Patents

Literature

189 results about "Lactulose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This medication is a laxative used to treat constipation.

Use of lactulose in the treatment of autism

InactiveUS20080058282A1Avoid accumulationReverses effectBiocideNervous disorderNervous systemAntibiotic Y

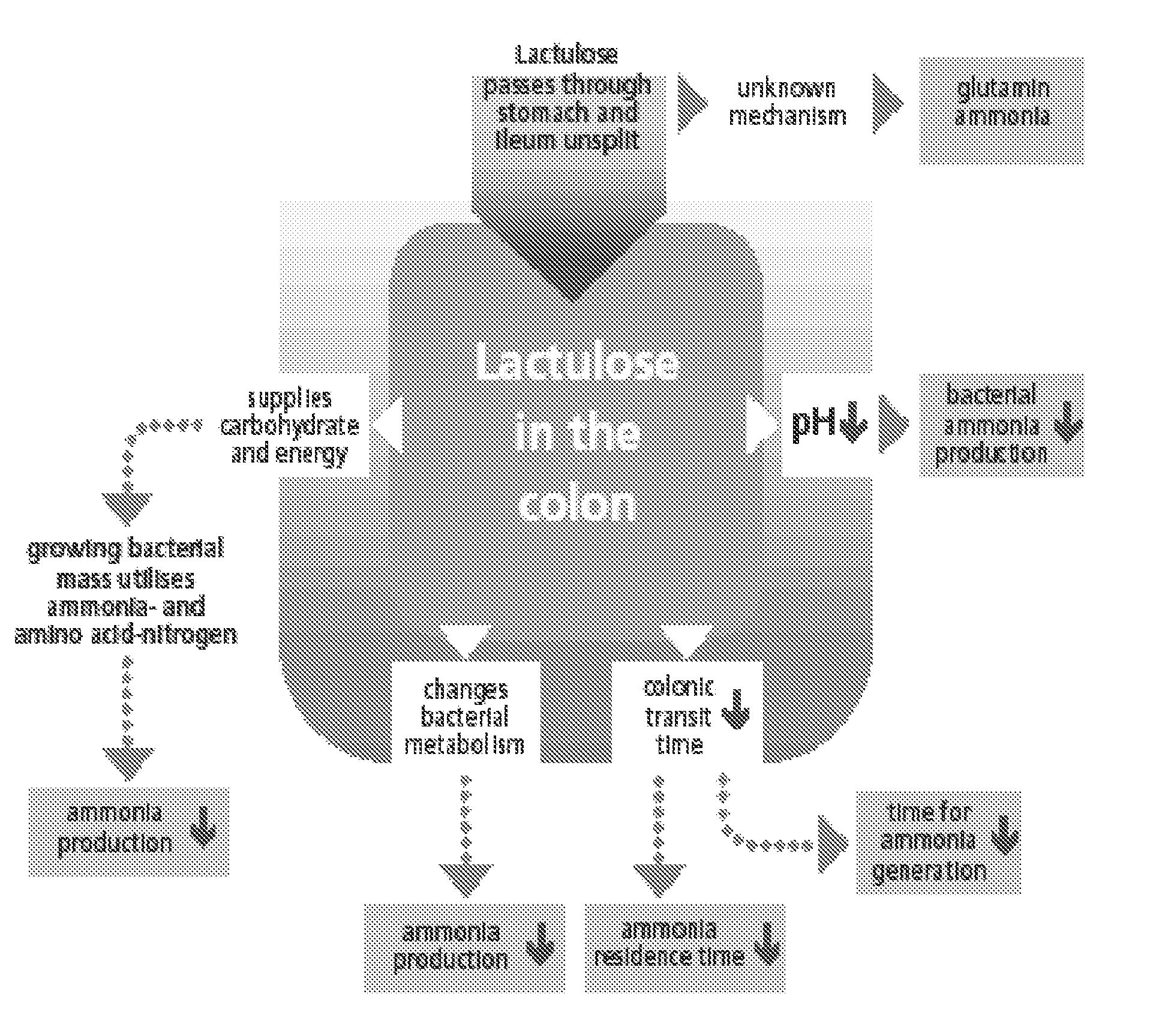

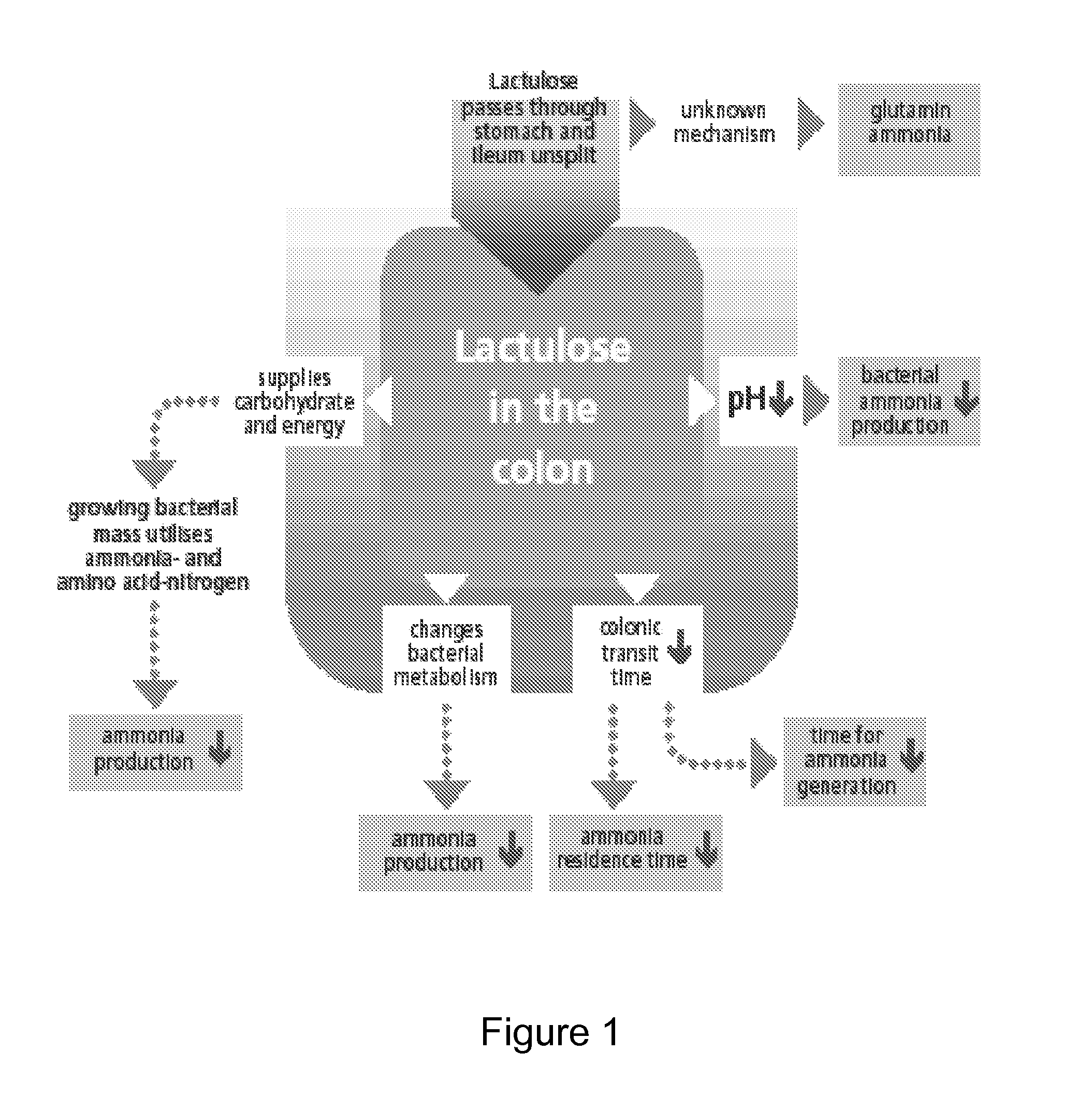

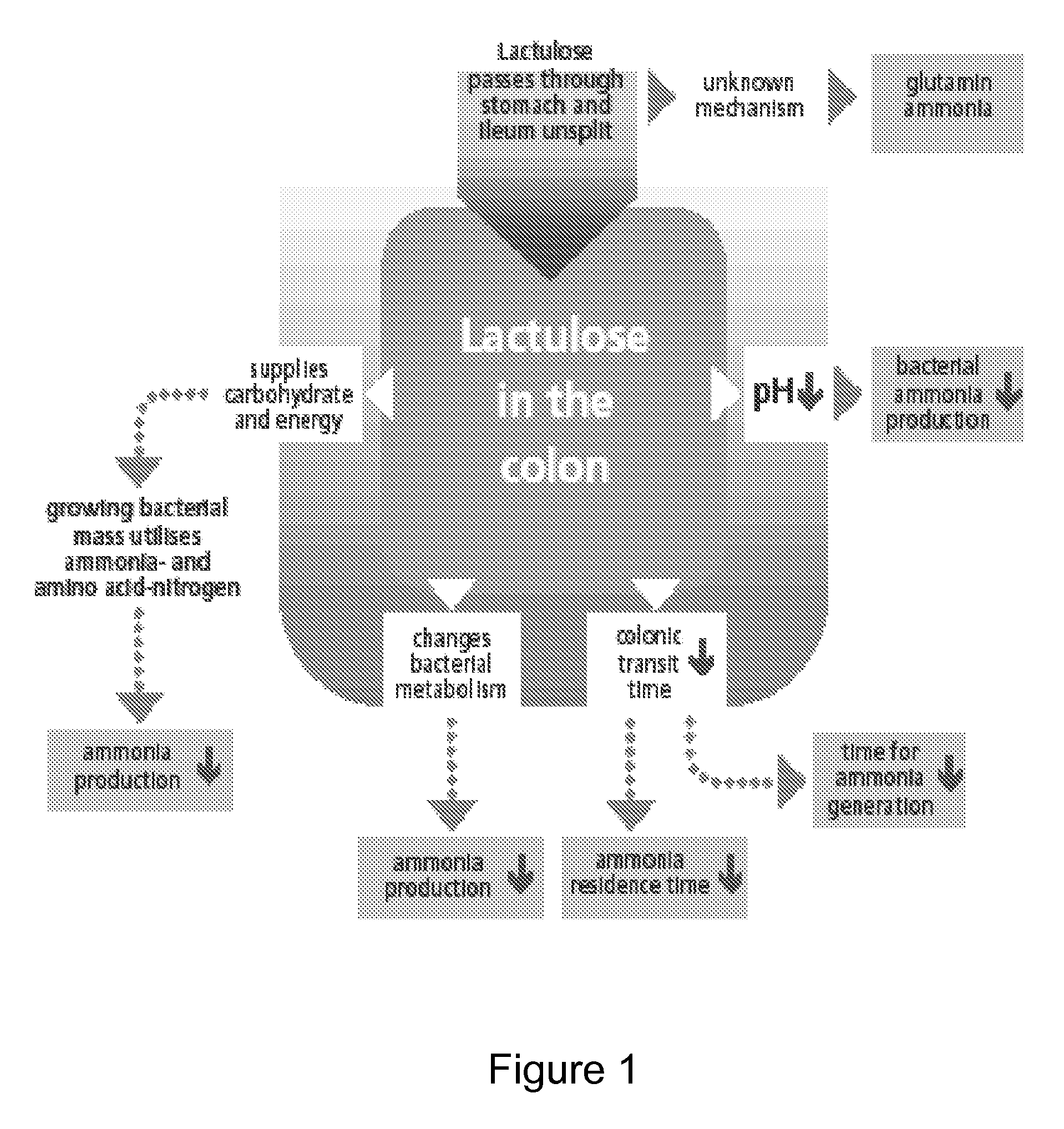

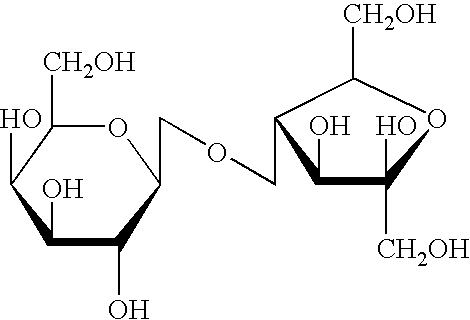

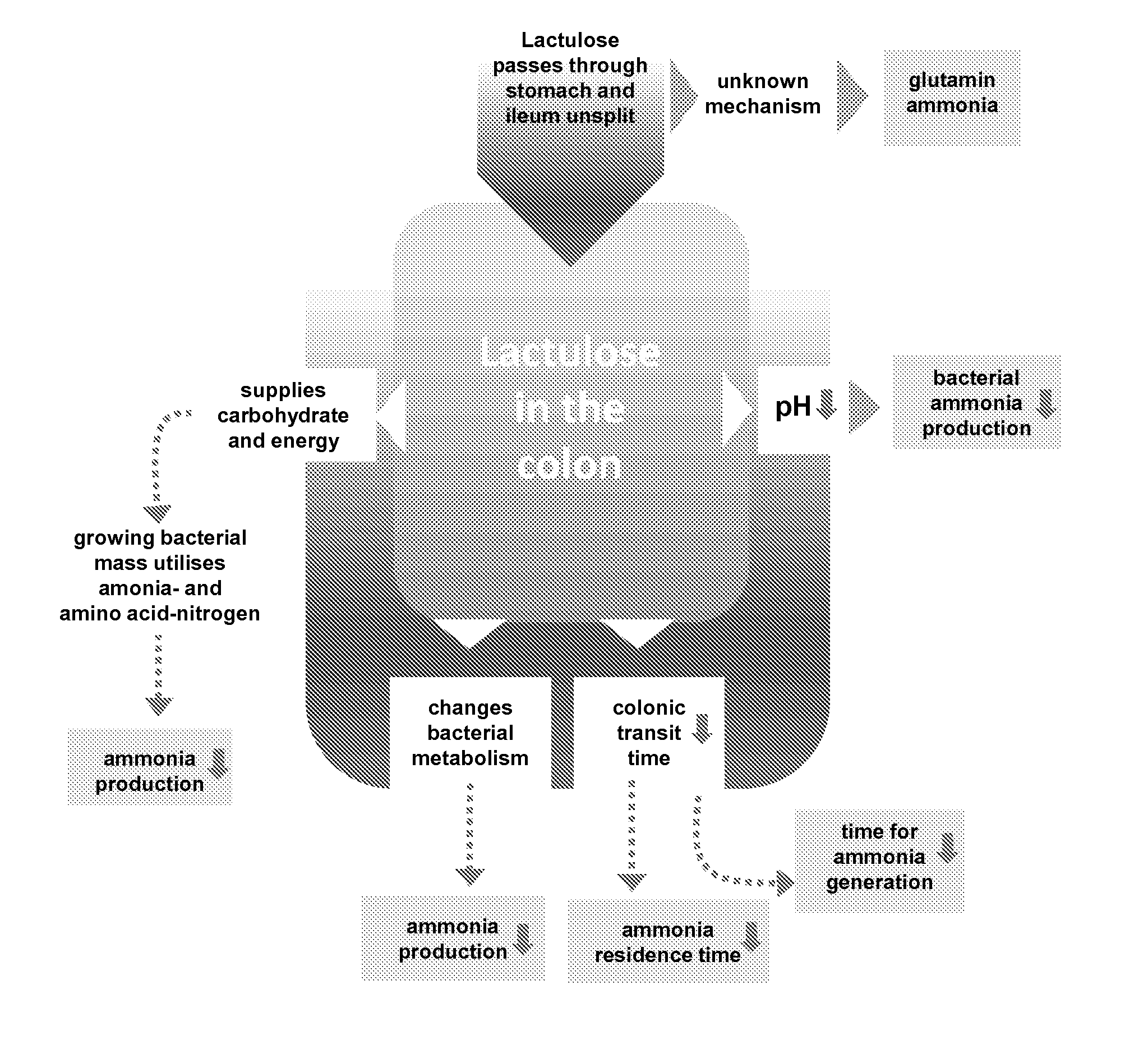

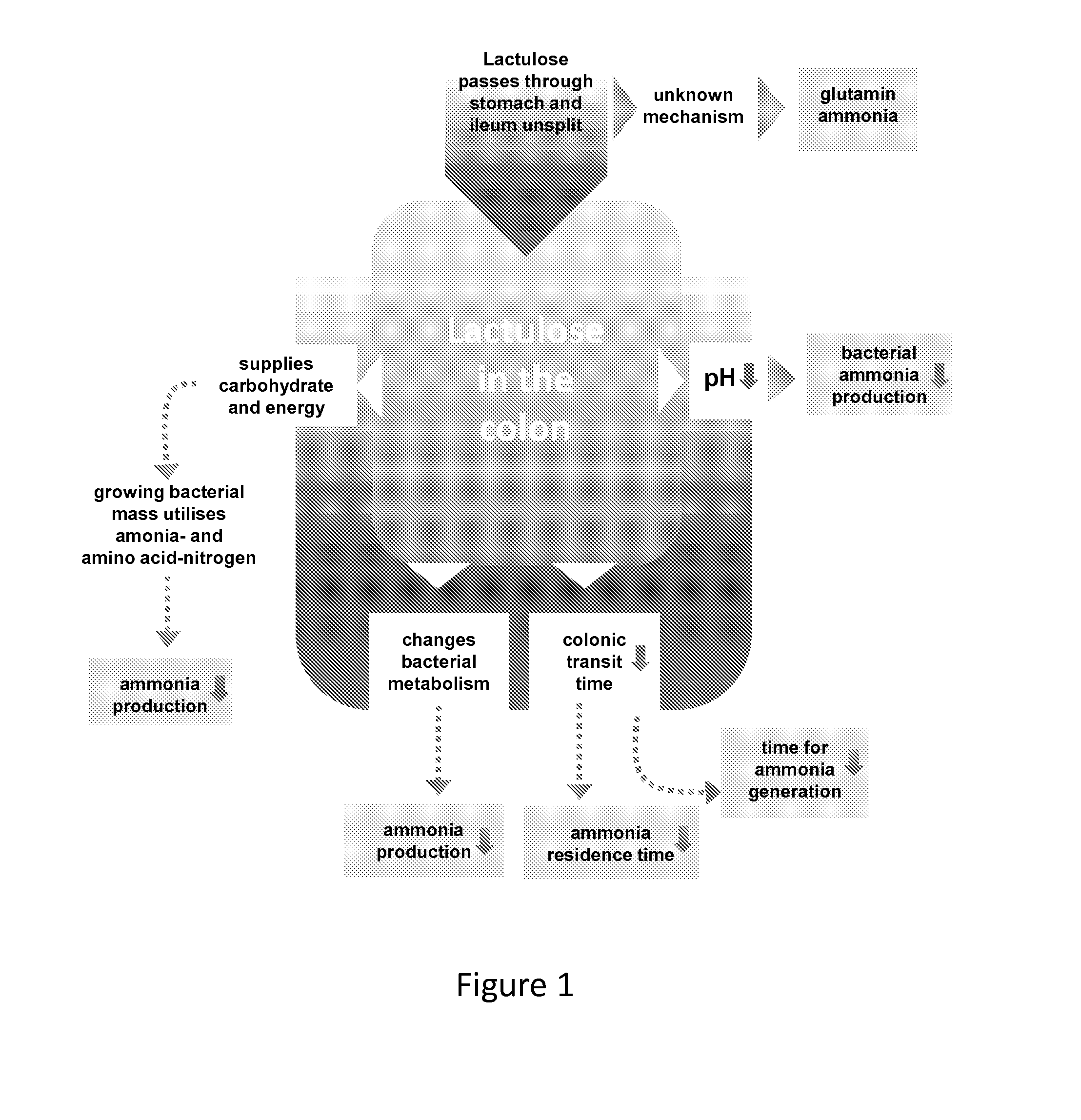

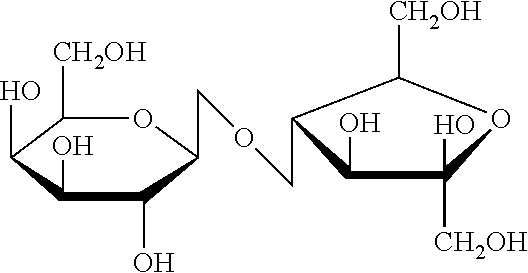

A treatment for autism in which an effective amount of lactulose is administered in order to bind excess ammonia in the gastrointestinal tract, the bloodstream, and the nervous system in order to prevent or reverse ammonia poisoning caused by the administration of certain antibiotics. Lactulose molecules in the colon are fermented by certain bacteria. The fermentation process lowers the colonic pH, and ammonia, in the form of ammonium ions, is used by the bacteria for amino acid and protein synthesis. This lowers the serum ammonia levels and reduces neurotoxicity.

Owner:CUREMARK

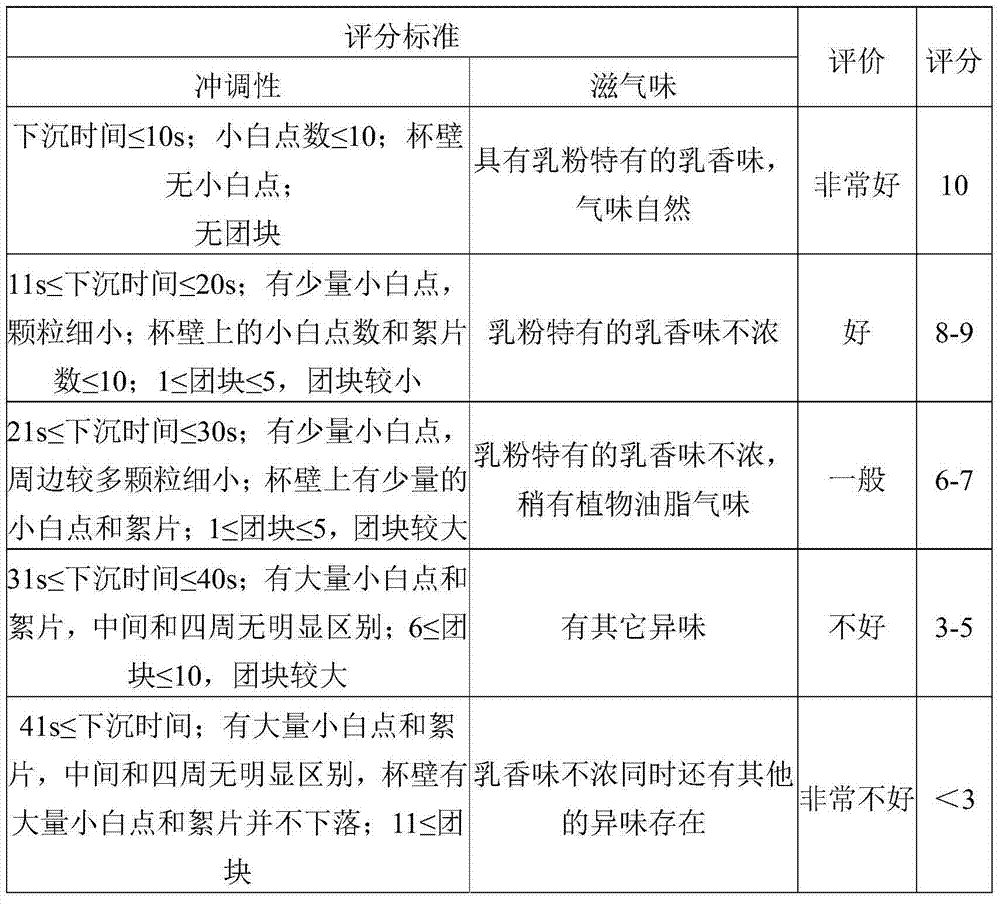

A kind of infant formula milk powder that does not get angry and its preparation process

ActiveCN102283289ANot ediblePromote digestion and absorptionMilk preparationVegetable oilFructooligosaccharide

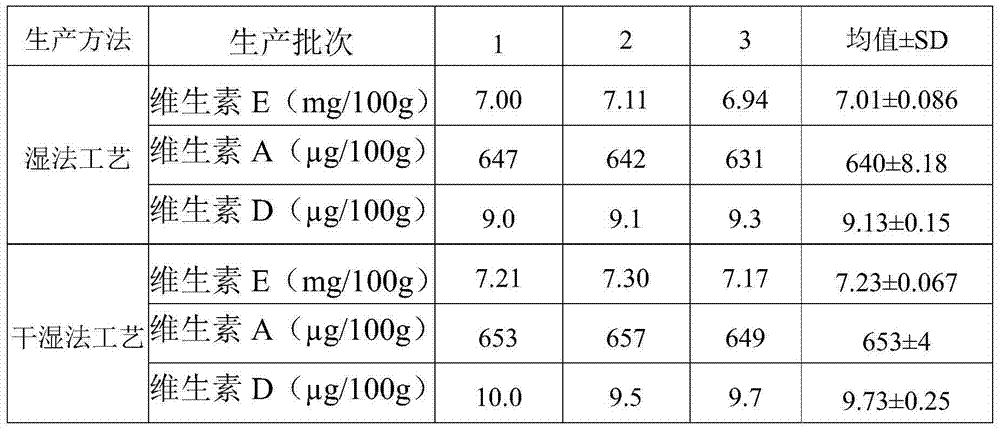

The invention relates to an anti-inflaming infant formula milk powder and a preparation process thereof. The anti-inflaming infant formula milk powder comprises the following components in percentage by weight: 22%-50% of lactose, 10%-20% of goat milk whey protein concentrate, 9.8%-20% of structural grease 1,3-dioleoyl 2-palmitoyl triglyceride, 10%-13.5% of non-fat goat milk powder, 8%-10% of vegetable oil, 2%-8% of beta-casein, 0.8%-1.6% of fructooligosaccharides, 0.5%-1.5% of mineral premix, 0.3%-1% of galactooligosaccharide, 0.2%-1% of immunoglobulin G, 0.2%-0.5% of lactulose, 0.10%-0.45% of