Patents

Literature

98results about How to "Avoid secondary reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

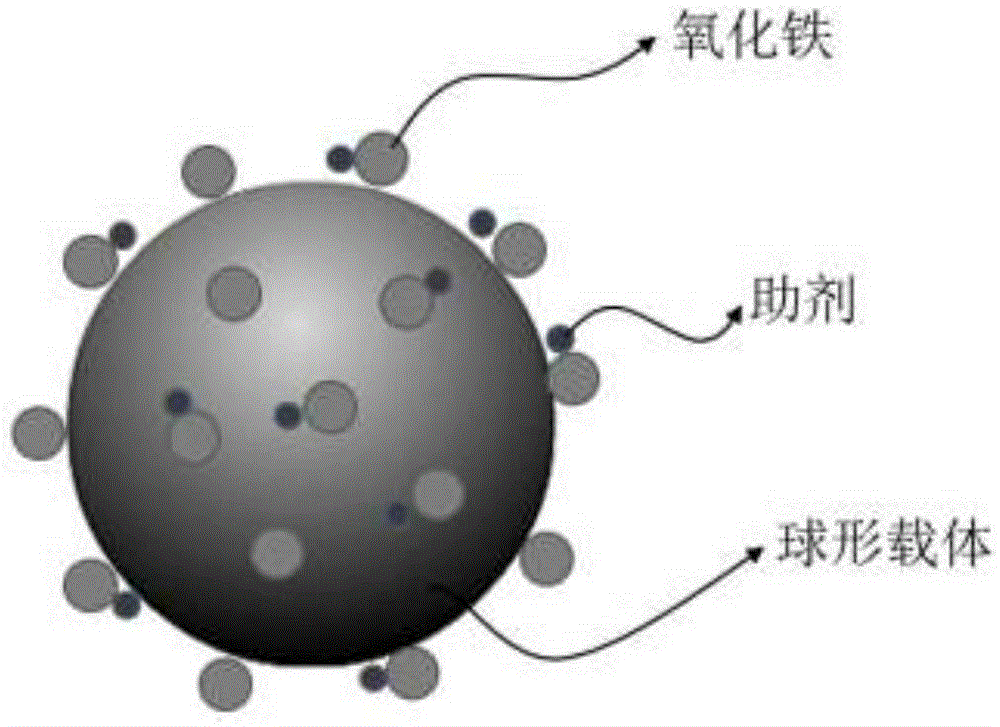

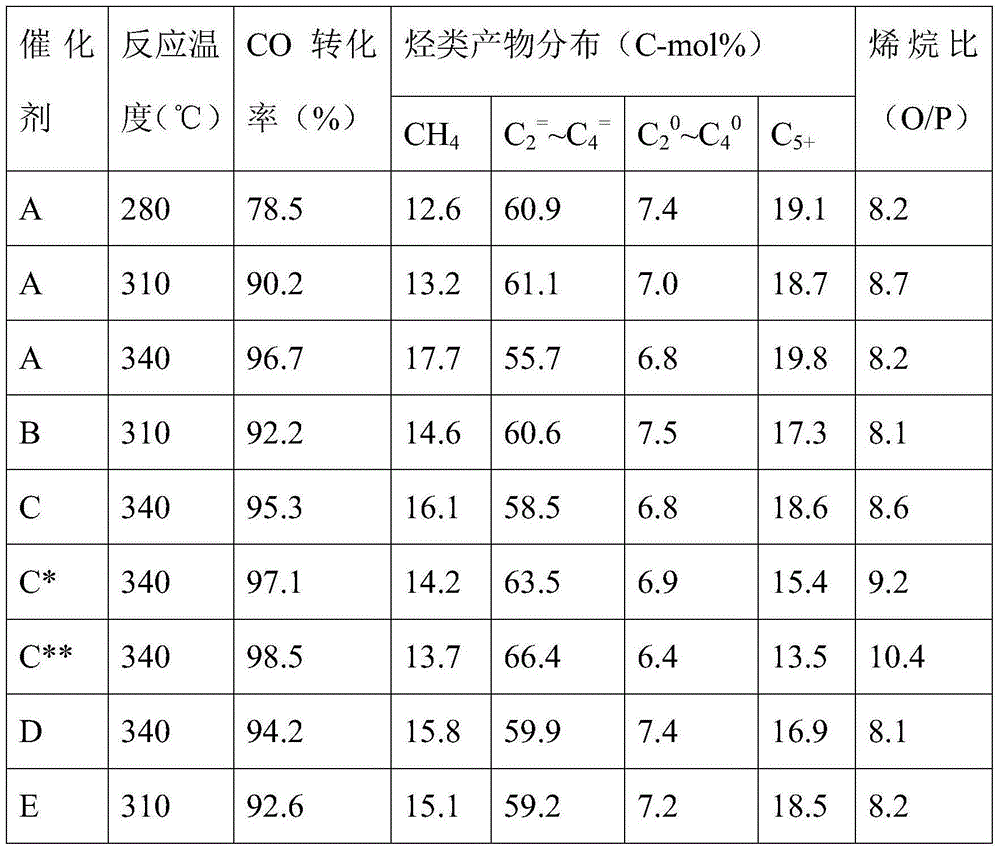

Catalyst facilitating direct preparation of light olefins from syngas as well as preparation and application of catalyst

ActiveCN105195189AEasy to prepareEasy to operateHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionAlkaneSyngas

The invention discloses a preparation method of a catalyst facilitating highly selective synthesis of light olefins from syngas. A compound adopting a spherical or ellipsoidal structure is taken as a carrier to be loaded with iron oxide and added with auxiliaries and is used for Fischer-Tropsch reaction for the syngas. The catalyst has very high catalytic activity on one hand and can effectively reduce alkane generated through secondary reaction hydrogenation of light olefins, and the selectivity of light olefins is improved. The preparation method of the catalyst is simple, and the catalyst has very good application prospects.

Owner:JIANGNAN UNIV

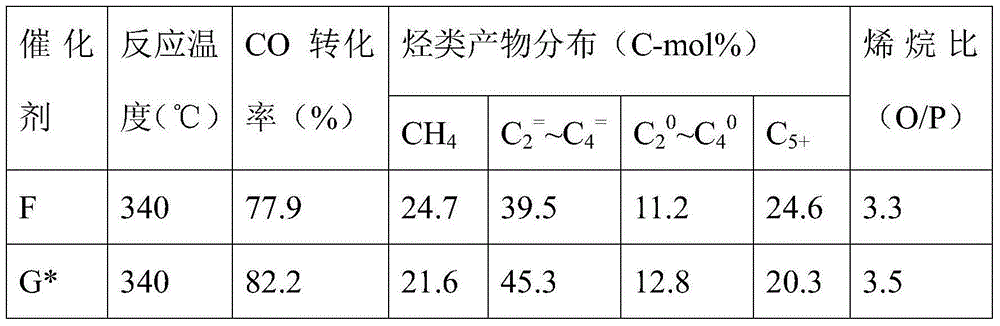

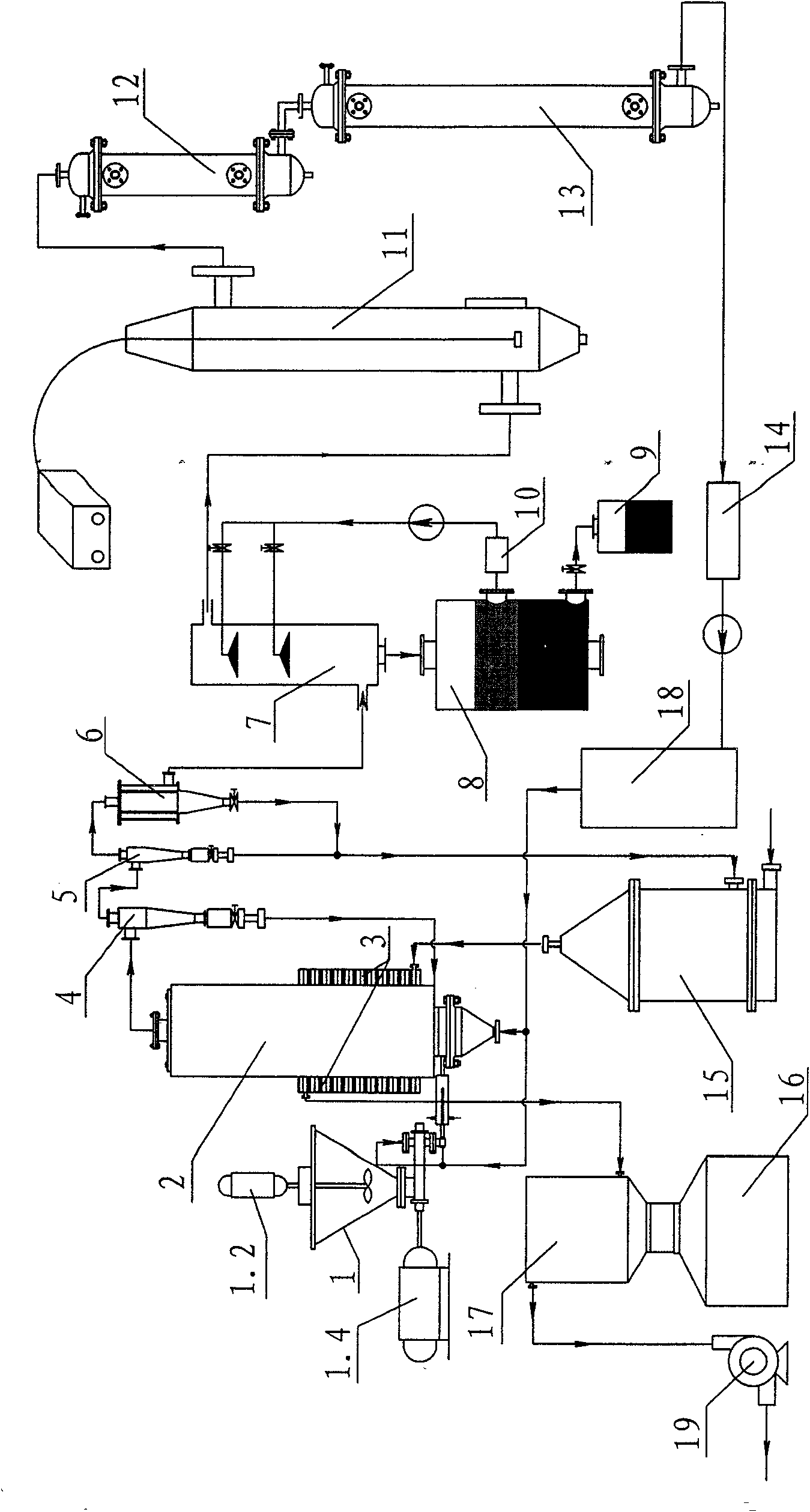

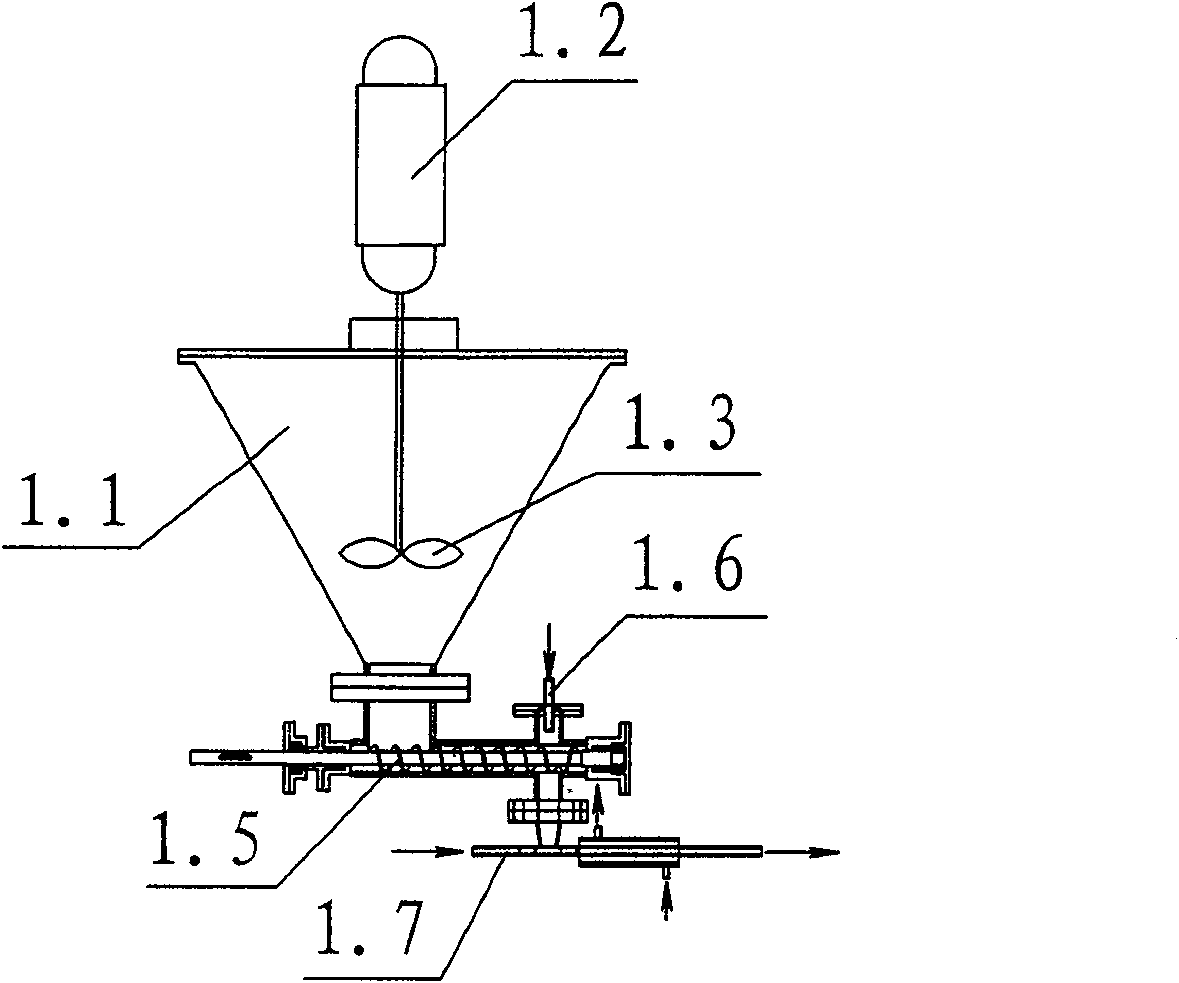

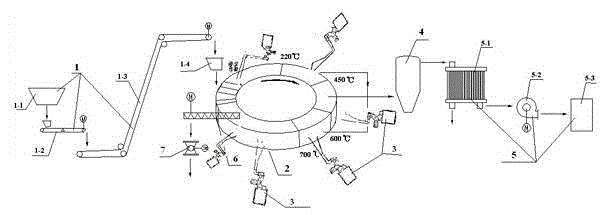

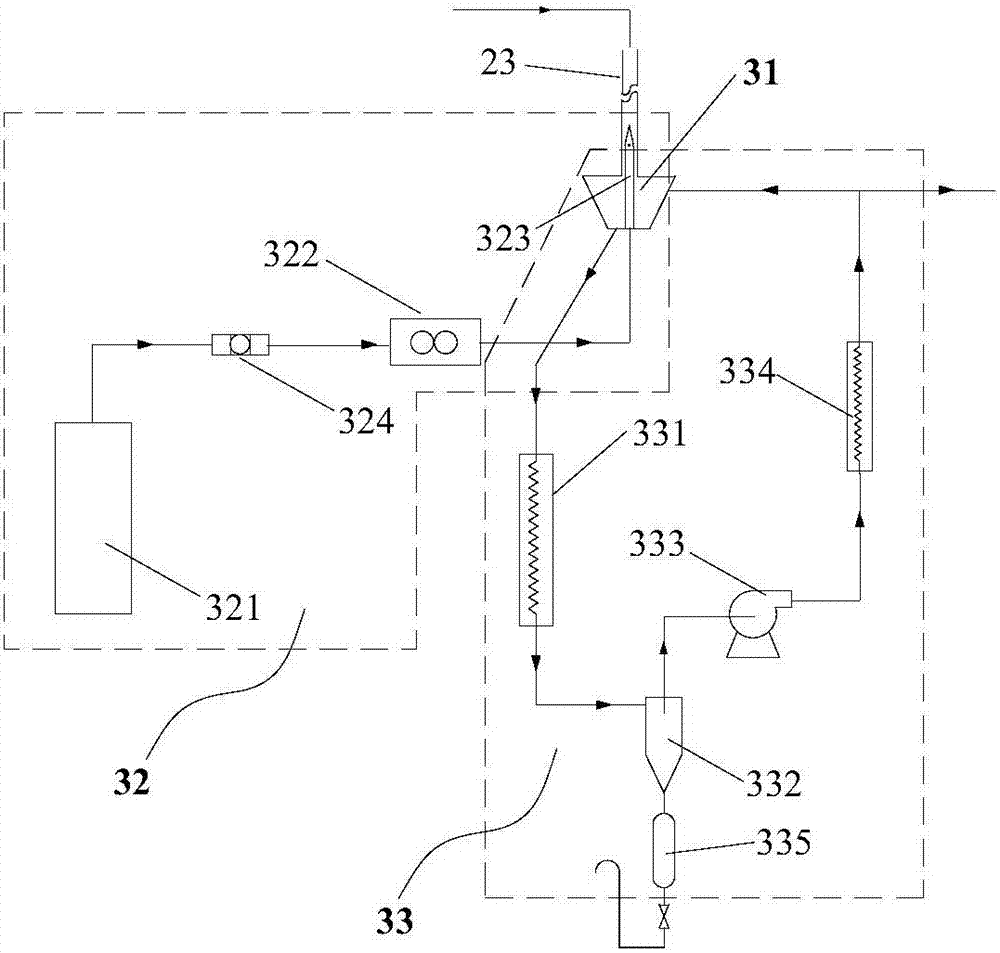

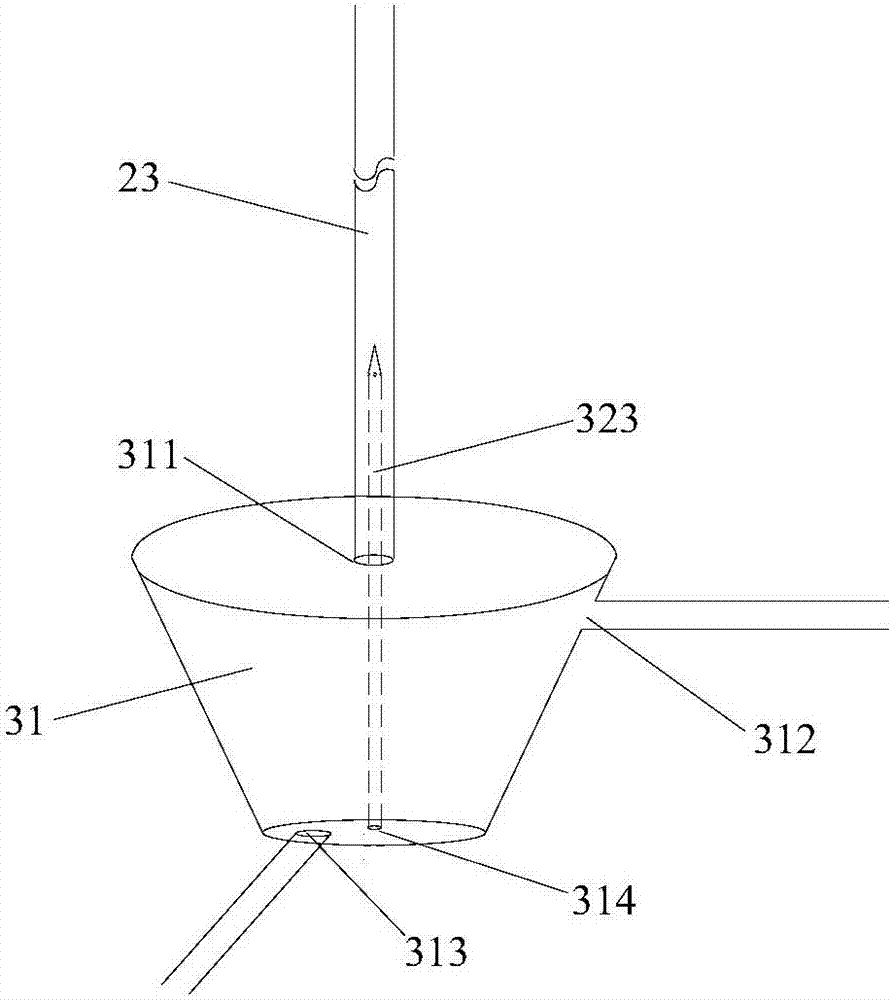

Method for preparing liquid fuels by self-heating self-circulating thermal cracking of biomass and device thereof

InactiveCN101560405ARealize self-heatingAvoid secondary reactionsLiquid hydrocarbon mixture productionCycloneElectricity

The invention relates to a method for preparing liquid fuels by self-heating self-circulating thermal cracking of biomass and a device thereof. Solid substances and carbon can be effectively reclaimed through a two-stage cyclone separator and a carbon filter, most of heavy oil components in thermal cracking volatile components are collected by adopting spray condensing, micro oil drops in the volatile components are further caught by electric catching, light oil components are complementally collected by cooling through a final dividing wall type water cooler, the volatile components are gradually cooled at an inlet of a cooling system at a temperature of 200 DEG C to collect biological oil, and finally, condensable parts in the volatile components are basically collected at an outlet at a temperature of below 30 DEG C. Through quick thermal cracking technology and stepped cooling and collecting processes, cellulose biomass wastes are converted into the liquid fuels of different levels, and simultaneously, volatile gas and coke products in the thermal cracking process are reclaimed and utilized to realize self-heating for a complete thermal cracking system and save cost.

