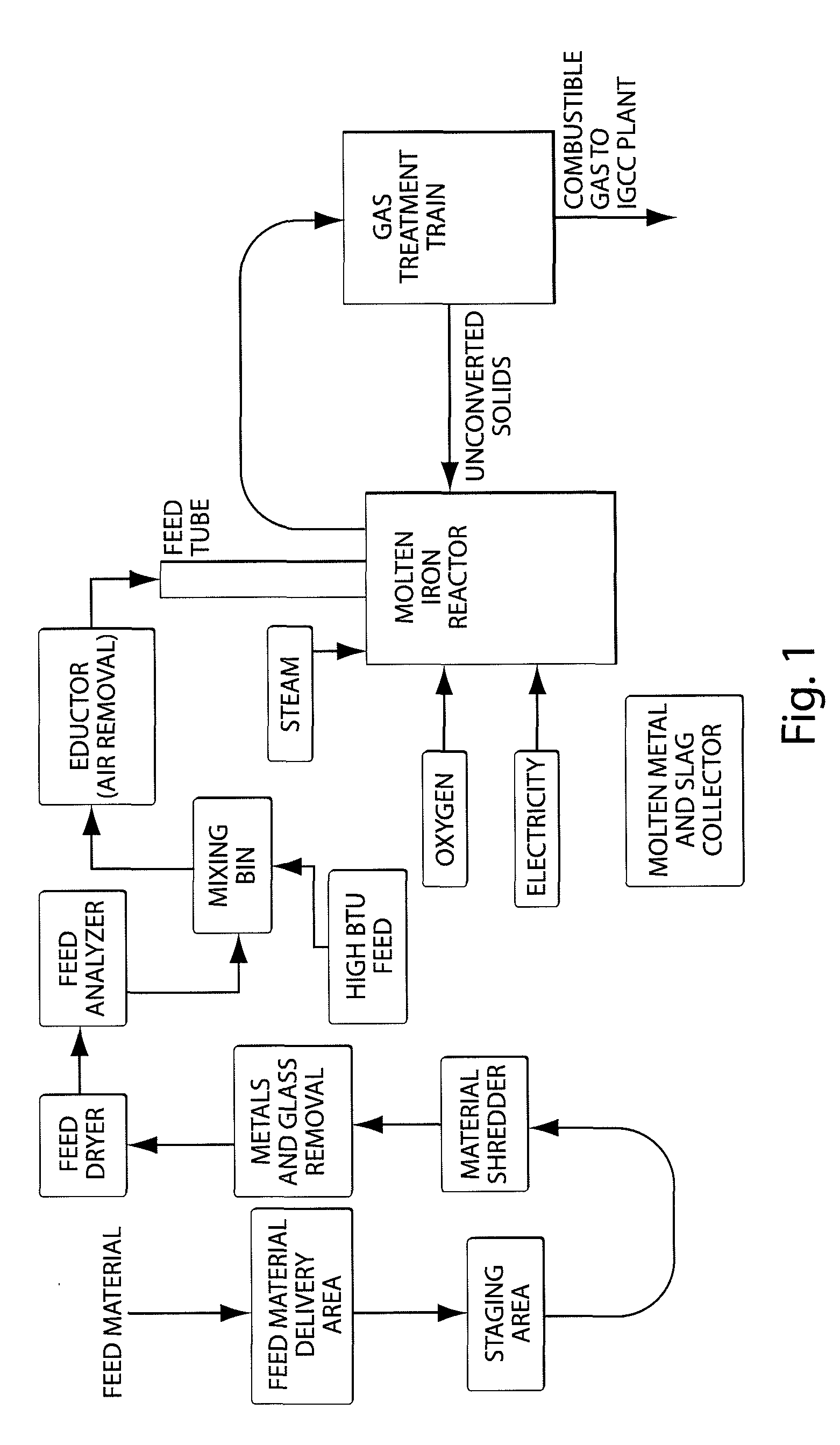

Method for controlling syngas production in a system with multiple feed materials using a molten metal bath

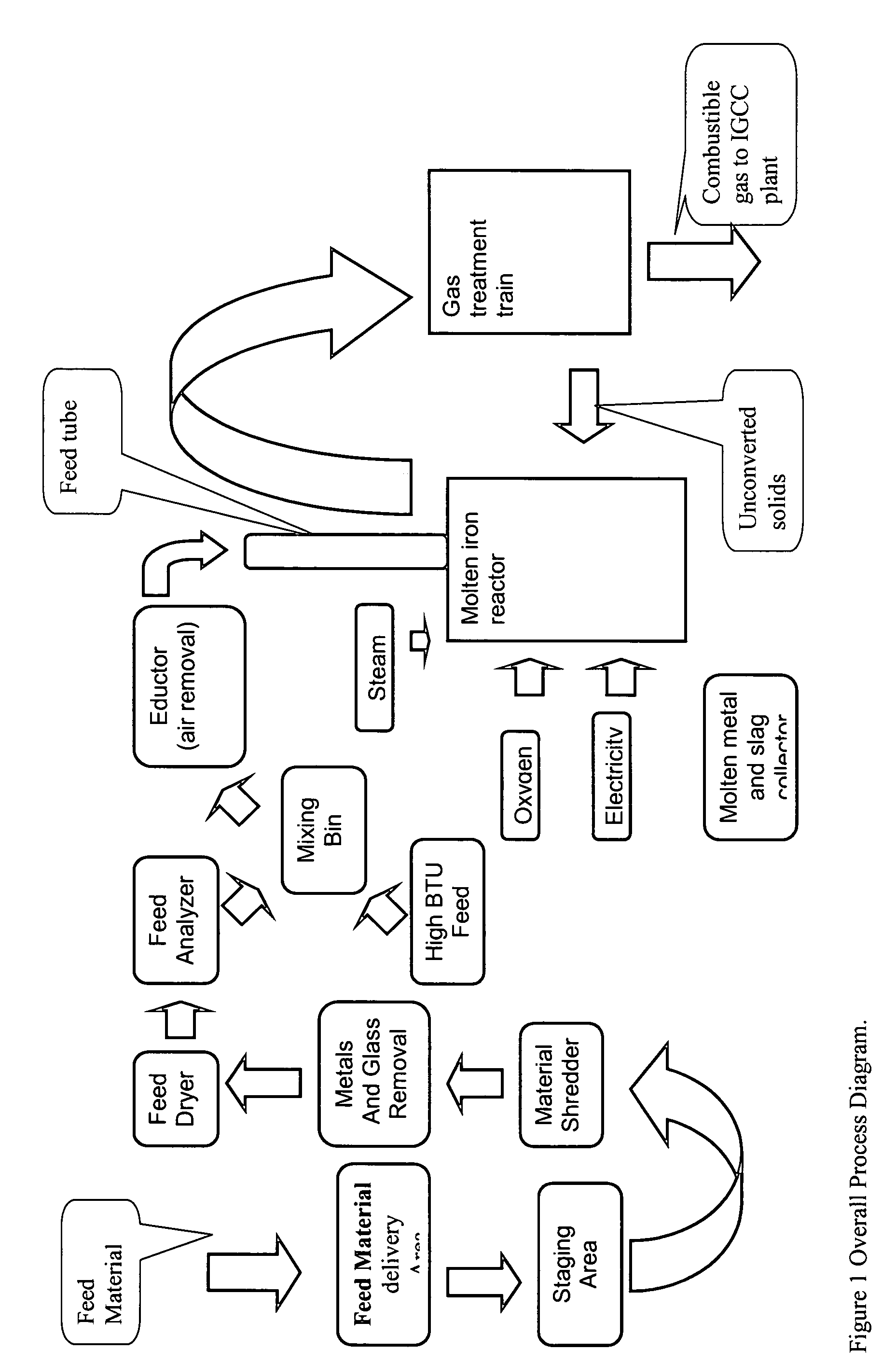

Processes and apparatus for treating organic and inorganic materials in a metal bath contained in a high temperature reactor to produce synthesis gas are provided. Two or more feed materials that possess differing syngas generation potentials are mixed in a mixer and fed as a composite feed stream into a gasifier to produce syngas. The feed materials are prepared and analyzed for heat value prior to injection and the composition of materials in and exiting the reactor are monitored. By controlling the feed rate of the mixture into the gasifier as well as the feed rates of one or more of the individual feed materials into the mixer, the syngas is produced at a target production rate, with target energy content (BTU). Based upon the results of the analysis and monitoring, oxygen, steam, and / or other feed materials are also injected into the reactor, to control processing and synthesis gas quality. Potential feed materials include, but are not limited to, construction and demolition (C&D) debris, municipal solid waste (MSW), other sewage-related solids, waste tires, and other substances that contain varying levels of organic compounds capable of producing a syngas.

Owner:ZE-GEN

Method for the gasification of moisture-containing hydrocarbon feedstocks

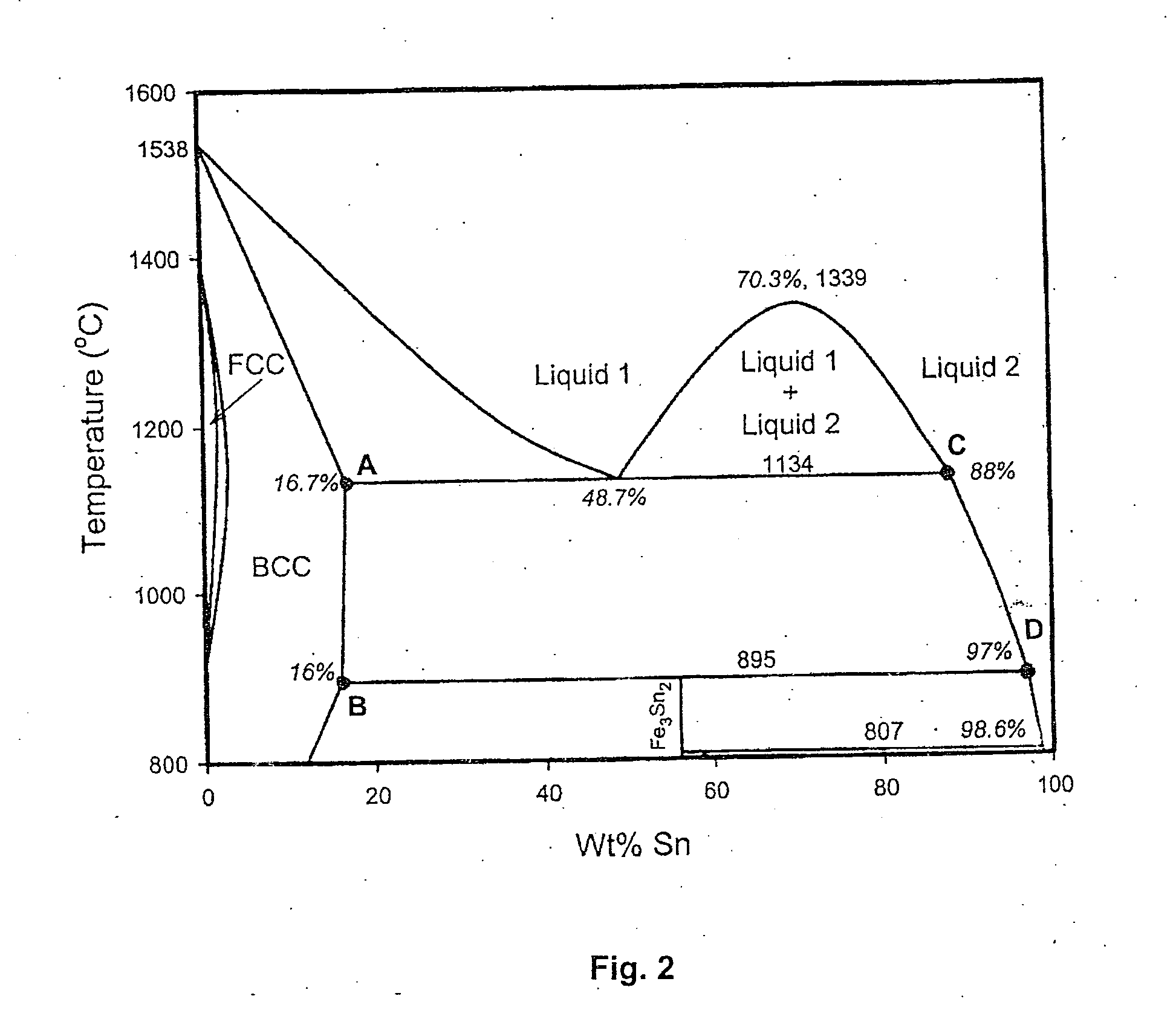

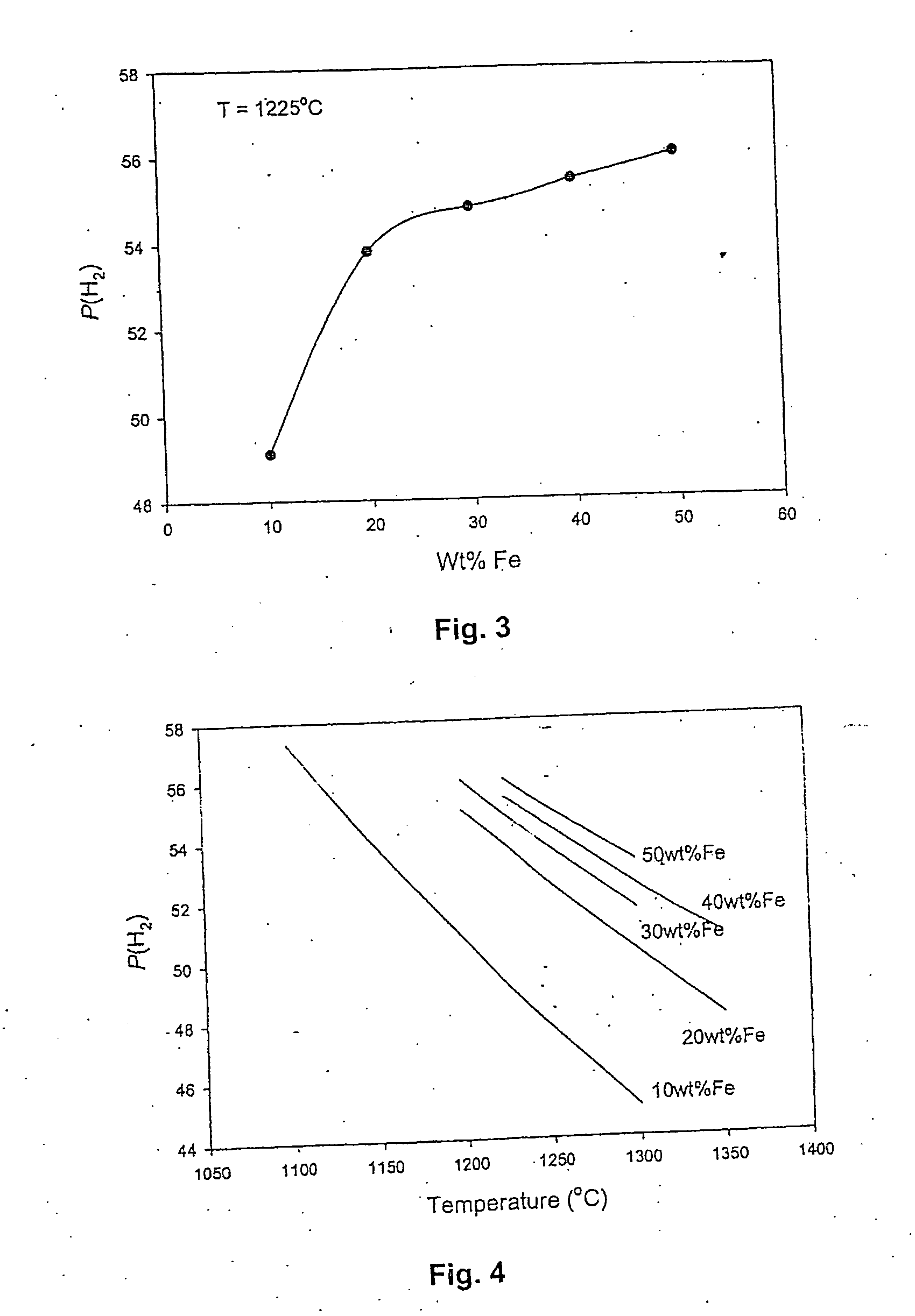

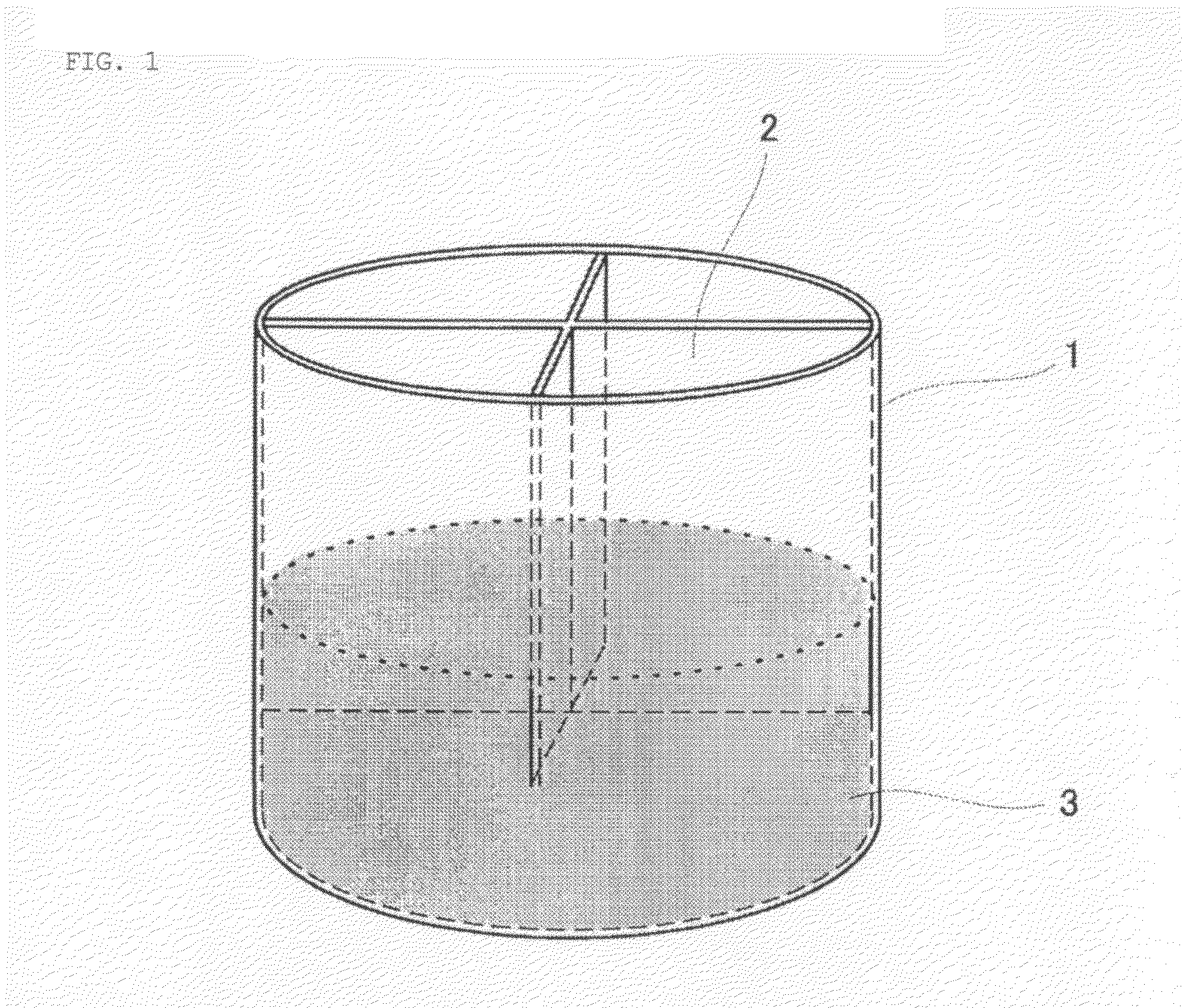

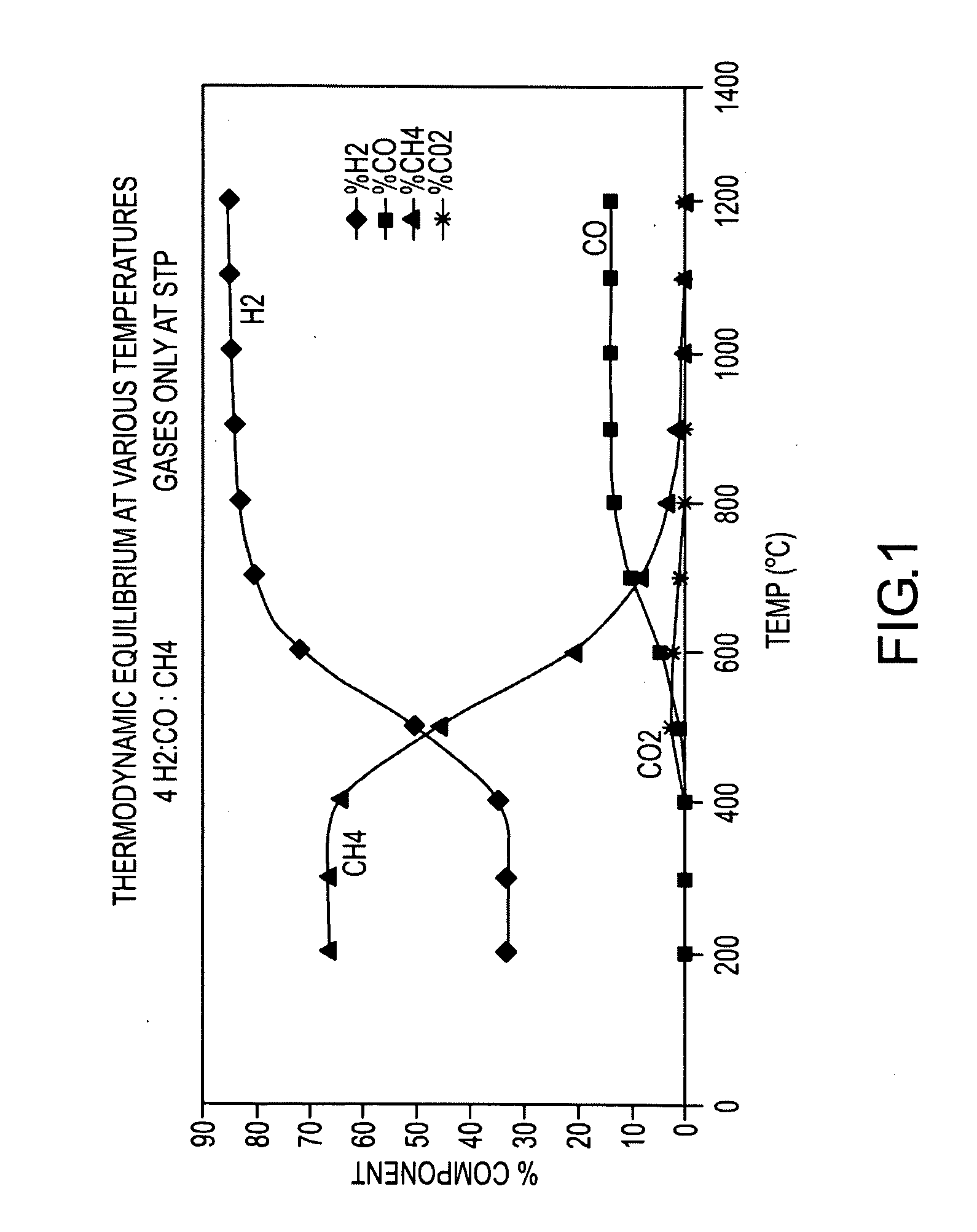

InactiveUS20070256360A1Lower cost of capitalRaise the ratioBioreactor/fermenter combinationsBiological substance pretreatmentsHydrogenAmmonia

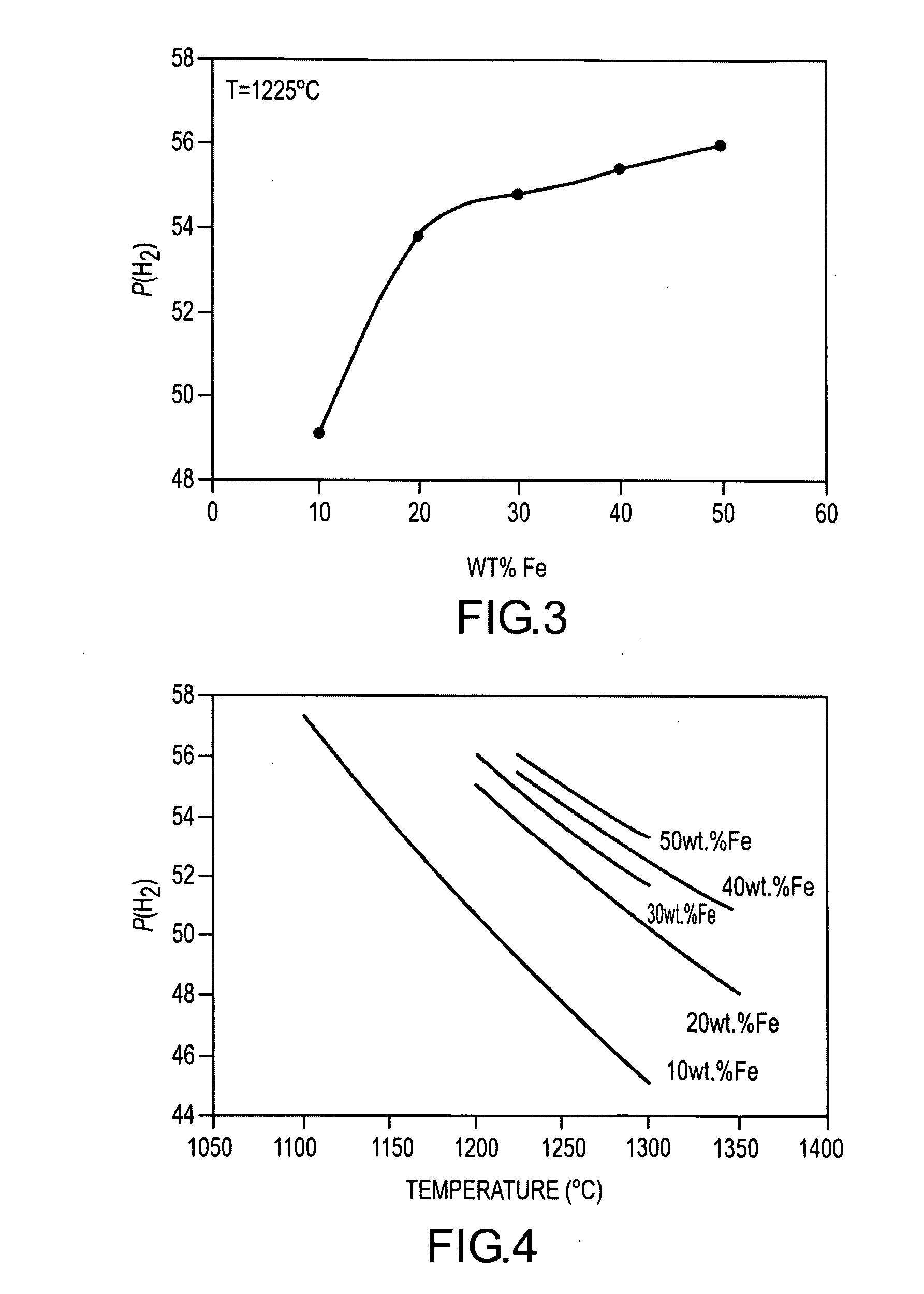

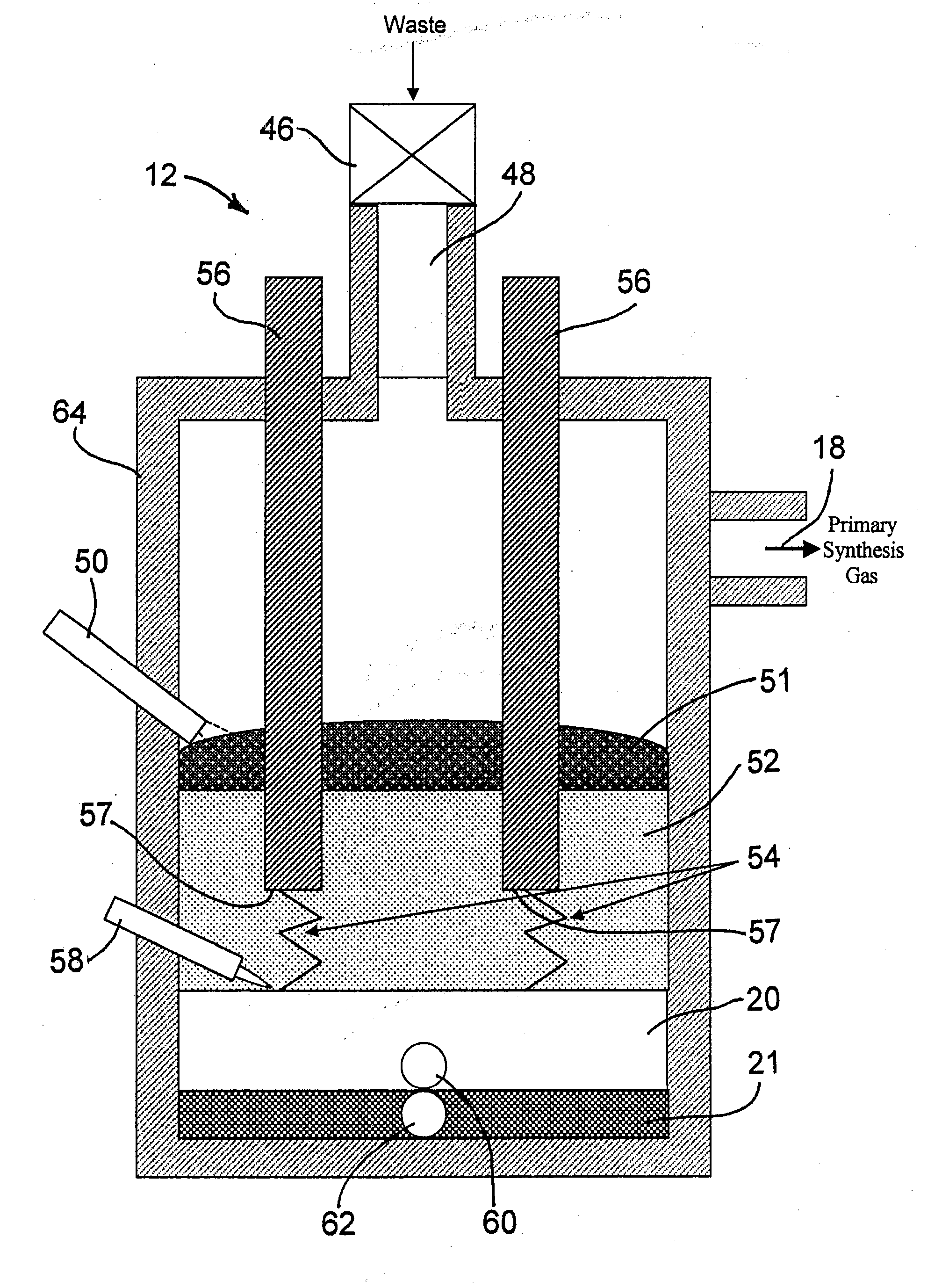

A method for the gasification of a hydrocarbon feedstock that has a high moisture content to produce useful co-products such as high-value hydrocarbon fuels, pure H2, electricity, and / or ammonia. The method advantageously gasifies the carbon in the feedstock to carbon monoxide (CO) without producing large quantities of carbon dioxide (CO2). Supplemental hydrogen (H2) is co-produced by reacting steam (H2O) generated from the moisture in the hydrocarbon feedstock with a molten metal.

