Patents

Literature

97results about How to "Rapid lysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Combined lysis and PCR buffer

InactiveUS20060286557A1Permit long-term storageRapid lysisMicrobiological testing/measurementMicroorganism lysisLysisNucleic acid sequencing

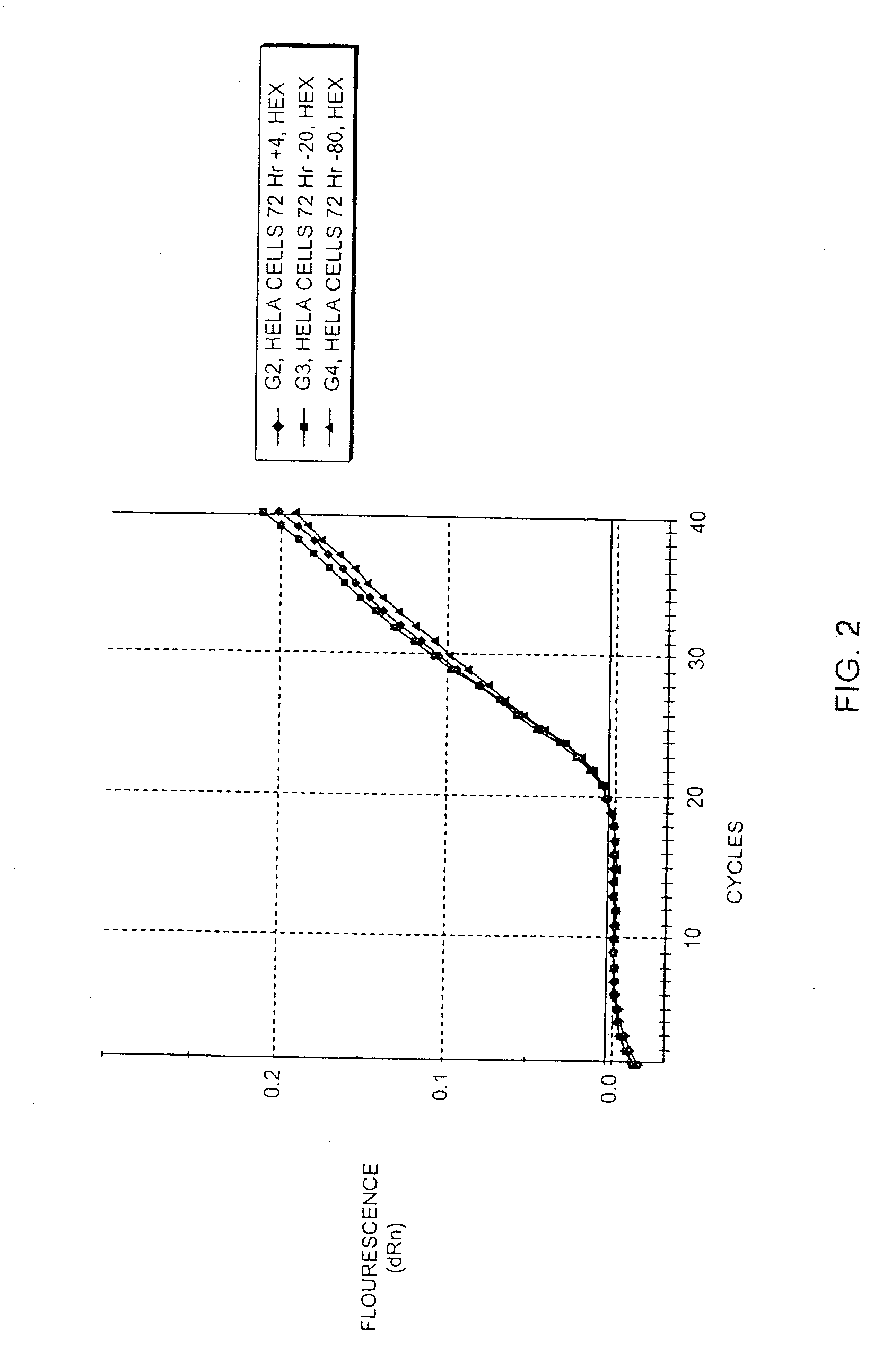

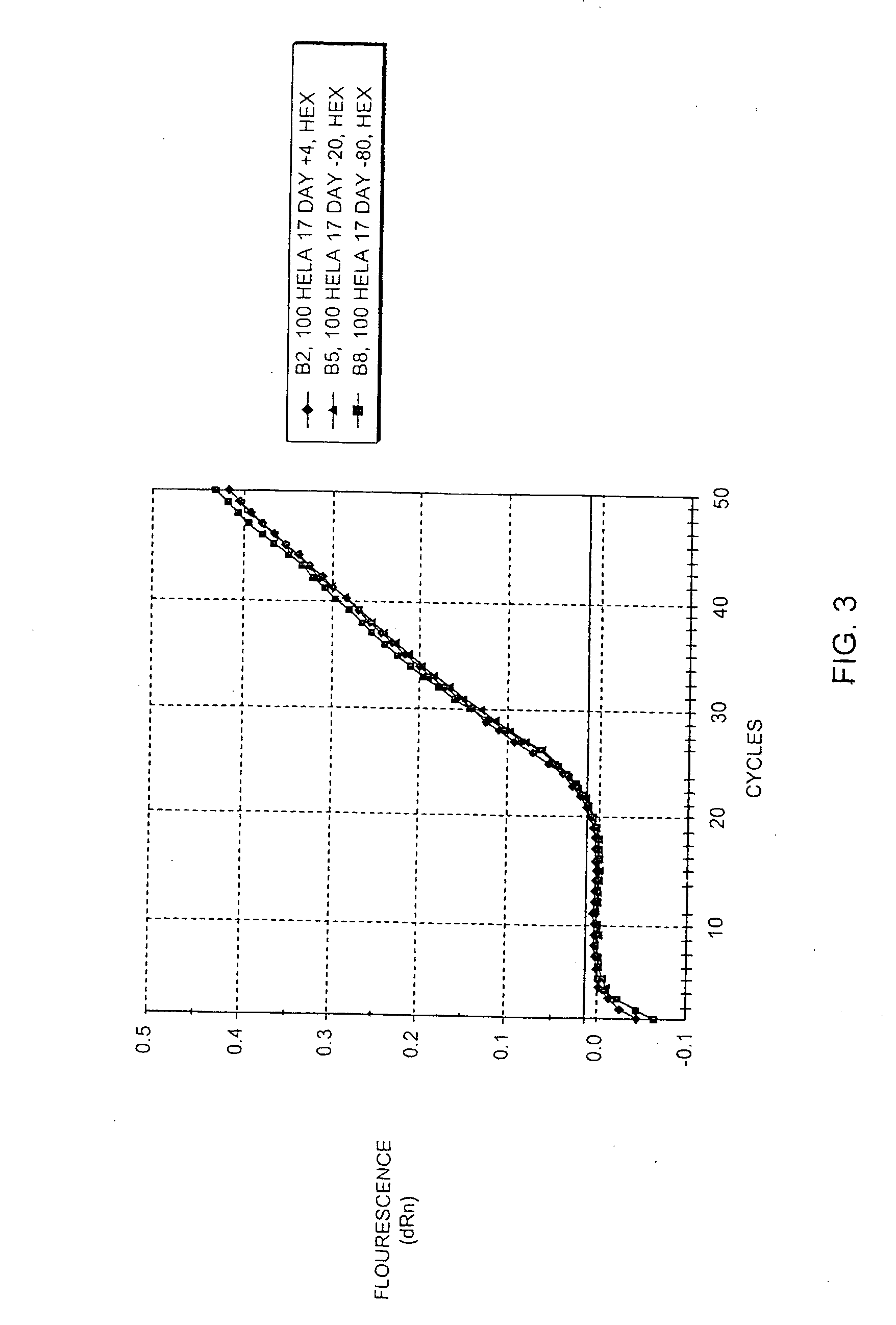

The present invention provides compositions, methods, and kits for lysing cells, storing nucleic acids, amplifying nucleic, and analyzing nucleic acids. Among other things, the compositions, methods, and kits are suitable for one-step lysis and amplification of nucleic acid sequences of interest. In general, the compositions comprise TCEP and a non-ionic detergent, such as Triton X-100.

Owner:STRATAGENE INC US

Lysis and stabilization buffer suitable for inclusion in PCR reactions

InactiveUS20070015185A1Permit long-term storageRapid lysisSugar derivativesMicrobiological testing/measurementLysisNucleic acid sequencing

The present invention provides compositions, methods, and kits for lysing cells, storing nucleic acids, amplifying nucleic acids, and analyzing nucleic acids. Among other things, the compositions, methods, and kits are suitable for one-step lysis and amplification of nucleic acid sequences of interest. In general, the compositions comprise TCEP and a non-ionic surfactant, such as Triton X-100.

Owner:STRATAGENE INC US

Liquid bacterial agent for rooting

InactiveCN103183567AQuick refillQuickly replenish crop deficient elements, crackingFertilizer mixturesDiseaseSolubility

The invention discloses a liquid bacterial agent for rooting, which comprises the following raw materials by weight parts: 20-80 parts of concentrated amino acid fermented liquid, 15-30 parts of urea, 5-20 parts of potassium fulvic acid, 10-20 parts of alginic acid, 5-15 parts of chitosan, 10-30 parts of bacillus subtilis, 5-20 parts of Alpha-pimacol, 10-35 parts of sodium nitrophenolate, 1-4 parts of indole butyric acid potassium, 5-15 parts of 5-nitrate and 10-20 parts of calcium nitrate. According to the invention, the liquid bacterial agent contains various high-activity strains including bacillus laterospor, bacillus licheniformis, bacillus subtilis and the like and dozens of high-purity nutritional ingredients. The liquid bacterial agent has super strong activity, and can quickly reach nutrient deficiency parts and bacteria infection parts of crops after being used so as to quickly complement the deficient elements, and can split mycelium and spore and remove soil-borne diseases so as to allow the crops to be quickly back to health. The liquid bacterial agent has the advantages of good water solubility, strong absorption ability, non-public hazard, no residue and no volatility after being used, and can not cause poison damage for the crops in the greenhouse.

