Patents

Literature

88results about How to "Meet lightweight needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

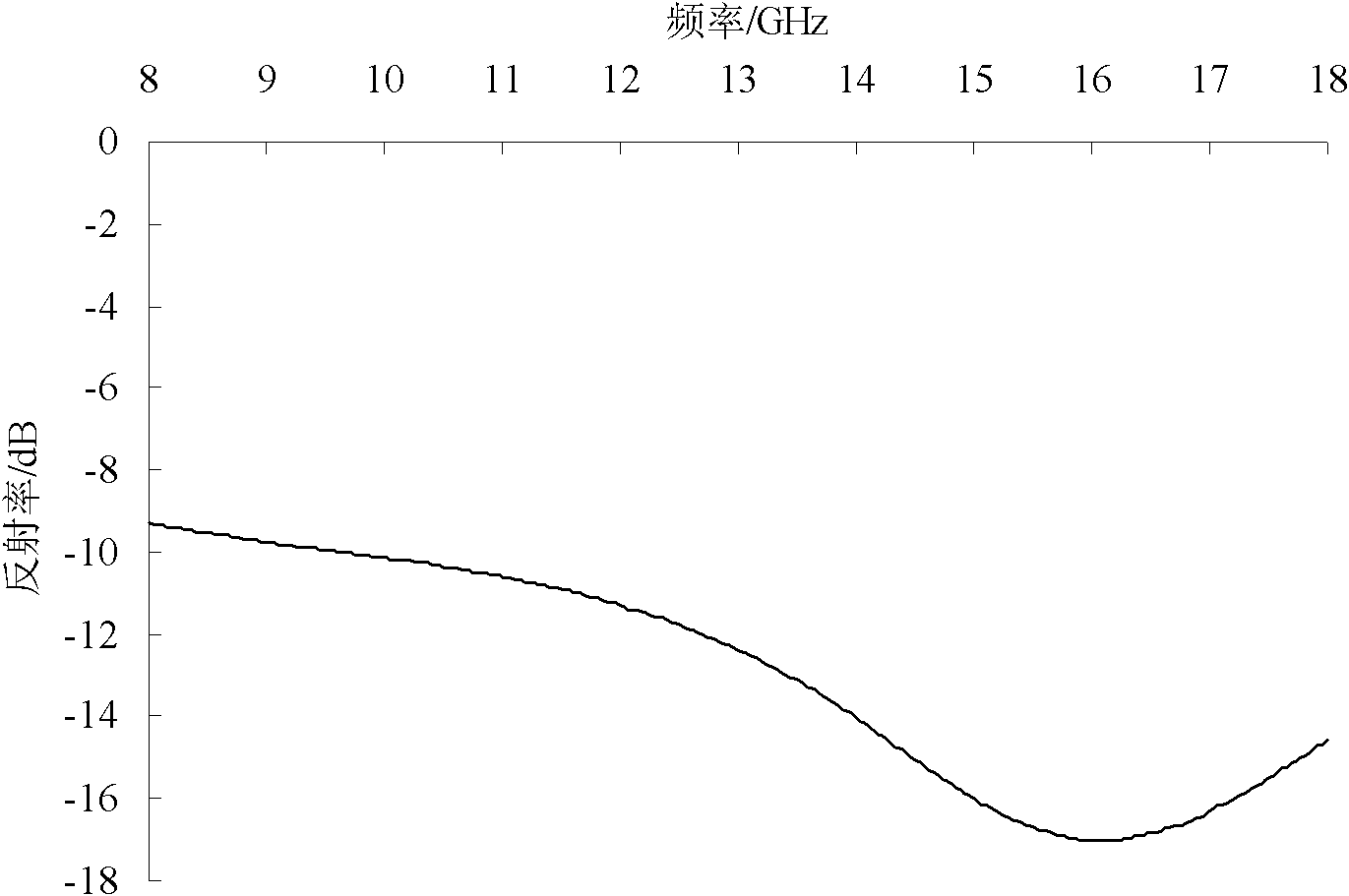

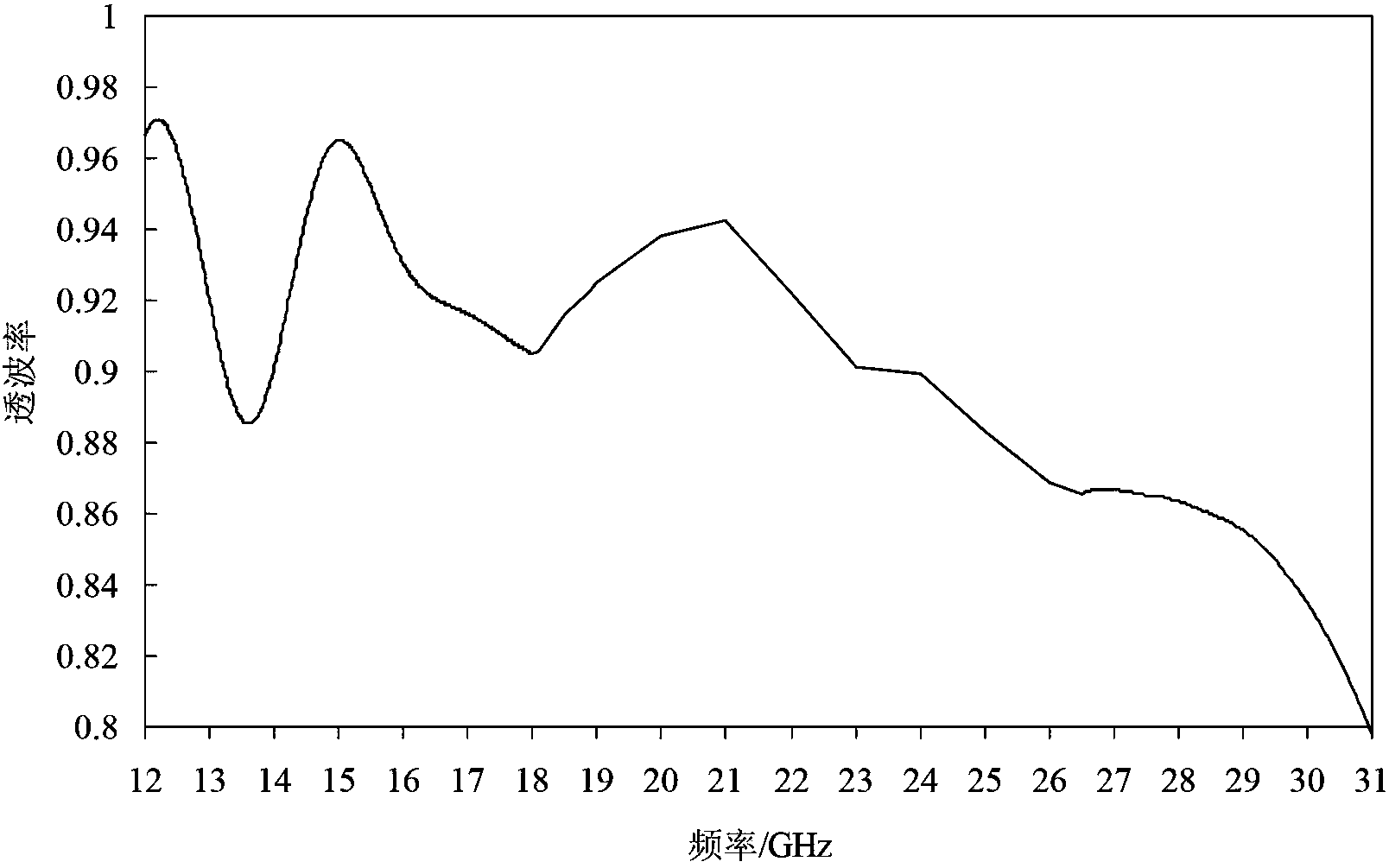

Wave-absorbing ceramic made of silicon carbide composite material and preparation method thereof

The invention discloses a wave-absorbing ceramic made of a silicon carbide composite material and a preparation method thereof. The wave-absorbing ceramic has a multifunctional superimposed structure comprising a matching layer, a consuming layer and a reflecting layer, wherein each functional layer is made of a continuous silicon carbide fiber reinforced silicon carbide-based composite material;and continuous silicon carbide fibers serving as a reinforced material of each functional layer have different resistivity. The preparation method for the wave-absorbing ceramic comprises the following steps of: selecting continuous silicon carbide fiber plain cloth; dipping and cracking the plain cloth of the consuming layer; mixing with polycarbosilane, divinylbenzene, dimethylbenzene and the like to prepare slurry; performing mould pressing, thermal crosslinking and cracking to prepare a wave-absorbing ceramic rough blank; and preparing the wave-absorbing ceramic made of the silicon carbide composite material by adopting a precursor dipping and cracking process. The wave-absorbing ceramic has wide absorption frequency band, high mechanical property and heatproof function.

Owner:NAT UNIV OF DEFENSE TECH

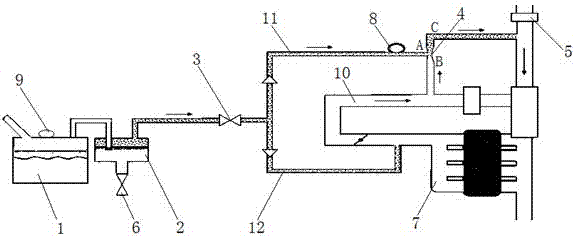

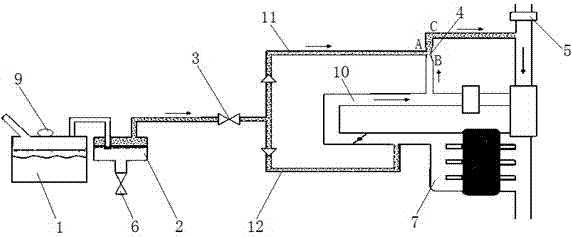

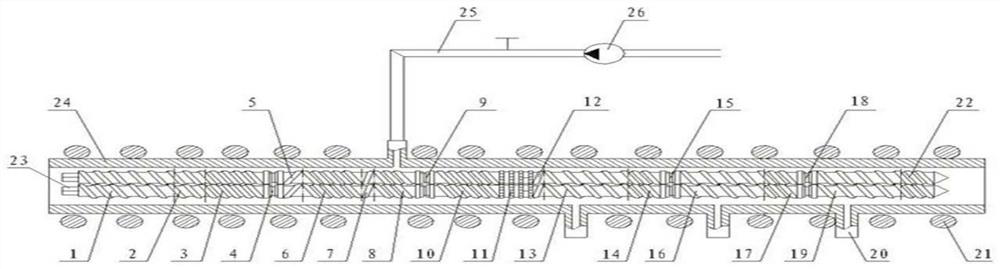