Owner:ALCHEMIX CORP

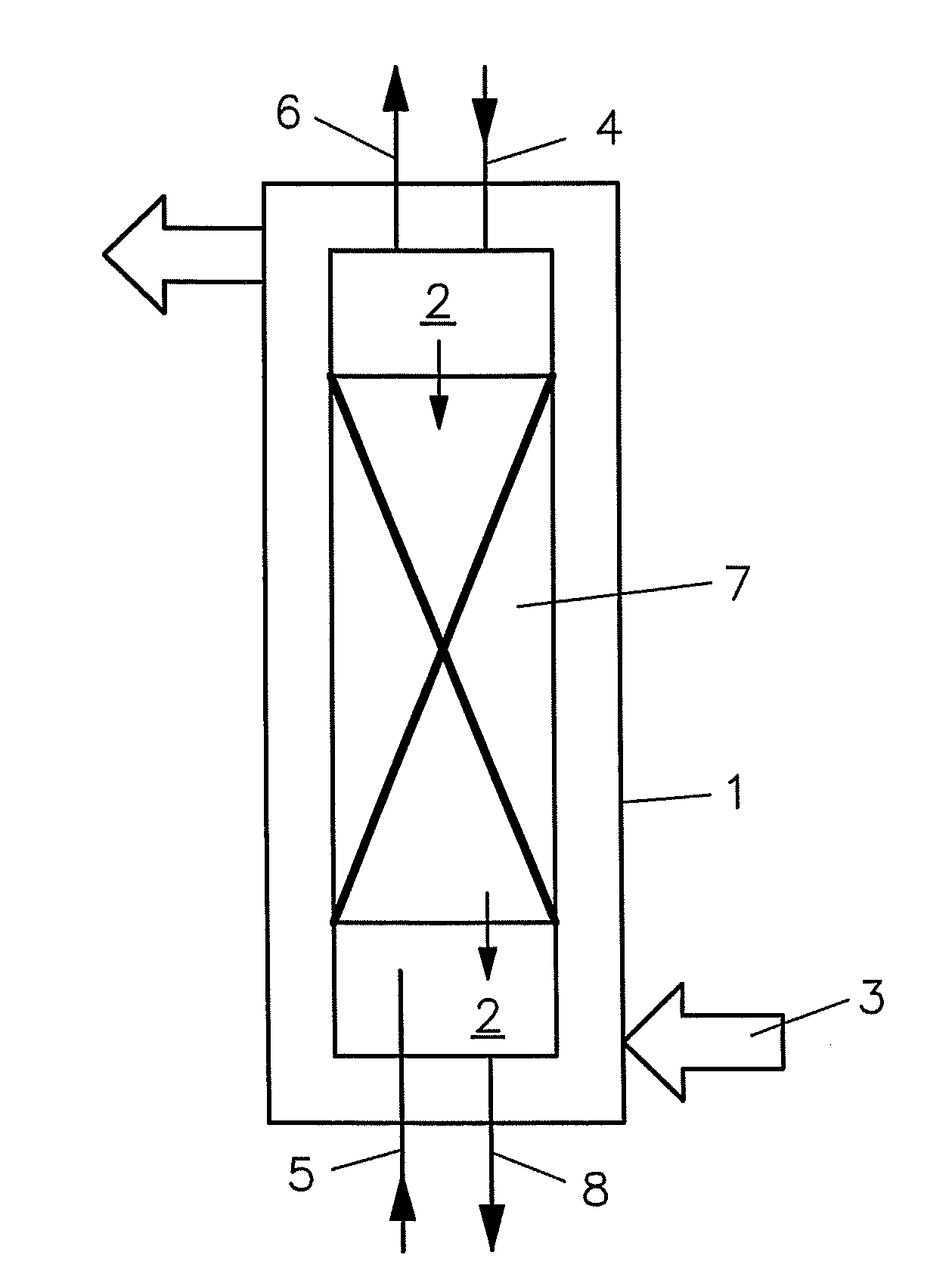

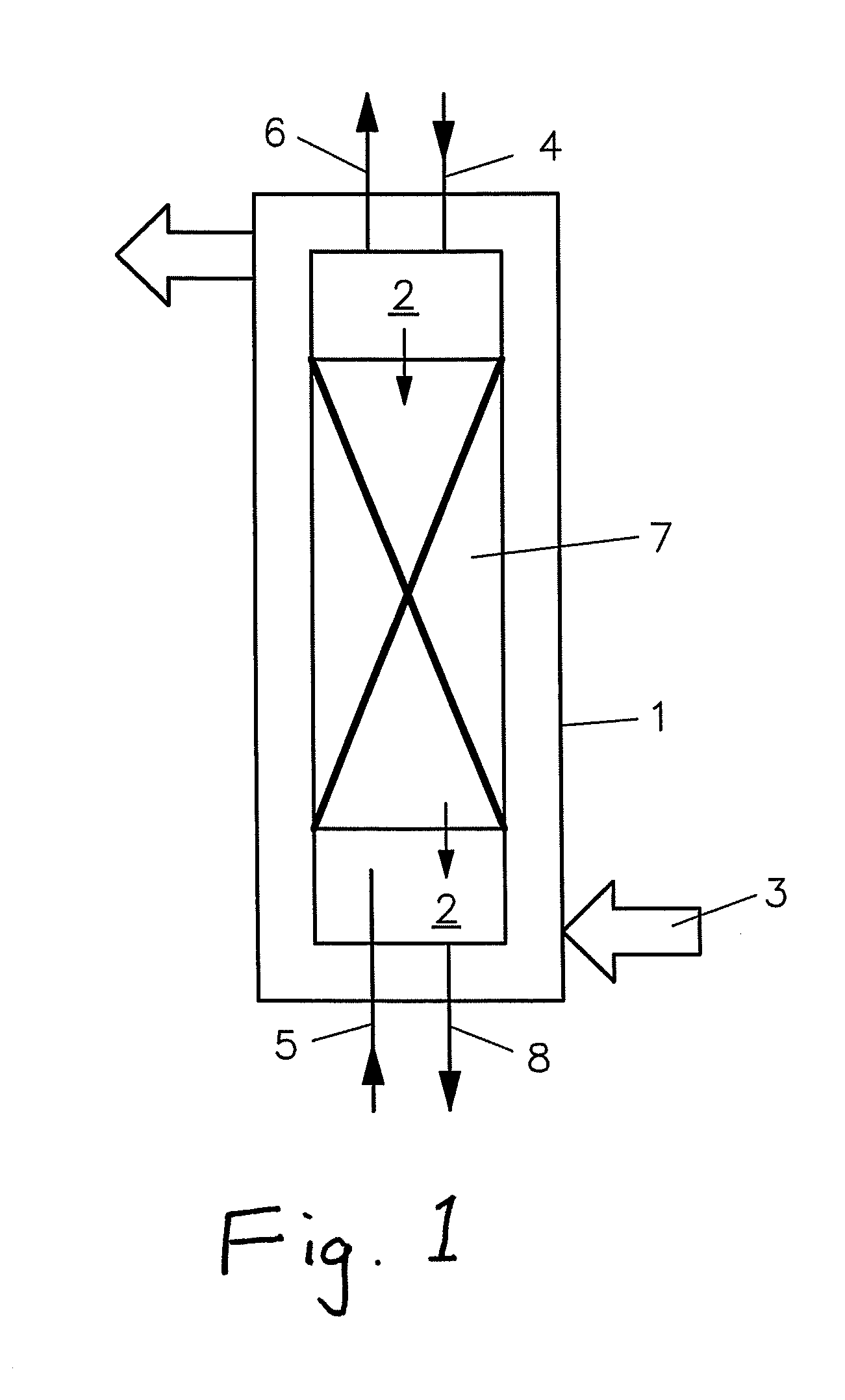

Process and device for gasification of waste

Gasification of waste is performed in a gasifier having a gasification space (1) and a liquid rotating slag bath (2). The slag bath (2) is preferably caused to rotate by tangentially injecting gasification medium and / or at least a portion of the waste via a burner toward the surface of the slag bath. Waste with a diameter of to 5 mm is preferably introduced into gasifier (1) above the slag bath (2), while larger waste is preferably introduced directly into the slag bath. Slag is a removed, together with cracked gas accumulated during gasification through the floor of the gasifier via a slag drain having a lateral opening which protrudes above the slag bath.

Owner:LINDE KCA DRESDEN

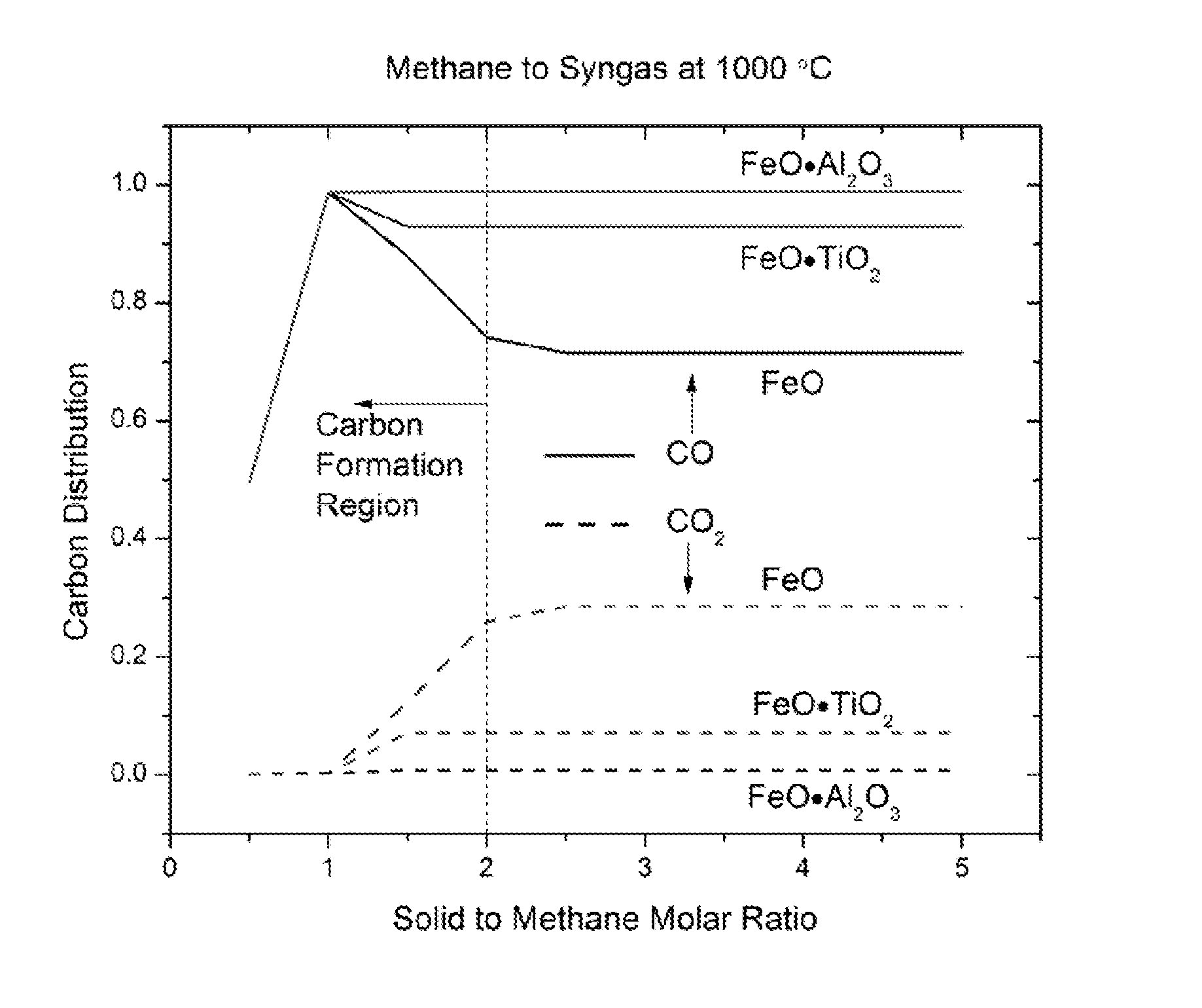

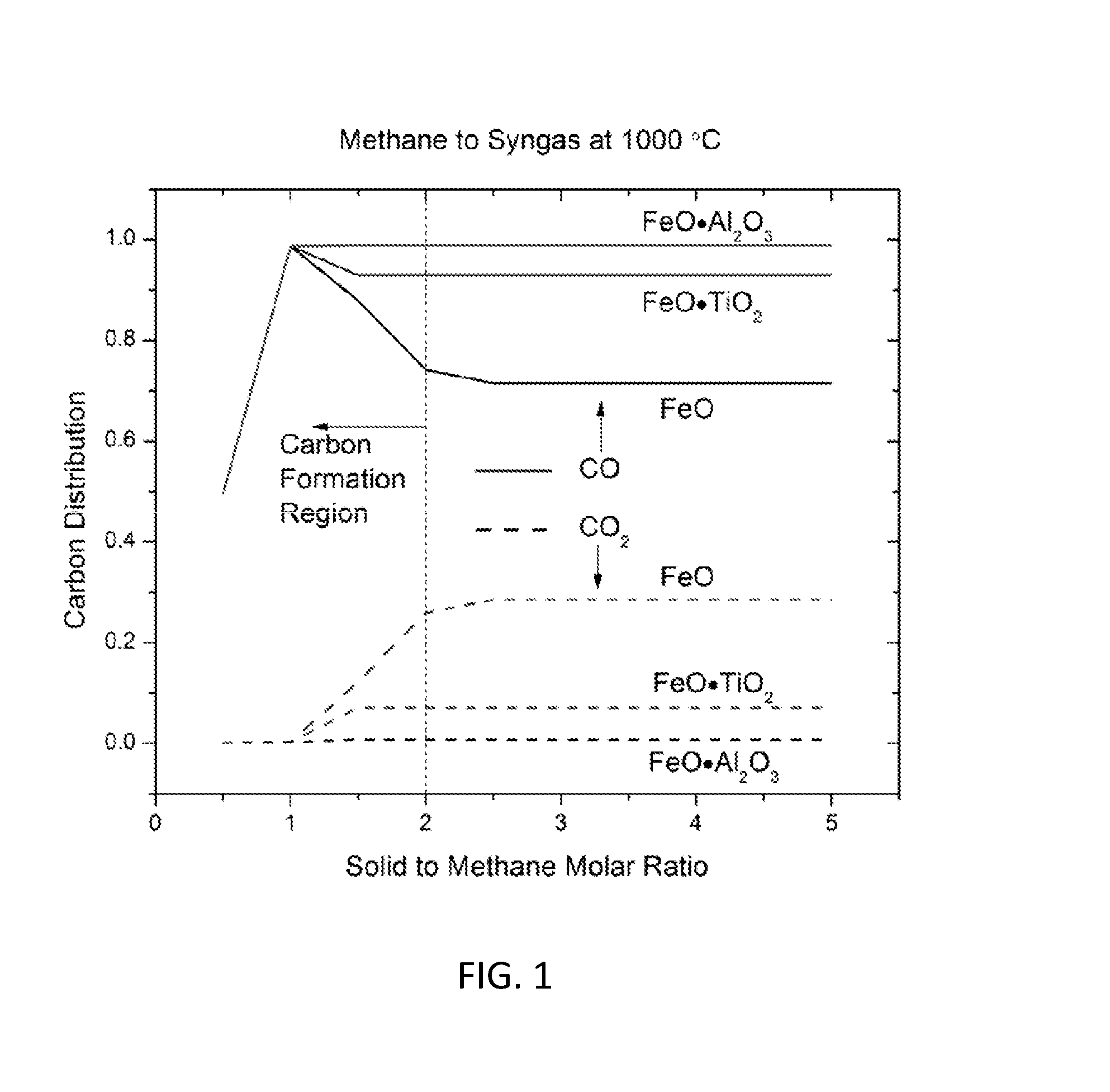

Methods for fuel conversion

In one embodiment described herein, fuel may be converted into syngas by a method comprising feeding the fuel and composite metal oxides into a reduction reactor in a co-current flow pattern relative to one another, reducing the composite metal oxides with the fuel to form syngas and reduced composite metal oxides, transporting the reduced composite metal oxides to an oxidation reactor, regenerating the composite metal oxides by oxidizing the reduced composite metal oxides with an oxidizing reactant in the oxidation reactor, and recycling the regenerated composite metal oxides to the reduction reactor for sub-sequent reduction reactions to produce syngas. The composite metal oxides may be solid particles comprising a primary metal oxide and a secondary metal oxide.

Owner:OHIO STATE INNOVATION FOUND

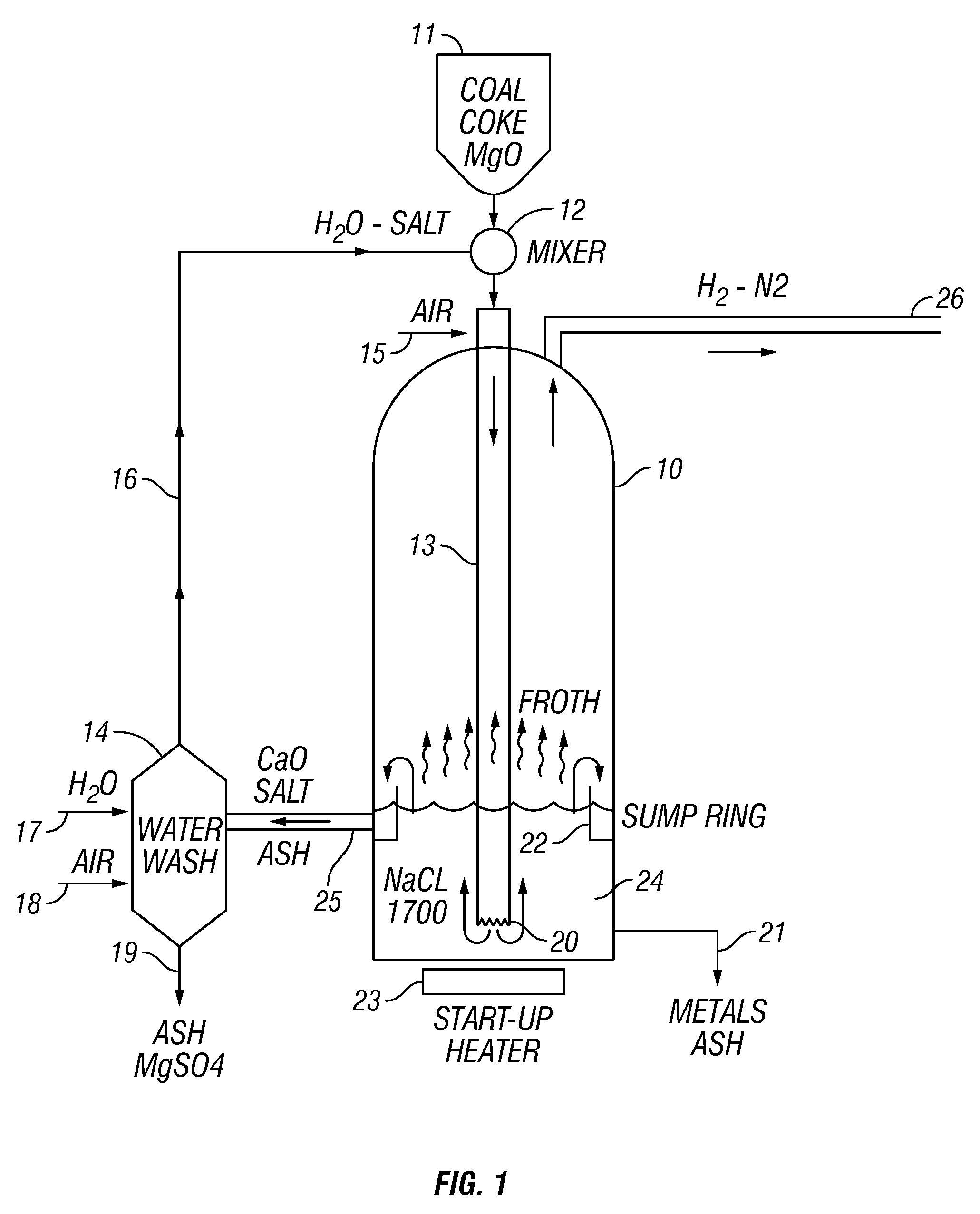

Process for production of hydrogen from coal and other fossil fuels

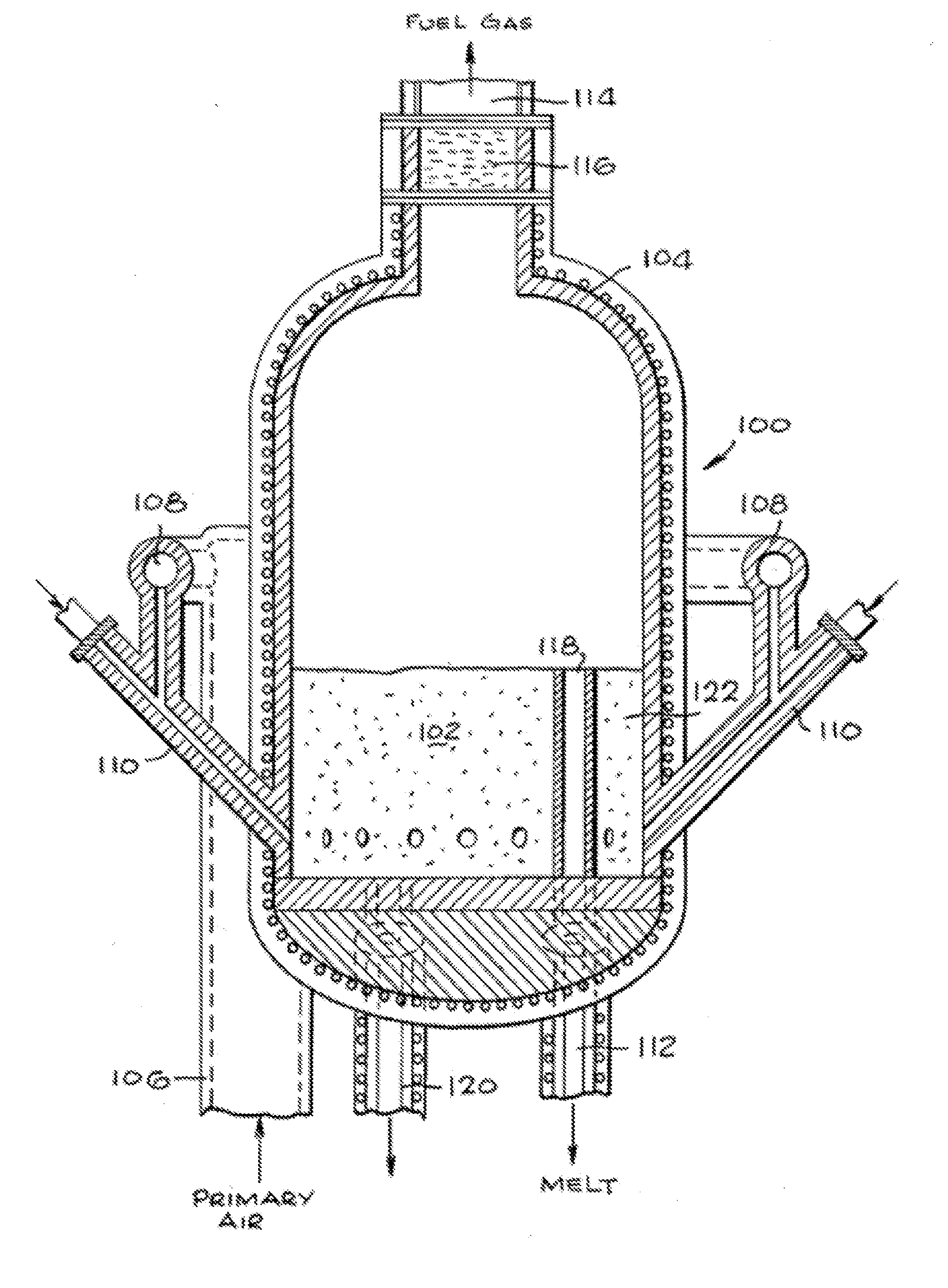

InactiveUS20090074656A1Improve heat transfer performanceGasifier feeding meansHydrogen separation using solid contactHydrogenMolten salt reactor

A process for converting coal or other fossil fuel to hydrogen by reacting the fossil fuel or coal with water in a molten salt reactor at elevated temperatures in the presence of a magnesium silicate wherein the magnesium silicate reacts with the CO2 produced in the reaction, thus removing it from the hydrogen gas product.