arachidonic acid, 0.1%-0.6% of docosahexaenoic acid, 0.06%-0.12% of vitamin premix, 0.04%-0.06% of lactoferrin, and 0.01%-0.06% of nucleotide. The invention also includes the preparation process ofthe infant formula milk powder. The nutrition constituents and the functions of the infant formula milk powder are close to those of breast milk, the infant formula milk powder is easy to assimilate,and infants do not get inflamed after eating the milk powder.

Owner:AUSNUTRIA DAIRY CHINA

Use of lactulose in the treatment of autism

InactiveUS20080161265A1Avoid accumulationReverses effectBiocideNervous disorderBacteroidesNervous system

A treatment for autism in which an effective amount of lactulose is administered in order to bind excess ammonia in the gastrointestinal tract, the bloodstream, and the nervous system in order to prevent or reverse ammonia poisoning caused by the administration of certain antibiotics. Lactulose molecules in the colon are fermented by certain bacteria. The fermentation process lowers the colonic pH, and ammonia, in the form of ammonium ions, is used by the bacteria for amino acid and protein synthesis. This lowers the serum ammonia levels and reduces neurotoxicity.

Owner:CUREMARK

Use of lactulose in the treatment of autism

ActiveUS20120004192A1Avoid accumulationReverses effectBiocideNervous disorderBacteroidesNervous system

A treatment for autism in which an effective amount of lactulose is administered in order to bind excess ammonia in the gastrointestinal tract, the bloodstream, and the nervous system in order to prevent or reverse ammonia poisoning caused by the administration of certain antibiotics. Lactulose molecules in the colon are fermented by certain bacteria. The fermentation process lowers the colonic pH, and ammonia, in the form of ammonium ions, is used by the bacteria for amino acid and protein synthesis. This lowers the serum ammonia levels and reduces neurotoxicity.

Owner:CUREMARK

Treatment of disease conditions through modulation of hydrogen sulfide produced by small intestinal bacterial overgrowth

