Patents

Literature

117results about How to "Efficient industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

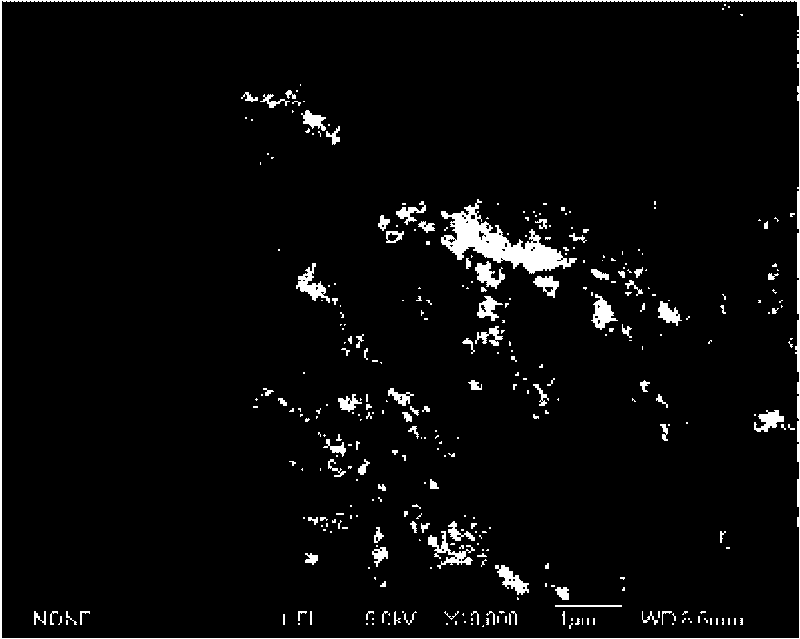

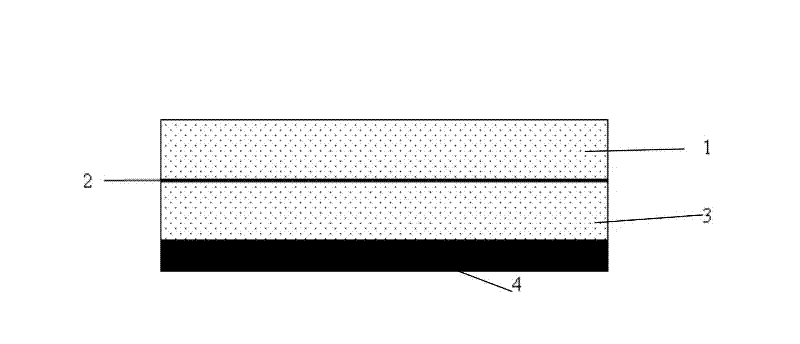

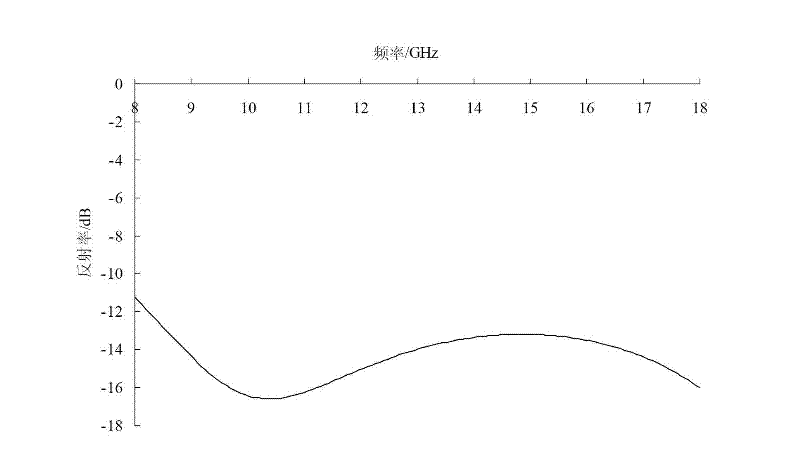

Wave-absorbing ceramic made of silicon carbide composite material and preparation method thereof

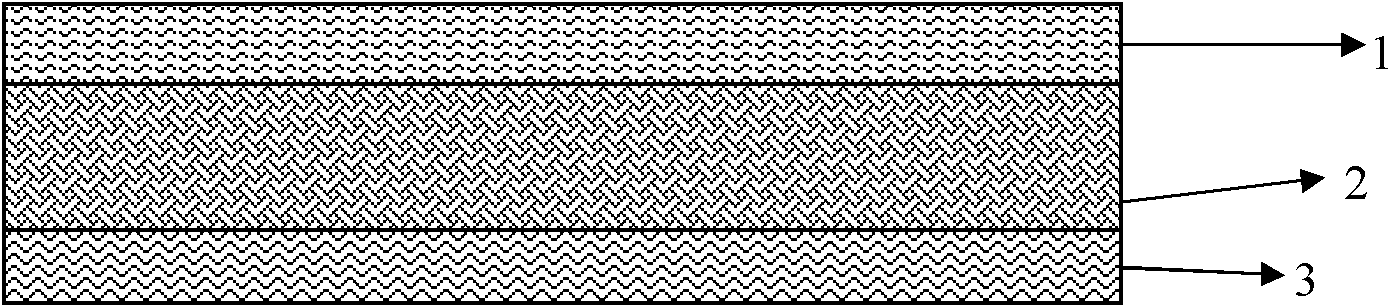

The invention discloses a wave-absorbing ceramic made of a silicon carbide composite material and a preparation method thereof. The wave-absorbing ceramic has a multifunctional superimposed structure comprising a matching layer, a consuming layer and a reflecting layer, wherein each functional layer is made of a continuous silicon carbide fiber reinforced silicon carbide-based composite material;and continuous silicon carbide fibers serving as a reinforced material of each functional layer have different resistivity. The preparation method for the wave-absorbing ceramic comprises the following steps of: selecting continuous silicon carbide fiber plain cloth; dipping and cracking the plain cloth of the consuming layer; mixing with polycarbosilane, divinylbenzene, dimethylbenzene and the like to prepare slurry; performing mould pressing, thermal crosslinking and cracking to prepare a wave-absorbing ceramic rough blank; and preparing the wave-absorbing ceramic made of the silicon carbide composite material by adopting a precursor dipping and cracking process. The wave-absorbing ceramic has wide absorption frequency band, high mechanical property and heatproof function.

Owner:NAT UNIV OF DEFENSE TECH

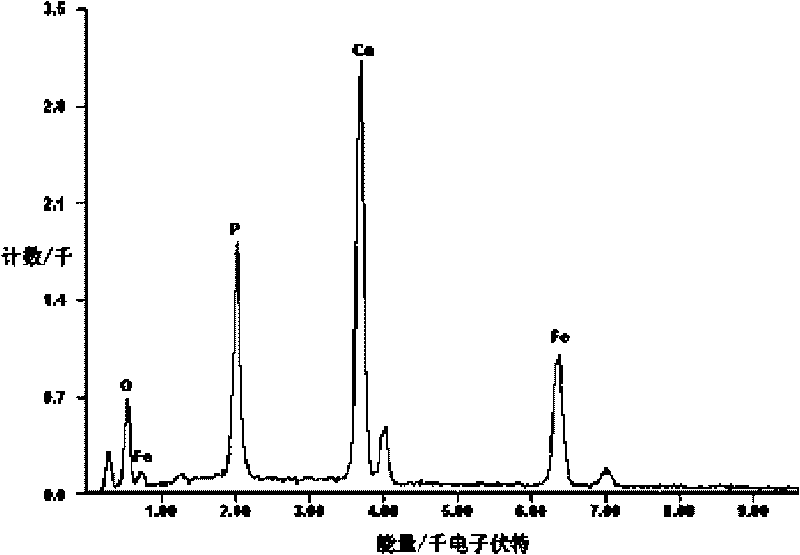

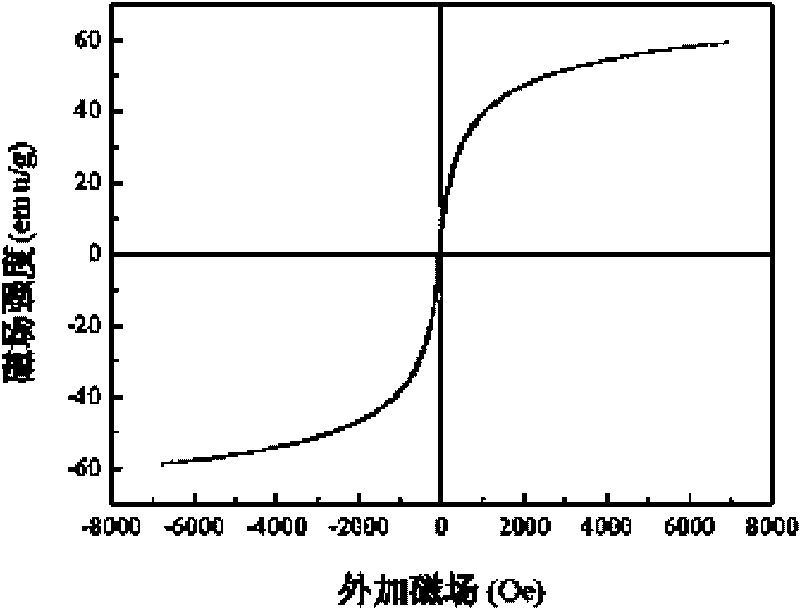

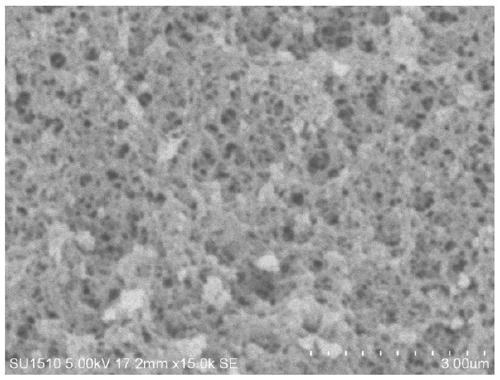

Magnetic nano hydroxyapatite adsorbent, preparation and application thereof

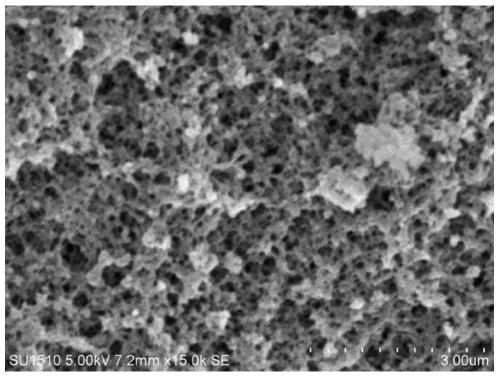

InactiveCN101703917AImprove adsorption efficiencyEasy to makeOther chemical processesWater contaminantsApatiteSorbent

The invention discloses a magnetic nano hydroxyapatite adsorbent, preparation and application thereof. Nano hydroxyapatite Ca10(PO4)6(OH)2 is used as a matrix of the adsorbent, and magnetic powder Fe3O3 is uniformly dispersed in the matrix, wherein the mass ratio of the nano hydroxyapatite to the magnetic powder Fe3O3 is (1.5-1):1. The preparation method comprises the following steps of: dissolving FeCl2 and FeCl3 with a mass ratio of (0.75-0.85):1 in deoxidized water; then adding an ammonia solution and uniformly stirring; simultaneously adding a Ca(NO3)2 solution and a (NH4)2HPO4 solution and uniformly stirring to obtain liliquoid; heating the liliquoid at the temperature of 90-100 DEG C; and then obtaining the magnetic nano hydroxyapatite adsorbent through cooling, separating, washing, drying and grinding. The magnetic nano hydroxyapatite adsorbent has large specific surface area, high adsorption efficiency, low cost and easy separation and can effectively remove heavy metal ions in waste water.

Owner:HUNAN UNIV

Building inner and outer wall decorating plate and manufacturing method thereof

ActiveCN102425284ASolve Adhesion ProblemsSolve the problems of transfer printing technologyCovering/liningsPretreated surfacesCalcium silicateCross-link

The invention discloses a method for building inner and outer wall decorating plate, which comprises two flows, each flow including steps of: a primer line processing flow: (1) thickness sanding and dedusting, (2) roller painting back seal coat and curing into a first UV seal coat layer, (3) roller painting UV penetrant twice, (4) leveling by infrared ray, (5) coating UV putty at the front and UV curing and generating a UV putty layer, (6) roller painting the UV seal coat for three times and respectively curing and generating three second UV seal coat layers, (7) fine sanding; and a roller painting finish line flow: (1) dedusting, (2) roller painting UV glue and generating a first UV glue layer, (3) coating the UV finish for five times and curing and generating five UV finish layers. The decorating plate can solve the problems that a UV curing penetrating agent is strongly, quickly and deeply penetrated into a fiber reinforced calcium silicate slab or a fiber cement slab, deeply cured to form a film and subjected to stereo chemical netlike cross-linking reaction with UV putty and UV sealing paint, and thoroughly solves the problem of adhesive force between the decorative surface layer and a substrate.

Owner:山东鲁泰装配式装修材料有限公司

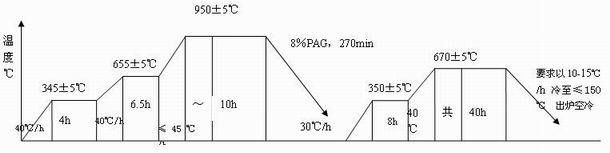

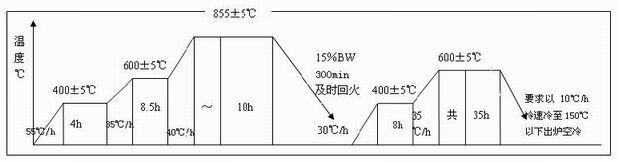

Environment-friendly heat treatment process for large shaft forgings

InactiveCN102115809AUniformly hardenedReduce cleaning costsFurnace typesHeat treatment process controlWater solubleLaser cooling

The invention discloses an environment-friendly heat treatment process for large shaft forgings. According to the heat treatment process, the traditional oil and tap water are substituted by a commercial water soluble quenching medium PAG (poly alkylene glycol) or BW, the concentration of the quenching medium PAG or BW is adjusted, and the process parameters such as the heating speed, holding time, quenching temperature, quenching time, tempering temperature, cooling speed and the like are strictly controlled, thereby solving the problems of deformation and even defects liable to occur by water cooling of large shaft parts and lower rigidity, environmental pollution and the like liable to occur by oil cooling of large shaft parts, and simultaneously solving the problems of heavy weight, great change of sectional dimension, uneven performance after heat treatment and the like of large shaft parts.

