Continuous cyclic preparation method of high-purity lactulose solution and product thereof

A technology for cyclic preparation of lactulose, which is applied in the preparation of sugar derivatives, chemical instruments and methods, disaccharides, etc., can solve the problems of many by-products, complicated separation and purification, and difficulty in industrialized production, so as to improve production efficiency, The effect of overcoming the low yield and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

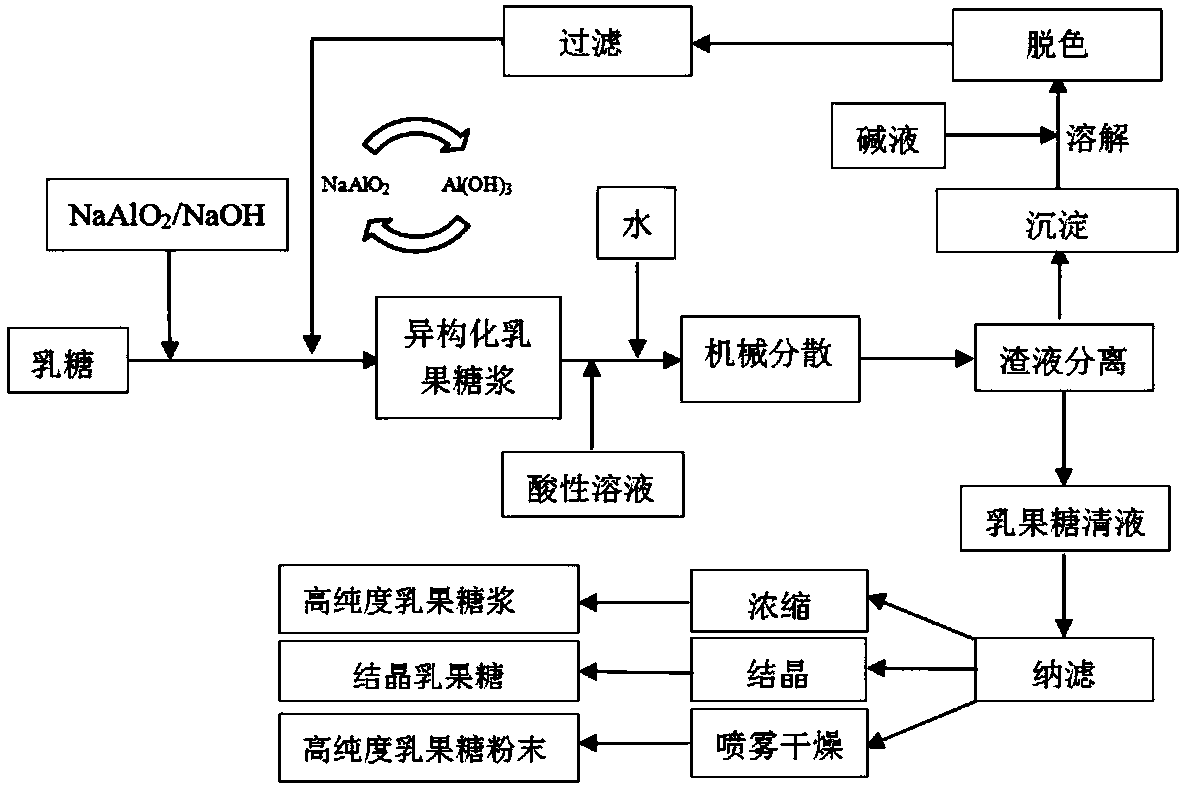

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: Preparation of high-purity lactulose syrup.

[0039] Under the condition of mechanical stirring, add 20kg food-grade lactose and 3kg sodium metaaluminate as the lactose substrate into 100L deionized water and dissolve, then add sodium hydroxide, and adjust the pH value of the system to 11.5, and then The reaction was stirred under low temperature for 2 hours. After the reaction was completed, the system was cooled to room temperature to obtain isomerized lactulose syrup. As determined by HPLC, the conversion rate of lactulose was 66%, and the mass concentration of lactulose was 135g / L.

[0040] Under the condition of mechanical stirring, 6 mol / L hydrochloric acid solution was added dropwise to the above-mentioned isomerized lactulose syrup to adjust the pH value of the system to 6.5 to form a mixed solution containing lactulose and flocculation precipitation system.

[0041]Add 100L of deionized water to the above mixed solution, and mechanically stir the...

Embodiment 2

[0046] Example 2: Preparation of crystalline lactulose.

[0047] Under the condition of mechanical stirring, 35kg of food-grade lactose and 8kg of sodium metaaluminate as the lactose substrate were added to 100L of deionized water and dissolved, then sodium hydroxide was added, and the pH value of the system was adjusted to 12.0, and then heated at 60°C The reaction was stirred under low temperature for 1 h, and after the reaction was completed, the system was cooled to room temperature to obtain isomerized lactulose syrup. As determined by HPLC, the conversion rate of lactulose was 85%, and the mass concentration of lactulose was 298g / L.

[0048] Under the condition of mechanical stirring, 10 mol / L sulfuric acid was added dropwise to the above-mentioned isomerized lactulose syrup, and the pH value of the system was adjusted to 5.0 to form a mixed solution containing lactulose and flocculation precipitation system.

[0049] Add 200L of deionized water to the above mixed solut...

Embodiment 3

[0054] Embodiment 3: Preparation of high-purity lactulose powder.

[0055] Under the condition of mechanical stirring, add 50kg food grade lactose and 24kg sodium metaaluminate as the lactose substrate into 100L deionized water and dissolve, then add sodium hydroxide, and adjust the pH value of the system to 12.5, and then The reaction was stirred under low pressure for 30 minutes. After the reaction was completed, the system was cooled to room temperature to obtain isomerized lactulose syrup. As determined by HPLC, the conversion rate of lactulose was 72%, and the mass concentration of lactulose was 360 g / L.

[0056] Under mechanical stirring conditions, 10 mol / L hydrochloric acid was added dropwise to the above-mentioned isomerized lactulose syrup, and the pH value of the system was adjusted to 4.5 to form a mixed solution containing lactulose and a flocculation precipitation system.

[0057] Add 300L of deionized water to the above mixed solution, and mechanically stir the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com