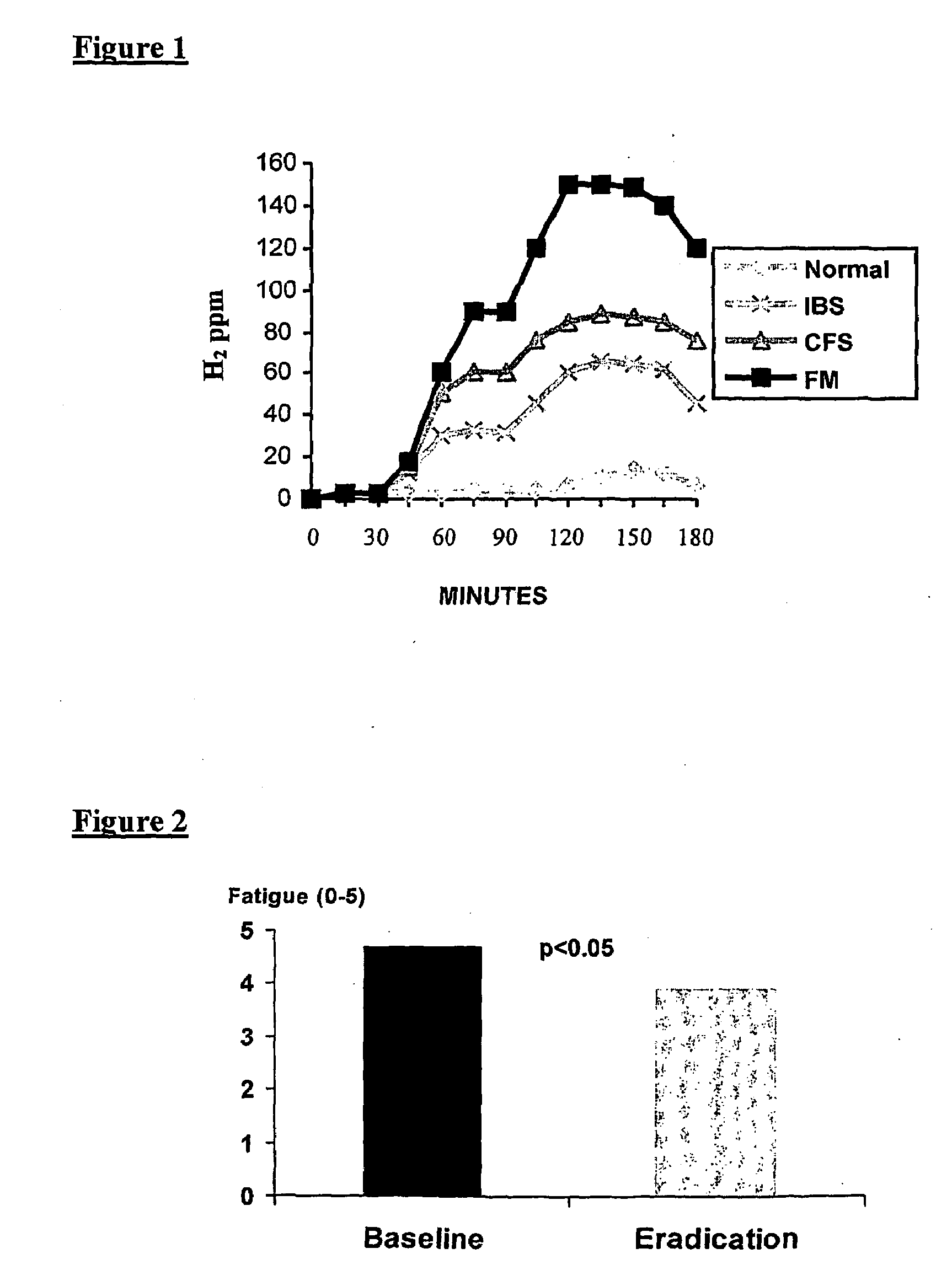

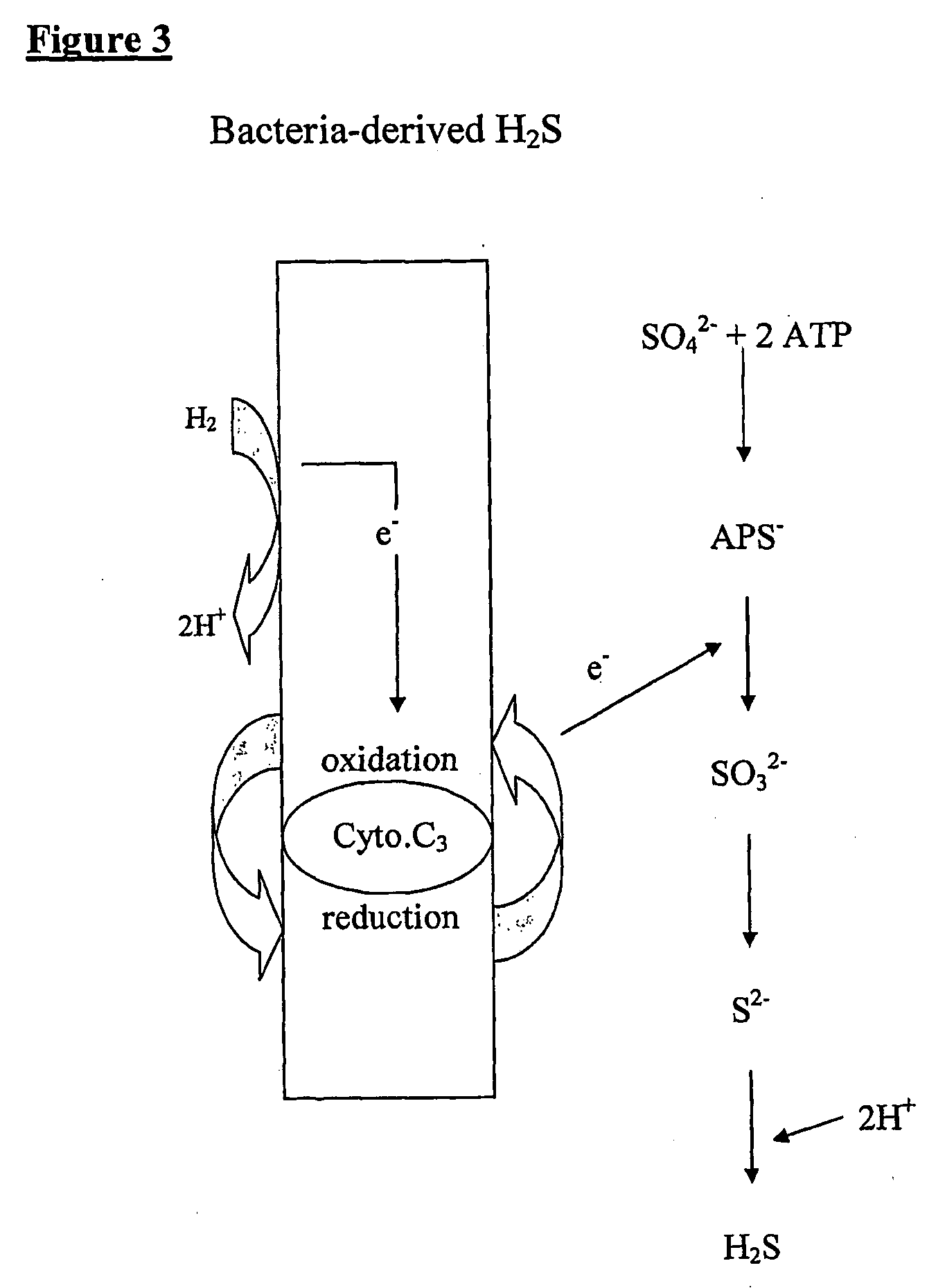

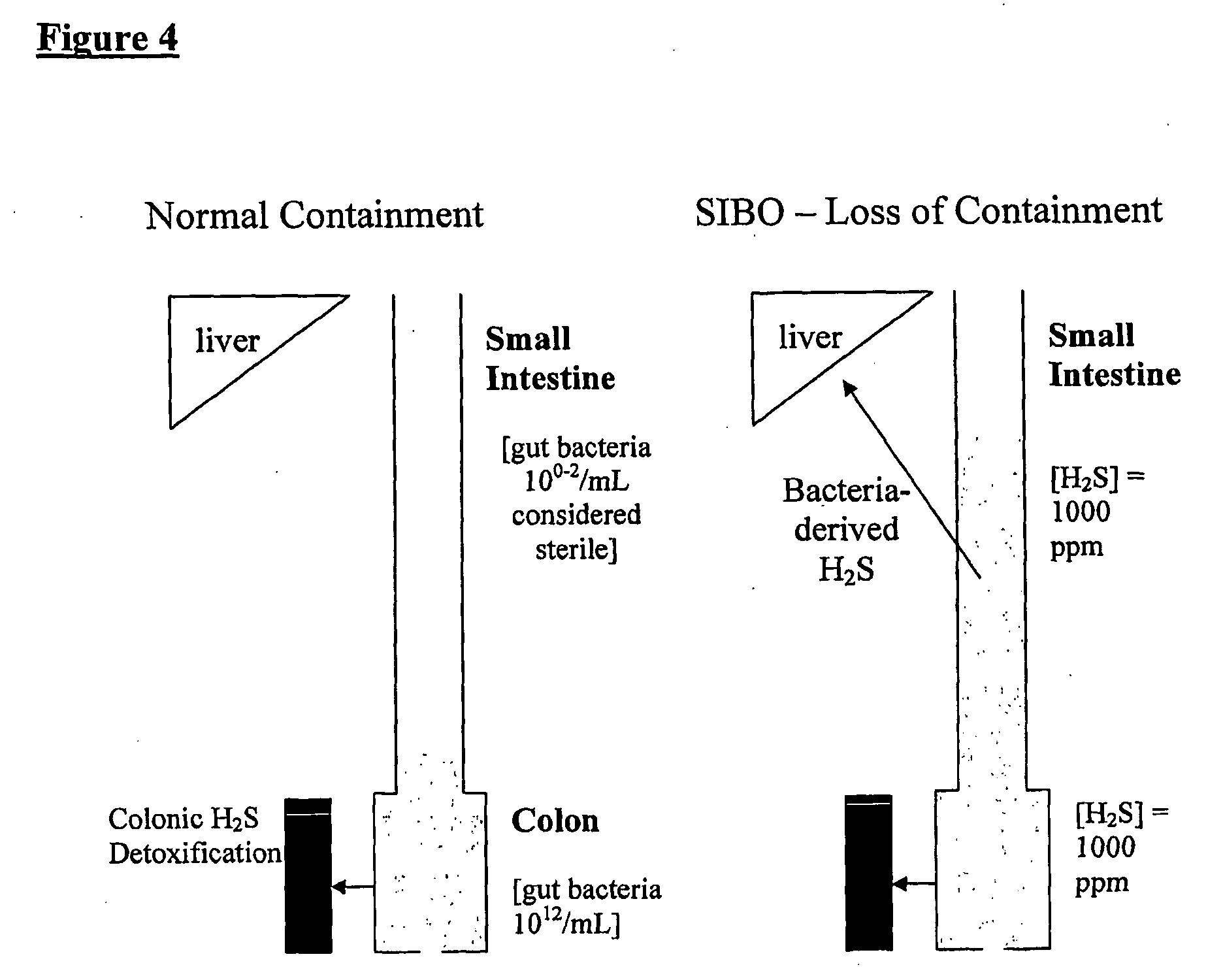

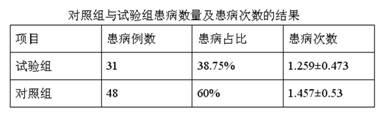

InactiveUS20090233888A1Lower Level RequirementsElevated level of H2SBiocideOrganic active ingredientsBacteroidesHyperhomocysteinemia

The present invention relates to the treatment of a wide array of diseases and physiologic conditions based on modulating the level of hydrogen sulfide (H2S) in the body by at least partially eradicating small intestinal bacterial overgrowth (SIBO) in the gut. An H2S or lactulose breath test and / or detection of H2S or thiosulfate in the blood or urine may be used as a diagnostic and / or prognostic for assessing a systemic H2S load that exceeds a mammal's natural detoxification capacity. These tests may similarly be used to monitor the effectiveness of a therapeutic intervention for SIBO and / or the diseases or physiologic conditions whose pathology is linked thereto. Because SIBO is related to hyperhomocysteinemia, diseases and physiologic conditions that relate to hyperhomocysteinemia may further be monitored and treated in connection with the methods of the present invention.

Owner:USC STEVENS UNIV OF SOUTHERN CALIFORNIA

Infant formula milk powder added with secretory immunoglobulin A and preparation method thereof

ActiveCN101953403AMeet the needs of healthy growth and developmentRich in nutrientsWhey manufactureBiotechnologyImmunologic substance

The invention discloses infant formula milk powder added with secretory immunoglobulin A and a preparation method thereof. The infant formula milk powder consists of demineralized whey powder, defatted milk powder, mixed vegetable oil, milk sugar, mineral substance premix, lecithin, arachidonic acid, lactulose, fructooligosaccharides, oligosaccharide, water soluble vitamin premix, secretory immunoglobulin A, calcium hydroxide, citric acid, docosahexenoic acid, milk phosphatide, lactoferrin, soyabean lecithin, liposoluble vitamin premix, nucleotide and L-carnitine. The invention also discloses a method for preparing the infant formula milk powder. The infant formula milk powder has important effects of improving infant immunologic function, preventing allergy and preventing mucous membrane infection. The provided secretory immunoglobulin A fluidized bed low-temperature addition technology contributes to effectively guaranteeing the activity of immunity substances.

Owner:AUSNUTRIA DAIRY CHINA

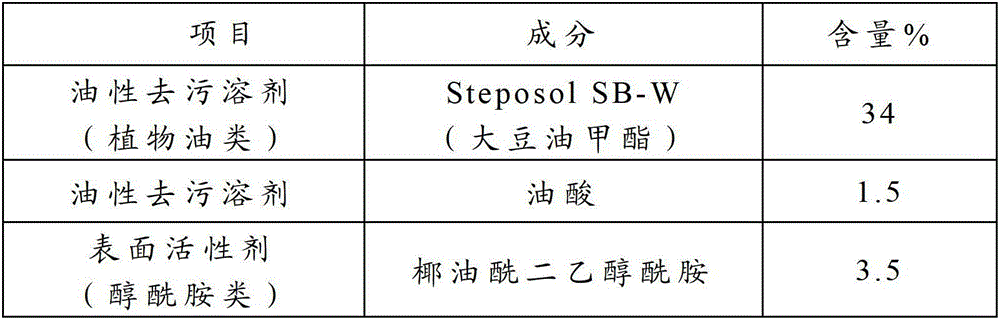

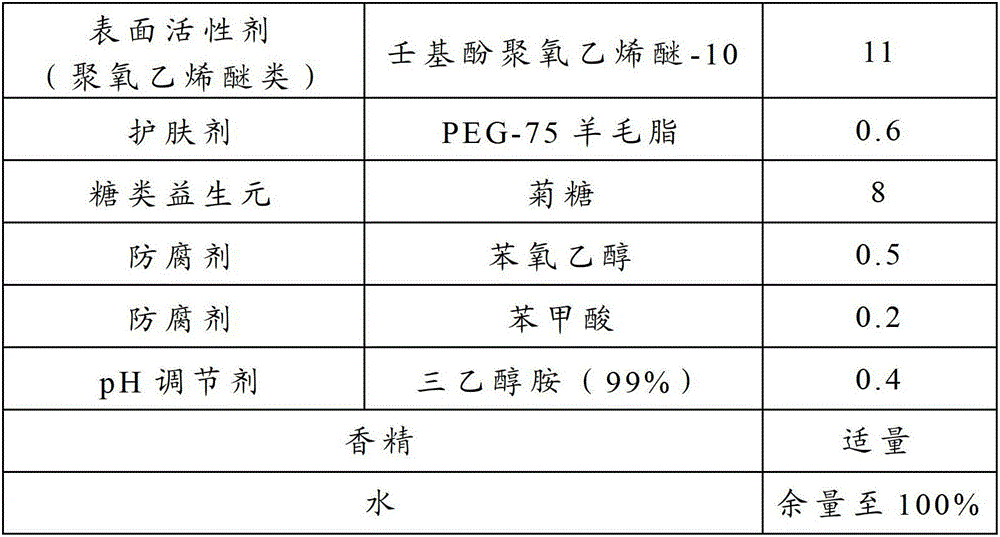

Hand cleaner composition

InactiveCN102871921ALess irritatingBlock the chance of directly attacking the skinCosmetic preparationsToilet preparationsPolyfructosanBenzoic acid

The invention discloses a hand cleaner composition. The hand cleaner composition comprises saccharide prebiotics, a preservative, a surfactant and water, wherein the ratio of the mass of the saccharide prebiotics to the mass of the preservative to the mass of the surfactant is (1-15):(0.1-2):(1-20); the saccharide prebiotics is at least one of polyfructosan, galacto-oligosaccharide, lactulose and raffinose; the preservative is at least one of nipagin ester, sodium nipagin acid ester, benzoic acid, sodium benzoate, sorbic acid, potassium sorbate, dehydroacetic acid, sodium dehydroacetate, benzyl alcohol and phenoxyethanol; and the surfactant is one of a nonionic surfactant, an anionic surfactant and an ampholytic surfactant. The hand cleaner composition can be used for rubbing hands without water, and has a good cleaning effect; and in addition, the saccharide prebiotics can effectively replace absorption fungus microorganisms on the surface of skin, so that the probability that bacteria directly attack the skin is eliminated.

