Combined process of hydrotreatment and catalytic cracking for residuum

A catalytic cracking and hydrotreating technology, applied in hydrotreating process, petroleum industry, treating hydrocarbon oil, etc., can solve the problem of no specific combination, and achieve the effect of reducing energy, facilitating separation, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

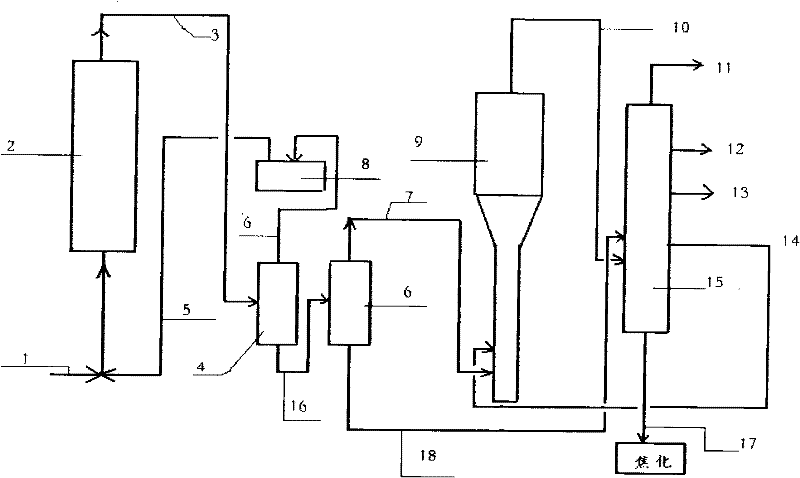

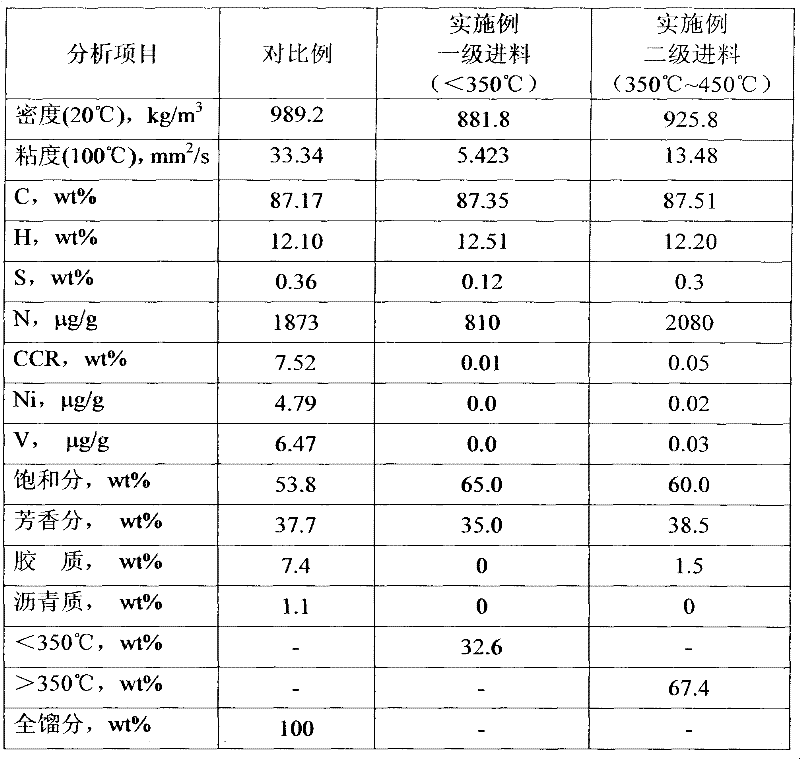

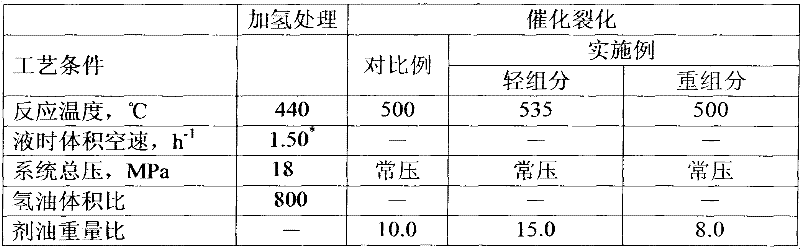

[0033] This embodiment adopts the combined method of fluidized bed residual oil hydrotreating and catalytic cracking provided by the present invention, and the flow chart is shown in figure 1 , wherein the hydrotreated liquid phase product fractionates light components and heavy components, and its cut point is 350°C. The second-stage feed inlet is above the first-stage feed, and the height from the first feed inlet accounts for the total height of the riser. 1 / 10 of the high. Table 2, Table 3, and Table 4 are the process conditions, product distribution and main product properties respectively.

[0034] The comparison results show that the oil produced by hydrogenation of residual oil is divided into light components and heavy components, which enter the riser reactor from the two-stage feed port for catalytic cracking reaction, and enter the catalytic cracking reaction together with the whole fraction of hydrogenated oil produced by residual oil Compared with the reactor, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com