Diagnosis method for desorption flow of high-load desorption pipeline of carbon tank

ActiveCN107420230ASimplifies wiring harness layoutMeet lightweight needsElectrical controlNon-fuel substance addition to fuelDiagnosis methodsDesorption

The invention relates to the field of vehicle emission, in particular to a diagnosis method for an emission system. A diagnosis method for desorption flow of a high-load desorption pipeline of a carbon tank comprises the following steps: selecting a vehicle with an intact desorption pipeline as a standard vehicle, starting the vehicle, opening an electromagnetic valve of the carbon tank, and closing a stop valve of the carbon tank; waiting for a certain time, and acquiring the vacuum degree in an oil tank; testing repeatedly under each residual fuel amount to obtain a function of the vacuum degree and the residual fuel amounts; and when the diagnosis is performed in actual travelling of the vehicle, comparing a vacuum degree threshold value obtained according to the actual residual fuel amount and the function with the actual vacuum degree to realize the diagnosis of the high-load desorption pipeline. In step S1, the vehicle is started and kept in an idle state. According to the diagnosis method, the diagnosis of the desorption flow of the high-load desorption pipeline is completed by using an existing sensor and an existing executor; and a pressure sensor is not required to be mounted in a Venturi pipe, so that the cost is reduced, meanwhile, the matched wiring harness layout of the sensor is also simplified, the system structure is simplified, and the requirement on light weight of a compact vehicle is met better.