Owner:HENAN UNIV OF SCI & TECH

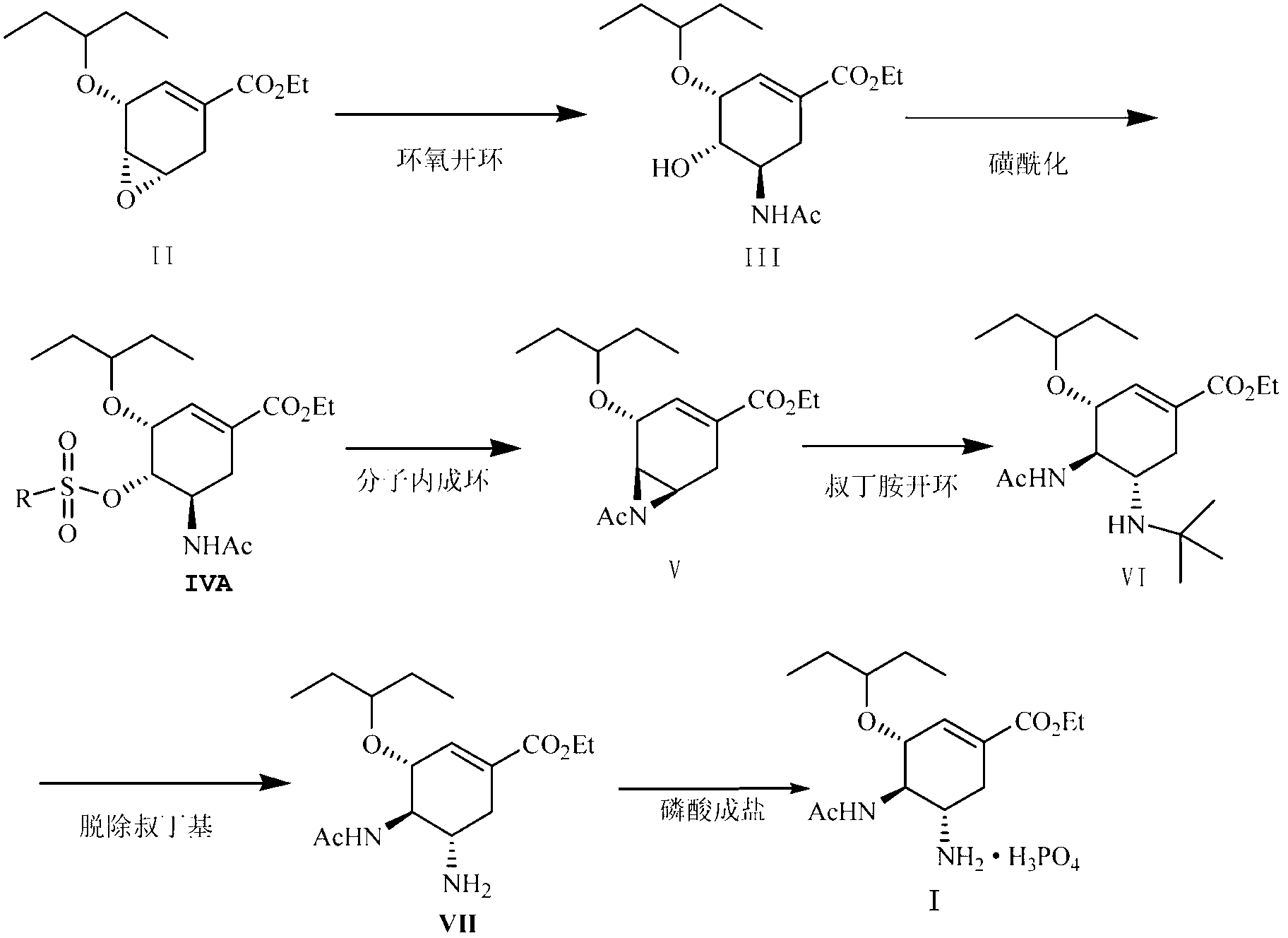

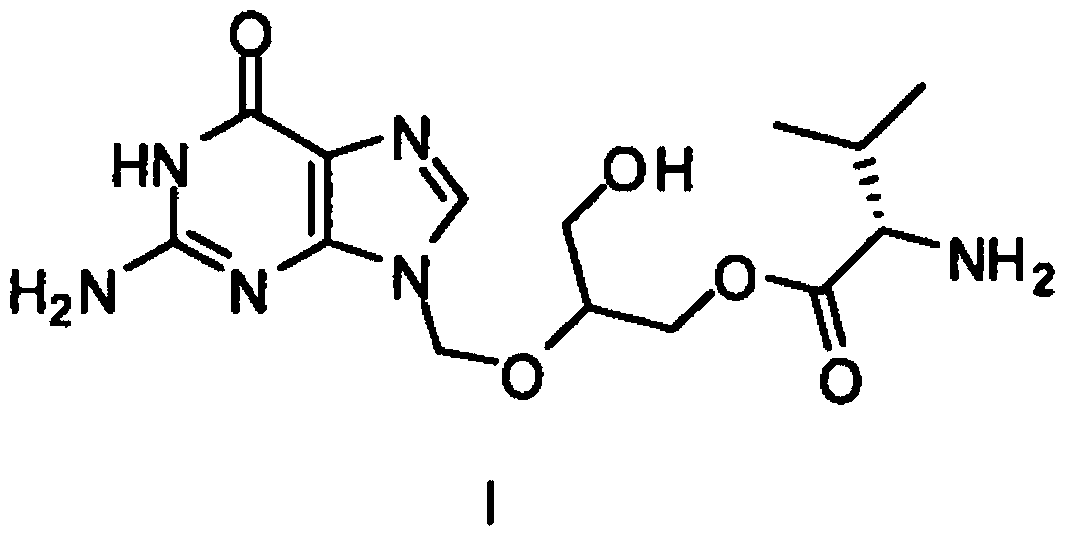

Method for synthesizing oseltamivir phosphate without using nitrine

ActiveCN103304437AIndustrial Production SafetyEfficient industrial productionOrganic compound preparationCarboxylic acid amides preparationEpoxyO-Phosphoric Acid

The invention discloses a method for synthesizing oseltamivir phosphate without using nitrine. The method comprises the following steps of: sequentially performing an epoxy ring-opening reaction, a hydroxyl acylation reaction, an intramolecular substitution reaction for ring formation, a selective ring-opening reaction, a reaction for removing tertiary-butyl and a phosphoric acid salt forming reaction on a raw material namely (3R, 4R, 5S)-4,5-epoxy-3-(1-ethyl-propoxy)-1-cyclohexene-1-ethyl ester carboxylate to obtain a product namely oseltamivir phosphate. The method is safe and high in efficiency and yield; compared with the prior art, the method has the biggest advantage that toxic explosive chemicals such as sodium azide and trimethyl-phosphine are not used, and is rich in raw material source and capable of performing large-scale production, so that the method can better meet requirements for strategic reserve of medicaments for preventing and treating bird flus by all human beings.

Owner:GUANGZHOU TROJAN PHARMATEC LTD

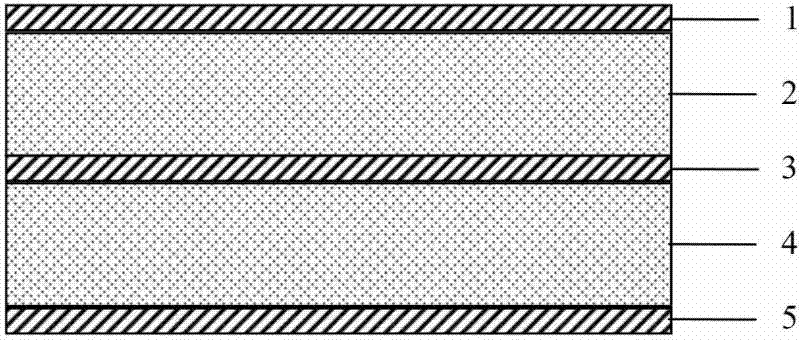

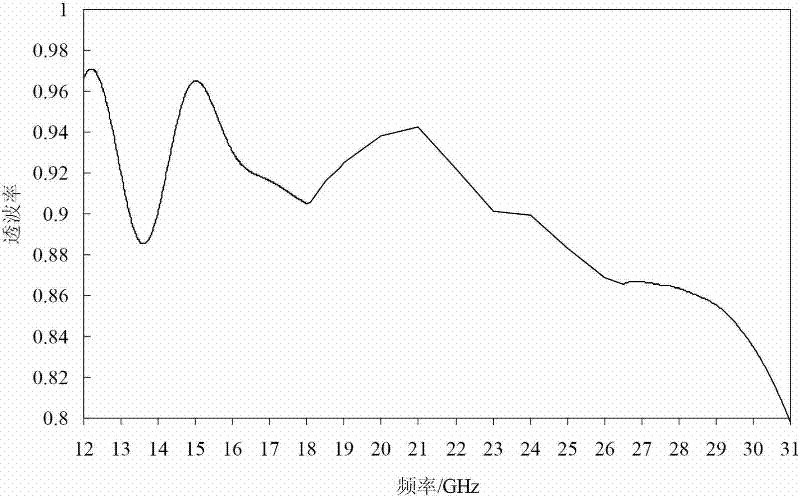

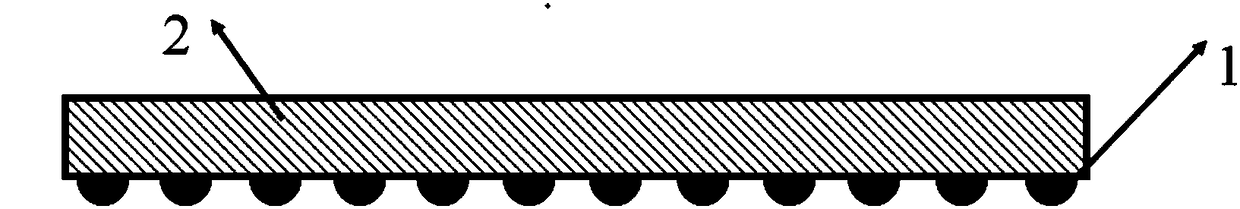

Wave-transmitting material with broadband resin matrix interlayer structure and preparation method of wave-transmitting material

ActiveCN102303441AImprove toughnessHigh strengthSynthetic resin layered productsPolymer scienceResin matrix

The invention discloses a wave-transmitting material with a broadband resin matrix interlayer structure and a preparation method of the wave-transmitting material. The wave-transmitting material comprises an outer skin layer, a first foam sandwich layer, a middle skin layer, a second foam sandwich layer and an inner skin layer which are sequentially overlapped and tightly combined, wherein the outer skin layer, the middle skin layer and the inner skin layer are made of continuous quartz fibre reinforced resin-base composite materials; the first foam sandwich layer and the second foam sandwich layer are made of polyurethane foams, the outer skin layer, the middle skin layer and the inner skin layer have dielectric constants of 3.1-3.2 and loss angle tangent values of 0.009-0.01; and the first foam sandwich layer and the second foam sandwich layer have dielectric constants of 1.10-1.15 and loss angle tangent values of 0.005-0.006. The preparation method comprises the steps of: preparing reinforced materials, and laying the reinforced materials according to the layering order and the thickness of each layer, pre-forming and curing to obtain the wave-transmitting material. The wave-transmitting material has the advantages of simple structure and high cost performance.