Owner:顾赛 +1

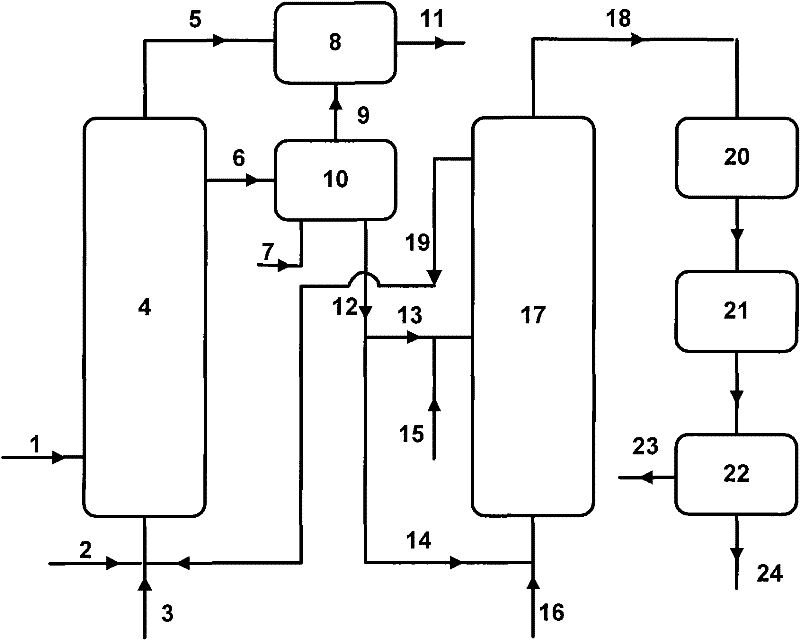

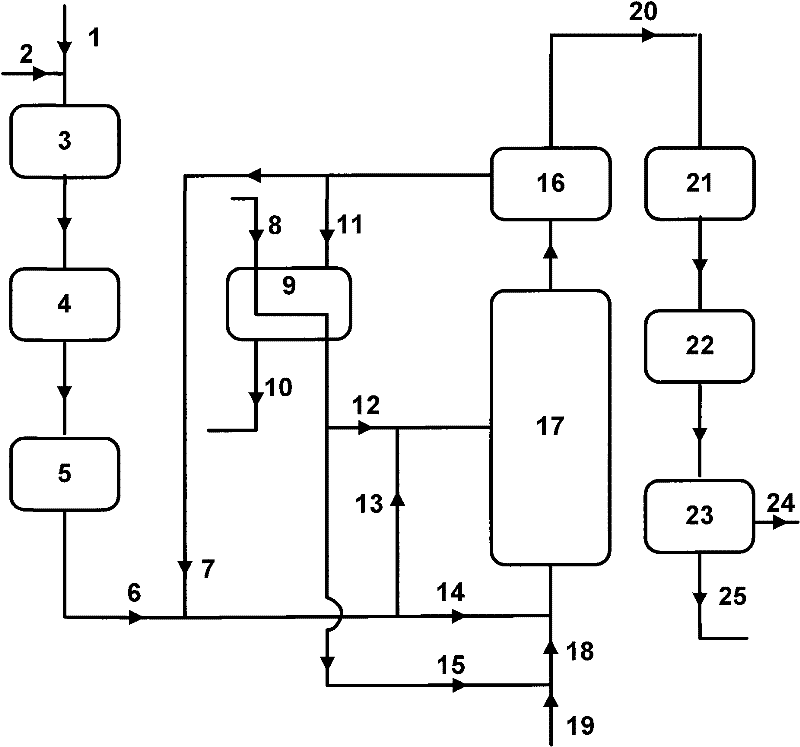

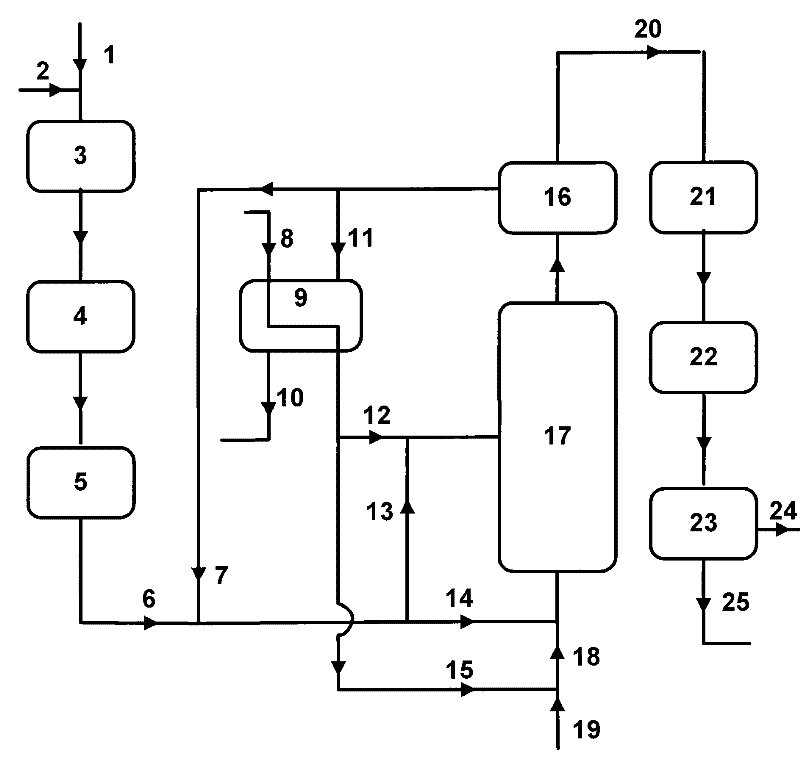

Method for processing inferior heavy oil

ActiveCN102234534AHigh economic valueHigh yieldTreatment with plural serial stages onlyGranular/pulverulent flues gasificationSyngasOil processing

A method for processing inferior heavy oil. The method comprises the following steps: allowing a heavy oil raw material to react with a contact agent in a reactor, performing a gasification reaction of the obtained catalyst in a gasifier to generate a syngas-containing gas product and to allow the catalyst to become a semi-regenerant; returning the semi-regenerant to the reactor. The method provided by the invention integrates two aspects of deep processing of inferior heavy oil and reasonable utilization of excess carbonaceous residues, adopts inferior heavy oil as a raw material, performs gasification of surplus coke in a gasifier to generate syngas with the proviso of light oil maximum production, makes reasonable use of residues of heavy oil processing, and produces a product with high economic value.

Owner:CHINA PETROLEUM & CHEM CORP +1

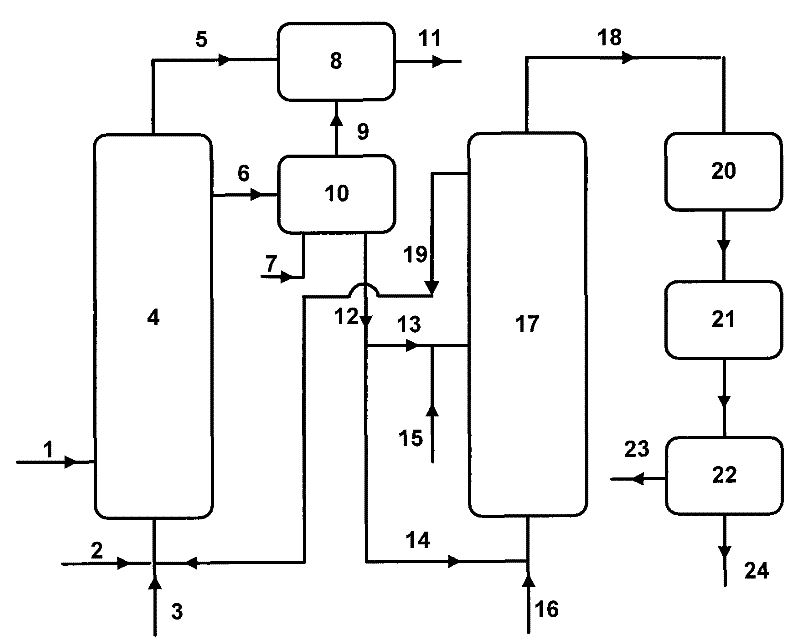

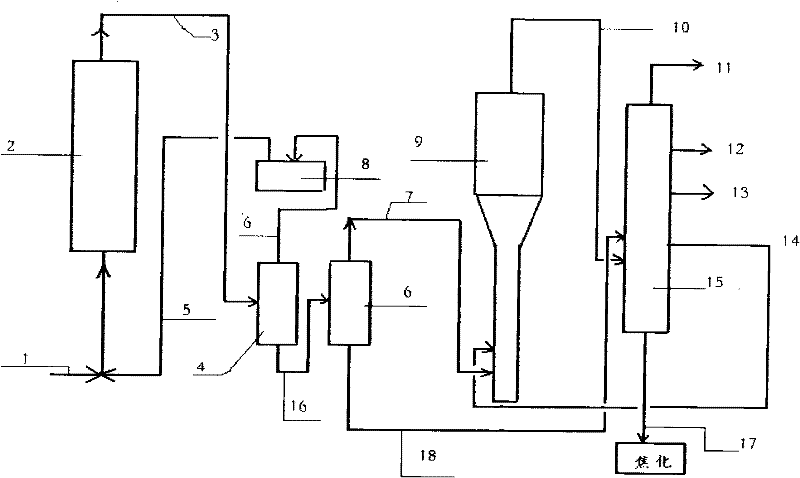

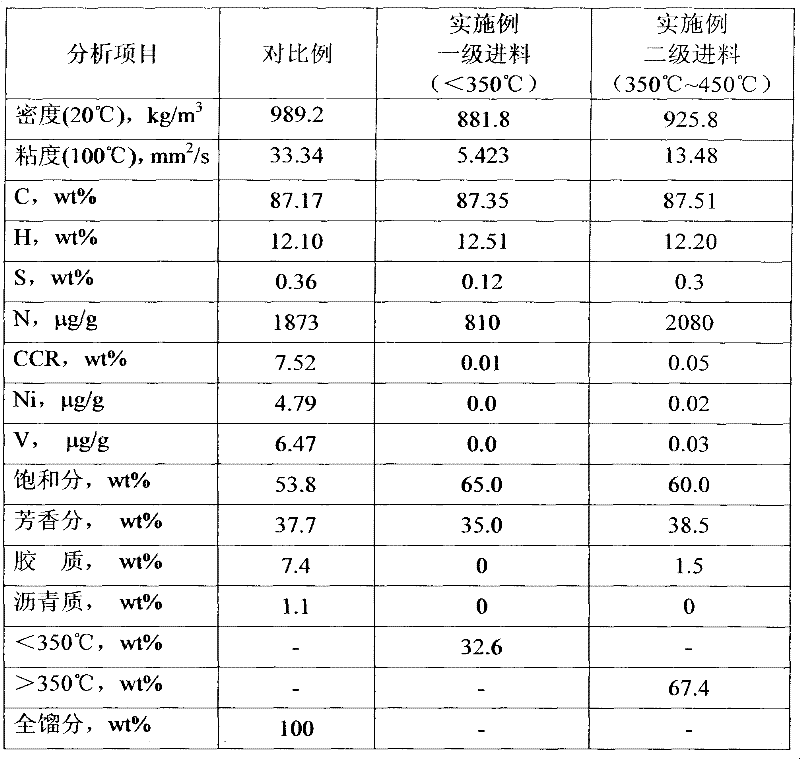

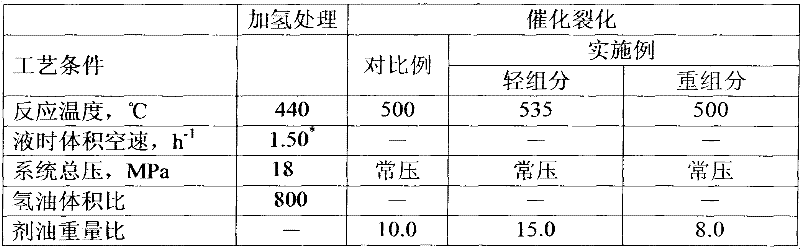

Combined process of hydrotreatment and catalytic cracking for residuum

ActiveCN102453543AYield maximizationAvoid secondary reactionsTreatment with hydrotreatment processesThermal energySlurry

The invention discloses a combined process of hydrotreatment and catalytic cracking for residuum. According to the process, a boiling bed hydrotreatment method is used in hydrotreatment of residuum, and the process comprises the following steps that: liquid phase products obtained after the raw material of residuum undergoes boiling bed hydrotreatment are subjected to fractional distillation so as to obtain light components and heavy components; the light components are used as first-stage charging materials and enter into a catalytic cracking riser reactor from the bottom of the reactor; the heavy components directly enter into a catalytic cracking fractionator and are subjected to fractional distillation together with effluent of a catalytic cracking reaction so as to isolate dry gas, liquefied gas, gasoline fraction, diesel oil fraction, recycle oil and slurry oil, wherein, the recycle oil is used as a second-stage charging material of the riser reactor, and the slurry oil is used as a charging component for delayed coking. Compared to the prior art, the process provided in the invention has the following characteristics: gasoline with a high octane number, diesel oil fraction and liquefied gas with a high added value can be produced; reaction thermal energy is fully utilized, thereby reducing energy consumption in production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Mitigation of deposits and secondary reactions in thermal conversion processes