Owner:GOLD HONG YE PAPER

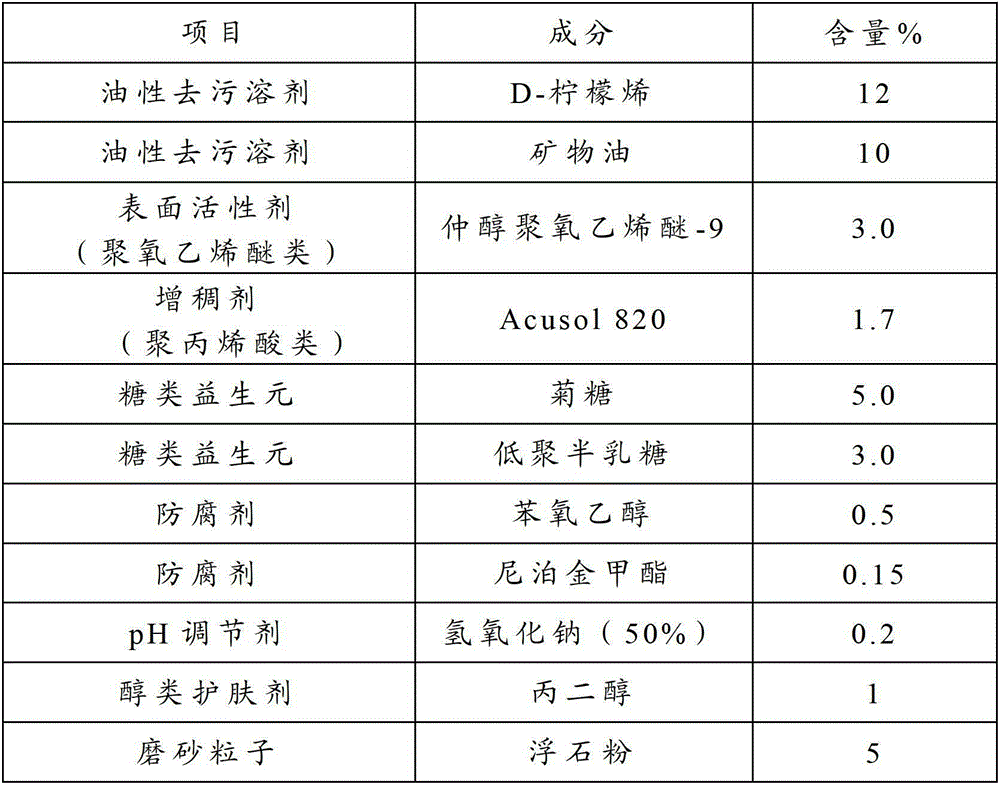

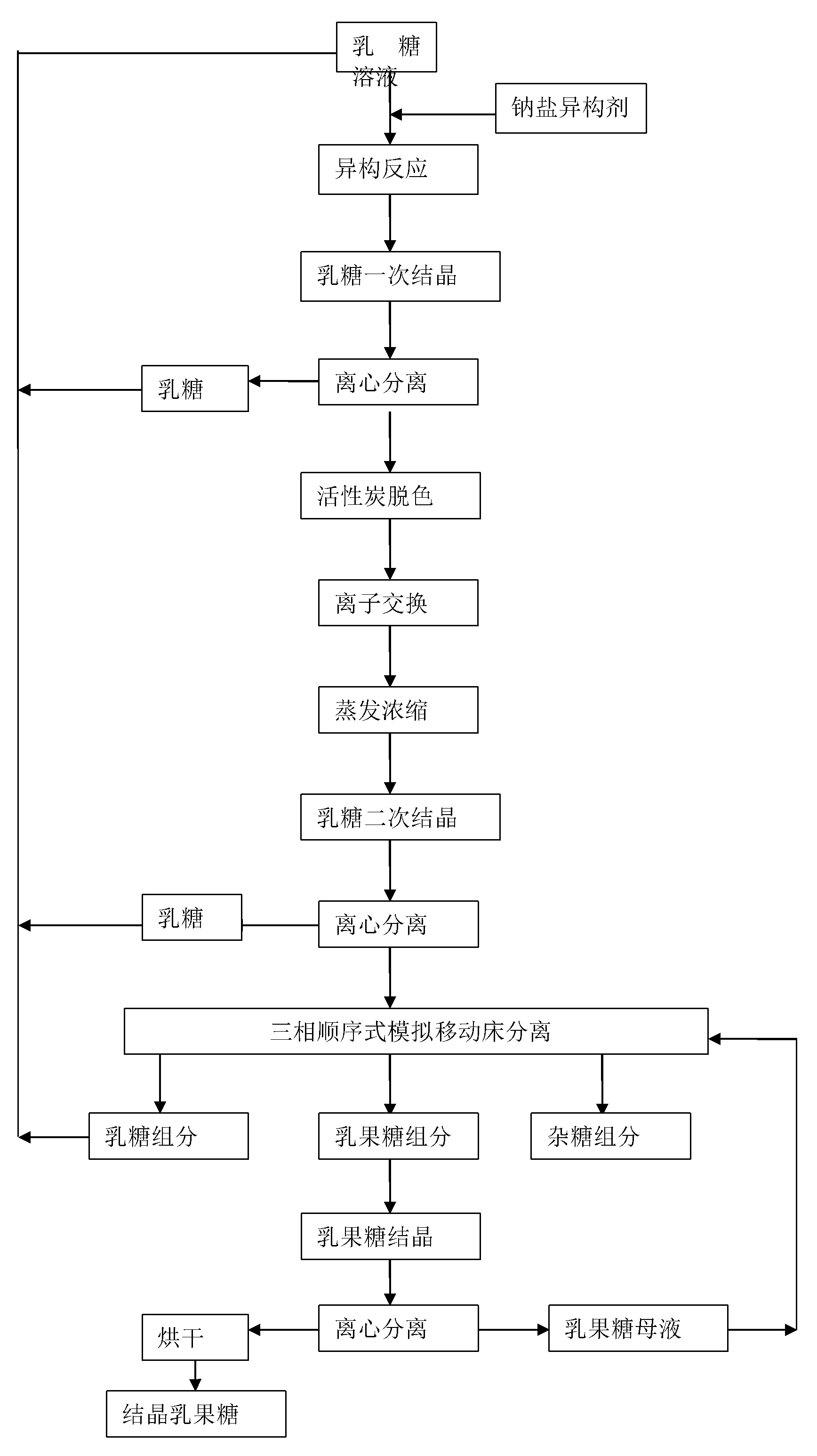

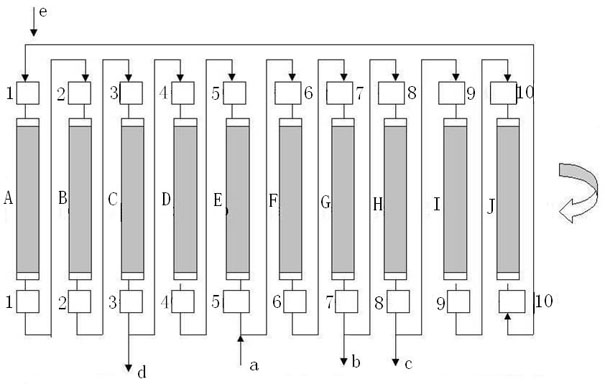

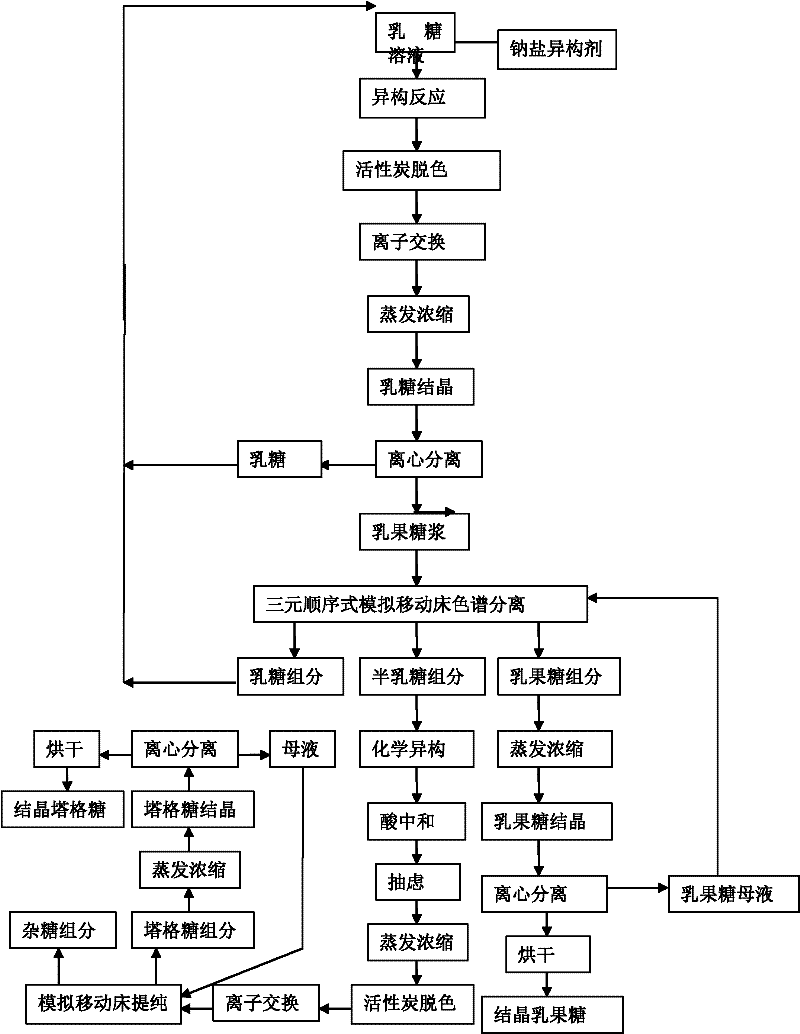

Production technique of crystalline lactulose

ActiveCN102153598AGood removal effectHigh yieldSugar derivativesDisaccharidesChromatographic separationSimulated moving bed

The invention discloses a production technique of crystalline lactulose, which uses lactose as a raw material and comprises the following steps: (1) preparing a lactose solution, adding an isomerizing agent to isomerize the lactose into lactulose under reflux, and centrifugalizing to remove crystalline lactose, thereby obtaining a centrifugate; (2) decoloring the centrifugate in the step (1) with activated carbon, carrying out ion exchange, concentrating by evaporation, cooling, carrying out secondary crystallization on the lactose, and centrifugalizing to obtain a preliminary purification liquid; (3) carrying out three-component sequential type simulated moving bed chromatographic separation on the preliminary purification liquid in the step (2) to obtain three components, including a lactose fraction, a lactulose fraction and an impure saccharide fraction; and (4) concentrating the lactulose component in the step (3) by evaporation, cooling to crystallize, centrifugalizing and drying to obtain the crystalline lactulose. The crystalline lactulose produced by the technique disclosed by the invention has the advantages of good quality and low cost, has obvious economic benefit and social benefit, and is an important breakthrough in the field of lactulose preparation.

Owner:山东绿健生物技术有限公司

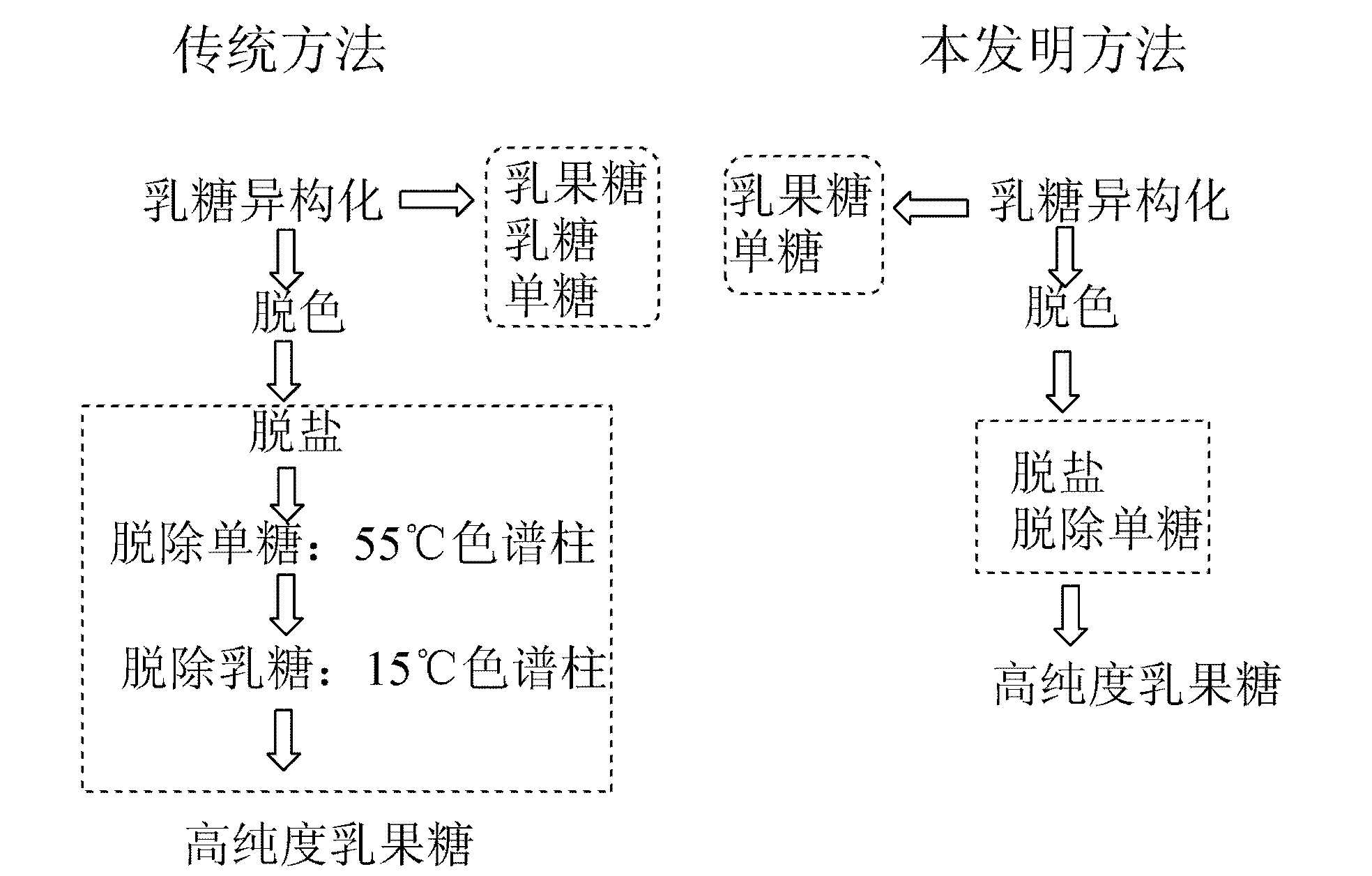

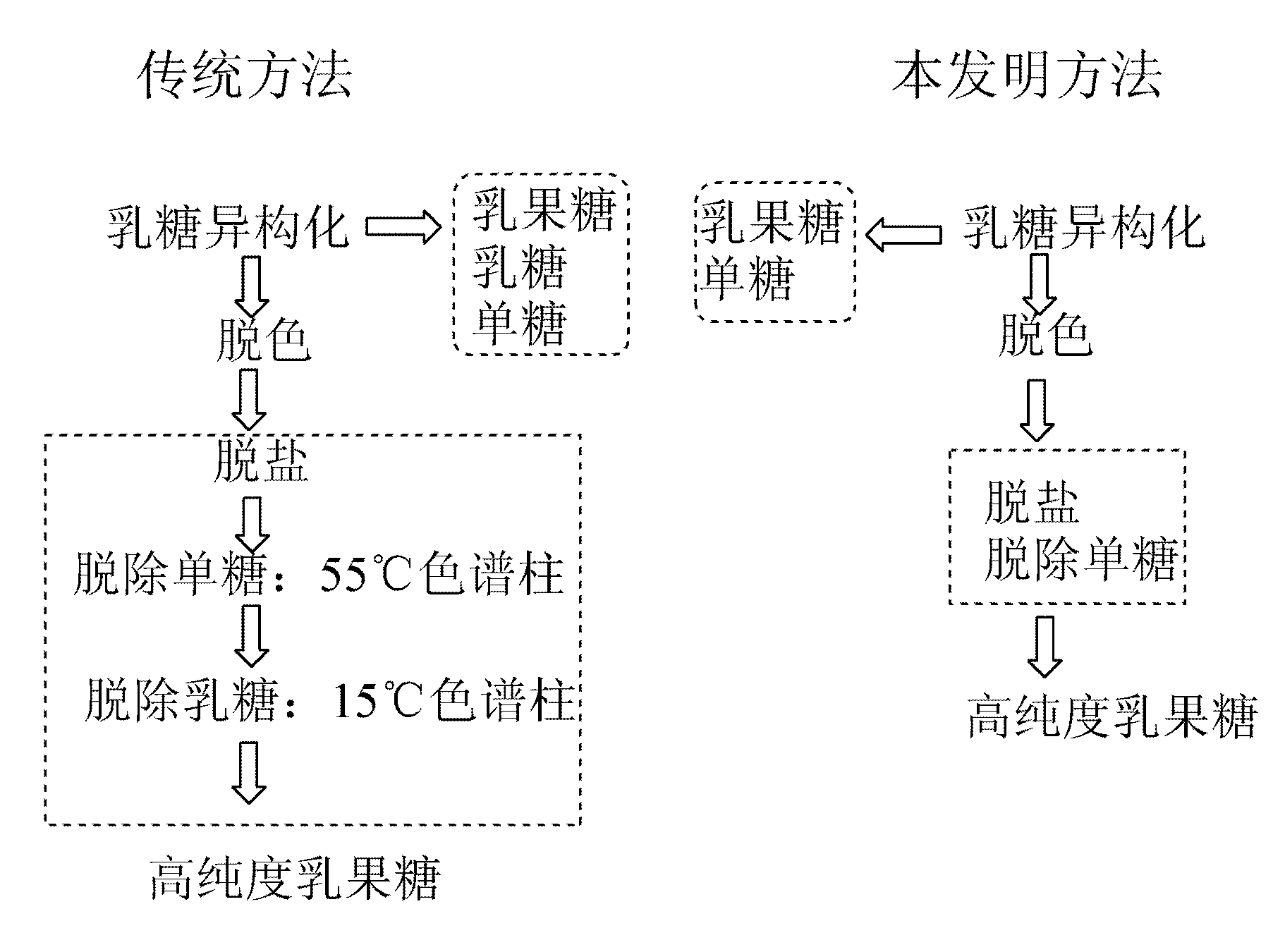

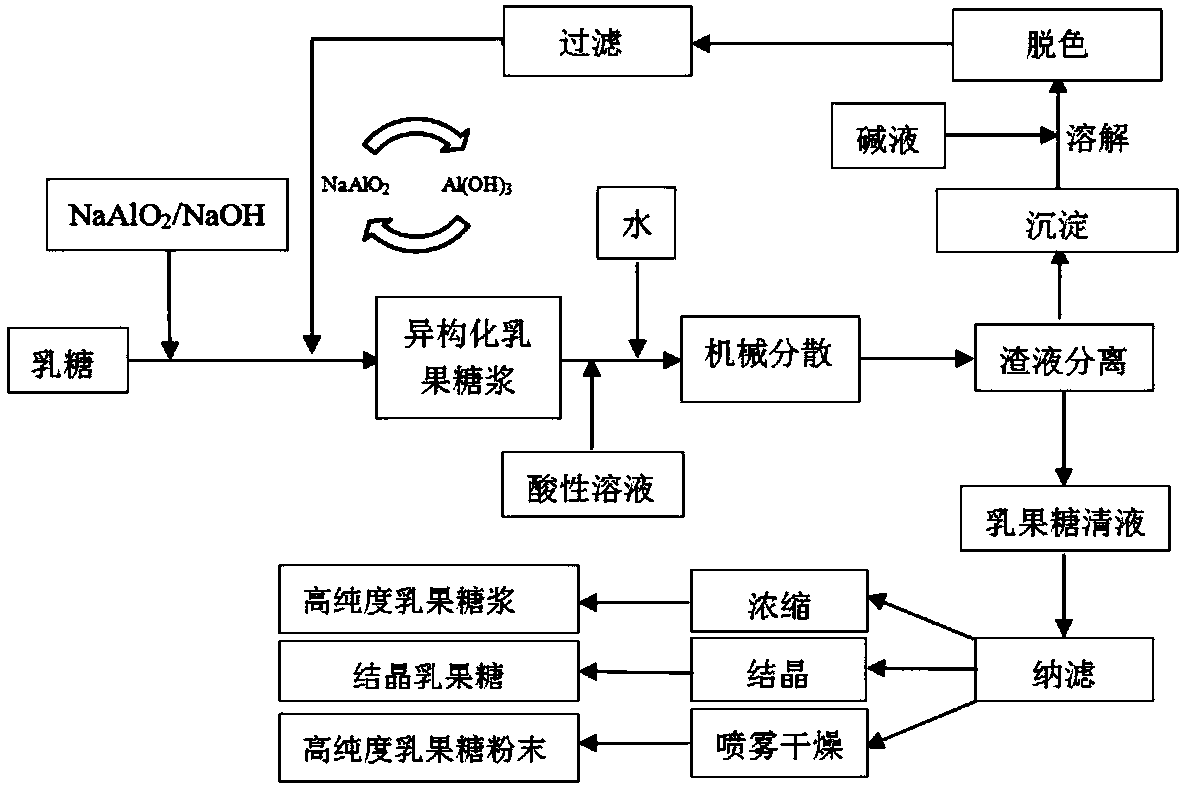

Method for preparing high-purity lactulose

InactiveCN102180913AHigh puritySimple production methodSugar derivativesChemical industryActivated carbonLactulose

The invention relates to a method for preparing high-purity lactulose, which comprises the following steps of: preparing lactulose syrup, decolorizing by using activated carbon, performing nanofiltration and purification on the lactulose syrup, removing residual boric acid, and spray-drying to obtain high-purity lactulose powder, wherein in the nanofiltration and purification step, operating pressure is controlled to be between 15 and 25bar, the temperature is controlled to be between 20 and 50 DEG C, and a catalyst, salt and single sugar in the syrup are removed by a nanofiltration membrane in one step. The invention has the advantages that: the obtained lactulose has high purity of over 97.0 percent (based on total sugar), and the production method is simple, high-efficiency and energy-saving by a nanofiltration technology, and suitable for mass production and low in operating cost, and the production mode is continuous.