Owner:NAT UNIV OF DEFENSE TECH

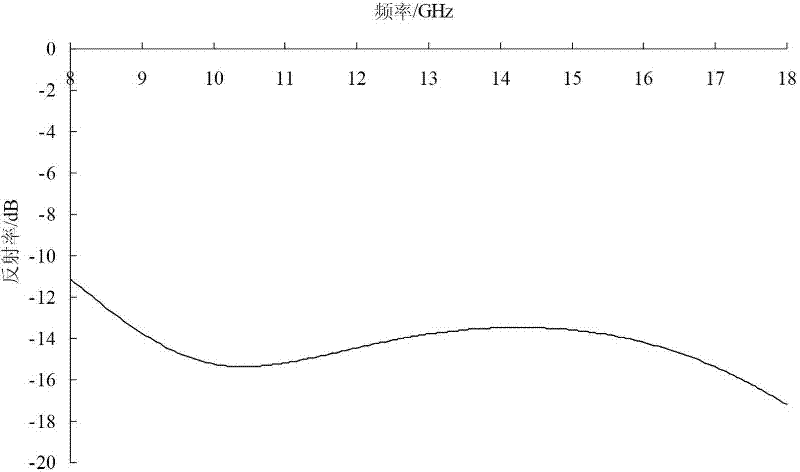

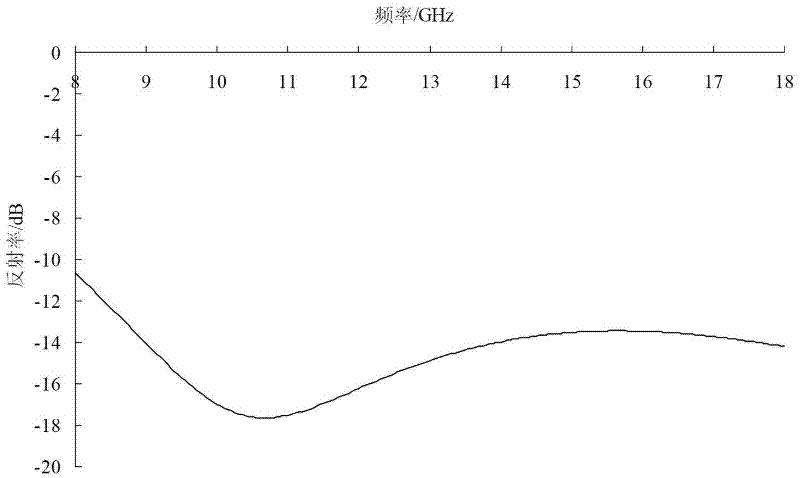

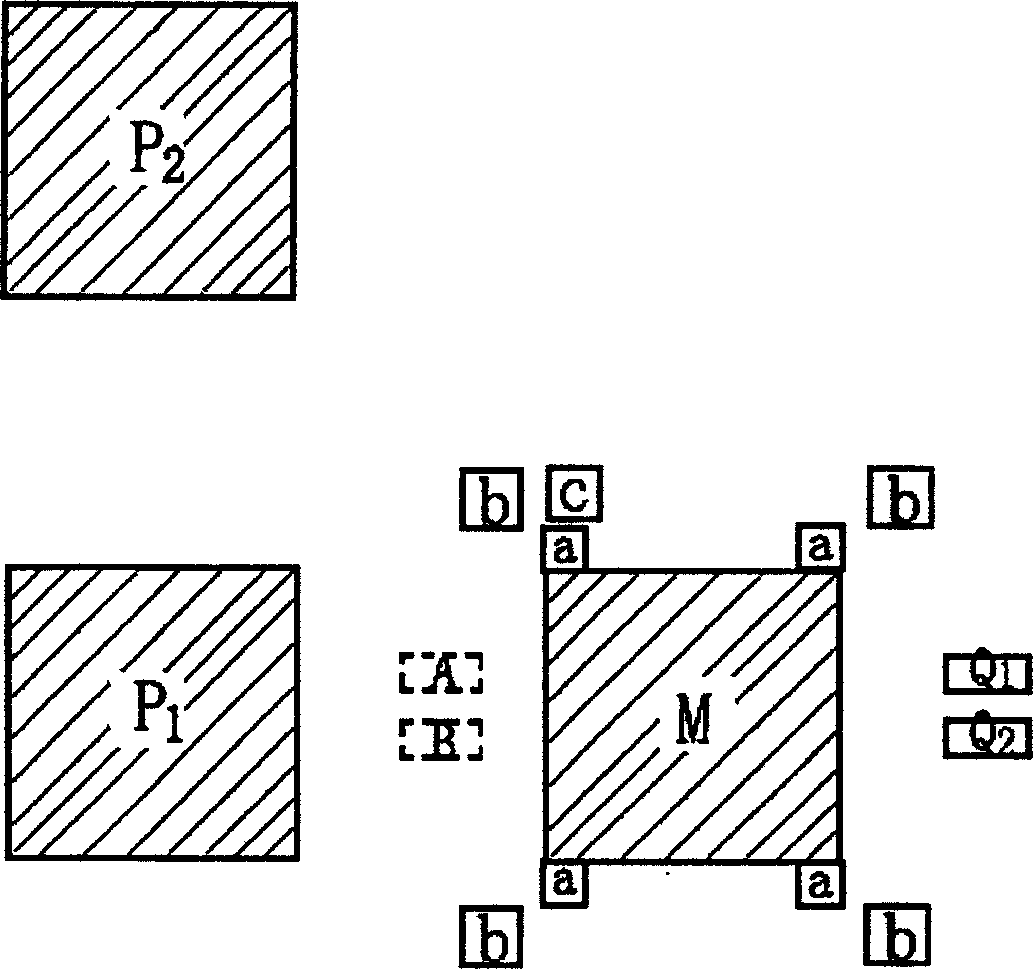

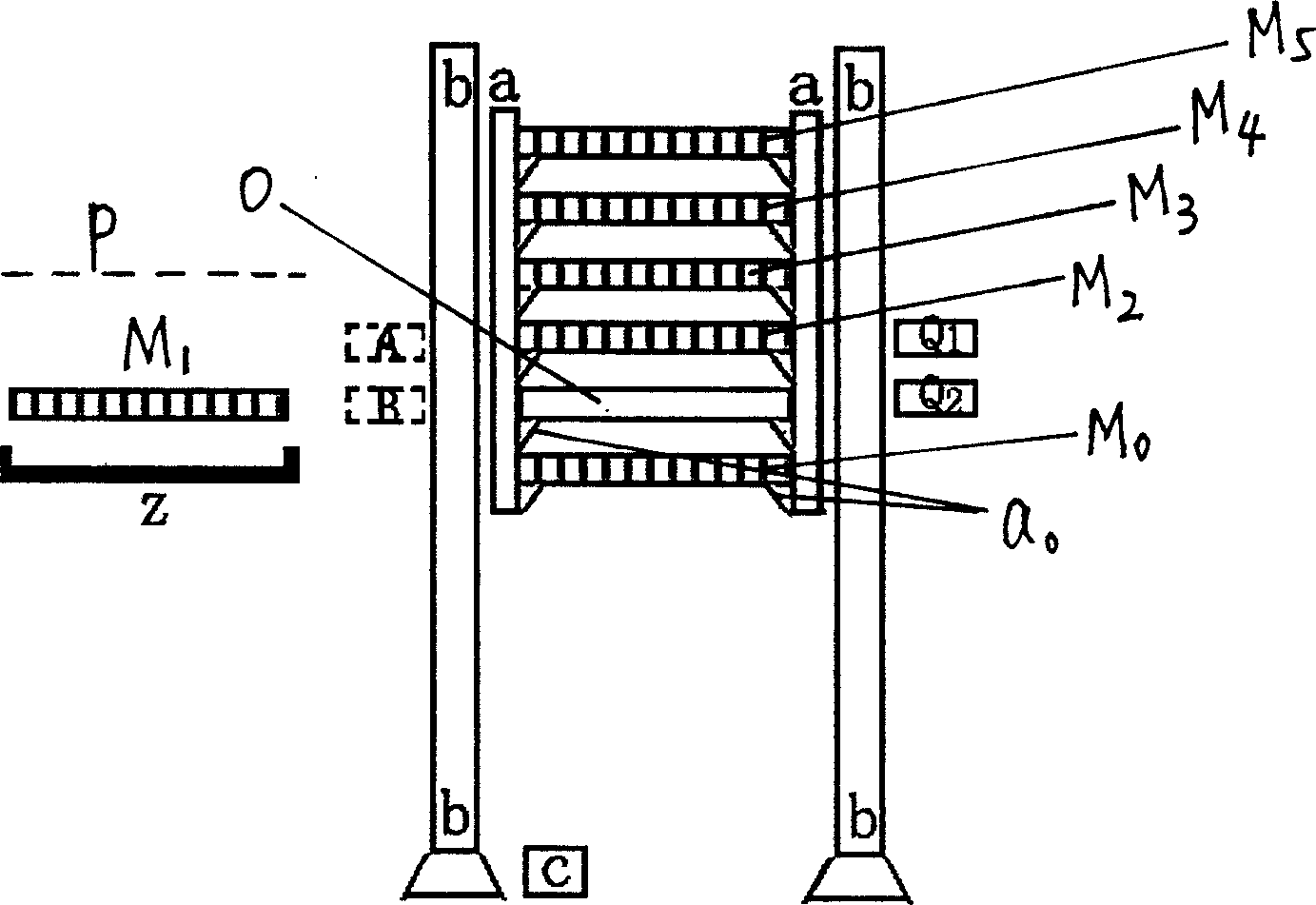

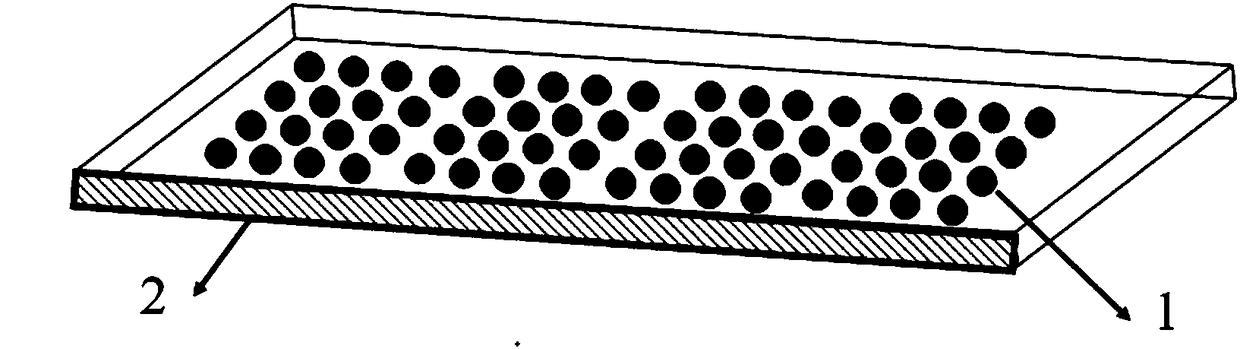

Wave-absorbing material for assorted fibre reinforced resin base sandwich structure and preparation method thereof

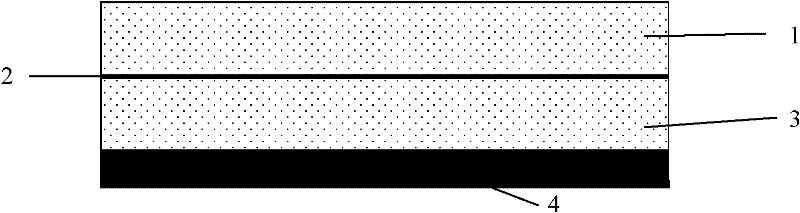

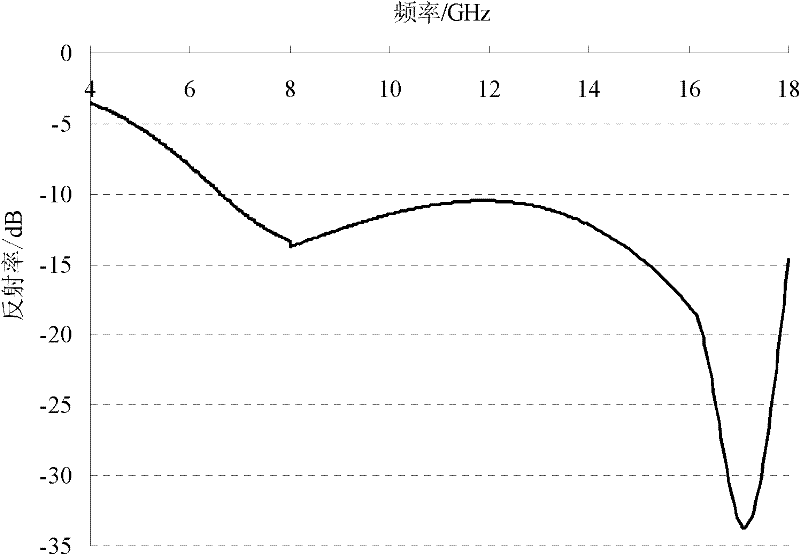

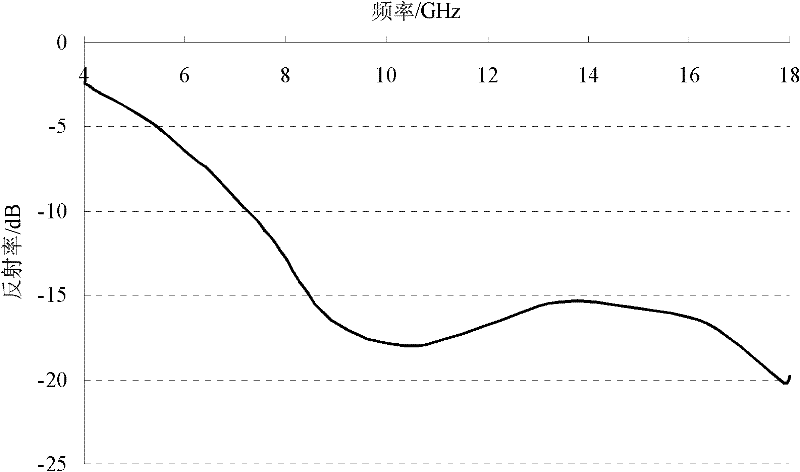

ActiveCN102218867AImprove toughnessHigh strengthSynthetic resin layered productsCarbon fibersResin-Based Composite

The invention discloses a wave-absorbing material for an assorted fibre reinforced resin base sandwich structure and a preparation method thereof. The wave-absorbing material has a multi-functional layer laminated structure. The structure comprises a first medium layer, an absorbing layer, a second medium layer and a reflection layer in sequence from the outside to the inside; the first medium layer consists of a basalt fibre reinforced resin base composite material; the absorbing layer consists of a continuous silicon carbide fibre reinforced resin base composite material; the second medium layer consists of a basalt fibre reinforced resin base composite material; and the reflection layer consists of a carbon fibre reinforced resin base composite material. The preparation method for the wave-absorbing material comprises the steps as follows: various fibres satisfying each functional layer are selected firstly; and then the resin is used as a basal body and the wave-absorbing materialis manufactured by adopting a resin base composite material forming technique according to the laminated sequence and thickness of each functional layer. The wave-absorbing material has the advantages of simple structure, good parameter tolerance level, easy forming, excellent wave-absorbing functions, low material cost, etc.