Owner:BILLINGS CALVIN

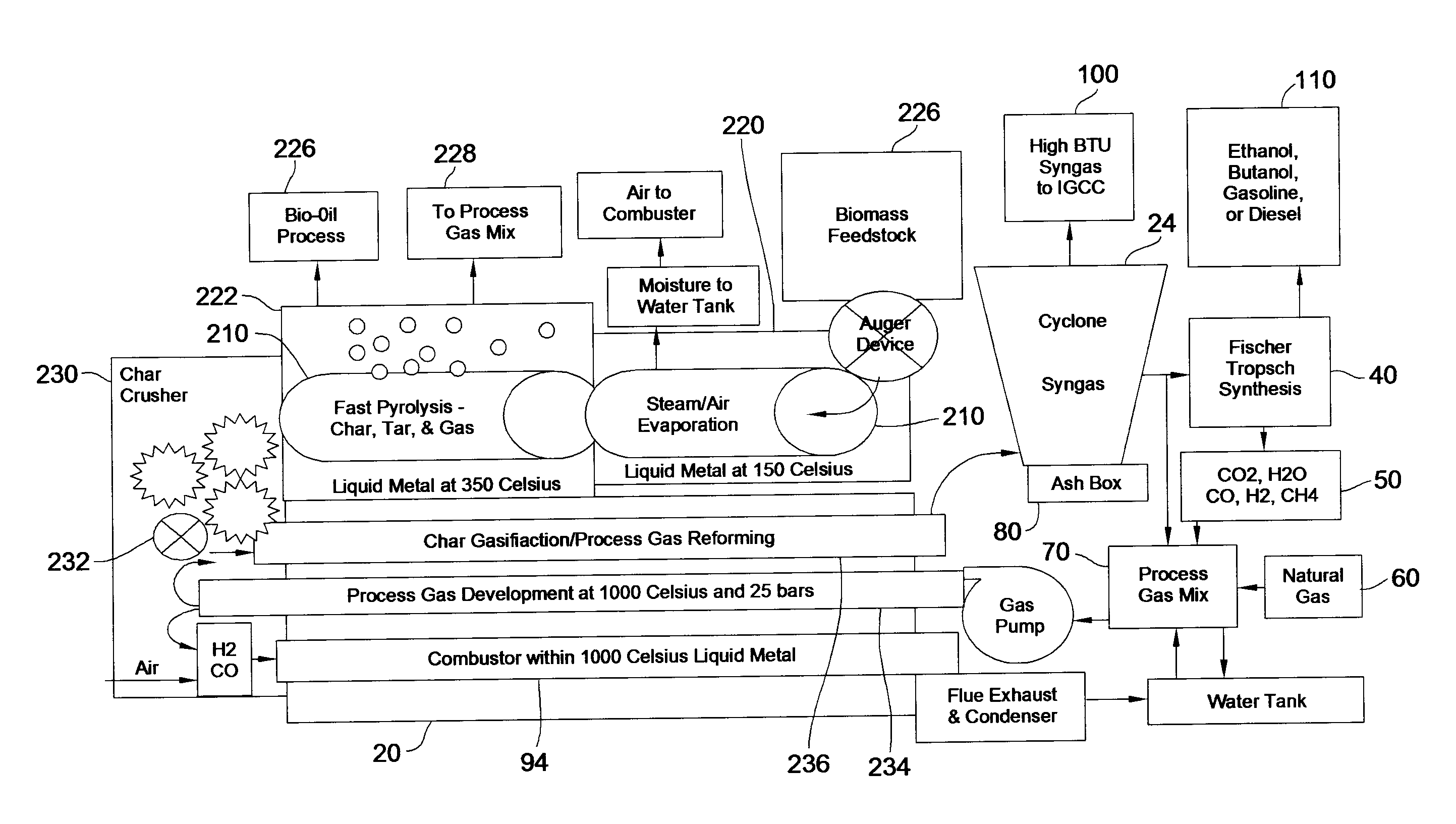

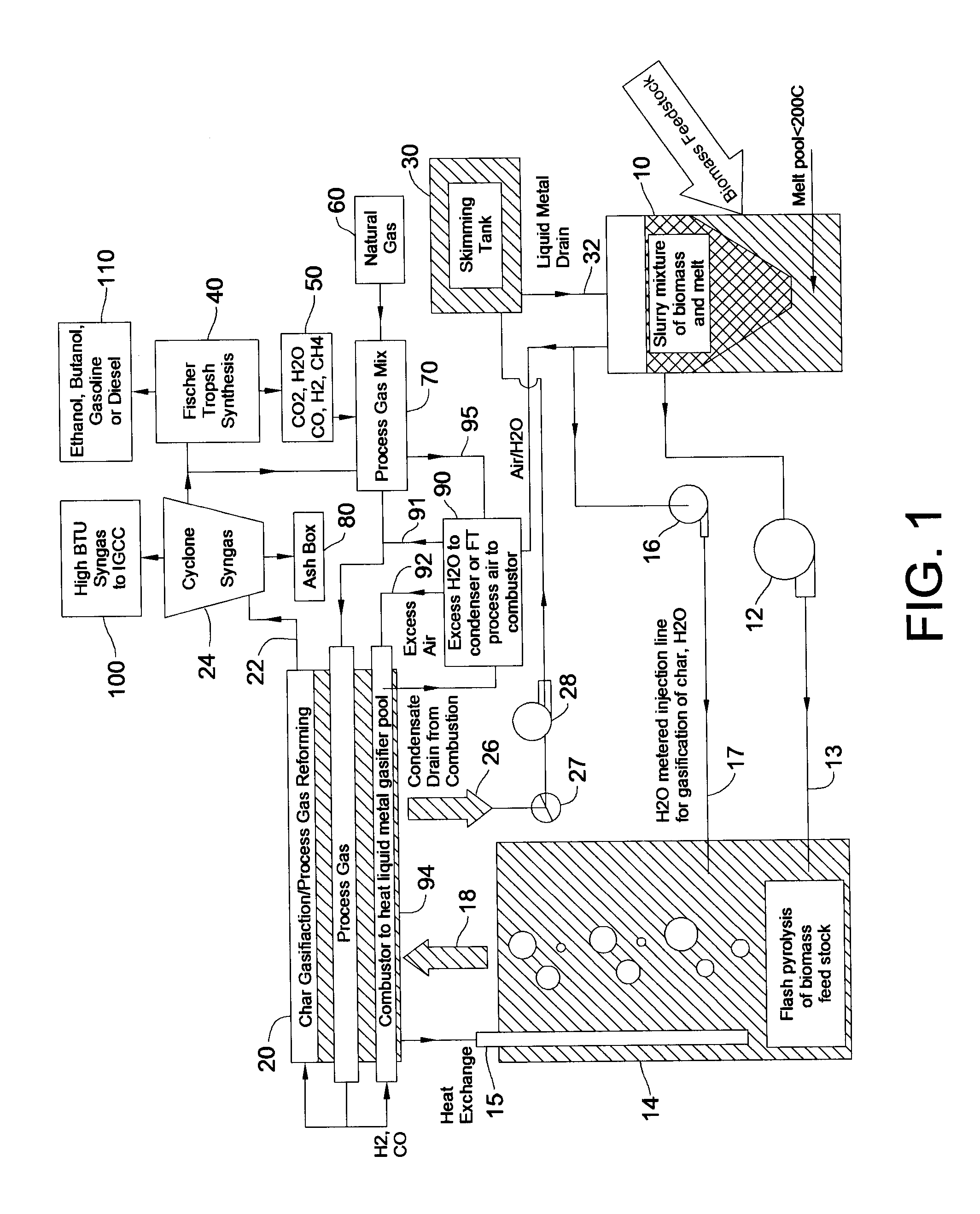

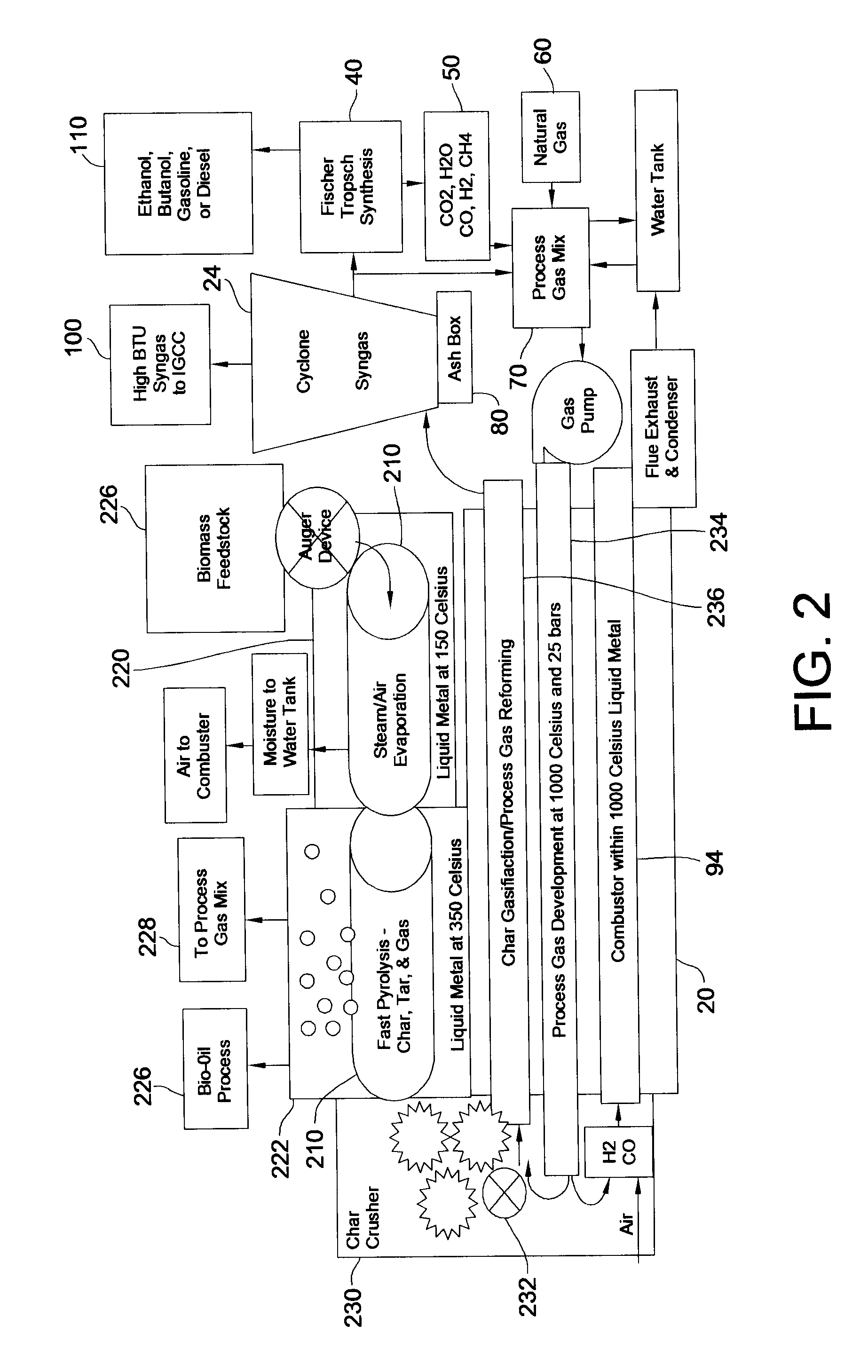

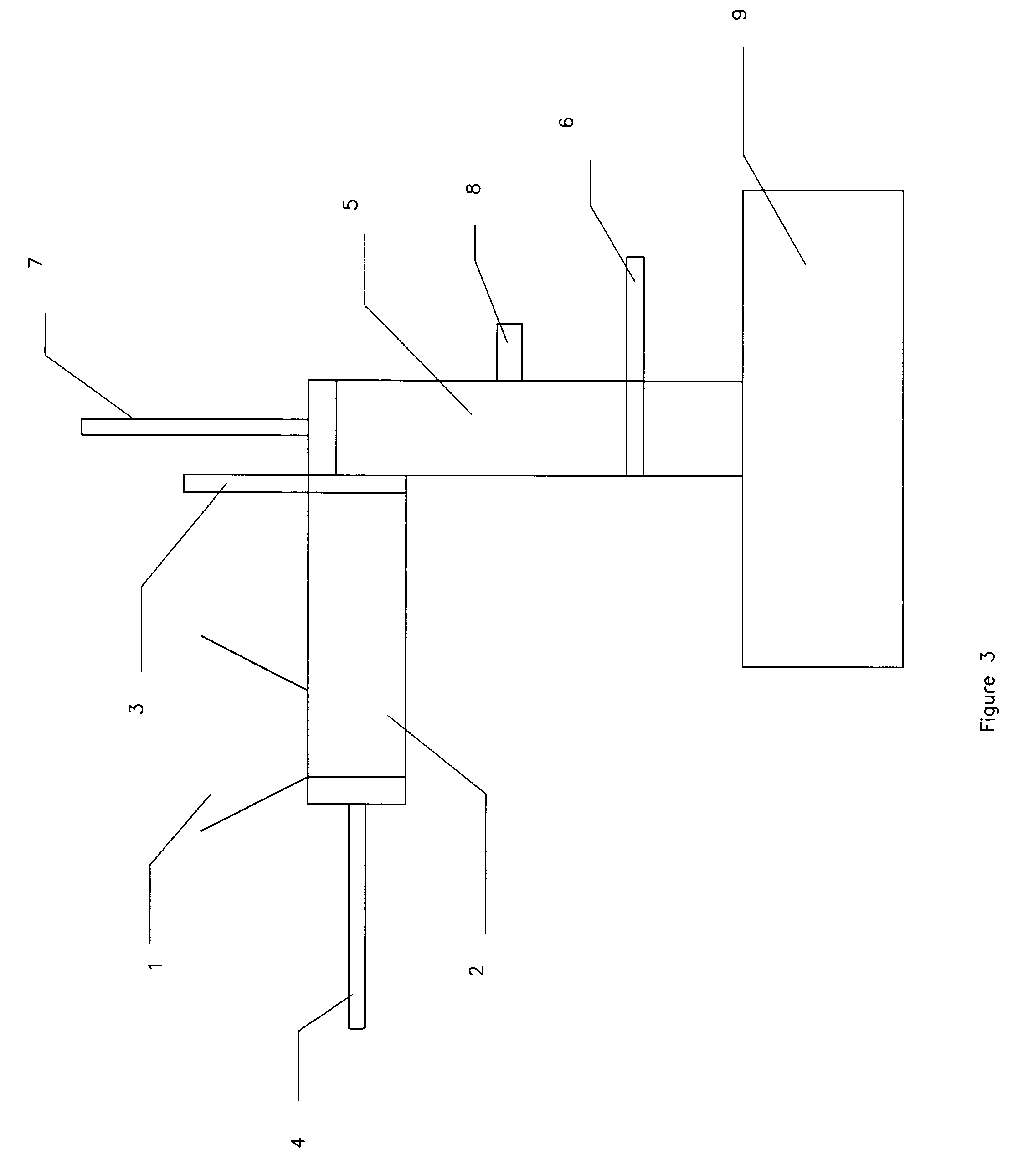

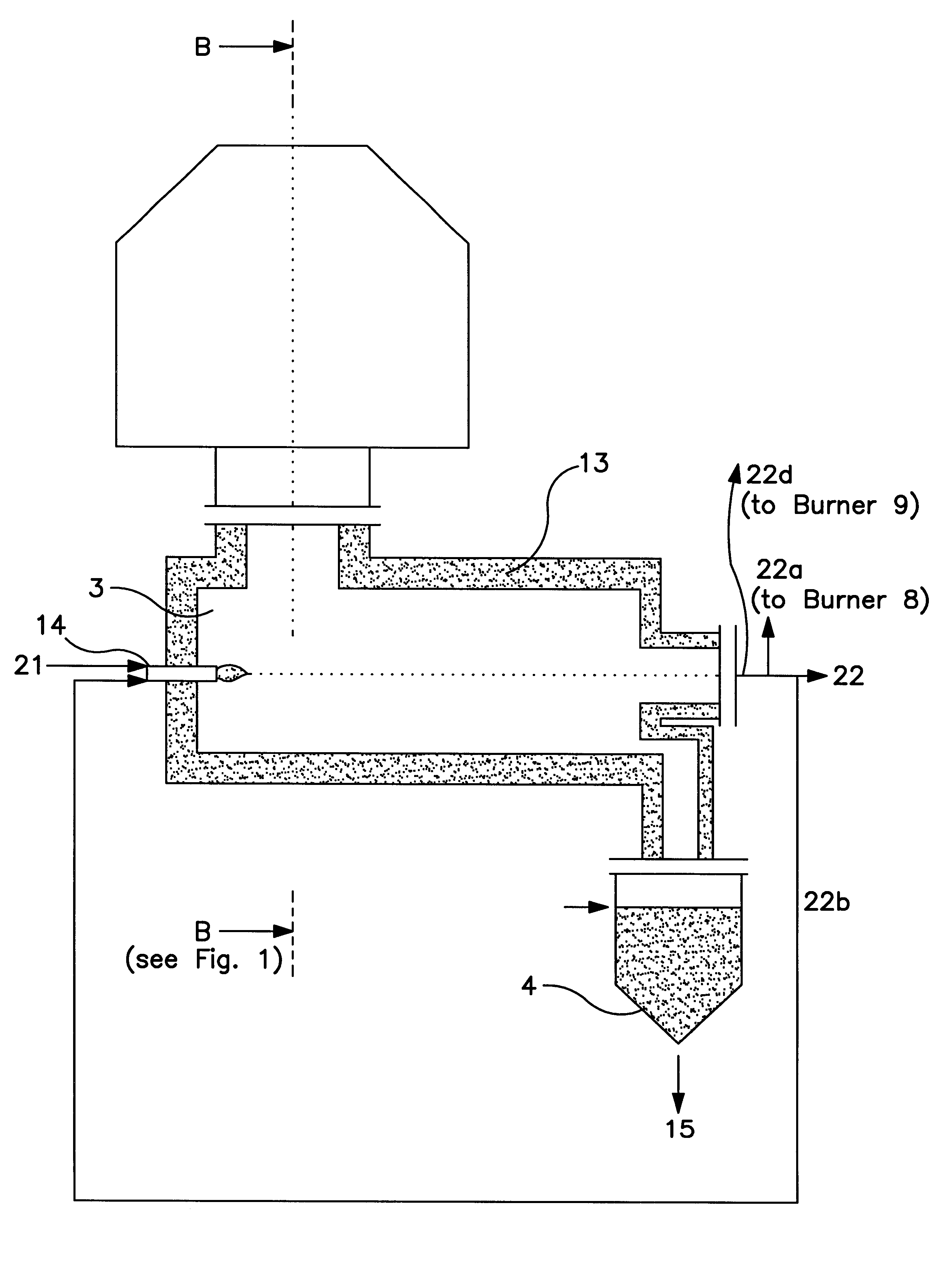

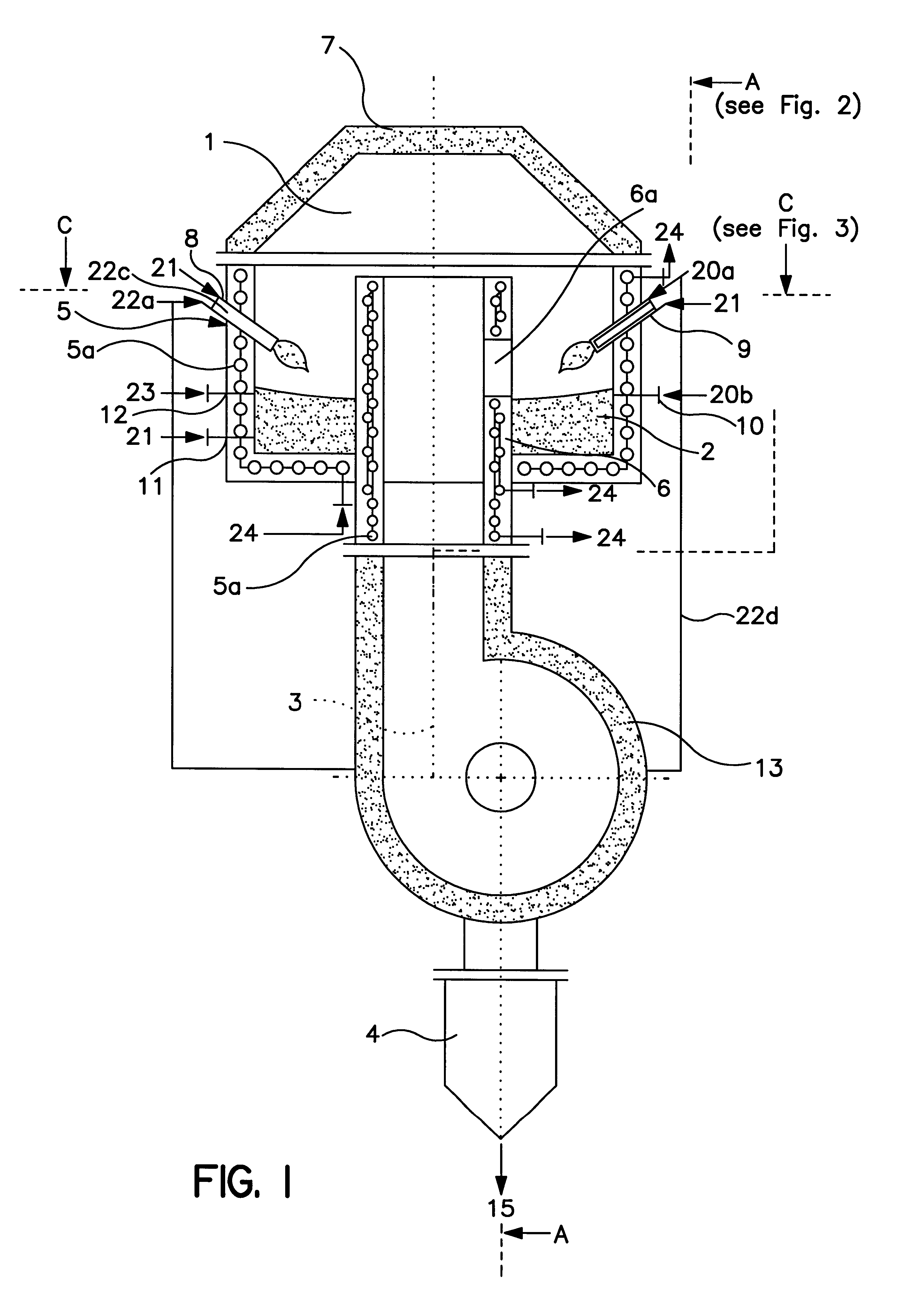

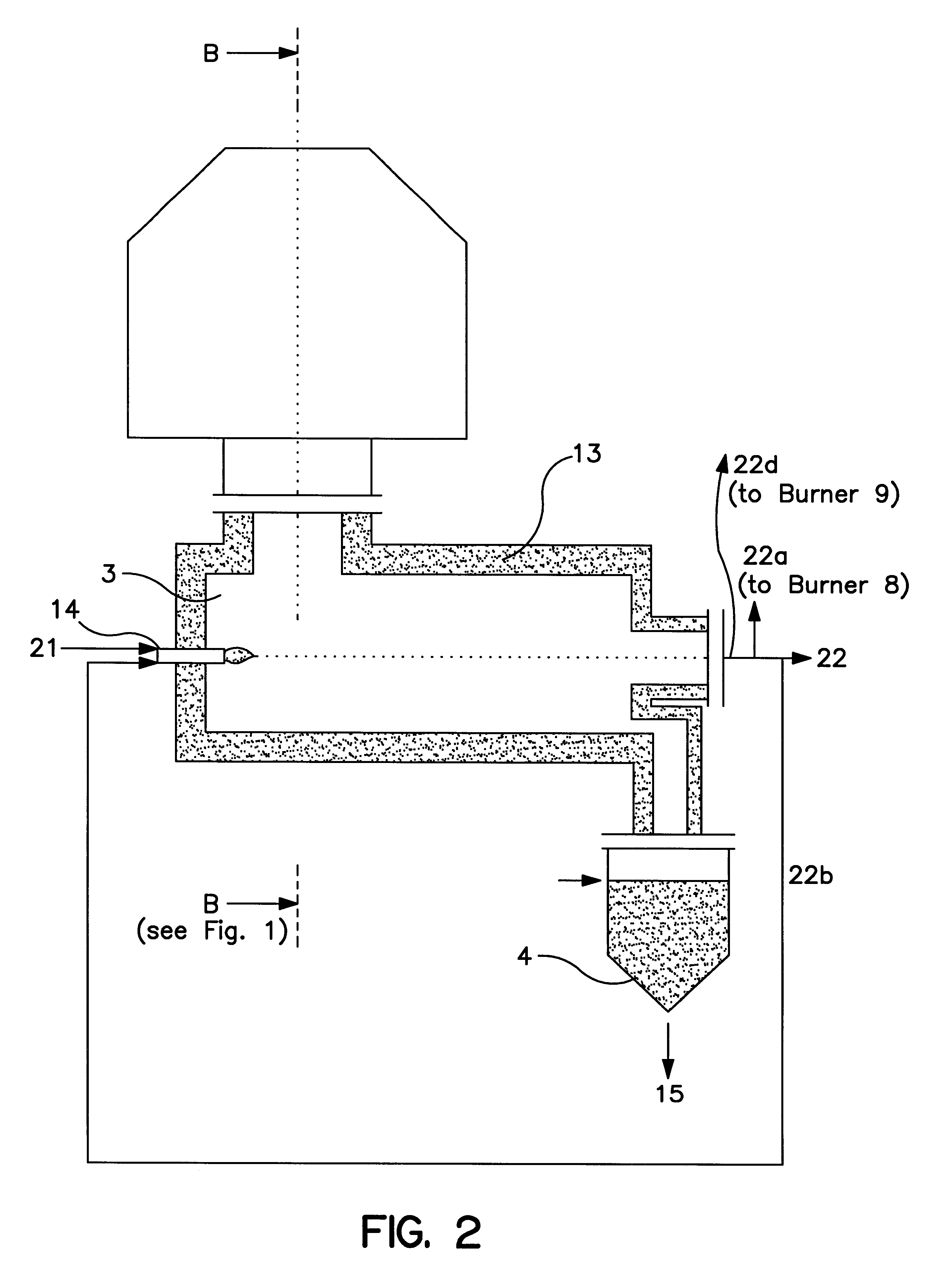

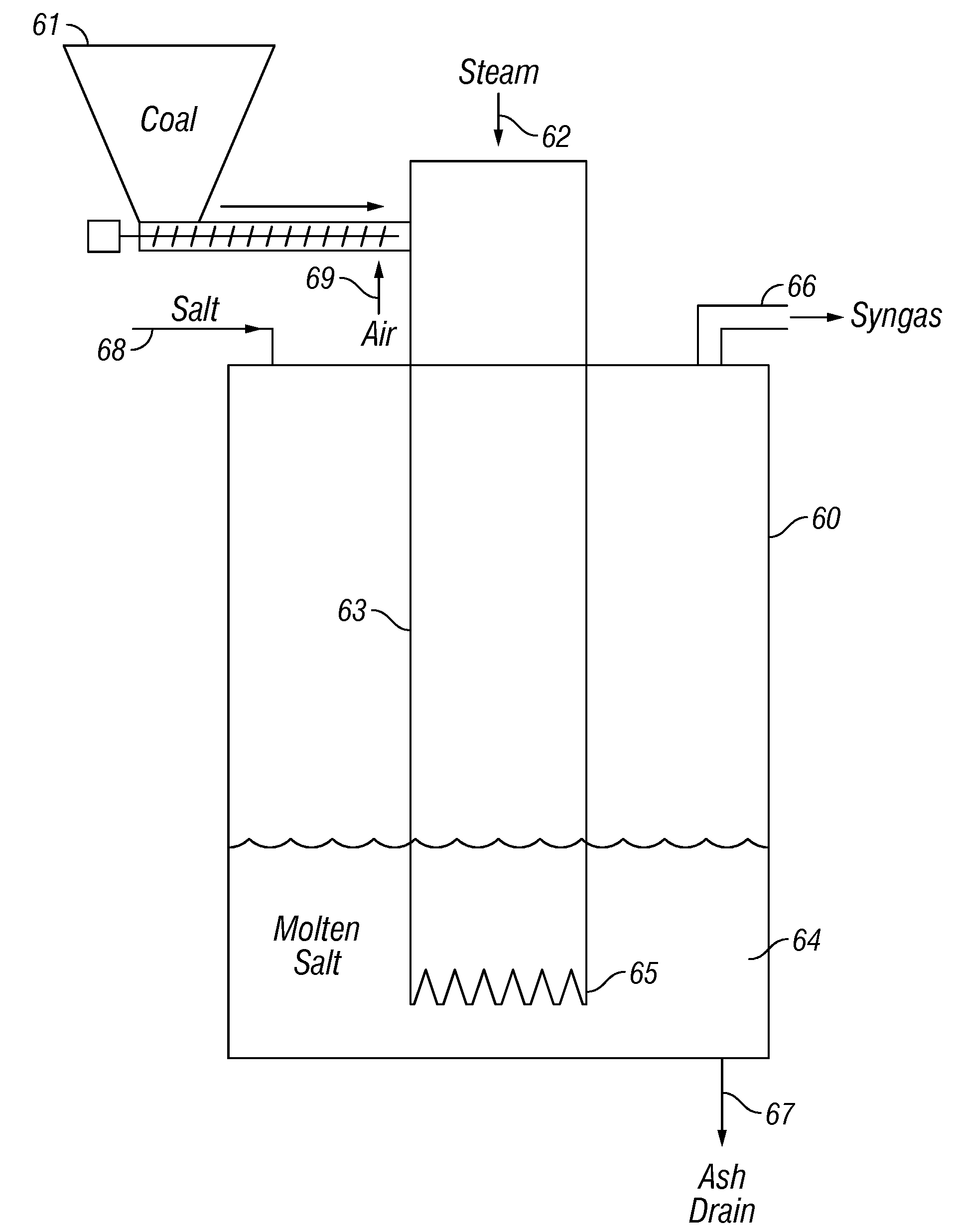

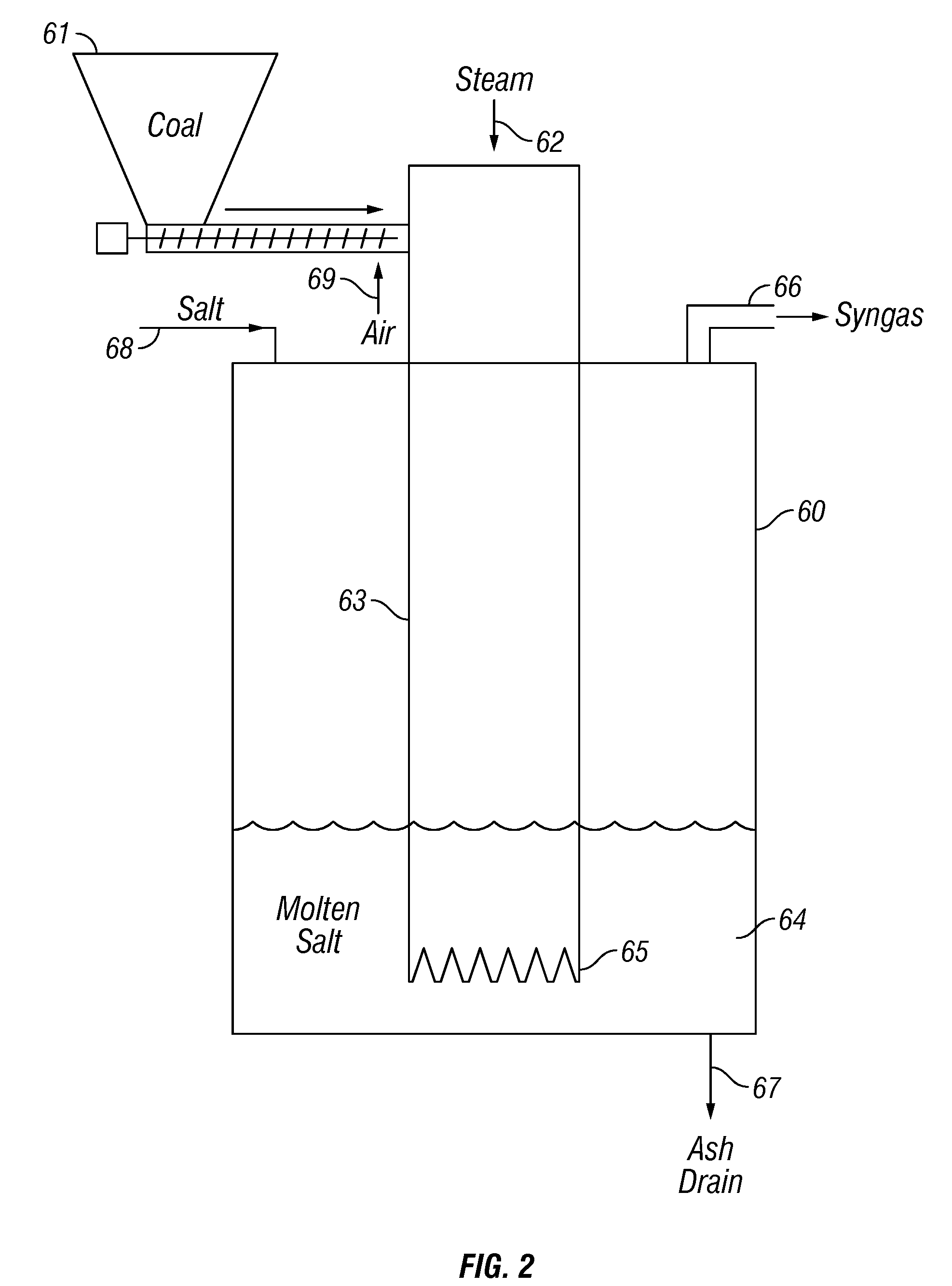

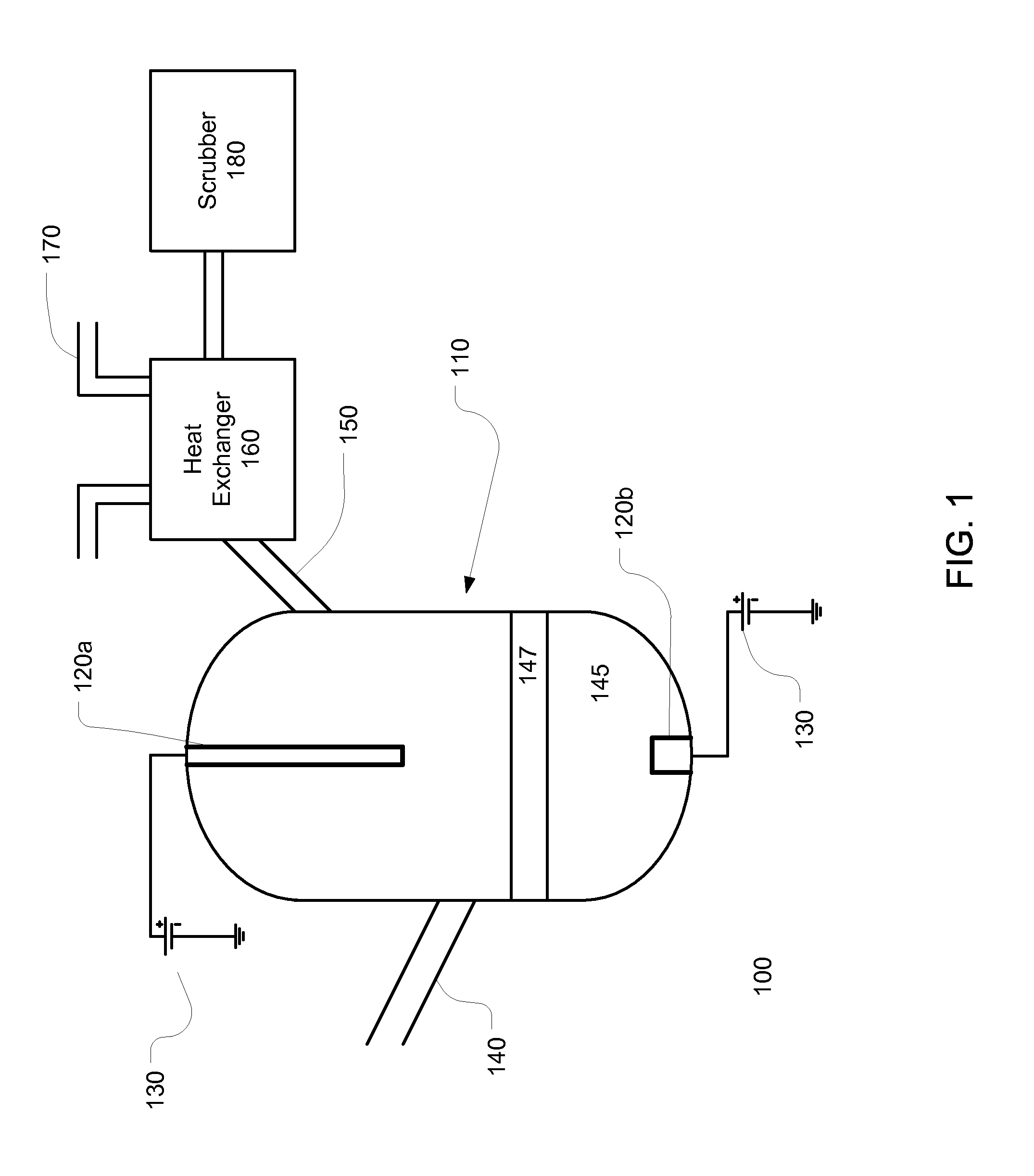

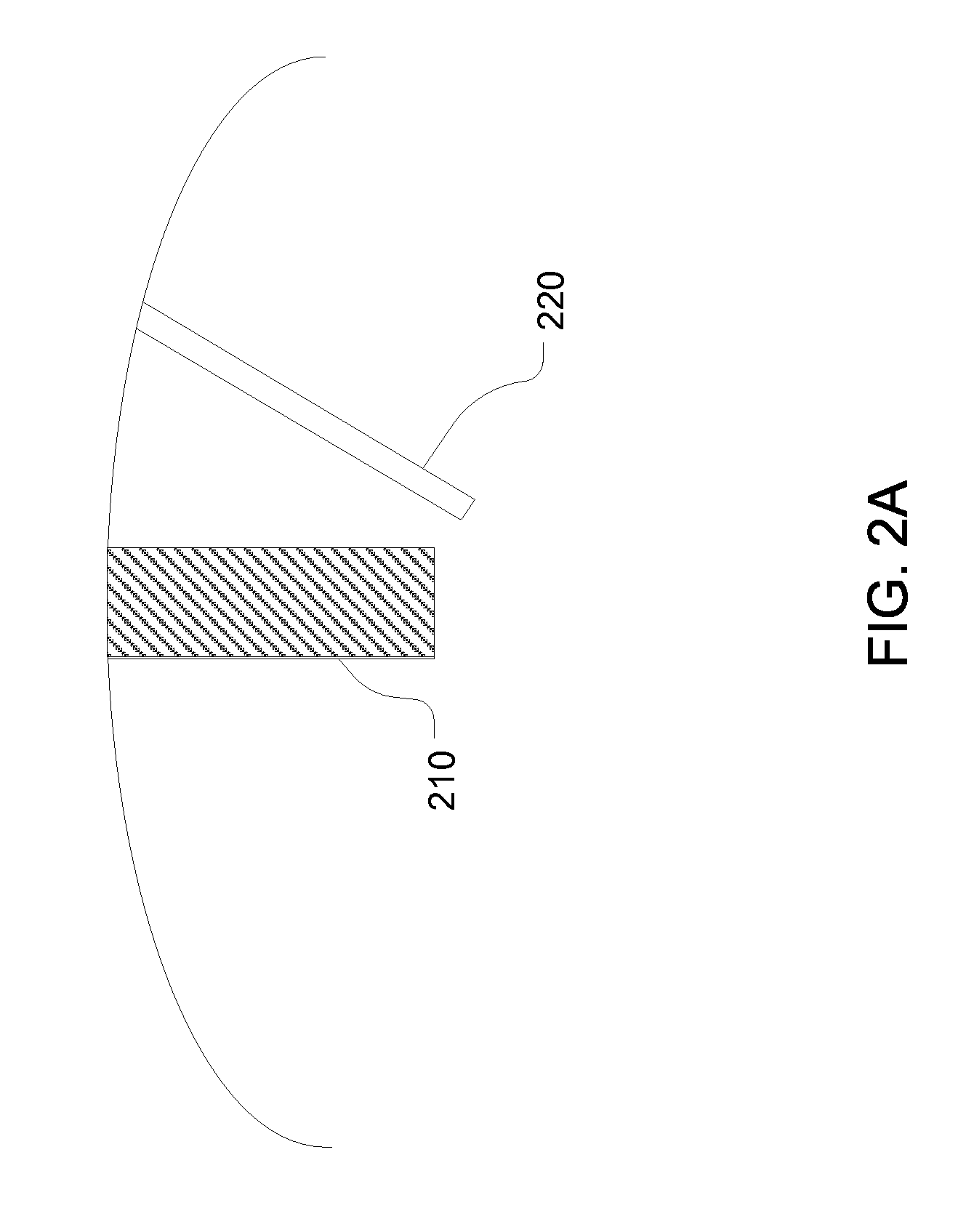

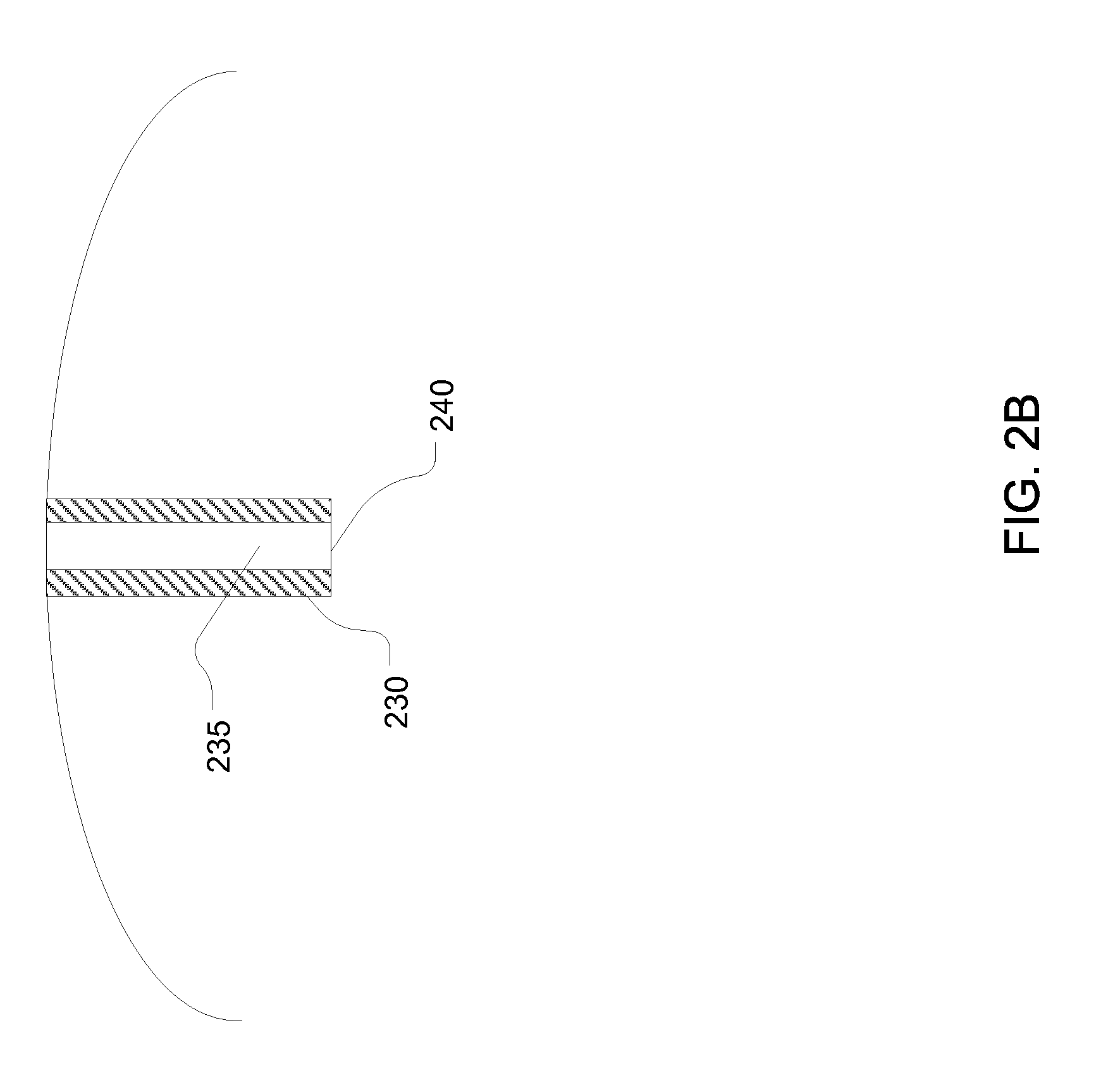

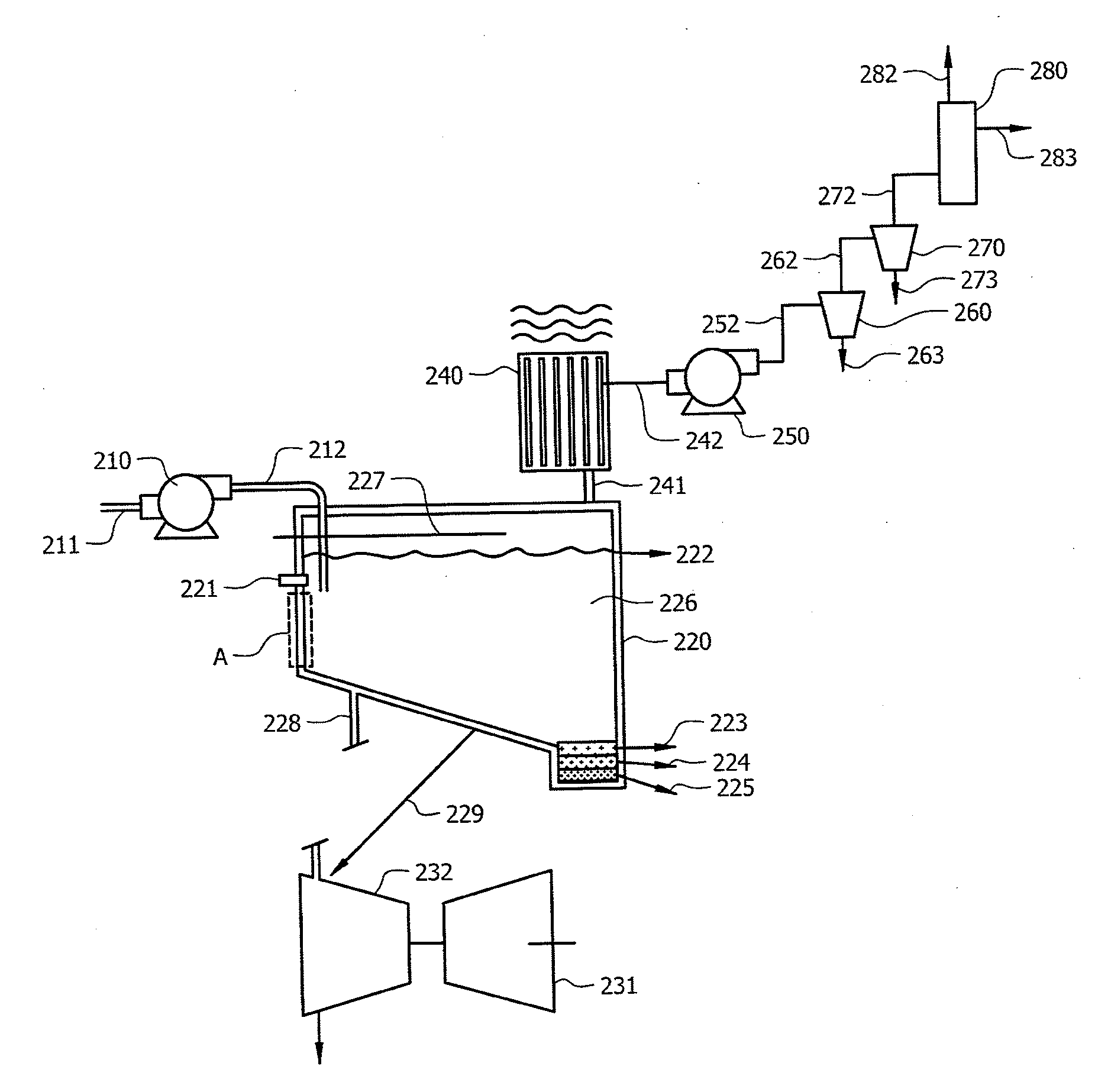

Method and apparatus to produce synthesis gas via flash pyrolysis and gasification in a molten liquid

InactiveUS7875090B2Improve efficiencyControlled heatingWaste based fuelRetortsFlash vacuum pyrolysisDecomposition

Disclosed are a method and a corresponding apparatus for converting a biomass reactant into synthesis gas. The method includes the steps of (1) heating biomass in a first molten liquid bath at a first temperature, wherein the first temperature is at least about 100° C., but less than the decomposition temperature of the biomass, wherein gas comprising water is evaporated and air is pressed from the biomass, thereby yielding dried biomass with minimal air content. (2) Recapturing the moisture evaporated from the biomass in step 1 for use in the process gas. (3) Heating the dried biomass in a second molten liquid bath at a second temperature, wherein the second temperature is sufficiently high to cause flash pyrolysis of the dried biomass, thereby yielding product gases, tar, and char. (4) Inserting recaptured steam into the process gas, which may optionally include external natural gas or hydrogen gas or recycled syngas for mixing and reforming with tar and non-condensable gases. (5) Further reacting the product gases, tar, and char with the process gas within a third molten liquid bath at a third temperature which is equal to or greater than the second temperature within the second molten liquid bath, thereby yielding high quality and relatively clean synthesis gas after a relatively long residence time needed for char gasification. A portion of the synthesis gas so formed is combusted to heat the first, second, and third molten liquid baths, unless external natural or hydrogen gas is available for this use.

Owner:US SEC AGRI +1

Method for converting waste into electricity