Owner:张元宝

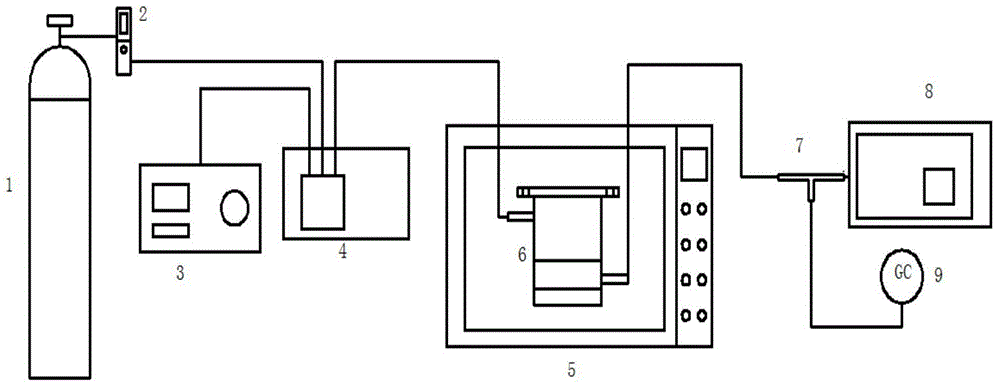

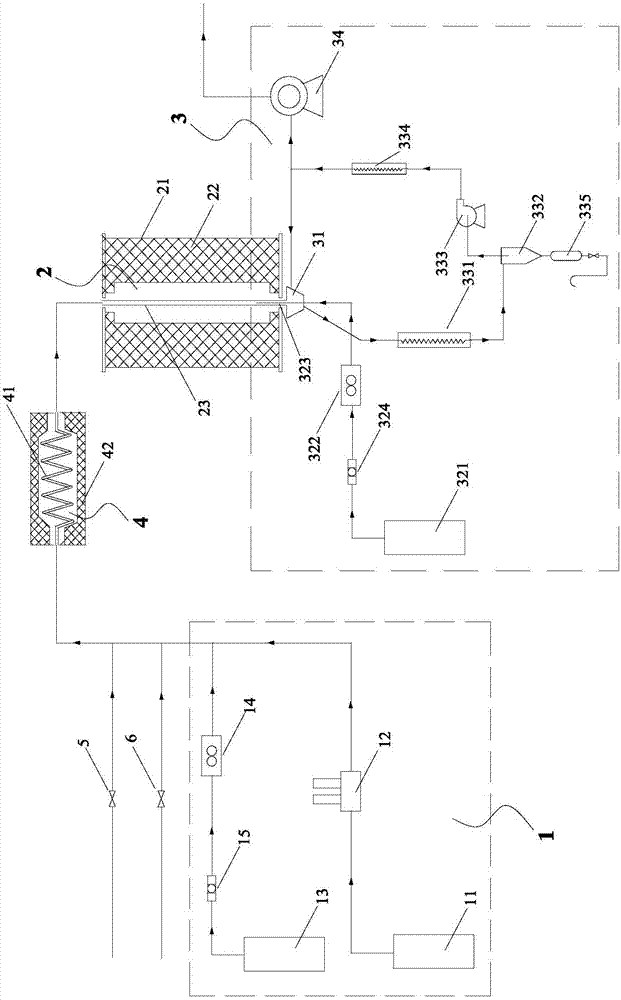

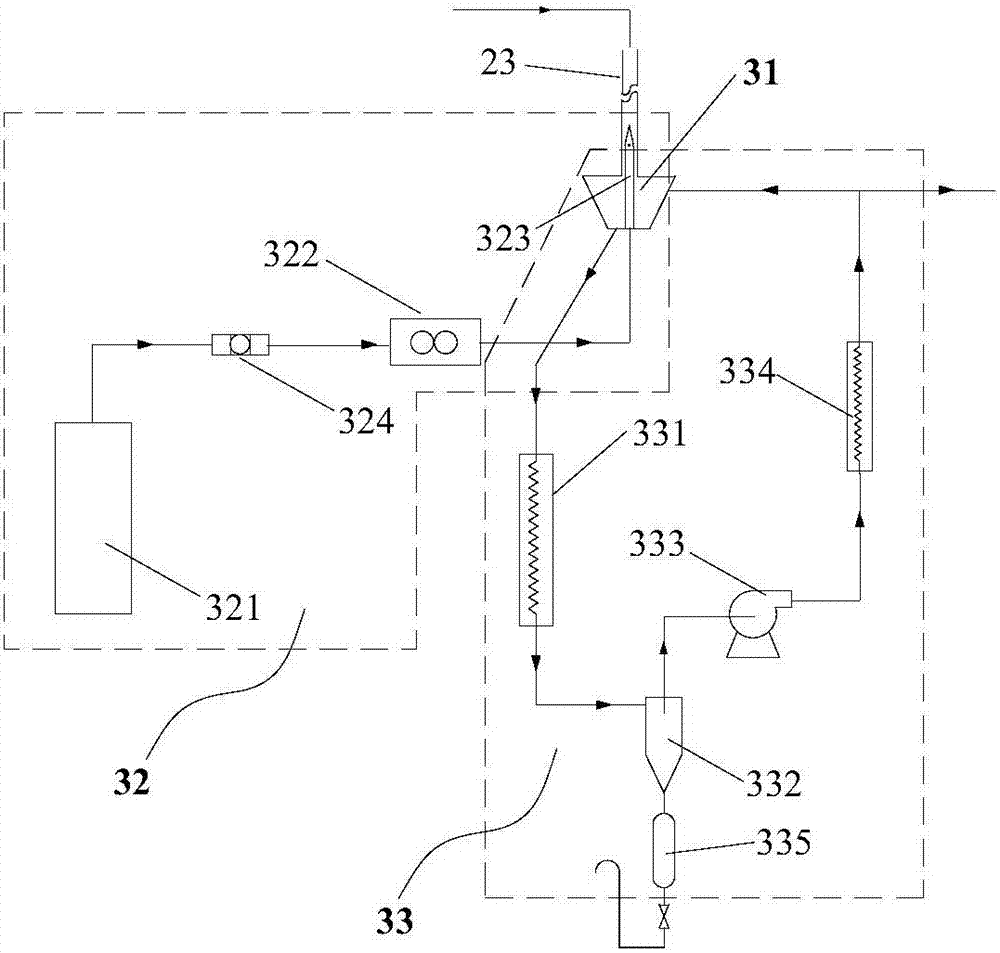

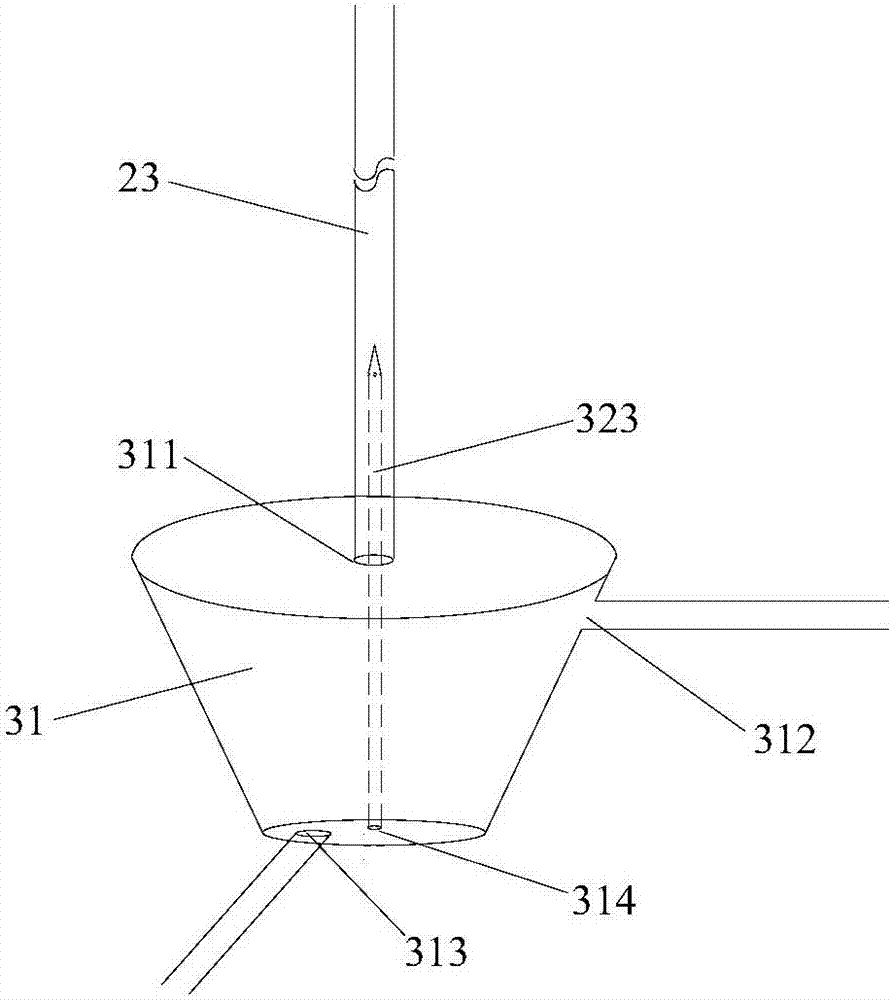

Kerosene heating system for supersonics burning test bed

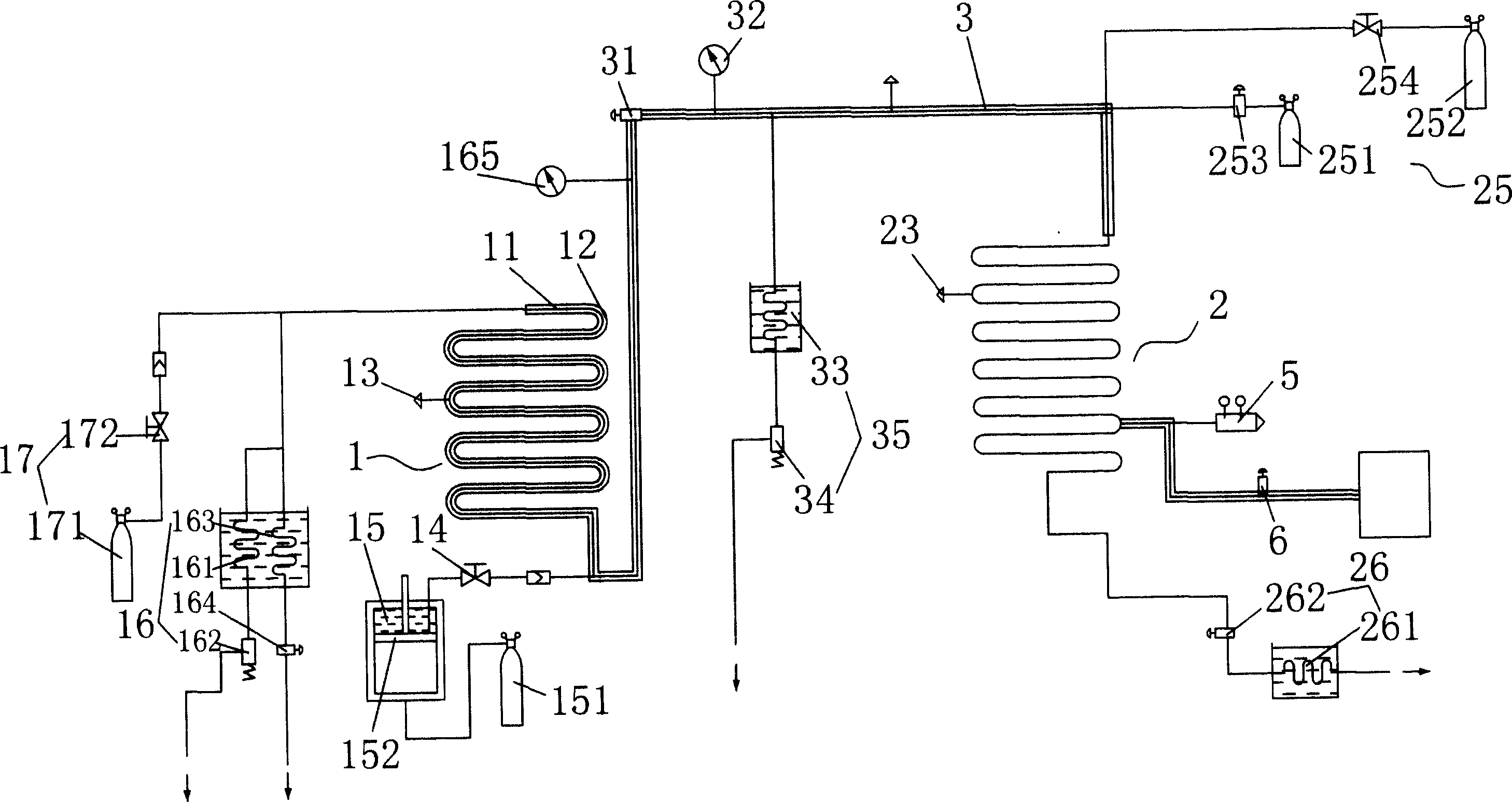

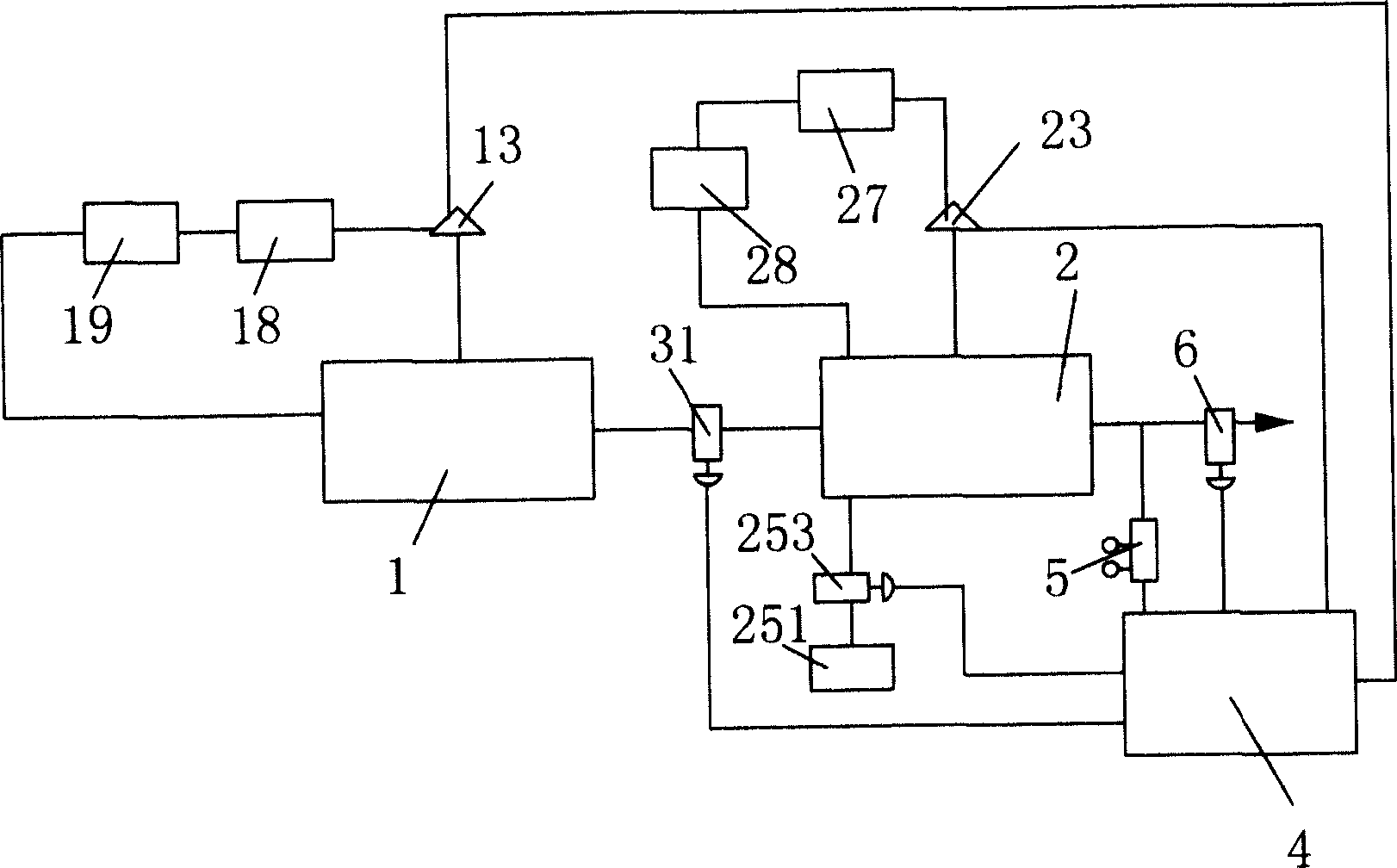

InactiveCN1687661AShorten the timeRapid lysisEngine testingPreparing sample for investigationCombustion chamberKerosene

The invention discloses a kerosene heating system for hypersonic combustion test-bed use. It is characterized in that the system comprises the primary heater and the secondary heater connecting the combustion chamber, and the primary and the secondary heaters are linked by the pipeline and the valves are set on the pipeline and between the combustion chamber and the secondary heater. The invention adopts the second-level heating to shorten the time that the kerosene is in the high temperature state and makes the kerosene split quickly in flowing state and greatly reduces the gathering and depositing of the coal.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

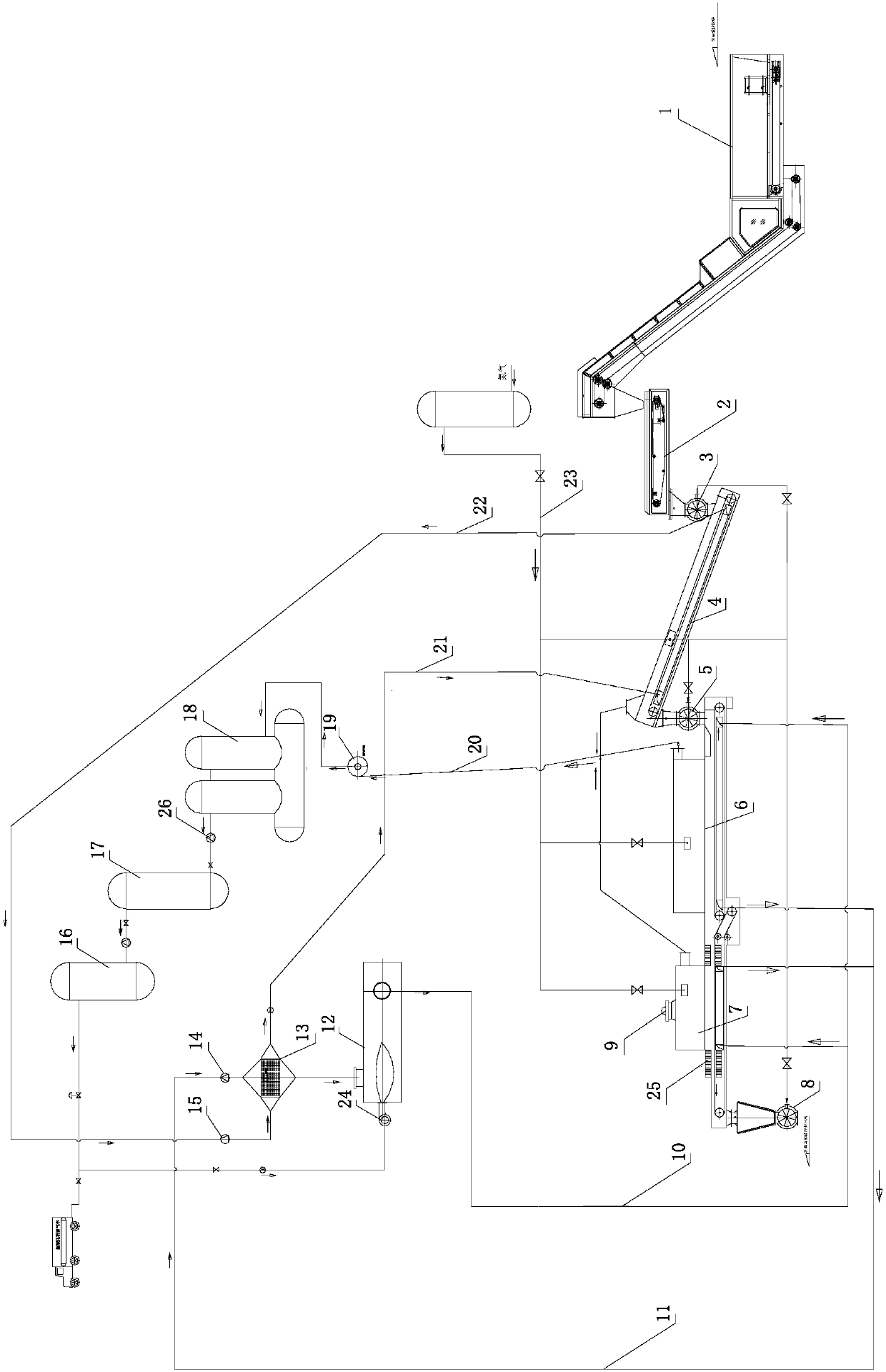

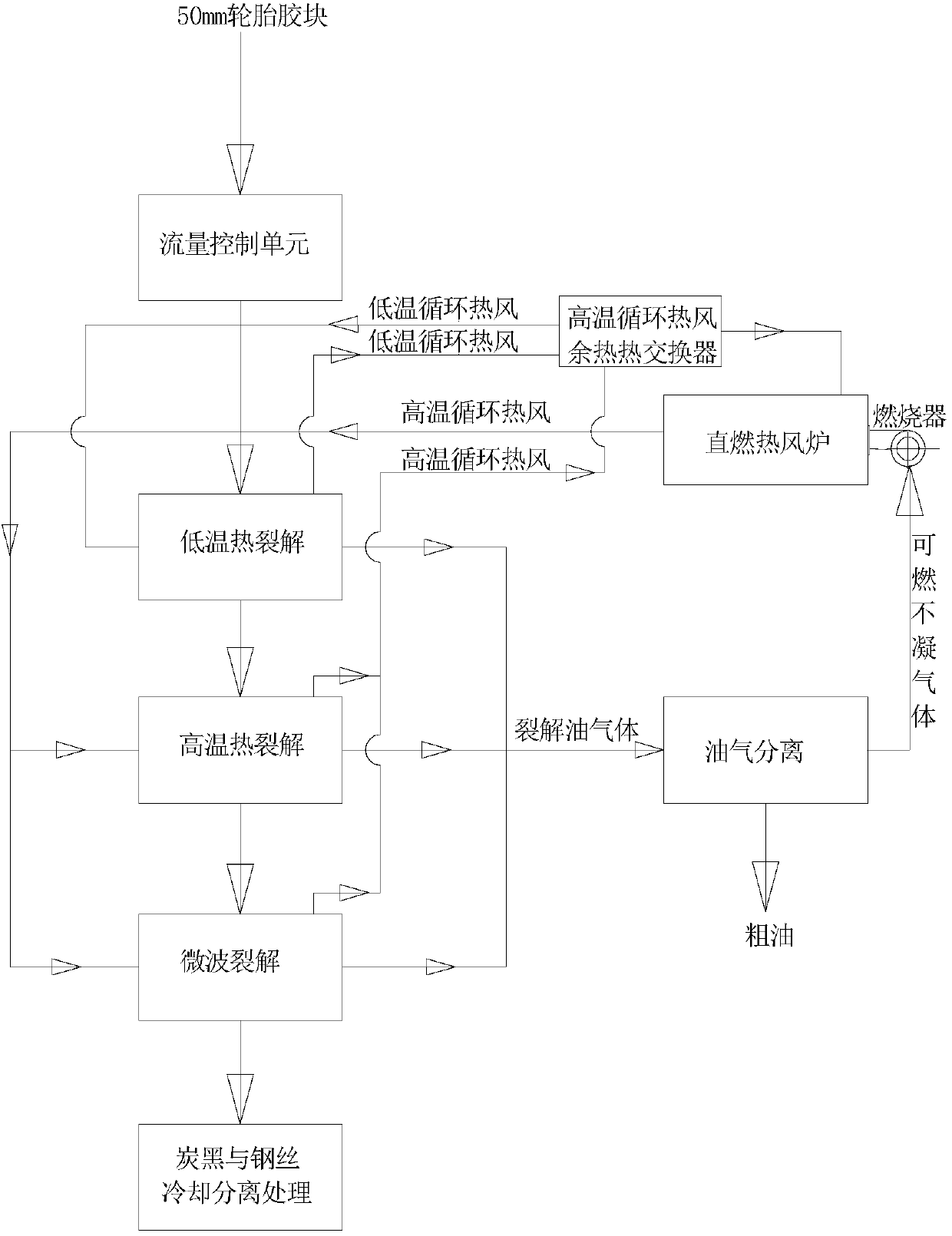

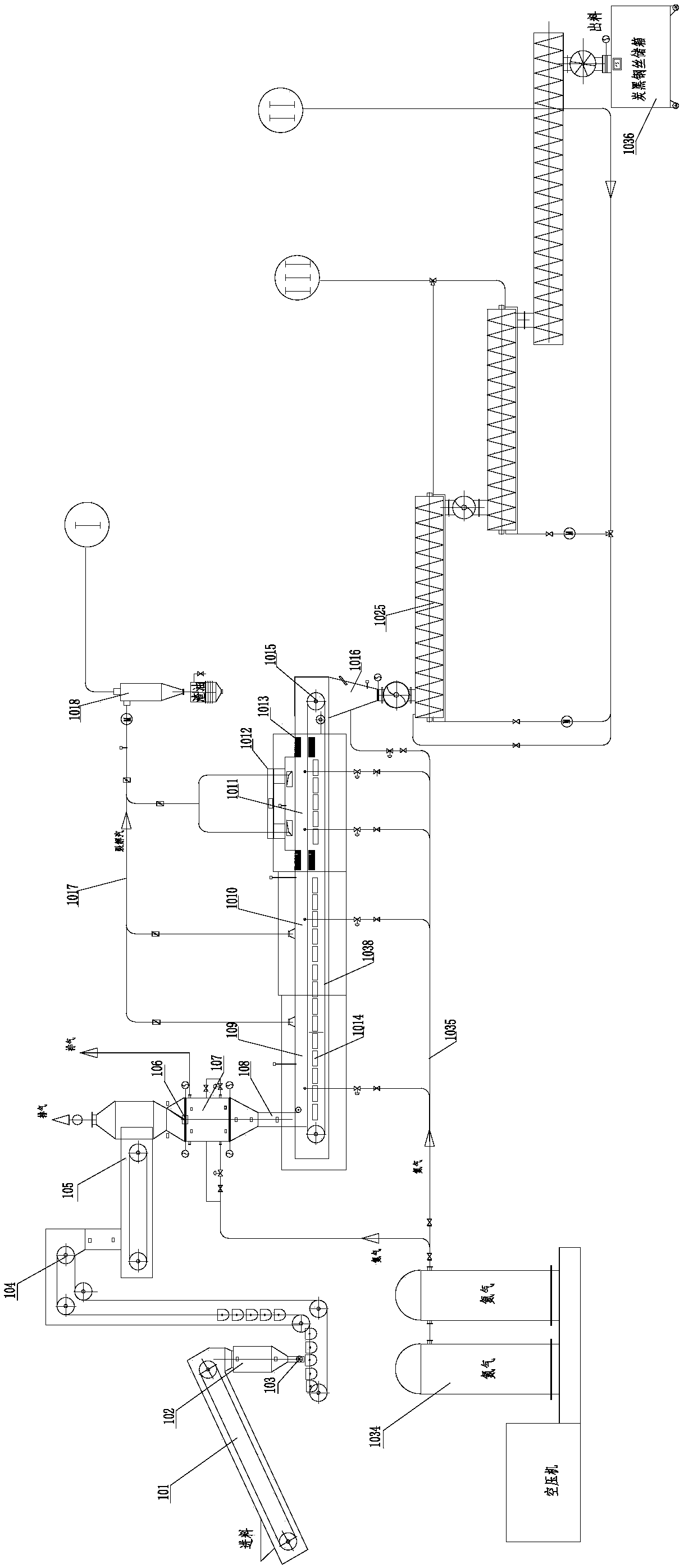

Method and system for cracking waste rubber

PendingCN108018062ARapid lysisReduce energy consumptionPigmenting treatmentTransportation and packagingMicrowaveWaste rubber

The invention provides a method and a system for cracking waste rubber. The waste rubber is sequentially sent to a low-temperature thermal cracking chamber, a high-temperature thermal cracking chamberand a microwave cracking chamber which respectively have an oxygen-free or oxygen-deficient environment, wherein thermal cracking of the waste rubber in the low-temperature thermal cracking chamber is carried out in a 200-400 DEG C environment, thermal cracking in the high-temperature thermal cracking chamber is carried out in a 500-800 DEG C environment, and microwave cracking in the microwave cracking chamber is carried out in a 500-800 DEG C environment; a cracking oil gas generated in the cracking process is continuously discharged from the low-temperature thermal cracking chamber, the high-temperature thermal cracking chamber and the microwave cracking chamber; and solids generated in the cracking process are recovered. The method and the system can effectively reduce the energy consumption in the cracking process and improve the cracking efficiency of the waste tire and the quality of cracked carbon black.