Owner:SAIC MOTOR

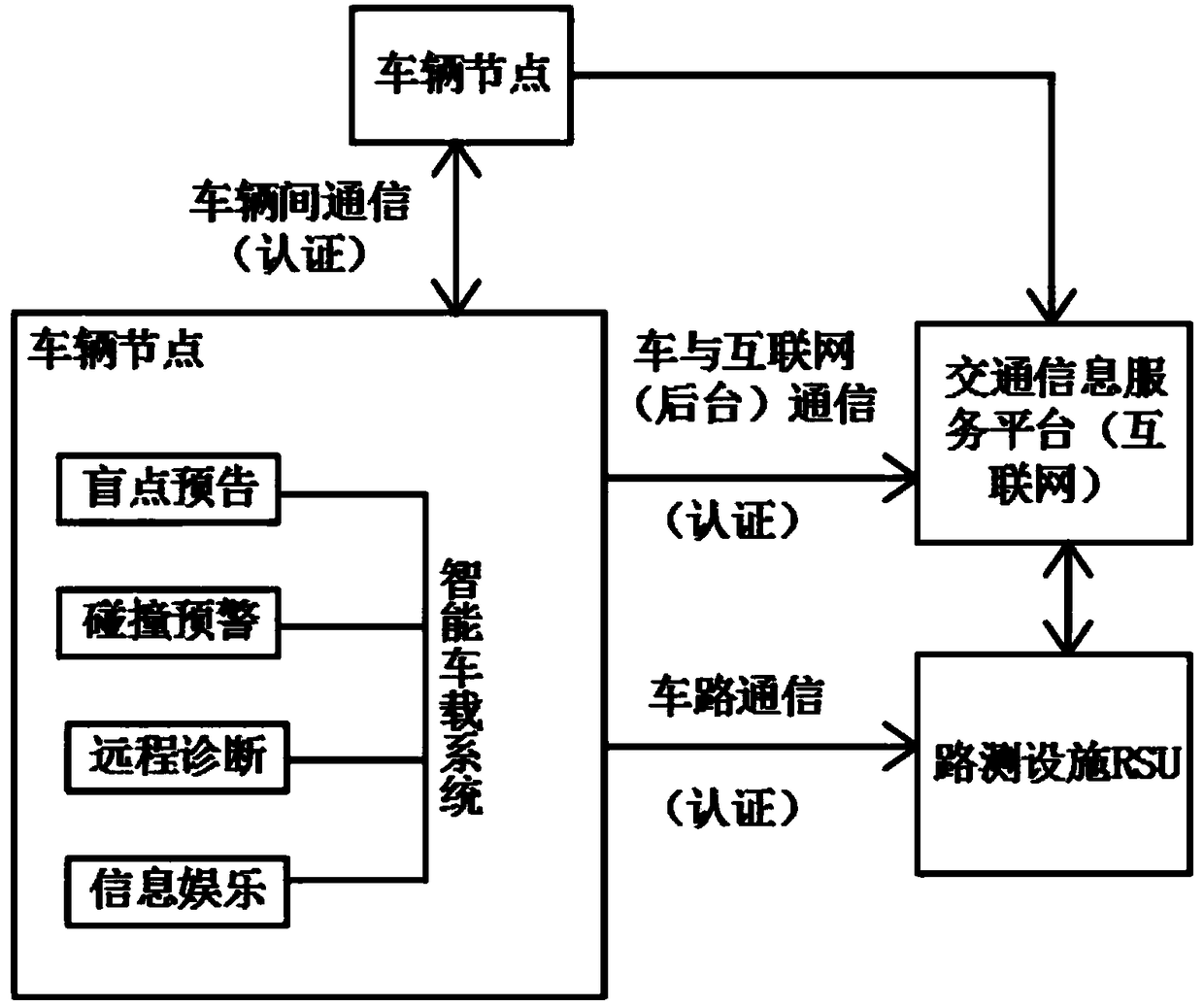

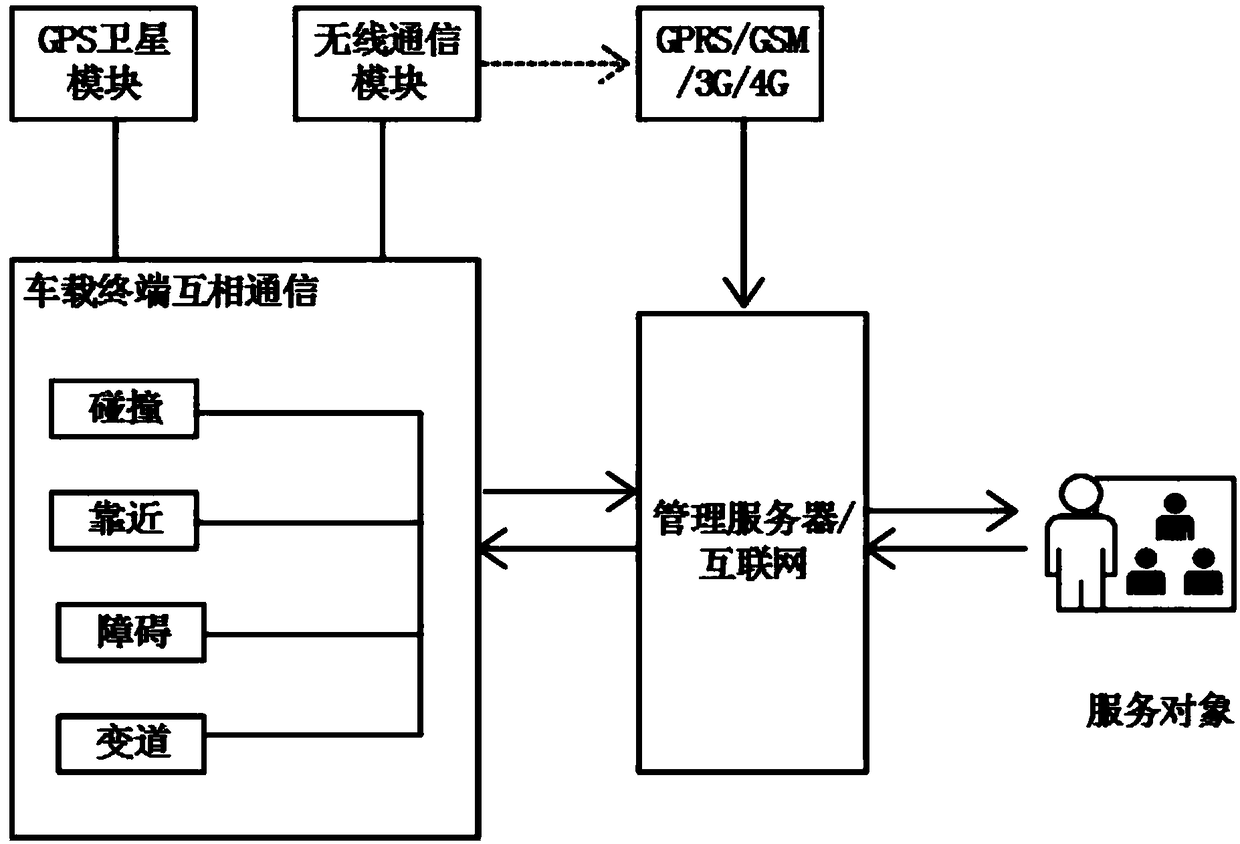

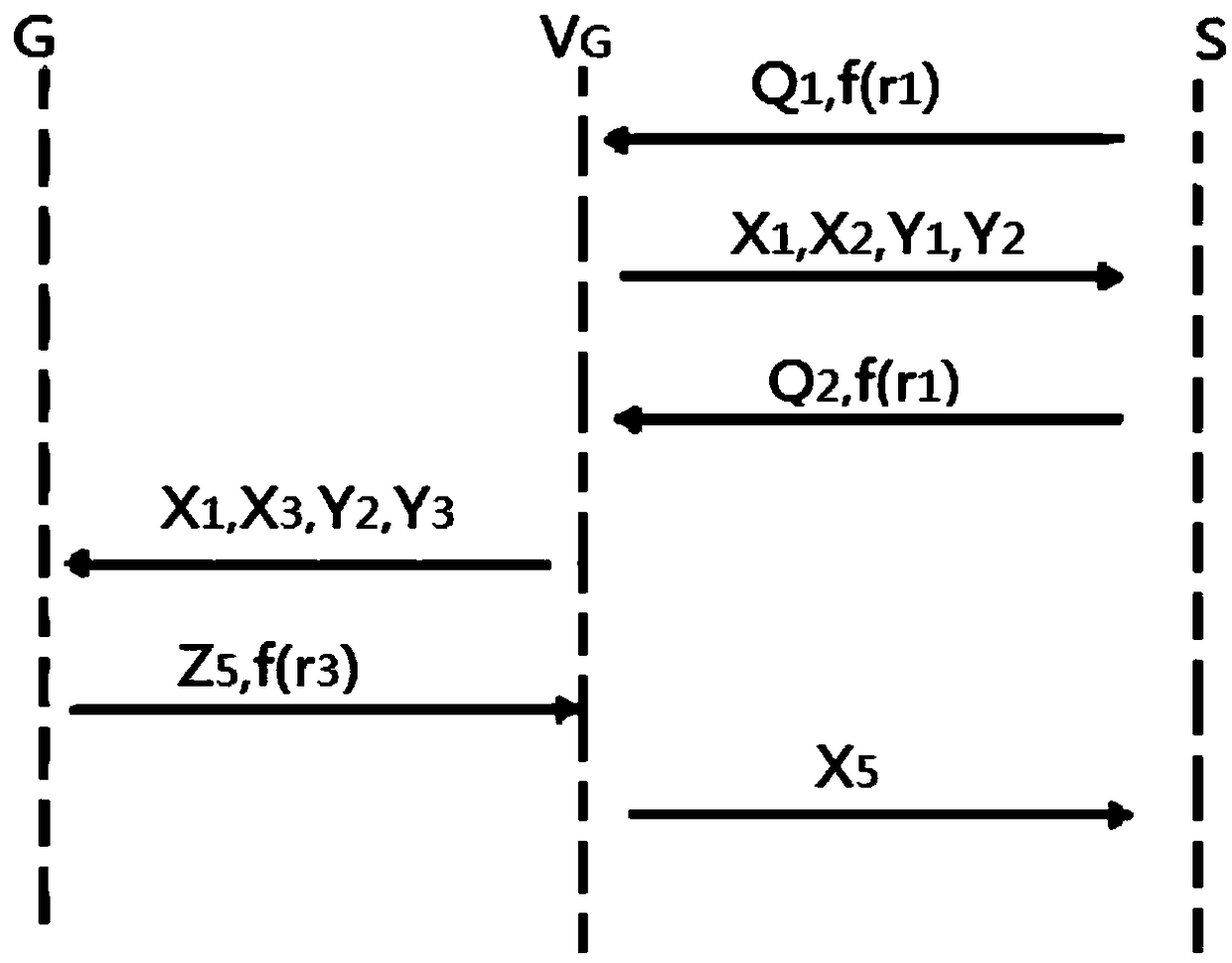

PUF-based lightweight IOV (Internet of Vehicles) system security authentication method

InactiveCN109245904AFix bugsSolve problemsUser identity/authority verificationSecurity arrangementSecurity authenticationInformation security

The invention relates to a PUF-based lightweight IOV (Internet of Vehicles) system security authentication method, and belongs to the field of computer information security. The method comprises the following steps: (1), first analyzing the communication process in the two scenarios of a vehicle-mounted mobile Internet and an inter-vehicle network: the first scenario is communication between a vehicle and the Internet, and the second scenario is communication between the vehicles; (2), performing the security analysis of the protocols in the two scenarios, starting from the authentication encryption algorithm and protocol authentication process adopted in the protocols, and analyzing whether the two protocols can resist various security threats or not; (3), starting from the authenticationencryption algorithm in the protocol and the interaction process of a subject involved in the protocols, and analyzing the calculation amount of the protocols, storage requirements and communicationrequirements. The method can protect the interactive data from being easily stolen, and protect the interaction process from being easily attacked.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