Owner:NAT UNIV OF DEFENSE TECH

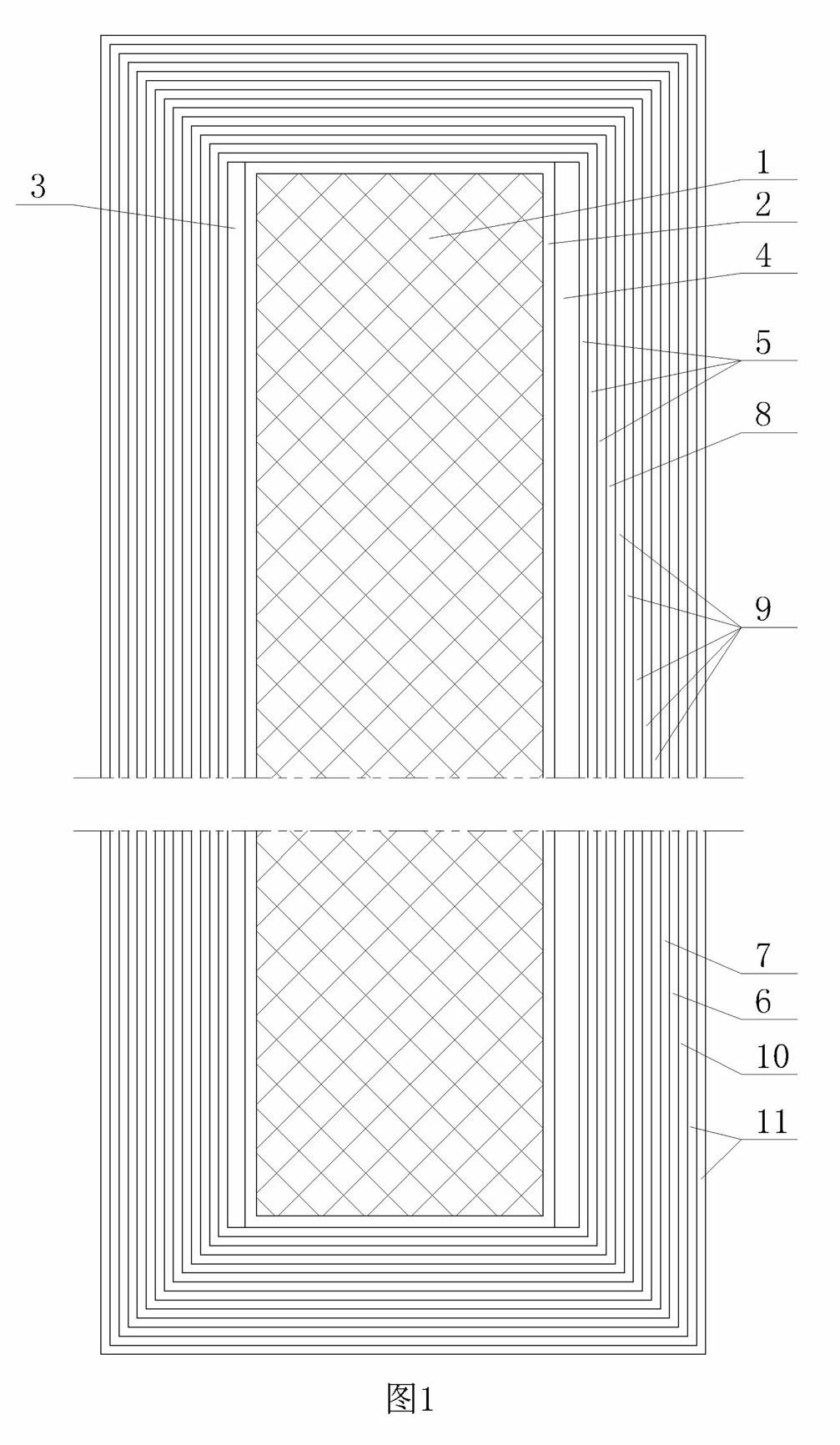

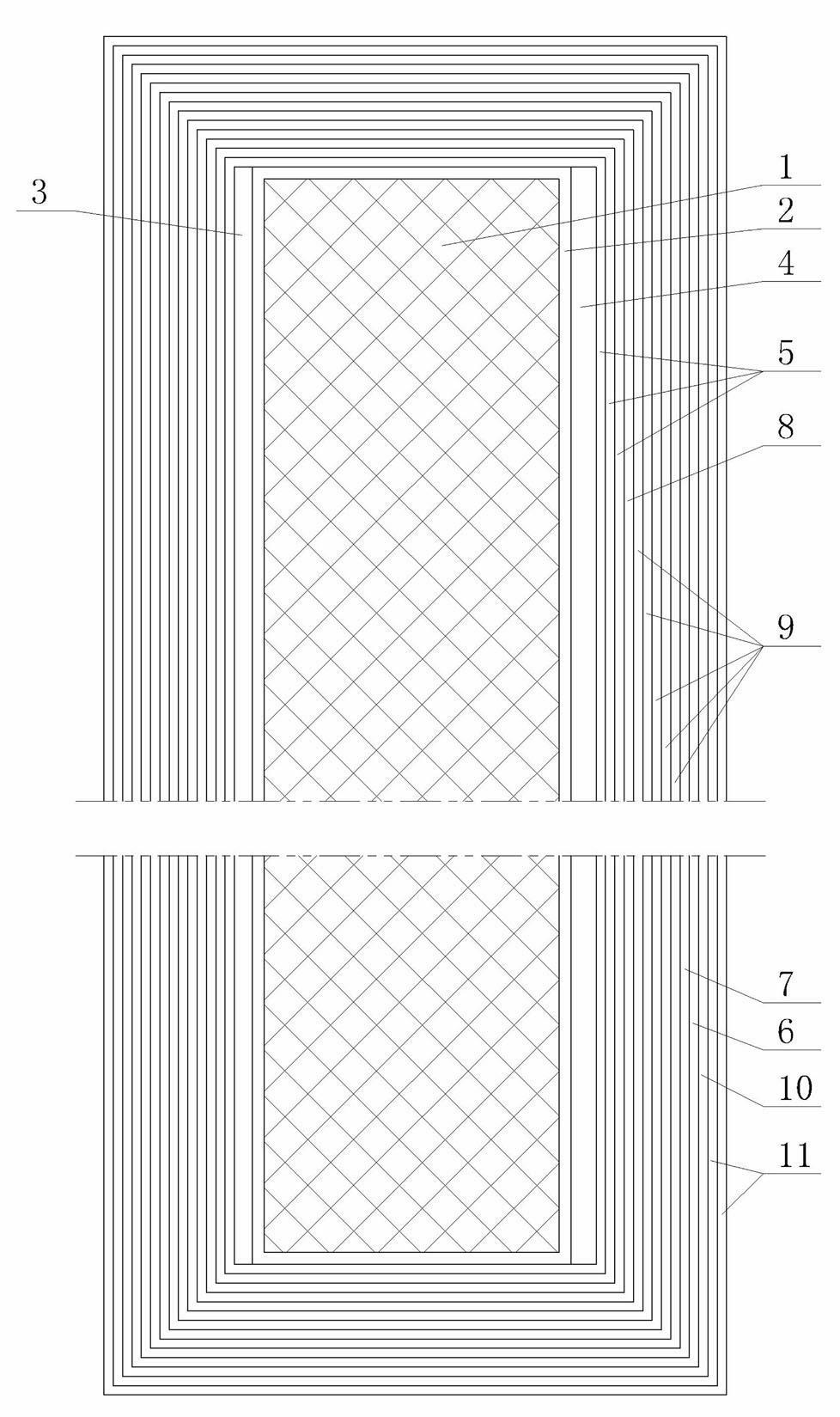

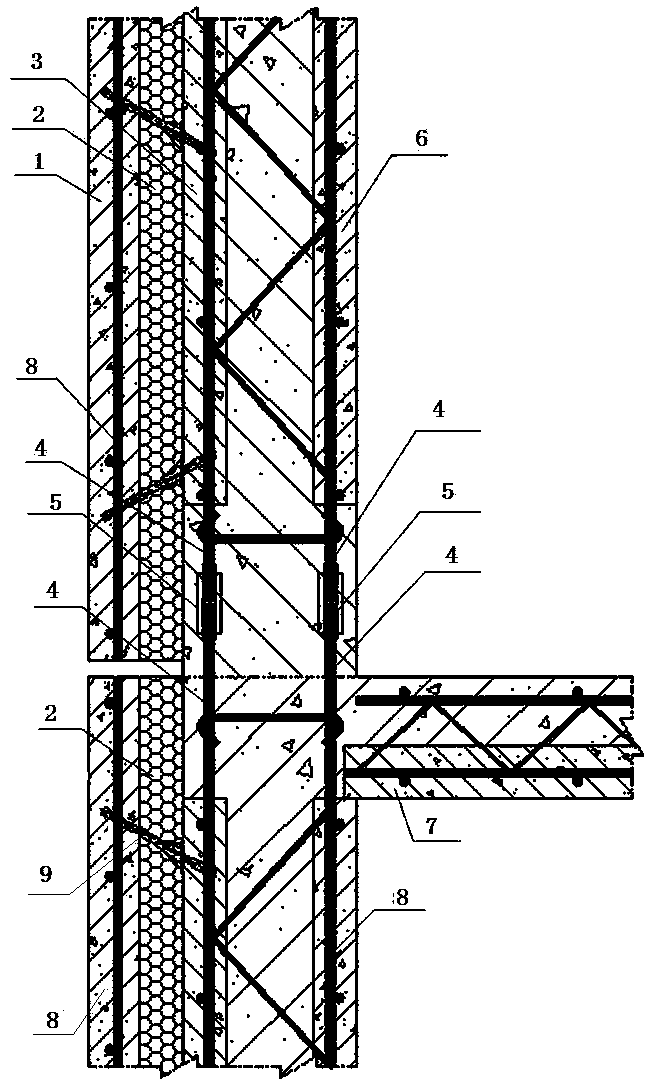

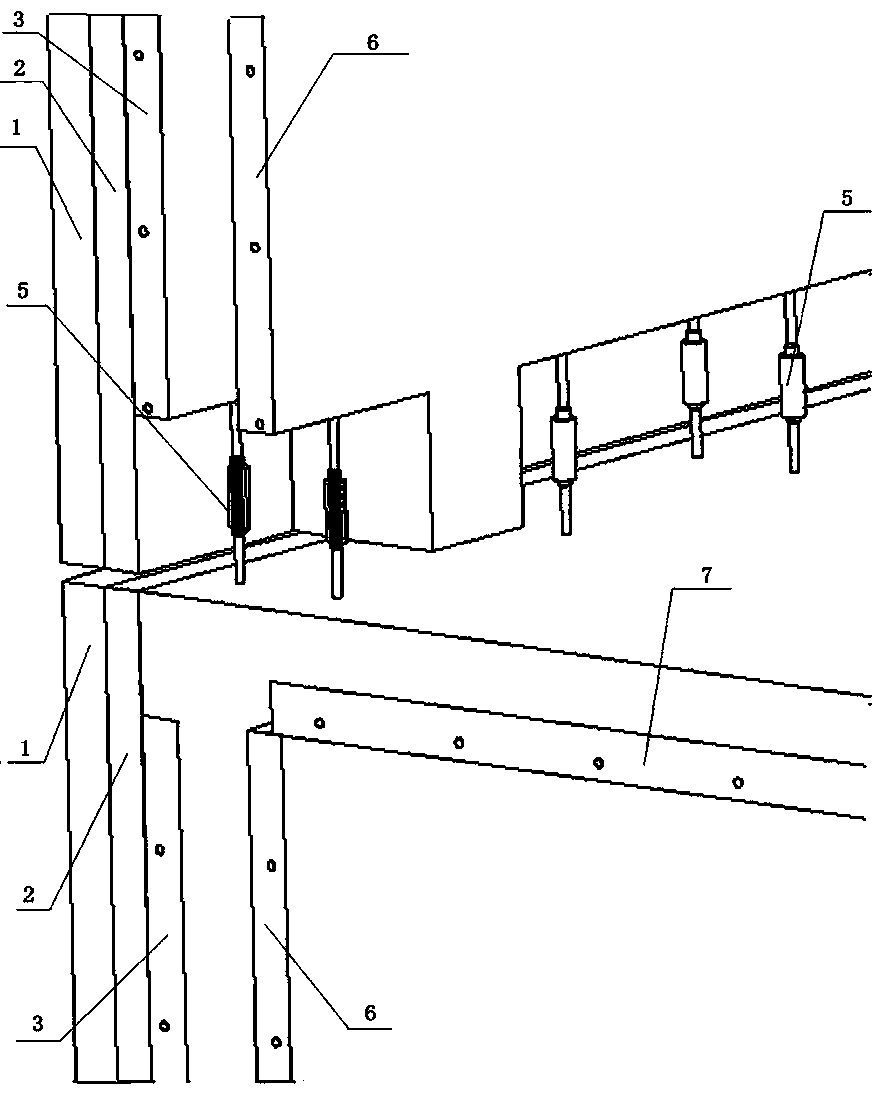

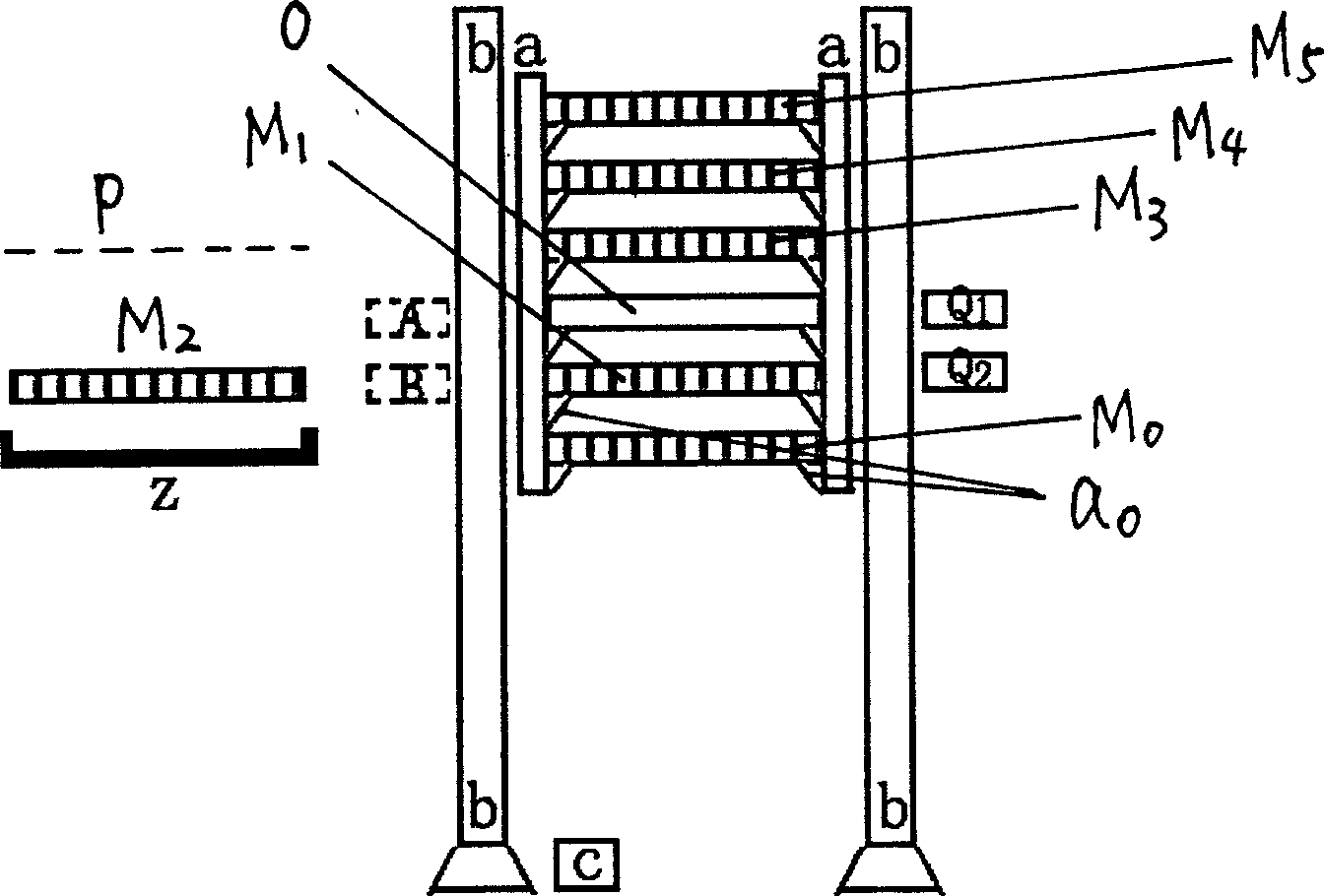

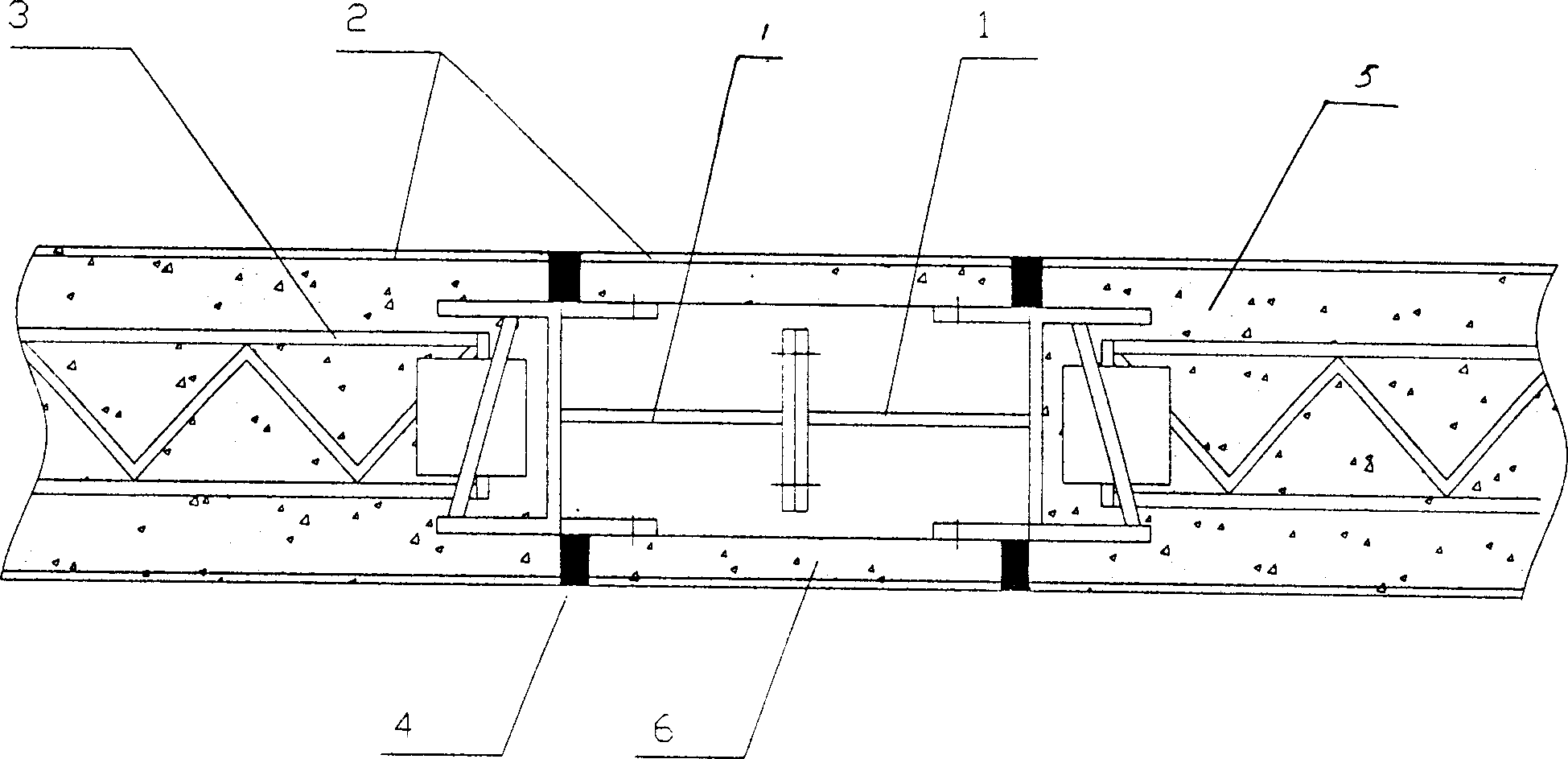

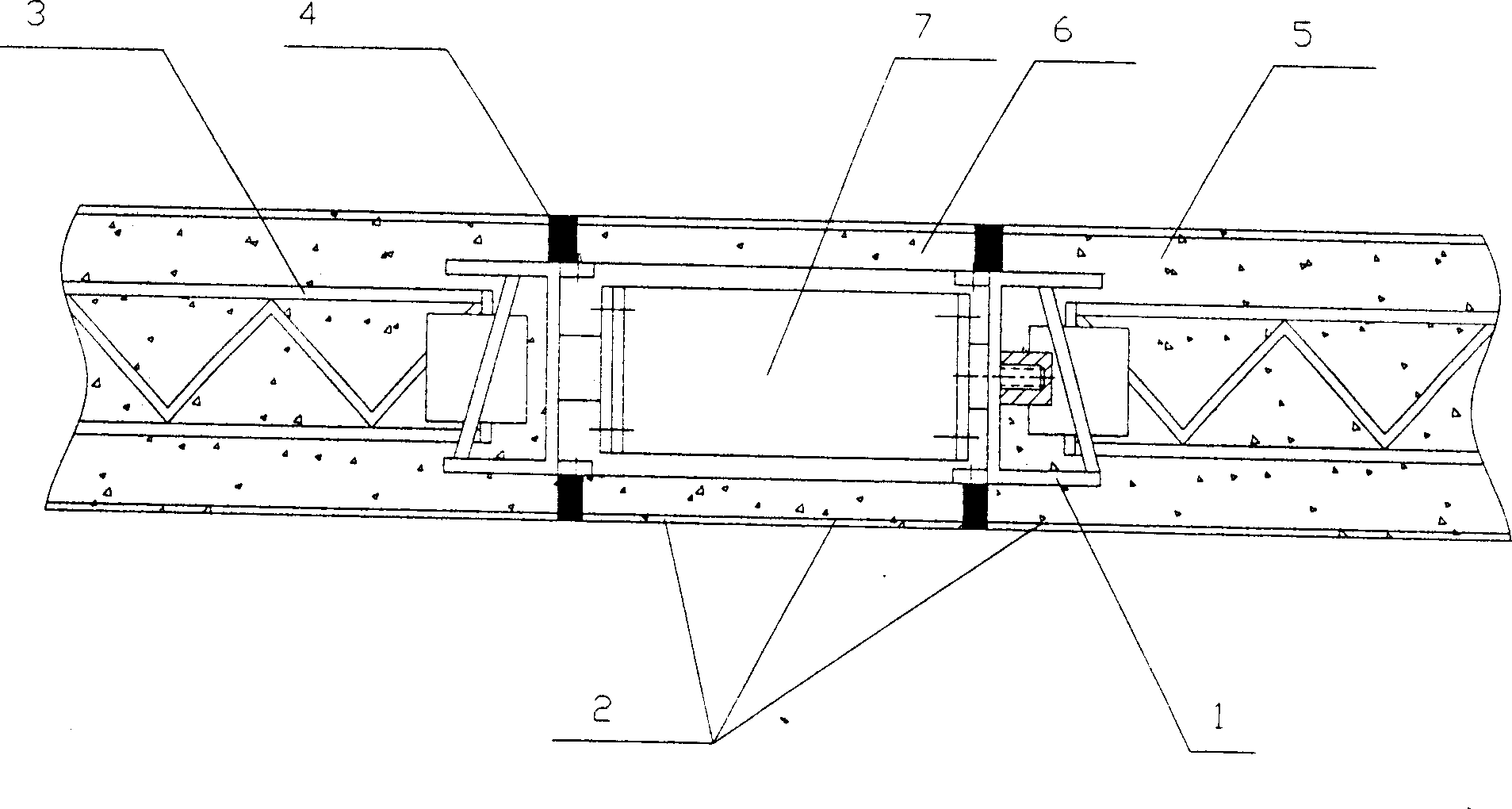

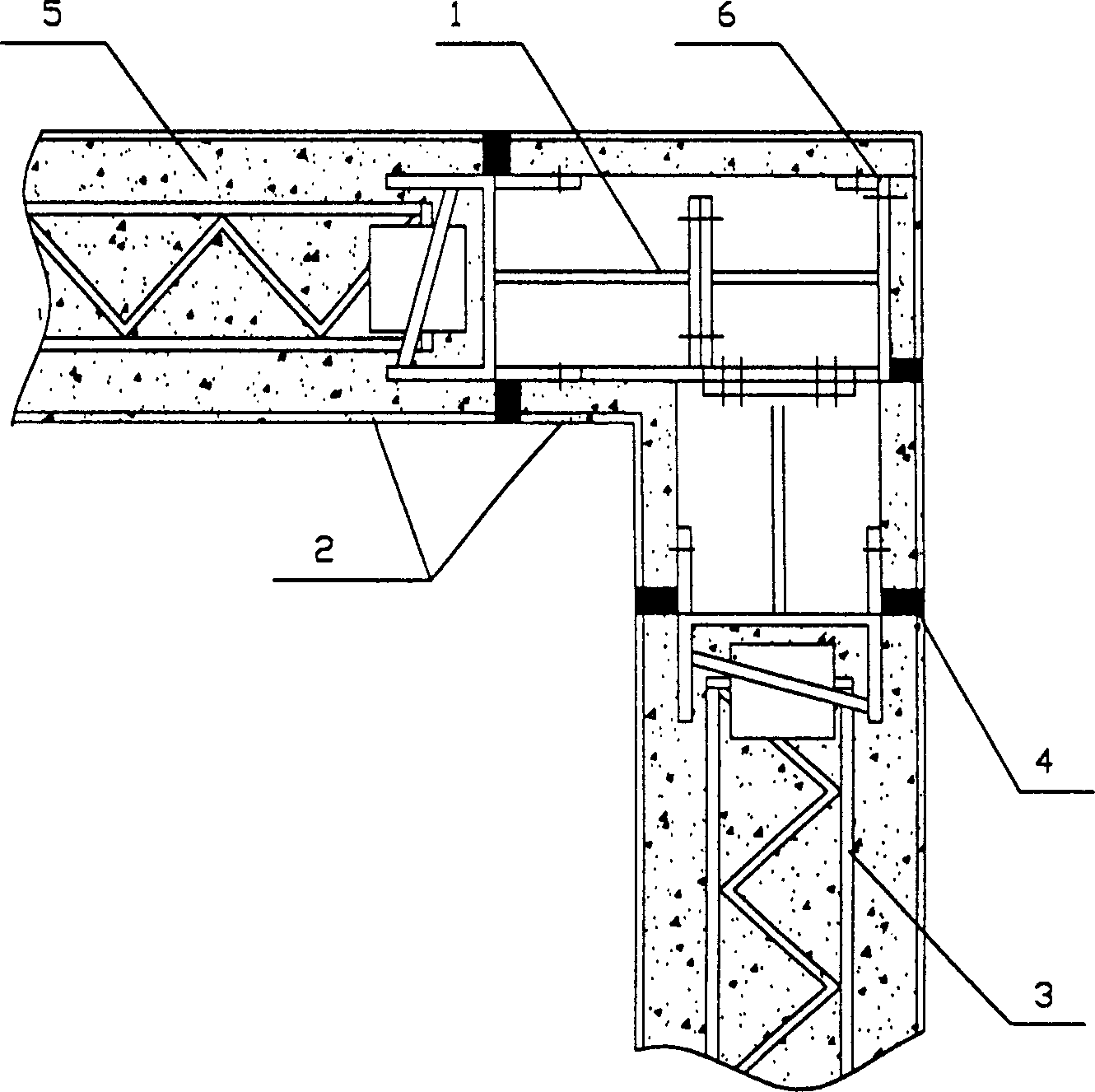

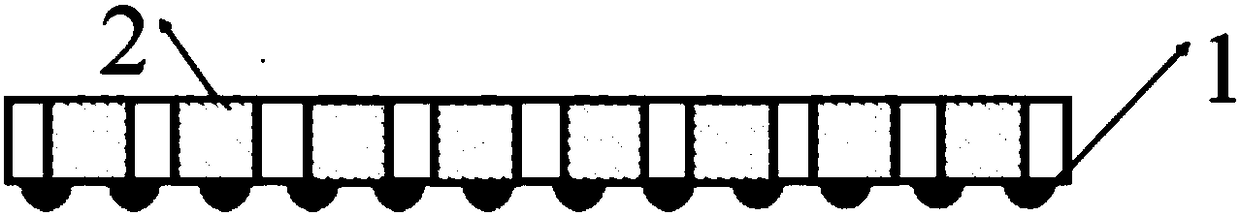

Cast-in-place shear wall structure equivalent to prefabricated sandwiched superposed shear wall continuous steel bar