Owner:JIANGNAN UNIV

Milk powder for middle and old age people and preparation method thereof

The invention discloses a milk powder for middle and old age people. The raw material of the milk powder comprises the following components in percentage by weight: 52.39-75.72% of milk powder and / or cow milk, 7.73-15.37% of maltodextrin, 3.84-11.59% of vegetal oil, 2.88-14.41% of lactose, 1.15-2.88% of a lactulose liquid, 0-22.11% of whey protein concentrate, 0.77-1.34% of a calcium source substance, 0.192-0.483% of an emulsifier, 0.028-0.056% of compound vitamins and the balance of water, wherein the use level of cow milk is that of dry matters and the percentage by weight is each compound in the total weight of the raw materials in the milk powder for middle and old age people except water. According to the milk powder for middle and old age people disclosed by the invention, lactulose and light calcium are organically combined, thereby facilitating proliferation of effective microbial community (bifidobacteria) and / or lactobacillus in the intestinal tract of the middle and old age people and further improving the symptoms of osteoporosis of the middle and old age people.

Owner:BRIGHT DAIRY & FOOD

Method for preparing high-purity lactulose

ActiveCN102020680AImprove conversion rateHigh yieldSugar derivativesDisaccharidesChromatographic separationIon exchange

The invention relates to the field of the preparation of functional sugar, and relates to a method for preparing high-purity lactulose. The method for preparing the high-purity lactulose comprises the following steps of: preparing lactose solution at the concentration of 15 to 20 percent; adding a boric acid and sodium hydroxide (NaOH) into the solution, and adjusting a reaction to obtain conversion liquid; performing ion exchange sodium ion (Na<+>)-removing treatment on the conversion liquid; decoloring a granular active carbon column; removing the boric acid from the lactose solution to obtain a lactose solution dry substance with the boric acid content of less than 1 mg / kg; concentrating the lactose solution until the concentration is 50 to 60 percent; separating by using a 10-bed continuous chromatographic separation device; and performing aqueous phase crystallization, wherein the cooling speeds are 0.8 DEG C per hour at the temperature of between 60 and 50 DEG C, 1 DEG C per hour at the temperature of between 50 and 30 DEG C and 1.1 DEG C per hour at the temperature of between 30 and 13 DEG C. The conversion rate of the lactulose can be increased, so that the yield of the lactulose products is greatly improved; granular active carbon is decolored; moving bed chromatographic separation is continuously simulated, so continuous chromatographic separation of the high-purity lactulose can be realized, the purity of the lactulose reaches over 92 percent so as to facilitate aqueous phase crystallization; and the purity can reach over 98 percent due to the aqueous phase crystallization.

Owner:BAOLINGBAO BIOLOGY

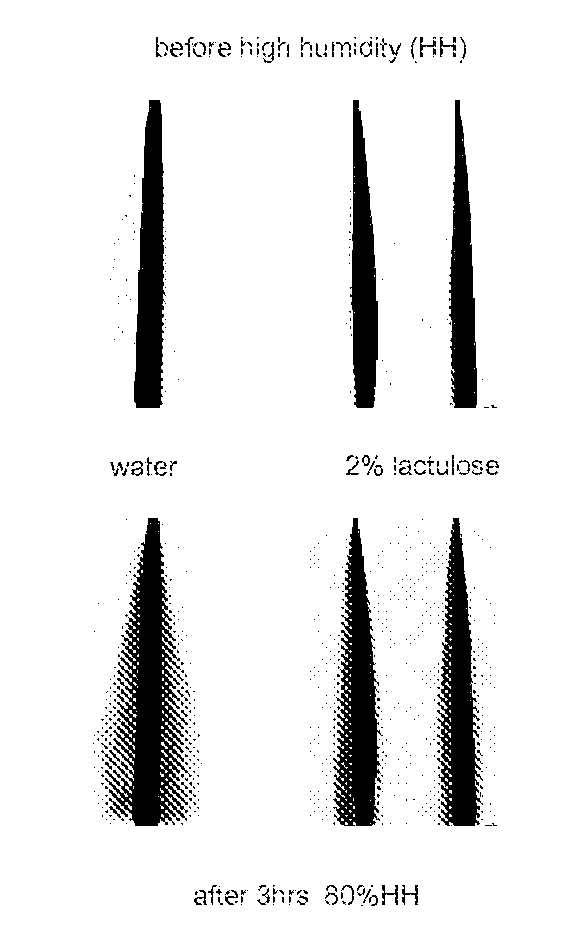

Method of treating hair with a sugar composition

A hair treatment composition comprising: i) a sugar comprising from three to four waters of crystallisation, esp. lactulose; ii) at least one further ingredient selected from the group consisting of a suitable carrier, a styling polymer or a surfactant.

Owner:CONOPCO INC D B A UNILEVER

Composition and method for treatment of hepatic encephalopathy

InactiveUS20050142099A1Decrease plasma levelReduce constipationBiocideDigestive systemSide effectLactulose

The inventions provide an improved treatment for hepatic encephalopathy characterized by hyperammonemia and / or constipation, comprising the oral administration of polyethylene glycol (PEG) in amounts sufficient to reduce plasma levels of ammonia and / or to alleviate constipation. Preferably, the PEG is administered in combination with lactulose, which provides a palatable composition for the treatment of HE with excellent therapeutic benefits and reduced side effects as compared to lactulose alone.

Owner:HALOW GEORGE M

Sour milk powder containing chitosan

InactiveCN1647660AHas a fresh-keeping effectMaintain and regulate balanceMilk preparationFood preparationIsomaltooligosaccharideFruit juice

The sour milk powder containing chitosan consists of chitosan 1-5 weight portions, milk powder 50-80 weight portions, souring agent 0.5-5 weight portions, fruit juice powder 5-15 weight portions, freeze dried active lactic acid powder 1-5 weight portions, and may also contains taste regulating sweetener, fructose oligose, galactose oligose, soybean oligose, lactulose and maltose oligose. It is suitable for the growth of lactic acid bacteria, and its contained chitosan can regulate micro environment inside intestinal tract, preserve and promote digestion. There are several different recipes suitable for various people of different ages.

Owner:黄恒燊

Method for making health care instant noodles food with enterogastric micro-ecological regulating action

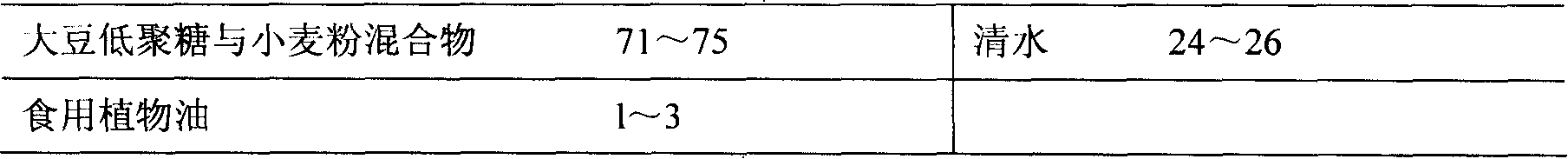

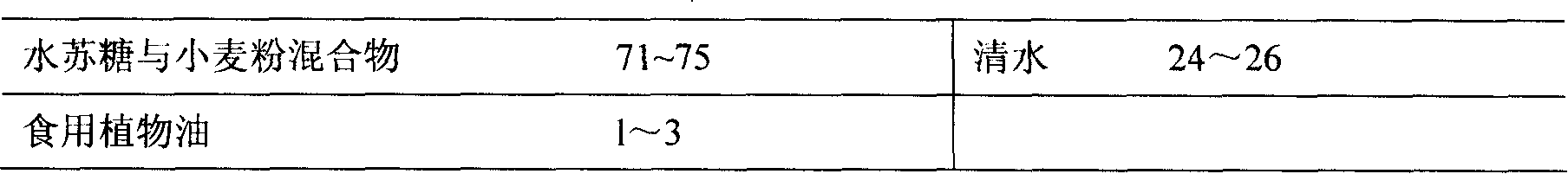

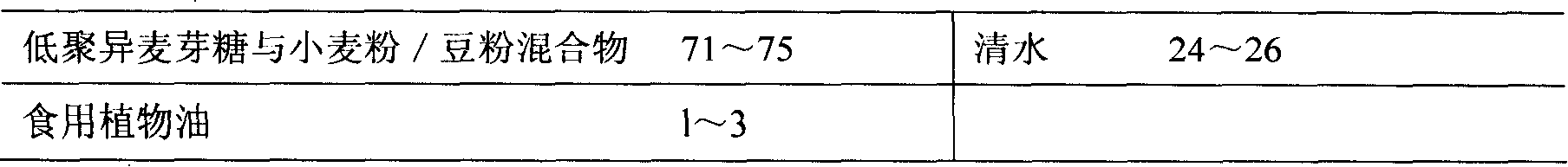

InactiveCN101185511ASimple preparation processLaxativeOrganic active ingredientsDough treatmentIsomaltooligosaccharideCholesterol

The invention provides a production method of a health instant noodle food which has a regulating effect on intestinal and gastric microecology and is characterized in adding the health instant noodle food with functional oligosaccharides which comprise xylo-oligosaccharide, galacto-oligosaccharide, manno-oligosaccharide, stachyose, raffinose, fructo-oligosaccharide, isomalto-oligosaccharide, malto-oligosaccharide, soybean oligosaccharide, chitosan, lactosucrose, gentio-oligosaccharide; the mixture comprising one or more of the oligosaccharides constitutes the functional oligosaccharides and the functional oligosaccharides of 0.02-2.00 percent by weight of flour are mixed evenly with flour and processed in the workmanship of normal instant noodle food. The functional oligosaccharides pertain to bifidus factors; therefore, the invention has the physiological function of regulating the intestinal and gastric microecology of body to relieve constipation and lowering cholesterol and blood-sugar level, thereby providing a popular health food which has the functions of preventing and curing diseases.

Owner:广州伯凯生物技术有限公司

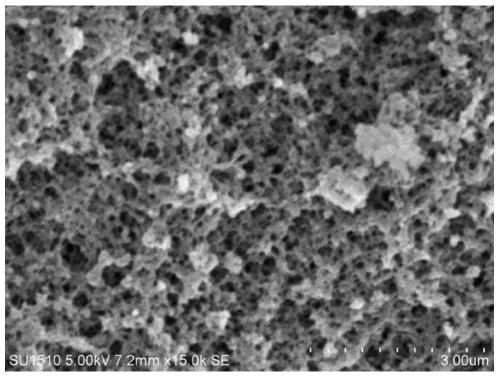

Arthrobacter mutant strain, method for producing lactase from mutant strain and method for preparing lactulose by using lactase

InactiveCN102168028ANot generatedHigh purityBacteriaMicroorganism based processesCatalytic methodLactase

The invention belongs to the technical fields of food and biology, and discloses an Arthrobacter mutant strain (Arthrobacter sp.jnsb-2), a method for producing lactase by fermentation culturing of the mutant strain and a catalytic method for synthesizing lactulose from lactose and levulose by using the lactase as a catalyst. In the invention, the Arthrobacter mutant strain jnsb-2 is used as the strain of which the preservation number is CCTCC NO:M209210, and is subjected to fermentation culturing on a fermentation culture medium composed of a carbon source, a nitrogen source and inorganic salt, thus obtaining the lactase; and by using the lactase as a catalyst, lactose and levulose can be used as substrates and converted into the lactulose by an enzyme method. The lactase produced by the fermentation of the strain has the advantages of extensive culturing conditions, short enzyme production cycle and convenient operation process; and by using the enzyme method to convert the lactase into the lactulose, the defects that the product is easy to degrade and the colored byproduct is difficult to remove in the lactulose preparation process based on the chemical method are overcome, and a high product purity is achieved.

Owner:JIANGNAN UNIV

Phenyl boronic acid-based polymer carrier and applications in selective adsorption of saccharide-based substances

ActiveCN110183574ALarge capacity of adsorption targetInhibition of competitive adsorptionOther chemical processesAlkali metal oxides/hydroxidesSorbentResource saving

The invention discloses synthesis of a phenyl boronic acid-based polymer carrier, and a method for selectively adsorbing and separating a saccharide-based substance having an ortho-cis hydroxy structure. According to the present invention, a strong surface hydrophobicity polymer carrier with a phenyl boronic acid group as the only functional group is prepared, the target saccharide-based substancehaving an ortho-cis hydroxy structure is efficiently and selectively adsorbed and separated from a saccharide-based mixing solution by using the carrier as an adsorbent, and through adsorption-desorption, lactulose with a purity of 10% can be purified to more than 95%, the purity of lactulose in the final eluent can reach more than 99% when the initial purity of lactulose reaches 25%, and the recovery rate is nearly 100%; and the phenyl boronic acid-based polymer carrier has stable structure, can achieve long-time continuous recycling or multi-batch batchwise separation and purification, meets resource-saving and environment-friendly production requirements, and easily promotes the clean, efficient and environmentally friendly industrial production of high-purity lactulose and related saccharides.

Owner:苏州福赛思生物科技有限公司

Composition and method for treatment of hepatic encephalopathy

InactiveUS20070269403A1Reduce ammonia levelsReduce constipationDigestive systemSynthetic polymeric active ingredientsSide effectPolyethylene glycol

The inventions provide an improved treatment for hepatic encephalopathy characterized by hyperammonemia and / or constipation, comprising the oral administration of polyethylene glycol (PEG) in amounts sufficient to reduce plasma levels of ammonia and / or to alleviate constipation. Preferably, the PEG is administered in combination with lactulose, which provides a palatable composition for the treatment of HE with excellent therapeutic benefits and reduced side effects as compared to lactulose alone.

Owner:HALOW GEORGE M

Process for the preparation of a lactulose syrup by lactose isomerization

Process for the preparation of lactulose wherein an aqueous solution or suspension of lactose is reacted with sodium aluminate in order to produce the isomerization of lactose and the mixture thus obtained is neutralized by treatment with gaseous CO2 under pressure, obtaining a suspension of aluminum hydroxide which can be easily separated from the lactulose solution.