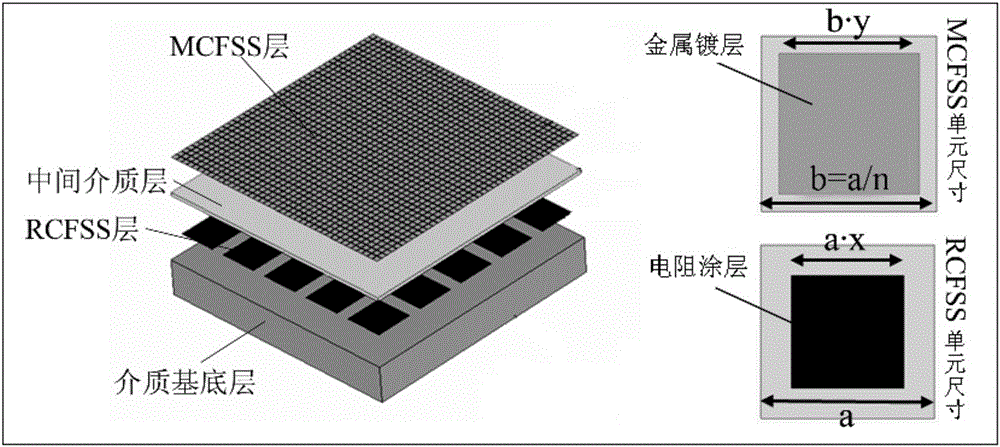

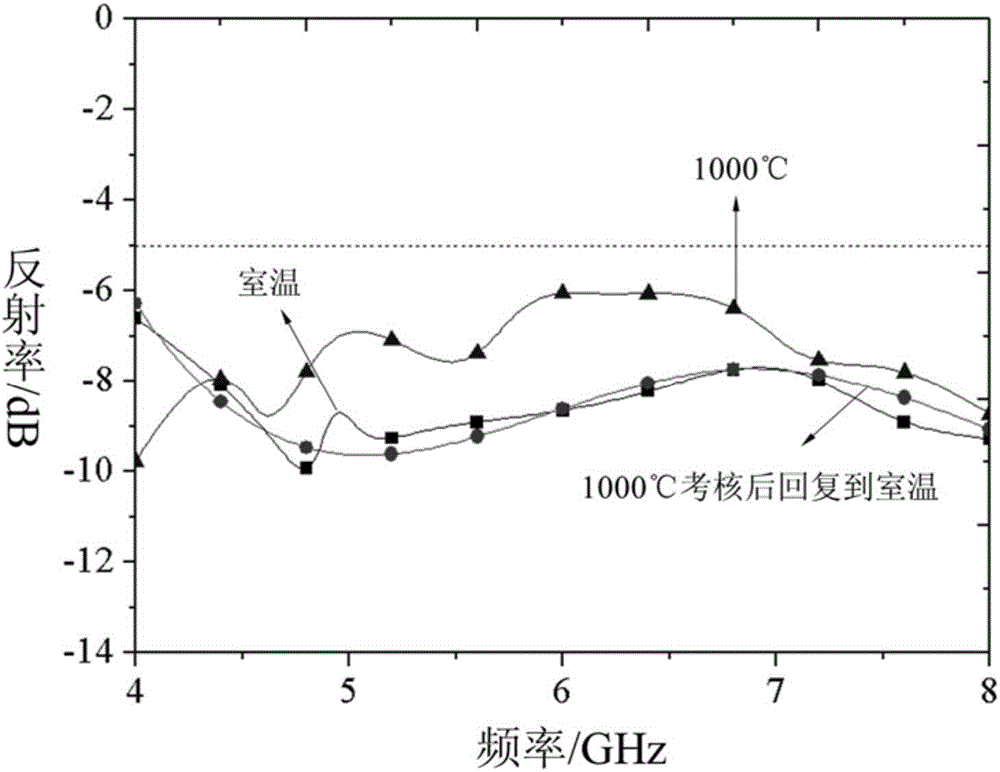

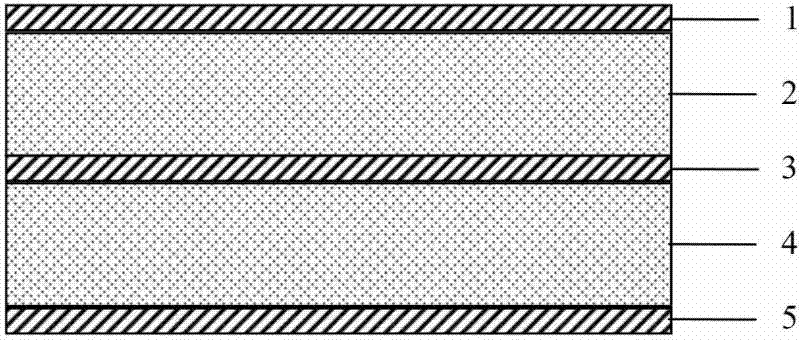

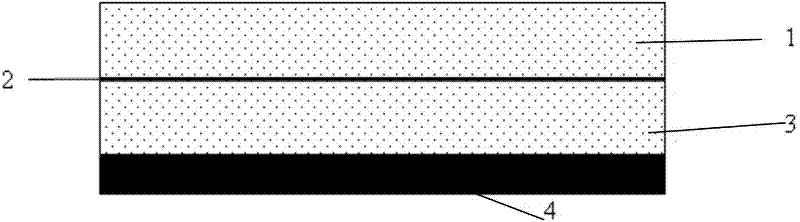

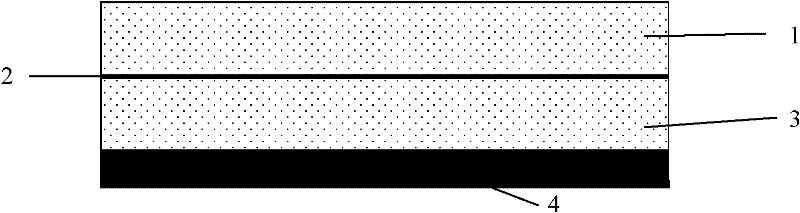

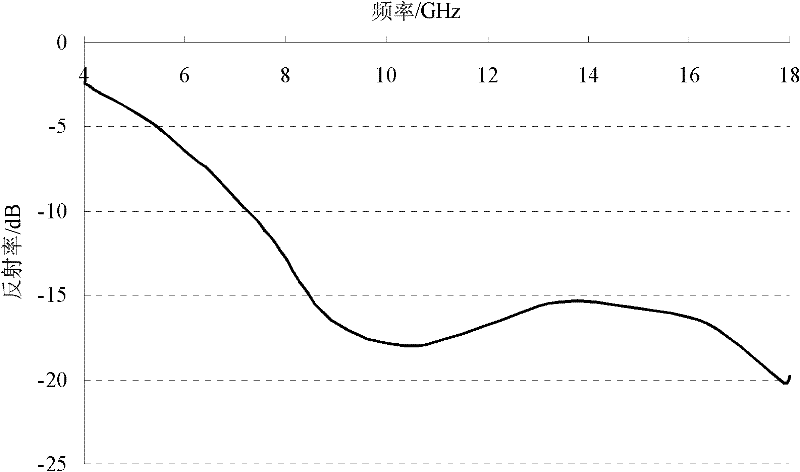

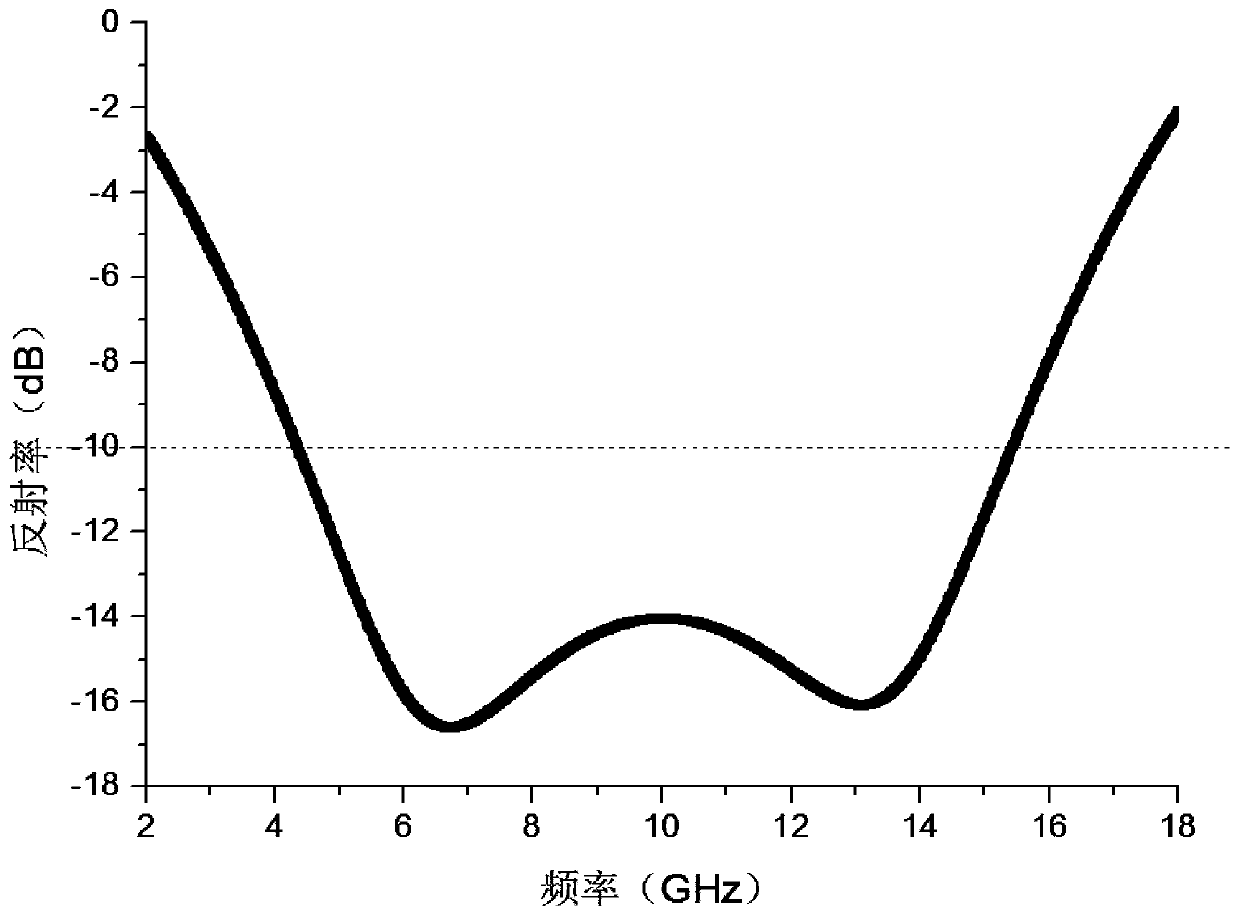

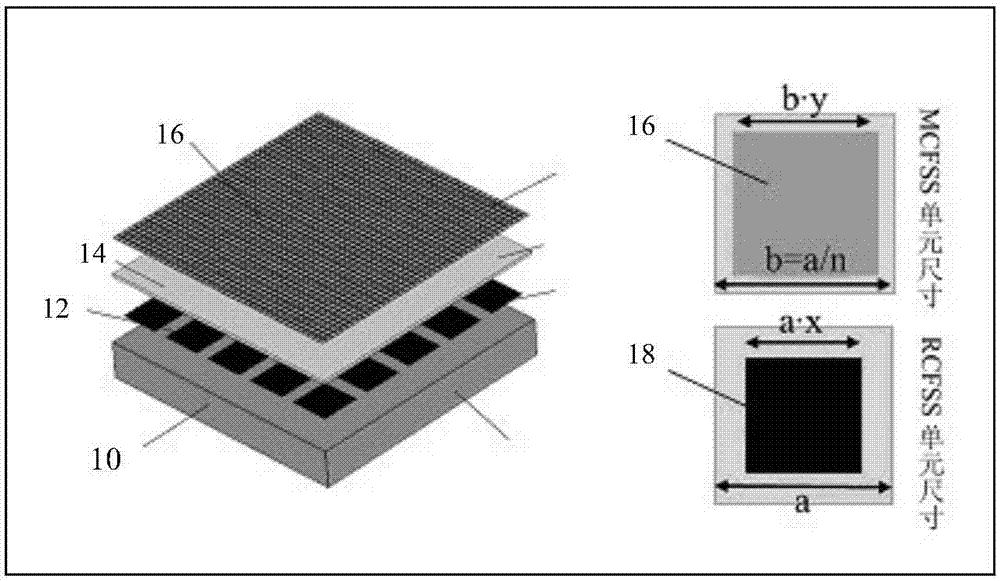

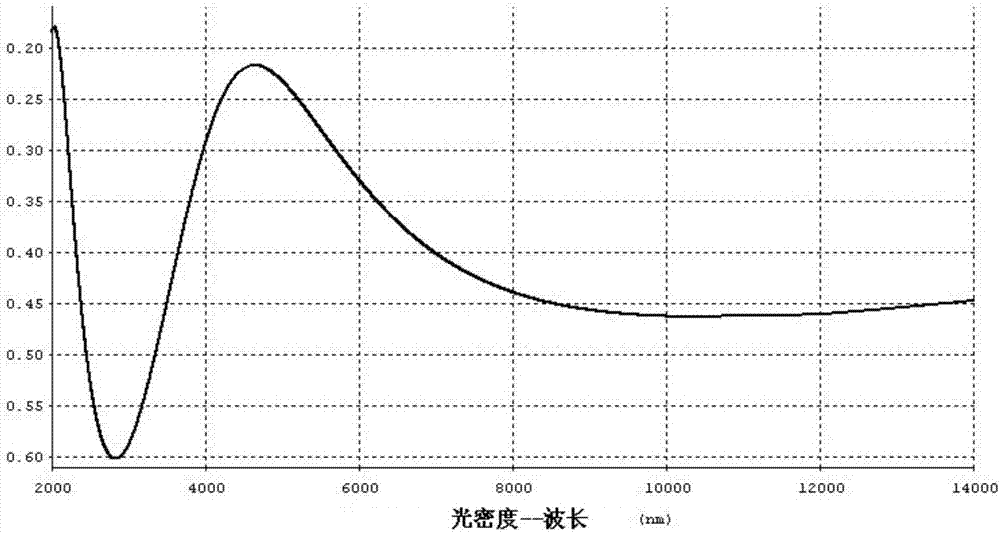

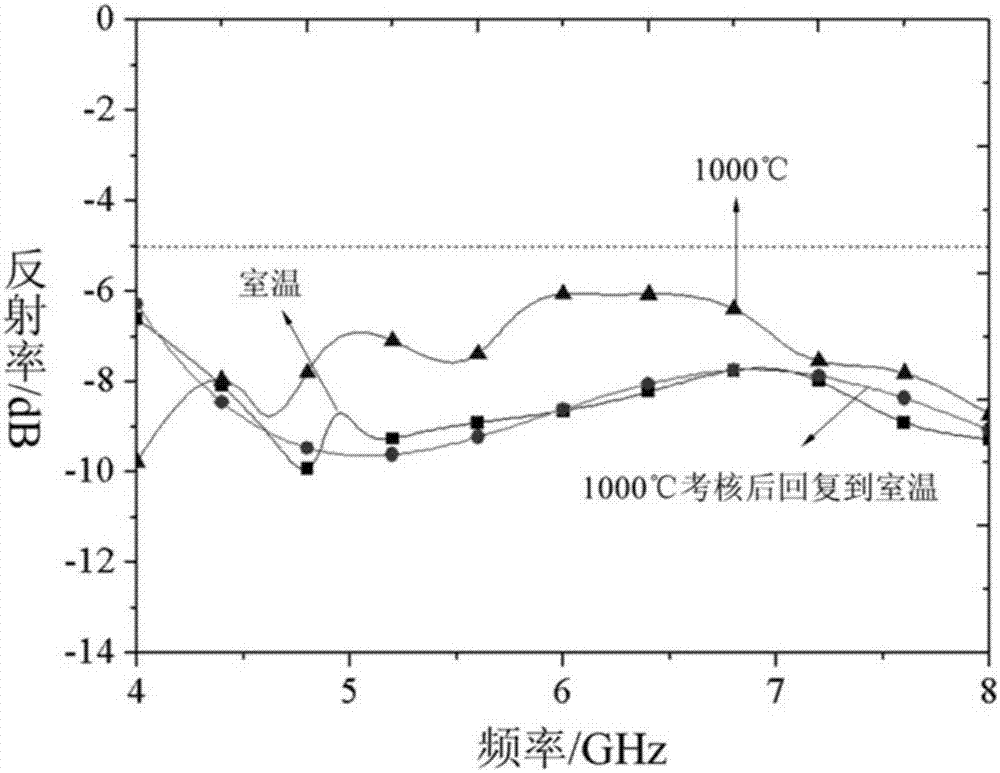

Radar and infrared compatible stealth material based double-layer frequency selective surface and preparation method of radar and infrared compatible stealth material

ActiveCN106007799AImprove high temperature resistanceImprove antioxidant capacityOther chemical processesDielectric substrateSelective surface

The invention discloses a radar and infrared compatible stealth material based on a double-layer frequency selective surface. The radar and infrared compatible stealth material adopts a layered structure and comprises a dielectric substrate layer, a resistor type capacitive frequency selective surface layer, an intermediate dielectric layer and a metal type capacitive frequency selective surface layer from inside to outside sequentially. The preparation method comprises steps as follows: the dielectric substrate layer is selected and prepared firstly, and the resistor type capacitive frequency selective surface layer is prepared on the dielectric substrate layer with a silk-screen printing technology; then the intermediate dielectric layer is prepared on the resistor type capacitive frequency selective surface layer with a brush-coating technology; finally, a metal plating film is prepared on the intermediate dielectric layer with a physical deposition technology, the frequency selective surface is prepared from the metal plating film through etching with a laser technology, and the radar and infrared compatible stealth material is prepared. The high-temperature-resistant radar and infrared compatible stealth material can be resistant to high temperature of at least 1,000 DEG C or higher, and has better high temperature resistance and excellent oxidation resistance.