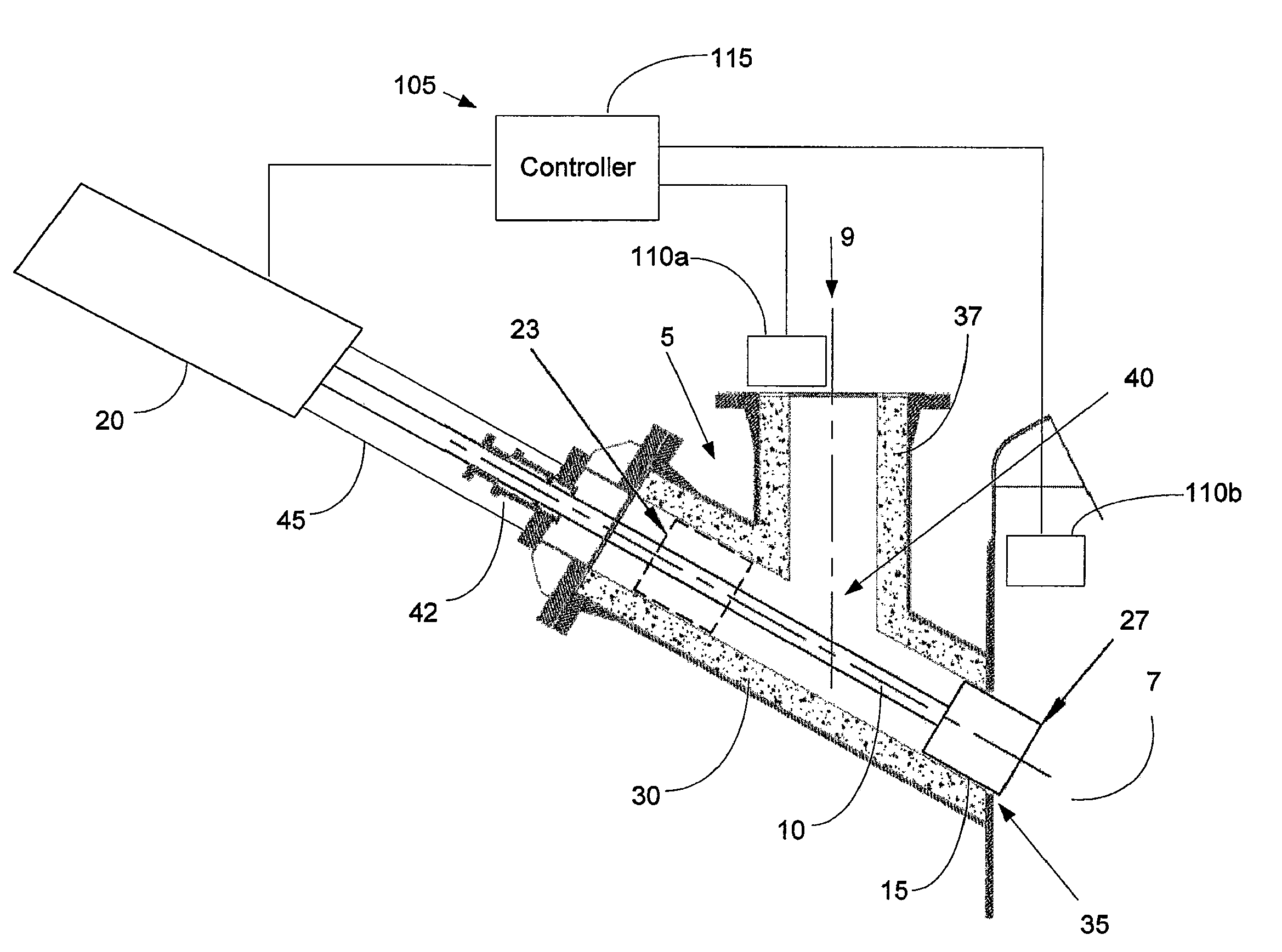

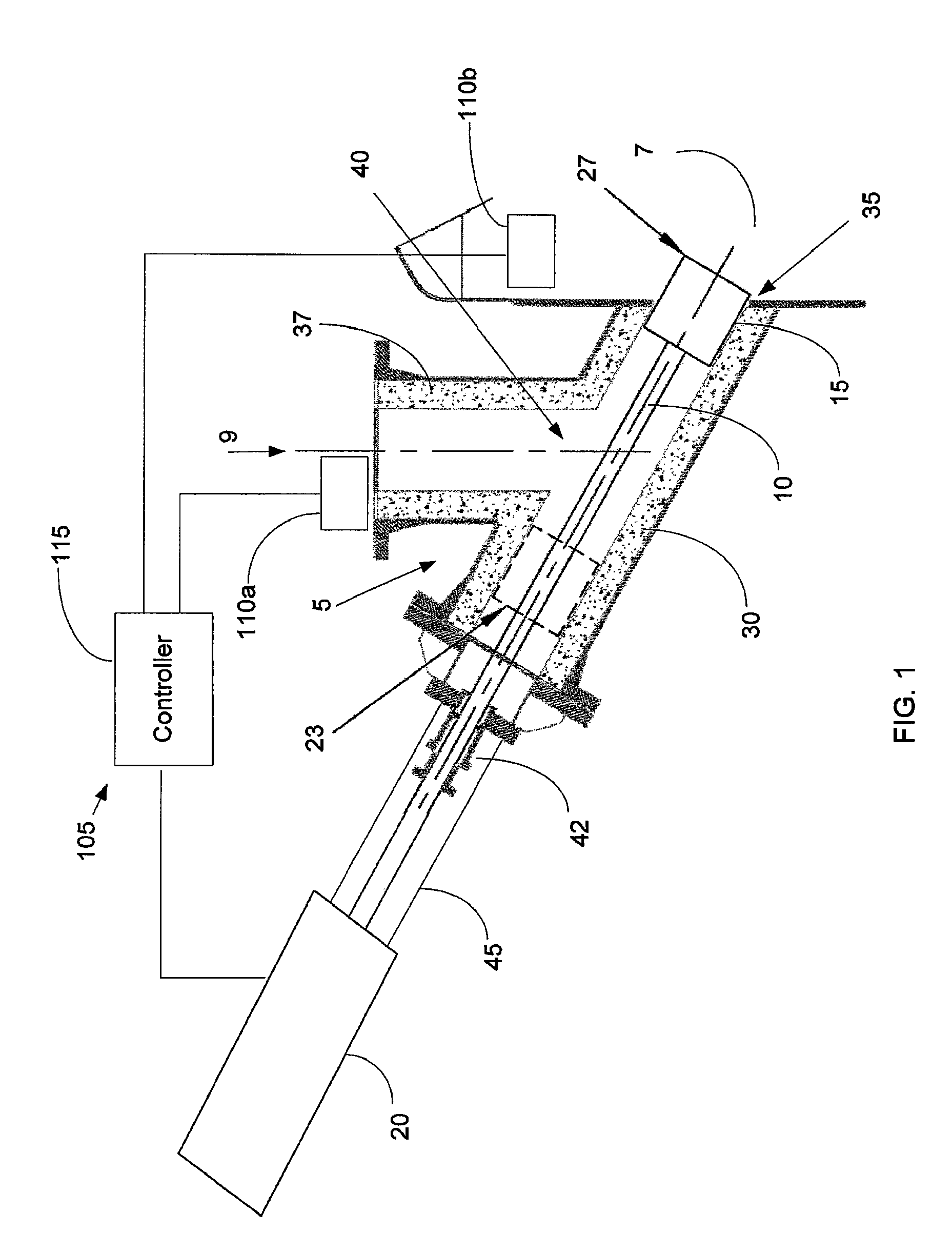

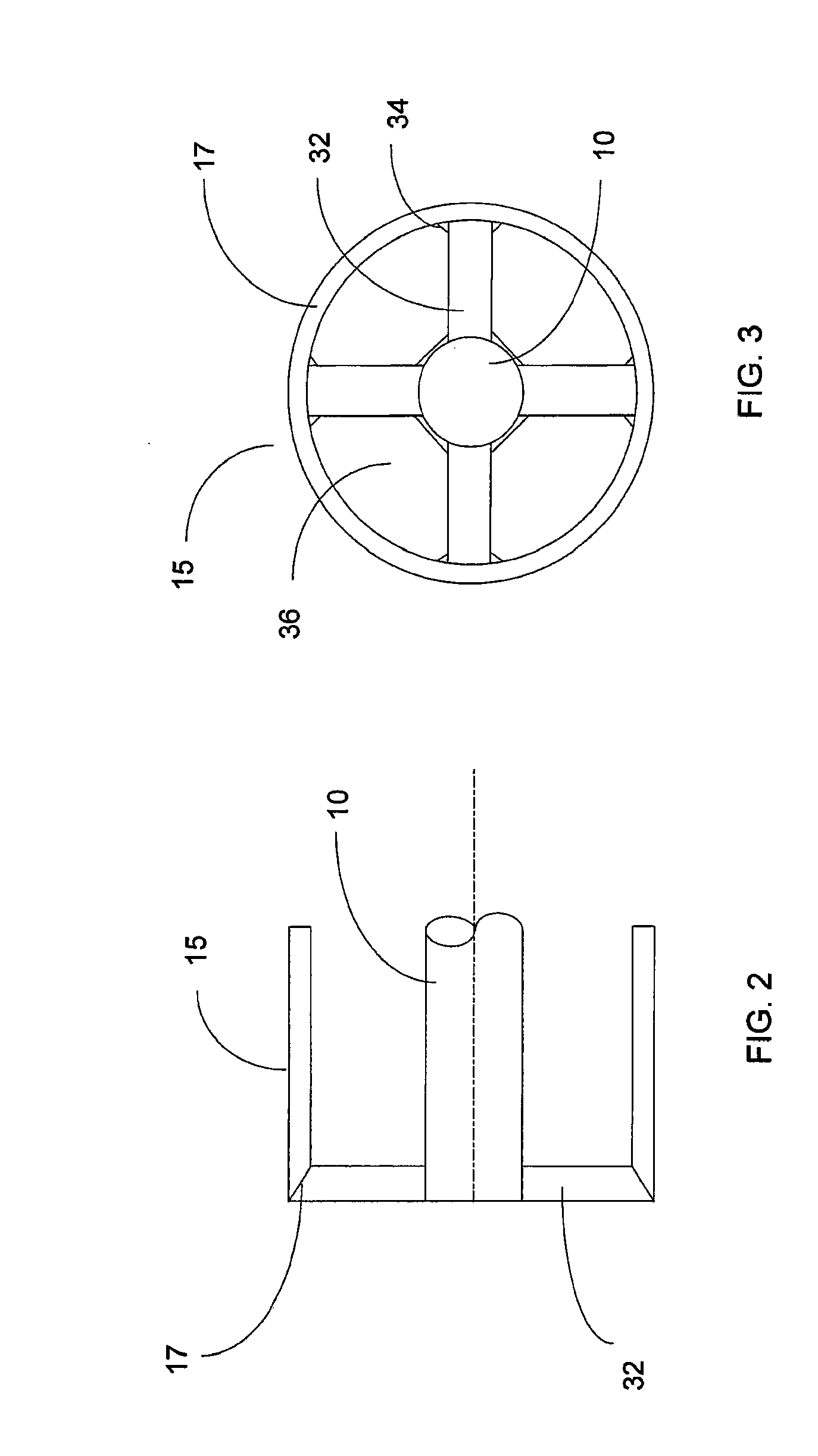

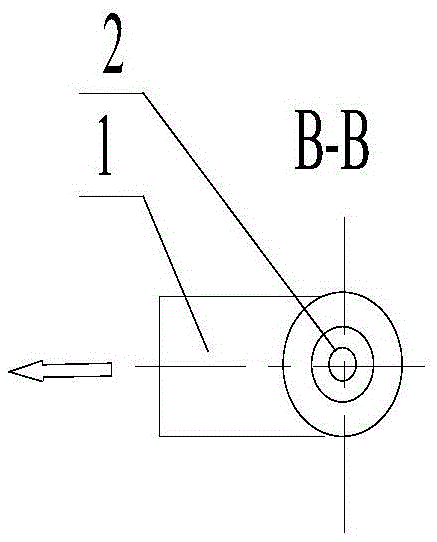

ActiveUS20090266380A1Reducing cumulative depositionReducing unwanted secondary thermal reactionHollow article cleaningCleaning using toolsProcess engineeringProduct gas

Described herein are systems and methods for reducing cumulative deposition and unwanted secondary thermal reactions in pyrolysis and other thermal conversion processes. In an embodiment, a system comprises a device, referred to as a reamer, for removing product deposits between thermal conversion and condensation operations of a pyrolysis process. The reamer may comprise, but is not limited to, a mechanical reciprocating rod or ram, a mechanical auger, a drill bit, a high-temperature wiper, brush, or punch to remove deposits and prevent secondary reactions. Alternatively or in addition, the reamer may use a high-velocity curtain or jet (i.e., a hydraulic or pneumatic stream) of vapor, product gas, recycle gas, other gas jet or non-condensing liquid to remove deposits. Preferably, the reamer removes deposits during the pyrolysis process allowing for continuous operation of the pyrolysis process.

Owner:ENSYN RENEWABLES

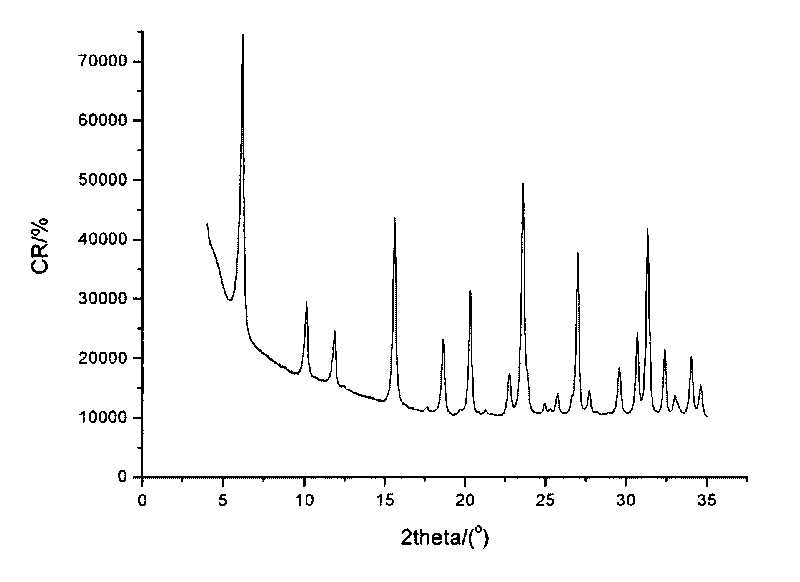

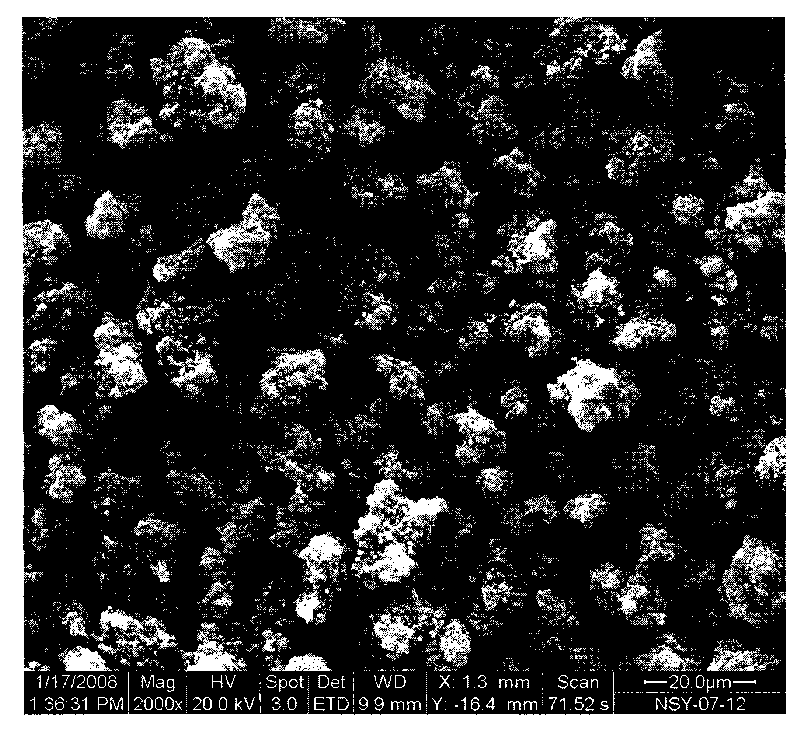

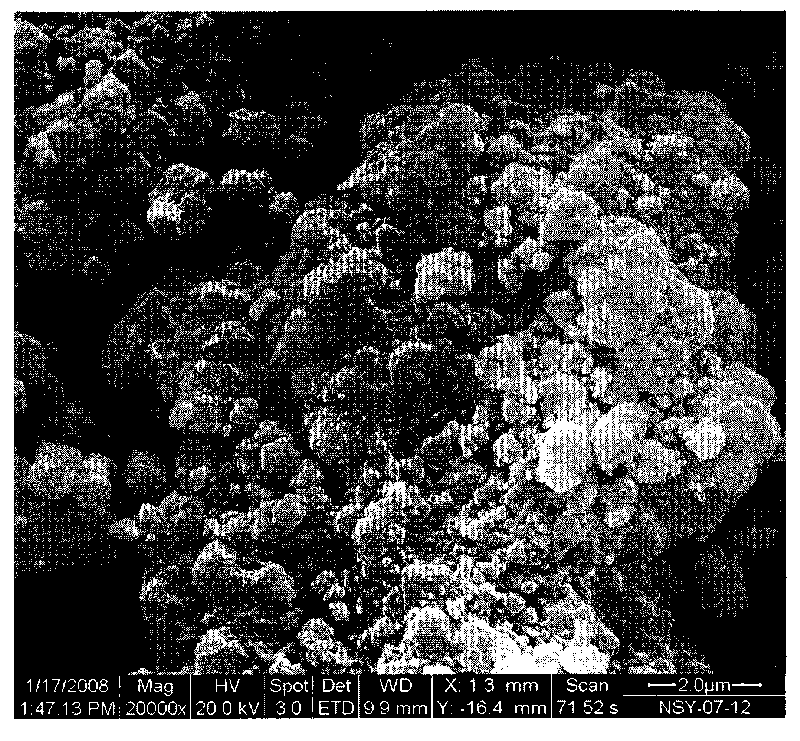

Composite material containing double-pore structure Y-type zeolite, and preparation method thereof

ActiveCN101746778AAvoid secondary reactionsFaujasite aluminosilicate zeoliteAmorphous matrixMaterials science

The invention discloses a composite material containing double-pore structure Y-type zeolite, which is characterized in that the composite material contains NaY zeolite and the balance of amorphous matrix; based on the weight of the composite material, the NaY zeolite accounts for 40 to 85 percent; the secondary structure of the composite material is a similar sphere; the similar sphere is formed by staggering and stacking Y-type zeolite generated by crystallization andmetakaolin amorphous intermediates generated during crystal transformation, and has gaps and holes; the sphere also has nest channels inside; the particle size is 3,000 to 25,000 nm; the surface area measured by a BET method is 280 to 800 M<2> / g; the total pore volume is 0.35 to 0.45 ml / g; the pore volume of 1.7 to 300 nm middle / big holes is 0.05 to 0.150 ml / g and accounts for 20 to 35 percent of the total pore volume.

Owner:CHINA PETROLEUM & CHEM CORP +1

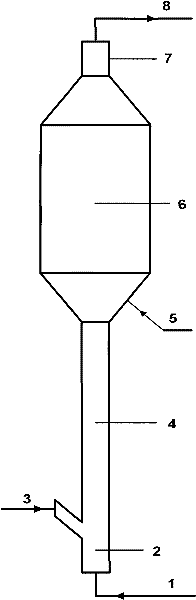

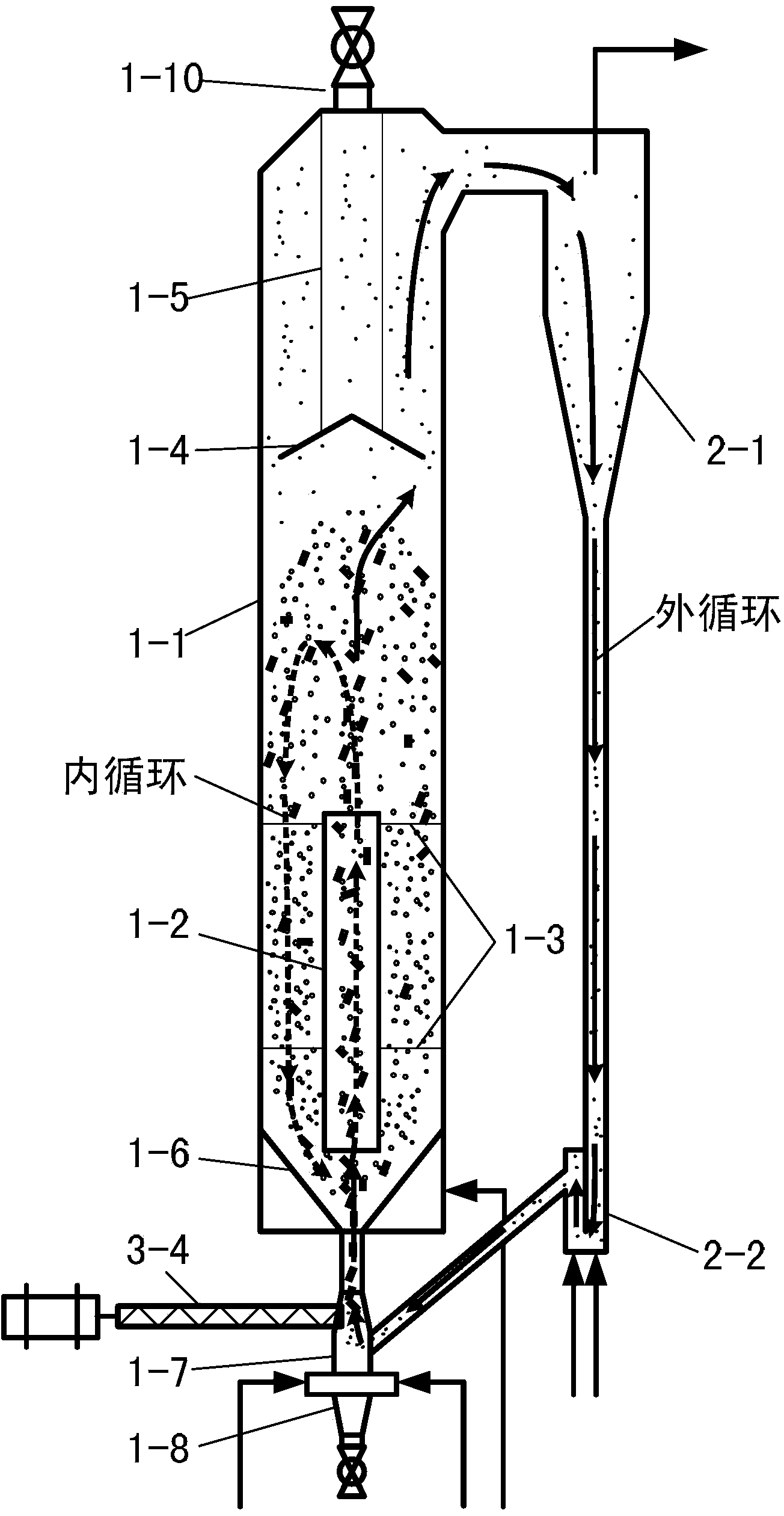

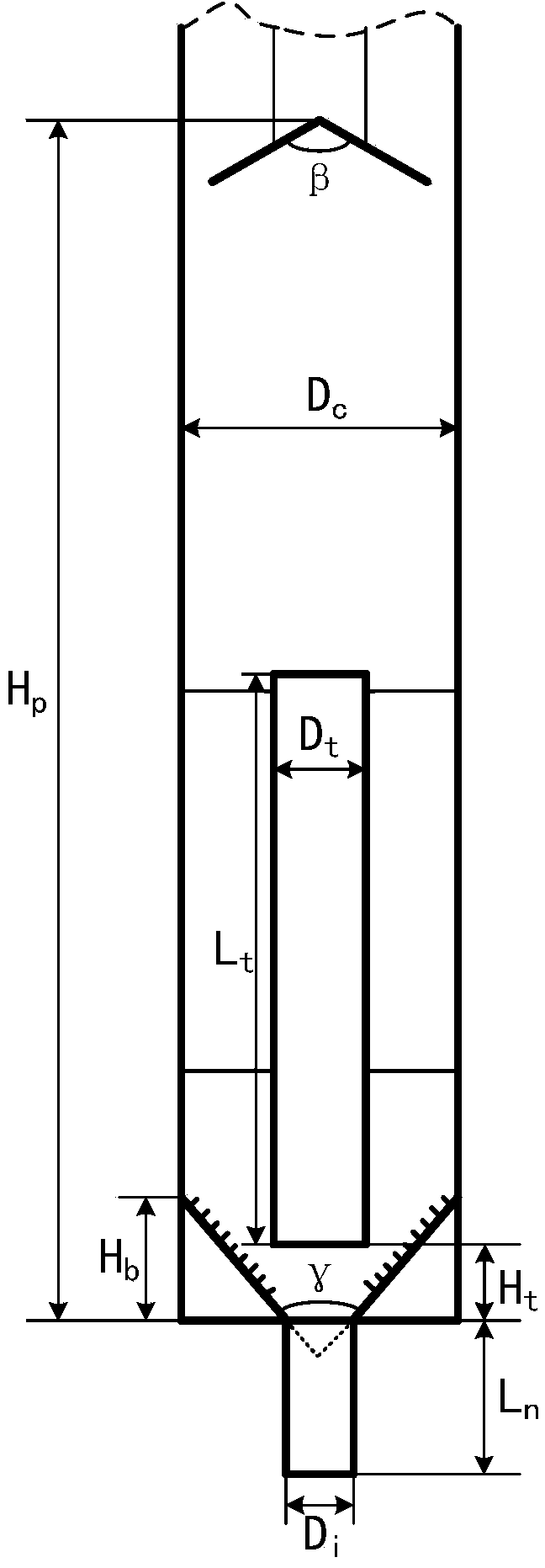

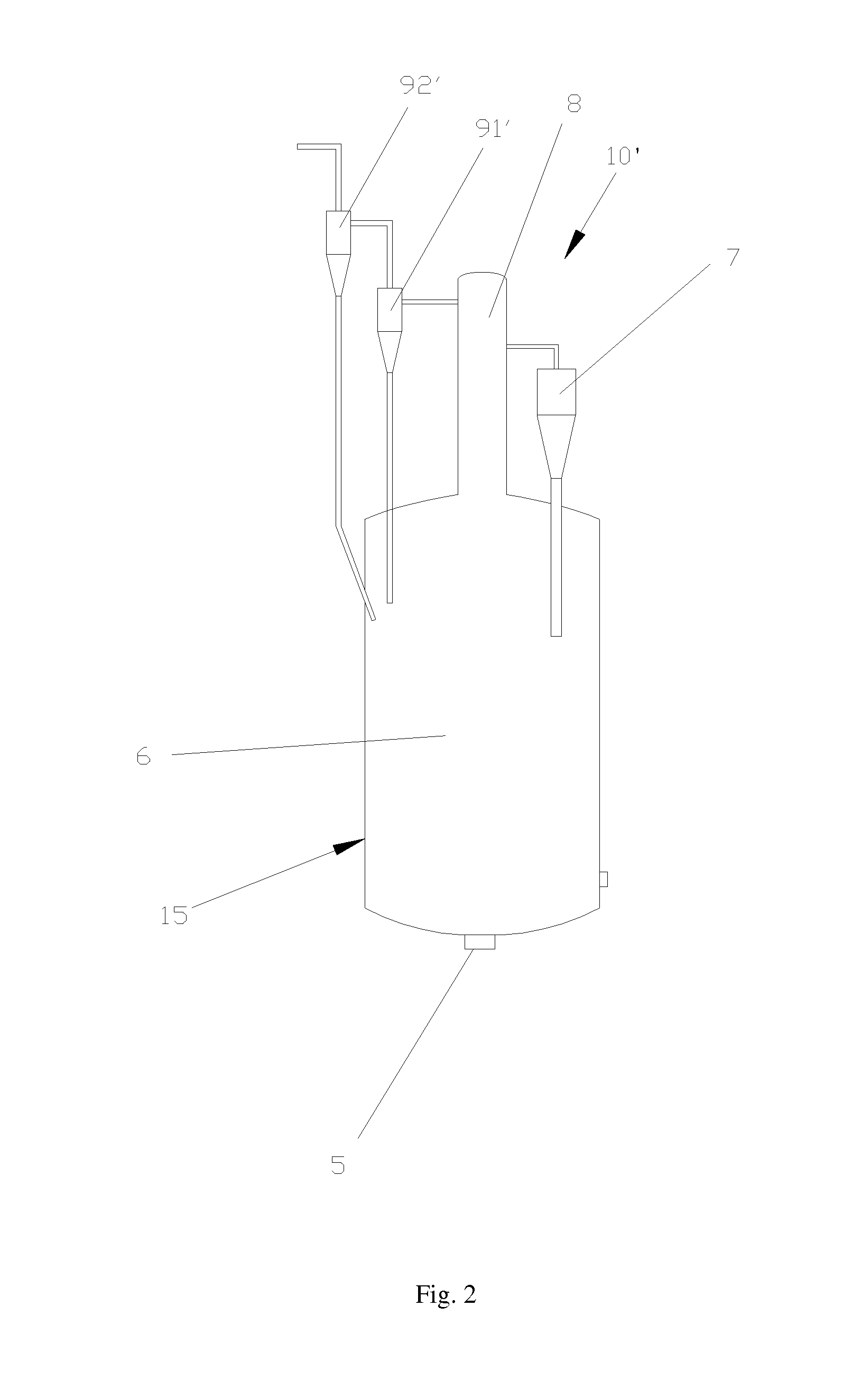

Biomass quick cracking device based on internal-external circulation spouted fluidized bed

ActiveCN103756712AShort stayGuaranteed dwell timeBiofuelsLiquid hydrocarbon mixture productionFluidized bedRetention time

The invention discloses a biomass quick cracking device based on an internal-external circulation spouted fluidized bed. The biomass particles are added through a bottom feeding chamber and conveyed into a pyrolysis reactor by spouted wind and generate a violet pyrolysis reaction through a guide pipe and a spouting area; the unreacted relatively large biomass particles form internal circulation along with a circulation medium through an annular space area; a catalyst and the unreacted tiny biomass particles are separated from the reaction area along with the pyrolysis gas and then return back into the bottom feeding chamber through a cyclone separator and a return feeder to form external circulation, and generate a pyrolysis reaction again. The device can perfectly meet the requirements of short gas phase retention time and sufficient solid phase reaction of the biomass pyrolysis technology, and the structure is simple and easy to enlarge; meanwhile, the external circulation of the catalyst particles and the early premixing and preheating thereof with the biomass particles in the bottom feeding chamber facilitate the direct efficient contact and sufficient mixing of the catalyst particles and the biomass particles, the utilization efficiency of the catalyst can be effectively improved, and the dosage of the catalyst is reduced.