The invention is a method for converting waste into electricity using a generator, heating the vessel that is part of the generator, loading waste comprising steel into the heated vessel, melting the loaded waste to a molten state using a non-transferred torch to cut and melt the waste and then using a transferred torch to maintain a molten metal pool, adding additional steel to raise the molten metal pool to a minimum depth, raising the temperature to 2000 degrees Centigrade, acquiring EPA approval, loading waste into the vessel at a defined rate, maintaining the molten metal pool further melting any non-melted waste into a molten status with the transferred torch, determining BTU content and gas flow, injecting steam into the vessel, flowing gas from the vessel through scrubbers into storage containers and into a steam boiler, and using the boiler to run a turbine to generate electricity.

Owner:PIERCE JR JOSEPH FR

Method for the production of hydrogen-containing gaseous mixtures

A method for the production of a hydrogen-containing gas composition, such as a synthesis gas including hydrogen and carbon monoxide. The molar ratio of hydrogen to carbon monoxide (H2:CO) in the synthesis gas can be well-controlled to yield a ratio that is adequate for the synthesis of useful products such as methane or methanol, without the need to remove carbon oxides from the gas stream to adjust the ratio.

Owner:ALCHEMIX CORP

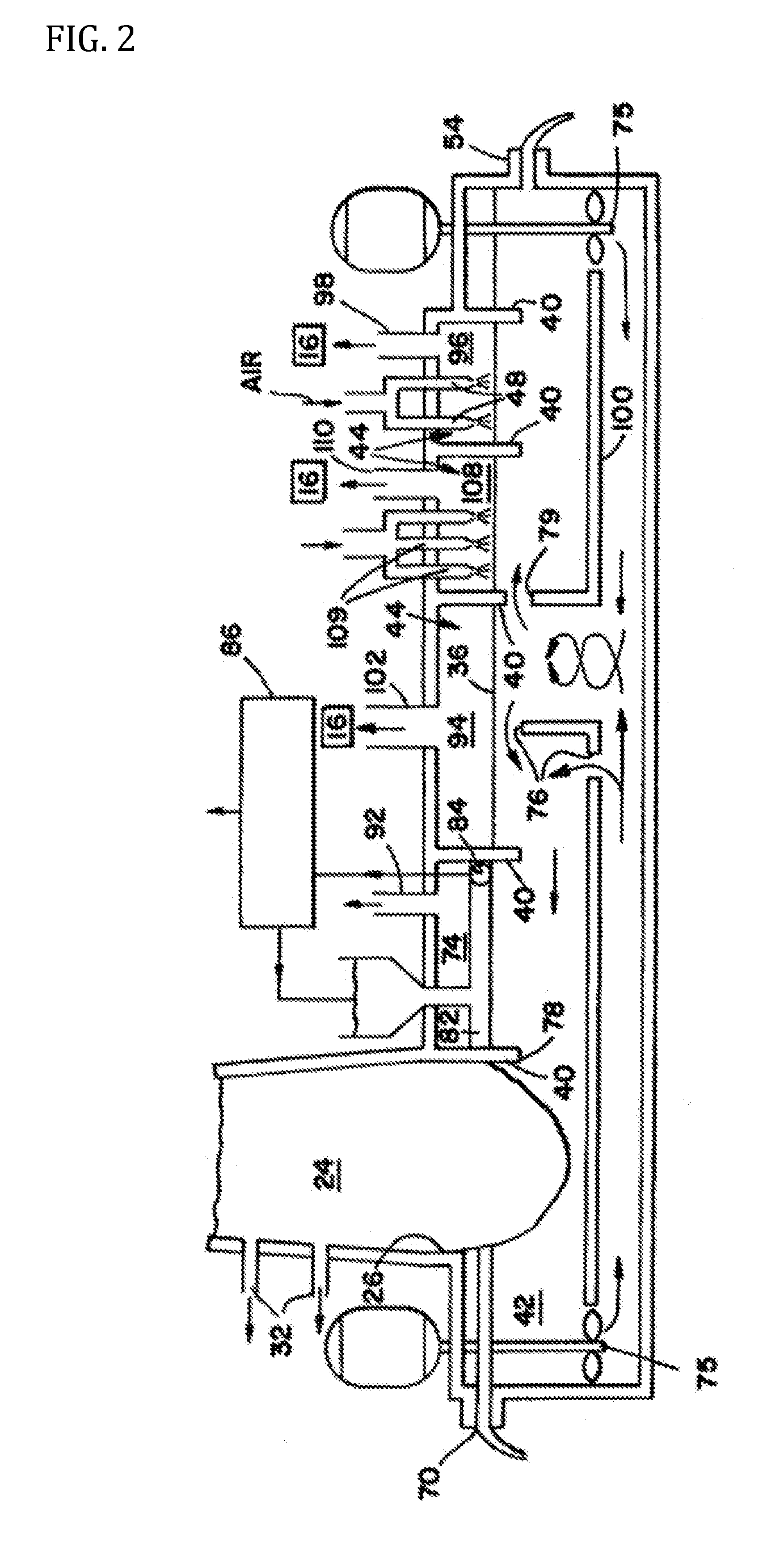

Two-stage plasma process for converting waste into fuel gas and apparatus therefor

InactiveUS20110107669A1Limited amountImprove energy efficiencyGasifier electrodesGaseous fuelsCyclonePlasma jet

A two-step gasification process and apparatus for the conversion of solid or liquid organic waste into clean fuel, suitable for use in a gas engine or a gas burner, is described. The waste is fed initially into a primary gasifier, which is a graphite arc furnace. Within the primary gasifier, the organic components of the waste are mixed with a predetermined amount of air, oxygen or steam, and converted into volatiles and soot. The volatiles consist mainly of carbon monoxide and hydrogen, and may include a variety of other hydrocarbons and some fly ash. The gas exiting the primary gasifier first passes through a hot cyclone, where some of the soot and most of the fly ash is collected and returned to the primary gasifier. The remaining soot along with the volatile organic compounds is further treated in a secondary gasifier where the soot and the volatile compounds mix with a high temperature plasma jet and a metered amount of air, oxygen or steam, and are converted into a synthesis gas consisting primarily of carbon monoxide and hydrogen. The synthesis gas is then quenched and cleaned to form a clean fuel gas suitable for use in a gas engine or a gas burner. This offers higher thermal efficiency than conventional technology and produces a cleaner fuel than other known alternatives.