The invention provides a cast-in-place shear wall structure equivalent to a prefabricated sandwiched superposed shear wall continuous steel bar, the cast-in-place shear wall structure is formed by connecting a prefabricated superposed shear wall outer acanthus, an insulating layer, a prefabricated superposed shear wall intermediate plate, a lattice steel bar and a prefabricated superposed shear wall inner acanthus, the upper ends and the lower ends of the prefabricated superposed shear wall intermediate plate and the prefabricated superposed shear wall inner acanthus are all shorter than the prefabricated superposed shear wall outer acanthus and the insulating layer, and the steel bar extends out; in construction and installation, the downward extended steel bars of the upper layer prefabricated superposed shear wall intermediate plate and inner acanthus are respectively fixedly connected with the upward extended steel bars of the lower layer prefabricated superposed shear wall intermediate plate and inner acanthus, and concrete is cast between the intermediate plate and the inner acanthus to form a structure system containing the insulating layer and equivalent to the cast-in-place shear wall. The cast-in-place shear wall structure provided by the invention is insulating and energy-saving, strong in seismic capacity, structure strength and anti-shear capacity, the technical problem that the sandwiched superposed shear wall cannot be applied to the high-rise building is broke through, and the industrial production is realized.

Owner:CHANGSHA BROAD HOMES IND GRP CO LED

Hybrid fiber reinforced resin matrix sandwich structural absorbing material and its preparation method

ActiveCN102229267AImprove toughnessHigh strengthSynthetic resin layered productsGlass/slag layered productsGlass fiberCarbide silicon

The invention discloses a hybrid fiber reinforced resin matrix sandwich structural absorbing material and its preparation method. The absorbing material has a multifunctional laminated structure from the outside to the inside comprising a first dielectric layer, an absorbed layer, a second dielectric layer and a reflecting layer, wherein the first dielectric layer and the second dielectric layer are both composed of a glass fiber reinforced resin matrix composite material; the absorbed layer is composed of a continuous silicon carbide fiber reinforced resin matrix composite material; and the reflecting layer is composed of a carbon fiber reinforced resin matrix composite material. The preparation method of the absorbing material comprises the following steps of: firstly, each kind of fiber that satisfies each functional layer is selected; secondly, with the resin as the matrix, according to the laminated order and thickness of each functional layer, the absorbing material provided by the invention is prepared by the resin matrix composite material molding technology. The absorbing material provided by the invention has advantages of simple structure, good parameter tolerance, excellent wave absorbing function and low material cost, and furthermore is easy to mold.

Owner:NAT UNIV OF DEFENSE TECH

Chloroethylene preparation method by catalytic cracking by barium chloride catalyst

InactiveCN102766018ALow operating costStable lifePreparation by hydrogen halide split-offPhysical/chemical process catalystsActivated carbonDichloroethane

Owner:EAST CHINA UNIV OF SCI & TECH

Magnesium-containing ft synthetic catalyst and preparation method thereof

InactiveCN101417231AHigh reactivityHigh selectivityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsAlkaneHigh selectivity

The invention relates to an Mg-contained Fischer-Tropsch synthesis catalyst and a preparation method thereof. According to the weight ratio, the catalyst comprises 100 of Fe, 0.5-20 of Mg, 0.5-4.9 of Cu, 0.3-15 of K and 5-50 of SiO2. The catalyst has good reaction activity and further improves the reaction selectivity, wherein, the selectivity of firedamp is less than 3 percent, the selectivity of the CO2 is less than 35 percent; furthermore, the catalyst has high selectivity for multi-carbon straight chain alkane and simple preparation process, and is suitable for industrial production in large scale.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

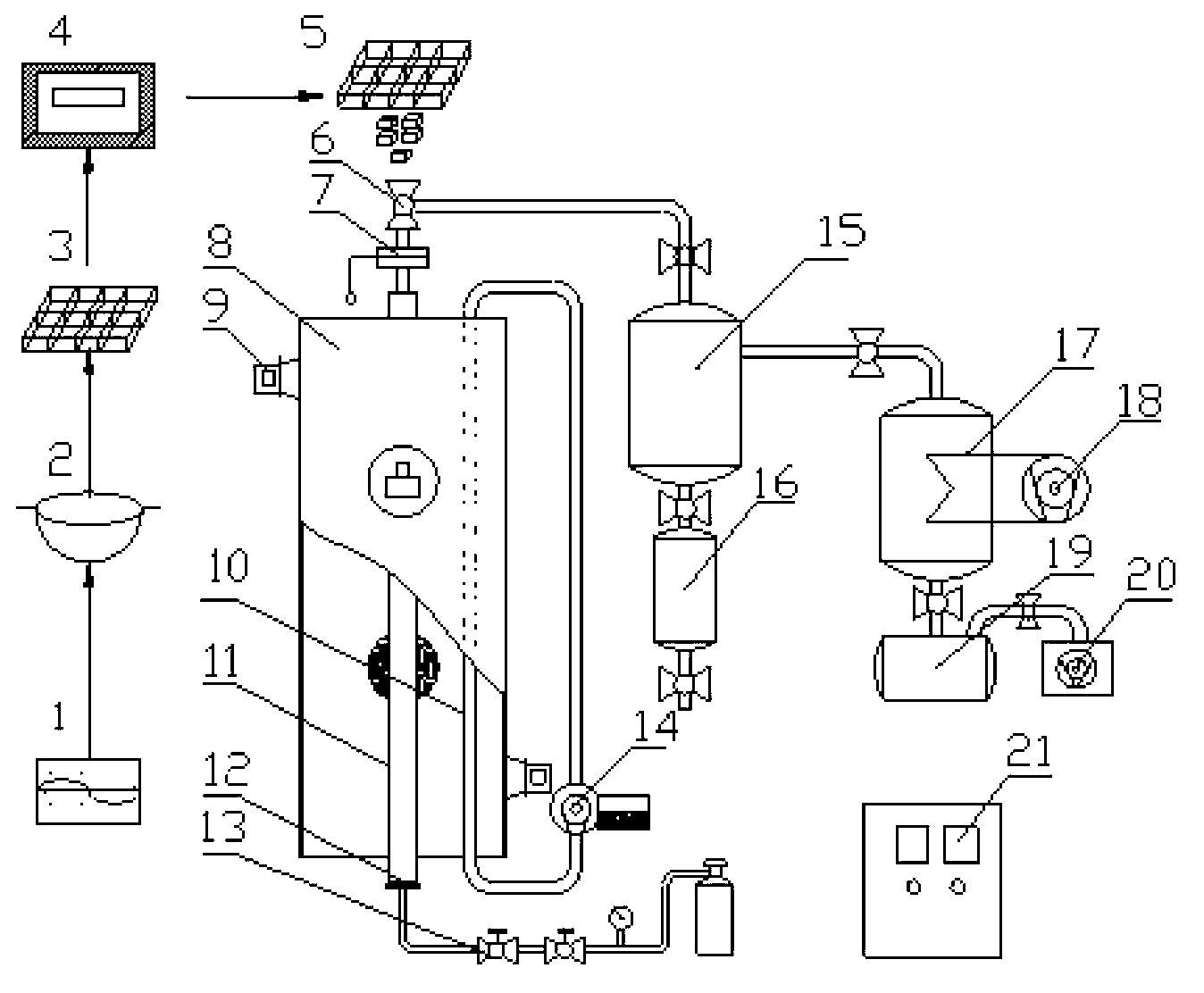

Hollow pattern template vertical circulating system for making decorative board and technological method

InactiveCN1891421AAccurate industrial productionAccurate and unmistakable combination of industrial productionFeeding arrangmentsSurface layerChange color

This invention relates to a hollow pattern template cubic circulation system for manufacturing decoration plates and its method characterizing that 2-50 blocks are placed levelly on their own supporting frames by hollow pattern templates of the pattern raw material and arrayed on the combined supporting frames in vertical direction orderly to manufacture circularly changed patterns, which can be operated industrially and form circularly changed color patterns effectively, accurately and quickly suitable for the manufacture of base color variance technology of ceramic surface layer powder pattern and flooring decoration materials of ceramic, glass, micro-crystal glass and artificial stones with resin.

Owner:杨德宁

Method for building built-up steel structure bearing walling

InactiveCN1420245AEfficient industrial productionQuick on-site installationWallsCombined methodRebar

A method for constructing the assembled load-bearing wall with steel structure includes joining a number of assembled architectural plates to form shaped steel beams or column structure frames, enclosing them with architectural plates, and sealing the gap between them. Said assembled architectural plate is composed of steel sections as frame, the reinforcing bar truss or steel section as reinforcing ribs, foamed cement as core and cement surface rinforced by anti-cracking material. Its advantages are high assembling speed, short construction period and low cost.