Owner:江苏林达智思环保科技有限公司

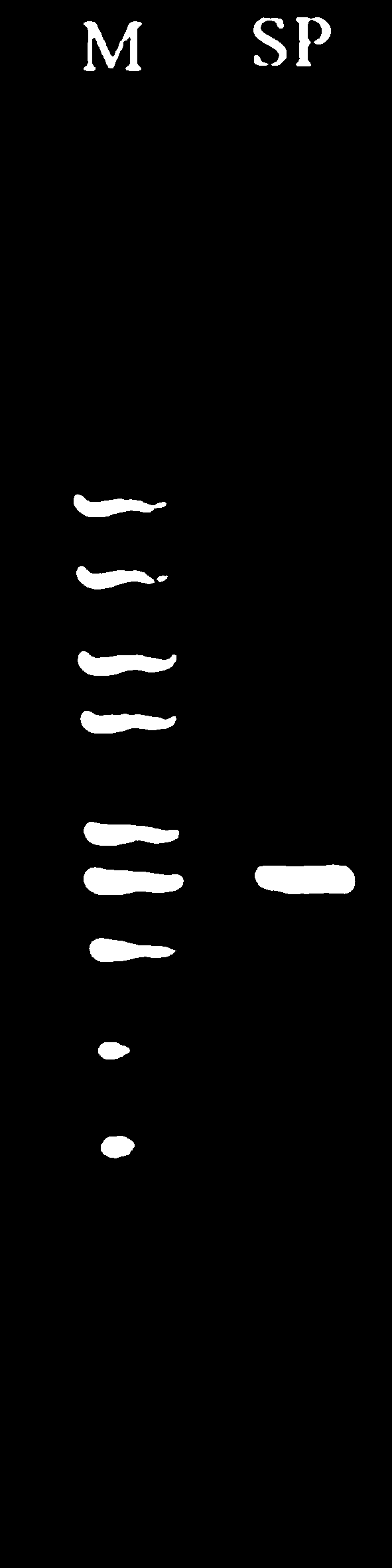

Lyase for killing staphylococcus and application of lyase

ActiveCN103122347ARapid lysisIncrease enzyme activityAntibacterial agentsBiocideMethicillin resistanceAdenosine

The invention discloses a lyase for killing staphylococcus and an application of the lyase and also discloses an amino acid sequence and an encoding gene sequence of the lyase. A recombined lyase constructed by using the disclosed encoding gene can realize soluble expression in Escherichia coli BL21 (DE3); the lyase can be used for efficiently killing various types of staphylococcus including clinically-separated methicillin-sensitive staphylococcus aureus (MSSA) and methicillin-resistant staphylococcus aureus (MRSA) in vitro and can also be used as an antibiotic for treating staphylococcus infection in vivo; and the disclosed lyase can also be used for rapidly cracking the cell wall of the staphylococcus and releasing substances in cells, such as adenosine triphosphate (ATP), DNA (Deoxyribonucleic Acid) and the like, and various detections on the staphylococcus can be realized through detecting released substances.

Owner:WUHAN INST OF VIROLOGY CHINESE ACADEMY OF SCI

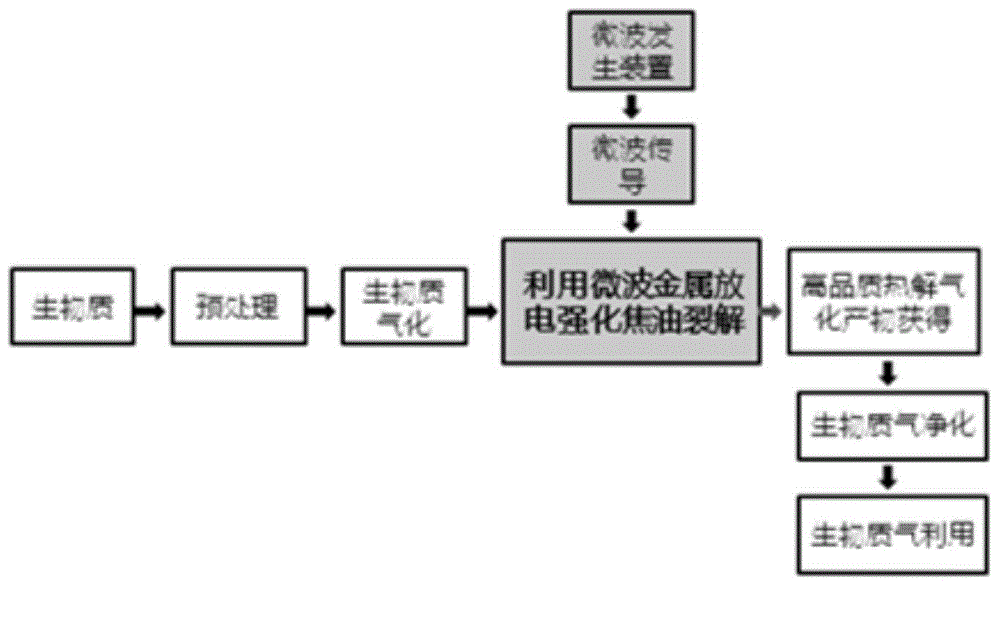

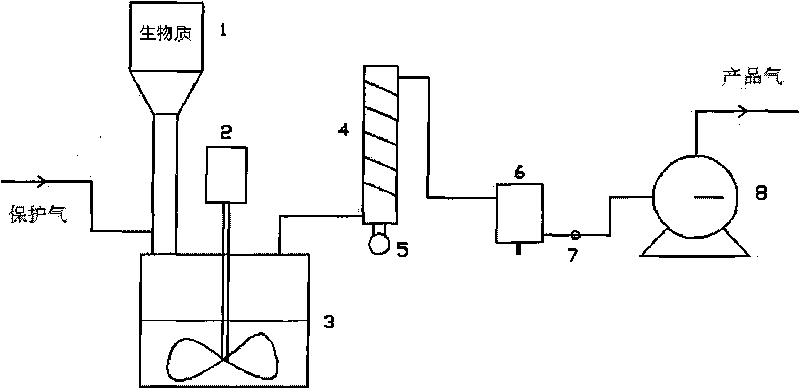

Device and method for intensifying tar cracking in biomass gasification pyrolysis process

InactiveCN104946281AReduce the component content of tarPromote improvement and refinementHydrogenChemical industryTarFlue

The invention discloses a device and a method for intensifying tar cracking in biomass gasification pyrolysis process. The device consists of a microwave generation device and a triggering discharge device, wherein microwaves generated from the microwave generation device are input into the triggering discharge device through waveguide; the triggering discharge device is internally provided with metal mediums Fe, Ni, Co or other alloys; the triggering discharge device is arranged in an area at the temperature of 200-800 DEG C on a biomass gasification pyrolysis device. The method is convenient to implement, a biomass gasification pyrolysis process does not need to be greatly adjusted or changed, no high temperature area is needed, and only a metal discharge area needs to be arranged. No catalyst is needed, so that the problem of catalyst deactivation can be avoided. Due to high-efficiency conversion of tar, problems of equipment blocking or corrosion caused by tar can be reduced or eliminated, the yield of a biomass gas can be increased, the quality of the biomass gas can be improved, and thus the energy utilization efficiency can be improved.

Owner:SHANDONG UNIV

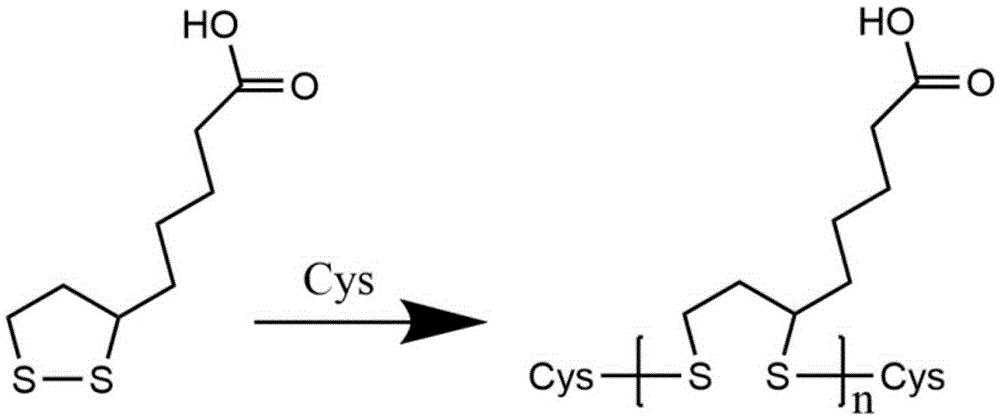

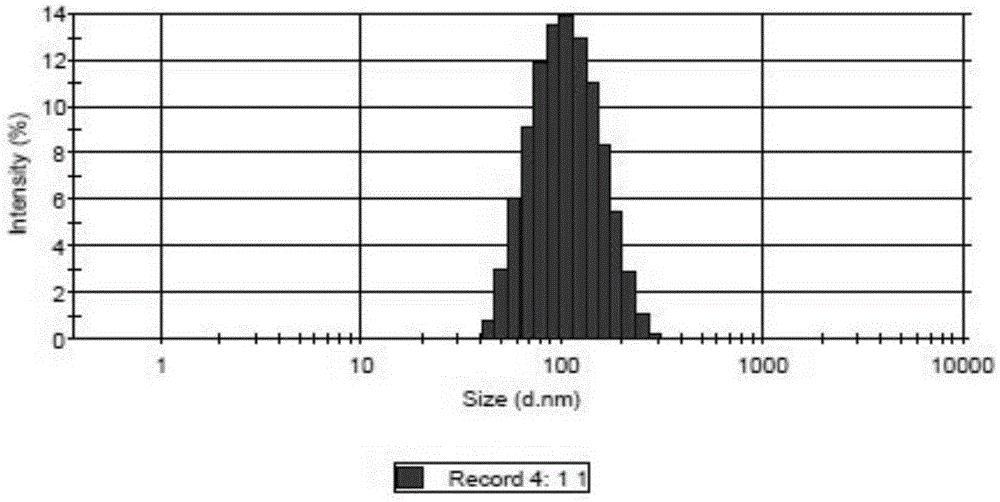

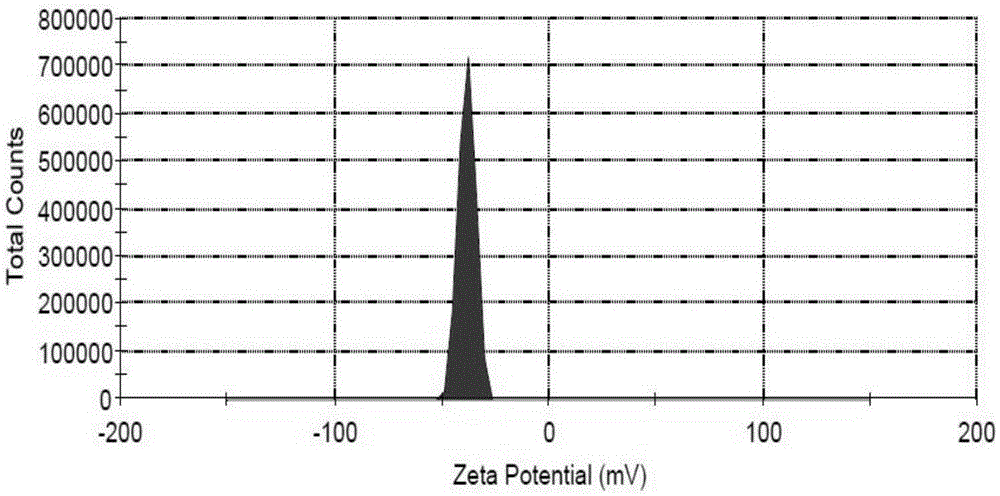

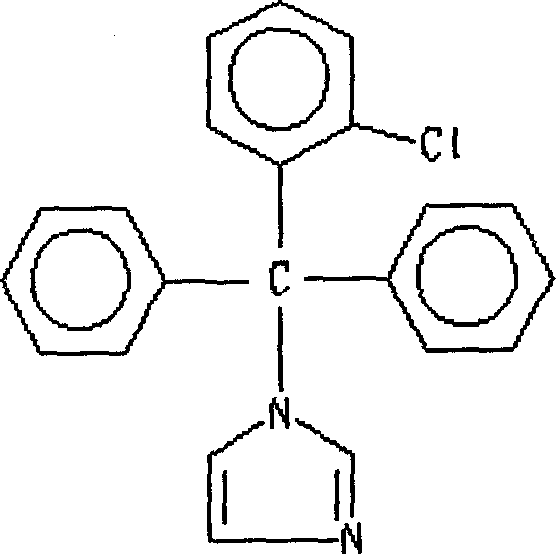

Nano carrier material as well as preparation method and application thereof

InactiveCN106729726AStable in natureLow toxicityPharmaceutical non-active ingredientsAntineoplastic agentsCysteinePolymer

The invention discloses a nano carrier material which is a polymer formed by crosslinking of thioctic acid reduced and cracked by cysteine. The invention further discloses a preparation method and an application of the nano carrier material. The nano carrier material is degradable and low in cytotoxicity, has the advantage of tumor cell environment response, can realize targeted drug delivery for a tumor cell, improves the efficacy of an anti-tumor drug, reduces the pain of a patient, and has a wide application prospect.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

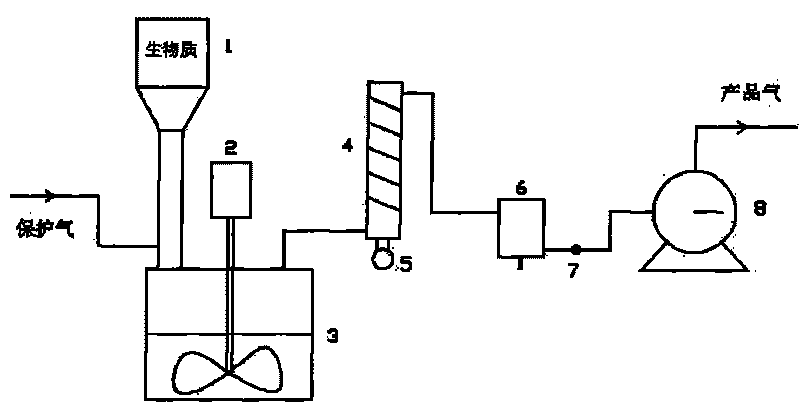

Process of generating hydrogen by cracking biomass with molten alkali

InactiveCN101759148AEasy to recycleRapid lysisHydrogen productionMolten salts/metals gasificationLiquid productGeneration process

The invention relates to a process of generating hydrogen by cracking biomass with a molten alkali. The process comprises the following steps: filling the molten alkali which is used as a heating, catalyzing and reacting medium into a reactor; introducing a protective gas into the reactor; and setting the reaction temperature between 320 and 900 DEG C and then at the preset temperature, adding the biomass into the reactor to depolymerize organic high polymers. The mass ratio of the molten alkali to the biomass is 50: 1-1: 1; and the pyrolysis product comprises a pyrolysis gas (which also can be called a product gas), a solid carbon and a liquid product. The process has the advantages that: the molten alkali is a good reacting catalyst, and is cheap and easily recyclable; the molten alkali is a good heating medium which quickly transfers heat to the biomass by tightly contacting the biomass so as to realize fast cracking of the biomass; the molten alkali used is low in temperature and can be operated at a relatively low temperature; and the hydrogen generation process has mild conditions, a cracking device is simple, the operation is convenient and the controllability is high.