Owner:PYROGENESIS CANADA INC

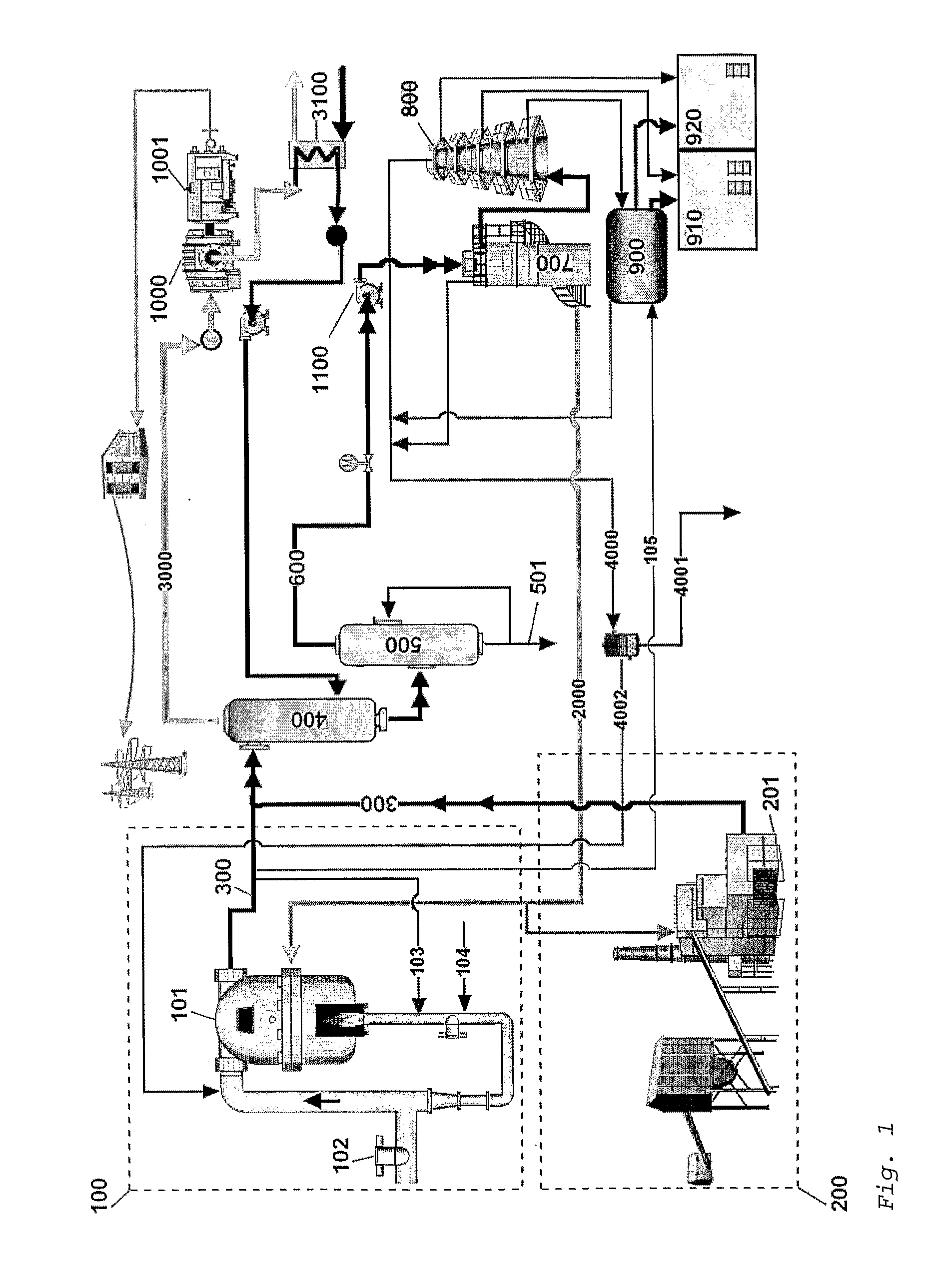

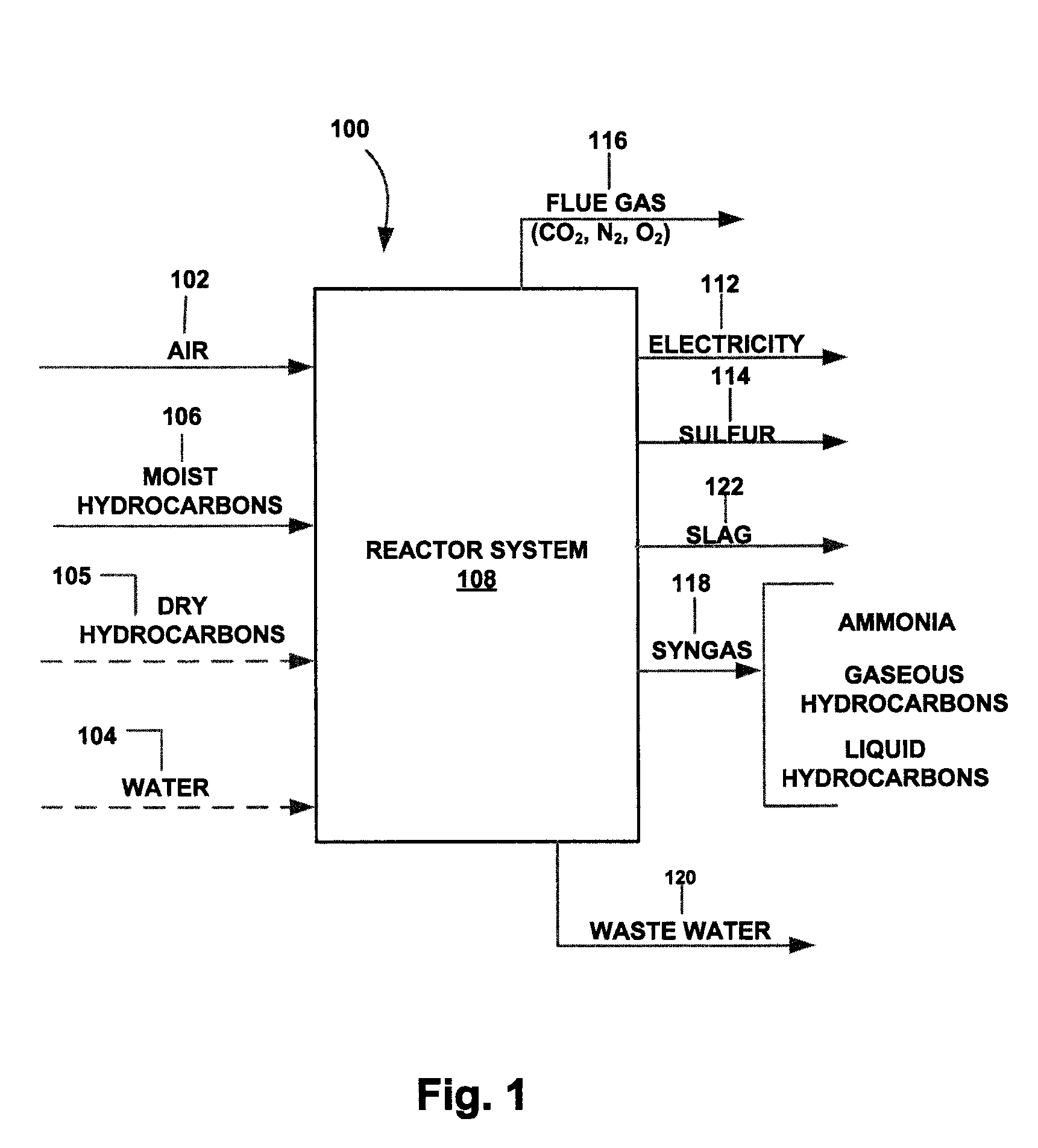

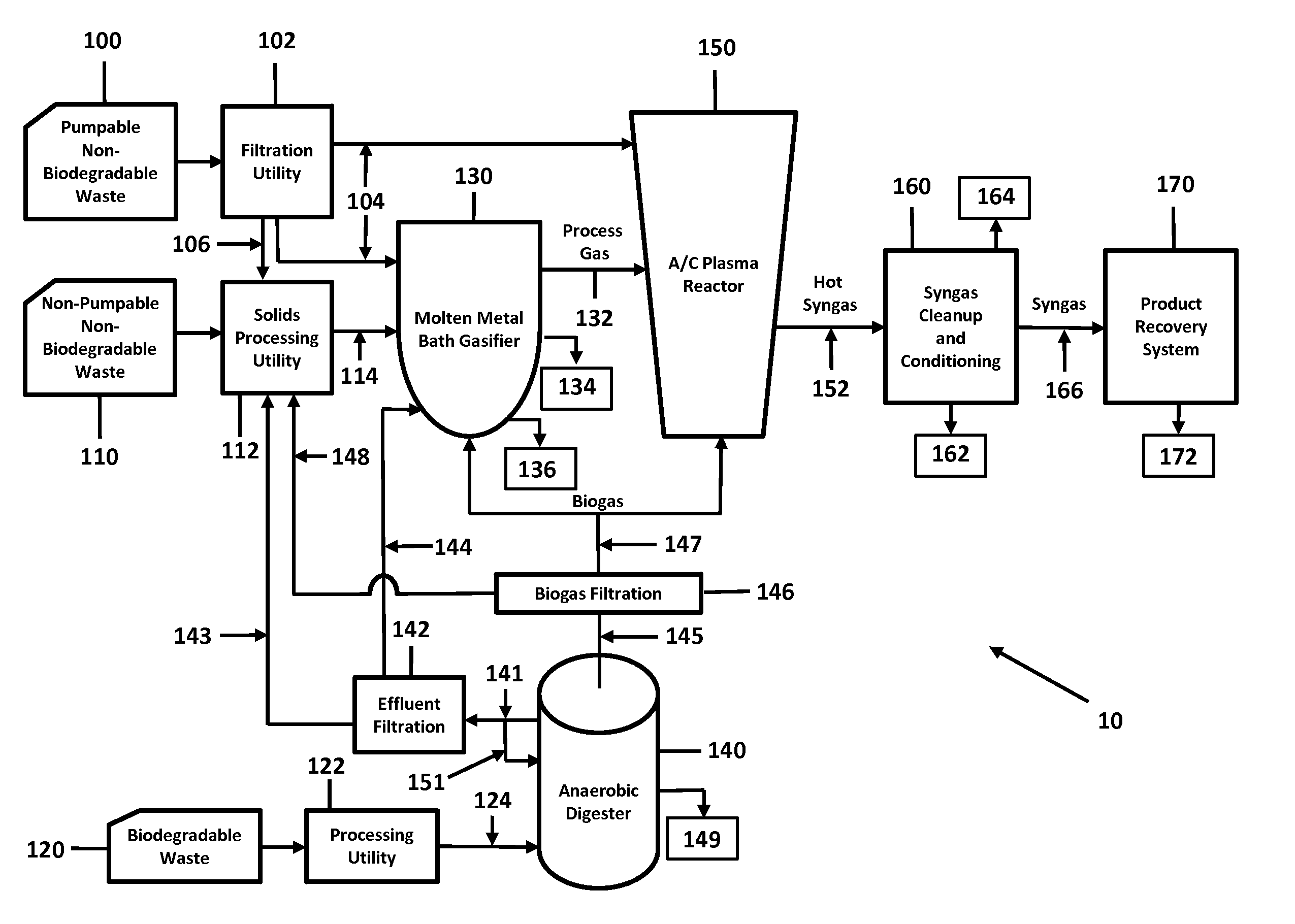

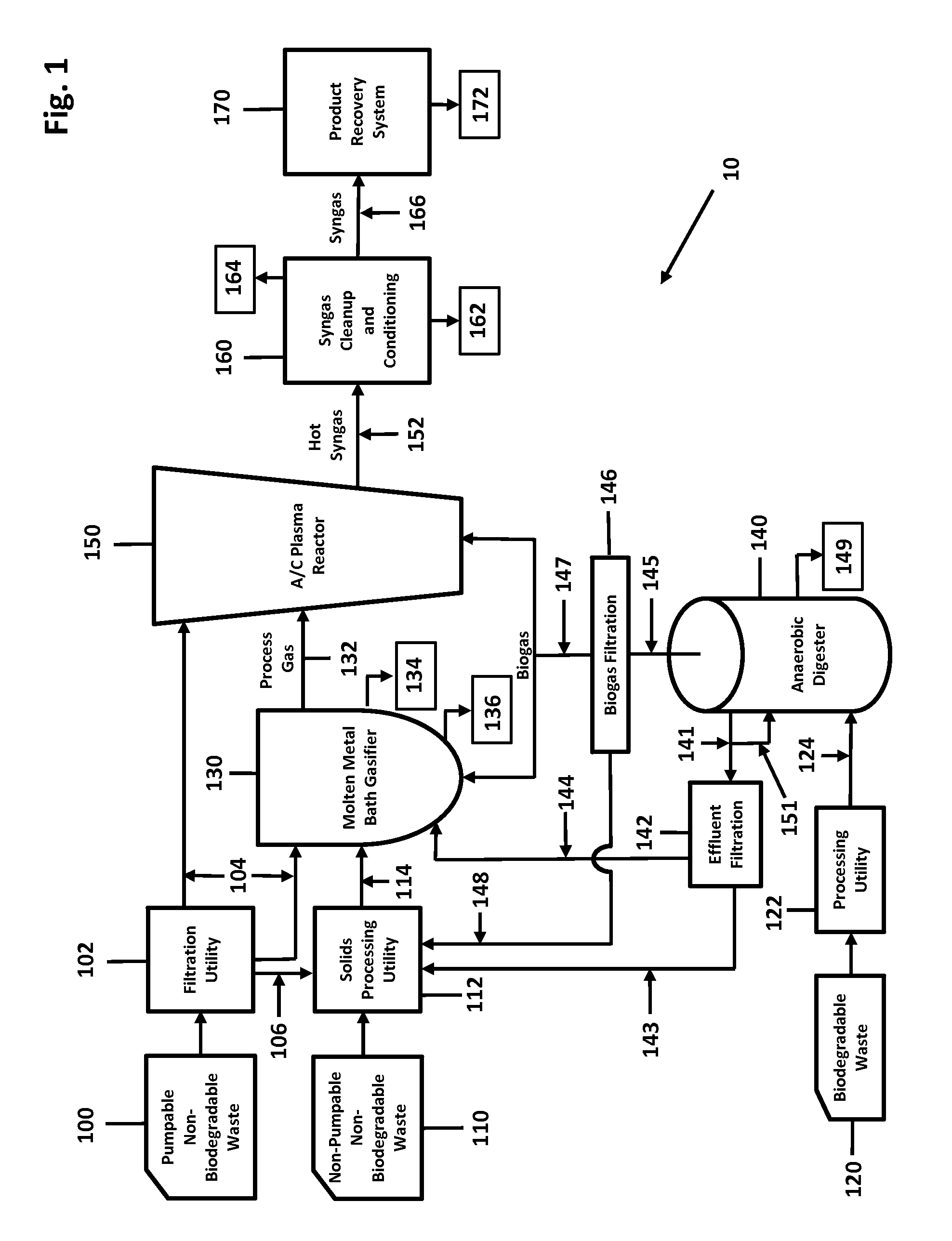

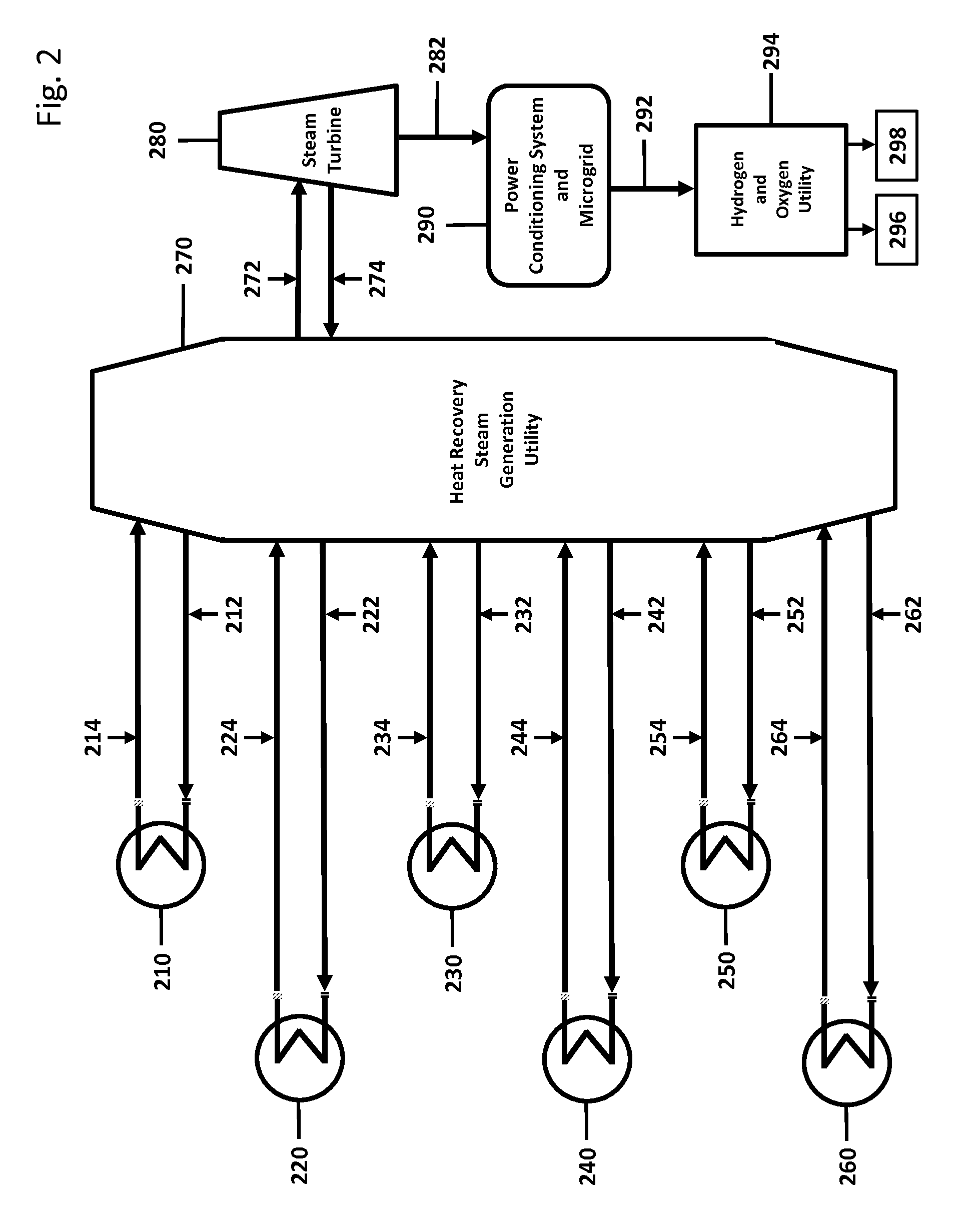

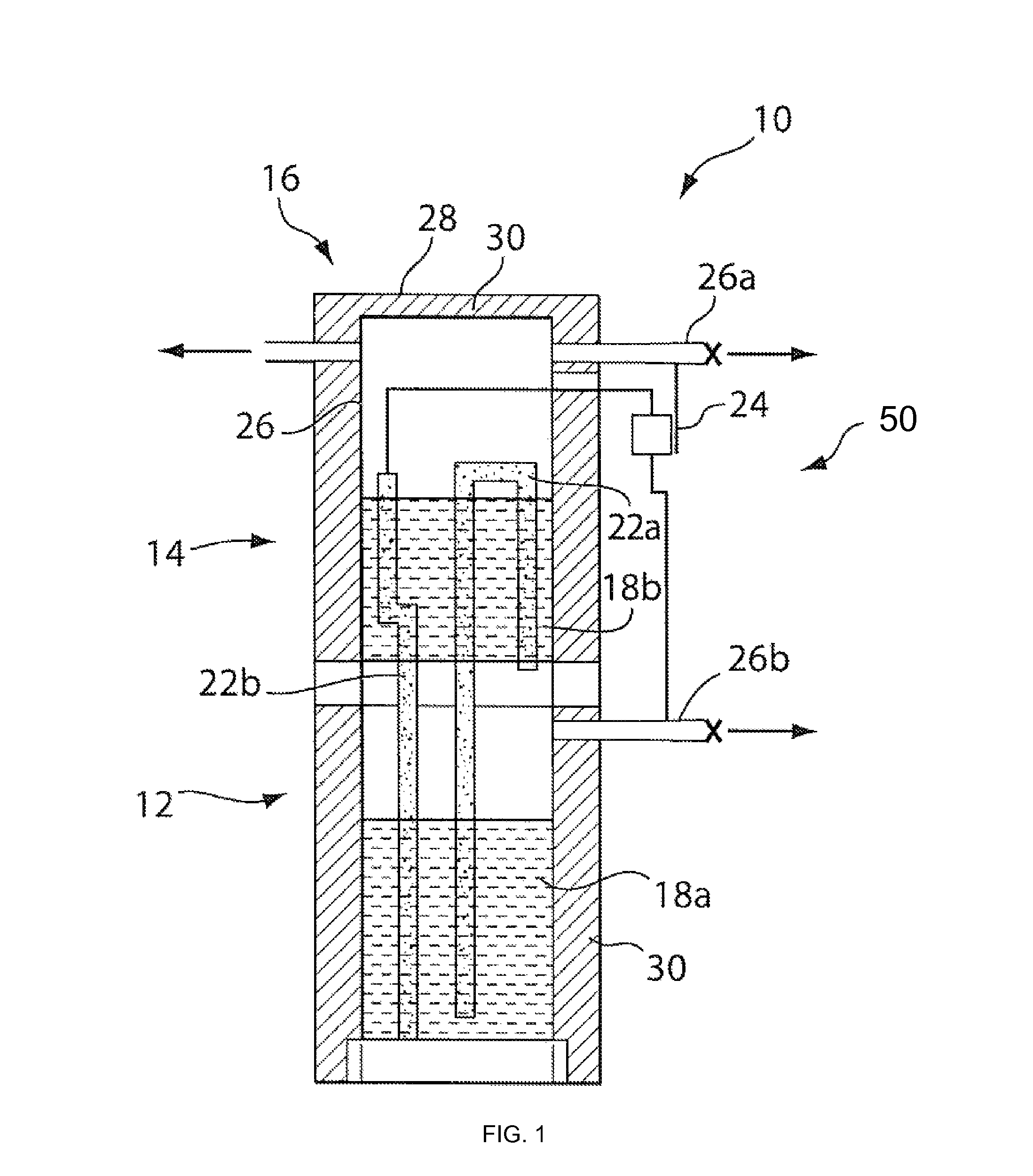

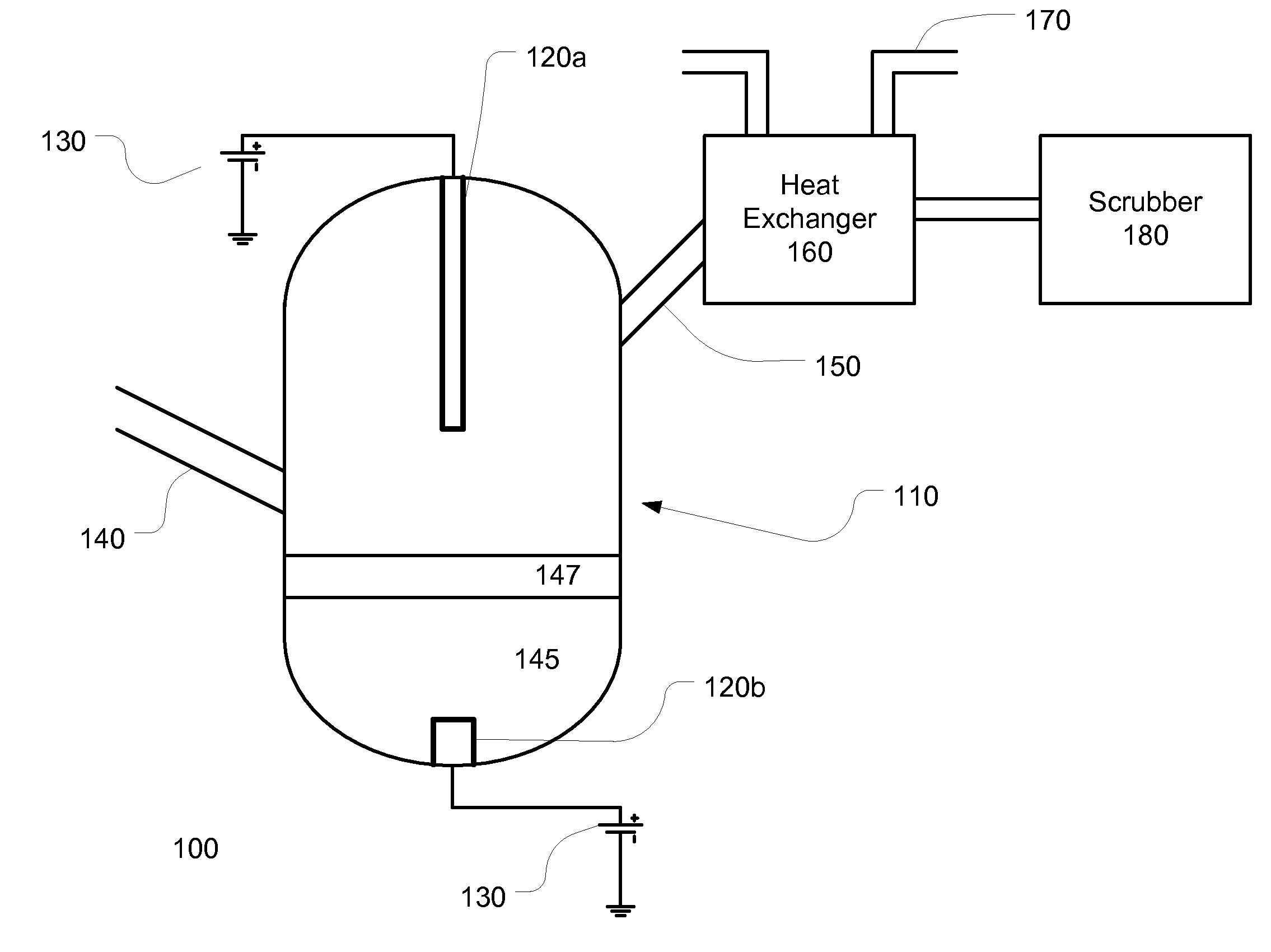

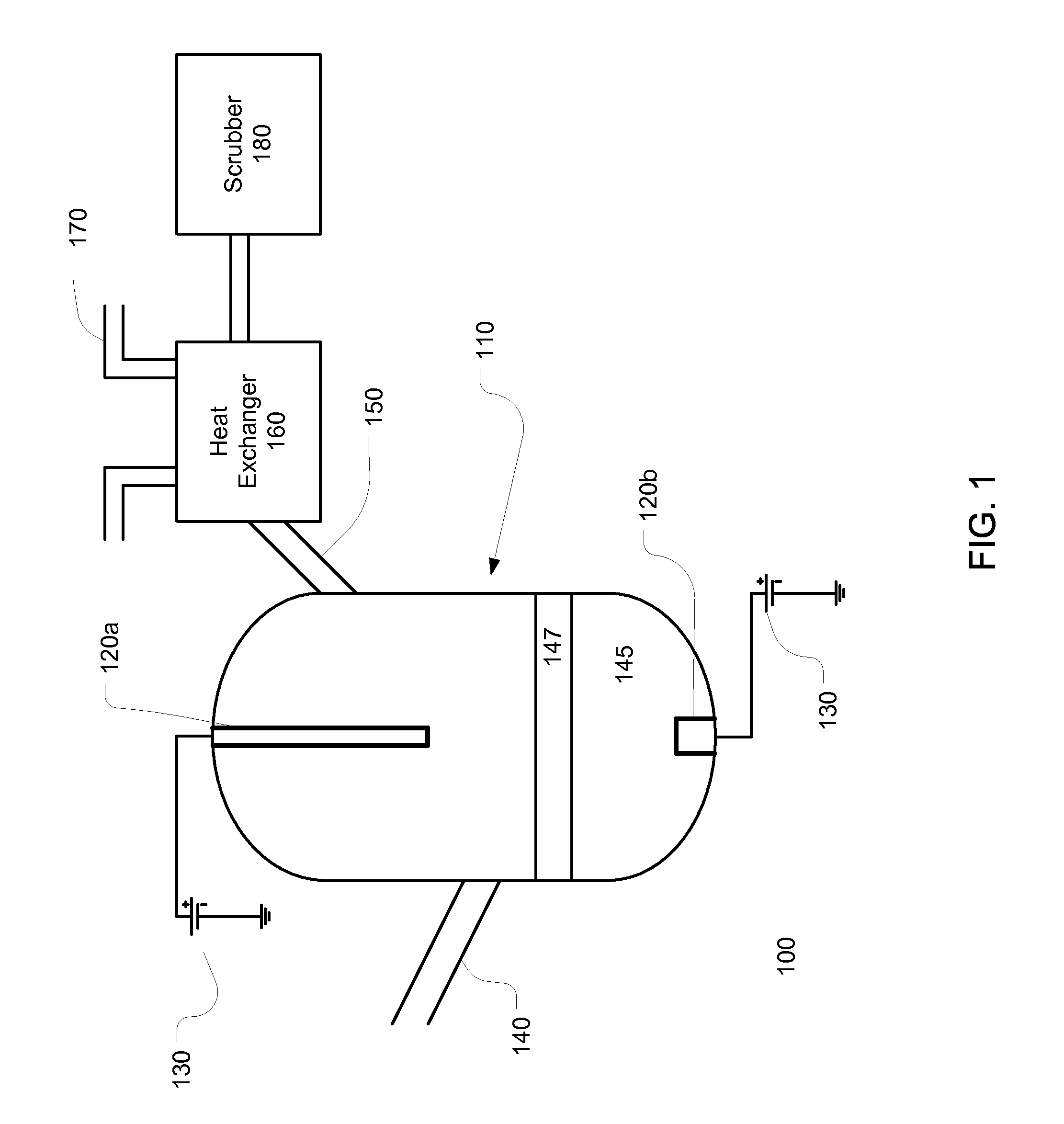

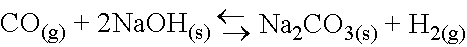

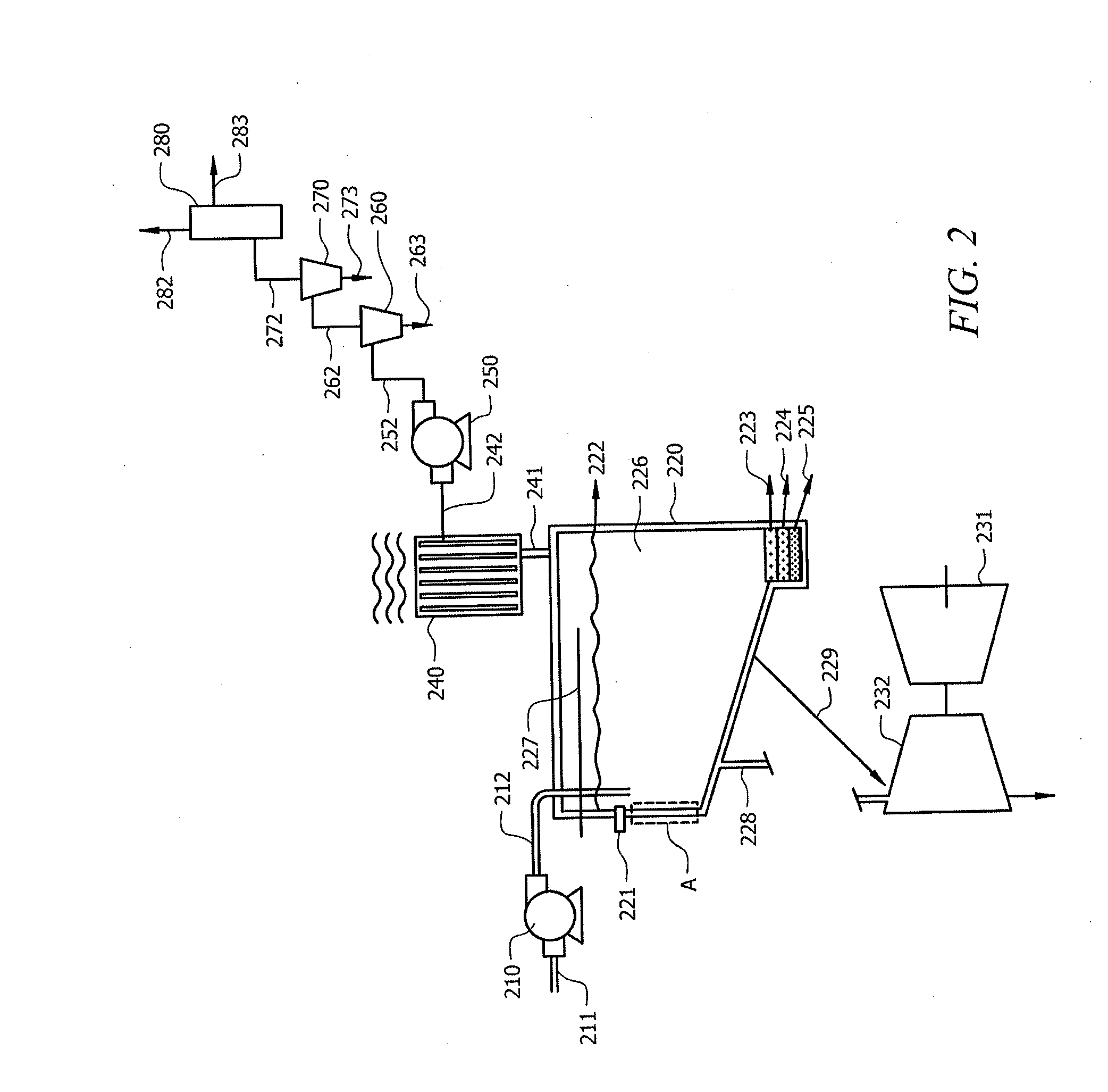

System and method for producing a consistent quality syngas from diverse waste materials with heat recovery based power generation, and renewable hydrogen co-production

ActiveUS9315735B2Processed effectively and safelyRisk minimizationDirect heating destructive distillationBiofuelsOxygenElectric power

A system and method for converting waste and secondary materials into synthesis gas (syngas) through the use of a molten metal bath gasifier for the initial breakdown of waste feeds and an A / C plasma reactor for complete dissociation of waste feeds into syngas, and an anaerobic digester. The system includes a heat recovery and steam power generation process for the production of electricity. The system produces a net output of electricity above plant load sufficient for the co-production of renewable Hydrogen and Oxygen. The process does not require the use of fossil fuels or fossil feedstocks during normal operations, and it eliminates combustion produced stack emissions or landfill residuals.

Owner:RENEWABLE OPPORTUNITIES

High pressure gasifier system using electrically assisted heating

ActiveUS20110126461A1Good and more complete processingIncrease temperatureGasifier electrodesEngine sealsElectricityMicrowave

The problems of the prior art are overcome by the apparatus and method disclosed herein. The reactor vessel of a plasma gasifier is operated at high pressure. To compensate for the negative effects of high pressure, various modifications to the plasma gasifier are disclosed. For example, by moving the slag, more material is exposed to the plasma, allowing better and more complete processing thereof. In some embodiments, magnetic fields are used to cause movement of the slag and molten metal within the vessel. An additional embodiment is to add microwave heating of the slag and / or the incoming material. Microwave heating can also be used as an alternative to plasma heating in a high pressure gasification system.