Owner:CUBIC DIGITAL TECH CO LTD

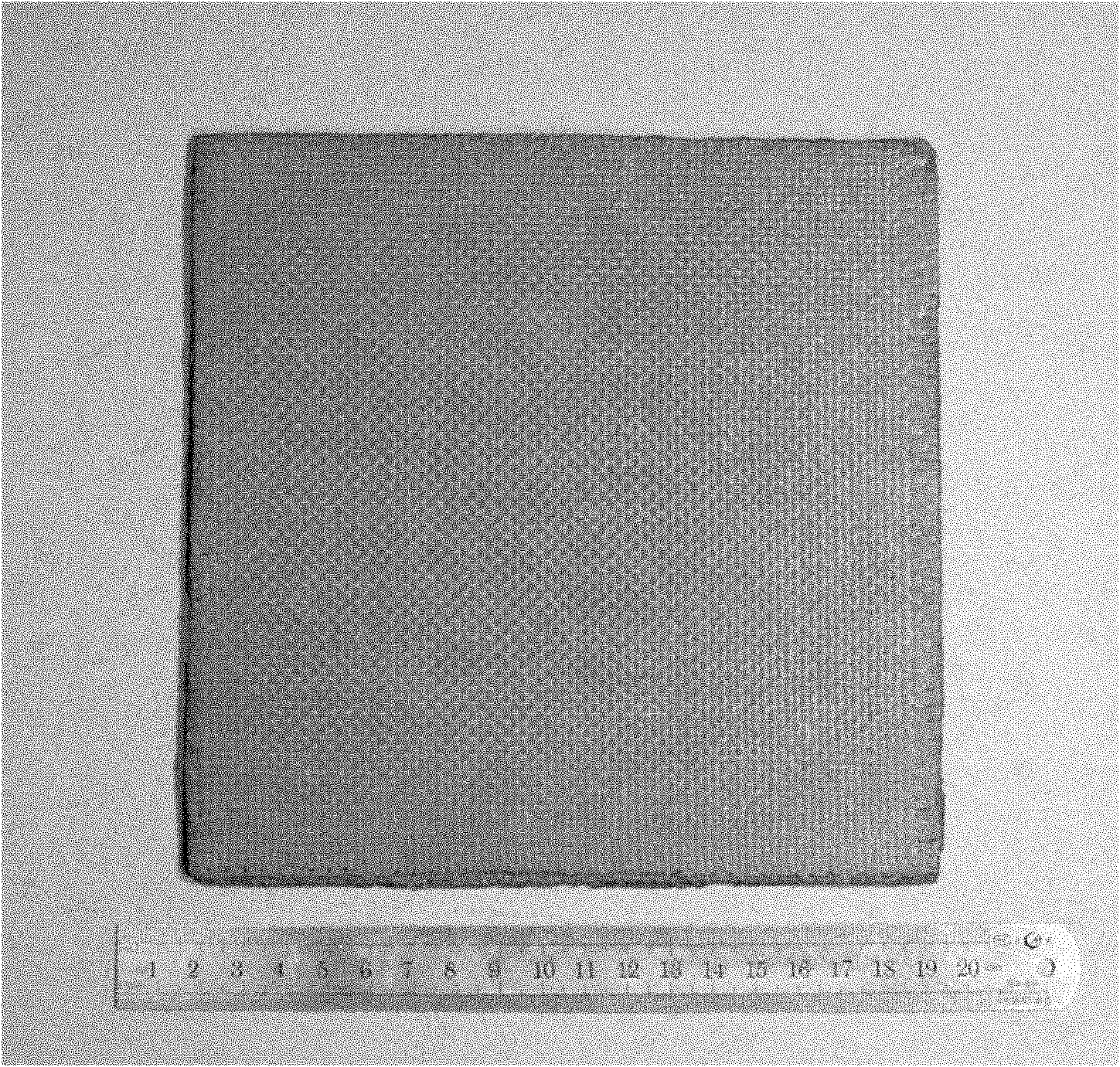

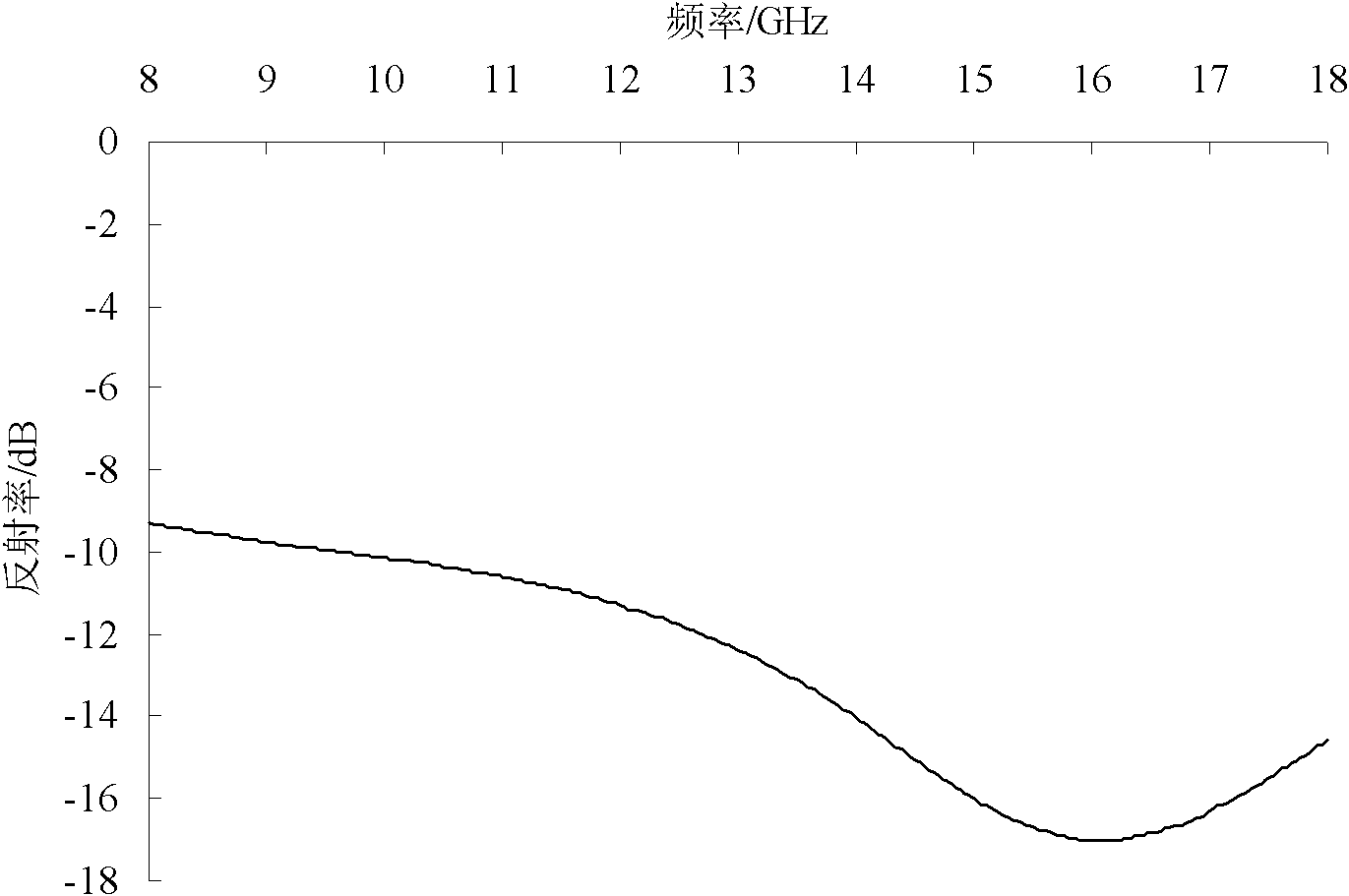

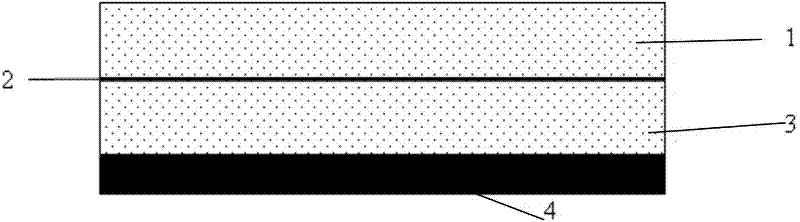

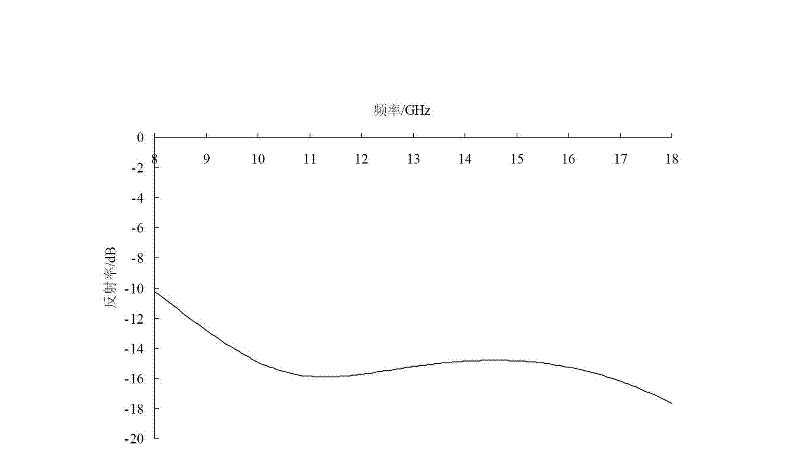

Wave-absorbing material for silicon carbide fibre reinforced resin base sandwich structure and preparation method thereof

ActiveCN102218868AImprove toughnessHigh strengthSynthetic resin layered productsResin-Based CompositeMedia layer

The invention discloses a wave-absorbing material for a silicon carbide fibre reinforced resin base sandwich structure and a preparation method thereof. The wave-absorbing material has a multi-functional layer laminated structure. The structure comprises a first medium layer, an absorbing layer, a second medium layer and a reflection layer; all the functional layers consist of a continuous silicon carbide fibre reinforced resin base composite material; and the continuous silicon carbide fibres serving as the reinforcing materials in each functional layer have different specific resistances. The preparation method for the wave-absorbing material comprises the steps as follows: the continuous silicon carbide fibres are selected firstly and woven into plain cloth; and then the resin is used as a basal body and the wave-absorbing material is manufactured by adopting a resin base composite material forming technique according to the laminated sequence and thickness of each functional layer. The wave-absorbing material has the advantages of simple structure, good parameter tolerance level, easy forming, excellent wave-absorbing functions, etc.

Owner:NAT UNIV OF DEFENSE TECH

Catalytic cracking process for producing vinyl chloride by using active carbon as accelerant

InactiveCN102766019ASolve the conversion rateSolve the problem of selectivityPreparation by hydrogen halide split-offHigh energyFixed bed

The invention discloses a catalytic cracking process for producing vinyl chloride by using active carbon as an accelerant. The method comprises the following steps: introducing dichloroethane into a fixed bed reactor with activated carbon catalyst, and separating the reaction products to obtain products of hydrogen chloride and liquid vinyl chloride. A preparation method of the active carbon catalyst comprises the following steps: pretreating coaly activated carbon, shell activated carbon or coconut shell activated carbon, and drying at a temperature of 80-100 DEG C for 20h-24h; and then activating in an atmosphere with nitrogen as a protective gas at a temperature of 200-250 DEG C for 10-24 h, so as to obtain the activated carbon catalyst. The invention solves problems of low conversion rate, poor selectivity and high energy consumption of dichloroethane high-temperature pyrolysis, and greatly reduces operating costs on the subsequent recovery and rectification separation of dichloroethane.

Owner:EAST CHINA UNIV OF SCI & TECH

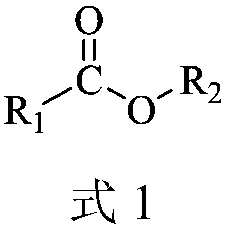

Carboxylic ester oximationmethod

ActiveCN110357793AAchieving near-atom-economical fabricationMild reaction conditionsOrganic chemistryHydroxylamineOrganic solvent

The invention discloses method for preparing(iso)hydroxamic acid salt or (iso)hydroxamic acid. The method for preparing (iso)hydroxamic acid salt or (iso)hydroxamic acidcomprises the steps that analkali, a hydroxylamine salt, and an organic carboxylic acid ester are directly subjected to hybrid reaction without an extra solvent, and thusan (iso) hydroxamic acid salt product is obtained; and or after the reaction is completed, a reaction system is cooled, an acid is added to the reaction system to obtain (iso)hydroxamic acid.According to themethod for preparing (iso)hydroxamic acid salt or (iso)hydroxamic acid,the (iso)hydroxamic acid salt or the (iso)hydroxamic acidcan be obtainedwith near atomic economy without additional organic solvents or water being added, environment-friendly effectis achieved, simpleness and efficiency are achieved, and industrial production is advantageous.

Owner:岳阳中科华昂精细化工科技有限公司

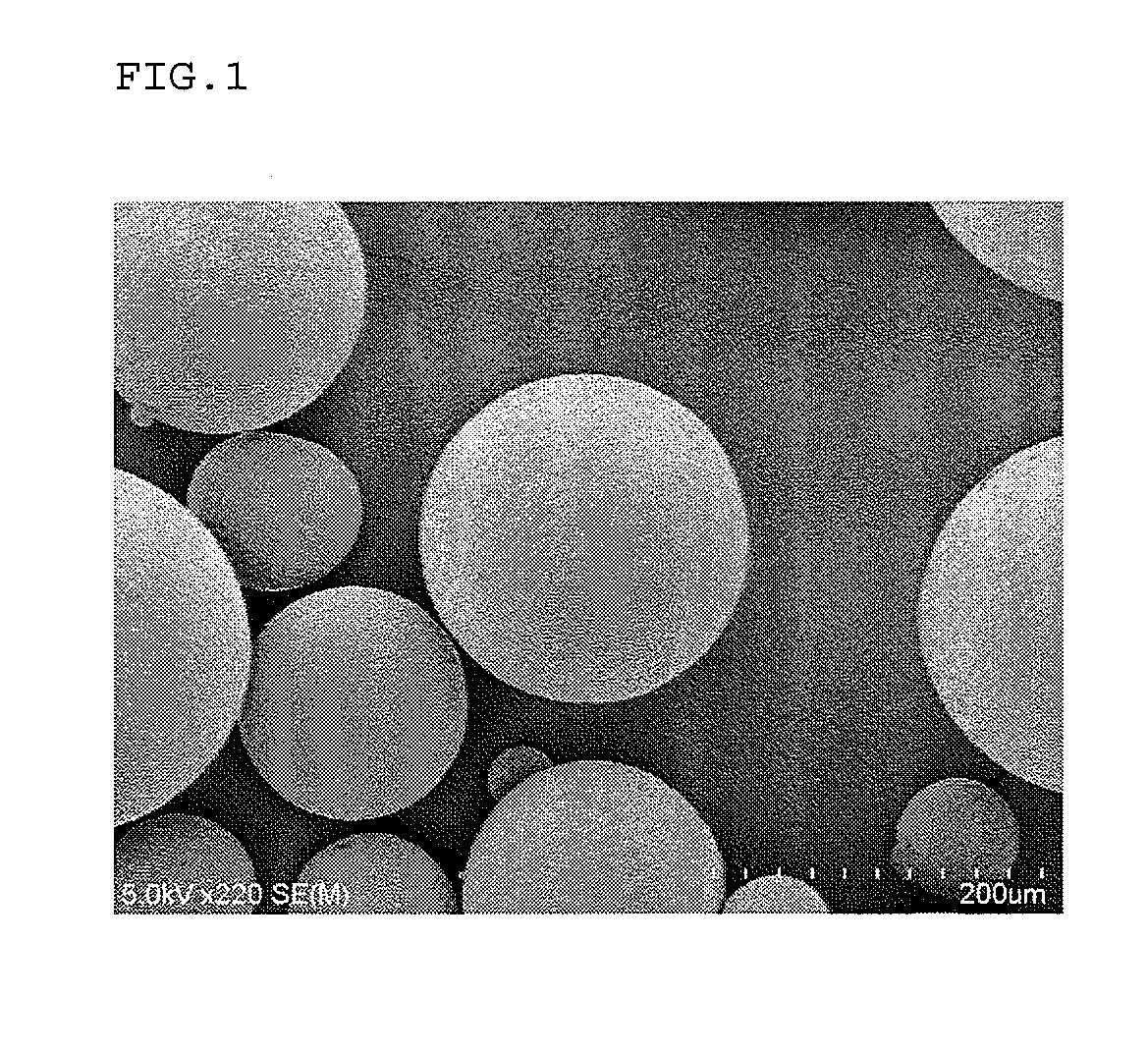

Method for production of microcapsules using solid fat

InactiveUS20100297222A1Increase contentFood with easePowder deliverySenses disorderEmulsionOrganic solvent

A method for production of fine microcapsules which encapsulate a hydrophilic bioactive substance at a high content and can be used in wide range of applications such as foods and medical drugs, which method enabling efficient industrial production, is provided. A method for production of S / O type microcapsules including the steps of: (1) emulsifying and dispersing a mixture of a solid fat and an aqueous solution containing a hydrophilic bioactive substance at a temperature of at least the melting point of the solid fat to obtain a W / O emulsion; (2) removing moisture in the W / O emulsion at a temperature of at least the melting point and lower than the boiling point of the solid fat to obtain an S / O suspension; (3) adding the S / O suspension into an aqueous phase containing at least one selected from a surfactant (B), a thickening agent and a hydrophilic organic solvent, and permitting liquid droplet dispersion at a temperature of at least the melting point and lower than the boiling point of the solid fat to obtain an S / O / W emulsion; and (4) cooling the S / O / W emulsion to lower than the melting point of the solid fat to harden the solid fat, and further removing the moisture at a temperature lower than the melting point of the solid fat.

Owner:KANEKA CORP

Light guide plate with quantum dot diaphragm array and quantum dot site and application of light guide plate

ActiveCN108072930AReduce dosageReduce restrictionsPlanar/plate-like light guidesNon-linear opticsGamutLight guide

The invention belongs to the field of backlight display, and particularly relates to a light guide plate with a quantum dot diaphragm array and a quantum dot site and application of the light guide plate. In order to solve the problem that an existing display device is very poor in color gamut stability and brightness stability, the light guide plate with the quantum dot diaphragm array and the quantum dot site and application of the light guide plate are provided. At least one quantum dot diaphragm is stuck on the light-in surface of the light guide plate, the quantum dot site is printed on the opposite face of the light-out surface of the light guide plate, and the quantum dot site includes red quantum dots and green quantum dots. The light guide plate is applied to a display device, andthe display device is good in color gamut stability and brightness stability.

Owner:NINGBO EXCITON TECH

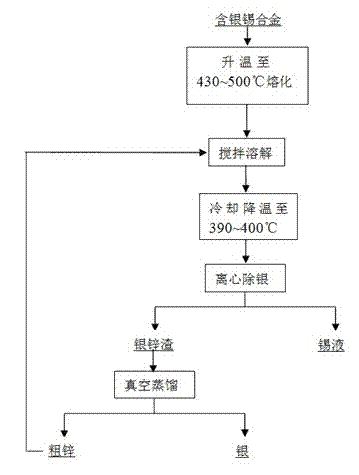

Method for extracting silver from silver-containing crude tin alloy

The invention provides a method for extracting silver from silver-containing crude tin alloy. The method comprises the following steps of: heating the silver-containing crude tin alloy to reach the temperature of 430 to 500 DEG C for melting; feeding a zinc ingot into the molten silver-containing crude tin alloy, and agitating to dissolve; cooling the dissolved mixture to reach the temperature of 390 to 400 DEG C; and centrifugally separating at a rotating speed of 200-700rpm until the surface of the liquid at the upper layer has no floating slags, so as to obtain the tin liquid at the upper layer and the sliver-zinc slags at the lower layer; naturally cooling and condensing the tin layer to obtain the tin alloy without silver; and distilling the silver-zinc slags under the vacuum to obtain the silver and the crude zinc, wherein the silver in the tin alloy subjected to silver extracting is less than 10g / t. According to the method, the whole process is safe and controllable; the method is convenient to operate, and has no exhaustion of three wastes; and the method has high universality to the raw materials; the tin alloys with different silver contents can be effectively processed; the continuous industrial production can be achieved; and high recovery rate of the tin and the silver can be ensured; the silver in the silver-containing tin alloy can be efficiently extracted; with adoption of the method, the quality of the tin can be improved, and large amounts of silver can be recovered for the enterprises.