Owner:ZHEJIANG UNIV OF TECH

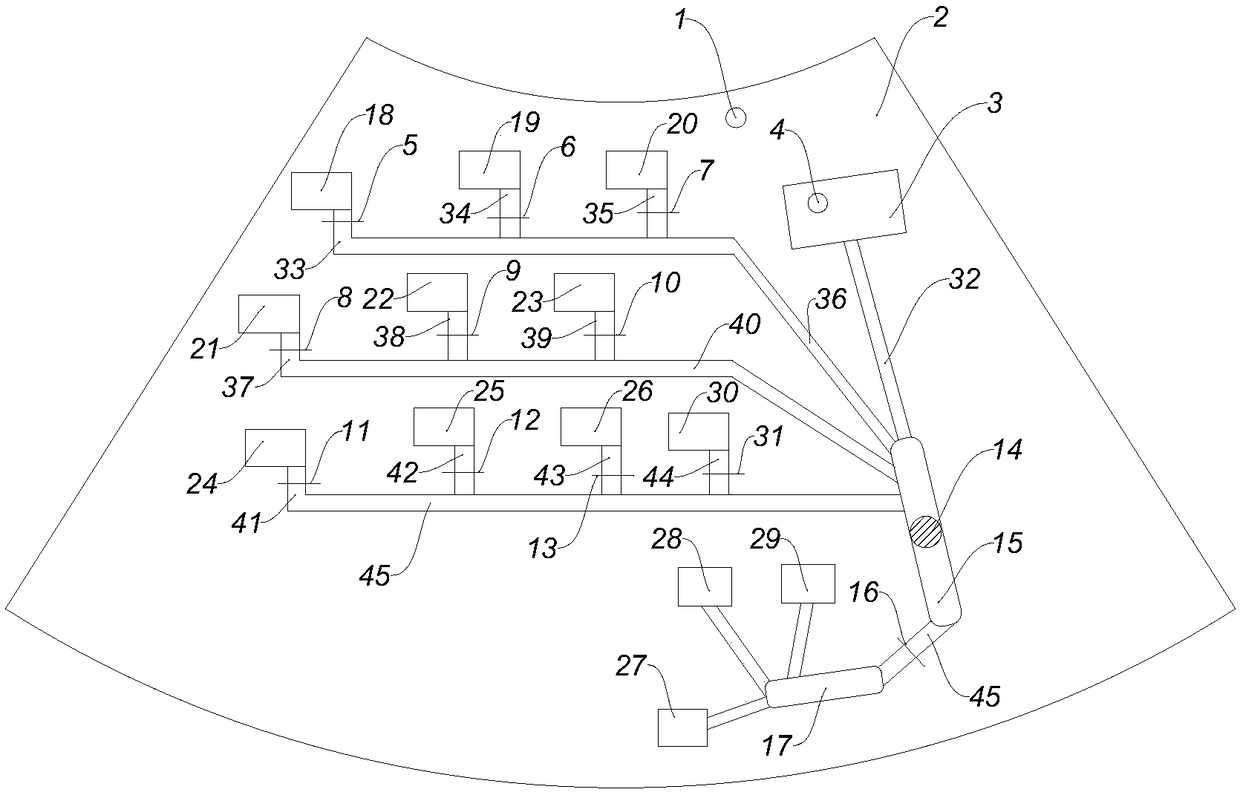

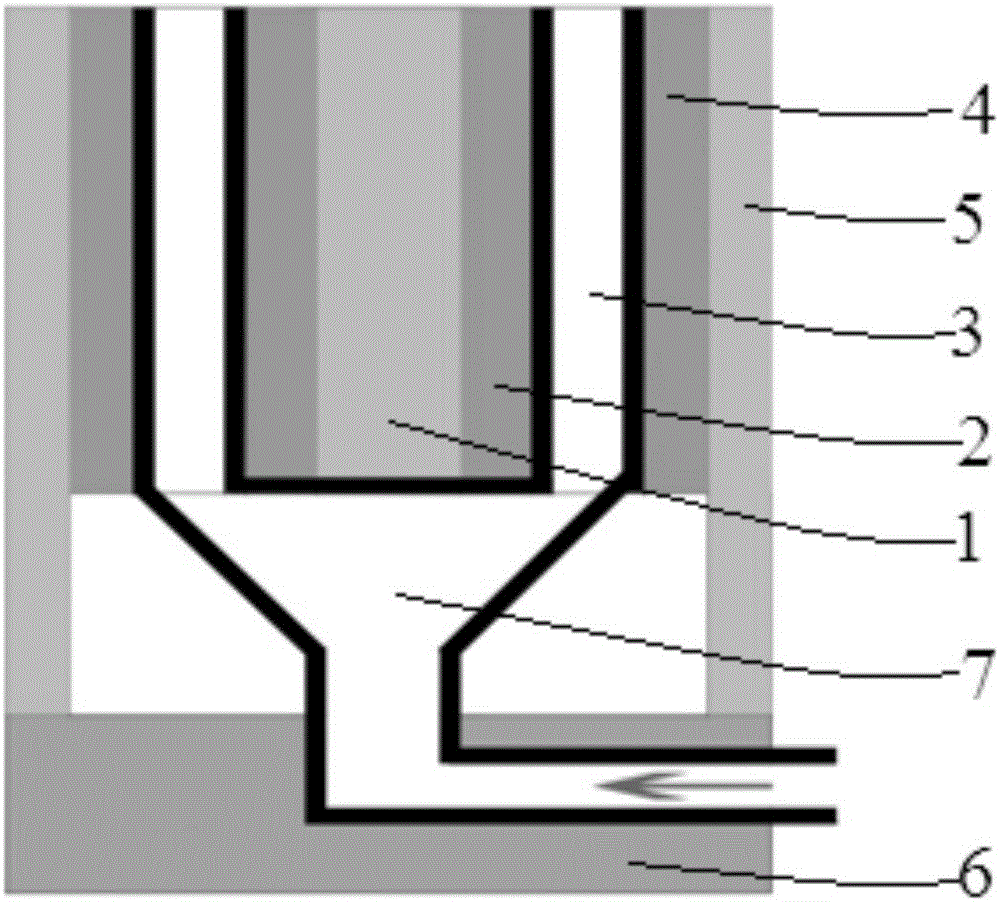

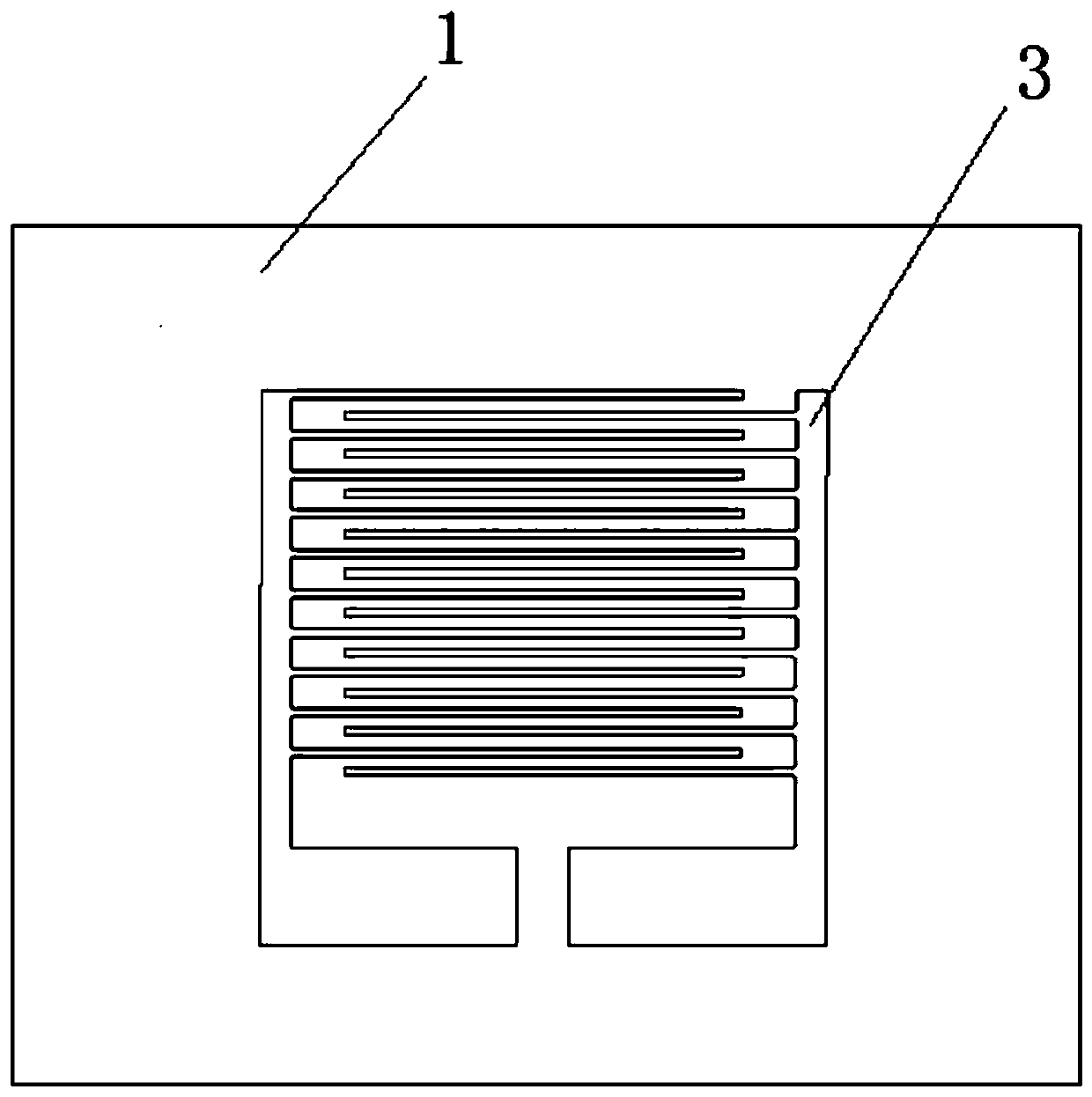

Micro-fluidic chip for extracting total nucleic acid of bacteria in human whole blood

PendingCN108949507ARapid lysisEasy to operateBioreactor/fermenter combinationsBiological substance pretreatmentsLeak detectionBiology

The invention discloses a micro-fluidic chip for extracting total nucleic acid of bacteria in human whole blood. The chip comprises a positioning hole and a main body. The main body comprises a sampling hole formed in a sampling cavity, the sampling cavity, a one-way valve, a nucleic acid extraction material, a nucleic acid extraction cavity, a PCR reaction cavity, a buffer solution I cavity, a buffer solution II cavity, an RNA enzyme inhibitor cavity, an MIX1 cavity, a DNase I cavity, a MIX2 cavity, a 70% ethanol cavity, a buffer solution II cavity, an MIX3 cavity, a PCR Master Mix cavity, aPCR primer cavity, a PCR reaction probe cavity and a buffer solution V cavity. The chip provided by the invention can split the bacteria quickly to release RNA, and is simple and convenient to operate, so that the extraction efficiency is improved greatly; the detection limit is reduced to the lowest, so that the probability of leaked detection is avoided; the operating process of pathogenic bacteria detection is simplified, and the detection error caused by manual operations is reduced.

Owner:SUZHOU TEST DROP DX BIOTECHNOLOGY CO LTD +2

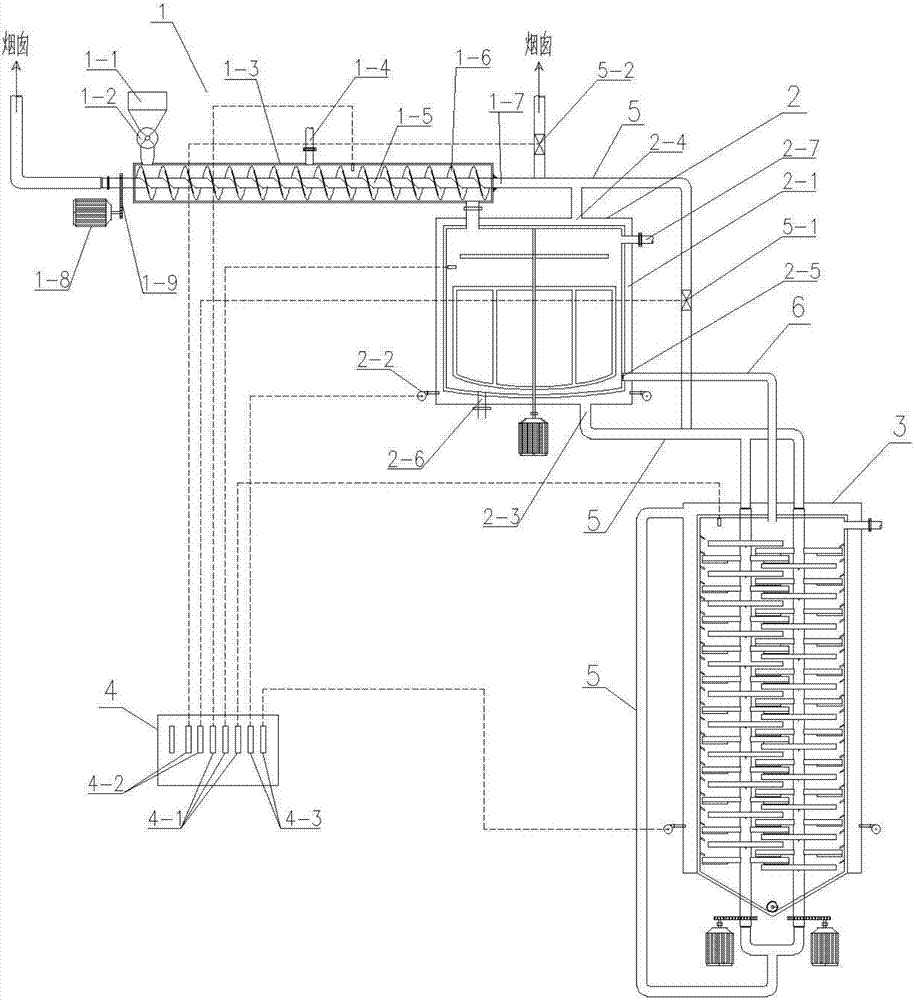

Energy-saving efficient continuous type plastic garbage thermal cracking refining equipment

PendingCN107446609AImprove pyrolysis efficiencySuitable for large-scale industrial productionLiquid hydrocarbon mixture productionHydrocarbon oils treatmentCombustion chamberFlue gas

The invention discloses energy-saving efficient continuous type plastic garbage thermal cracking refining equipment which comprises a supply system, a liquefaction system and a cracking system; the liquefaction system comprises a liquefaction device and a liquefaction combustion chamber; the liquefaction combustion chamber is arranged at the periphery of the liquefaction device; the cracking system comprises a cracking chamber and a cracking combustion chamber; the cracking combustion chamber is arranged at the periphery of the cracking chamber; the cracking chamber is internally provided with a hollow rotary shaft and a hollow blade; the supply system comprises a screw conveyer; the screw conveyer is provided with a feeding hollow rotary shaft and a hollow spiral blade; the cracking combustion chamber is communicated with the hollow rotary shaft; the hollow rotary shaft is communicated with the liquefaction combustion chamber and the feeding hollow rotary shaft through a flue gas pipeline; the liquefaction combustion chamber is communicated with the feeding hollow rotary shaft; and the exhaust end of the feeding hollow rotary shaft is connected with a chimney. The energy-saving efficient continuous type plastic garbage thermal cracking refining equipment provided by the invention has the advantages of continuous feeding of plastic garbage, good mass and heat transfer effect, rapid thermal cracking speed, high efficiency, energy conservation and the like, can realize continuous production, avoids that plastics coke in a furnace to influence the heat transfer effect and improves the quality of a finished oil product at the same time.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