Owner:INENTEC

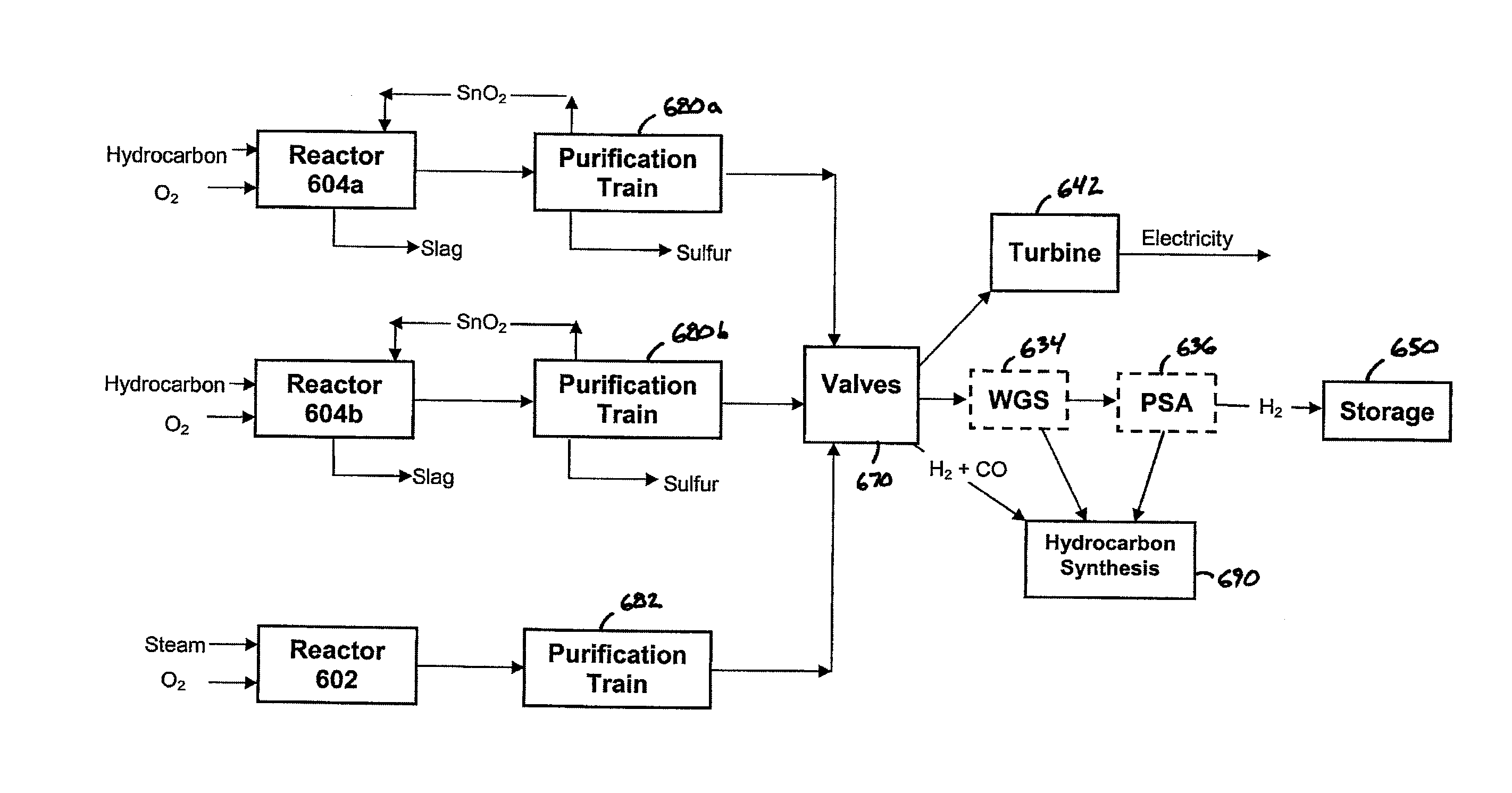

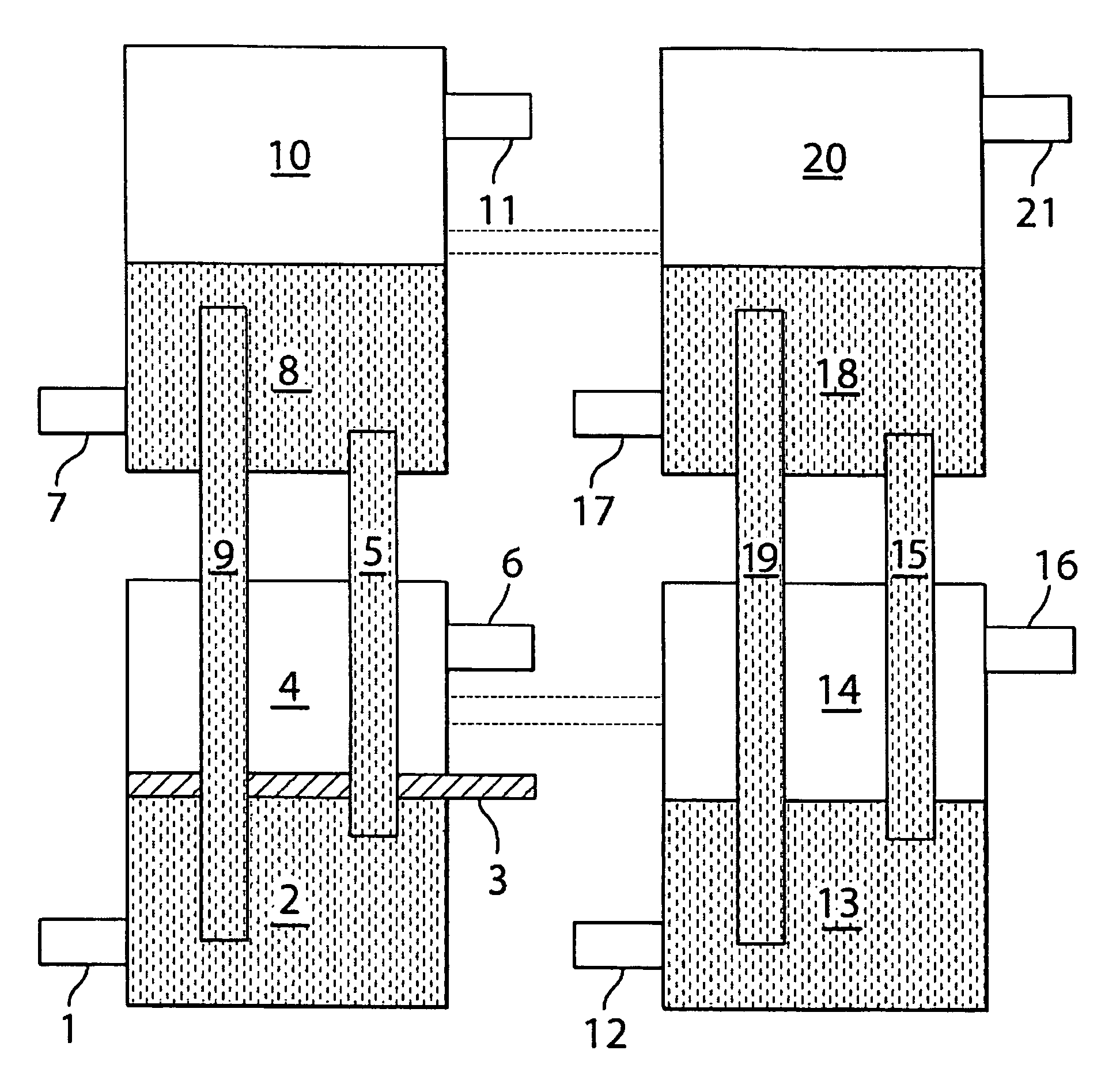

Gaseous transfer in multiple metal bath reactors

InactiveUS8303916B2High purityIncrease pressureBlast furnace componentsSulfur compoundsReactor systemProcess engineering

A reactor system for the transformation of solid, liquid, gaseous, and related hydrocarbon feedstocks into high-purity, high-pressure gas streams capable of withstanding high temperatures and high pressures. The system comprises a plurality of reactor housings and a plurality of molten-metal bath vessels within the housings, the bath vessels in fluid communication with each other via conduits, with communication facilitated by gravity and temperature / pressure differentials.

Owner:NC12 INC +1

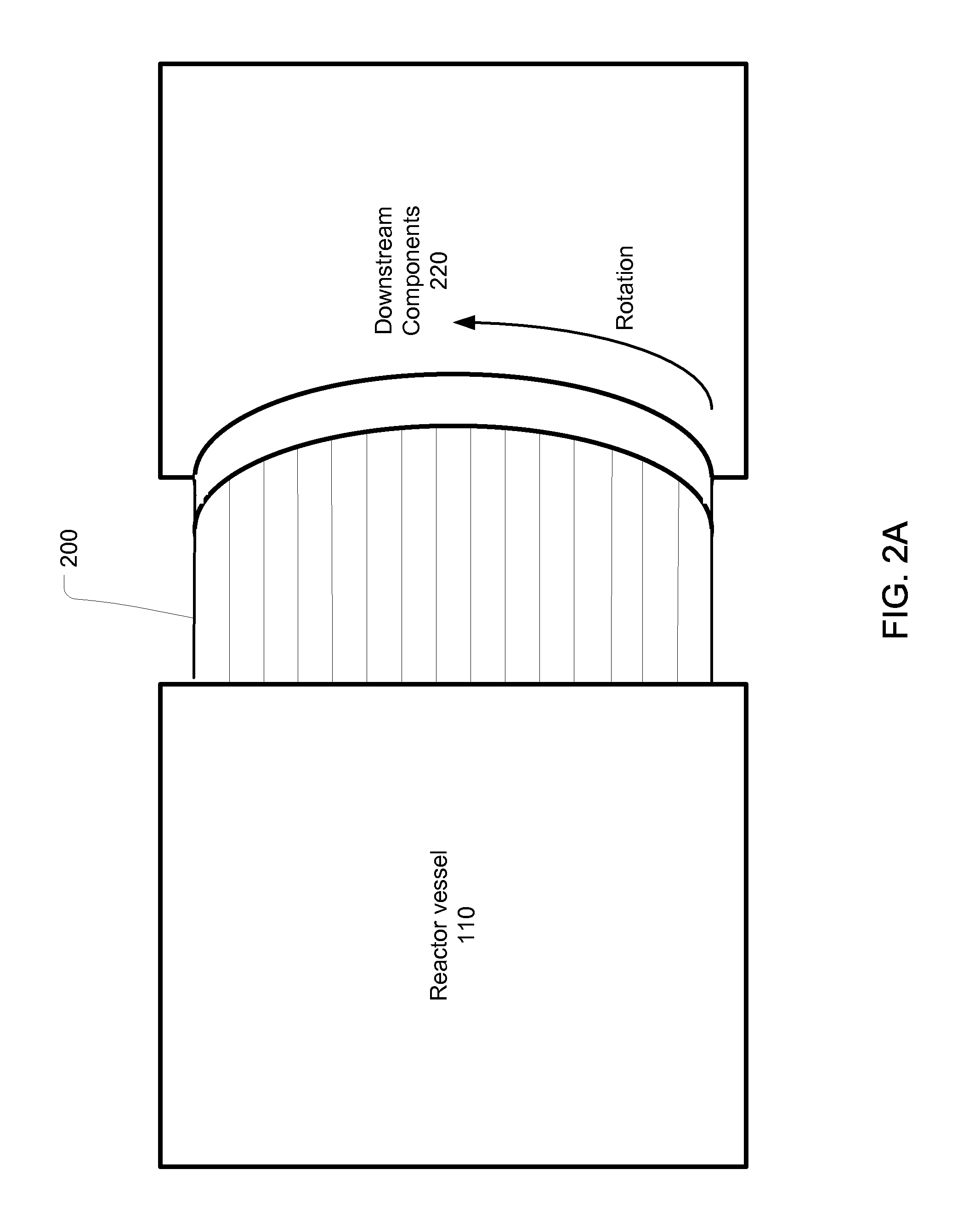

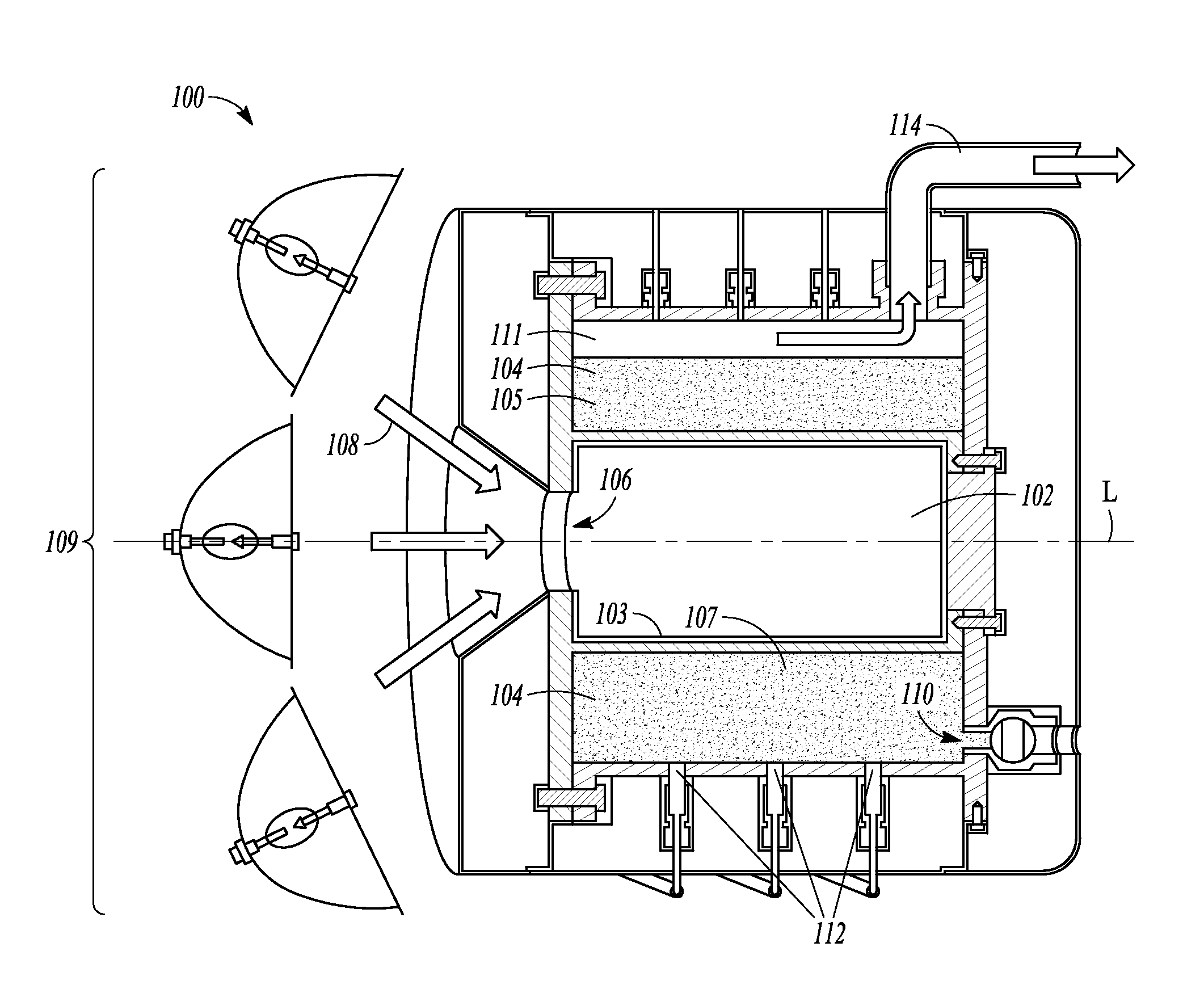

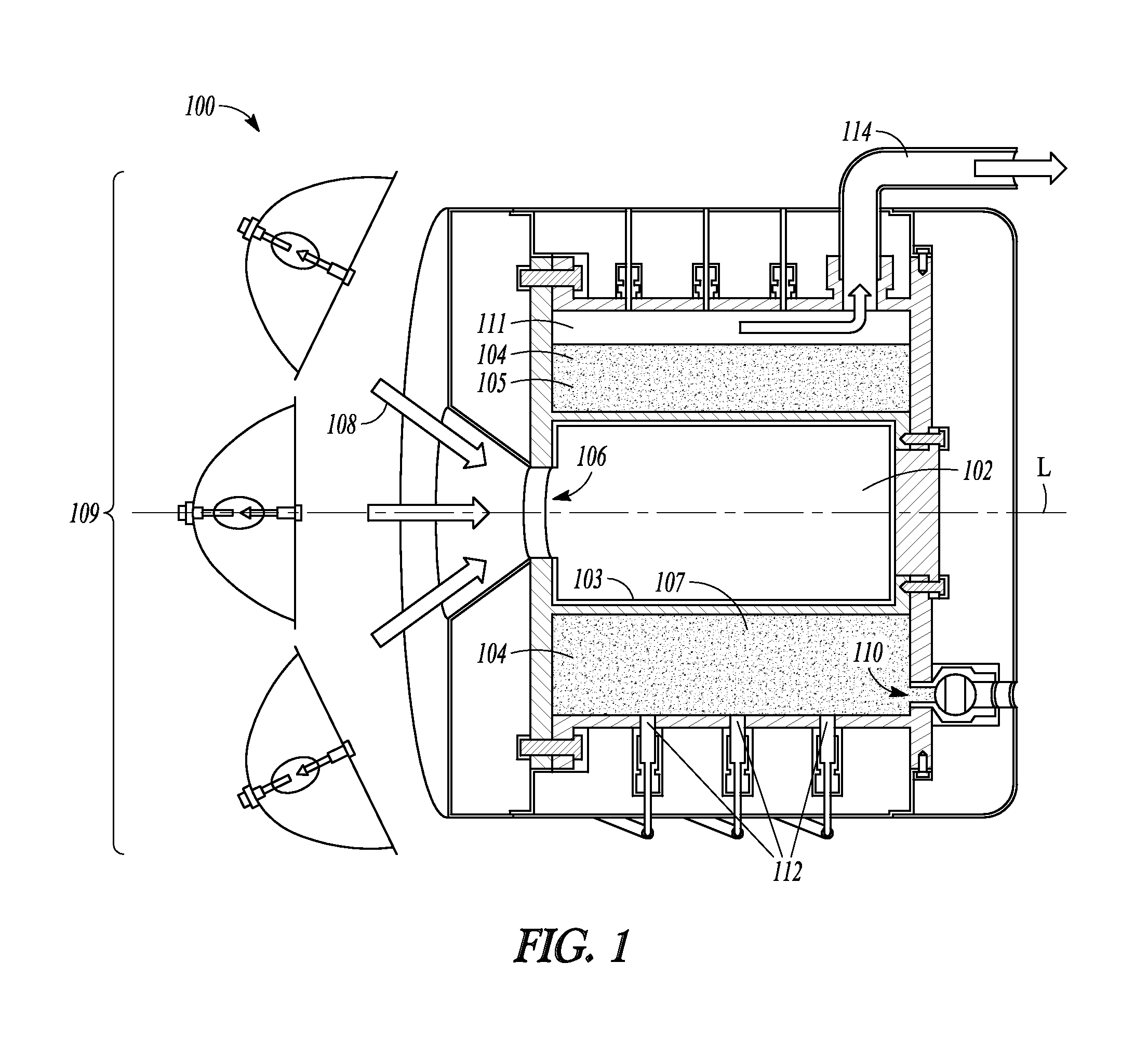

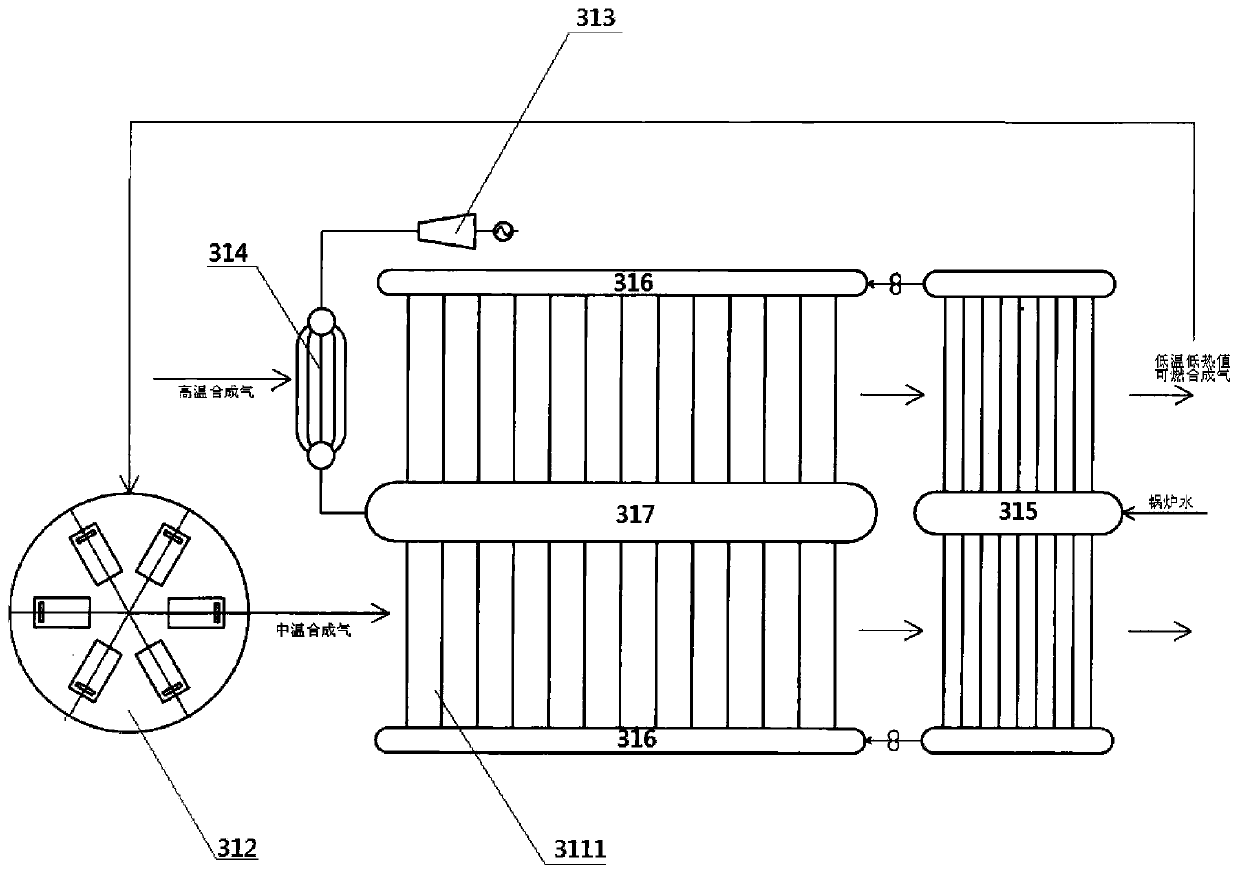

Regenerator for syngas cleanup and energy recovery in gasifier systems

ActiveUS20110126460A1Reduce heatReduce the amount requiredGasifier electrodesGasifier mechanical detailsSyngasParticulates

A rotating heat regenerator is used to recover heat from the syngas at it exits the reactor vessel of a waste or biomass gasifier. In some embodiments, three or more streams are passed through the heat exchanger. One stream is the dirty syngas, which heats the rotating material. A second stream is a cold stream that is heated as it passes through the material. A third stream is a cleaning stream, which serves to remove particulates that are collected on the rotating material as the dirty syngas passes through it. This apparatus can also be used as an auto-heat exchanger, or it can exchange heat between separate flows in the gasifier process. The apparatus can also be used to reduce the heating requirement for the thermal residence chamber (TRC) used downstream from the gasification system.

Owner:INENTEC

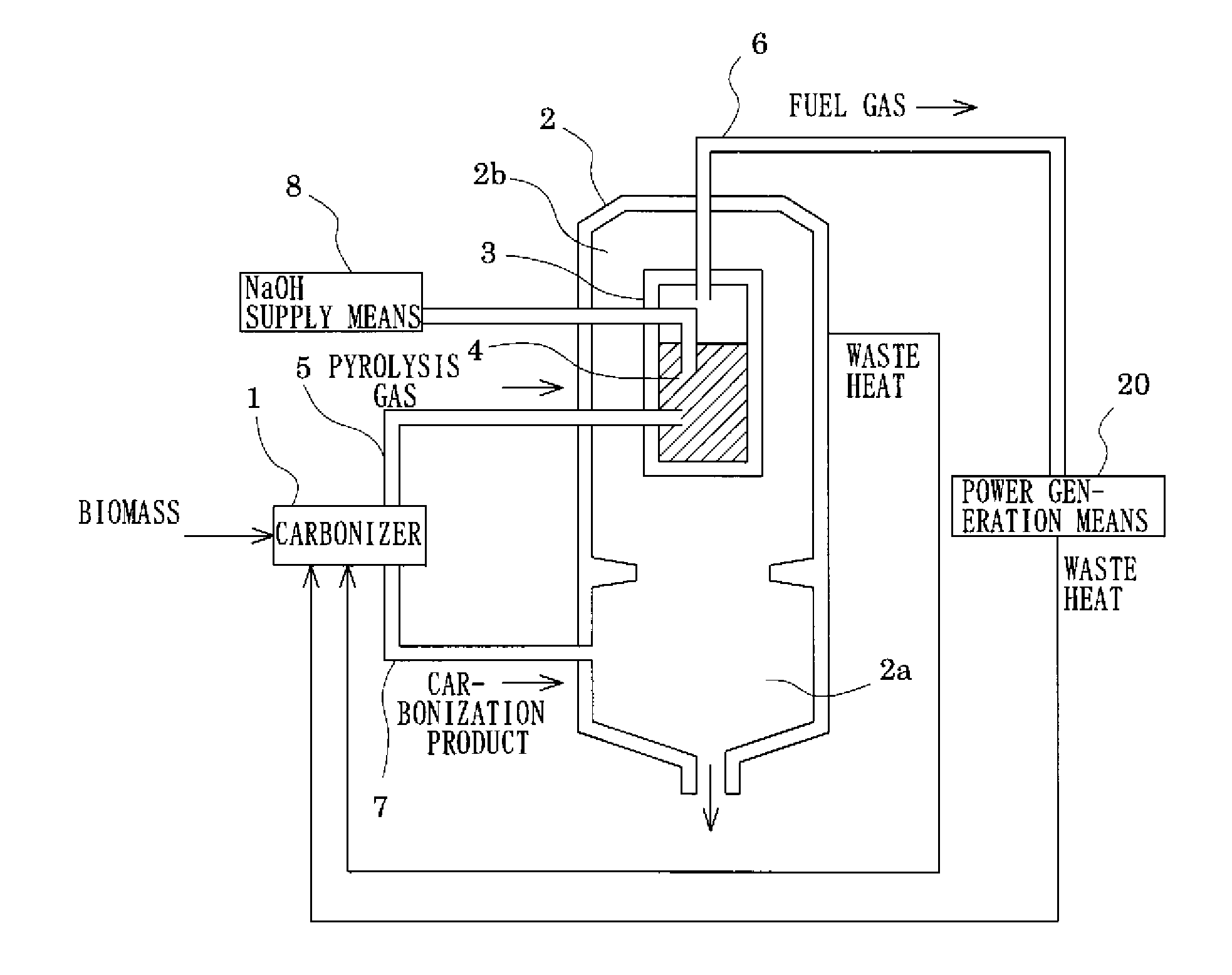

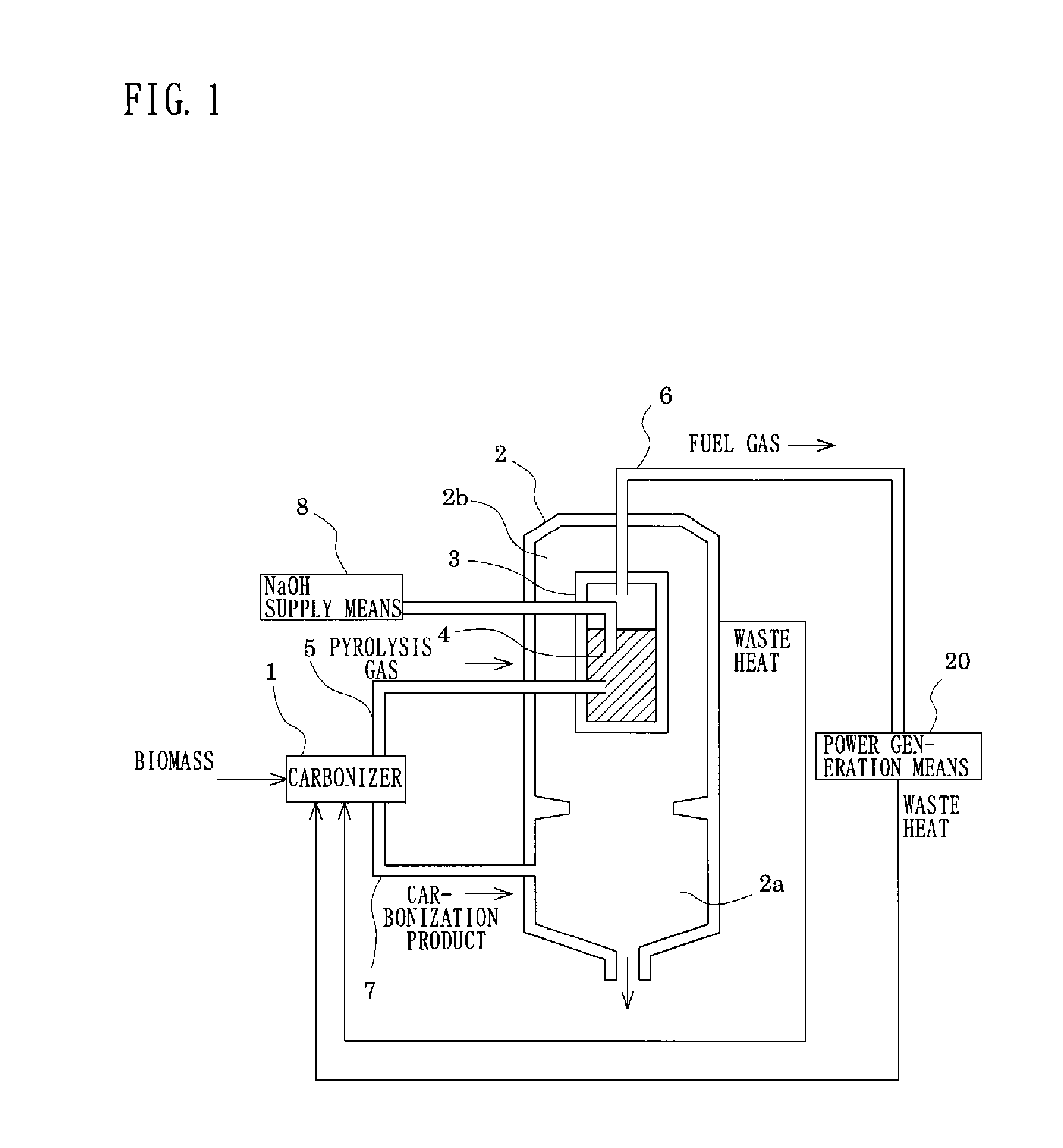

Fuel gas purification apparatus, power generation system, and fuel synthesis system

