Process of generating hydrogen by cracking biomass with molten alkali

A technology of molten alkali and biomass, which is applied in the field of hydrogen production from molten alkali cracking biomass, which can solve the problems of low hydrogen yield, harsh process conditions, and high temperature and pressure, and achieve low melting temperature, good controllability, and hydrogen production The effect of mild process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0017] Using sodium hydroxide as the heating medium, the reactor was heated to 450°C, nitrogen protective gas was introduced at a flow rate of 240L / h, and then 34.9g of rice straw was added. The straw begins to crack rapidly in the reactor. The pyrolysis product is 1.8g solid charcoal, 2.2g liquid product (wherein water content is 95%), 42.97L product gas. The product gas contains H2 in the product gas through gas chromatography analysis and is 69.69% (v%, the same below), CH4 is 16.69%, and O2 is 13.62%. The hydrogen yield was 0.80 Nm3 / kg rice straw, or 71.28 g / kg rice straw.

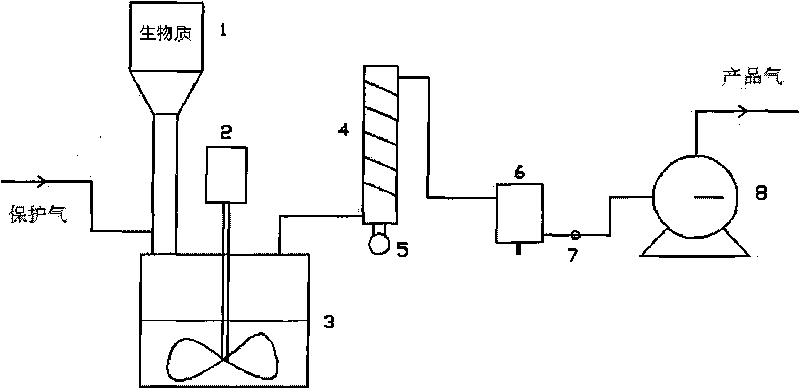

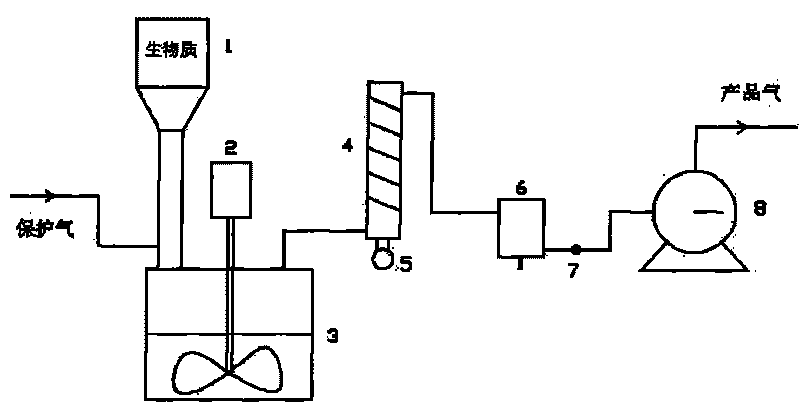

[0018] A kind of technological process of the above-mentioned molten alkali cracking biomass hydrogen production is as attached figure 1 shown. The operation process is as follows: put the alkali in the reaction kettle 3, heat it to the set temperature, pass in the protective gas, turn on the stirring motor 2, and use the biomass as the processed material to continuously enter the reaction kettle fr...

example 2

[0020] Using sodium hydroxide as the heating medium, when the reactor is heated to 400°C, a nitrogen protective gas is introduced at a flow rate of 240L / h, and then 46.3g of rice straw is added. The straw begins to crack rapidly in the reactor. The pyrolysis product is 1.2g solid charcoal, 2.6g liquid product (water content 95%), and 48.2L product gas. The product gas contained H2 was 71.50% (v%, the same below) through gas chromatography analysis, CH4 was 20.31%, and O2 was 8.19%. The hydrogen yield was 0.69Nm3 / kg rice straw.

example 3

[0022] Using potassium hydroxide as the heating medium, the reactor was heated to 400°C, nitrogen protective gas was introduced at a flow rate of 240L / h, and then 44.5g of rice straw was added. The straw begins to crack rapidly in the reactor. The pyrolysis product is 1.0g solid charcoal, 1.0g liquid product (95.6% water content), 40.6L product gas. The product gas contains H2 in the product gas through gas chromatography analysis and is 77.87% (v%, the same below), CH4 is 14.59%, and O2 is 7.54%. The hydrogen yield was 0.66Nm3 / kg rice straw.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com