Owner:KUNMING UNIV OF SCI & TECH

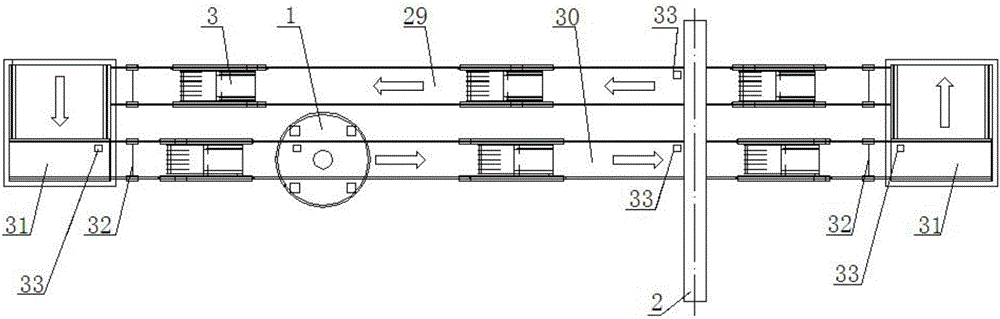

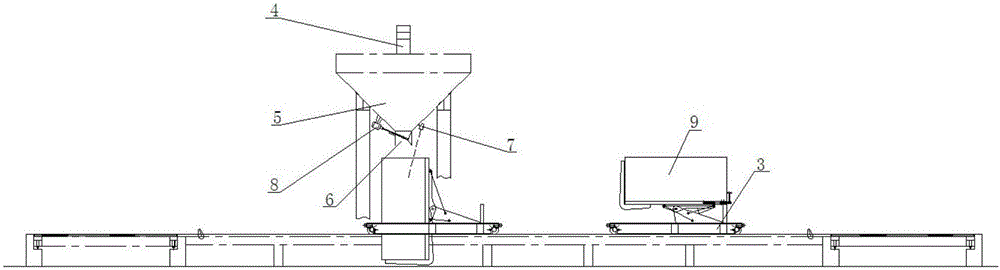

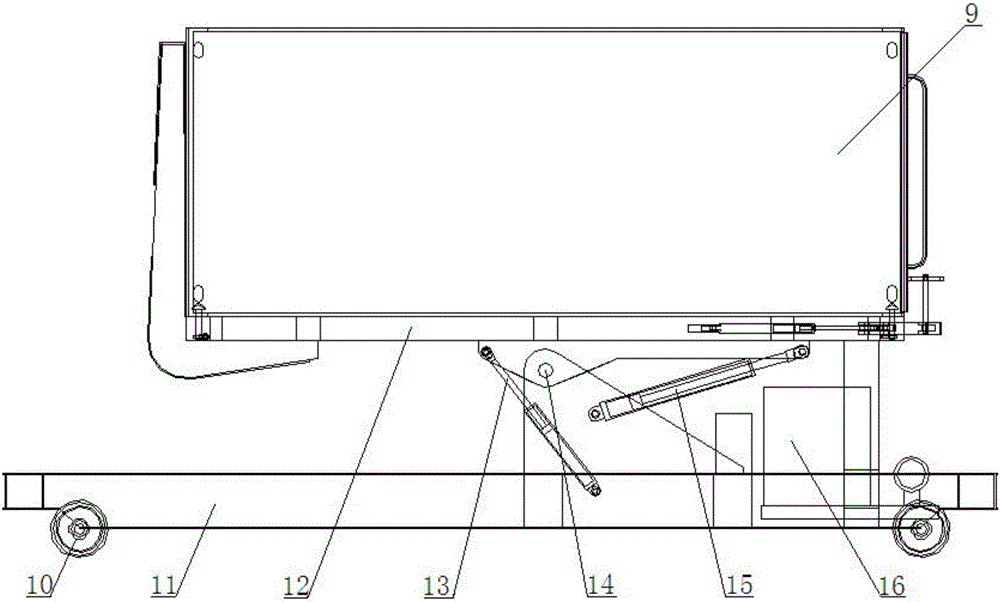

Lump coal boxing system and boxing method thereof

ActiveCN104986582AImprove dumping efficiencyAchieve brokenControl devices for conveyorsLoading/unloadingControl systemMechanical engineering

The invention discloses an automated lump coal boxing system and a boxing method thereof. A control system in the automated lump coal boxing system is connected with overturning trolleys (3) and trolley moving tables (31) respectively, detecting switches (33) are uniformly distributed on the trolley moving tables (31) in the lump coal boxing system, an empty trolley line (29) and a boxing line (30)which are under a hoisting device (2), and the boxing line (30) under a feeding mechanism (6), and the detecting switches (33) are connected with the control system; a hopper position detecting device (7) and a door opener (8) are arranged on a hopper (5) of a hopper device (1), and the hopper position detecting device (7) and the door opener (8) are respectively connected with the control system. The boxing method disclosed by the invention comprises the following steps: charging lump coal; controlling the overturning trolleys (3) to travel and overturn; and enabling a container (9) to be hoisted and placed to a transporting vehicle by the hoisting device (2). Through the adoption of the automated lump coal boxing system and the boxing method thereof, the overturning efficiency and the dismounting efficiency of the container are improved, and large-scale industrial production can be realized.

Owner:WUHAN POWER EQUIP WORKS

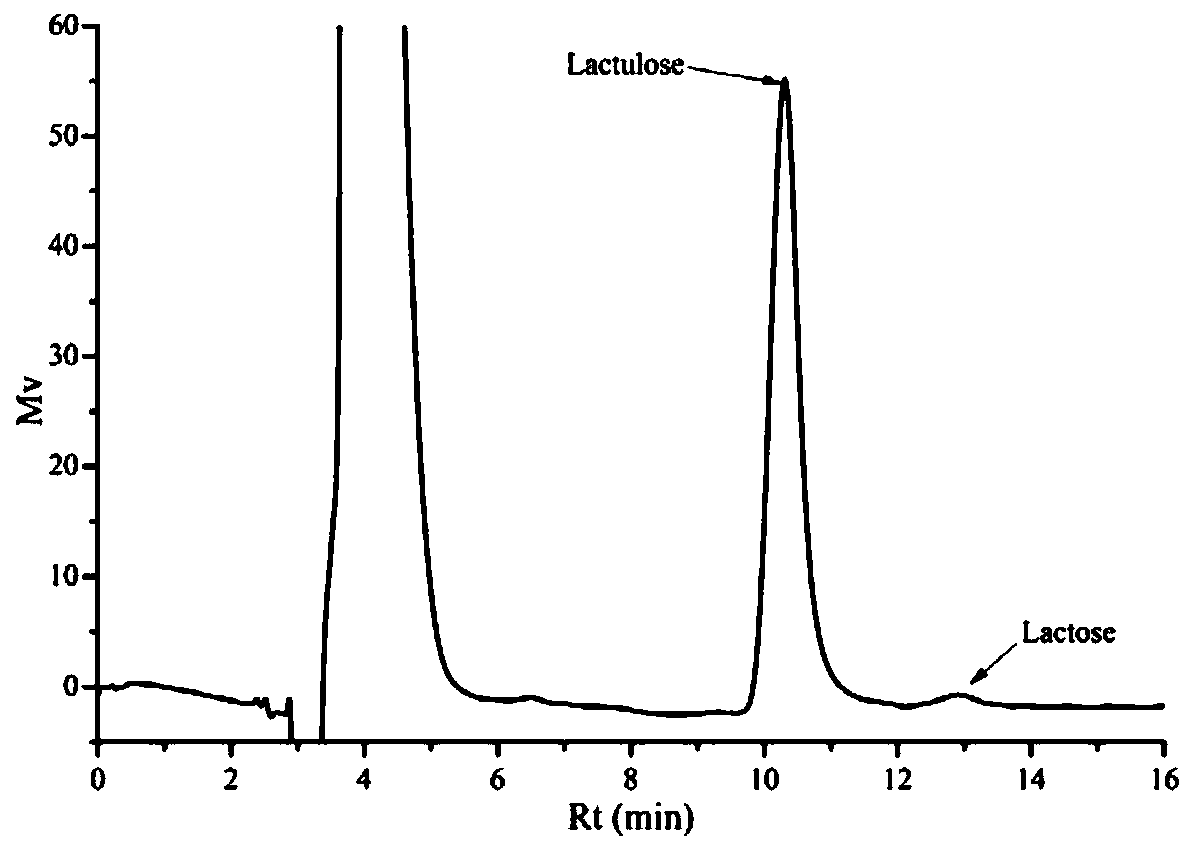

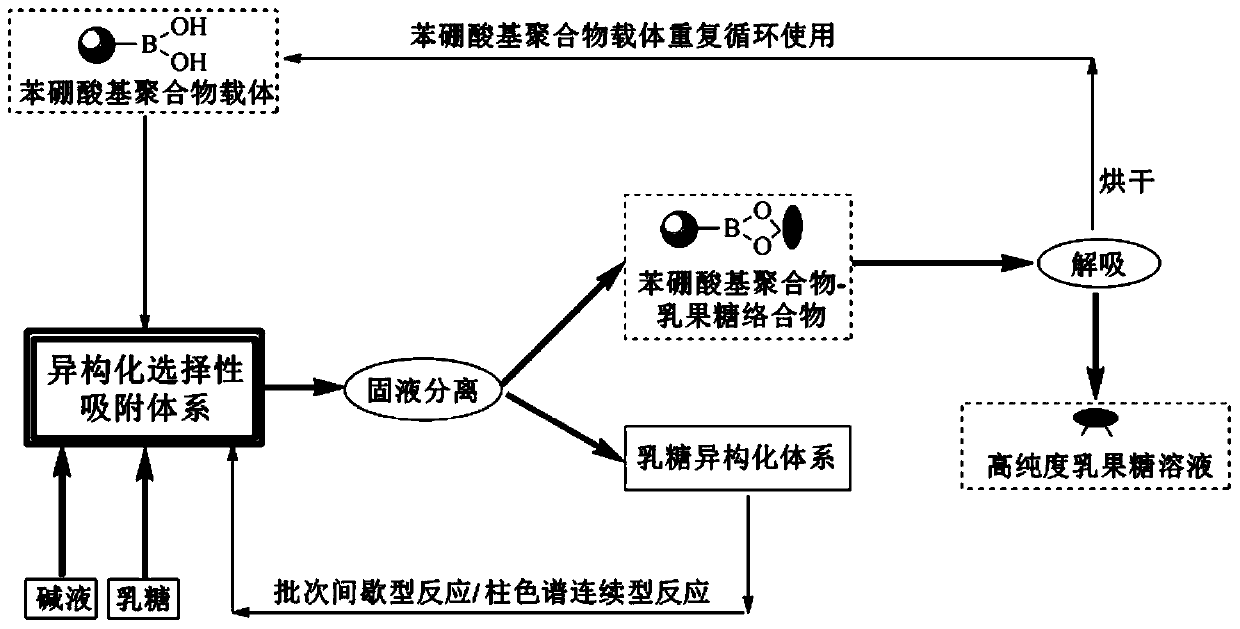

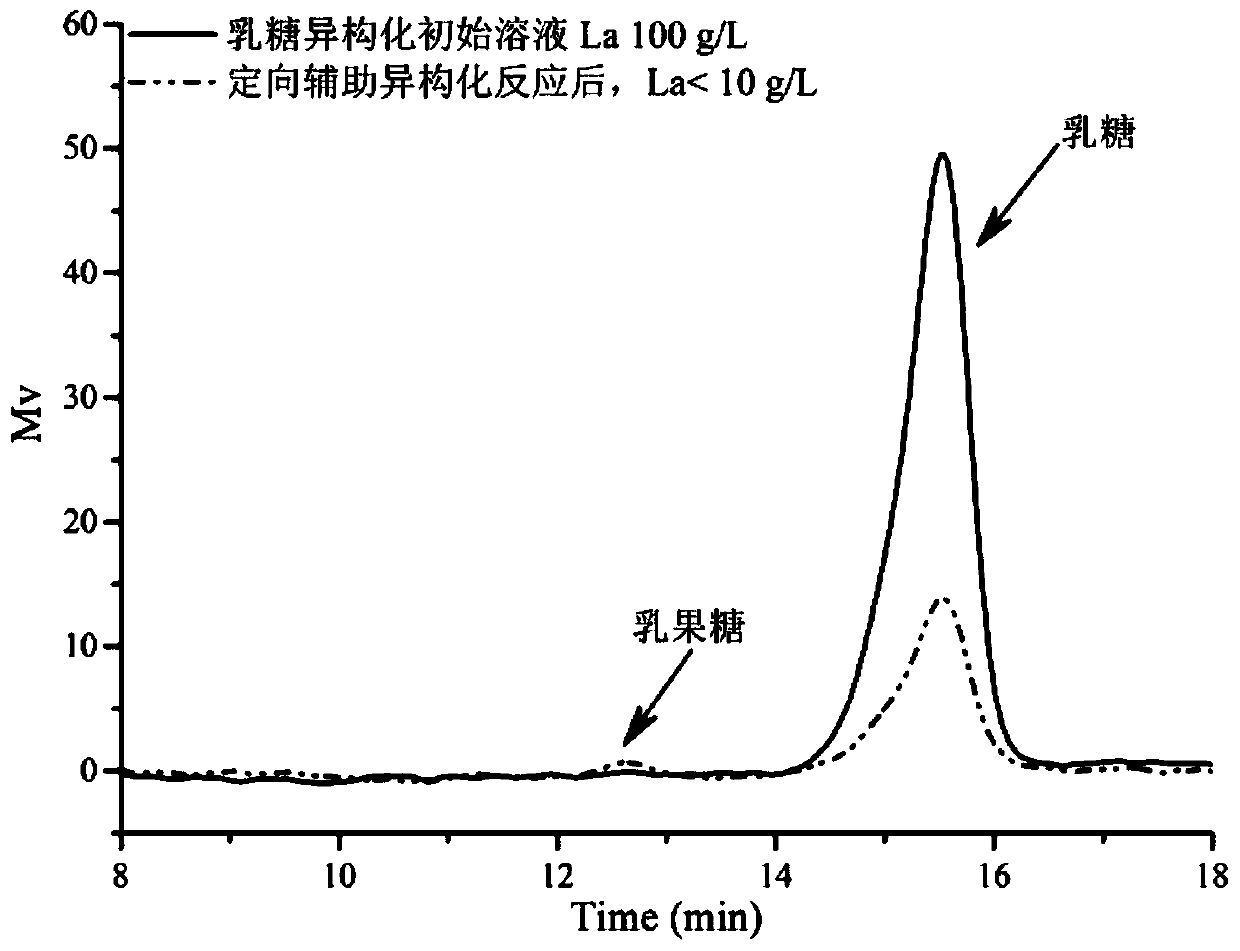

Phenyl boronic acid-based polymer carrier and applications in selective adsorption of saccharide-based substances

ActiveCN110183574ALarge capacity of adsorption targetInhibition of competitive adsorptionOther chemical processesAlkali metal oxides/hydroxidesSorbentResource saving

The invention discloses synthesis of a phenyl boronic acid-based polymer carrier, and a method for selectively adsorbing and separating a saccharide-based substance having an ortho-cis hydroxy structure. According to the present invention, a strong surface hydrophobicity polymer carrier with a phenyl boronic acid group as the only functional group is prepared, the target saccharide-based substancehaving an ortho-cis hydroxy structure is efficiently and selectively adsorbed and separated from a saccharide-based mixing solution by using the carrier as an adsorbent, and through adsorption-desorption, lactulose with a purity of 10% can be purified to more than 95%, the purity of lactulose in the final eluent can reach more than 99% when the initial purity of lactulose reaches 25%, and the recovery rate is nearly 100%; and the phenyl boronic acid-based polymer carrier has stable structure, can achieve long-time continuous recycling or multi-batch batchwise separation and purification, meets resource-saving and environment-friendly production requirements, and easily promotes the clean, efficient and environmentally friendly industrial production of high-purity lactulose and related saccharides.

Owner:苏州福赛思生物科技有限公司

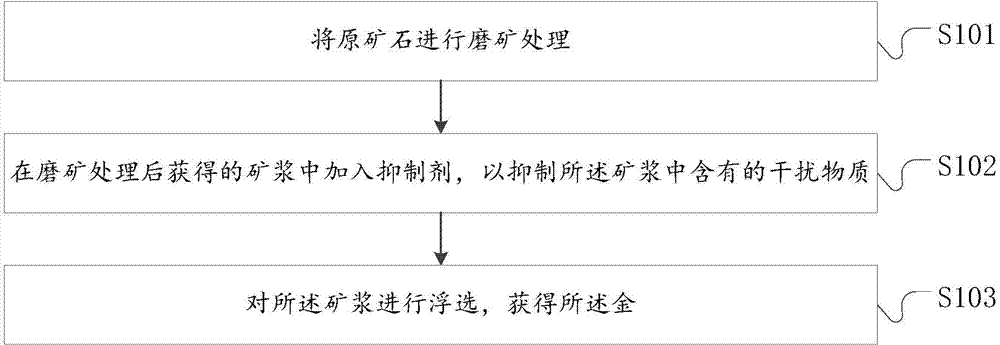

Recovery method of gold

InactiveCN104492591AHigh recovery rateSuppress interferenceFlotationWet separationRecovery methodCarboxymethyl cellulose

The invention discloses a recovery method of gold, and is applicable to carlin-type gold deposits. An inhibitor which at least comprises carboxymethyl cellulose (CMC) is added into ore pulp, fine slime obtained by interference flotation and non-purposive substance minerals (for example, carbonate, aluminosilicate and the like) are inhibited, and then gold carrying minerals are activated and then floated. The technological process is simple and the operation is convenient. Since the interference of interference substances to the ore pulp can be effectively inhibited by the inhibitor, previous slime removal operation can also be saved, and the gold recovery rate is improved.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

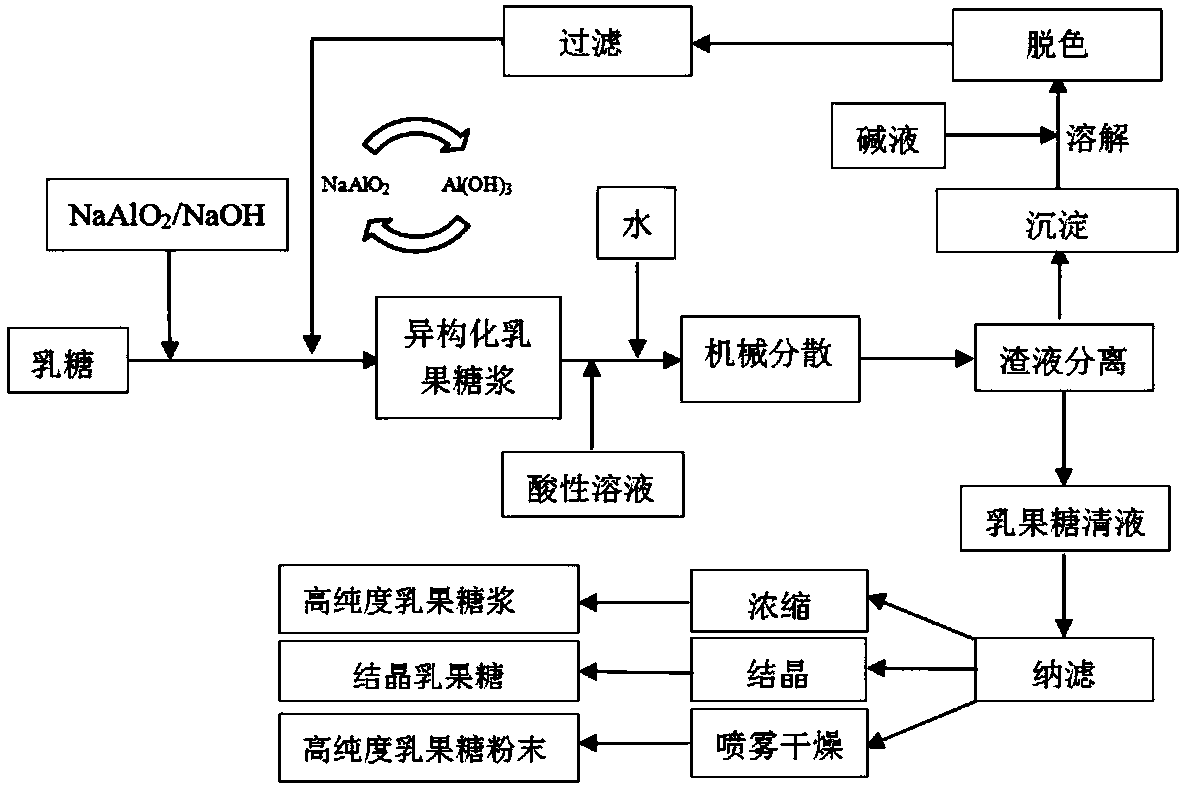

Continuous cyclic preparation method of high-purity lactulose solution and product thereof