Owner:INALCO SPA

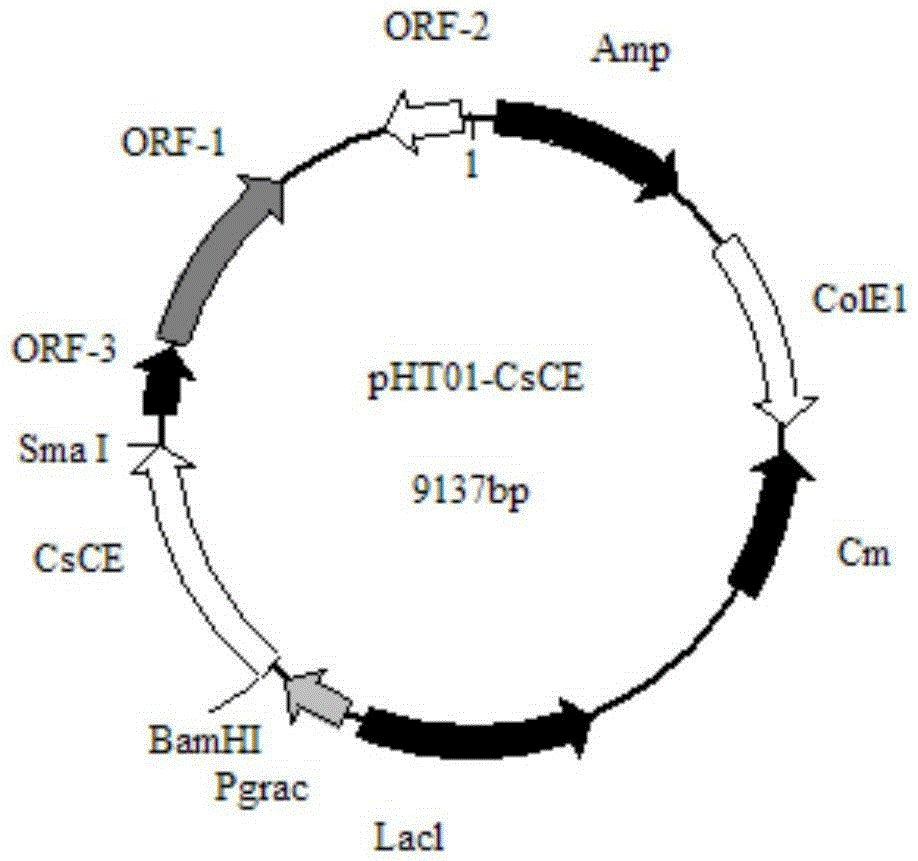

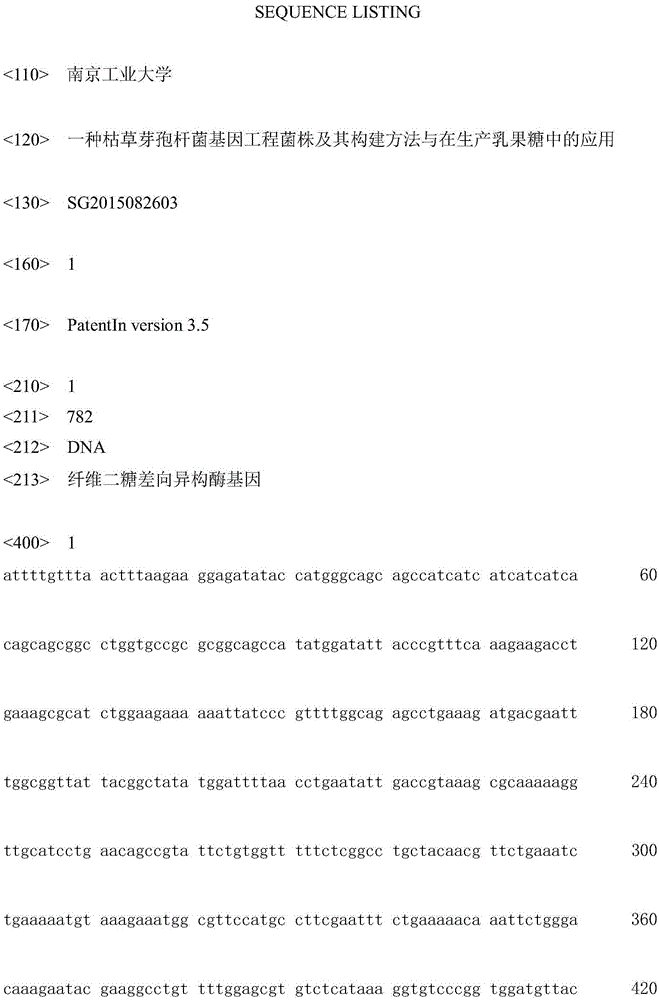

Bacillus subtilis gene engineering strain, construction method thereof and application in lactulose production

ActiveCN105255805AEasy to operateAvoid loss of enzyme activityBacteriaMicroorganism based processesThiogalactosidesBio engineering

The invention discloses a method for producing lactulose by means of a recombinant bacillus subtilis, and belongs to the technical field of bioengineering technology. The recombinant bacillus subtilis is used as the production strain, the recombinant bacillus subtilis includes cellobiose epimerase capable of catalyzing lactose for producing the lactulose, and induction expression is performed through the lactose or isopropyl-beta-D-isopropylthiogalactoside (IPTG) so as to use the lactose or whey as a substrate for a biological catalysis reaction. Bacillus subtilis wet cells or a fermentation solution is used for the catalysis reaction, the method is simple and easy to implement, and enzyme activity losses and cost waste in the enzyme separation and purification process are avoided; the food-grade bacillus subtilis is used as the production strain, the method is safe and reliable, and the effective references are provided for industrial and environment-friendly lactulose production.

Owner:NANJING UNIV OF TECH

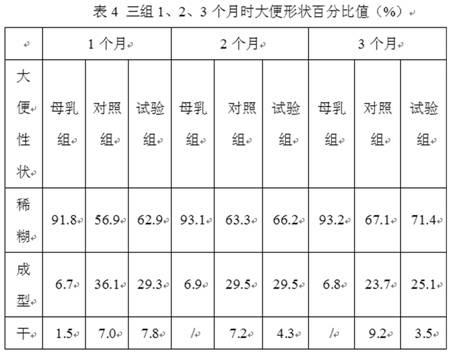

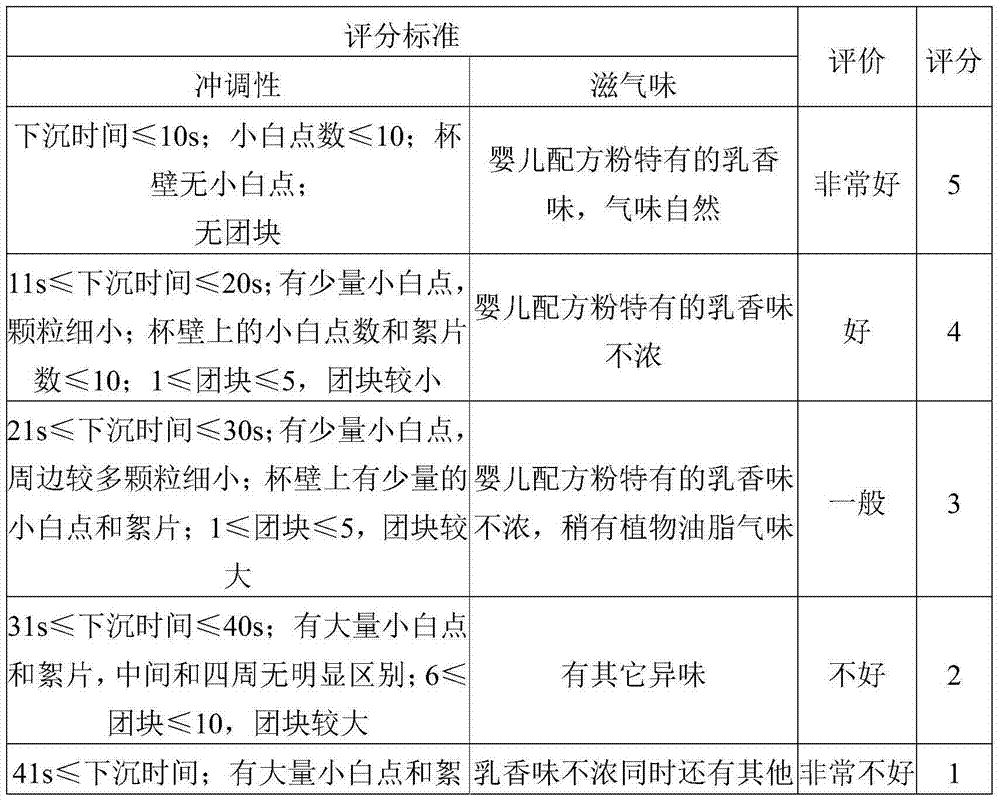

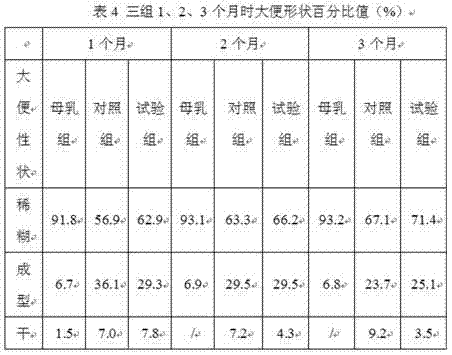

Infant formula milk powder containing lactulose and preparation method

InactiveCN104489132AImprove stool propertiesDoes not affect sensory propertiesWhey manufactureWhey proteinLactose

The invention discloses infant formula milk powder containing lactulose and a preparation method of the formula milk powder. The infant formula milk powder containing lactulose is prepared from raw materials consisting of the following components: 21.55-43.10% of a milk source, 13.68-20.12% of vegetable fat, 16.47-40.00% of desalted whey powder, 6.47-17.98% of lactose, 8.99-10.01% of concentrated whey protein, 0.60-1.19% of lactulose, 0.15-0.25% of complex mineral substance, 0.20-0.30% of complex vitamin and 0.41-0.57% of other nutrients, wherein the percentages mean the mass percentages of various components in the raw materials, excepting for water, of the infant formula milk powder. According to the infant formula milk powder disclosed by the invention, just lactulose which is relatively high in content is added to the formula powder, so that sensory characteristic is not affected, the constitution of carbohydrate is improved, oligosaccharide inside the formula powder is enhanced, selective proliferation of intestinal flora is achieved and the fecal characters of babies are improved.

Owner:BRIGHT DAIRY & FOOD

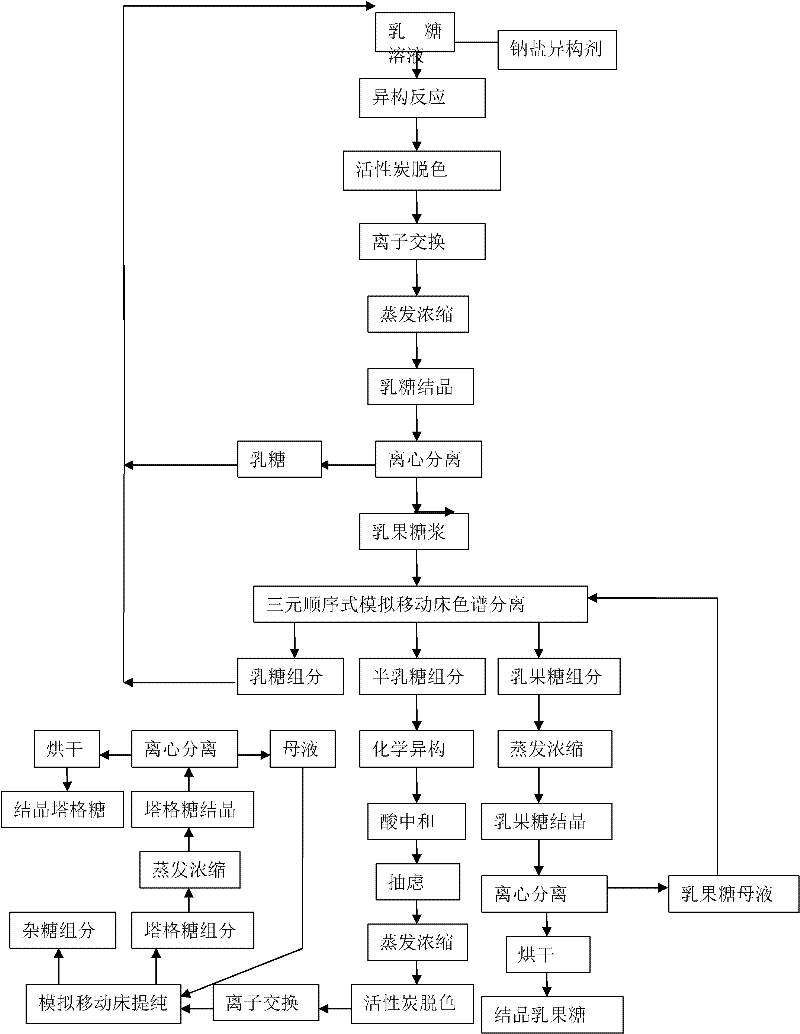

A process for simultaneous production of lactulose and tagatose

ActiveCN102296129AIncrease component contentImprove purposeFructose productionLactose productionTagatoseIsomerization

The invention discloses a technology for simultaneously producing lactulose and tagatose. According to the technology, lactose is used as a raw material; and while simultaneously producing lactulose, a by-product galactose is utilized to produce tagatose, thus fully utilizing resources. The technology provided by the invention comprises the following steps of: (1) allowing lactose to undergo refluxing and isomerization, followed by evaporation, cooling and crystallization to obtain a mixed liquid; (2) carrying out decolouring and ion exchange on the mixed liquid, followed by simulated moving bed separation?? to obtain a lactose component, a lactulose component and a galactose component; (3) allowing the lactulose component to undergo evaporative concentration, followed by crystallization,centrifugation and drying to obtain crystal lactulose; (4) allowing the galactose component to undergo isomerization to obtain a galactose isomerization liquid; (5) neutralizing the galactose isomerization liquid by the use of acid, followed by extraction filtration to remove deposits to obtain a tagatose slurry; (6) carrying out evaporative concentration on the tagatose slurry, followed by decolouring and ion exchange to obtain a clean fluid; (7) carrying out simulated moving bed separation on the clean fluid to obtain a tagatose slurry; and (8) carrying out evaporative concentration on the tagatose slurry, followed by crystallization, centrifugation and drying to prepare crystal tagatose.

Owner:山东绿健生物技术有限公司

Continuous cyclic preparation method of high-purity lactulose solution and product thereof

ActiveCN108148099AIncrease concentrationRealize repeated useSugar derivativesDisaccharidesHigh concentrationResource saving

The invention belongs to the technical field of oligosaccharide preparation, and relates to a continuous cyclic preparation method of a high-purity lactulose solution and a product thereof. Specifically speaking, the preparation method comprises the following steps: (1) performing lactulose isomerisation; (2) performing acidity adjustment; (3) diluting, dispersing and separating; (4) purifying clear lactulose liquid; (5) performing cyclic utilization of a catalyst. Through the preparation method, high-concentration lactulose solution and a subsequent product thereof can be prepared. Accordingto the continuous cyclic preparation method of the high-purity lactulose solution and the product thereof, sodium metaaluminate / an alkaline matter is taken as an alkaline complexing catalyst for the first time in China, and the conversion rate and lactulose concentration achieved by preparing the lactulose by taking the sodium metaaluminate / an alkaline matter as the alkaline complexing catalyst are far higher than those achieved by adopting a boracic acid / sodium hydroxide system; repeated cyclic use of a sodium metaaluminate catalyst is realized; the defect that precipitate wraps the lactuloseis overcome. The preparation method provided by the invention meets resource-saving and environment-friendly production requirements, and provides beneficial experience and reference for promoting clean, high-efficiency and environment-friendly lactulose industrial production.