InactiveUS20100326087A1Simple configurationInternal combustion piston enginesBiofuelsNuclear engineeringCarbonization

Owner:CENTRAL RESEARCH INSTITUTE OF ELECTRIC POWER INDUSTRY

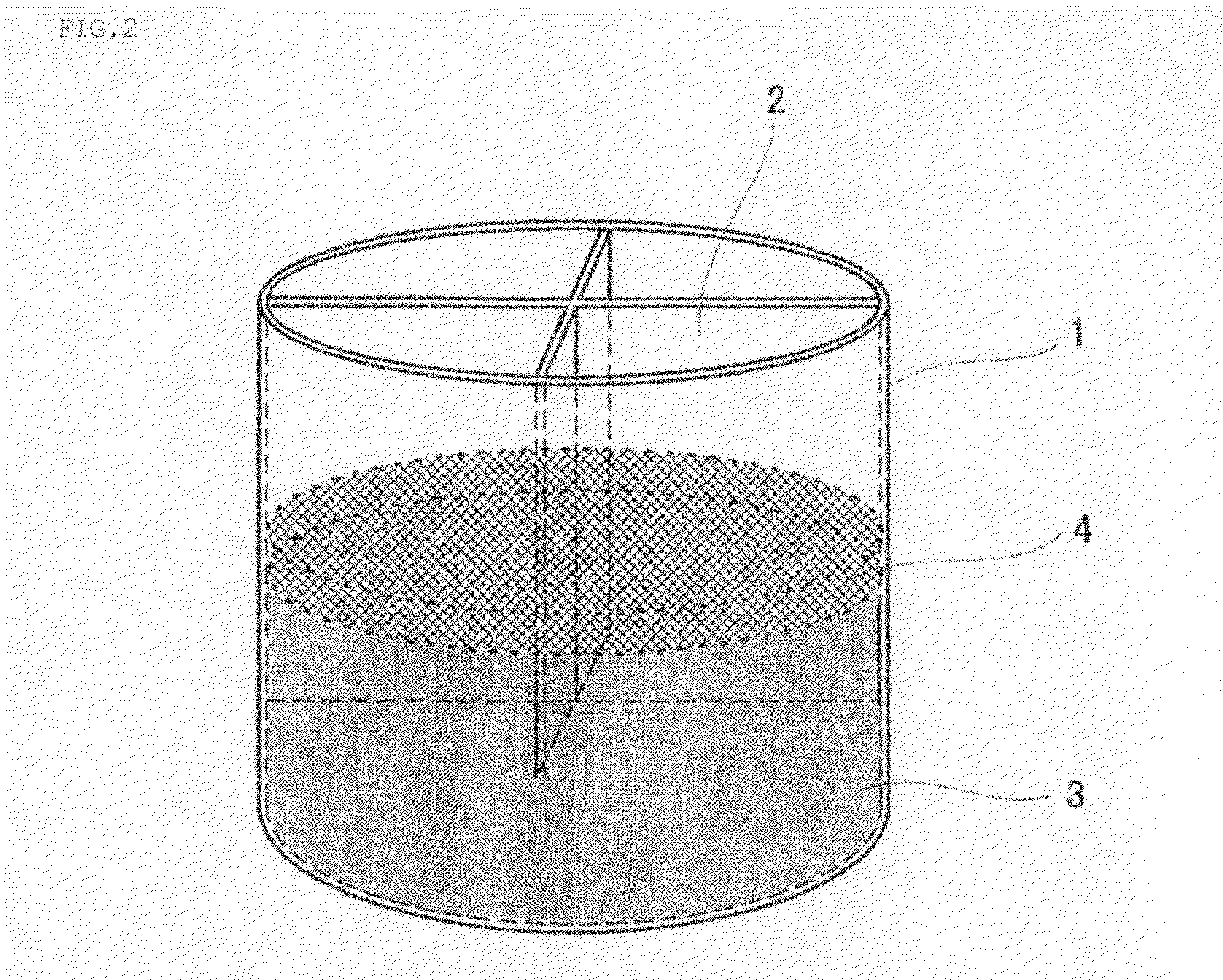

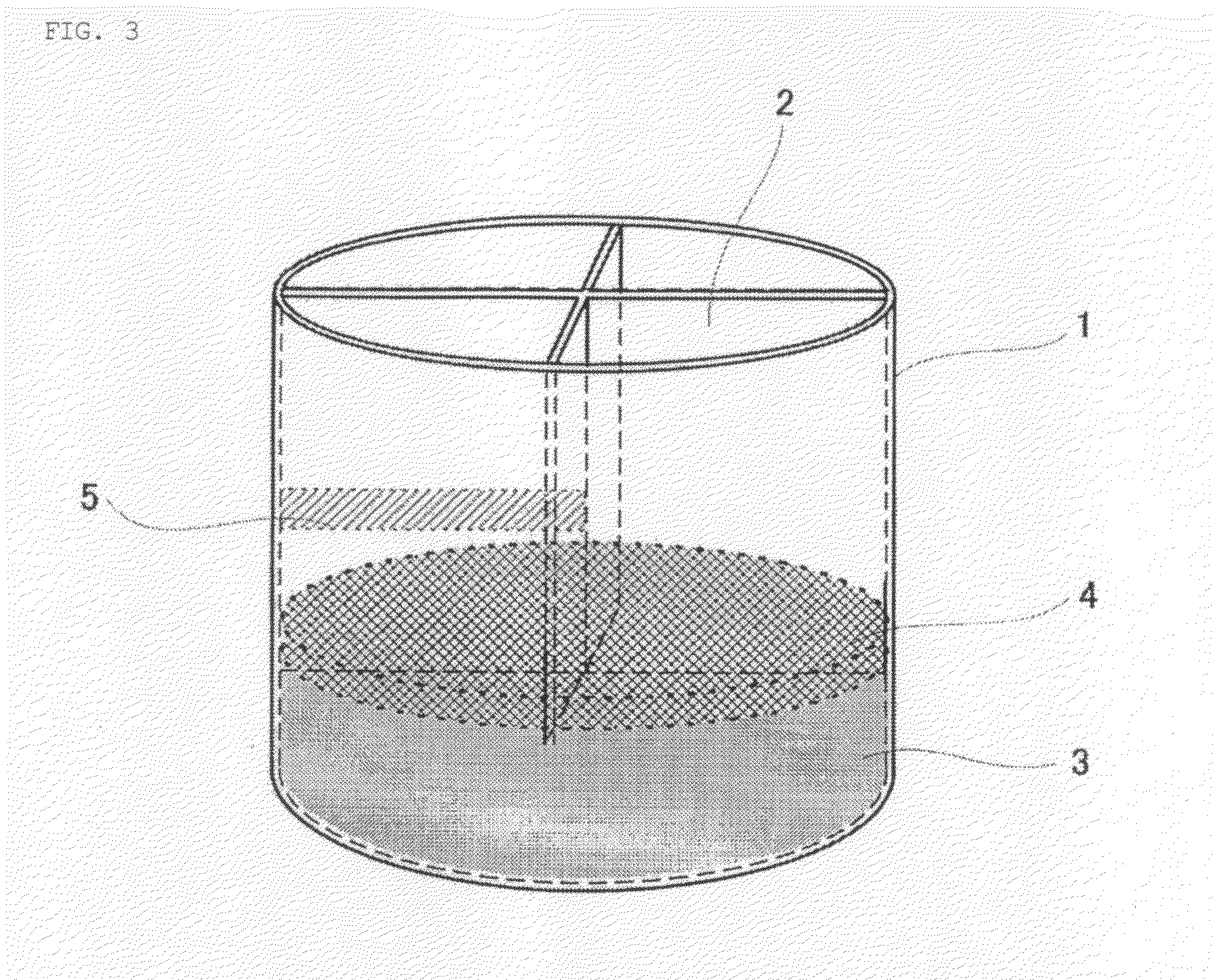

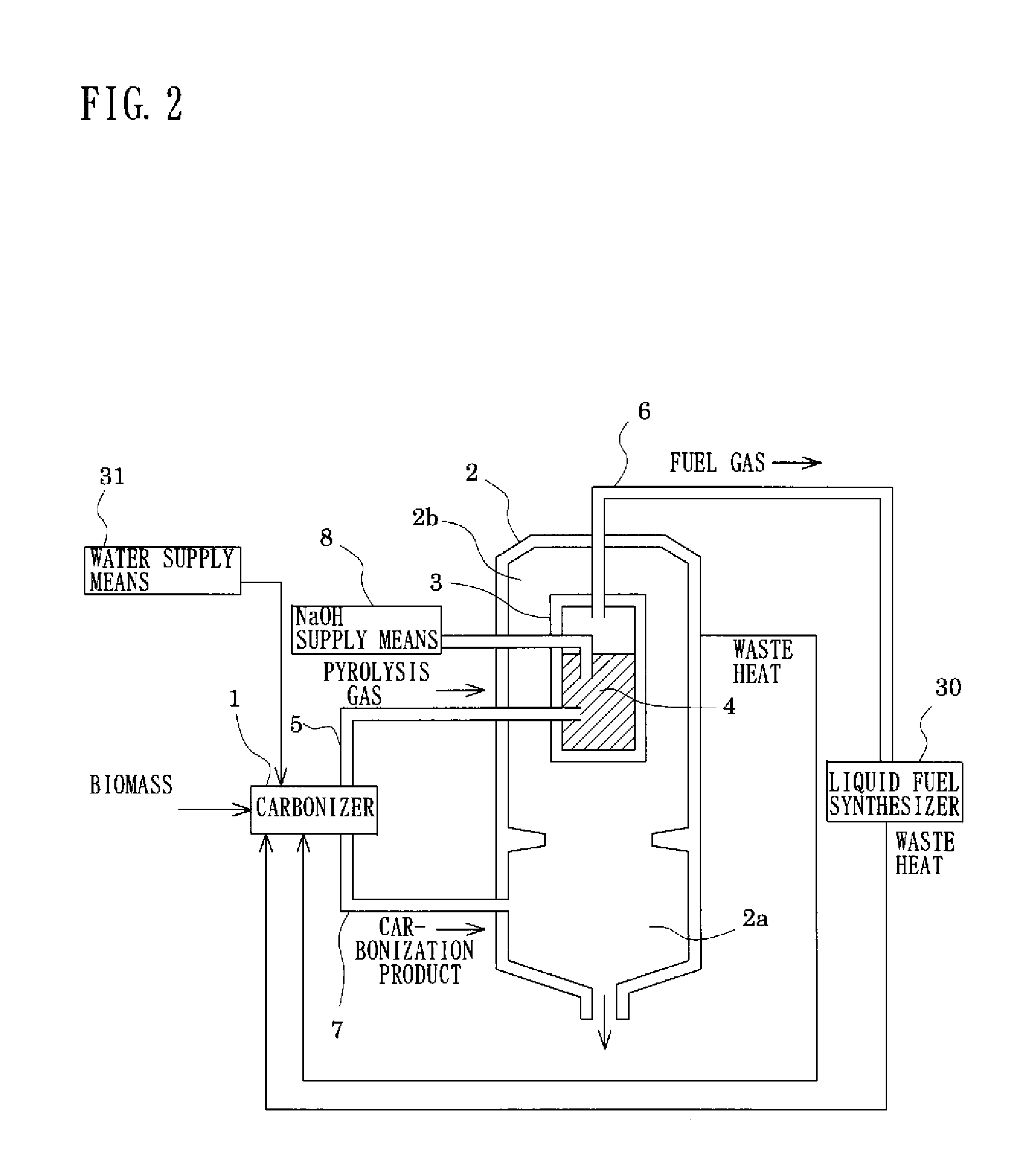

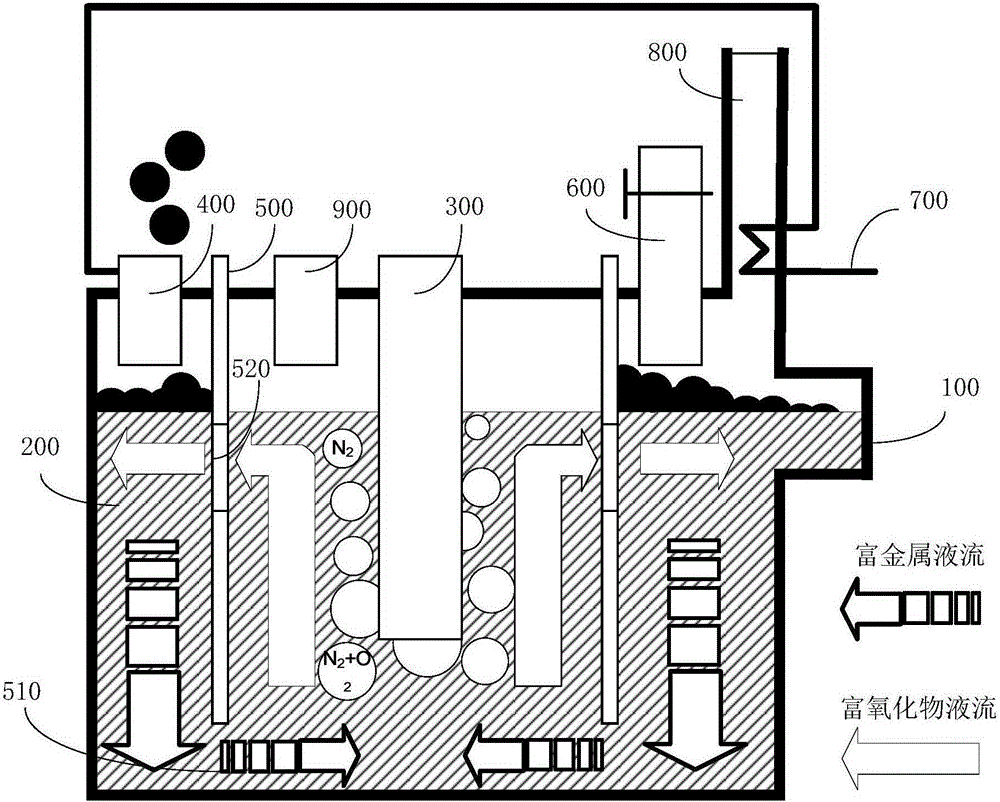

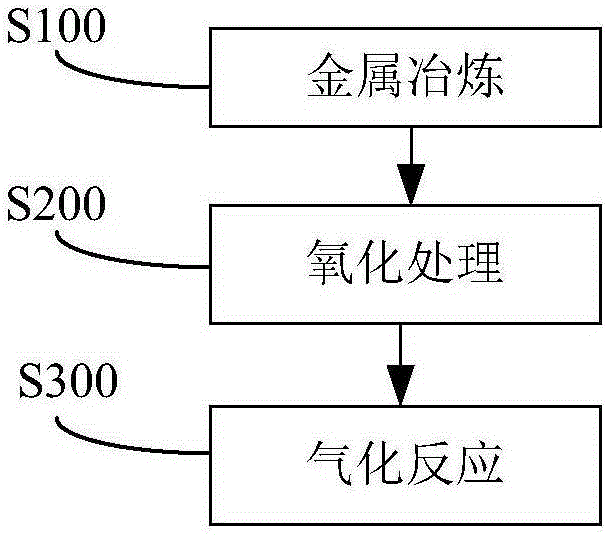

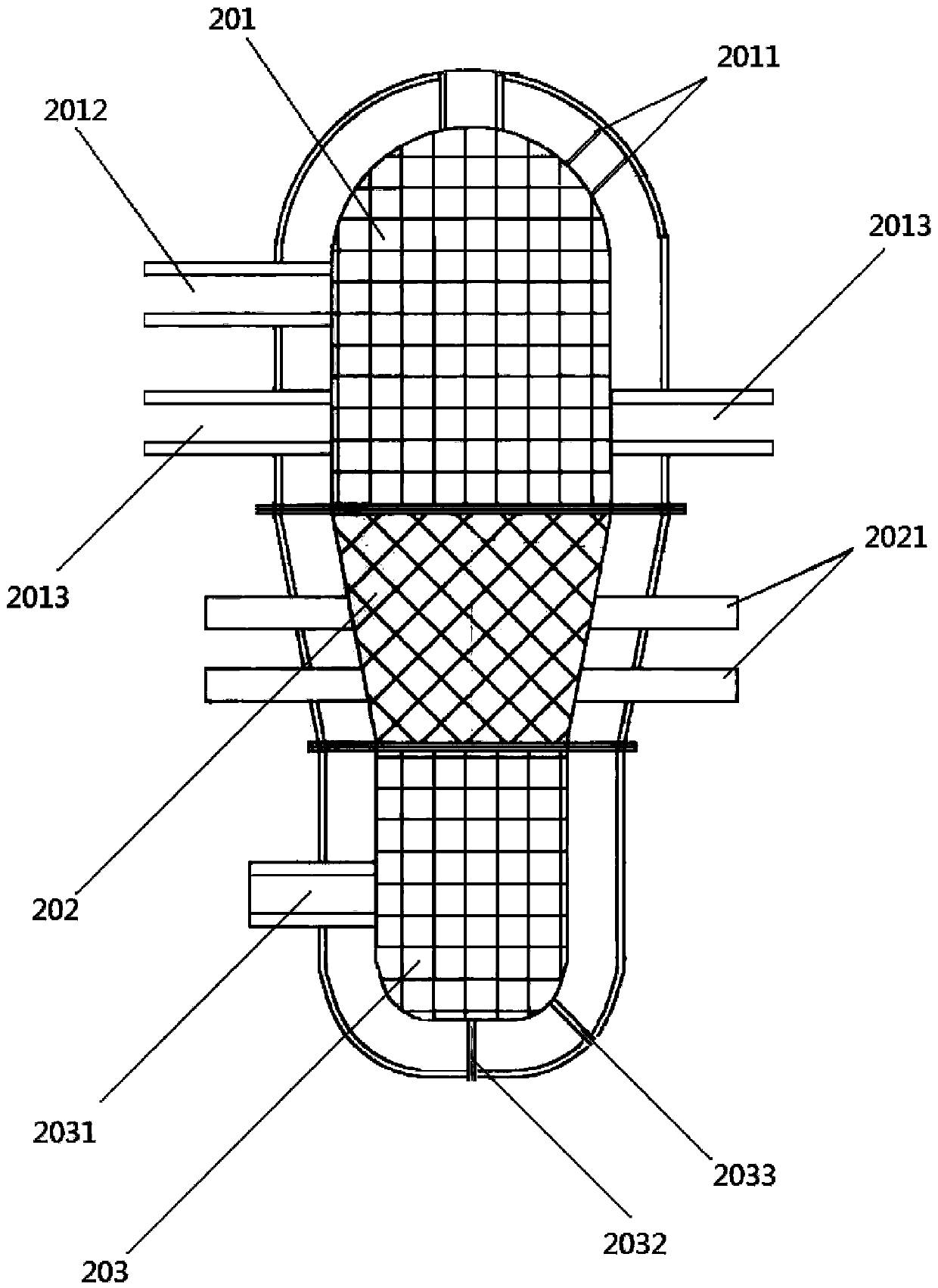

Gasifier and method for conducting gasification treatment on carbon-bearing raw materials

ActiveCN105176595ASimple structureGood mass transfer propertiesMolten salts/metals gasificationGranular/pulverulent flues gasificationSyngasDensity difference

The invention discloses a gasifier and method for conducting gasification treatment on carbon-bearing raw materials. The gasifier comprises a shell, a smelting pool, an air pipeline and a spray gun, wherein a smelting space is defined by the shell, the smelting pool is arranged at the bottom of the smelting space and used for smelting metal raw materials so as to obtain molten metal, the air pipeline is arranged on the shell, extends into the smelting pool and is used for providing air for the smelting pool so as to utilize the air to conduct oxidation treatment on the molten metal and obtain molten metal oxides, and the spray gun is arranged on the shell, extends into the smelting space and is used for providing the carbon-bearing raw materials and gasifying agents for the smelting space, so that the carbon-bearing raw materials make contact with the gasifying agents, the molten metal oxides and the molten metal, and synthesis gas of hydrogen and carbon monoxide is obtained. According to the gasifier, the density difference of metal and the metal oxides is utilized to serve as driving force, a high-temperature metal circulation pump which is high in price is not needed, and natural circulation of bed materials in the gasifier can be achieved.

Owner:TSINGHUA UNIV

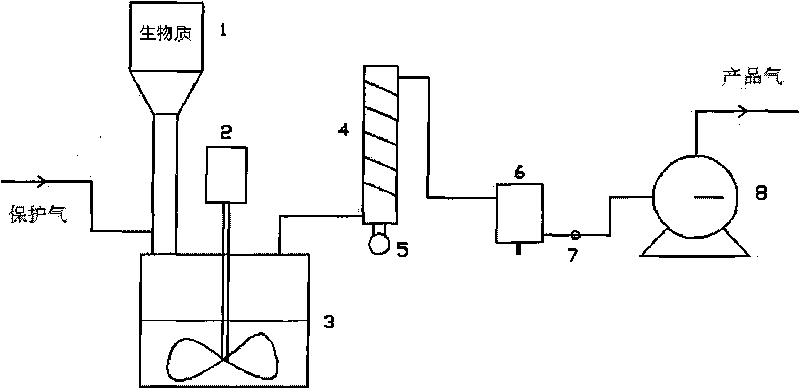

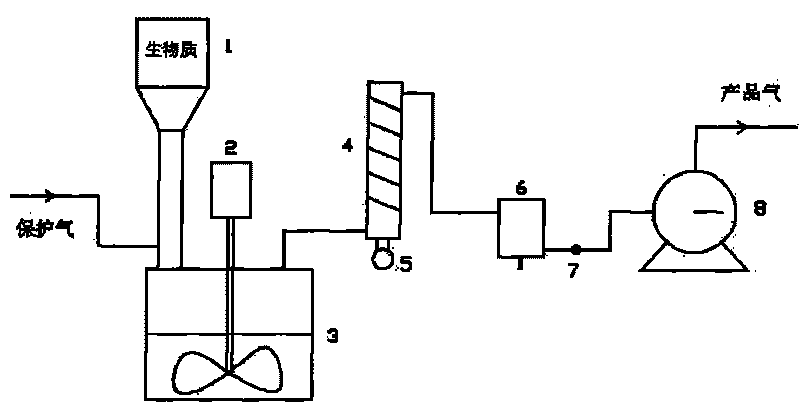

Process of generating hydrogen by cracking biomass with molten alkali

InactiveCN101759148AEasy to recycleRapid lysisHydrogen productionMolten salts/metals gasificationLiquid productGeneration process

The invention relates to a process of generating hydrogen by cracking biomass with a molten alkali. The process comprises the following steps: filling the molten alkali which is used as a heating, catalyzing and reacting medium into a reactor; introducing a protective gas into the reactor; and setting the reaction temperature between 320 and 900 DEG C and then at the preset temperature, adding the biomass into the reactor to depolymerize organic high polymers. The mass ratio of the molten alkali to the biomass is 50: 1-1: 1; and the pyrolysis product comprises a pyrolysis gas (which also can be called a product gas), a solid carbon and a liquid product. The process has the advantages that: the molten alkali is a good reacting catalyst, and is cheap and easily recyclable; the molten alkali is a good heating medium which quickly transfers heat to the biomass by tightly contacting the biomass so as to realize fast cracking of the biomass; the molten alkali used is low in temperature and can be operated at a relatively low temperature; and the hydrogen generation process has mild conditions, a cracking device is simple, the operation is convenient and the controllability is high.