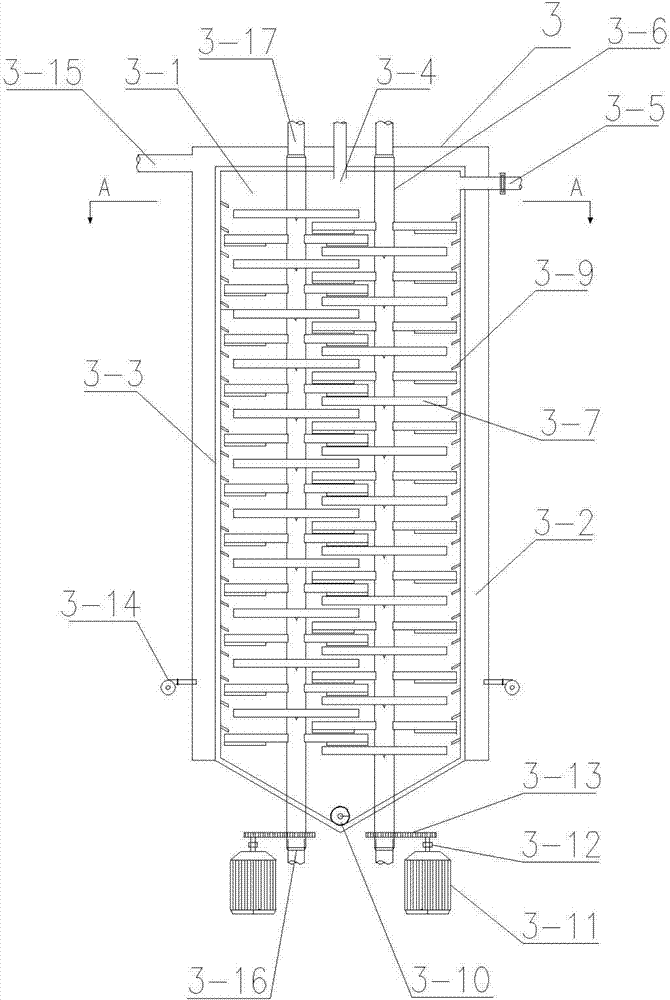

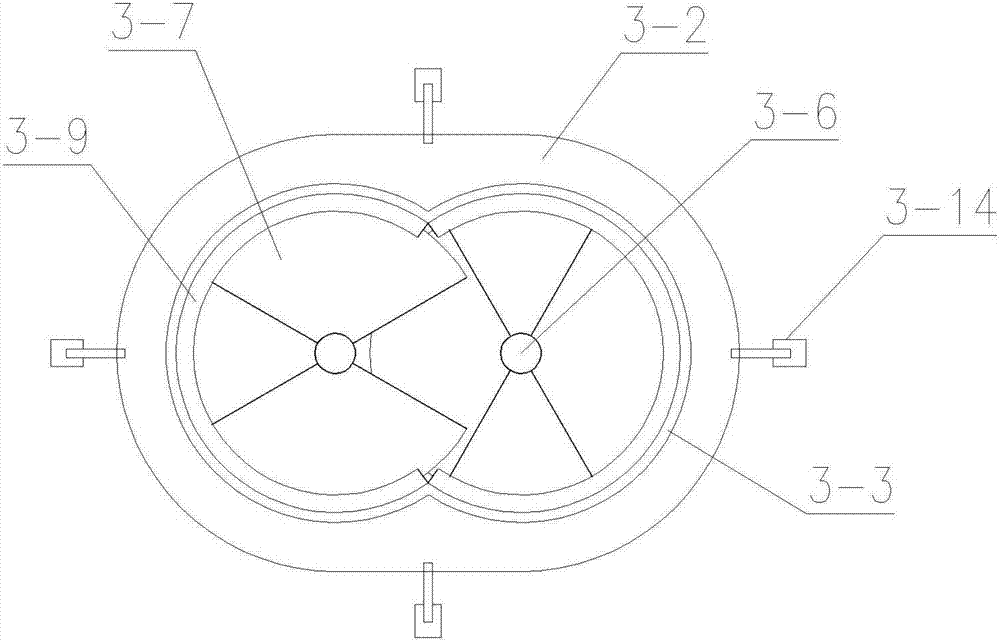

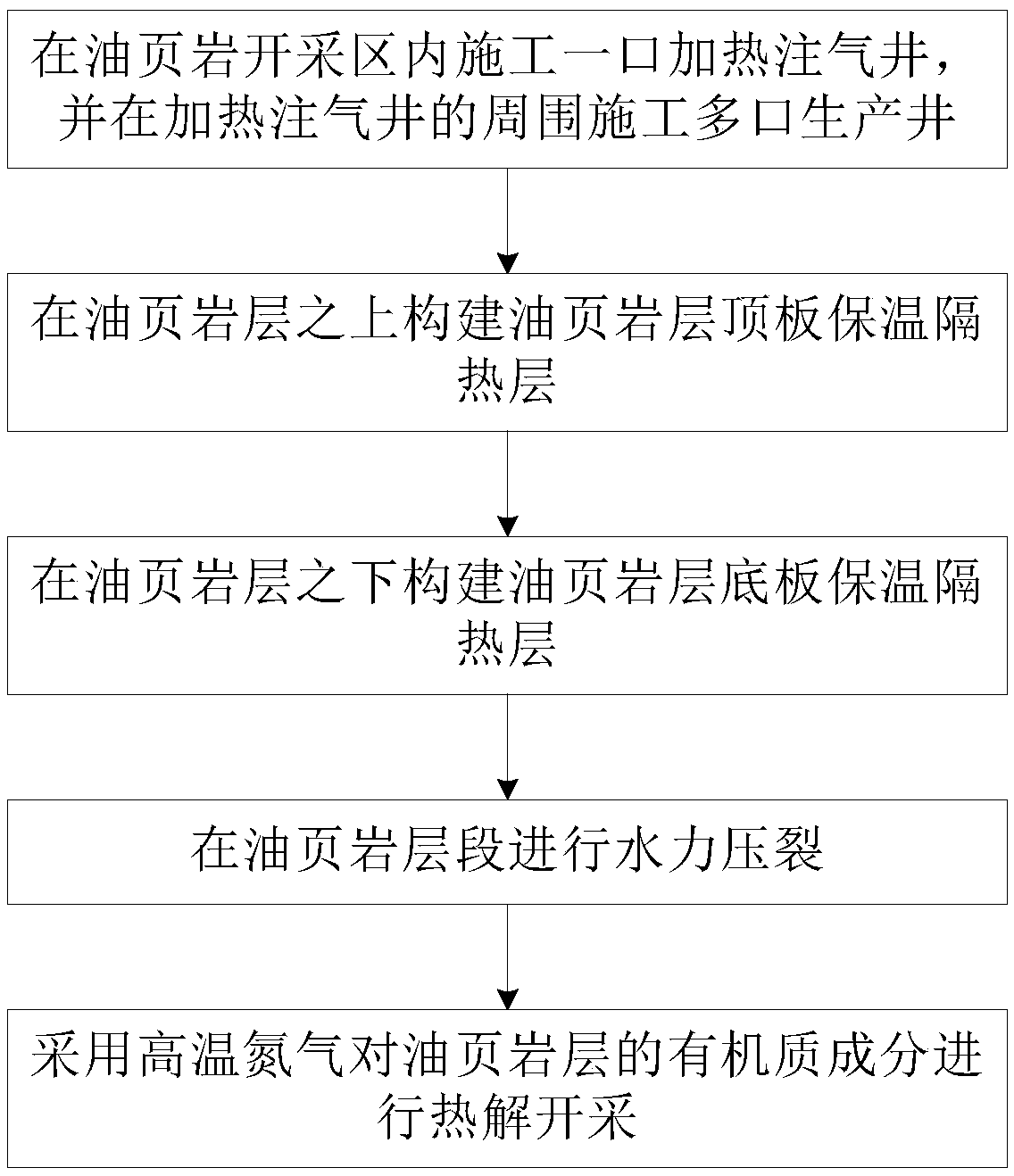

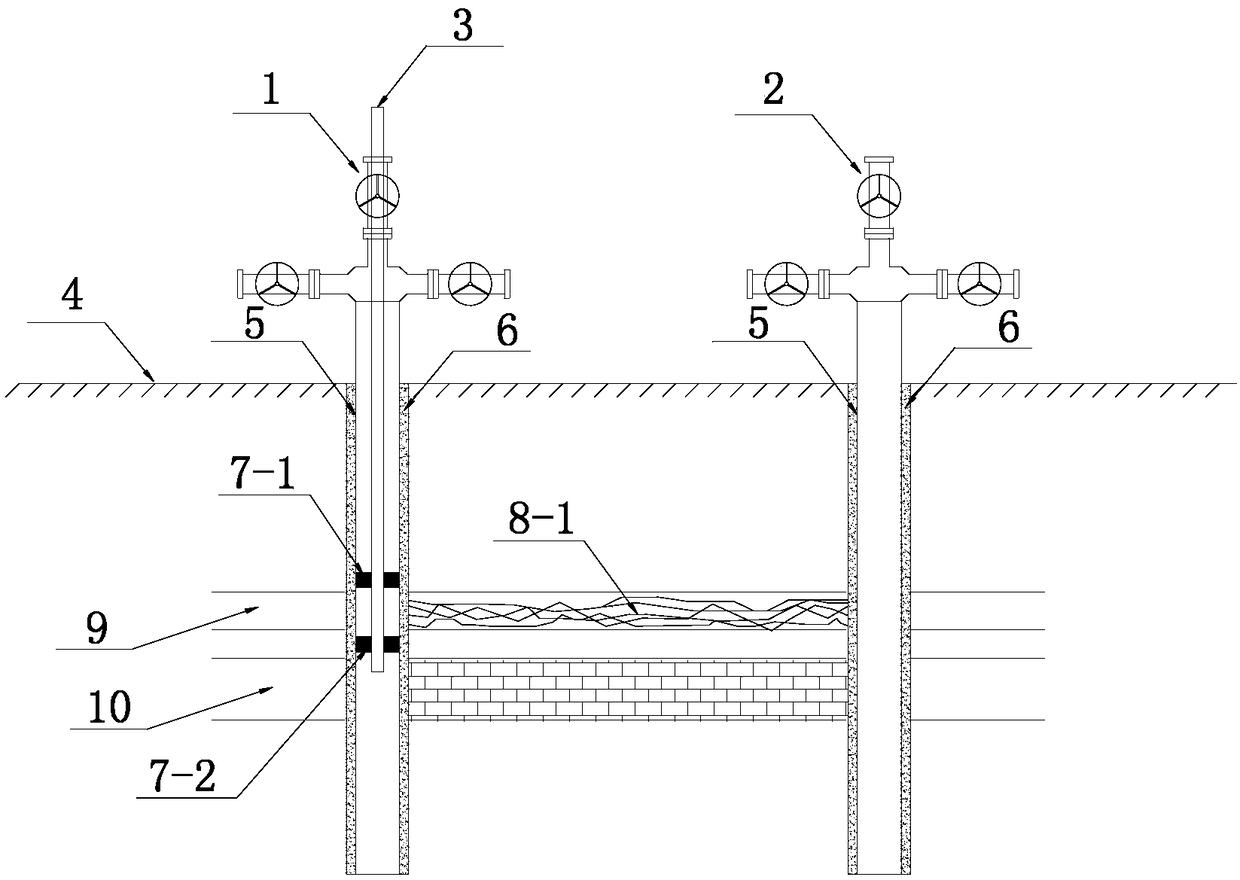

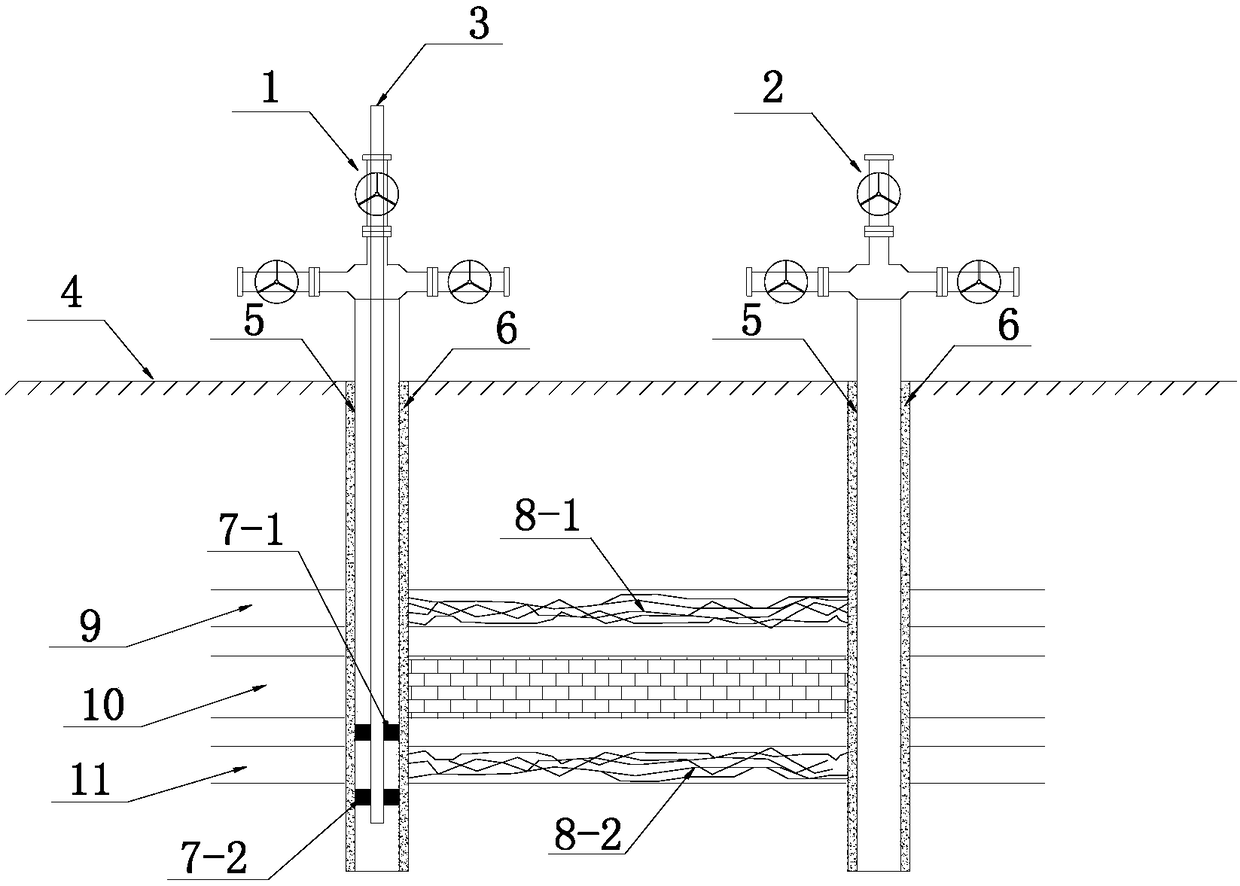

Method and system for heat insulation and efficiency enhancement in-situ conversion of oil shale

ActiveCN108756839AImproves ability to lock in heatHeating up fastGeothermal energy generationFluid removalInsulation layerThermal insulation

The invention discloses a method and system for heat insulation and efficiency enhancement in-situ conversion of oil shale. The method comprises the following steps that 1, a heating gas injection well is constructed in an oil shale mining area, and a plurality of production wells are constructed on the periphery of the heating gas injection well; 2, an oil shale layer top plate heat insulation layer is built above an oil shale layer; 3, an oil shale bottom plate heat insulation layer is built under the oil shale layer; 4, hydraulic fracturing is carried out on an oil shale layer section; and5, pyrolyzing and mining are carried out on organic matter components of the oil shale layer by adopting high-temperature nitrogen. The system comprises the heating gas injection well, the multiple production wells, the oil shale layer top plate heat insulation layer above the oil shale layer and the oil shale layer bottom plate heat insulation layer built under the oil shale layer as well as a heating fluid flow channel and a high-temperature nitrogen transportation system for pyrolysis and mining. The method and system for for heat insulation and efficiency enhancement in-situ conversion ofoil shale have a simple construction process, a fast heating speed of oil shale formation, a high energy utilization rate, high practicability, a good use effect and convenient popularization and use.

Owner:XIAN UNIV OF SCI & TECH

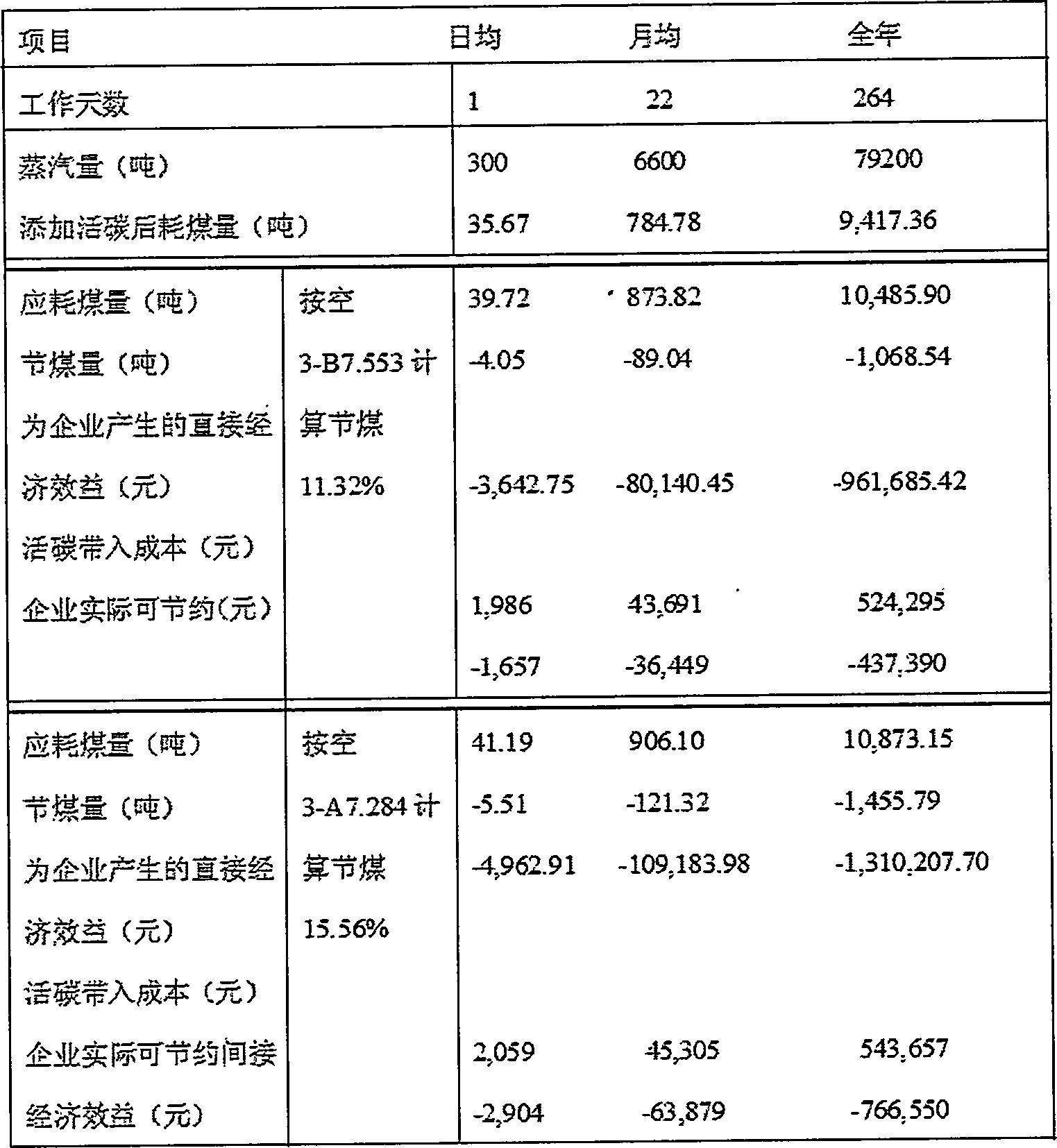

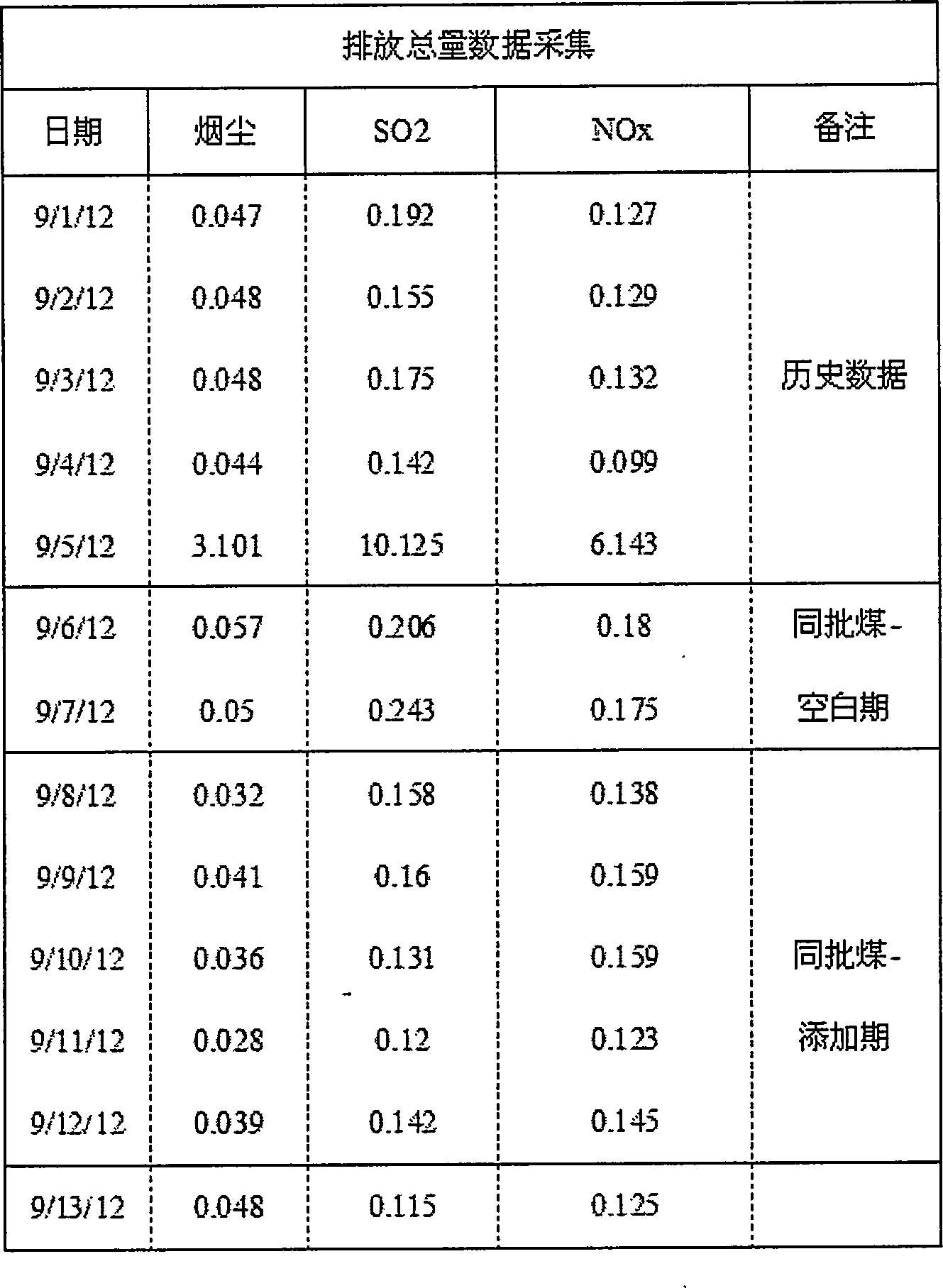

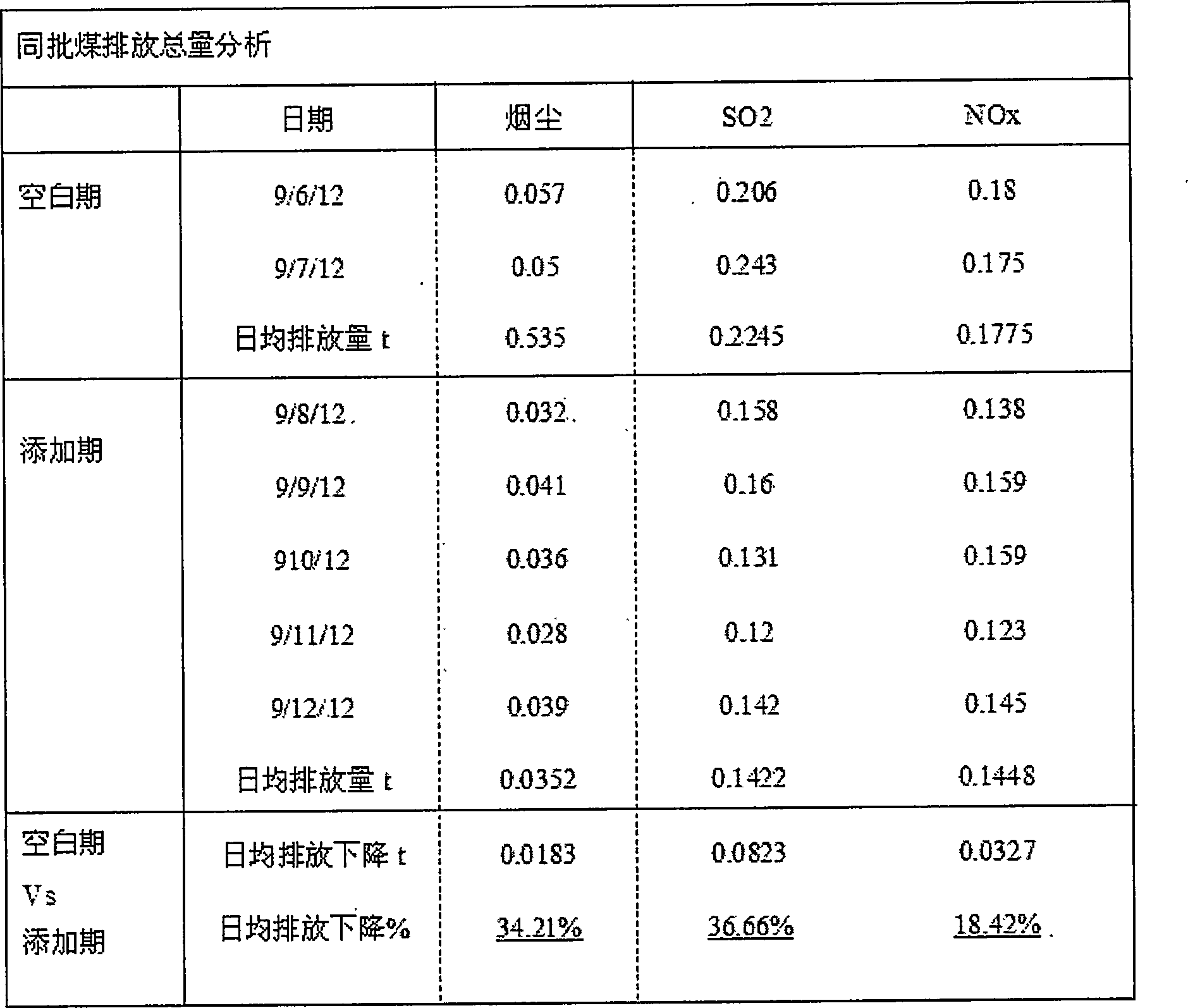

Coal additive

ActiveCN103320195APlay a catalytic roleLower the ignition temperatureSolid fuelsRare-earth elementCombustion

The invention provides a coal additive. The coal additive comprises an emulsifier, a dispersant, a corrosion inhibitor and a penetrant. The coal additive contains O, Mg, Al, Si, S, Ca, Ba and Mn. The coal additive has the advantages that the emulsifier, the dispersant, the corrosion inhibitor and the penetrant are used and the rare earth elements improve catalyst activity so that a traditional exterior-to-interior combustion mode is changed into an interior-exterior synchronous combustion mode and thus a coal complete-combustion degree is improved and a heat loss caused by chemical incomplete combustion and mechanical incomplete combustion of coal in a furnace is reduced; and through composite carriers having mesoporous structures, catalyst activity is improved, a hydrodesulfurization process is finished and discharge amounts of flue dust and harmful gas in exhaust gas are reduced so that coal saving and sulfur fixation are realized.