Owner:JIANGNAN UNIV

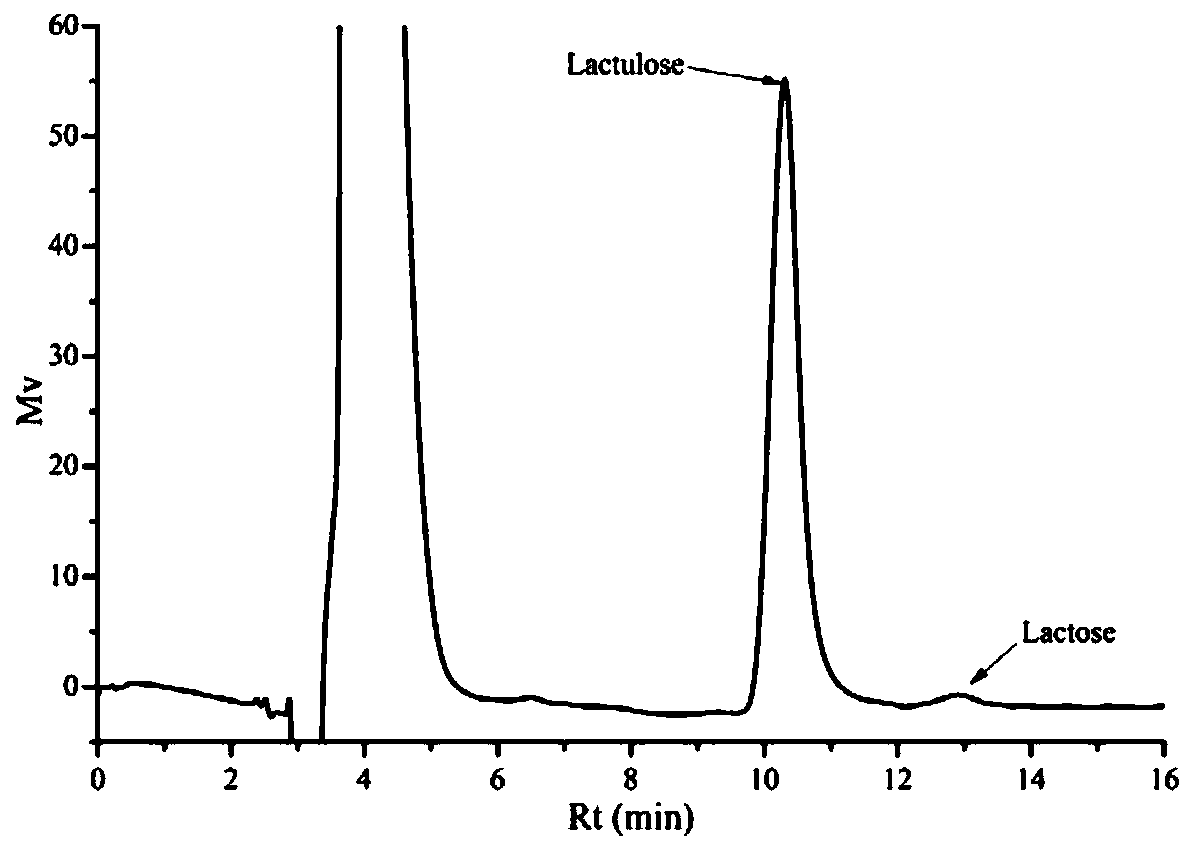

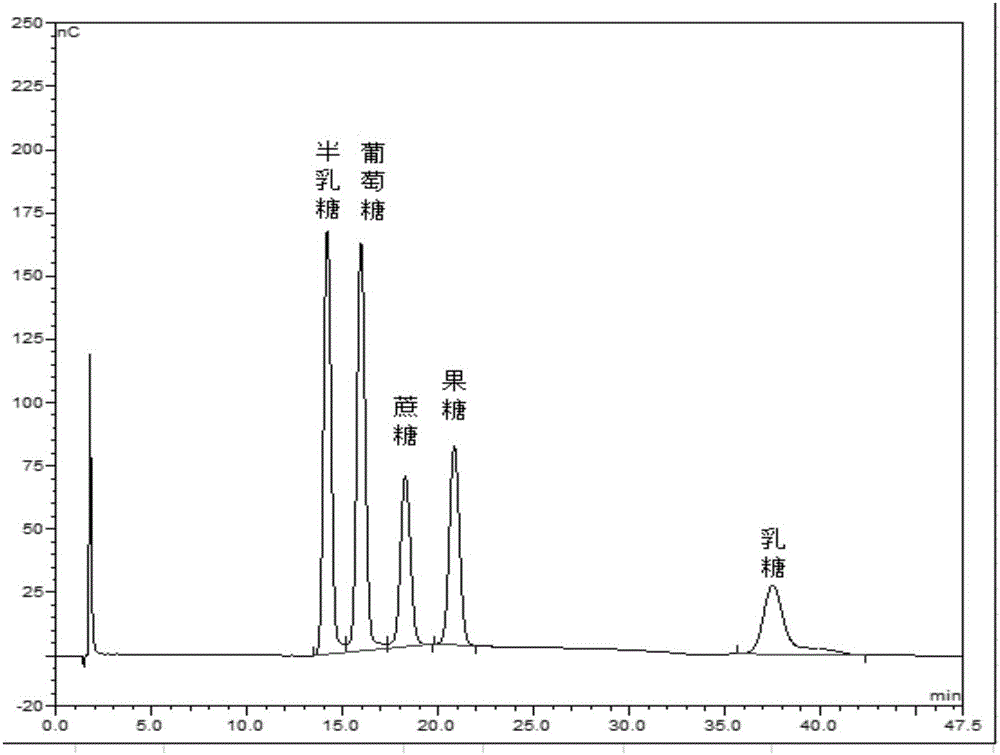

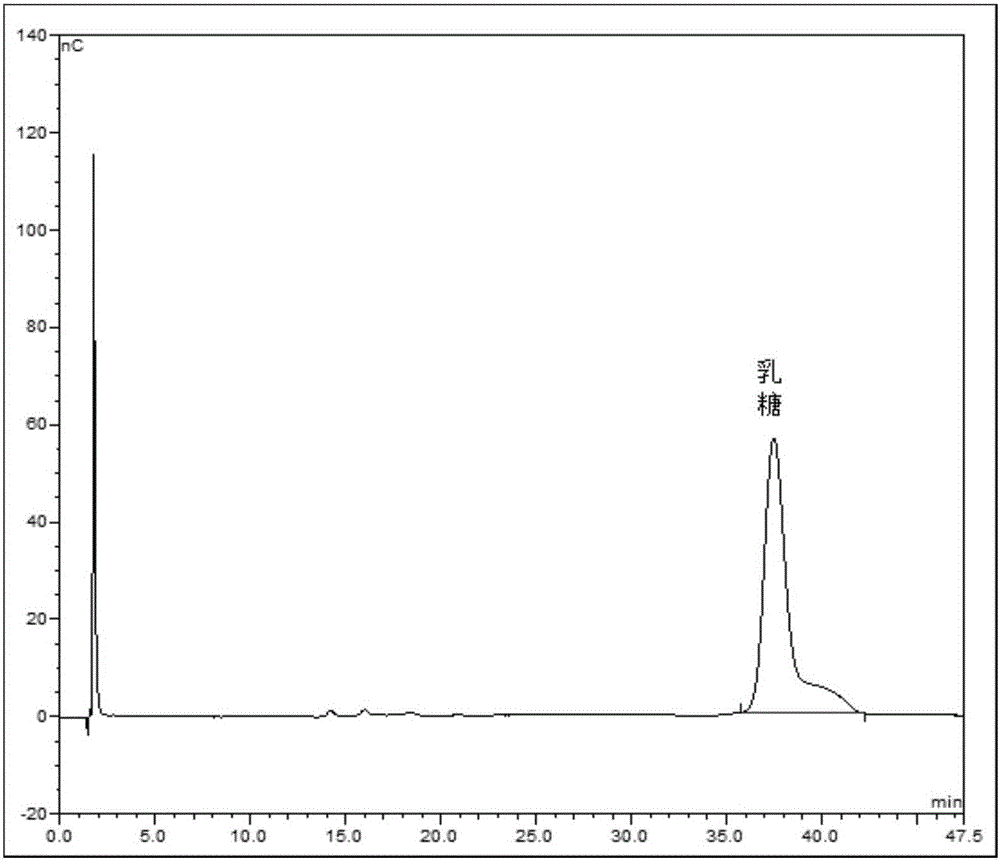

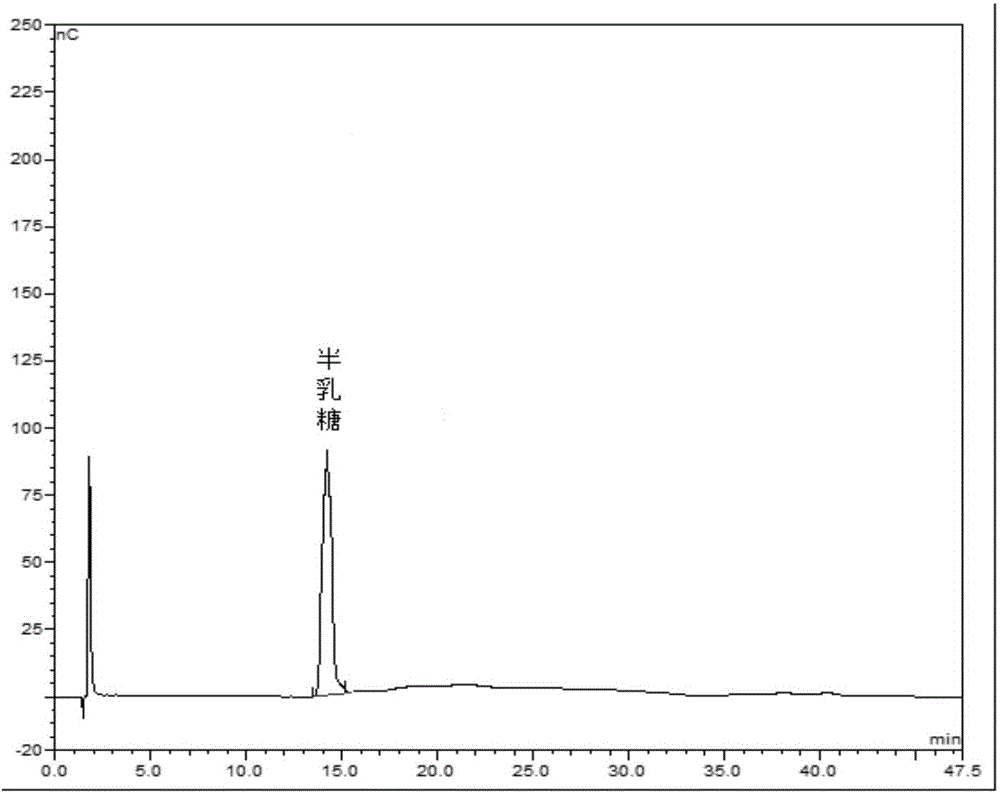

Method for detecting lactulose in milk

ActiveCN105784868AEliminate distractionsSolve the inability to convert lactoseComponent separationGluconic acidCow milk

The invention relates to a method for detecting lactulose in milk.The method comprises the steps that lactose and lactulose in the milk react and are hydrolyzed into galactose, glucose and fructose through beta-D-galactosidase, glucose oxidase is added to oxidize most of the glucose into gluconic acid, finally catalase is added to remove hydrogen peroxide, and a testing solution is obtained; an ion chromatograph with an ampere detector is used for analyzing the testing solution, and the content of the lactulose is obtained.According to the method, the content of the lactulose in the milk can be accurately and sensitively measured by means of easy and convenient operation.

Owner:SHANGHAI BINO TESTING TECH SERVICE CO LTD

Pharmaceutical composition of enterosorbent and prebiotics, dosage forms, and the method for prevention and treatment of gastrointestinal disorders

InactiveCN101460183AEnhanced potencyGood curative effectOrganic active ingredientsDigestive systemAllergic dermatitisIntestinal microorganisms

The pharmaceutical composition is a combination of hydrolytic lignin with moisture of 55% to 65% consisting of the particles measuring 0.15 mm to 0.55 mm, a 45% to 55% aqueous lactulose solution, and a 50% to 55% aqueous oligosaccharide solution at the following ingredient ratio (weight percent): 10-60 of an aqueous lactulose solution; 10-60 of oligosaccharides; sufficient quantity of hydrolytic lignin. Hydrolytic lignin, lactulose and fructose oligosaccharides are sequentially added and mixed using a rotor blender. The composition is administered orally for no less than 14 days and no more than 30 days, two to four times a day, depending on the patient's weight and age. The composition is used as a medicine for treatment of the gastrointestinal disorders, including bacterial, viral, protozoal enteric infections, food poisoning, acute and chronic hepatitis and cirrhosis, diarrhea, peptic ulcer, Crohn's disease, ulcerative colitis, irritable bowel syndrome, mineral disorders with Ca / Mg deficiency, including osteoporosis and other alterations of the bone formation, as an immunomodulator in atopic dermatitis and immunodeficiency conditions, for protection and recovery of intestinal flora after antibiotic therapy, chemotherapy, and radiotherapy. The result is accelerated achievement of the effect and the enhanced action on the state of intestinal microbiocenosis as well as increased effectiveness of treatment of hepatitis and liver cirrhosis, elimination of undesired adverse effects in clinical usage, and extension of indications, i.e. the extended spectrum of usage in prevention and treatment.