Owner:SOUTHEAST UNIV

Preparation method of 2, 3, 3, 3-tetrafluoropropene

ActiveCN102675038AAccurate control of volume ratioReduce the probability of exposureHalogenated hydrocarbon preparationRetention timeProduct gas

The invention provides a preparation method of 2, 3, 3, 3-tetrafluoropropene, which comprises the following steps: taking monochlorodifluoromethane (R22) and methane chloride (methyl chloride) as raw materials and carrying out thermal cracking reaction at a high temperature of 600-1000 DEG C under the condition that N2 exits to prepare the 2, 3, 3, 3-tetrafluoropropene, wherein the volume ratio of the monochlorodifluoromethane to the methane chloride is 1-3:1, and the retention time of a reactant is 0.01-0.2 seconds. The reaction raw material used in the preparation method is easy to obtain, the defect of high cost of the used raw material in the prior art is overcome, the production cost is greatly reduced, and the reaction process is simple. The prepared 2, 3, 3, 3-tetrafluoropropene has the advantages of zero ODP and low GWP and can be used as a substitute of an automotive air-conditioning refrigerant.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

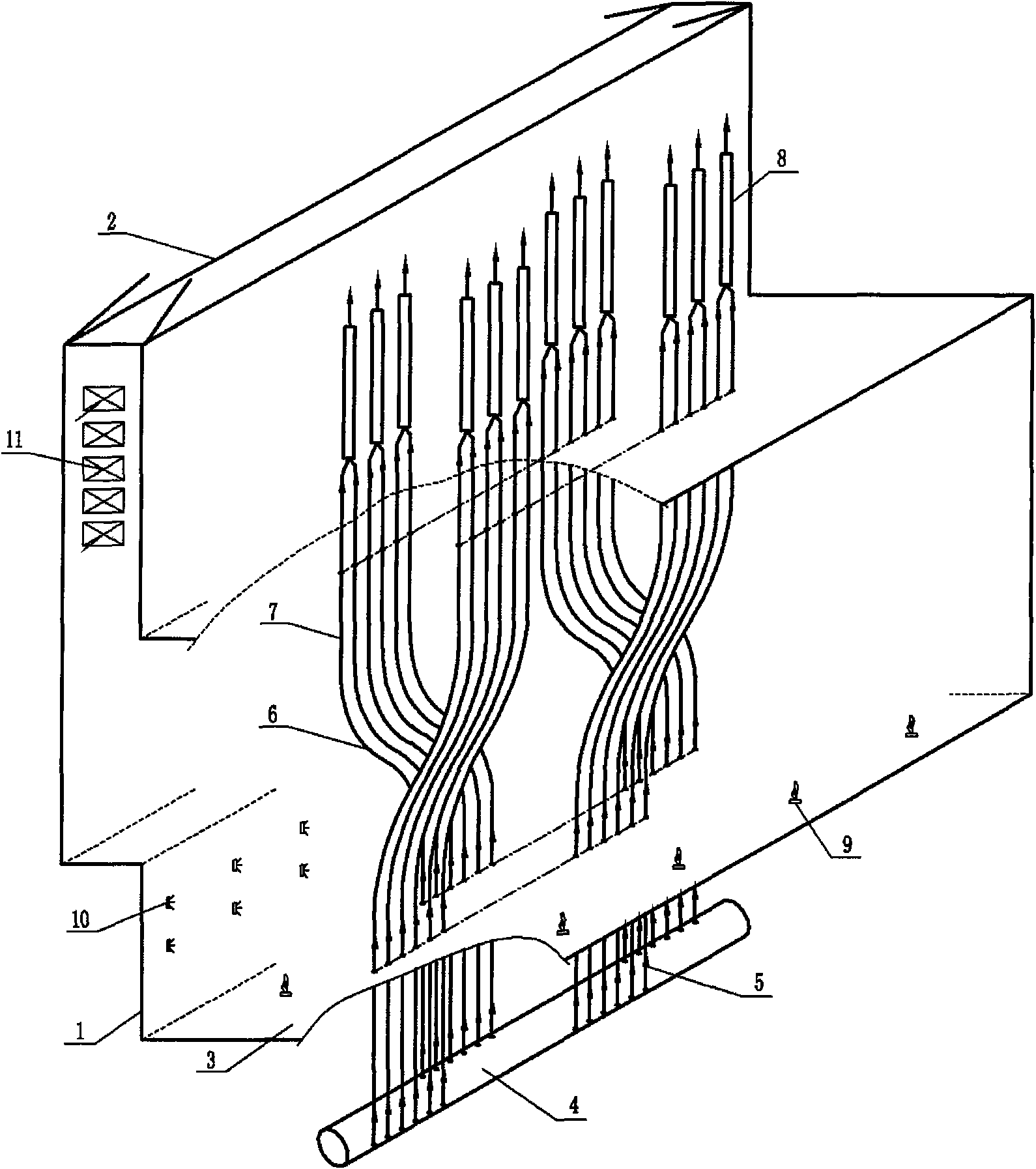

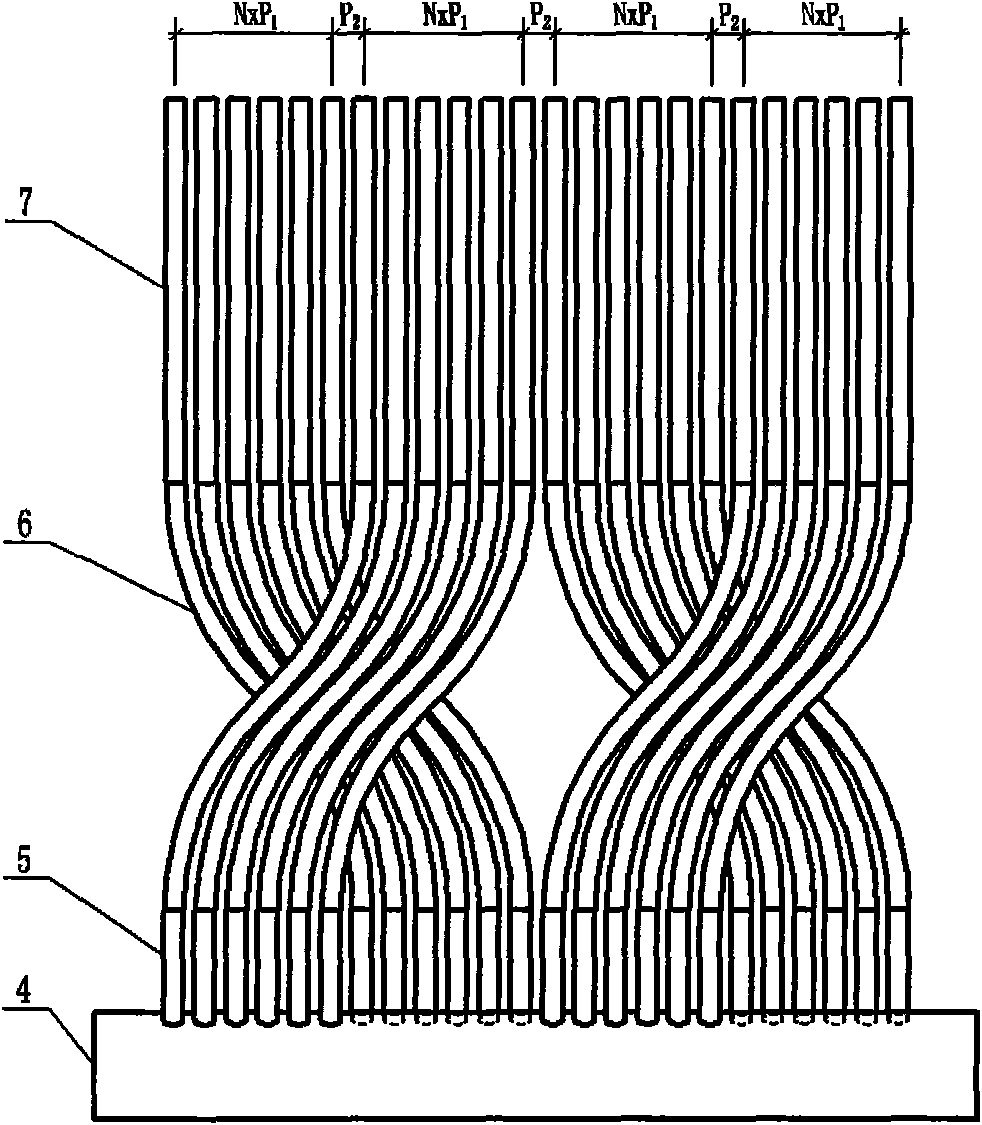

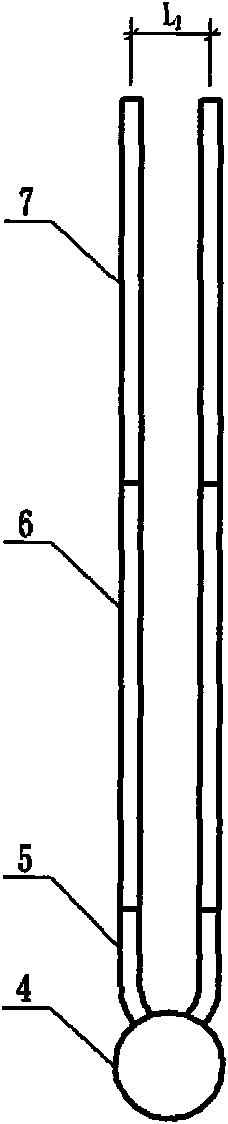

One-way radiating furnace tube ethane cracking furnace

ActiveCN101619012AReduce the impactReduce bendingThermal non-catalytic crackingHydrocarbon by hydrocarbon crackingQuenchingConvection

The invention relates to a one-way radiating furnace tube ethane cracking furnace. The cracking furnace comprises a radiating section, a convection section, a quenching furnace, a collecting pipe and an allotting pipe, wherein the radiating section is arranged at the left side of the cracking furnace, and a radiating chamber is arranged in the radiating section; a radiating furnace tube, a bottomcombustor and a side wall combustor are installed in the radiating chamber; the convection section is arranged at the upper part of the cracking furnace; a convection coil pipe is arranged at the lower part of the convection section; the quenching furnace is arranged at the top of the radiating section; the collecting pipe is arranged at the lower part of the radiating section; one end of the allotting pipe is connected with the collecting pipe, and the other end of the allotting pipe is connected with the radiating furnace tube. Compared with the prior art, the invention utilizes the furnacetube space at maximum and reduces the geometric dimension and the occupation area of the cracking furnace; the furnace tubes in adjacent groups are in a symmetrical structure so as to be uniformly heated, and the running period is prolonged; the influence of the furnace tube differential expansion on the furnace tubes can be effectively reduced and the bending degree of the furnace tubes is lightened by a bent pipe structure; and the adopted linear quenching furnace effectively blocks the secondary reaction of cracked gases and improves the yield of products.

Owner:WISON ENG

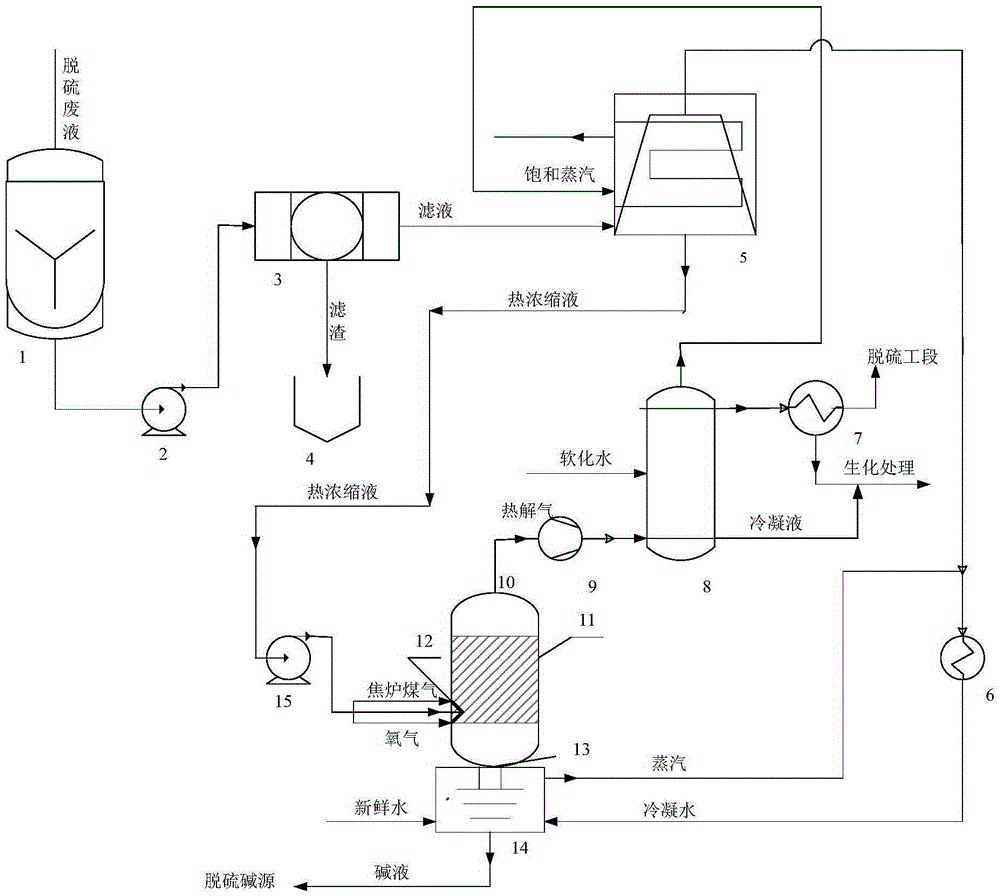

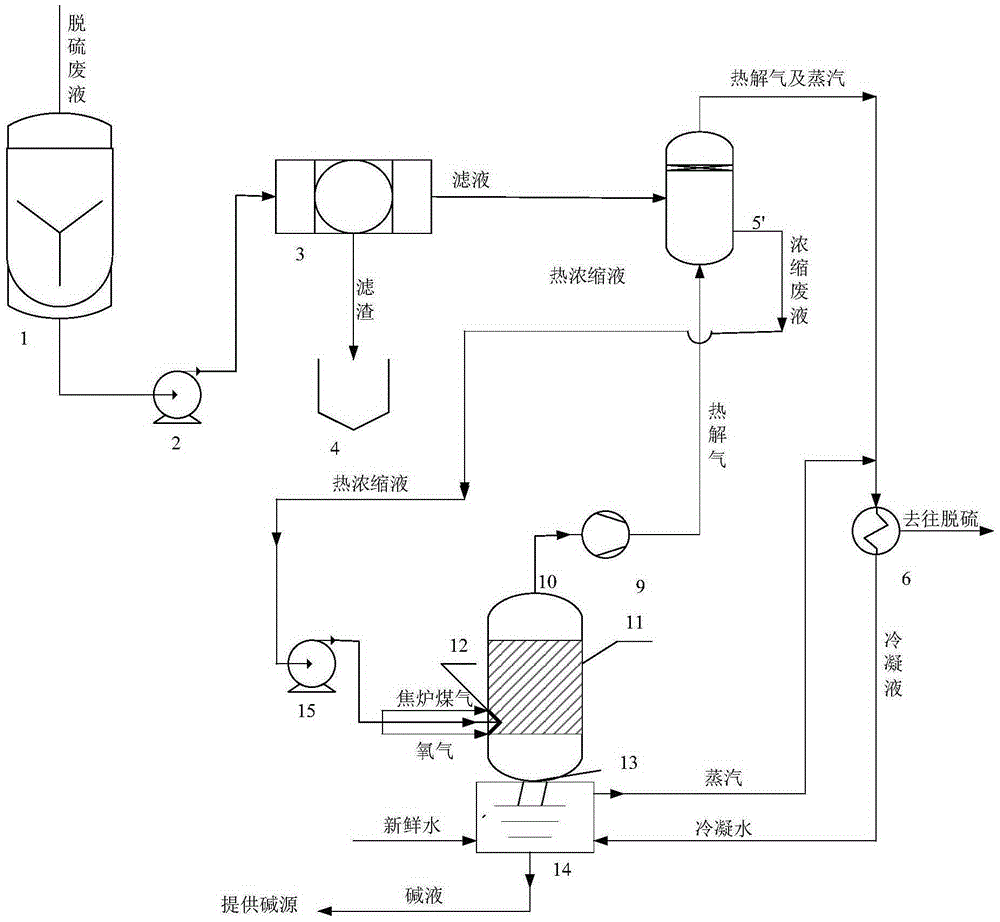

Method used for pyrolyzing wet oxidation desulfurization mixed waste liquid in partial oxidation environment

ActiveCN105236647AComply with relevant policy requirements for protectionRealize whole component processingEnergy inputWaste water treatment from gaseous effluentsPartial oxidationIndirect Method

The invention discloses a method used for pyrolyzing wet oxidation desulfurization mixed waste liquid in partial oxidation environment. According to the method, a desulfurization waste liquid mixture obtained via ammonia alkaline method and sodium alkali method is filtered; an obtained filtrate is subjected to reduced pressure vaporization preheating, a desulfurization waste liquid concentrated solution obtained via vaporization is subjected to pressurization, is subjected to atomization using a three-channel combined pressure atomization nozzle, and then is delivered into a pyrolysis reactor together with hydrogen-rich gas, such as coal gas, and oxygen for pyrolysis; pyrolysis gas obtained via pyrolysis is subjected to vaporization preheating of desulfurization waste liquid via a direct method or an indirect method; pyrolyzed molten salt obtained via pyrolysis is discharged via the bottom of the pyrolysis reactor, is cooled using a cooling system, and then is recycled back to a desulfurization workshop section to provide alkali sources. The method is simple; operation is continuous and stable; application range is wide; desulfurization waste liquid obtained via ammonia alkaline method and sodium alkali method, and a mixture of desulfurization waste liquid obtained via ammonia alkaline method and sodium alkali method can be processed effectively; all-component harmless treatment of waste liquid is realized, and problems that mixed waste liquid is difficult to process, processing processes are complicated, and application range is limited, are solved completely.