Owner:甘肃泰聚环保科技有限公司

Nucleic acid releasing agent and HPV virus nucleic acid detection kit

PendingCN111172240AAct quicklySubsequent experiment impactMicrobiological testing/measurementDiethylene glycol monoethyl etherNucleic acid detection

The invention discloses a nucleic acid releasing agent. The nucleic acid releasing agent comprises a composition of Triton X-100 and diethylene glycol monoethyl ether (DCDE) with a mass ratio of 1: (1-3). The low-cost composition of Triton X-100 and DCDE is adopted to replace a traditional guanidine salt and a detergent, and the obtained nucleic acid releasing agent has advantages of safe use, easy degradation, simple operation, and low manufacturing cost, can effectively lyse serum samples containing pathogens, quickly release nucleic acids therein, reduce inhibition of downstream experiments, and has high pathogen lysis efficiency. The invention also discloses an HPV virus nucleic acid detection kit. The kit comprises the nucleic acid releasing agent, is simple and convenient to operate,and high in working efficiency, effectively avoids a link that may occur during the experimental operation, reduces loss of HPV DNA in an extraction process, and has a quantification limit of 45 IU / mL and a detection limit of 22 IU / mL.

Owner:苏州博方生物技术有限公司

Low-cost wall brick

InactiveCN106220143AMaterial selection scienceThe preparation method is simple and easyCeramic materials productionClaywaresIndustrial constructionBrick

The invention discloses a low-cost wall brick, belonging to the technical field of building materials. The low-cost wall brick is prepared from the following raw materials: 20-30 parts by weight of cinder, 35-45 parts by weight of construction waste soil, 25-28 parts by weight of grinding wheel ash, 3-5 parts by weight of straw, 5-10 parts by weight of limestone, 1-2 parts by weight of vermiculite and 80-90 parts by weight of river water; the low-cost wall brick is prepared by the steps of pre-activating, crushing, aging in a sealing way, making adobe, drying and sintering. The low-cost wall brick is scientific in material selection and fully utilizes industrial construction waste, thus reducing the production cost and increasing the enterprise profit; a preparation method of the low-cost wall brick is advanced, and improves the activity and adhesiveness of raw materials through a pre-activating method so as to enable the raw materials to be blended together closely; therefore, the low-cost wall brick is close in texture, non-powdered, high in compressive strength and wear resistance and good in anti-cracking performance, can be used for a long time in a low-temperature environment, and is long in service life, wide in use and strong in adaptability to construction.

Owner:滁州市瑞景园林股份有限公司

Method for quickly preparing rough laminar pyrolytic carbon

The invention discloses a method for quickly preparing rough laminar pyrolytic carbon. The method comprises the following steps: heating a silicon carbide tube by adopting microwaves; controlling a temperature of a deposition area to 1000-1400 DEG C; carrying out cracking reaction on a carbon source gas which is introduced into the silicon carbide tube; enabling generated rough laminar pyrolytic carbon to deposit and grow in the deposition area, thereby obtaining the rough laminar pyrolytic carbon. According to the method for quickly preparing rough laminar pyrolytic carbon disclosed by the invention, the microwaves are adopted for heating the silicon carbide tube, so that a carbon source can be uniformly heated in a cavity of the silicon carbide tube, and is quickly cracked, and the deposited rough laminar pyrolytic carbon is uniform in tissue structure and is controllable in microstructure. Besides, the method is high in efficiency of preparing the rough laminar pyrolytic carbon and is easy for process condition control; the prepared rough laminar pyrolytic carbon is stable in tissue structure, so that production cost is reduced.

Owner:SHENZHEN UNIV

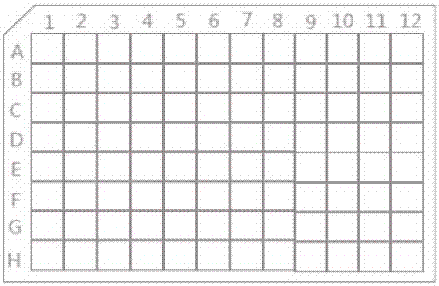

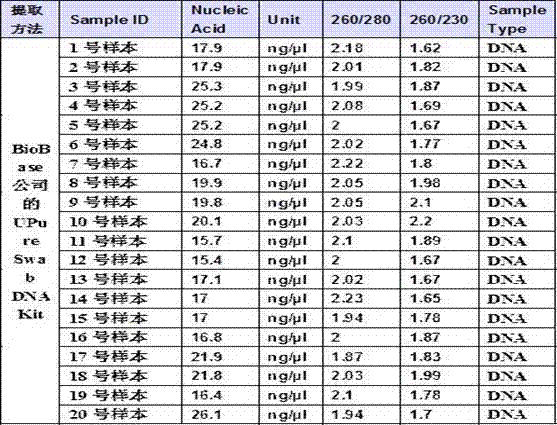

Whole blood DNA quick extraction kit

InactiveCN107043763AHigh degree of automationReduce human error and experimental errorDNA preparationChemistryLysis

The invention discloses a whole blood DNA quick extraction kit which comprises a lysis solution, a proteinase K, a combined solution, a magnetic bead, a cleaning solution 1, a cleaning solution 2 and an eluent. The 96-pore pre-split deep hole plate mode is adopted and a nucleic acid automatic extraction instrument can be combined for automatically extracting nucleic acid, so that the whole blood DNA can be quickly and effectively extracted in abundance.

Owner:GUANGZHOU HEAS BIOTECH CO LTD

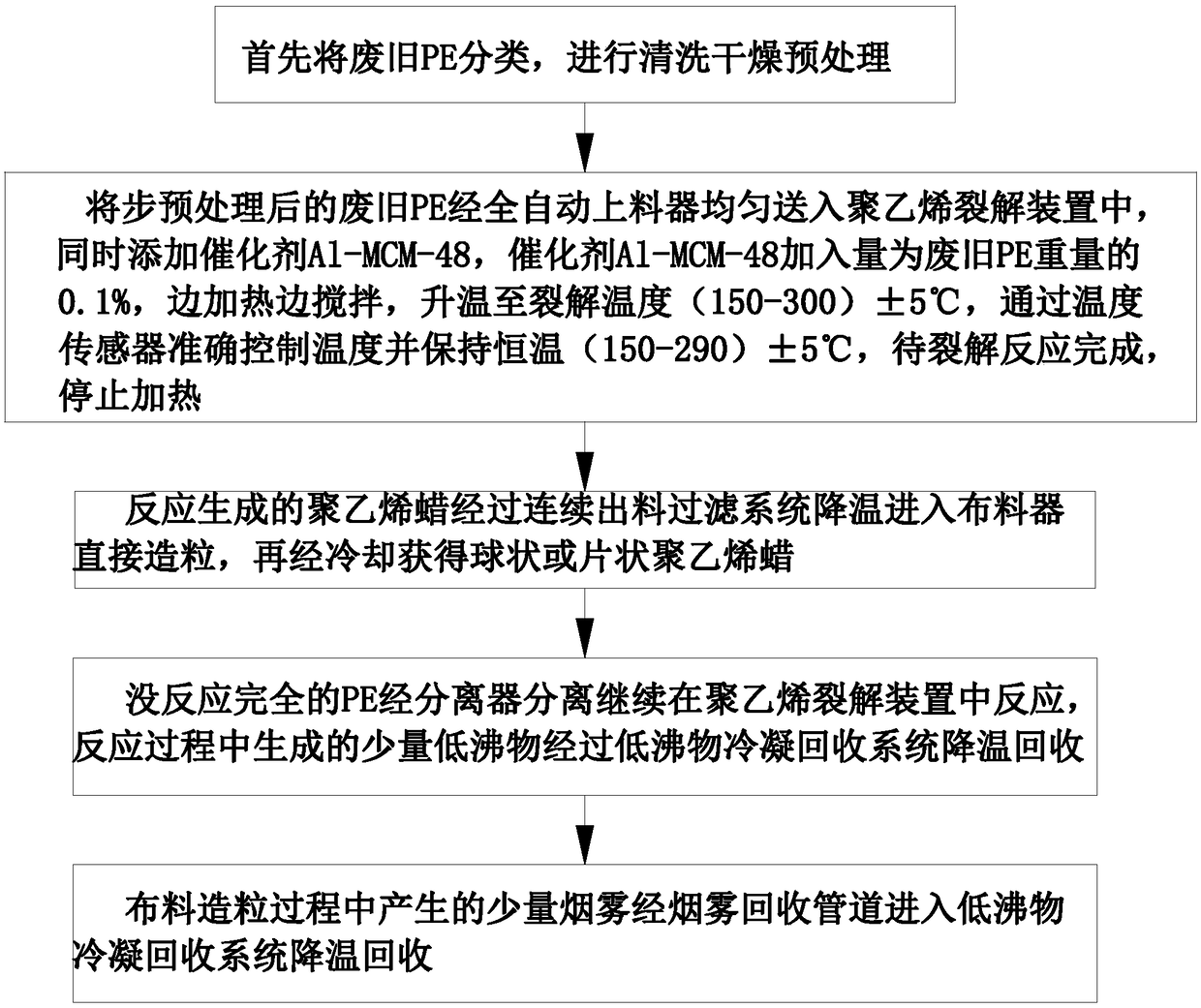

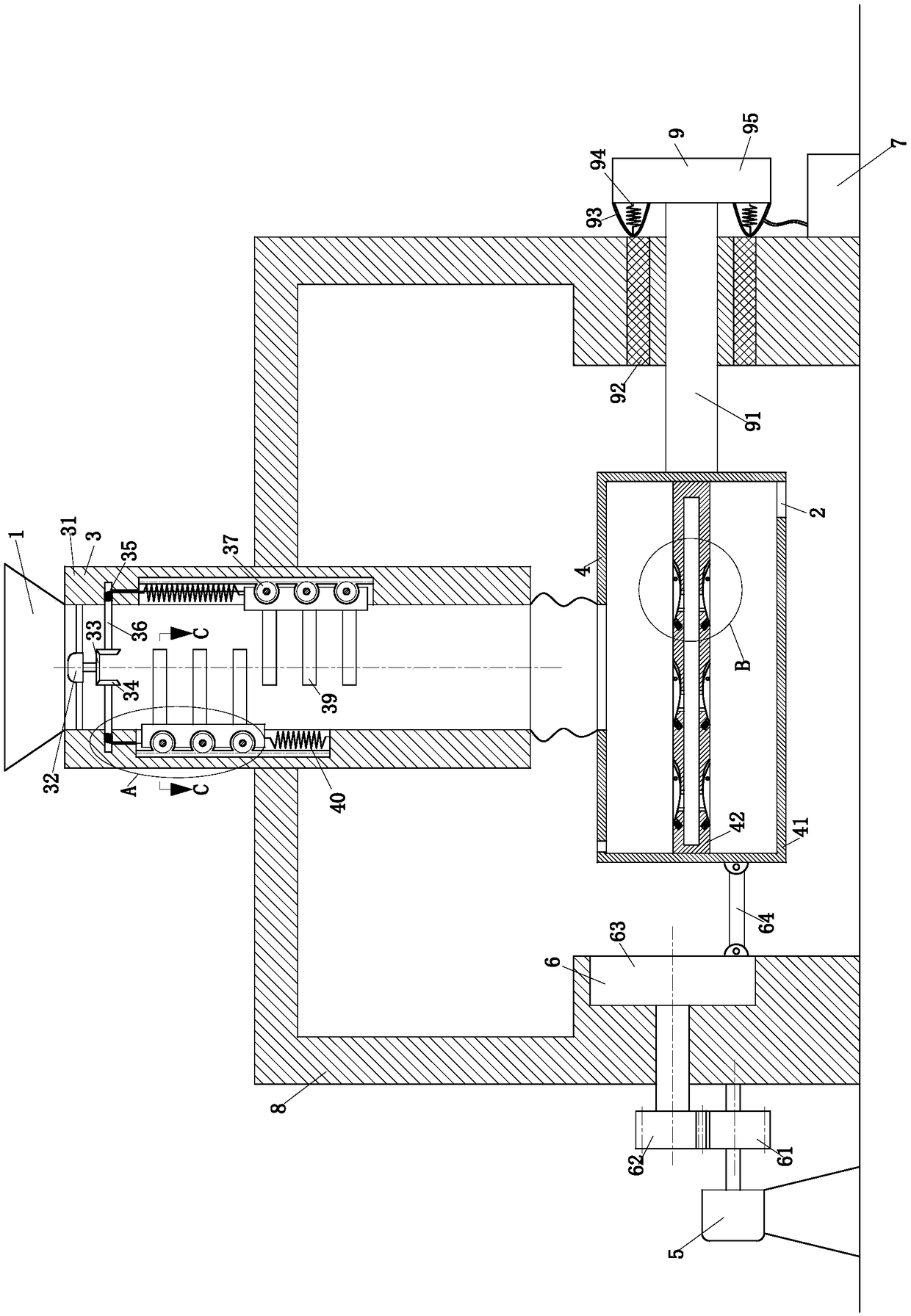

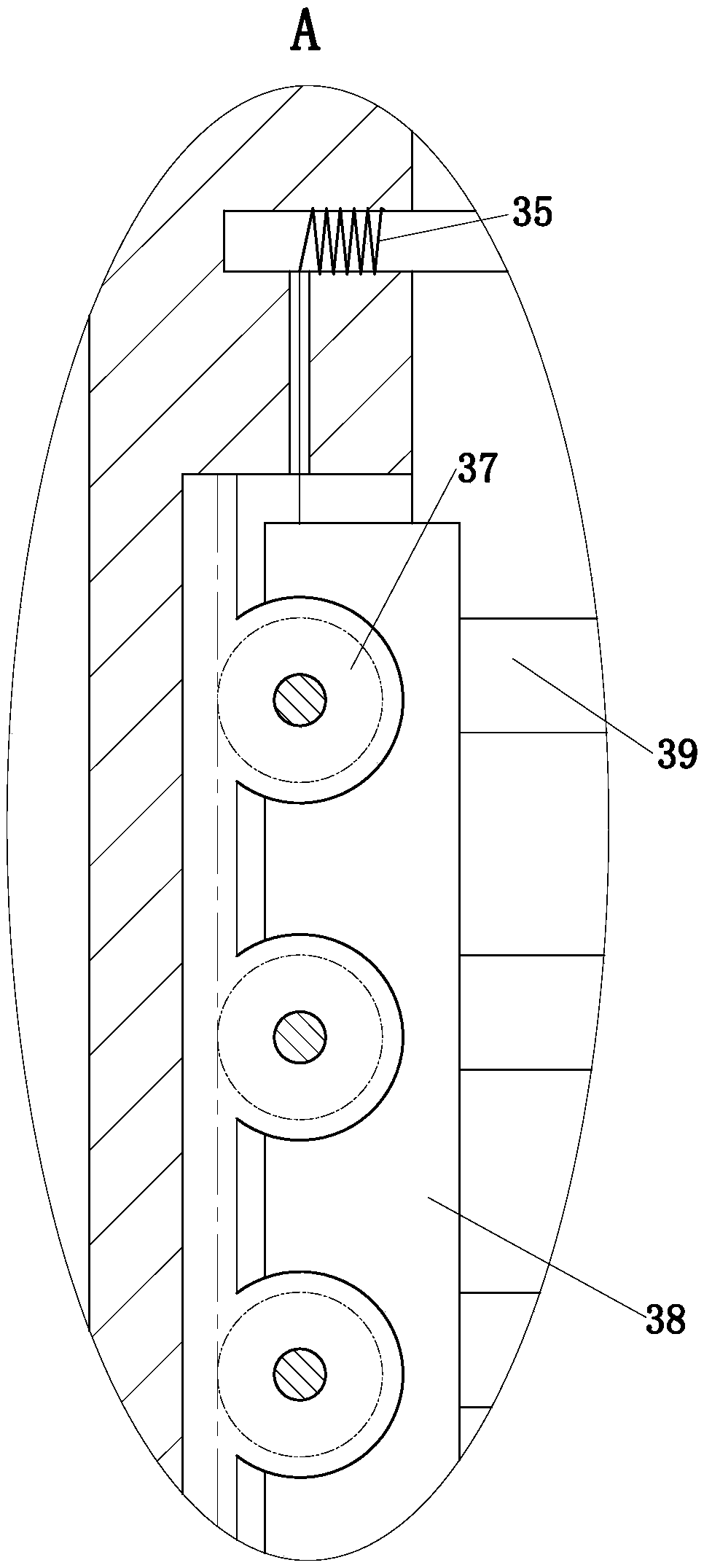

Production technology of polyethylene wax

ActiveCN108772034AIncrease productivitySimple processChemical/physical/physico-chemical stationary reactorsBoiling pointEngineering

The invention belongs to the technical field of chemical production and in particular relates to a production technology of polyethylene wax. The technology comprises the following steps: classifyingwaste PE (Polyethylene) and carrying out washing and drying pre-treatment; uniformly feeding the pre-treated waste PE into a polyethylene cracking device through a full-automatic feeding device; meanwhile, adding a catalyst Al-MCM-48, wherein the adding amount of the catalyst Al-MCM-48 is 0.1 percent of the weight of the waste PE; heating and stirring at the same time; after cracking reaction is finished, stopping heating; cooling the polyethylene wax generated by the reaction through a continuous discharging and cooling system and conveying the polyethylene wax into a material distribution device and directly granulating; then cooling to obtain spherical or sheet-shaped polyethylene wax. The PE which does not react completely is separated through a separator and continually reacts in thepolyethylene cracking device; a few of low-boiling-point substances generated in a reaction process are cooled and recycled through a low-boiling-point substance condensation and recycling system; ina material distribution and granulation process, less generated smoke enters the low-boiling-point substance condensation and recycling system through a smoke recycling pipeline and is cooled and recycled. The technology is used for producing the polyethylene wax in batches; the technology is simple and the manufacturing cost is relatively low.

Owner:江苏天问新材料科技有限公司

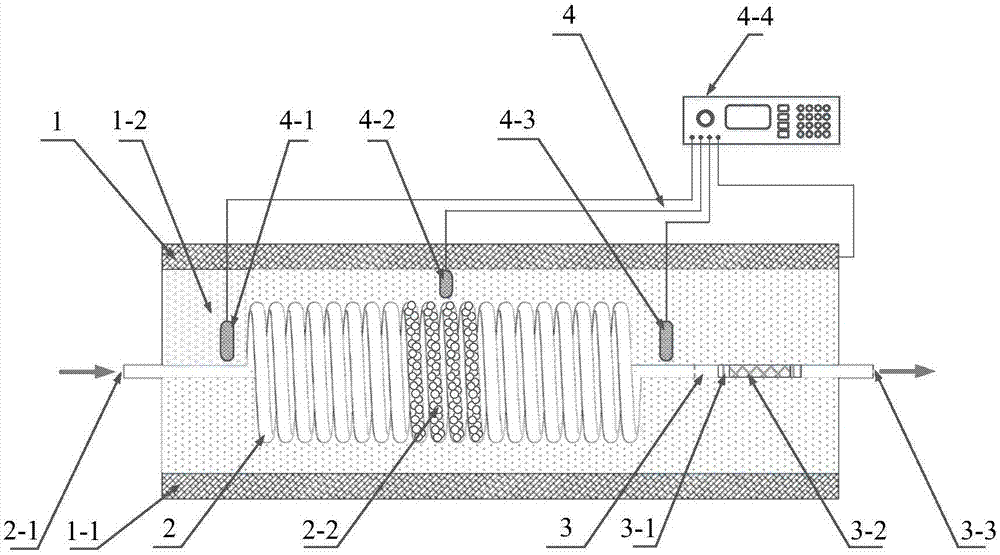

High-temperature pyrolyzing type gaseous mercury form conversion device and method

InactiveCN107238527AAvoid the problem of poison inactivationShort conversion timePreparing sample for investigationFurnace typesHeat fluxTime efficient

The invention discloses a high-temperature pyrolyzing type gaseous mercury form conversion device and a method. The device adopts a high temperature cracking furnace for heating the incoming flue gas on the basis of the high-temperature pyrolyzing characteristic of mercury under oxidation state, the in-furnace pipeline adopts the spiral arrangement for increasing the staying time of the flue gas in the cracking furnace and the heat exchange area of the gas flow in the pipe is expanded; and meanwhile, a granular inertial ceramic heat storage material is filled in a central area of a spiral pipe, the heat flux in the core area is increased, the heating uniformity of the gas flow in the pipe is promoted and the cracking time of the mercury under oxidation state is shortened; and an acidic gas absorbent is filled in a straight pipe on an outlet section of the cracking furnace, so that the secondary oxidation of the mercury under element state is eliminated and the measuring deviation of the mercury concentration is avoided. The device disclosed by the invention can completely realize the conversion of the mercury under oxidation state to the mercury under element state in the gas phase and can realize the real-time efficient conversion and online accurate measurement for the mercury form concentration in the gas phase under a practical flue gas condition.