Owner:ZHEJIANG UNIV OF TECH

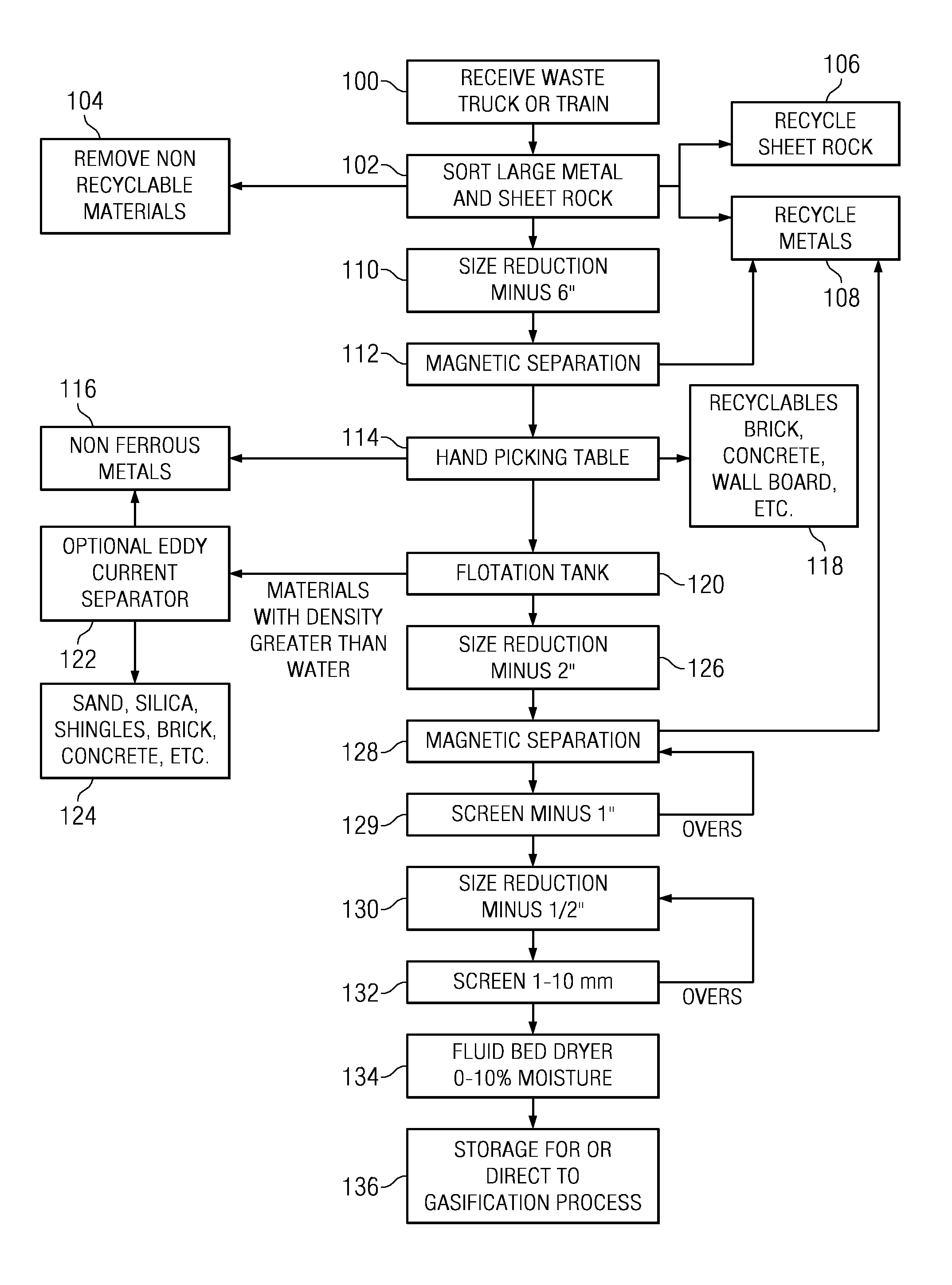

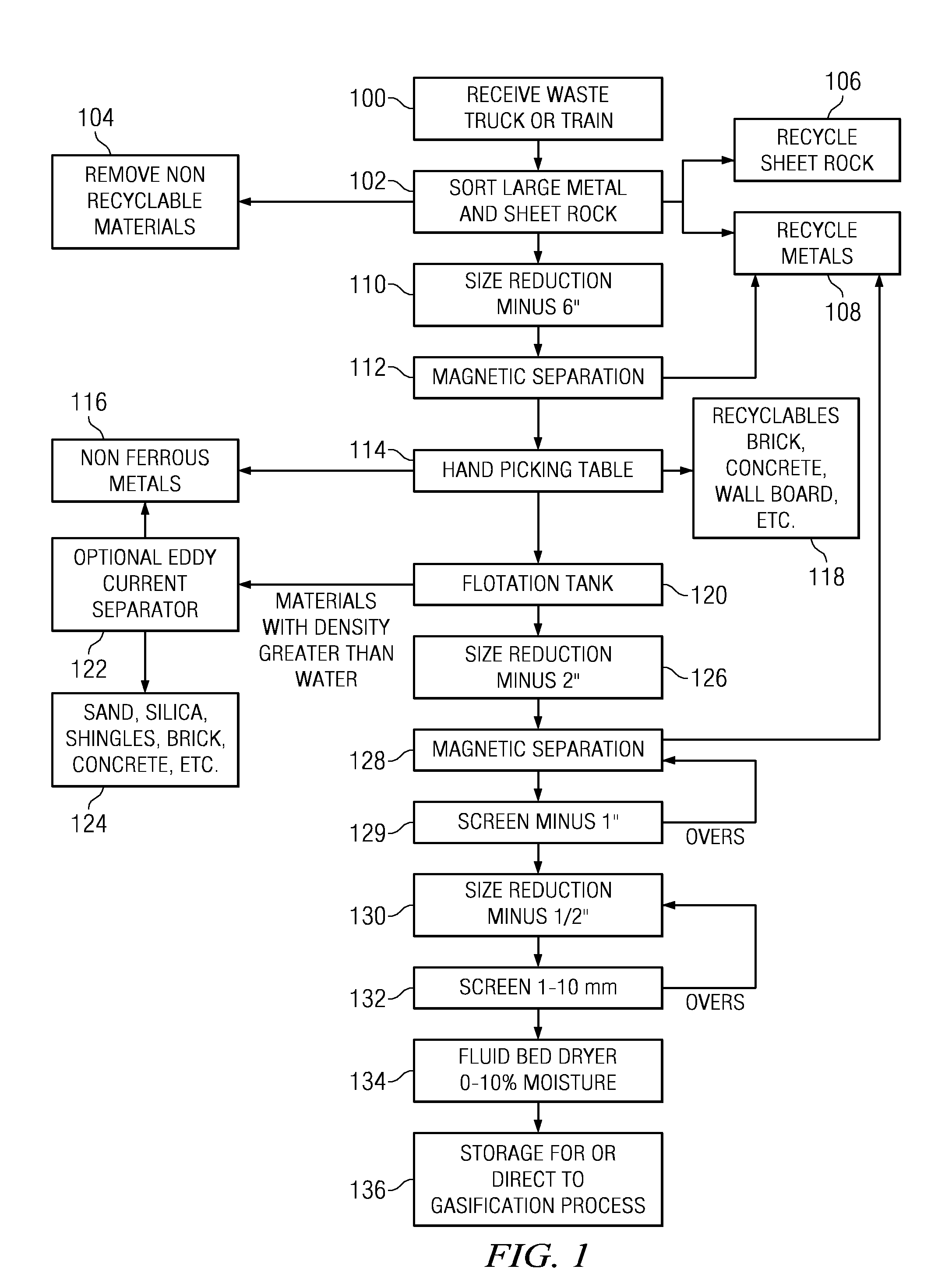

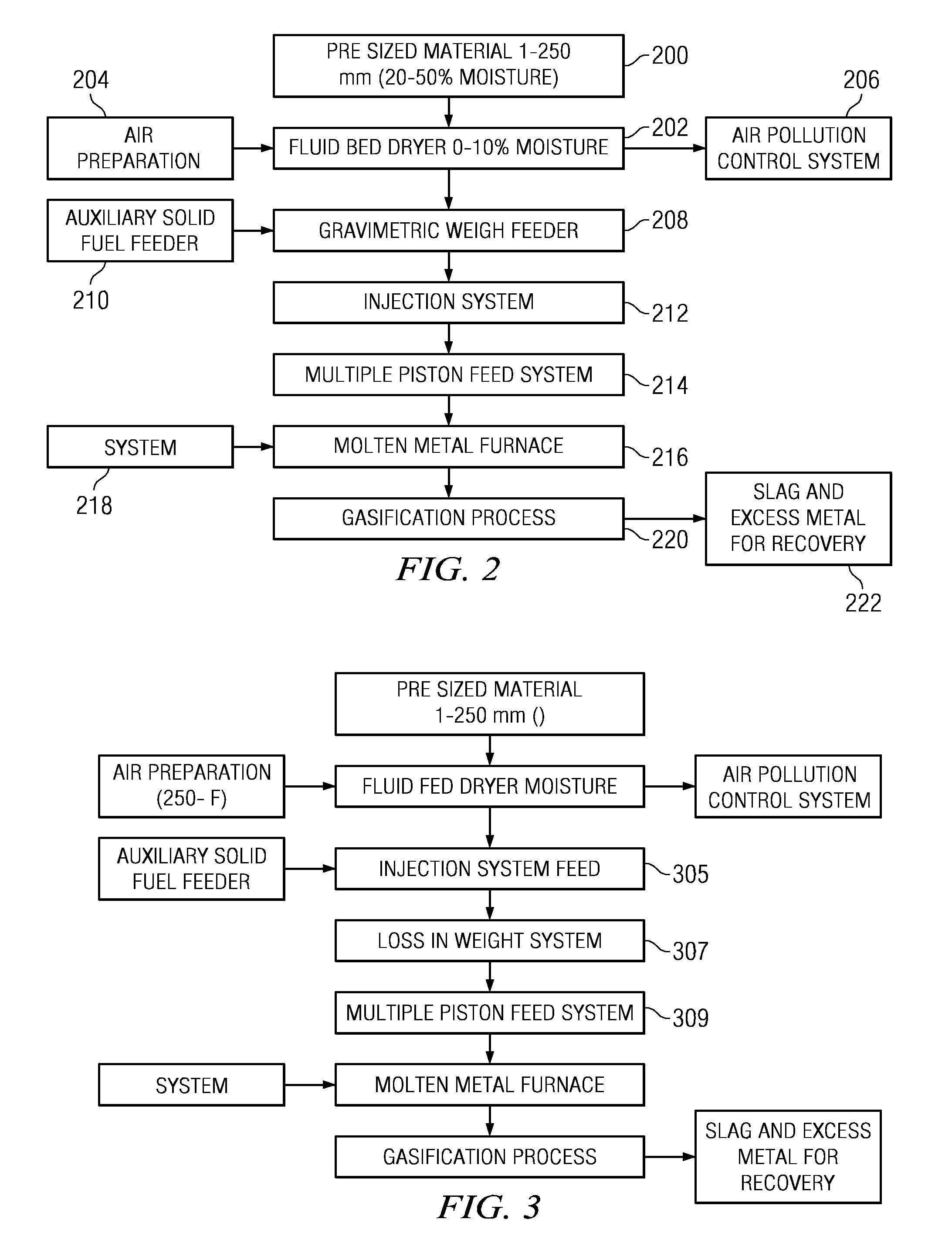

Construction & demolition debris (C&D) materials processing

InactiveUS20090188844A1Constant energy outputConstruction waste recoveryBiofuelsEnvironmental engineeringMaterials processing

A method of processing construction and demolition (C&D) debris at a location includes a set of processing steps. The method begins upon receipt of bulk C&D debris at the location. The bulk C&D debris is sorted into at least a first portion for further processing, and a second portion that is set aside. The first portion is then processed into a substantially homogenous wood waste material having particles of a given size by the unordered steps of shredding, screening, metals separation and flotation. The substantially homogenous wood waste material is then dried so that the particles have moisture content within a desired range. The wood waste material particles are then delivered into a molten metal bath at a submerged depth for gasification. Preferably, the process operates in a continuous or partially-continuous manner within a given facility, or within co-located facilities.

Owner:ZE-GEN

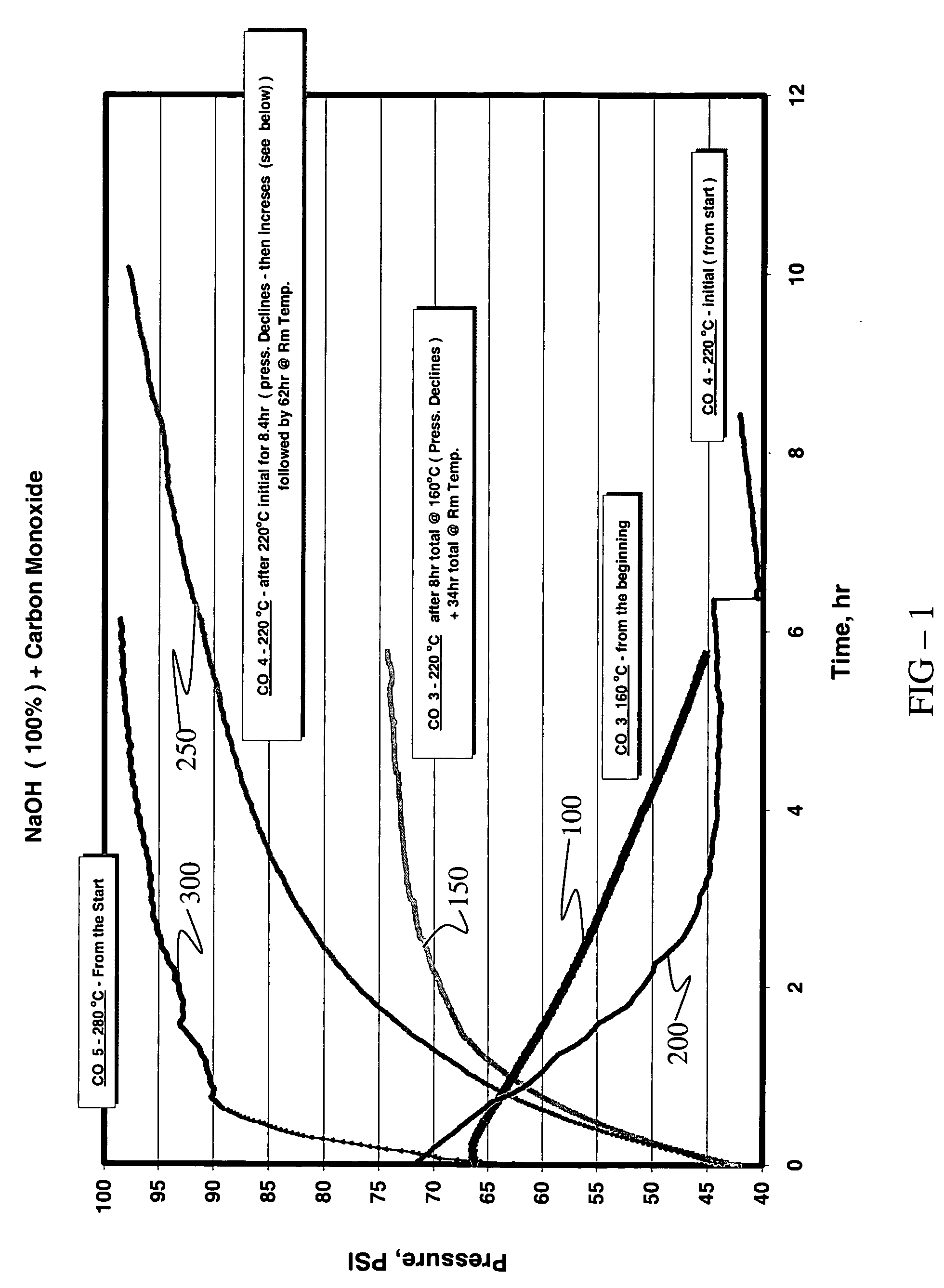

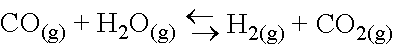

Production of hydrogen via a base-faciliated reaction of carbon monoxide

InactiveUS20050163706A1Improve thermodynamic spontaneityPromote conversionProductsElectrolysis componentsReaction rateRates reactions

A method of producing hydrogen gas from a reaction of carbon monoxide with a base. Hydrogen is produced in a reaction of a base with carbon monoxide that proceeds through the formation of a bicarbonate or carbonate compound as a by-product. In some embodiments, the reaction may occur in the presence of water and may produce carbon dioxide as a by-product. The instant base-facilitated hydrogen-producing reactions are thermodynamically more spontaneous than the water-gas shift reaction and are able to produce hydrogen gas from carbon monoxide at greater reaction rates than is possible with the water-gas shift reaction. Carbon monoxide in a purified or unpurified state or as a component within a mixture of gases is suitable for use in the instant invention. Metal hydroxides are the preferred base reactant. The base reactant can be in the solid phase, molten phase, liquid phase or solution phase.

Owner:TACTICAL FUEL CELLS

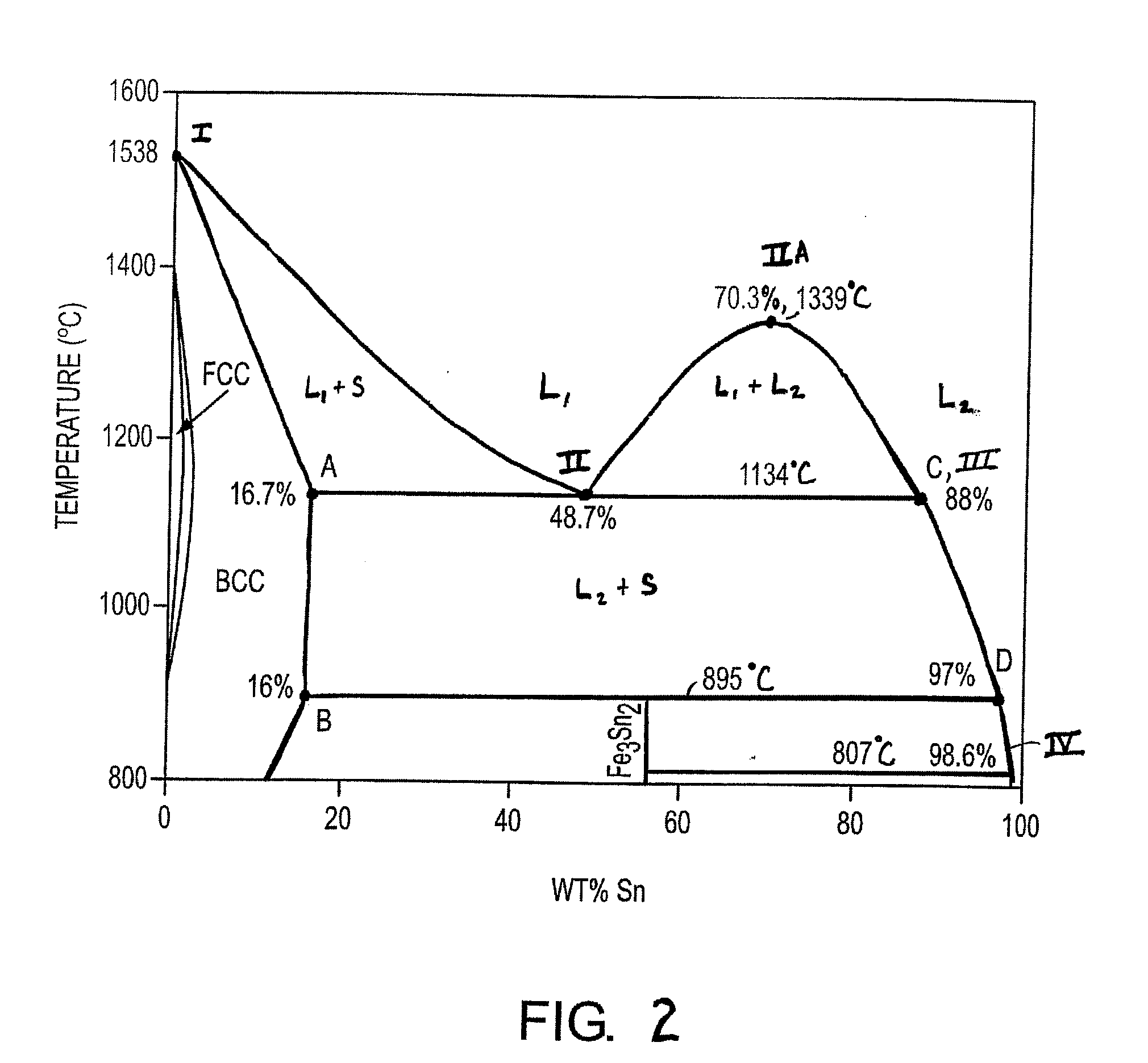

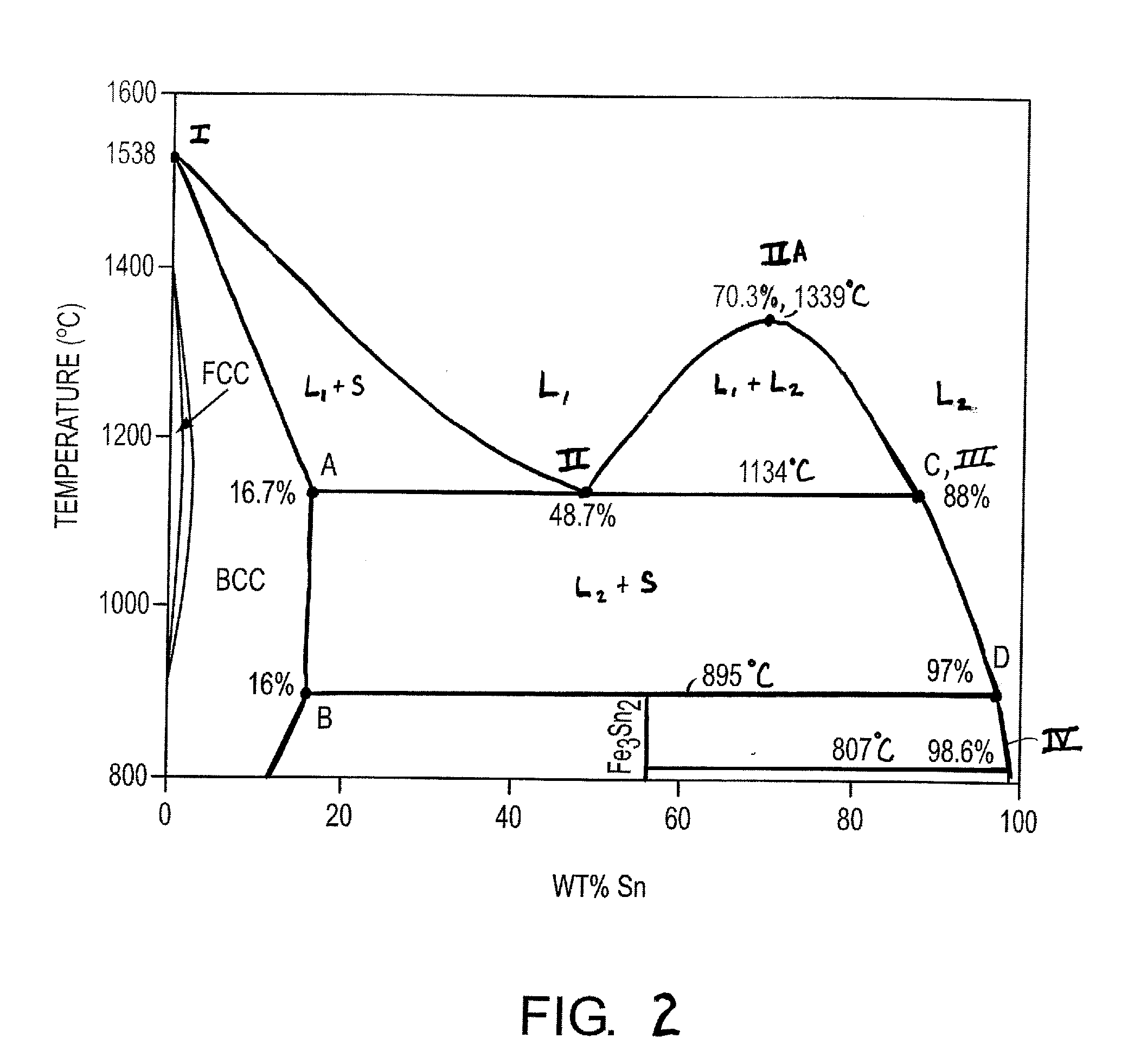

Gasification or Liquefaction of Coal Using a Metal Reactant Alloy Composition

ActiveUS20120304822A1Bond can breakDirect heating destructive distillationSulfur preparation/purificationElectricityCoal

This invention relates to a method and apparatus for gasifying or liquifying coal. In particular, the method comprises reacting a coal with a molten aluminum or aluminum alloy bath. The apparatus includes a reaction vessel for carrying out the reaction, as well as other equipment necessary for capturing and removing the reaction products. Further, the process can be used to cogenerate electricity using the excess heat generated by the process.

Owner:ELEMENTAL RECYCLING INC

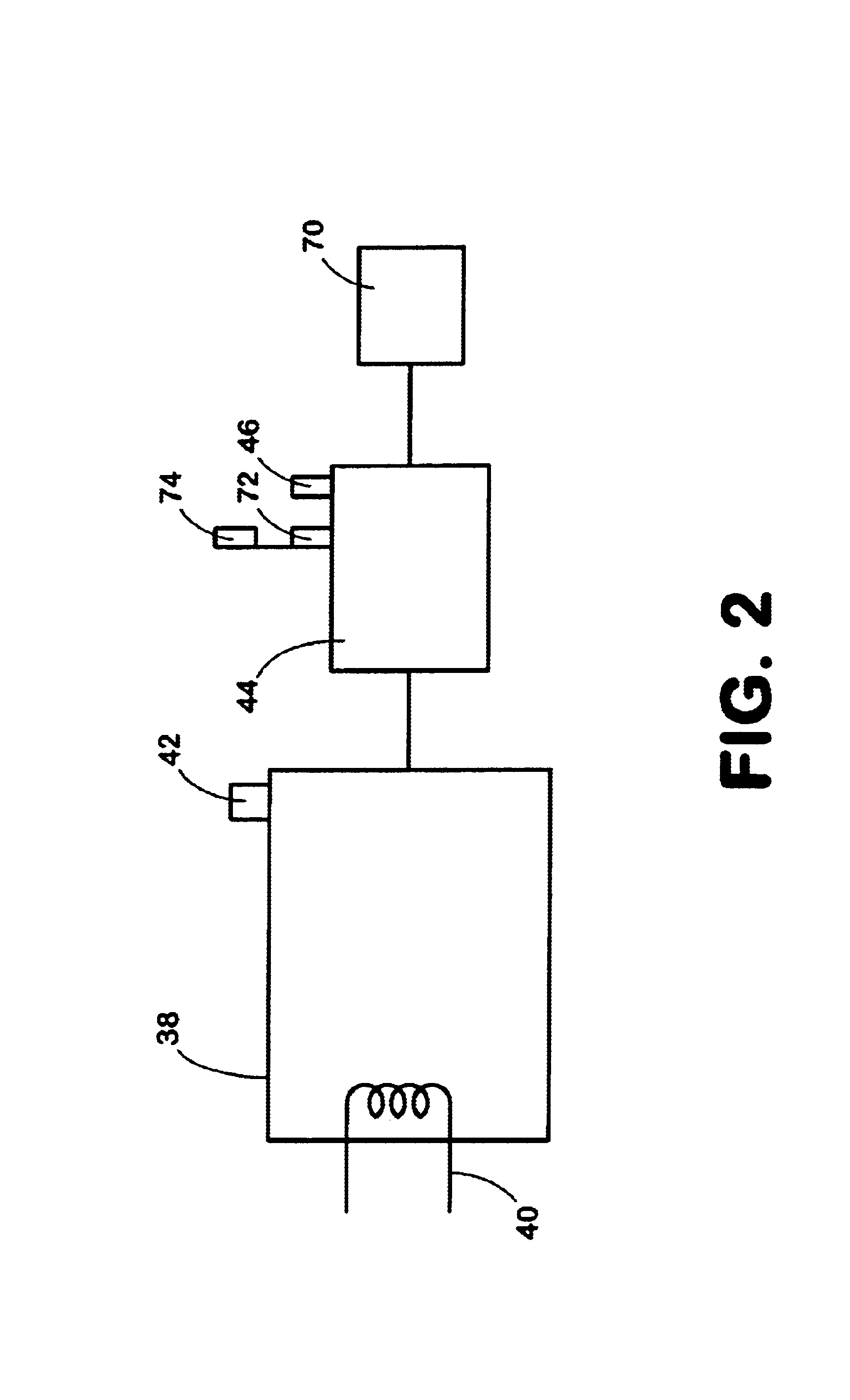

Melt gasifier system

A method to perform gasification in a gasification reactor is having a molten metal material disposed within a refractory lined vessel of the gasification reactor for converting a feed into product syngas by contacting feed into melt. A melt is formed by inductive melting by one or more induction coil apparatuses. A feed is injected into contact with the melt to dissolve at least a portion of the feed into the melt. A refractory-lined vessel is tilted at a pre-determined tilt angle about a horizontal plane to cause the refractory-lined vessel to be tilted at said pre-determined tilt angle from said horizontal plane during a conversion of the feed into a product syngas. A molten slag material is directed to flow away from the refractory-lined vessel at a predetermined molten slag material flow rate and product syngas is directed to flow from the refractory-lined vessel to a powerplant for electric power generation, a first chemical catalytic reactor to chemically reform product syngas into a determined hydrocarbon product, a second chemical catalytic reactor to chemically reform product syngas into anhydrous ammonia product, a third chemical catalytic reactor to chemically reform product syngas into methanol product, or a combination thereof.

Owner:GUEH HOW KIAP

Process and device for converting biomass to gaseous products

InactiveUS20090308726A1Improve responseAvoid failureDirect heating destructive distillationWaste based fuelMolten saltProcess engineering

A device for converting biomass with a water content of at least 50% to gaseous products includes a reactor filled at least partially with a packing including at least one filler body for accommodating supercritical water and a hydrothermal molten salt. A heater is arranged to heat up the reactor and its content. A first feeding pipe is coupled to the reactor to feed water and salt solution into the reactor. A second feeding pipe is coupled to the reactor to feed to biomass into the reactor. A discharge pipe is coupled to the reactor to discharge gaseous products from the reactor. An outlet is proved in the bottom of the reactor for removing portions of the molten salt.

Owner:KERNFORSCHUNGSZENTRUM KARLSRUHE GMBH

Solar gasifier

ActiveUS20130199093A1Improve efficiencyImprove the heating effectSolar heating energyMuffle furnacesPhotochemistryReaction chamber

In various embodiments, the present invention provides a reaction chamber, including a catalyst, and a heating chamber configured to receive light. The heating chamber is positioned underneath at least a portion of the reaction chamber.

Owner:RGT UNIV OF MINNESOTA

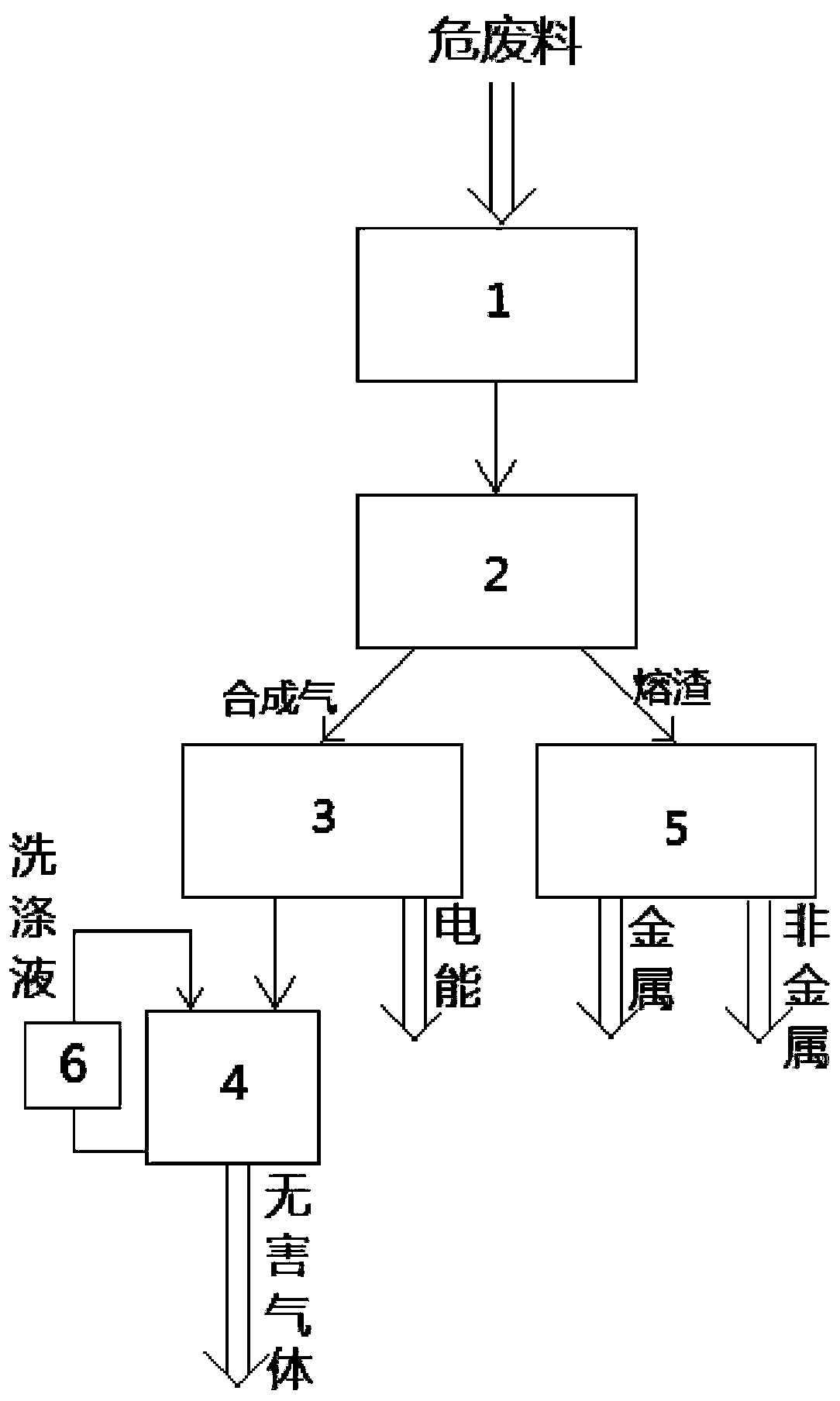

Harmless high-temperature plasma broad-spectrum waste treatment system

ActiveCN103962363AComplete gasificationEnsure diversitySolid waste disposalUsing liquid separation agentElectricitySyngas

The invention relates to the technical field of waste treatment, in particular to a waste treatment system. The harmless high-temperature plasma broad-spectrum waste treatment system comprises a feeding system, a plasmas treatment system, a synthesis gas recycling system, a residual gas treatment system, a washing circulating fluid regeneration treatment system and a waste residue treatment system, wherein the waste flows through the systems sequentially and is changed into slag and synthesis gas, the synthesis gas is recycled and used for generating electricity, produced tail gas is purified and discharged, the washing fluid is treated and recycled, and the slag is recovered and reused. With the adoption of the technical scheme, the defects of single waste treatment type and incomplete treatment by means of a conventional technology are overcome, a secondary pollution source cannot be generated, waste heat and the synthesis gas are sufficiently recovered, the treated slag can further be recycled to generate new economic benefits, resource recycling is further facilitated while the environment is protected, and the harmless high-temperature plasma broad-spectrum waste treatment system has huge social and economic values and commercial utilization prospect.

Owner:吉天师能源科技(上海)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com