Owner:TAIYUAN UNIV OF TECH

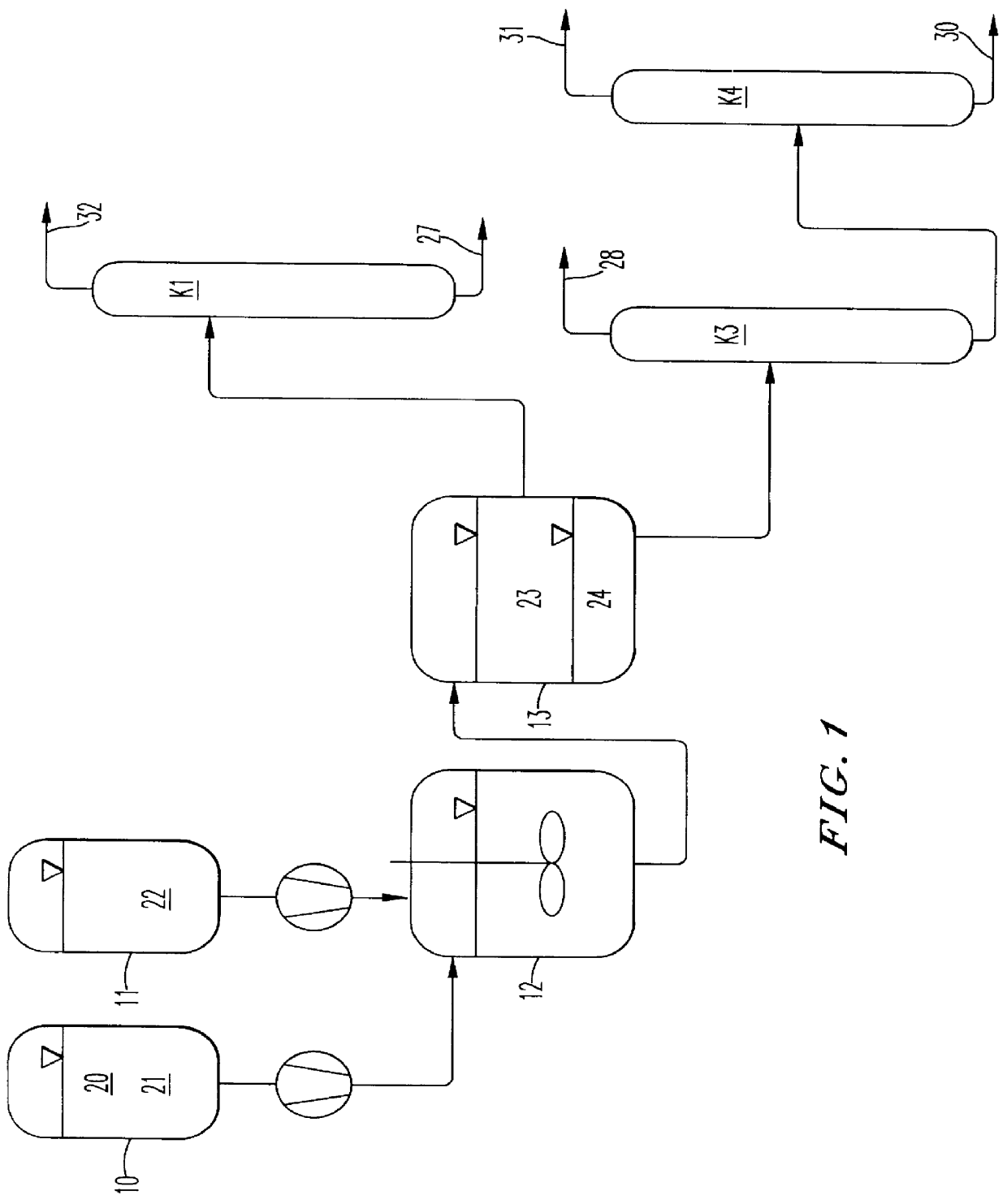

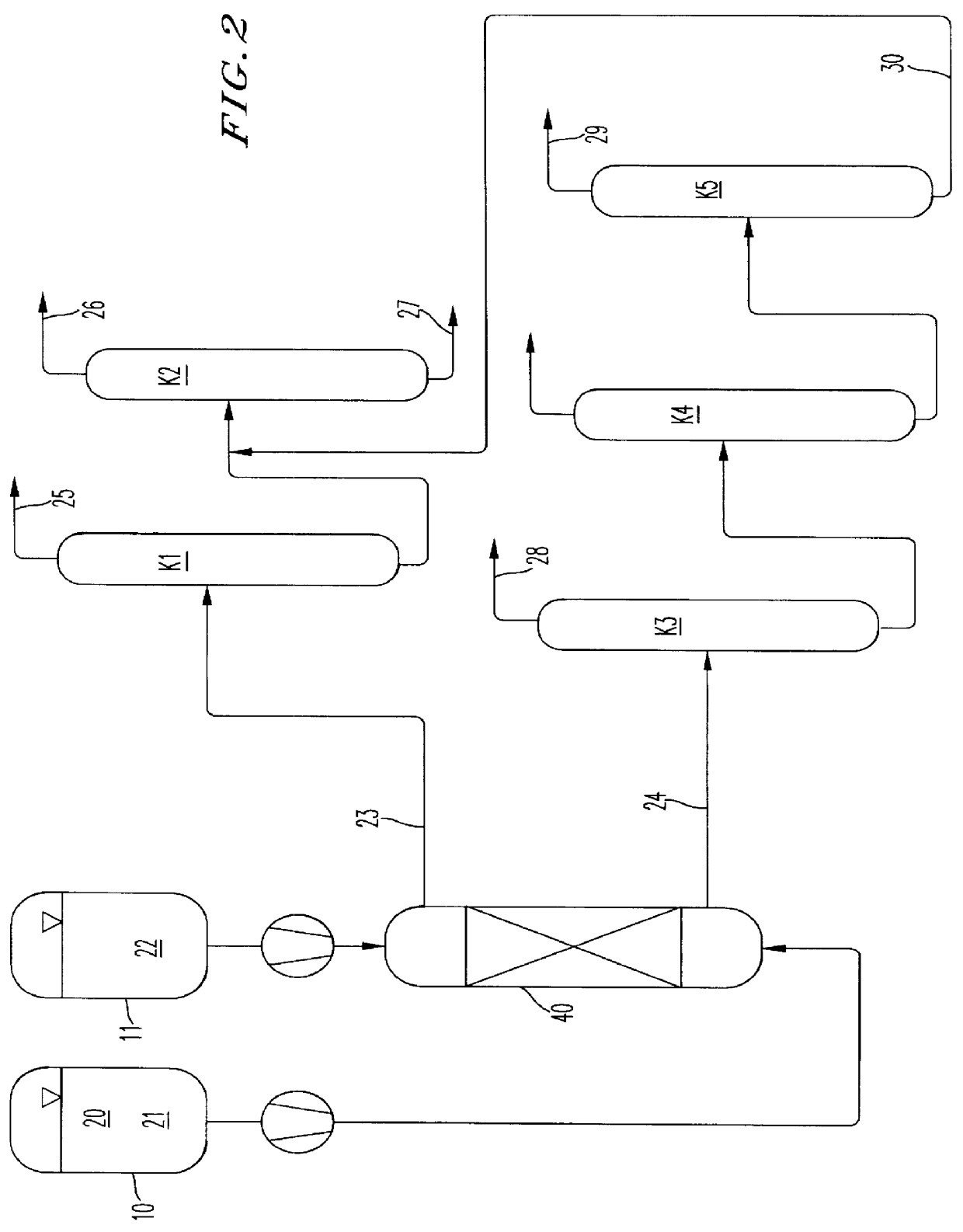

Separation device for use in fluidized bed reactor, reaction regeneration apparatus and process for preparing olefins, and process for preparing aromatic hydrocarbons

ActiveUS20160101396A1Less impuritiesIncrease separation speedCatalytic crackingReversed direction vortexFluidized bedProcess engineering

Device for use in a fluidized bed reactor includes a gas-solid separator communicated with an outlet of the fluidized bed reactor; a vertically arranged damper, a solid outlet of the gas-solid separator communicated with a lower region of the damper, a gas outlet of the gas-solid separator communicated with an upper region of the damper; a fine gas-solid separator, an inlet of the fine gas-solid separator communicated with the upper region of the damper, and a solid outlet of the fine gas-solid separator communicated with the lower region of the damper. Product from the fluidized bed reactor is fed into the preliminary gas-solid separator, most solid catalysts separated and fed into the lower region; the product entraining the rest catalysts is fed into the upper region, and into the fine gas-solid separator, the rest catalysts fed into the lower region; and final product is obtained from the fine gas-solid separator.

Owner:CHINA PETROCHEMICAL CORP +1

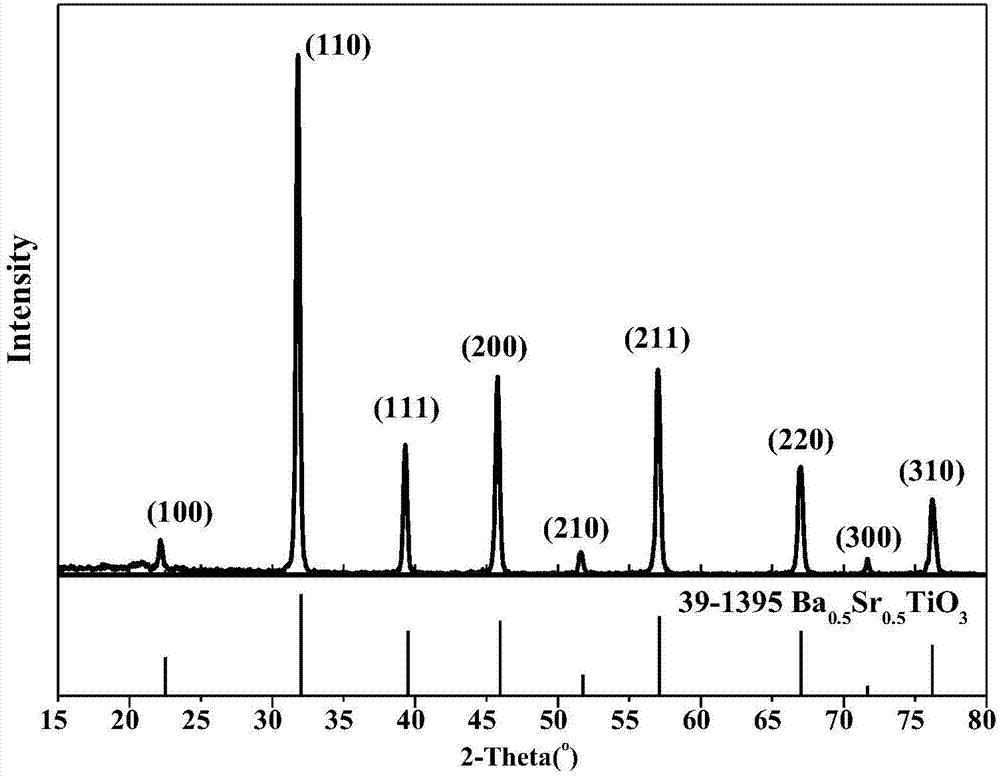

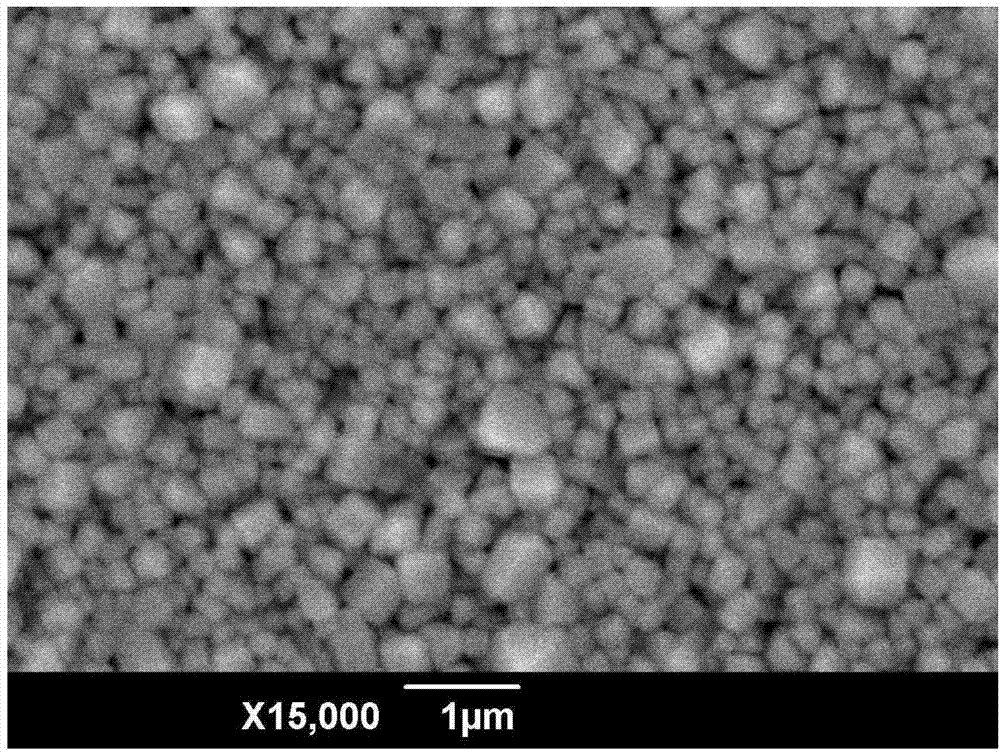

Method for preparing (Ba, Sr) TiO3 nano powder by virtue of Mg<2+> doped hydro-thermal method

ActiveCN104773755AHigh purityGrain refinementMaterial nanotechnologyTitanium compoundsNanoparticleThermal methods

The invention relates to a method for preparing (Ba, Sr) TiO3 nano powder by virtue of a Mg<2+> doped hydrothermal method. The method comprises the following steps: taking BaTiO3 powder and SrTiO3 powder which are synthesized by a hydrothermal method, adding water, mixing fully, then adding MgCl2, and mixing uniformly to obtain a mixed solution; and pouring the mixed solution into a hydrothermal kettle, preserving the heat at 120-180 DEG C for 4-8 hours to perform hydrothermal reaction, and performing centrifugal drying on a generated precipitate to obtain Mg<2+> doped (Ba, Sr) TiO3 nano powder. According to the method provided by the invention, the BaTiO3 powder and SrTiO3 powder which are prepared by the hydrothermal method are adopted as raw materials, then a minute quantity of MgCl2 is doped into the raw materials, and then the Mg<2+> doped (Ba, Sr) TiO3 powder is prepared by using the hydrothermal method under the condition that a mineralizer is not added, so that secondary reaction is effectively avoided, and the prepared powder is high in purity and uniform and meticulous in crystal grain, reaches a nano scale, and can effectively improve the energy storage characteristic and the breakdown resistance of ceramic when used for preparing the ceramic.

Owner:SHAANXI UNIV OF SCI & TECH

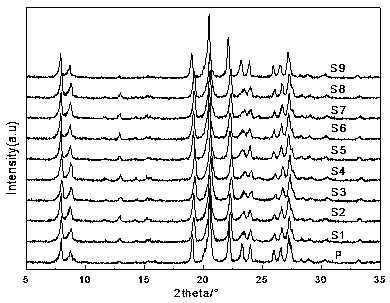

Preparation method of hierarchically porous zeolite molecular sieve

ActiveCN109626390AAvoid it happening againAvoid destructionMolecular sieve catalystsCrystalline aluminosilicate zeolitesMolecular sieveSilicon

The invention relates to the technical field of molecular sieve preparation, and discloses a preparation method of a hierarchically porous zeolite molecular sieve. The specific surface area of a hierarchically porous EU-1 molecular sieve is improved. The method comprises the steps that a template agent part of EU-1 molecular sieve original powder is firstly removed through temperature controlling,then the processed EU-1 molecular sieve is placed in an acid solution to be reacted for 12-48 hours at the temperature of 100-150 DEG C, and finally the EU-1 molecular sieve is placed in an alkali solution where CTAB is dissolved to be reacted for 2-48 hours at the temperature of 80-180 DEG C to obtain the hierarchically porous EU-1 molecular sieve after sintering is conducted. The method has theadvantages that the hierarchically porous molecular sieve is prepared by the joint processing of desilicification and CTAB auxiliary secondary crystallization bonding through sintering temperature controlling and acid treatment, the method is simple, the outer specific surface area of the formed hierarchically porous EU-1 molecular sieve is increased, the dispersing performance of the molecular sieve is improved, and the catalytic activity is further improved.

Owner:TAIYUAN UNIV OF TECH

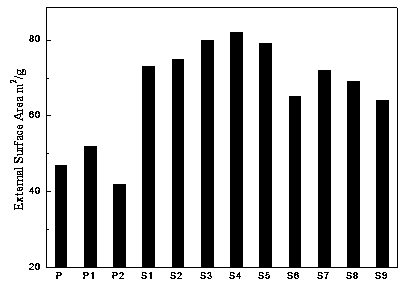

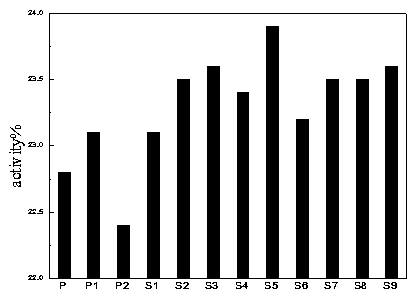

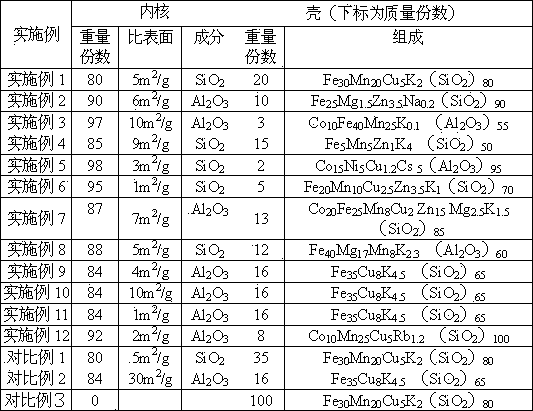

Catalyst for preparing olefin by using synthetic gas, and preparation method thereof

ActiveCN104107698AAffect long-term operationPromote escapeHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsAlkeneMetal

The invention relates to an iron-based catalyst for preparing olefin by using synthetic gas, and a preparation method thereof. A problem of low carbon olefin selectivity in Fischer-Tropsch synthesis is mainly solved. The catalyst comprises 80-98 parts by weight of a core selected from SiO2 and Al2O3 and 2-20 parts by weight of a shell, wherein the specific surface area of the core is less than 30m<2> / g, and the shell comprises 50-100 parts of a carrier selected from SiO2 and Al2O3, 5-50 parts by weight of at least one metal of Fe and Co or oxide thereof loaded on the carrier, 1-30 parts by weight of at least one metal of Mn, Zn, Mg and Cu or oxide thereof, and 0.1-5 parts by weight of at least one metal of K, Na, Rb and Cs or oxide thereof. The catalyst well solves the problem, and can be used in the industrial production of the preparation of olefin by using the synthetic gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of synthesis gas by gasifying carbonaceous materials

ActiveCN102234545AIncrease profitEasy to operateBulk chemical productionGranular/pulverulent flues gasificationSyngasCombustion

The invention relates to a preparation method of a synthesis gas by gasifying carbonaceous materials. The preparation method comprises the following steps: mixing the carbonaceous materials with an optional gasification catalyst, drying and dewatering, and pulverizing to obtain carbonaceous particles; separately introducing the carbonaceous particles and gasification agents with different oxygen contents to different parts of a gasifier in a segmented manner, and carrying out reaction in the gasifier to generate a gas product containing the synthesis gas and ash; and mixing all or part of the ash with the carbonaceous particles and returning to the gasifier, and discharging the remaining part out of the system. The preparation method provided by the invention has high adaptability to raw materials and is adaptable to any carbonaceous materials with carbon contents of 1-100wt%, can optimally control the combustion and gasification of the carbonaceous materials and the secondary reaction of the products, and couple fast combustion reaction with slow gasification reaction to realize the autothermal equilibrium of the system and obtain high-yield synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for the preparation of a lactulose syrup by lactose isomerization

Process for the preparation of lactulose wherein an aqueous solution or suspension of lactose is reacted with sodium aluminate in order to produce the isomerization of lactose and the mixture thus obtained is neutralized by treatment with gaseous CO2 under pressure, obtaining a suspension of aluminum hydroxide which can be easily separated from the lactulose solution.

Owner:INALCO SPA

Process for preparing alkoxysilanes

InactiveUS6150550ARapidly and effectively removedAvoid contactSilicon organic compoundsAlcoholSolvent

Owner:EVONIK DEGUSSA GMBH

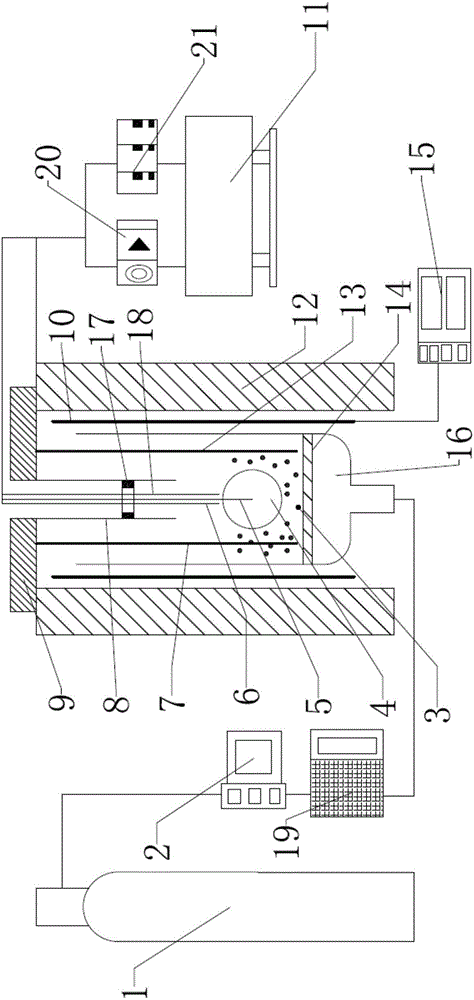

System for measuring real-time conditions of gas-solid reaction in fluidized bed

ActiveCN106290700AImprove accuracy and reliabilityAvoid the problem of difficult temperature measurementMaterial thermal analysisChemical methods analysisReaction dynamicsTime reaction

The invention discloses a system for measuring real-time conditions of gas-solid reaction in a fluidized bed, comprising a gas circuit unit, a fluidized bed reactor unit, a furnace temperature control unit and a real-time condition measuring unit; the gas circuit unit comprises a gas source, a flow meter and an air preheater; the fluidized reactor unit comprises a fluidized bed and an air distribution plate; the air preheater is connected with the bottom end of the fluidized bed through a gas circuit, and the flow meter is connected with the gas source and the air preheater; the air distribution plate is disposed at the bottom end of the fluidized bed, and reaction gas enters a gas-liquid reaction area from the air distribution plate; the furnace temperature control unit comprises a temperature display control device and a furnace heating rod; the temperature display control device adjusts current of the furnace heating rod by using an electronic control device such that heath temperature of a high-temperature furnace body is under control; the real-time condition measuring unit is used for acquiring real-time condition data of the gas-solid reaction and can be connected with a computer to further acquire real-time reaction speed and reaction dynamic parameters of fixed sample particles.