Owner:SOUTHEAST UNIV

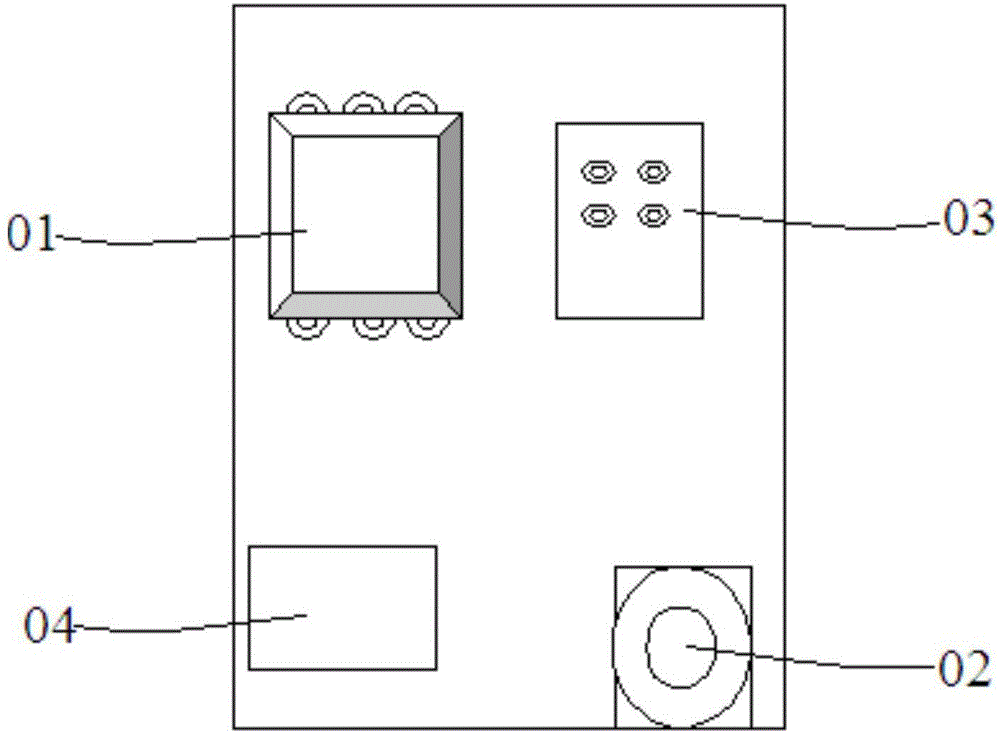

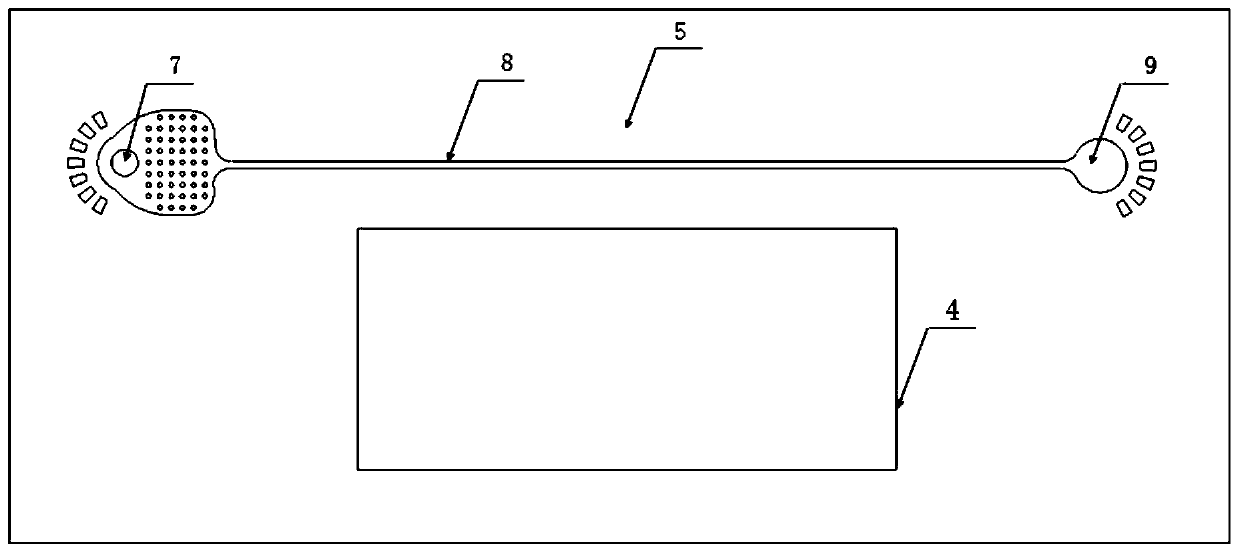

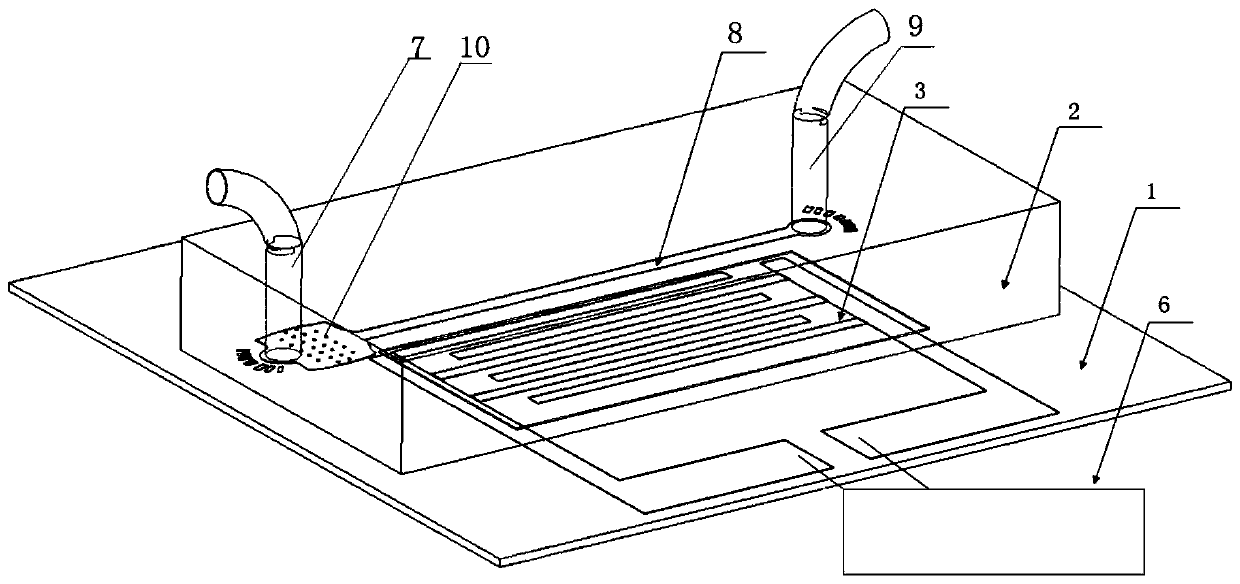

Micro bacteria cracking reactor based on surface acoustic waves and bacteria cracking method

ActiveCN109868218AAvoid cross infectionAvoid pollutionBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringControl system

The invention discloses a micro bacteria cracking reactor based on surface acoustic waves and a bacteria cracking method. The reactor comprises a lower bottom plate and an upper cover plate which arealigned and bonded together; a group of surface acoustic wave generation structures are arranged on the lower bottom plate; a groove is formed in one side of the upper cover plate, and a micro-channelstructure allowing liquid to flow through is arranged in the middle of the upper cover plate; a signal control system is used for controlling the surface acoustic wave generation structures; the micro-channel structure comprises a sample introduction hole, a reaction area and a product outflow hole. The method is suitable for cracking different types of bacteria, does not need any chemical reagent, and avoids the pollution of the chemical reagent to a cracked product.

Owner:XI AN JIAOTONG UNIV

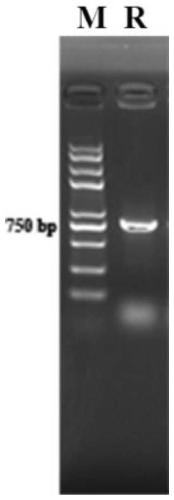

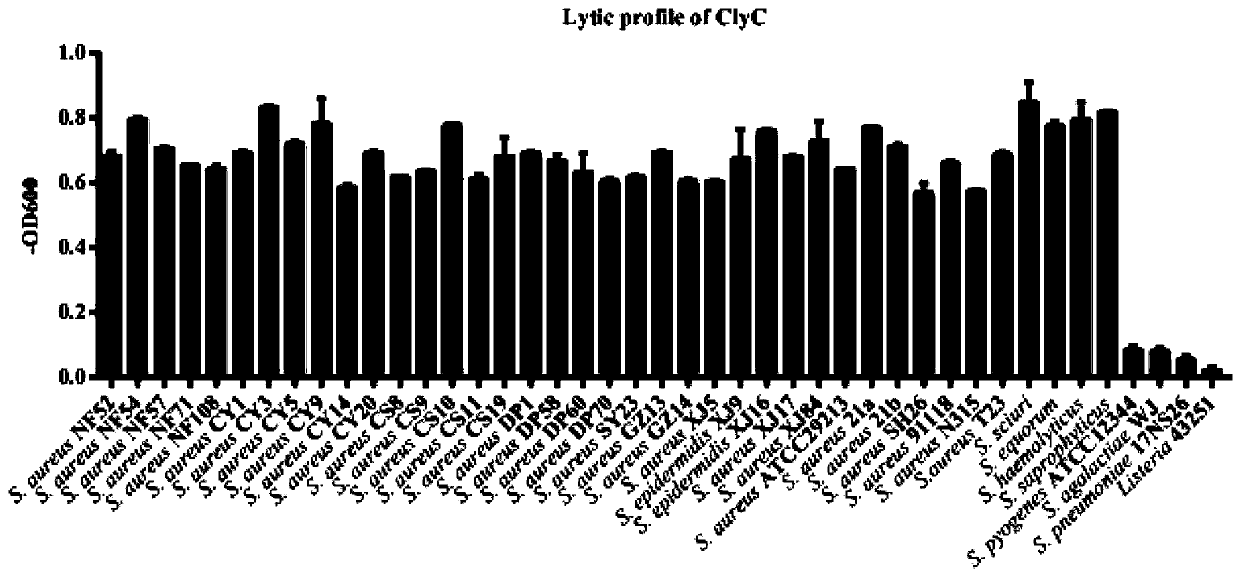

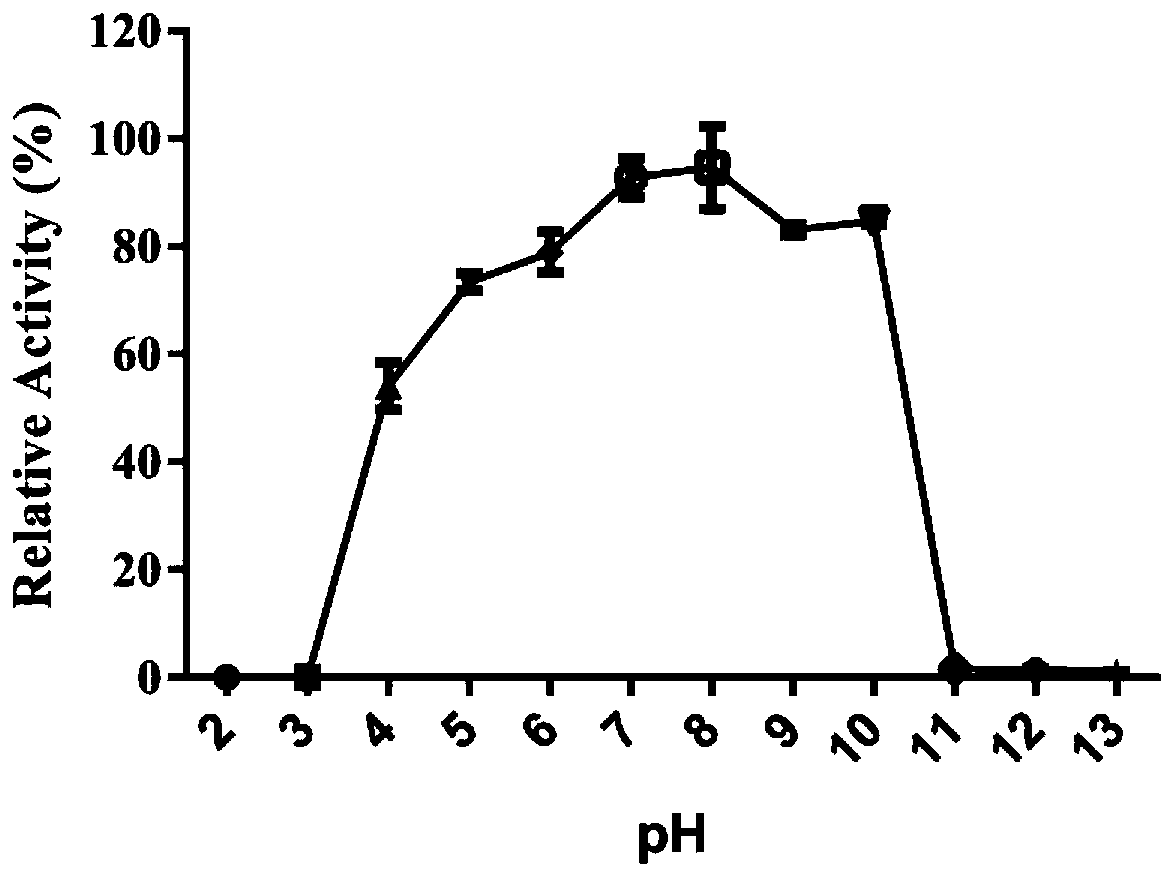

Staphylococcus lyase and preservation method and application thereof

ActiveCN110117587AHigh expressionLow cytotoxicityAntibacterial agentsPeptide/protein ingredientsEscherichia coliStaphylococcus haemolyticus

The invention relates to a lyase capable of killing staphylococcus, in particular to staphylococcus aureus, staphylococcus sciuri, staphylococcus equorum, staphylococcus haemolyticus, staphylococcus saprophyticus and other staphylococcus, and a preservation method and application of the lyase. The amino acid sequence of the staphylococcal lyase is shown as SEQ ID NO.1, and the nucleotide sequenceof a gene for encoding the staphylococcal lyase is shown as SEQ ID NO.2. The pH range of the lyase for effect exertion is wide, the activity for lysing the staphylococcus is kept at the pH of 6-10, and a recombinant protease constructed by the encoding gene can be subjected to soluble expression in escherichia coli BL21 (DE3). The lyase can be used as an antibiotic for treating in-vivo and in-vitro staphylococcal infection and can also quickly lyse the cell walls of the staphylococcus to release substances in cells, and therefore the lyase is used for nucleic acid extraction and preparation ofmedicaments for staphylococcal detection and identification. It is proved through tests that after the staphylococcus lyase is lyophilized, the bactericidal activity of the protein of the staphylococcus lyase is not reduced, and therefore the staphylococcus lyase can be prepared into lyophilized powder for storage.

Owner:WUHAN INST OF VIROLOGY CHINESE ACADEMY OF SCI

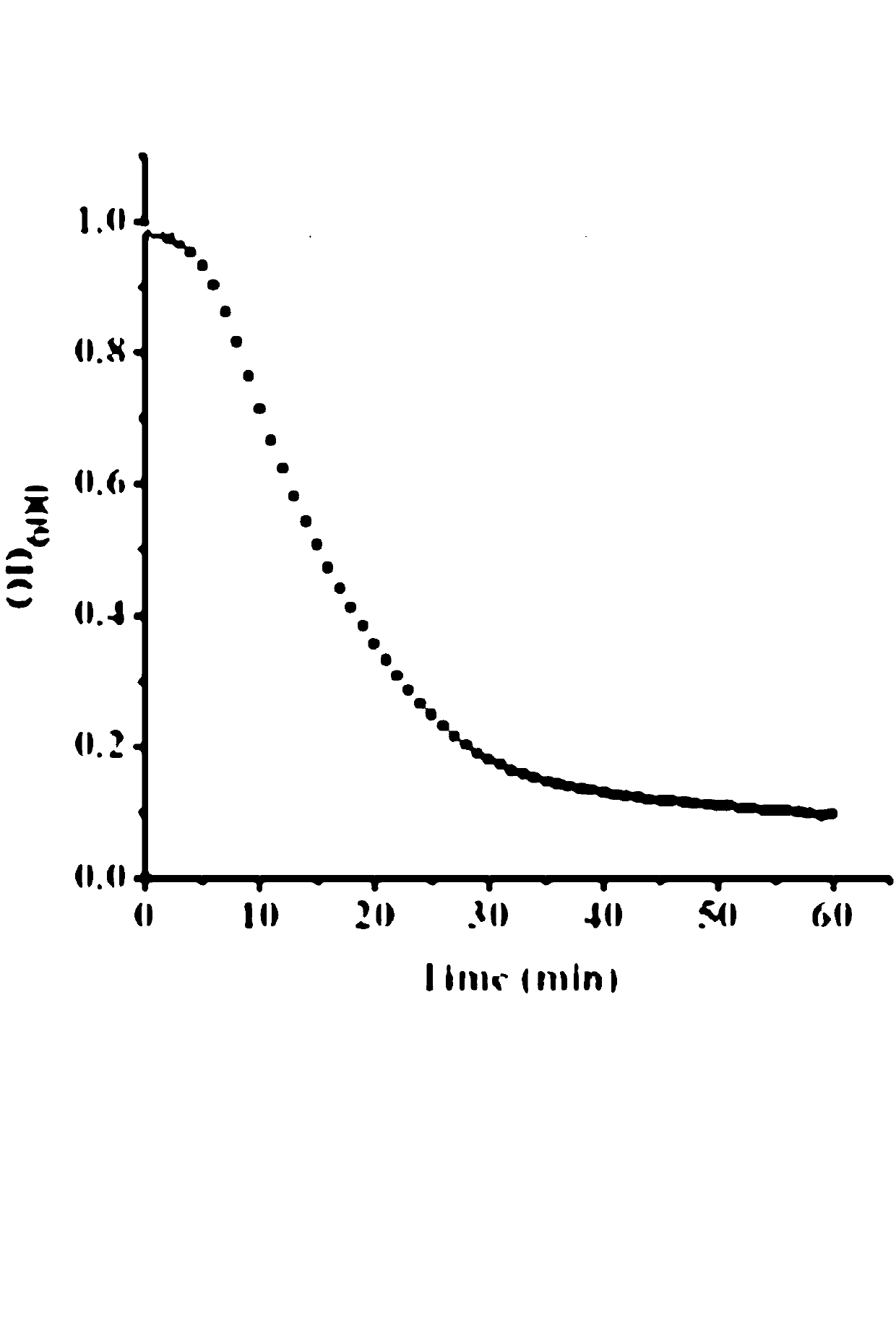

Pyrolysis phycophage MACPNOA1 and application thereof

ActiveCN109097339ABroad cracking spectrumRapid lysisMicroorganism based processesRecovery/purificationPhylum CyanobacteriaAnabaena

The invention discloses pyrolysis phycophage MACPNOA1 and a separation method and application thereof, and relates to biological treatment of eutrophic water. MACPNOA1 is preserved in China General Microbiological Culture Collection Center in October 24th, 2016, and the preservation number is CGMCC No.12996. MACPNOA1 has a wide alge-lysing spectrum, and widely lyses common water-blooming cyanobacteria; when MACPNOA1 is added into cyanobacterial water-blooming liquid belonging to seven categories of Microcystis, Aphanizomenon, Chroococcus, Planktothrix, Nostoc, Oscillatoria and Anabaena, MACPNOA1 has strong pyrolysis effects on all the measured seven categories. When MACPNOA1 is applied to algal bloom treatment, the obvious effect of protecting animals in water is achieved. The pyrolysis phycophage MACPNOA1 has the advantages of being safe, efficient and quick.