Owner:亚历山大·弗拉基米罗维奇·迪科夫斯基

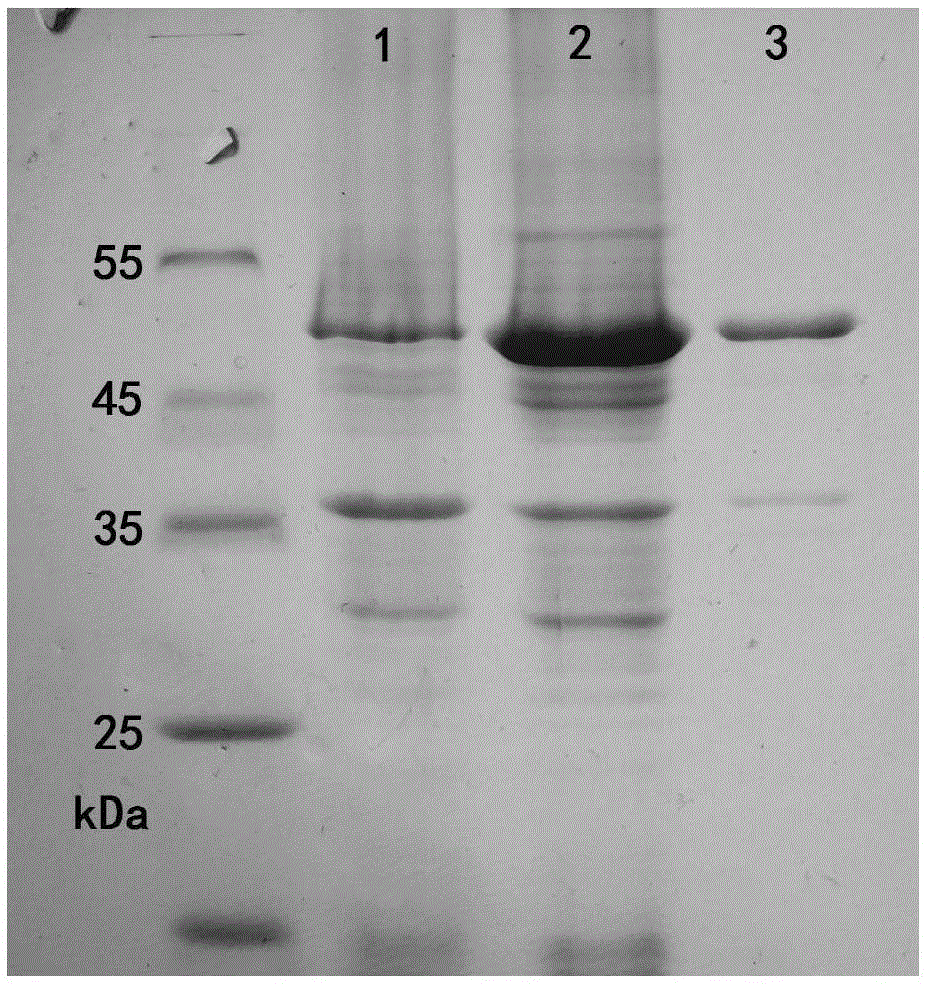

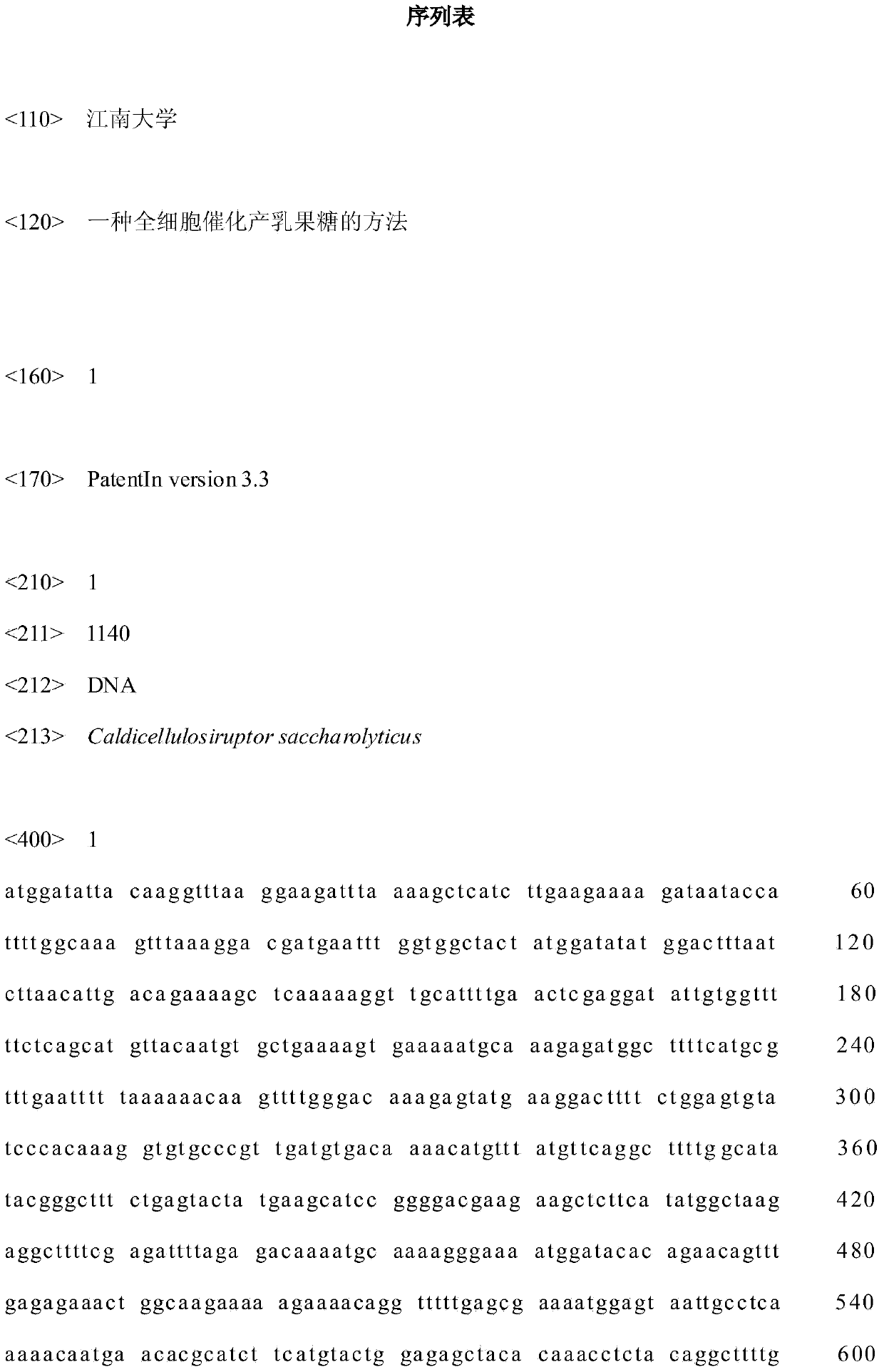

Method for producing lactulose through whole-cell catalysis

InactiveCN104004699AAvoid loss of enzyme activityReduce dosageBacteriaMicroorganism based processesFreeze-dryingThiogalactosides

The invention discloses a method for producing lactulose through whole-cell catalysis, and belongs to the field of the food biotechnology. According to the method, recombinant escherichia coli E. coli BL 21 (DE3) for producing cellobiose epimerase is taken as production bacterial strains, lactose is used for replacing isopropyl-beta-D-sulfo-galactoside (IPTG) and taken as an inductive agent for fermental cultivation, and thalluses obtained through centrifugation are subjected to ethyl alcohol permeabilization and vacuum freeze drying to serve as a cell biocatalyst for directly converting the lactose to produce the lactulose. The maximum percent conversion of the lactulose can reach 65.1%, the concentration of the lactulose reaches 390.6 g / L, the production rate of the lactulose reaches 195.3 g / (L*h), and the production quantity of by-product epidepride lactulose is smaller than 2%(w / w). According to the method, microbial cells are directly used for converting the lactose to produce the lactulose, and the method is simple and easy to implement, avoids the loss of enzyme activity in the separation and purification process, greatly reduces the cost of producing the lactulose through an enzymic method and is beneficial for achieving industrialization of lactulose production through the enzymic method early.

Owner:JIANGNAN UNIV

Anti-inflaming infant formula milk powder and preparation process thereof

The invention relates to an anti-inflaming infant formula milk powder and a preparation process thereof. The anti-inflaming infant formula milk powder comprises the following components in percentage by weight: 22%-50% of lactose, 10%-20% of goat milk whey protein concentrate, 9.8%-20% of structural grease 1,3-dioleoyl 2-palmitoyl triglyceride, 10%-13.5% of non-fat goat milk powder, 8%-10% of vegetable oil, 2%-8% of beta-casein, 0.8%-1.6% of fructooligosaccharides, 0.5%-1.5% of mineral premix, 0.3%-1% of galactooligosaccharide, 0.2%-1% of immunoglobulin G, 0.2%-0.5% of lactulose, 0.10%-0.45% of arachidonic acid, 0.1%-0.6% of docosahexaenoic acid, 0.06%-0.12% of vitamin premix, 0.04%-0.06% of lactoferrin, and 0.01%-0.06% of nucleotide. The invention also includes the preparation process ofthe infant formula milk powder. The nutrition constituents and the functions of the infant formula milk powder are close to those of breast milk, the infant formula milk powder is easy to assimilate,and infants do not get inflamed after eating the milk powder.

Owner:AUSNUTRIA DAIRY CHINA

Arthrobacter for producing beta-fructofuranosidase and application of arthrobacter

ActiveCN106148243AImprove the ability to convert into lactulose oligosaccharidesIncrease vitalityBacteriaMicroorganism based processesBiotechnologyNitroso

The invention relates to arthrobacter for producing beta-fructofuranosidase and application of the arthrobacter. The Arthrobacter sp. BLCY-004 is preserved in the China General Microbiological Culture Collection Center on August 16th, 2016, the address is the Institute of Microbiology, Chinese Academy of Sciences, No. 3, No.1 Yard, Beichen West Road, Chaoyang District, Beijing, and the preservation number is CGMCC No. 12855. The arthrobacter is separated from soil, the high-producing strain of high-producing beta-fructofuranosidase is obtained by means of mutagenic treatment technologies such as ultraviolet mutagenesis, nitrosoguanidine mutagenesis and the like and is named as BLCY-004, the enzyme activity reaches 1100U / ml and is improved by more than 50% as compared with that of conventional beta-fructofuranosidase, the capacity that sucrose is converted into lactosucrose can be highly improved by applying the arthrobacter to production of lactosucrose, and production cost is lowered significantly.

Owner:SHANDONG BAILONG CHUANGYUAN BIO TECH

Oligosaccharide nutrient

InactiveCN107927788ALow calorific valuePromote fermentationFood ingredient functionsEthylenediamineIsomaltooligosaccharide

An oligosaccharide nutrient is prepared from raw materials as follows: glucan syrup, polydextrose, fructooligosaccharide, xylooligosaccharide, galactooligosaccharide, isomaltooligosaccharide, lactulose, vitamin B6, vitamin C, magnesium sulfate, L-calcium lactate and EDTA ferric sodium salt. The absorption and conversion of fat are reduced while the oligosaccharide nutrient is quickly absorbed andutilized by the human body; multiple oligosaccharides are compounded in certain addition quantities, the proliferation effect of the oligosaccharide nutrient on intestinal tract probiotics is guaranteed, so that the proper pH and osmotic pressure are kept in intestinal tracts, and the burden on intestinal tracts due to ultrahigh osmotic pressure is prevented. Besides, the oligosaccharide nutrientcan be used as an external nutrient solution for improving skin as well as a functional drink, and the oligosaccharides are coordinated with vitamins and mineral elements to promote nutrition supply of skin, expand peripheral blood vessels, improve permeability of blood vessels and further improve skin metabolism.

Owner:溧阳市迪贝乐生物科技有限公司

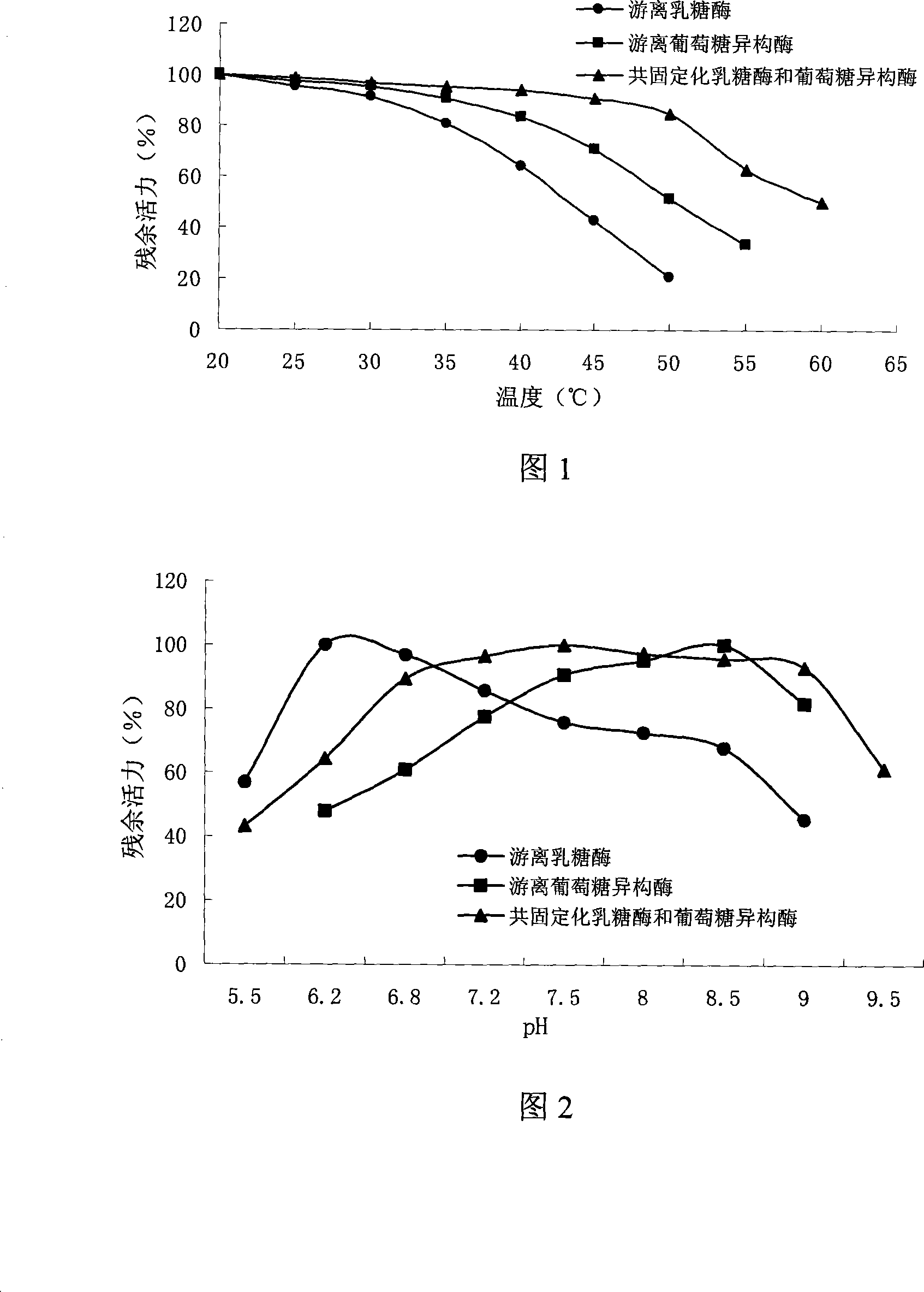

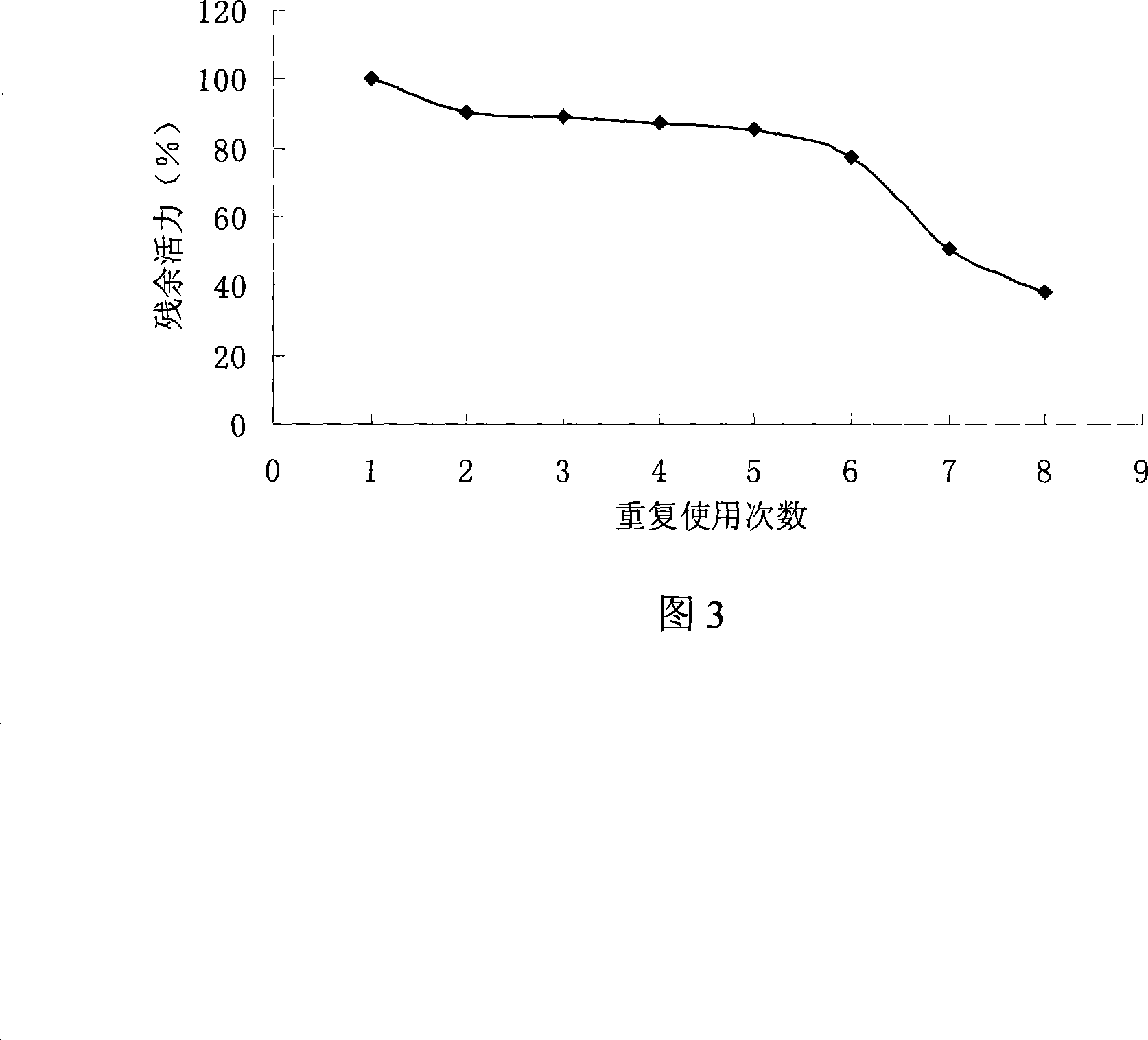

Lactose enzyme and common immobilization method of glucose isomerase

InactiveCN101182508ASimplify downstream separation stepsReduce economic costsOn/in organic carrierLactaseCarrageenan

A co-immobilization method for lactase and glucose isomerase belongs to the food biology technology area. The invention uses gelatine, sodium polymannuronate and / or carrageenan as the carrier; the first embedding and after cross linking process is applied; or the nylon net is used as the carrier; the first cross linking and after covalent combination method is used for the co-immobilization of lactase and glucose isomerase. The distinct characteristics of the invention are that the co-immobilization of lactase and glucose isomerase can not only realize recycle utilization of the enzyme which saves the economic cost and simplifies the downstream separation steps, but also exert the cooperation function between two enzymes which improves the reaction efficiency. The invention has a novel idea, a simple process and a strong practicality. The obtained lactase and glucose isomerase can be used for the transformation of lactose for the preparation of lactulose. The invention has good application prospect.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com