Owner:HUAZHONG UNIV OF SCI & TECH +1

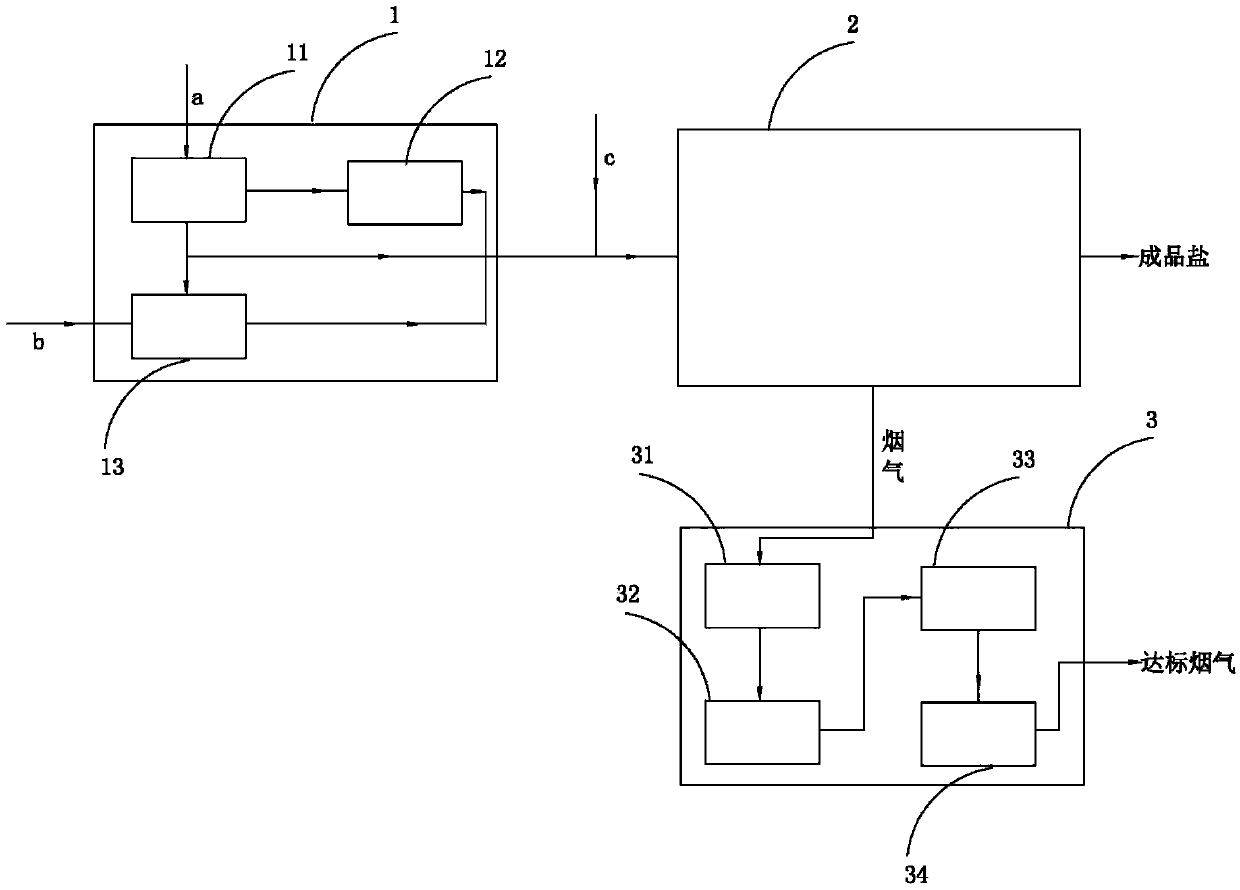

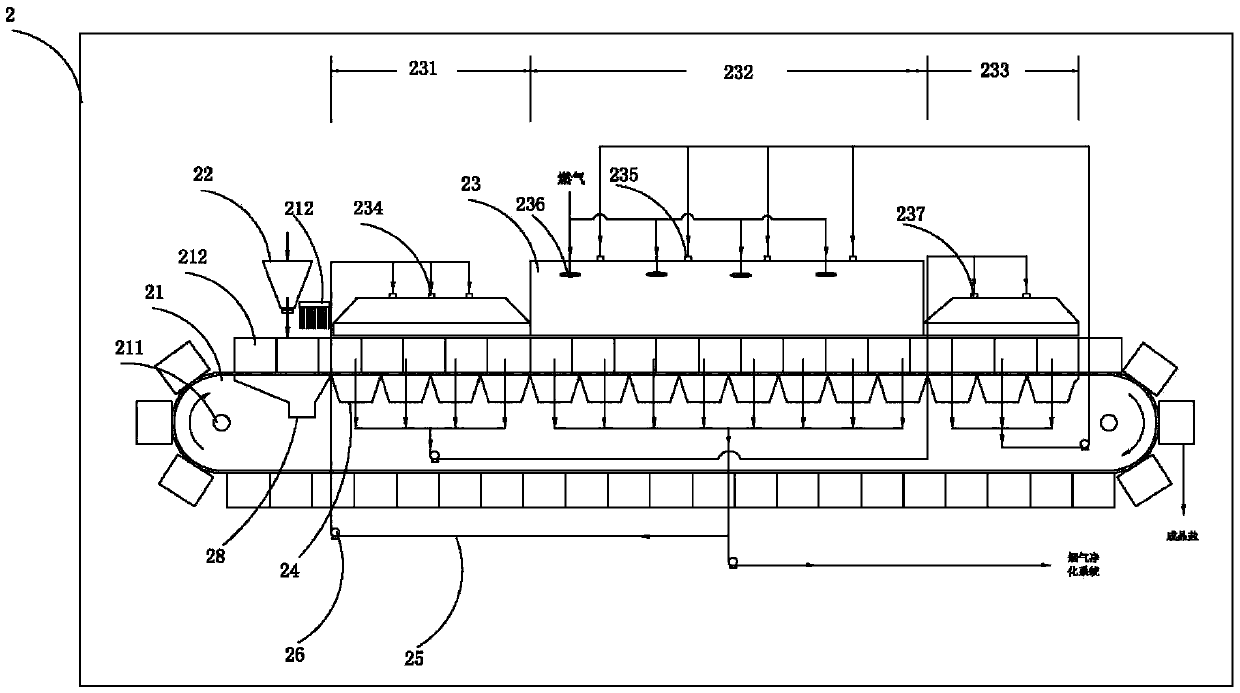

Method and system for treating chemical abraum salt containing organic matter through self-propagating pyrolysis method

PendingCN109519928AStable and controllable pyrolysis temperatureUniform temperature distributionIncinerator apparatusPelletizingPre treatment

The invention relates to the field of solid waste treatment, in particular to a method and system for treating chemical abraum salt containing organic matter through a self-propagating pyrolysis method. The method comprises the following steps that pretreatment is carried out in a pelletizing or washing or treating-free mode according to particle size distribution of chemical abraum salt; 2, materials are distributed; 3, pyrolysis treatment is carried out, and particularly organic matter in a material layer is pyrolyzed into a gas compound through a self-propagating pyrolysis method; 4, the pyrolyzed material layer is cooled to obtain finished salt; and 5, flue gas treatment is carried out, and particularly flue gas containing the gas compound is introduced into a flue gas purifying treatment system for purifying treatment. The finished salt obtained from the abraum salt treated through the method has no melting and agglomeration phenomenon, the TOC content is as low as 10.00ppm, and the requirements of ionic membrane caustic soda can be met. The invention further provides a treating system adopting the method, a self-propagating pyrolysis device in the system can sufficiently utilize heat, can stably control pyrolysis temperature and is suitable for treatment various kinds of abraum salt.

Owner:CHONGQING ANGRUIYUE SCI & TECH

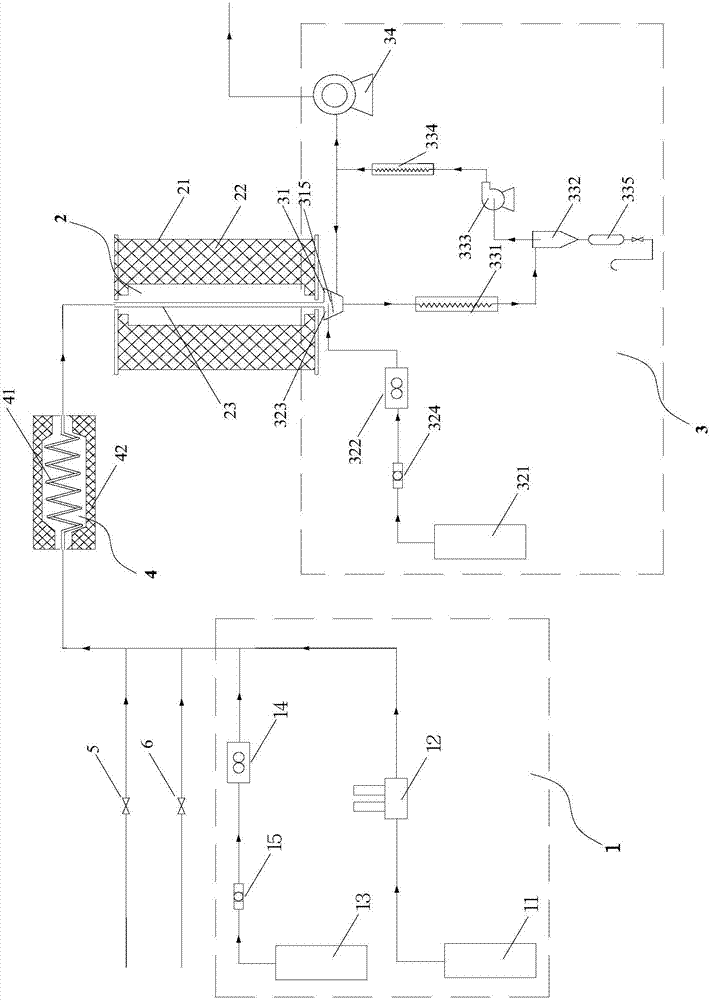

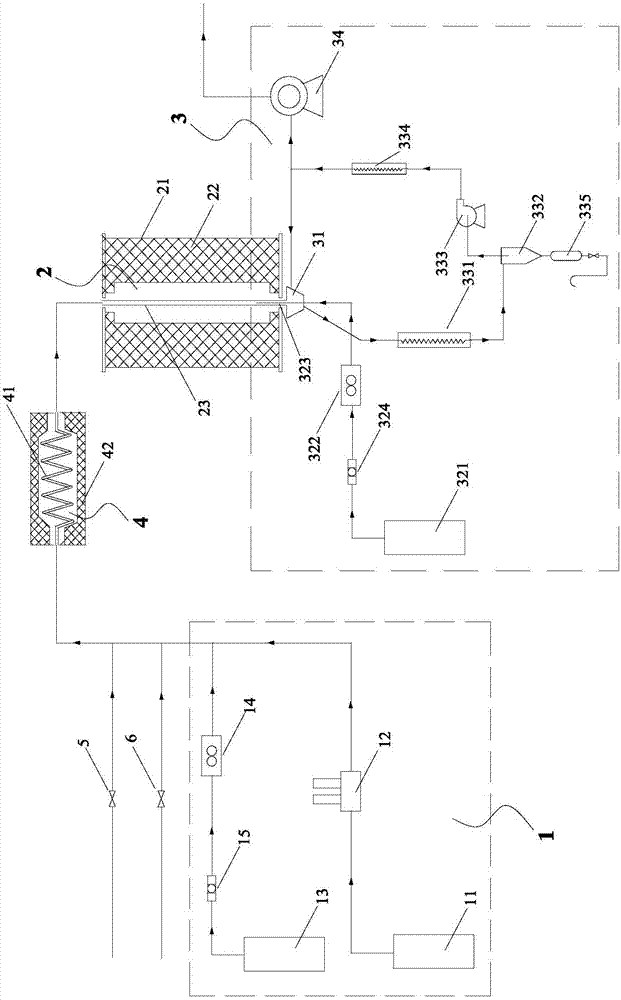

Coal microwave dry distillation equipment and coal microwave dry distillation treatment method thereof

InactiveCN104962300AImprove heating efficiencyUniform material surfaceIndirect heating destructive distillationEnergy based chemical/physical/physico-chemical processesCollection systemTar

The invention discloses coal microwave dry distillation equipment and a coal microwave dry distillation treatment method thereof. The coal microwave dry distillation equipment comprises a feeding system (1), a microwave dry distillation furnace (2), a microwave generator (3), a dedusting system (4), a tar and gas cooling and collection system (5), a tailings cooling system (6) and a discharging system (7), the microwave generator (3) is mounted on the microwave dry distillation furnace (2) which is connected with the dedusting system (4), the tar and gas cooling and collection system (5) is connected with the dedusting system (4), the tailings cooling system (6) is connected with the microwave dry distillation furnace (2), and the discharging system (7) is connected with the tailings cooling system (6). High-power microwave technology is utilized in a sealed state to heat low-quality coal, and low-quality coal less than 5% in water content in an oxygen isolating state is heated to 600 DEG C for pyrolysis to obtain high-added-value products including tar, semi-coke and coal gas. By the use of the coal microwave dry distillation equipment and the coal microwave dry distillation treatment method, harmless and reductive treatment of coal resources can be realized, and the problem that the low-quality coal is low in heat value and causes serious burning pollution can be solved.

Owner:NANJING SANLE MICROWAVE TECH DEV +1

Method for removing thiophene sulfur-containing compound from petroleum

ActiveCN102093909AHigh cost of desulfurizationReduce the impactTreatment with plural serial refining stagesHydrocarbon oils refiningPtru catalystSulphur compound

The invention discloses a method for removing a thiophene sulfur-containing compound from petroleum, which belongs to the field of petrochemical industry and relates to a method for alkylation desulfation. The method comprises the following steps of: performing an alkylation reaction on the thiophene sulfur-containing compound in a petroleum component and olefin under the catalytic effect of a cation exchange resin which is complexed with Fe<3+> ions and is taken as a catalyst to transform the thiophene sulfur-containing compound into a high-boiling-point sulfur-containing compound; and separating the sulfur-containing compound from a hydrocarbon compound by fractionating on the basis of difference between boiling points. The catalyst used in the method is a composite catalyst with a complex structure, and the Fe<3+> ions undergo a complexation reaction with an active sulfonic acid group on a resin framework to form a new activity center, so that the acid catalytic activity of the resin is remarkably enhanced, selectivity to alkylation of thiophene is high, a small quantity of secondary reactions is performed, conversion rate is high, and the yield of product petroleum can be incrased. By the method, alkylation of the sulfur-containing compound and distillation and separation of light hydrocarbon components are performed in the same reaction-distillation tower.

Owner:车春玲

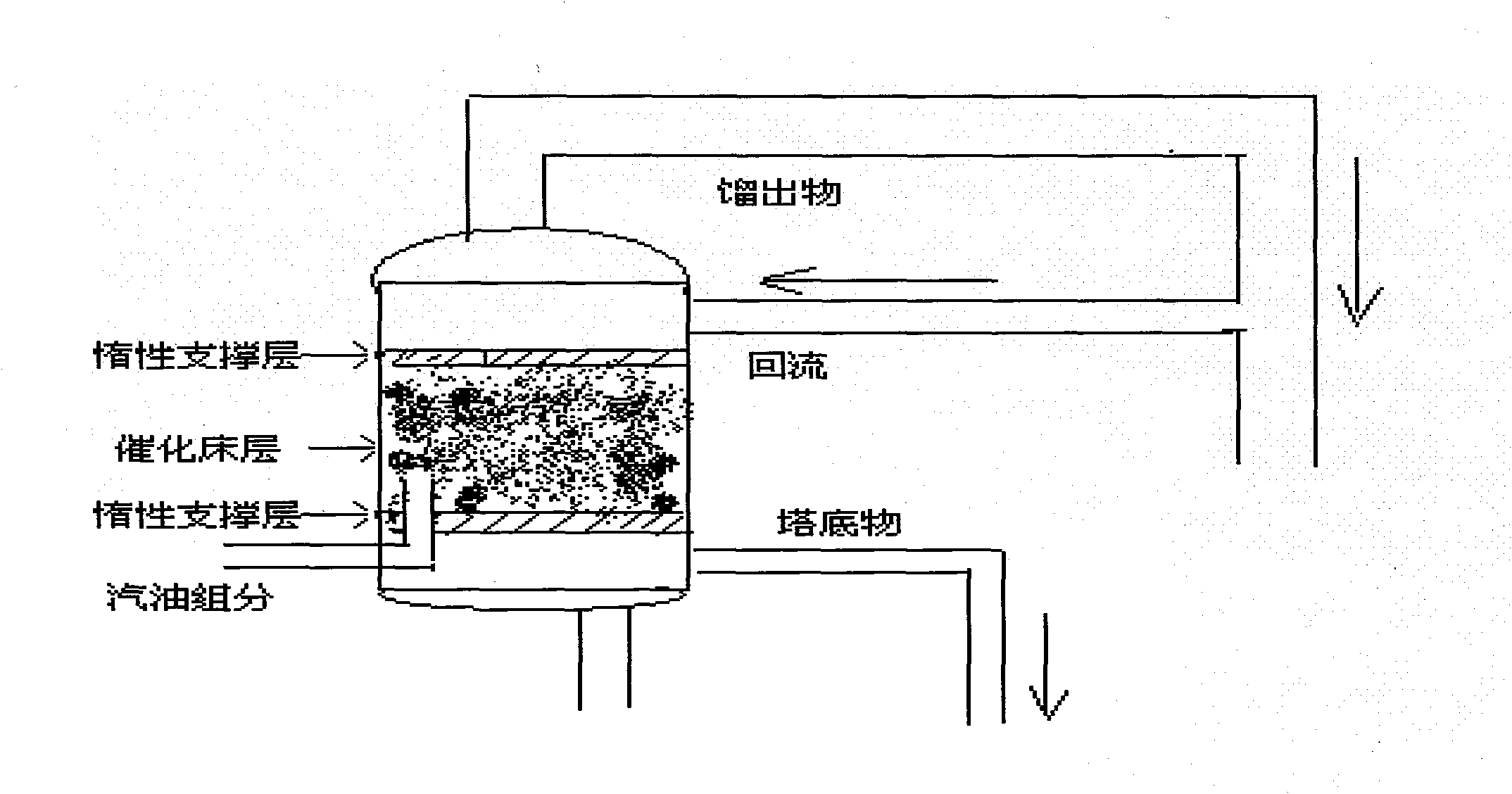

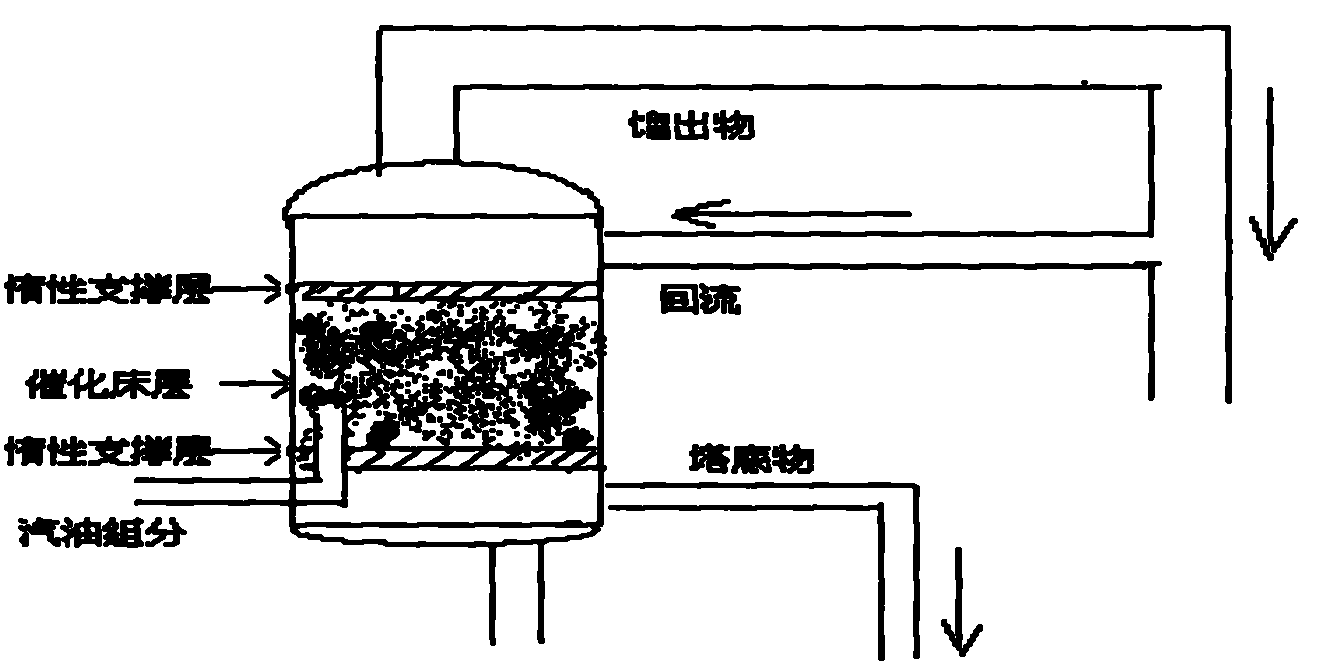

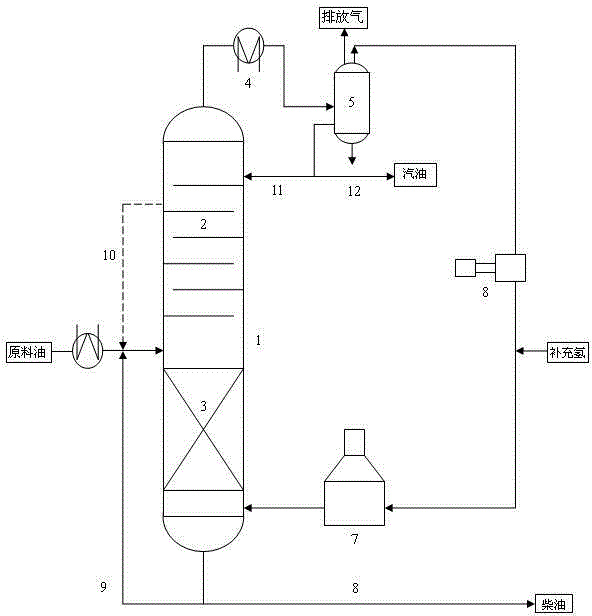

Catalytic diesel fuel reaction distillation method

ActiveCN104611049ABoost octaneIncrease cetane numberTreatment with hydrotreatment processesIsomerizationPoor quality

The present invention discloses a catalytic diesel fuel reaction distillation method. According to the method, equipment mainly comprises a reaction distillation tower and a hydrogen circulation system, the stripping section of the reaction distillation tower adopts a hydrocracking catalyst as a filler, the rectification section is provided with the rectification tower plate, the tower plate can be provided with an isomerization catalyst, one part of the tower bottom oil is circulated to the material inlet of the tower, the remaining part is discharged out from the equipment and is adopted as the product, a hydrogen circulation heating furnace is arranged, the heated hydrogen gas enters the bottom of the tower, and the gasoline distillate is obtained from the top of the tower. With the method, the characteristics of the hydrocracking and the reaction distillation process are completely utilized so as to reduce the secondary reaction of the light distillates and improve the hydrogenation reaction speed of the gasoline distillate. According to the present invention, the poor-quality cracking diesel fuel is adopted as the raw material to produce the high octane number naphtha and the high-quality diesel fuel, such that the obtained products can respectively be adopted as the blending component of the high octane number naphtha and the blending component of the high-quality diesel fuel; and compared with the conventional hydrogenation process, the method of the present invention has characteristics of simple process and energy saving.