ActiveCN108148099AIncrease concentrationRealize repeated useSugar derivativesDisaccharidesHigh concentrationResource saving

The invention belongs to the technical field of oligosaccharide preparation, and relates to a continuous cyclic preparation method of a high-purity lactulose solution and a product thereof. Specifically speaking, the preparation method comprises the following steps: (1) performing lactulose isomerisation; (2) performing acidity adjustment; (3) diluting, dispersing and separating; (4) purifying clear lactulose liquid; (5) performing cyclic utilization of a catalyst. Through the preparation method, high-concentration lactulose solution and a subsequent product thereof can be prepared. Accordingto the continuous cyclic preparation method of the high-purity lactulose solution and the product thereof, sodium metaaluminate / an alkaline matter is taken as an alkaline complexing catalyst for the first time in China, and the conversion rate and lactulose concentration achieved by preparing the lactulose by taking the sodium metaaluminate / an alkaline matter as the alkaline complexing catalyst are far higher than those achieved by adopting a boracic acid / sodium hydroxide system; repeated cyclic use of a sodium metaaluminate catalyst is realized; the defect that precipitate wraps the lactuloseis overcome. The preparation method provided by the invention meets resource-saving and environment-friendly production requirements, and provides beneficial experience and reference for promoting clean, high-efficiency and environment-friendly lactulose industrial production.

Owner:JIANGNAN UNIV

Method for extracting, separating and purifying anthocyanin from blueberry peel and residues

The invention relates to a method for extracting, separating and purifying anthocyanin from blueberry peel and residues and belongs to the technical field of agriculture and food science. Effective ingredients are separated and extracted from fruit processing waste residues, so the method is also relevant to three-waste utilization. According to the method, edible alcohol is used for extracting anthocyanin crude extracts from blueberry peel and residues at 45 to 50 DEG C, and in addition, AB-8 macroporous resin is used for separation and purification. The method provided by the invention has the characteristics that the technology is novel, the operation and the production are simple and convenient, the low cost is low, the yield is high, the environment-friendly effect is realized; and the utilization rate of blueberry fruits is improved, the content of the anthocyanin in the separated product is greater than or equal to 26 percent, the requirements of various function food, health care food, medicine and food additives on the anthocyanin are met, and wide purposes are realized.

Owner:GUIYANG UNIV

Method for making instant chicken sauce slices through microwave spouted freeze-drying

InactiveCN103238887AEfficient dryingDry evenlyDrying using combination processesDrying solid materials with heatMicrowaveAdditive ingredient

The invention discloses a method for making instant chicken sauce slices through microwave spouted freeze-drying, and belongs to the technical field of food and seasoning processing. The method takes modified starch, beta cyclodextrin, maltodextrin and chicken sauce as raw materials, and comprises the steps of formula selection, ingredient mixing, stewing, preparing, die filling, freezing forming, stripping, freezing, microwave spouted freeze-drying, and finished product packaging. The method is reasonable in formula design, simple in technology and easy to operate, realizes spouting and rotation of the materials during the microwave freeze-drying course, and achieves the purpose of high-efficiency and uniform drying of the materials. Compared with the traditional making method, the materials are good in instant effect and low in processing cost; the freeze-drying cycle can be shortened by above 50%; and the high-efficiency industrial production of the high-grade instant chicken sauce slices can be realized.

Owner:GUANGDONG JIAHAO FOOD +1

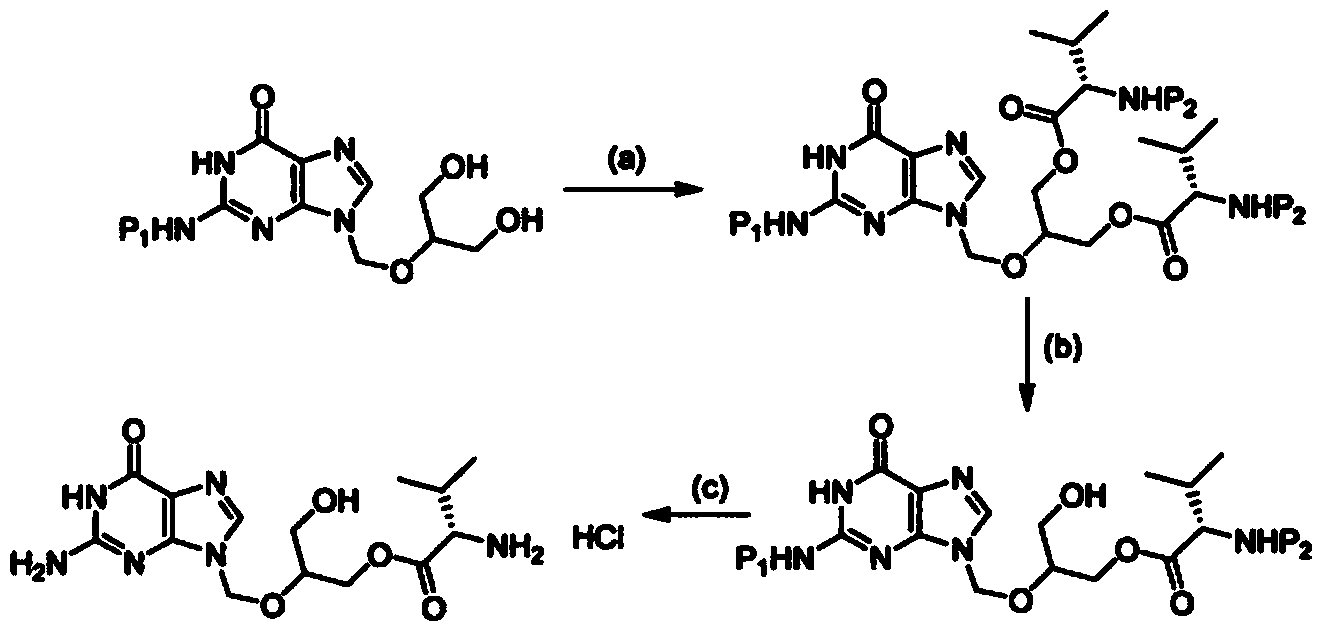

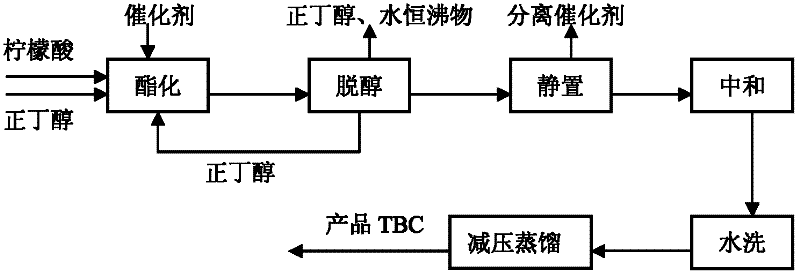

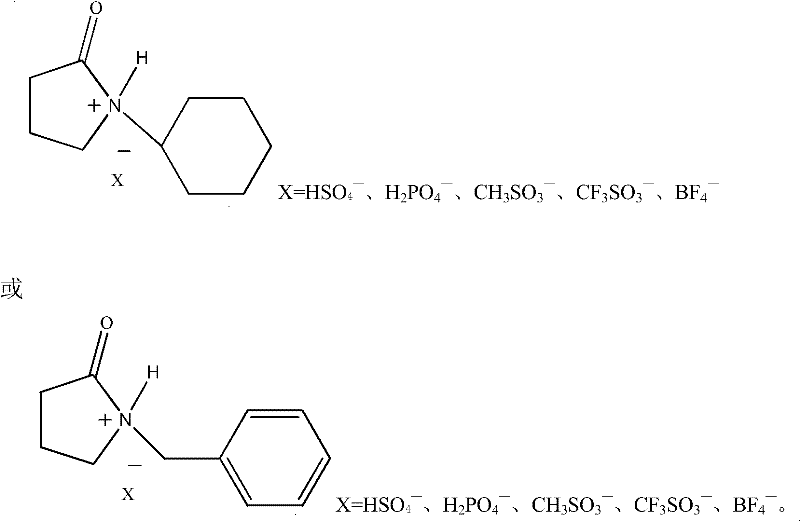

The method that adopts composite ionic liquid catalyst to synthesize tri-n-butyl citrate

ActiveCN102285883AEasy to separateThe synthesis process is simpleOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsDistillationFiltration

The invention provides a method for synthesizing tributyl citrate (TBC) by adopting a composite ionic liquid catalyst. The method is characterized by comprising the following steps: firstly carrying out esterification on taking citric acid and n-butyl alcohol which serve as raw materials in the presence of the catalyst, after esterification is qualified, directly utilizing the waste heat to reduce pressure and eliminate alcohol in a reaction kettle to obtain a crude product of tributyl citrate containing the catalyst, then carrying out acetylation and finally carrying out deacidification, standing, cooling, catalyst separation, neutralization, washing and reduced pressure distillation, thus obtaining the colorless transparent liquid TBC without decoloration and pressure filtration. The method has the following advantages: the same amount of the same catalyst is used in esterification and acetylation, thus realizing reuse of the catalyst; the conversion rate is high, the by-products are few and the yield is more than 98%; aftertreatment is simple and convenient, excessive alkaline water for neutralization and washing is not needed, the washing clear water can be reused and no pollutants are discharged; and the reaction temperature is low, the production period is short, the equipment investment is low, the energy consumption is low, and the cost is low.

Owner:YICHANG WUDI ELECTROMECHANICAL CO LTD

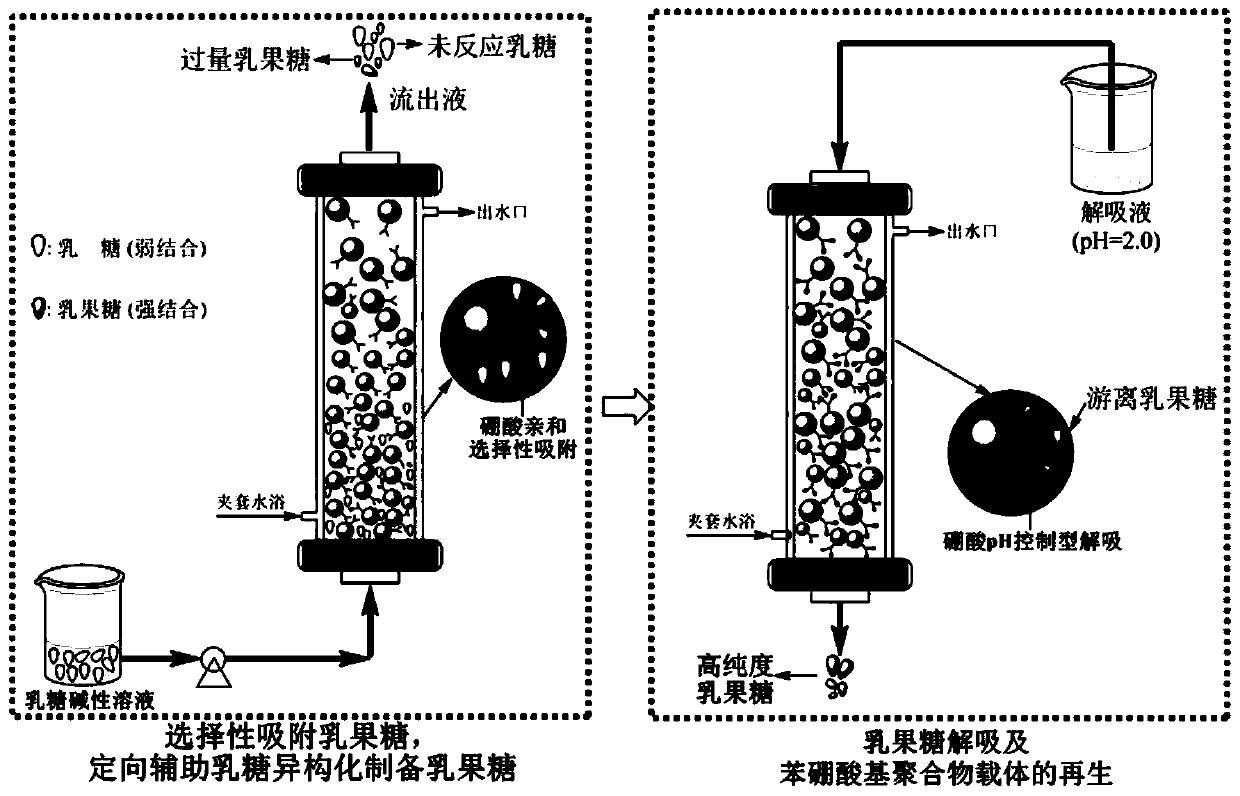

Method for preparing, separating and purifying lactulose by directionally assisting lactose isomerization by using phenylboronic acid-based carrier

PendingCN111454305AReduced catalytic efficiencyAchieve selective adsorptionSugar derivativesDisaccharidesPhenylboronic acidIsomerization

The invention discloses a method for preparing lactulose by directionally assisting lactose isomerization by using a phenylboronic acid-based polymer carrier and separating and purifying the product lactulose at the same time. The preparation method comprises the following steps: firstly, realizing directional selective adsorption of lactulose in a lactose isomerization system by utilizing a specific affinity adsorption effect between a phenylboronic acid functional group loaded by a phenylboronic acid-based polymer carrier and lactulose containing an ortho-position cis-hydroxyl structure, andpromoting an isomerization reaction to be carried out in the direction of generating lactulose; the conversion rate of the target product can be greatly improved, and the final lactulose yield can reach 65% or above. Meanwhile, the phenylboronic acid-based polymer carrier for directionally and selectively adsorbing lactulose can obtain a high-purity lactulose desorption solution through desorption operation, and the purity of the desorption solution can reach 95% or above.

Owner:苏州福赛思生物科技有限公司

Epothilone B separating and extracting method based on membrane filtration technology

The invention relates to an epothilone B separating and extracting method based on a membrane filtration technology. The method comprises the following steps: adsorbing a fermentation liquid by using a macroporous resin; then leaching the absorbed macroporous resin by using ethyl acetate and collecting a leaching liquid; filtering the leaching liquid by using an ultrafiltration membrane; washing and filtering the leaching liquid by using the ethyl acetate; combining filtrates; concentrating; performing detection through preparative HPLC (High Performance Liquid Chromatography); and crystallizing the epothilone B component obtained in a separating manner, thereby obtaining the epothilone B. The method is moderate in condition, simple and convenient to operate, few in separating steps and good in selectivity, and can be used for obviously increasing the yield of the epothilone B, thereby providing conditions more favorable for industrial production. The method with combination of membrane filtration and crystallization is adopted, so that a part of macromolecular impurities can be effectively removed; meanwhile, the application of an organic reagent is avoided, so that the industrial production pollution is reduced. Thus, the loss of the epothilone B in other complicated preparation processes is avoided. The epothilone B prepared in a crystallization manner has relatively high purity. Thus, the epothilone B is broad in application prospect and economic benefit.

Owner:SHAANXI UNIV OF SCI & TECH

High temperature resistant antistatic coating and preparation method thereof

ActiveCN102250545AGood flexibilityImprove adhesionElectrically-conductive paintsPolymer scienceTemperature resistance

The invention discloses a high temperature resistant antistatic coating, which is prepared from bi-component modified organic silicon resin serving as a matrix and metal oxide semiconductor powder serving as a conductive filler in a mass ratio of (9-14):6. The antistatic coating has excellent antistatic property and high temperature resistance, can replace most conventional antistatic coatings onradomes, and can meet the antistatic requirement under the 250DEG C high temperature condition. The invention correspondingly discloses a method for preparing the antistatic coating, which comprises process steps of ball milling, spraying, curing, thermal treatment and the like; and the whole preparation process has simple steps and high controllability and can be effectively applied to industrial production.

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com