Owner:NINGBO UNIV

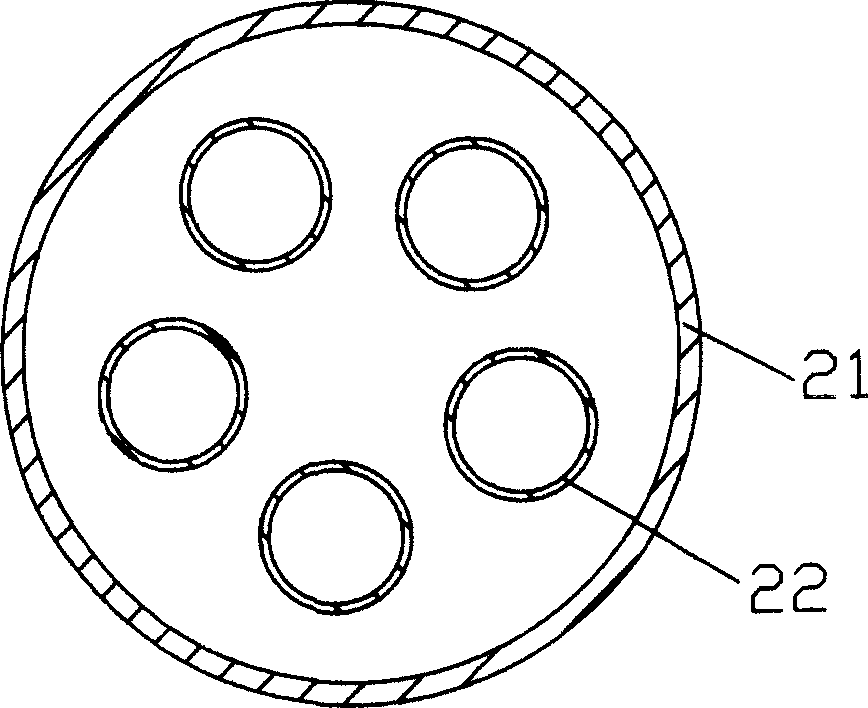

Grinding wheel ash hollow brick and production method thereof

InactiveCN106187096AThe preparation method is simple and easyReduce manufacturing costCeramic shaping apparatusCeramic materials productionIndustrial constructionBrick

The invention discloses a grinding wheel ash hollow brick. The grinding wheel ash hollow brick comprises, by weight, 15-20 parts of grinding wheel ash, 30-40 parts of river silt, 25-30 parts of coal cinder, 90-105 parts of water, 20-30 parts of montmorillonite, 35-40 parts of basalt, 2-5 parts of wood chip, 1-3 parts of polystyrene beads and 2-5 parts of quicklime, and is produced through the steps of pre-activating, crushing, sealed aging, green body making, drying, sintering and the like. Industrial construction waste is fully utilized, production cost is lowered, corporate profit is increased, the production method is advanced, raw material activity and adhesiveness are improved by means of pre-activating, the raw materials are closely fused together, and the grinding wheel ash hollow brick is compact in texture, non-chalking, high in compressive strength and wear resistance, good in cracking resistance, long in service life, wide in application, high in construction adaptability and capable of being used for a long time under the condition of low temperature.

Owner:安徽琮玥工程项目管理有限公司

Cell periodic detection kit

InactiveCN108866146ADetermination of precisionHigh fluorescence intensityMicrobiological testing/measurementIndividual particle analysisPhosphoric acidCell cycle

The invention discloses a cell periodic detection kit. The cell periodic detection kit comprises a reagent I and a reagent II; the reagent I comprises a DMEM culture medium, 0.05 to 0.5 percent trypsin and cleaning buffering solution; and the reagent II comprises 2 to 5 ml of Cystain DNA1 step, 100 to 120 micro liter of low-permeability cracking buffering solution, 0.5 to 5 micro liter of phosphoric acid histochemical protein H3 primary antibody and 0.2 to 2.0 micro liter of phosphoric acid histochemical protein H3 secondary antibody. The kit utilizes flow cytometry technology, so that the cell period can be rapidly and accurately determined, and the period G2 and the period M can be distinguished.

Owner:INST OF RADIATION MEDICINE CHINESE ACADEMY OF MEDICAL SCI

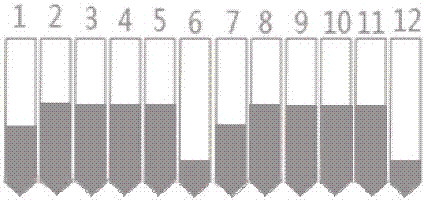

Quick extraction kit for blood sampling card

InactiveCN107201362AImprove extraction efficiencyShorten the timeMicrobiological testing/measurementDNA preparationMagnetic beadPolyethylene glycol

The invention discloses a quick extraction kit for a blood sampling card. The quick extraction kit is prepared from the following components: blood film digestive juice, lysate, tris(2-carboxyethyl)phosphine, a binding solution, magnetic beads, a washing solution 1, a washing solution 2, a washing solution 3 and eluant. In order to increase the nucleic acid extraction efficiency of the kit, the tris(2-carboxyethyl)phosphine is used for replacing protease k, and polyethylene glycol (PEG)-6000 is added into the eluant. Furthermore, a 96-hole pre-subpackaged deep-well plate mode is used by the kit, and the kit can be matched with an automatic nucleic acid extractor-smart 32 of DA AN Gene Co. Ltd. of Sun Yat-sen University for use so as to realize automatic nucleic acid extraction; after the quick extraction kit is adopted, a great deal of deoxyribonucleic acid (DNA) of the blood sampling card can be rapidly and effectively extracted.

Owner:GUANGZHOU HEAS BIOTECH CO LTD

Steam thermal cracking simulation experiment device and process

ActiveCN107541239AAvoid secondary reactionsReduce injection volumeThermal non-catalytic crackingHydrocarbon by hydrocarbon crackingGas phaseProduct gas

The invention provides a steam thermal cracking simulation experiment device and process. The steam thermal cracking simulation experiment device comprises a raw material feeding device, a cracking furnace and a product quenching recovery device which are sequentially connected; the product quenching recovery device comprises a direct quenching system and a circulating quenching recovery system; the circulating quenching recovery system comprises a cracked gas circulating quenching loop composed of a gas-phase mixer, an indirect quencher, a cyclone separator, a gas circulating pump and a cooler; the gas-phase mixer is connected to a cracking furnace pipe discharging hole in a sealing way; the direct quenching system is used for vertically inserting a quenching water injection pipe in the cracking furnace pipe discharging hole through the center inside the gas-phase mixer; a water injection hole is formed in the end of the inserted end; and quenching water is injected into a cracking furnace pipe by the water injection hole. The steam thermal cracking simulation experiment device has the advantages that high-temperature cracked gas is directly quenched twice after being sequentiallyinjected with the quenching water and a circulating gas product, so that the cooling efficiency is high, the injection quantity of the quenching water is small, secondary reaction of the cracked gascan be effectively avoided, and the accuracy of a simulation effect of the cracking furnace is improved.

Owner:PETROCHINA CO LTD

Mycoporin vaginal soft capsule and its preparing method

InactiveCN1899285AGuaranteed stabilityRapid lysisOrganic active ingredientsCapsule deliverySoftgelWhite petrolatum

The present invention relates to soft mycosporin capsule for vagina and its preparation process. Each of soft mycosporin capsules contains mycosporin in 50-300 mg and medicinal supplementary material vaseline and paraffin, and the capsule shell contains gelatin in 10 weight portions and glycerin in 4.0-5.5 weight portions. The preparation process includes the steps of dissolving gelatin in water and adding glycerin and proper amount of preservative, vacuum deairing, mixing mycosporin and medicinal supplementary material, and pressing into soft capsule. Compared with available mycosporin preparation forms, the soft mycosporin capsule has the advantages of stable quality, convenient carrying and administration, and fast leaching of the effective components.

Owner:赵宗平

A coated double slow release fertilizer and a preparing method thereof

InactiveCN105967838AExtend the lifespanPromote absorptionMagnesium fertilisersSewage/sludge fertilisersSulfite saltCyclodextrin

A coated double slow release fertilizer and a preparing method thereof are disclosed. The fertilizer is prepared from papermaking black liquid, a sulfuric solution having a concentration of 10 wt%, a formaldehyde solution having a concentration of 5%, sodium sulfite, montmorillonite powder, cyclodextrin, agar powder, aldol resin, citric acid, magnesium sulfate, farm-oriented rare earth, potassium chloride, ammonium humate, oxalic acid, manganese sulfate, potassium permanganate and a proper amount of water by weight parts. Coating is adopted, the water content of particles of the fertilizer is controlled firstly, and the particles are sprayed with a coating material adopting stone powder as a main material, thus effectively preventing adhesion among the fertilizer particles, preventing rapid splitting of the fertilizer particles, and largely prolonging the fertilizer using time. Surfaces of modified lignin particles are provided with certain sodium lignosulphonate components capable of adsorbing cations, thus promoting fertilizer absorption and preventing water and soil loss.

Owner:ANHUI FENGYANG DECHENG TECH

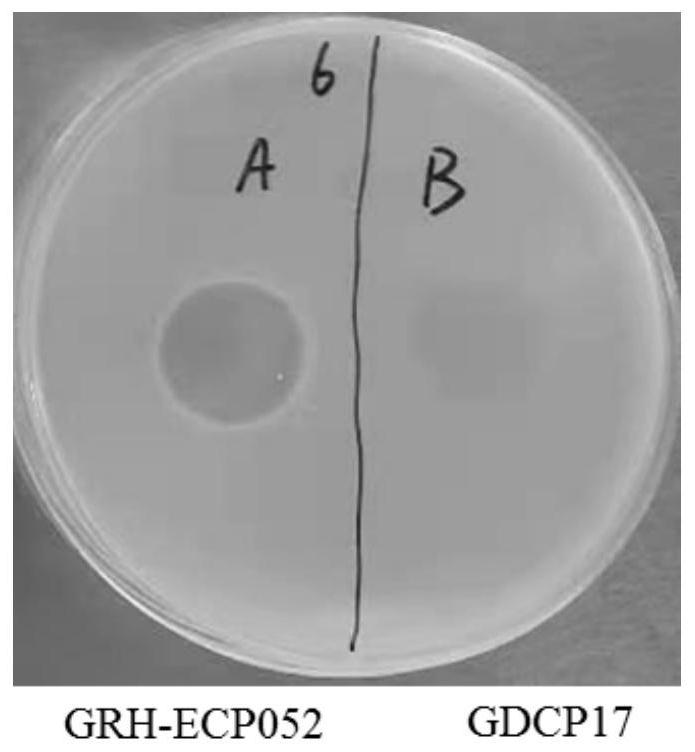

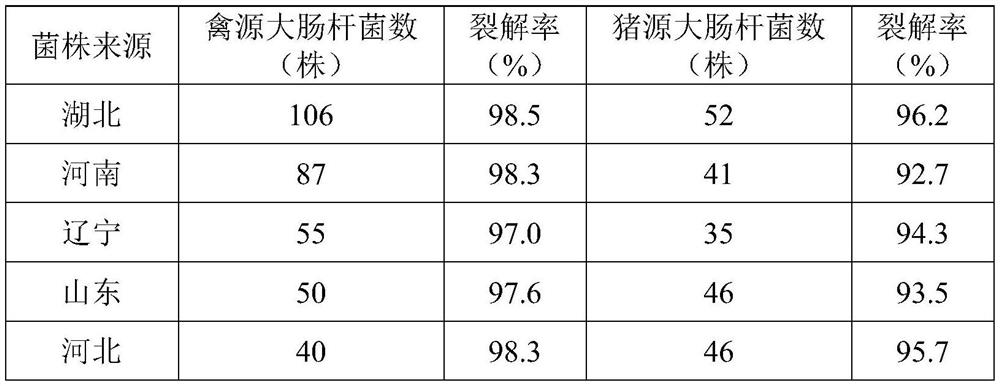

Broad-spectrum phage for rapidly cracking livestock and poultry escherichia coli and application

PendingCN113604441ABroad cracking spectrumImprove fermentation efficiencyAntibacterial agentsDigestive systemColiphageLivestock

The invention belongs to the technical field of agricultural microorganism application, and particularly relates to a broad-spectrum phage for rapidly cracking livestock and poultry pathogenic escherichia coli and application. The escherichia coli phage GRH-ECP052 which is rapid in cracking and wide in cracking spectrum is obtained through screening, the phage is preserved in the China center for type culture Collection, and the preservation number is CCTCC NO: M20211009. The phage has a good prevention and treatment effect on poultry colibacillosis and piglet yellow-white dysentery.

Owner:武汉观海生物科技有限公司

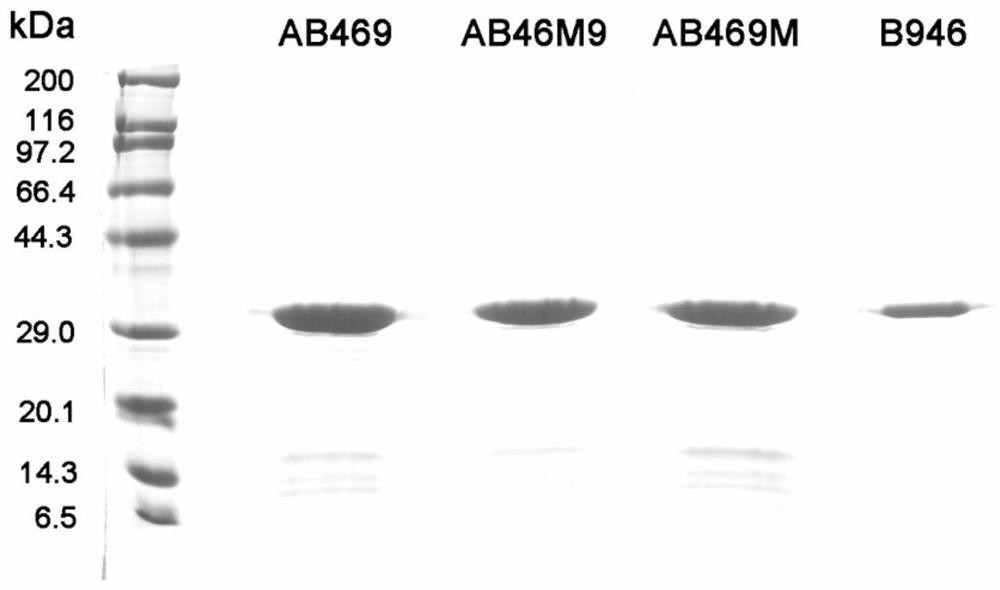

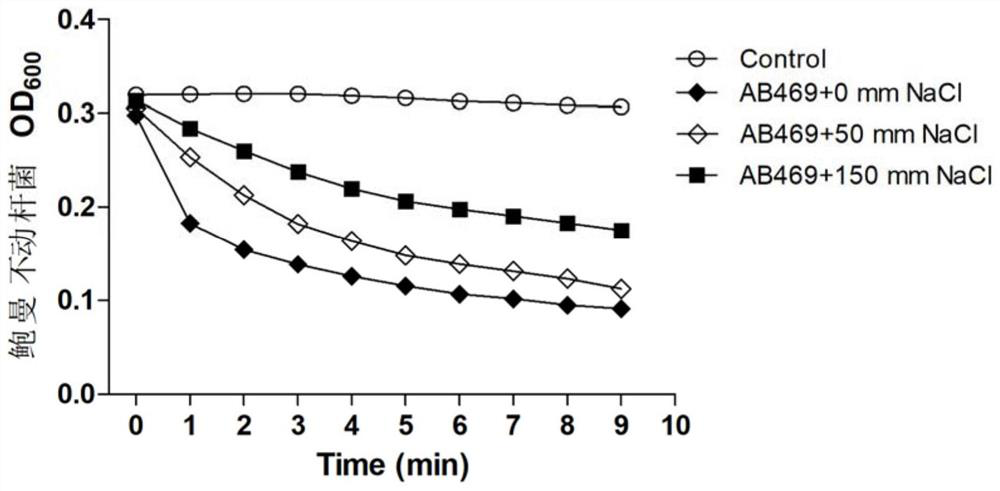

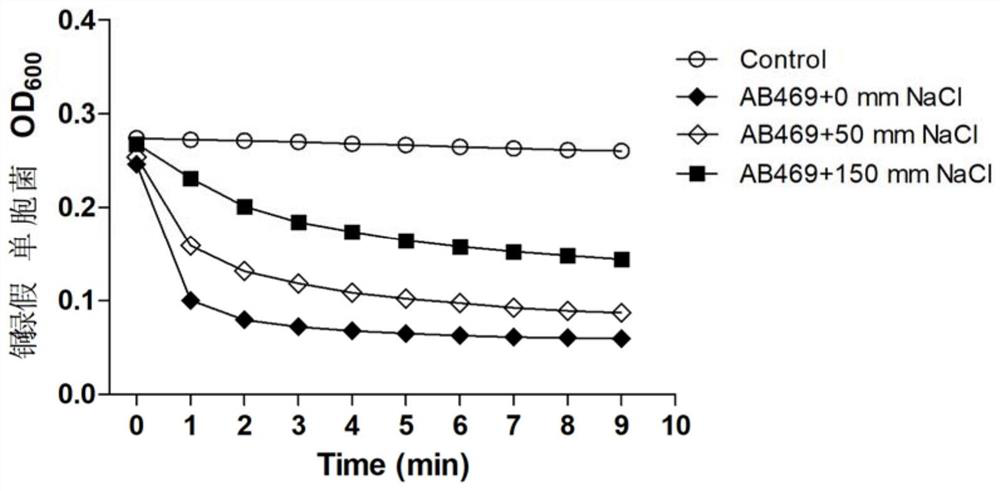

Hybrid antibacterial protein with strong bactericidal effect and application thereof

ActiveCN112724257AHigh purityRapid lysisAntibacterial agentsPeptide/protein ingredientsBacilliSaccharomyces

The invention discloses a heterozygous antibacterial protein with strong bactericidal effect and an application thereof, the heterozygous antibacterial protein with strong bactericidal effect comprises an amino acid sequence as shown in SEQ ID NO 1, and is named as AB469, a heterozygous protein composed of the sequences similar to the catalytic domain of the AB469, a heterozygous protein composed of the sequences similar to the binding domain of the AB469 or a heterozygous protein composed of the catalytic domain and the binding domain of the AB469 through position exchange. The heterozygous antibacterial protein disclosed by the invention is expressed by utilizing escherichia coli or saccharomycetes and the like, and high-purity hybrid antibacterial protein is obtained after purification; the protein can rapidly split gram-negative bacteria such as acinetobacter baumannii, pseudomonas aeruginosa, klebsiella pneumoniae, salmonella and escherichia coli. An antibacterial preparation prepared from the antibacterial protein can be used for preventing and treating bacterial infection, and can be prepared into an antibacterial preparation for preventing and treating bacterial infection, sterilizing medical instruments and medical places and the like.

Owner:JIANGXI YUANSHENG BIOLOGICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com