Owner:CHINA PETROLEUM & CHEM CORP +1

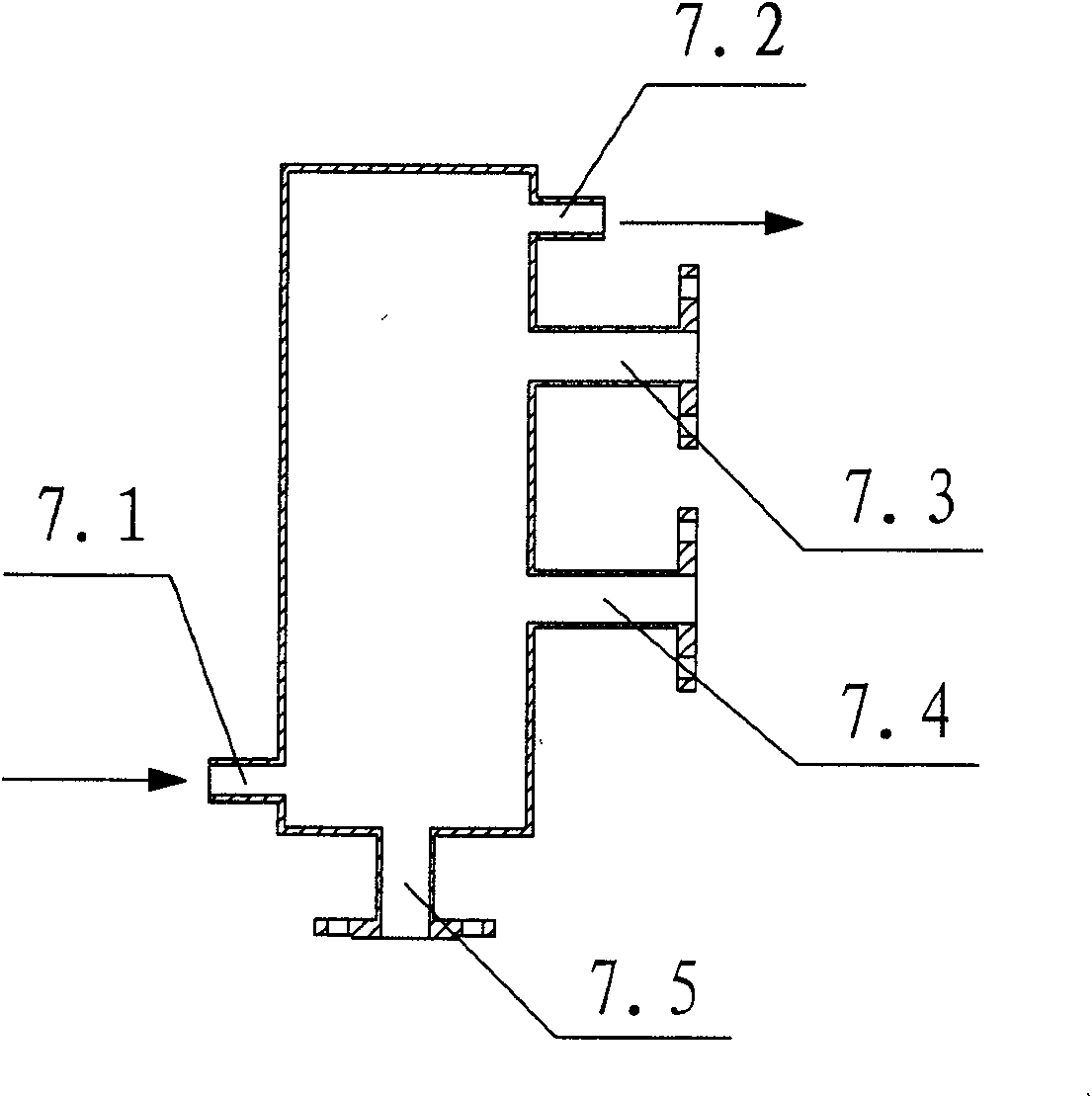

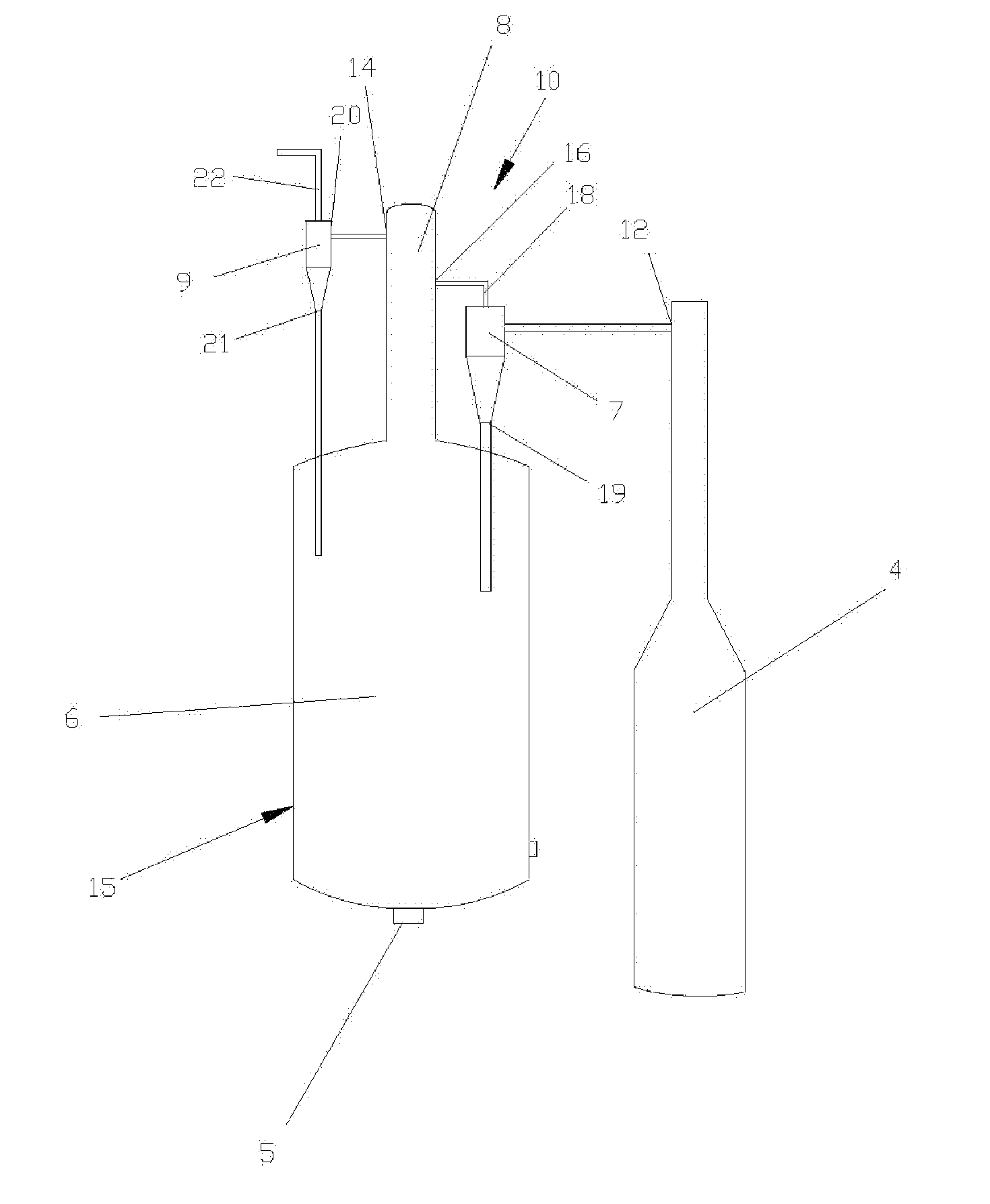

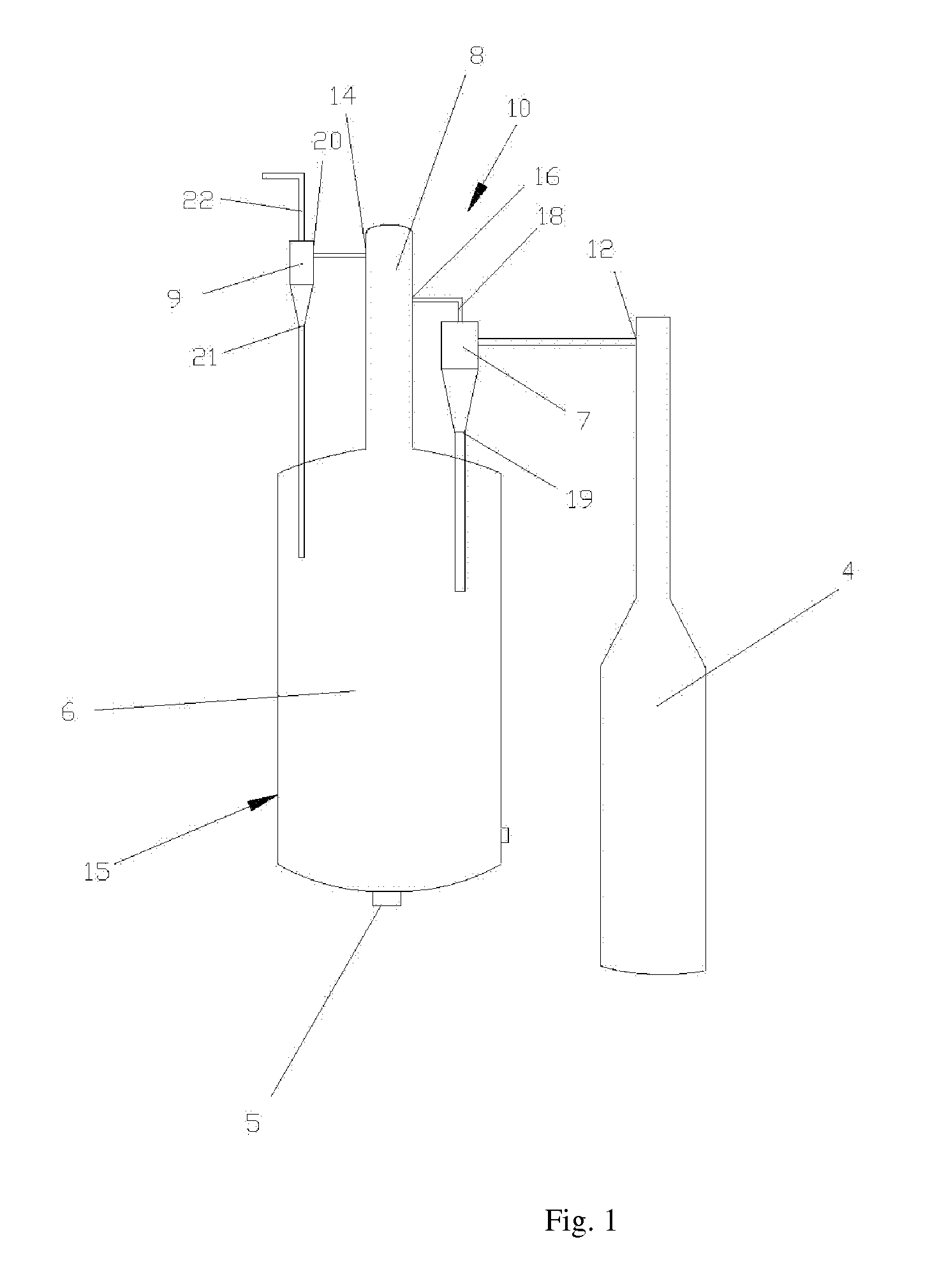

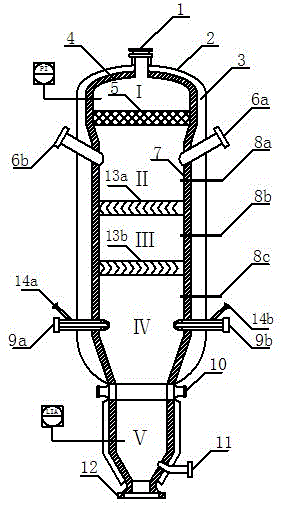

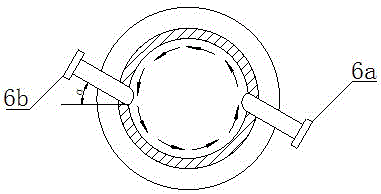

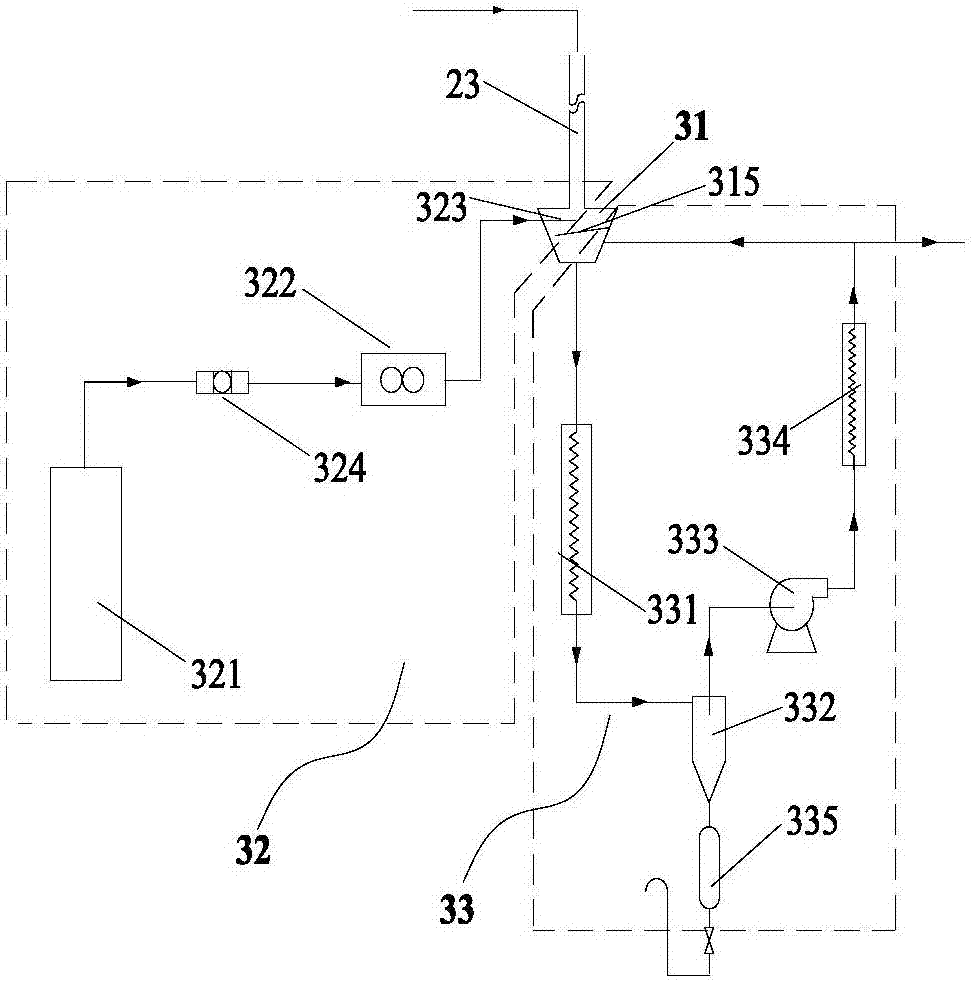

Pyrolysis device for processing desulfurization waste liquid in partial oxidation environment

InactiveCN103951131AAchieve recyclingFlexible operationMultistage water/sewage treatmentLiquid wastePartial oxidation

The invention discloses a pyrolysis device for processing desulfurization waste liquid in a partial oxidation environment. The pyrolysis device comprises a pressure-bearing housing, a jacket, an insulating layer and a refractory brick which are arranged from outside to inside and connected together, and a gas separation section I, a spray pyrolysis section II, a mixed flow pyrolysis section III, an inactive salt pyrolysis section IV and a pyrolysis salt chilling section V are communicated from top to bottom to treat the desulfurization waste liquid in the partial oxidation environment. The device adopts a segmental treatment mode, so that decomposition of aromatic compounds and organic matters in the desulfurization waste liquid is ensured in the partial oxidation environment, COD and sulfides in the generated wastewater are reduced, meanwhile, pyrolysis of the inactive salt in the desulfurization waste liquid in the reducing atmosphere is ensured; therefore, the pollution problem of the desulfurization waste liquid is thoroughly solved and effective components in the desulfurization waste liquid can be recycled.

Owner:TAIYUAN UNIV OF TECH

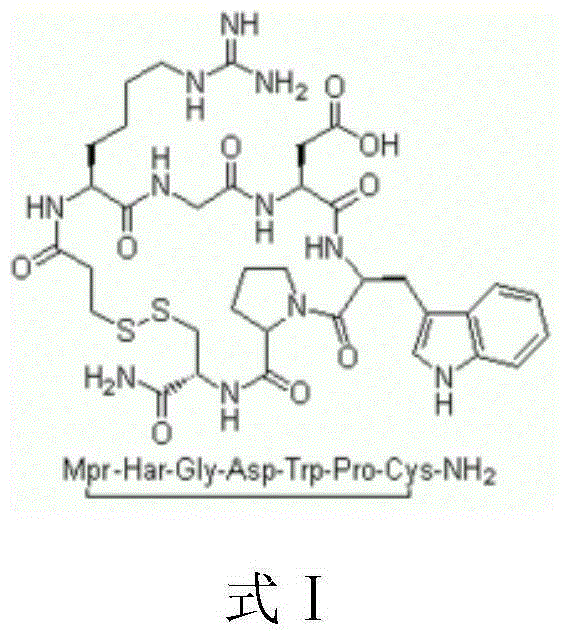

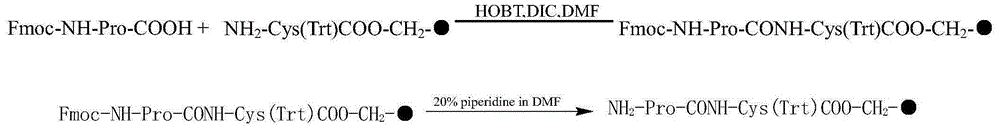

Preparation method for eptifibatide

ActiveCN105037496AAvoid it happening againReduce the difficulty of purificationPeptide preparation methodsFreeze-dryingAcetonitrile

The invention discloses a preparation method for eptifibatide. The method includes the steps of sequentially coupling and connecting Fmoc-protected amino acid and a protected amino acid tripeptide section with Fmoc-Cys(Trt) resin as a coupling resin carrier, splitting eptifibatide resin through a split agent, oxidizing reduced type eptifibatide in an acetonitrile aqueous solution, conducting condensation after oxidation, and conducting purification, salt transfer and freeze drying on crude eptifibatide product concentrated liquor to obtain a fine eptifibatide product. By means of the preparation method, production cost can be effectively reduced, yield is increased, and the content of impurities in the finished product is reduced.

Owner:SICHUAN JISHENG BIOPHARM CO LTD

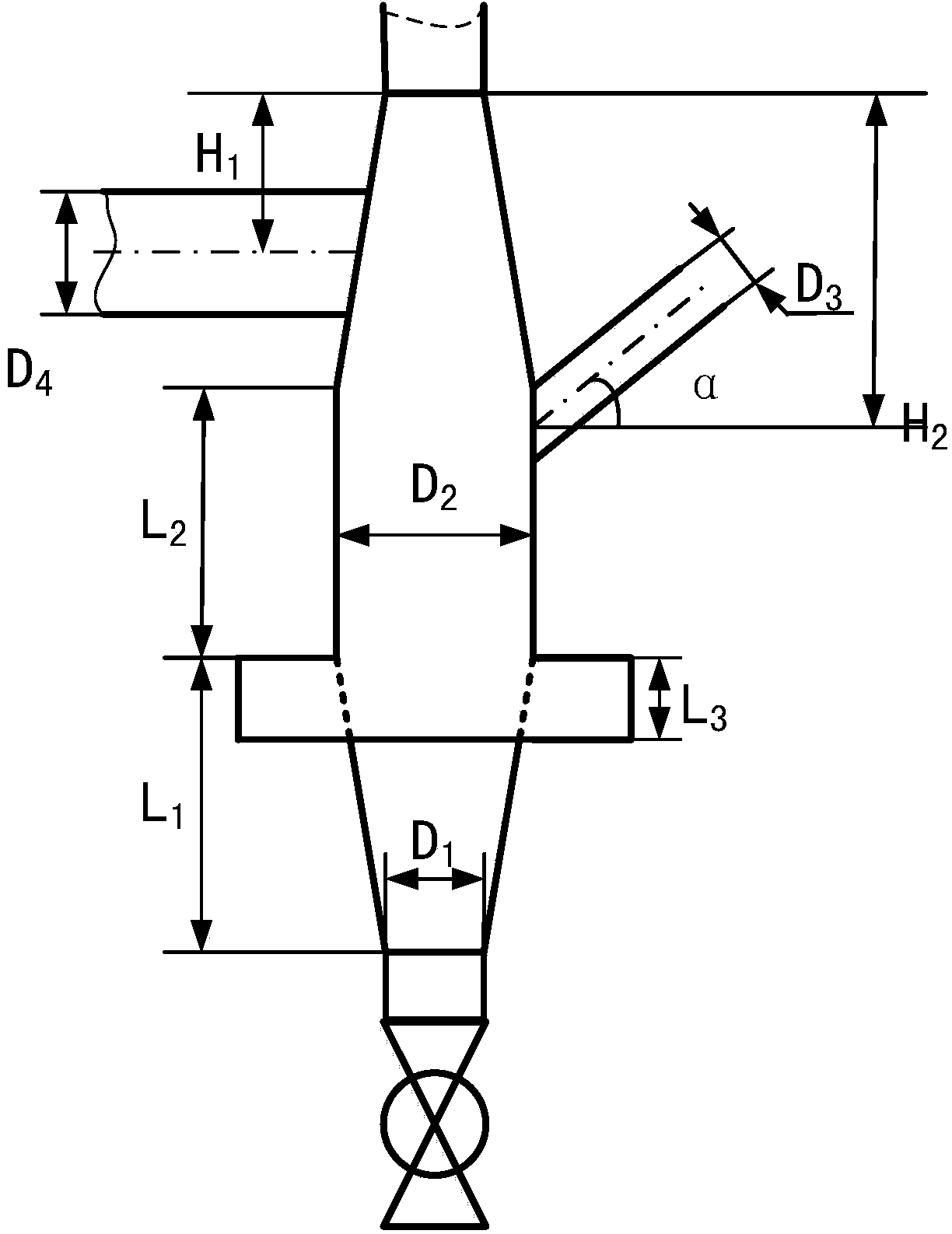

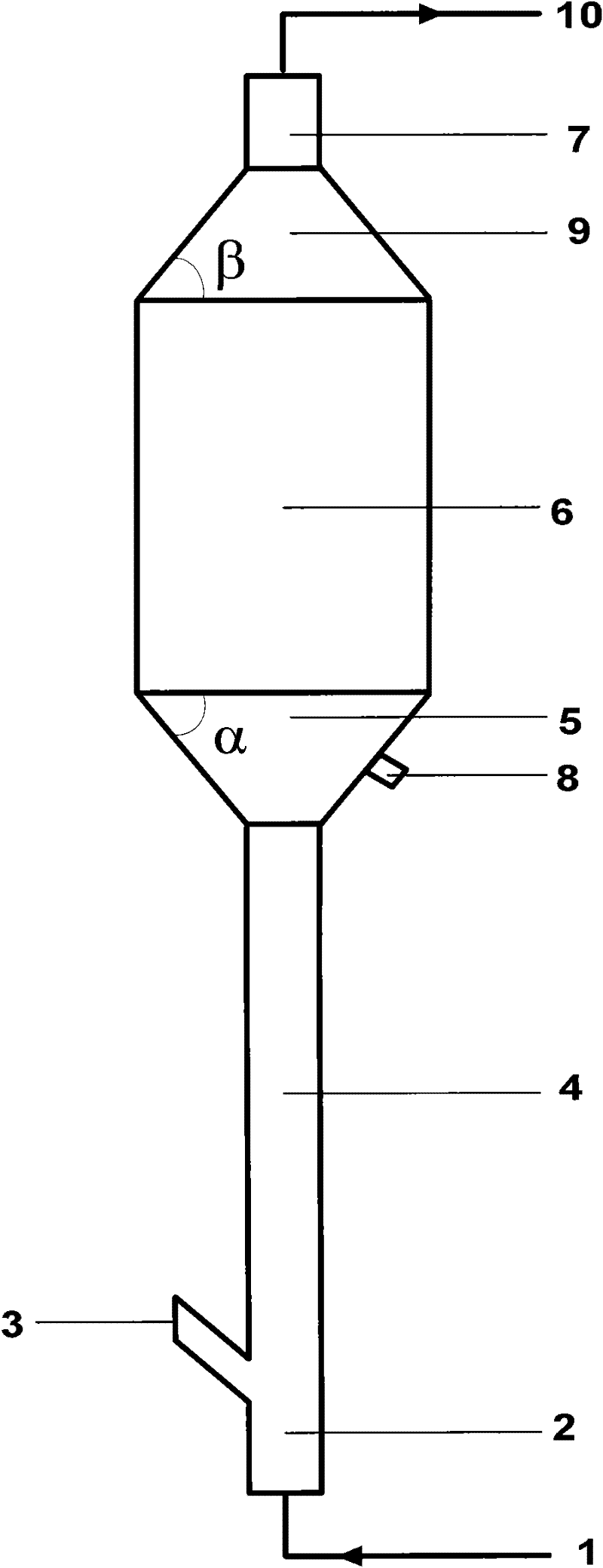

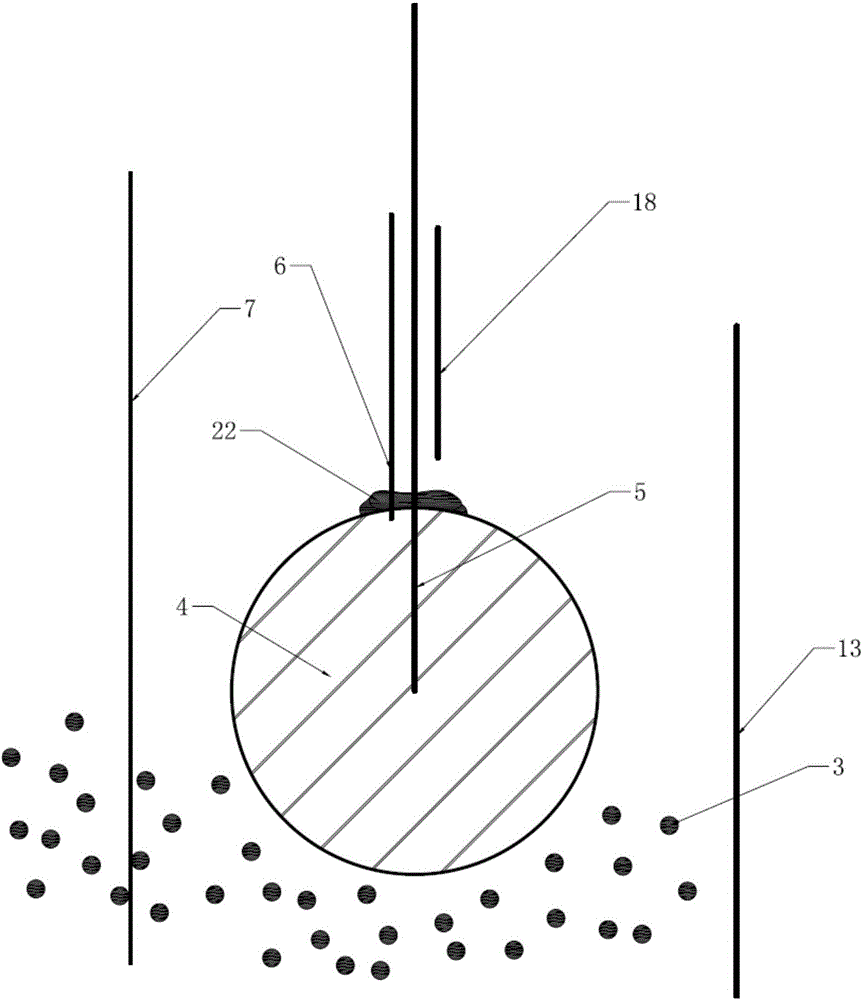

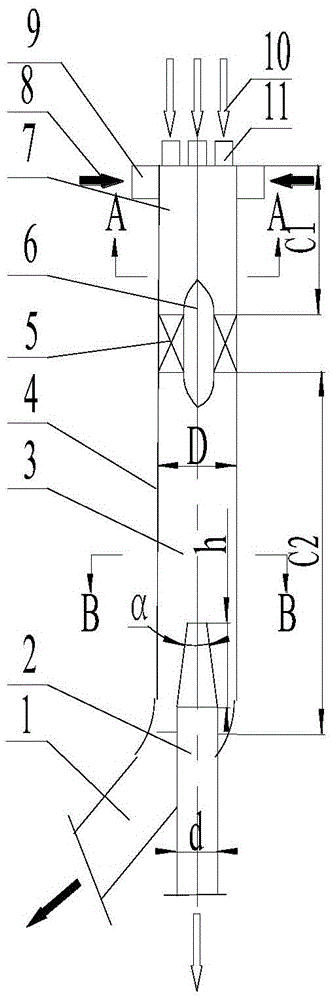

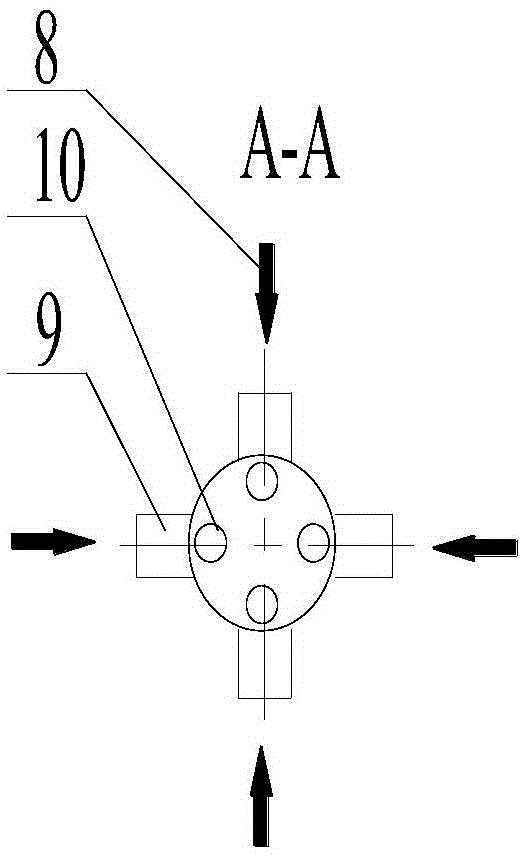

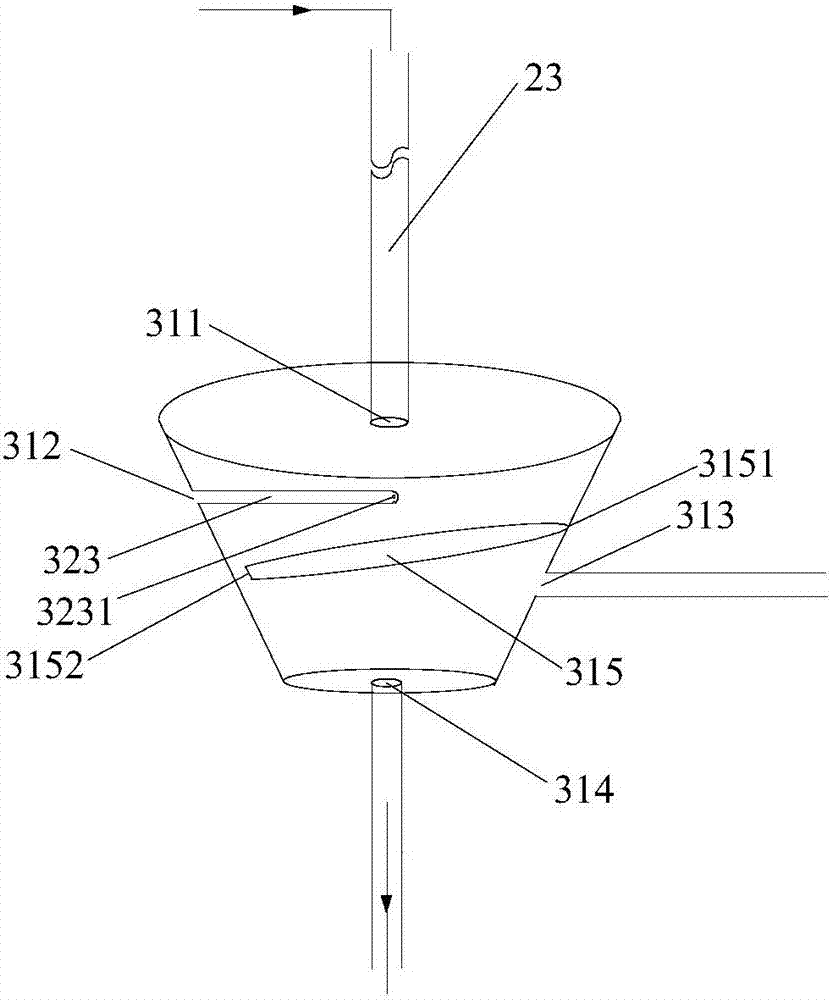

Flow guiding cyclone type biomass pyrolysis reactor

ActiveCN105647553AReduce restrictionsSave materialDirect heating destructive distillationBiofuelsCycloneCoupling

The invention discloses a flow guiding cyclone type biomass pyrolysis reactor, and belongs to the field of biomass pyrolysis equipment for heating solid thermal carriers. The flow guiding cyclone type biomass pyrolysis reactor comprises a barrel body (4), guiding blades (5), a flow guiding cone (6), a biomass inlet pipe (9), thermal carrier inlet pipes (11), a dust discharging cone (1) and an exhaust pipe (2); the flow guiding cyclone type biomass pyrolysis reactor is characterized in that the guiding blades (5) are arranged on the flow guiding cone (6); the guiding blades (5) and the flow guiding cone (6) are both arranged in the barrel body (4) in common; the barrel body is divided into a contact pre-reaction area (7) arranged at the upper part and a reaction separation coupling area (3) arranged at the lower part; the guiding blades (5) are used as the boundary; the biomass inlet pipe (9) and the thermal carrier inlet pipes (11) are arranged at the upper part of the contact pre-reaction area (7). According to the flow guiding cyclone type biomass pyrolysis reactor disclosed by the invention, effective coupling of a pyrolysis reaction process and a separating process of a product and the thermal carriers is realized, the heat transfer effect is good, the real-time separation efficiency is high, and the generation of excessive pyrolysis reactions and other non-ideal secondary reactions is effectively prevented.

Owner:SHANDONG UNIV OF TECH

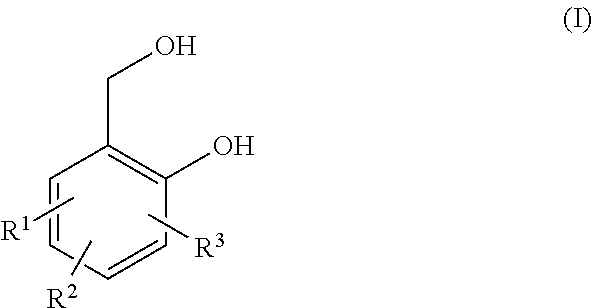

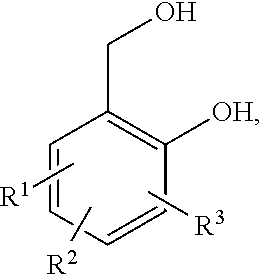

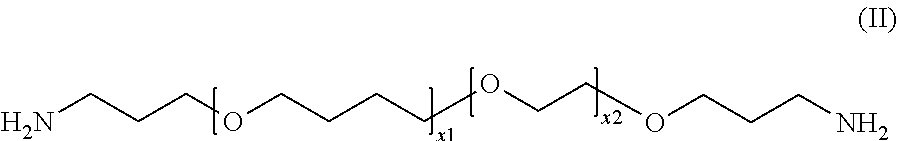

New reactive polymer catalysts for 2-component epoxy resin systems

ActiveUS20150018500A1Avoid secondary reactionsOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyPolymer science

An oligomeric condensation product can be obtained from at least one (hydroxymethyl)phenol of general formula (I),in which R1 is hydrogen or —CH3, R2 is —CH2OH, and R3 is hydrogen or —CH3, at least one polyamine, and optionally at least one phenol compound having two centres reactive by means of a reaction with the methylol groups of the (hydroxymethyl)phenol.

Owner:SIKA TECH AG

Method for preparing soft magnetic manganese-zinc-iron composite material by using manganese-containing waste liquid and zinc mud produced in the production of hydroquinone

ActiveCN104086168BSolve the pollution of the environmentRealize high value utilizationInorganic material magnetismSesquioxideSludge

The invention discloses a method for preparing a soft magnetic manganese-zinc-iron composite material by using manganese-containing waste liquor and zinc sludge produced during production of p-dihydroxybenzene. The method comprises the following steps: adding the zinc sludge into the manganese-containing waste liquor, leaching under stirring, filtering, adding a flocculating agent into filtrate to remove silicon and aluminum impurities, adding ammonium bicarbonate into purified liquid containing manganese and zinc for co-precipitating, and washing to obtain co-precipitated powder; calcining the co-precipitated powder for decomposing, and washing by using organic acid to obtain a manganese-zinc composite material; and adding iron sesquioxide or a mixture of iron sesquioxide and at least one of manganous-manganic oxide and zinc oxide into the manganese-zinc composite material, and pre-burning to obtain the soft magnetic manganese-zinc-iron composite material. By taking the manganese-containing waste liquor and the zinc sludge produced during production of p-dihydroxybenzene as raw materials, the problem of environmental pollution is solved, high-value utilization of waste is fully realized, and a manufactured magnetic device is free from crystal spots, is non-crispy, and has high shearing resistance as well as fully-qualified physicochemical indexes and electromagnetic performance.

Owner:CHONGQING SHANGJIA ELECTRONIC CO LTD

Thermal cracking simulation experiment device and method

ActiveCN107541238AAvoid secondary reactionsReduce injection volumeThermal non-catalytic crackingHydrocarbon by hydrocarbon crackingProduct gasCirculating pump

The invention discloses a thermal cracking simulation experiment device and method. The thermal cracking simulation experiment device comprises a raw material feeding device, a cracking furnace and aproduct quenching recovery device which are sequentially connected; the product quenching recovery device comprises a direct quenching system and a circulating quenching recovery system; the circulating quenching recovery system comprises a cracked gas circulating quenching loop composed of a mixing quencher, an indirect quencher, a cyclone separator, a gas circulating pump and a cooler; the mixing quencher is connected to a cracking furnace pipe discharging hole in a sealing way; the direct quenching system is used for horizontally arranging a quenching water injection pipe in an upper regioninside the mixing quencher; and a water injection hole is formed in the end of the water injection pipe. The thermal cracking simulation experiment device has the advantages that a high-temperature cracking product is directly quenched in the mixing quencher by sequentially using quenching water and a circulating gas product, so that the cooling efficiency is high, the injection quantity of the quenching water is small, the phenomenon that coking happens near the water injection hole of the quenching water injection pipe can be effectively avoided, and the accuracy of a simulation effect of the cracking furnace is improved.

Owner:PETROCHINA CO LTD

Steam thermal cracking simulation experiment device and process

ActiveCN107541239AAvoid secondary reactionsReduce injection volumeThermal non-catalytic crackingHydrocarbon by hydrocarbon crackingGas phaseProduct gas

The invention provides a steam thermal cracking simulation experiment device and process. The steam thermal cracking simulation experiment device comprises a raw material feeding device, a cracking furnace and a product quenching recovery device which are sequentially connected; the product quenching recovery device comprises a direct quenching system and a circulating quenching recovery system; the circulating quenching recovery system comprises a cracked gas circulating quenching loop composed of a gas-phase mixer, an indirect quencher, a cyclone separator, a gas circulating pump and a cooler; the gas-phase mixer is connected to a cracking furnace pipe discharging hole in a sealing way; the direct quenching system is used for vertically inserting a quenching water injection pipe in the cracking furnace pipe discharging hole through the center inside the gas-phase mixer; a water injection hole is formed in the end of the inserted end; and quenching water is injected into a cracking furnace pipe by the water injection hole. The steam thermal cracking simulation experiment device has the advantages that high-temperature cracked gas is directly quenched twice after being sequentiallyinjected with the quenching water and a circulating gas product, so that the cooling efficiency is high, the injection quantity of the quenching water is small, secondary reaction of the cracked gascan be effectively avoided, and the accuracy of a simulation effect of the cracking furnace is improved.

Owner:PETROCHINA CO LTD

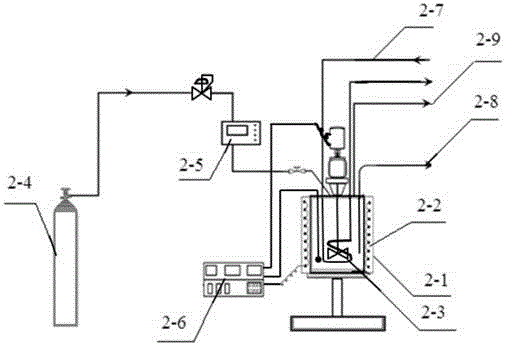

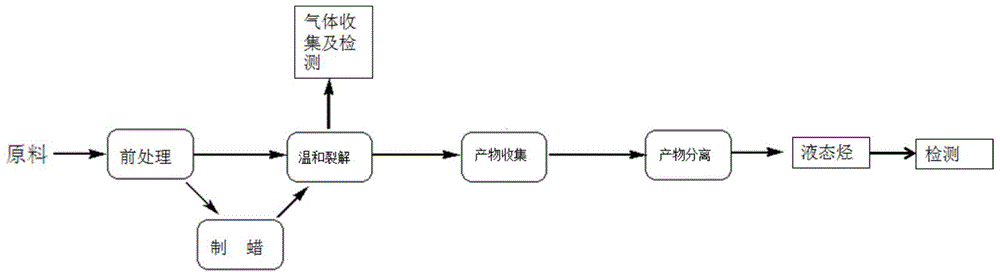

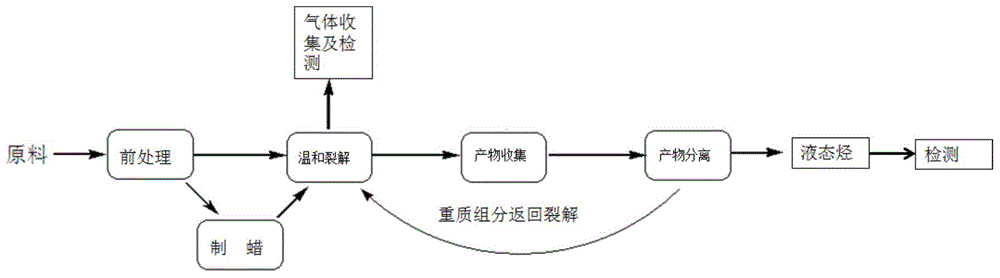

Mild pyrolysis method for preparing liquid hydrocarbon through waste polyolefin

InactiveCN105018126AAvoid inactivationLow cracking temperatureLiquid hydrocarbon mixture productionWaxPolyolefin

The invention discloses a mild pyrolysis method for preparing liquid hydrocarbon through waste polyolefin. The method includes the following steps of firstly, conducting pretreatment; secondly, manufacturing wax; thirdly, conducting mixing and copyrolysis; fourthly, terminating mixing and copyrolysis; fifthly, conducting product collection. According to the method, the low heating rate is adopted, cleavage reaction happens to materials in the temperature rise process, the constant-temperature process and the cooing process, the yield of the liquid hydrocarbon is increased, secondary polymerization or dehydrogenation reaction are little during reaction, and the obtained liquid hydrocarbon is mainly composed of alkane and is extremely low in arene content.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com