Owner:NAT UNIV OF DEFENSE TECH

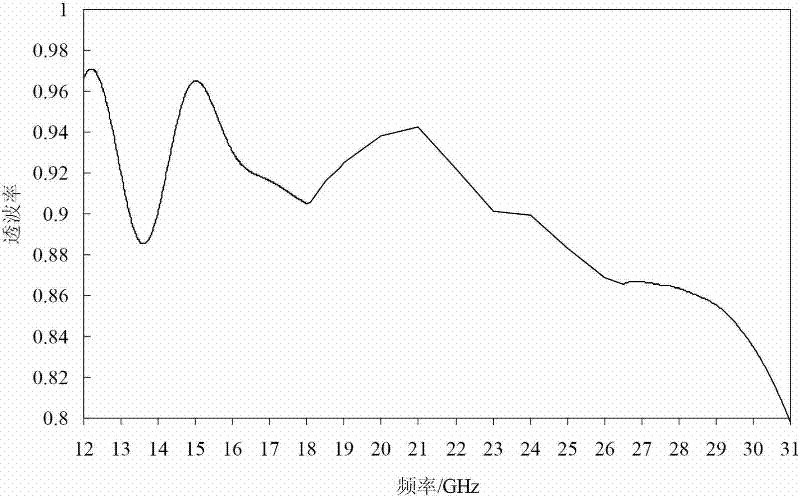

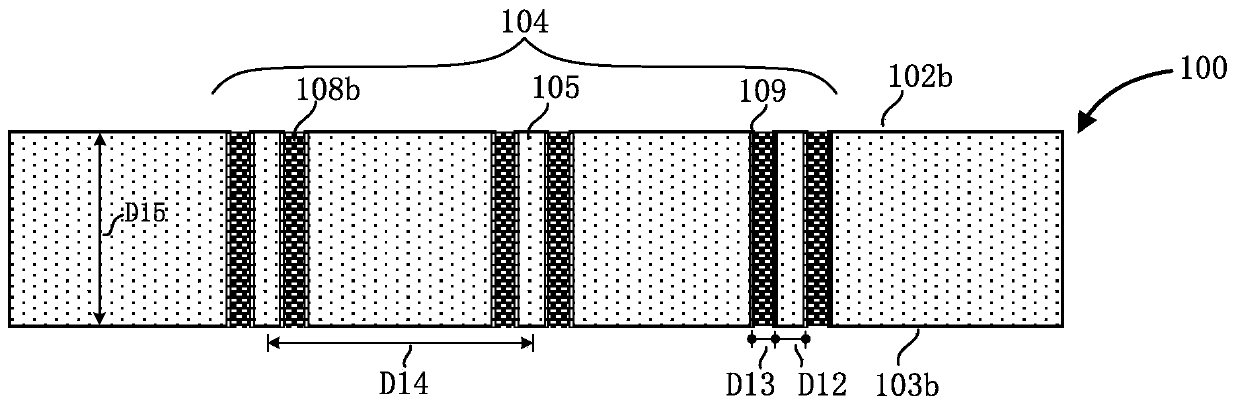

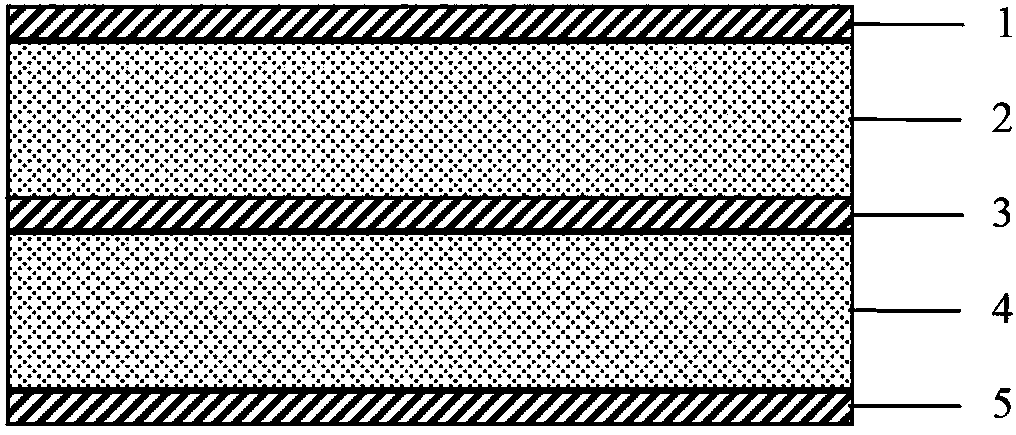

Wave-transmitting material with broadband resin matrix interlayer structure and preparation method of wave-transmitting material

ActiveCN102303441AImprove toughnessHigh strengthSynthetic resin layered productsPolymer scienceResin matrix

The invention discloses a wave-transmitting material with a broadband resin matrix interlayer structure and a preparation method of the wave-transmitting material. The wave-transmitting material comprises an outer skin layer, a first foam sandwich layer, a middle skin layer, a second foam sandwich layer and an inner skin layer which are sequentially overlapped and tightly combined, wherein the outer skin layer, the middle skin layer and the inner skin layer are made of continuous quartz fibre reinforced resin-base composite materials; the first foam sandwich layer and the second foam sandwich layer are made of polyurethane foams, the outer skin layer, the middle skin layer and the inner skin layer have dielectric constants of 3.1-3.2 and loss angle tangent values of 0.009-0.01; and the first foam sandwich layer and the second foam sandwich layer have dielectric constants of 1.10-1.15 and loss angle tangent values of 0.005-0.006. The preparation method comprises the steps of: preparing reinforced materials, and laying the reinforced materials according to the layering order and the thickness of each layer, pre-forming and curing to obtain the wave-transmitting material. The wave-transmitting material has the advantages of simple structure and high cost performance.

Owner:NAT UNIV OF DEFENSE TECH

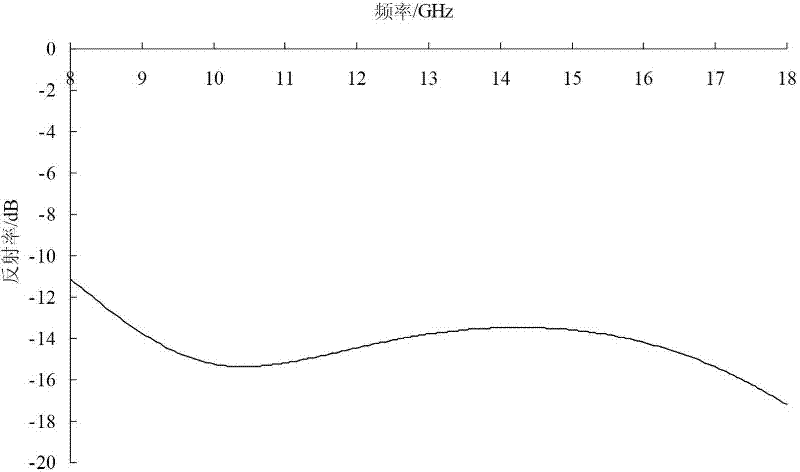

Wave-absorbing material for assorted fibre reinforced resin base sandwich structure and preparation method thereof

ActiveCN102218867AImprove toughnessHigh strengthSynthetic resin layered productsCarbon fibersResin-Based Composite

The invention discloses a wave-absorbing material for an assorted fibre reinforced resin base sandwich structure and a preparation method thereof. The wave-absorbing material has a multi-functional layer laminated structure. The structure comprises a first medium layer, an absorbing layer, a second medium layer and a reflection layer in sequence from the outside to the inside; the first medium layer consists of a basalt fibre reinforced resin base composite material; the absorbing layer consists of a continuous silicon carbide fibre reinforced resin base composite material; the second medium layer consists of a basalt fibre reinforced resin base composite material; and the reflection layer consists of a carbon fibre reinforced resin base composite material. The preparation method for the wave-absorbing material comprises the steps as follows: various fibres satisfying each functional layer are selected firstly; and then the resin is used as a basal body and the wave-absorbing materialis manufactured by adopting a resin base composite material forming technique according to the laminated sequence and thickness of each functional layer. The wave-absorbing material has the advantages of simple structure, good parameter tolerance level, easy forming, excellent wave-absorbing functions, low material cost, etc.

Owner:NAT UNIV OF DEFENSE TECH

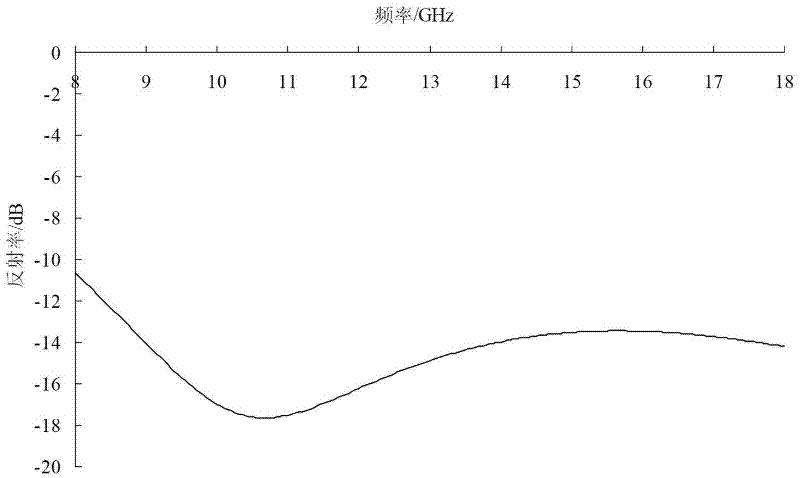

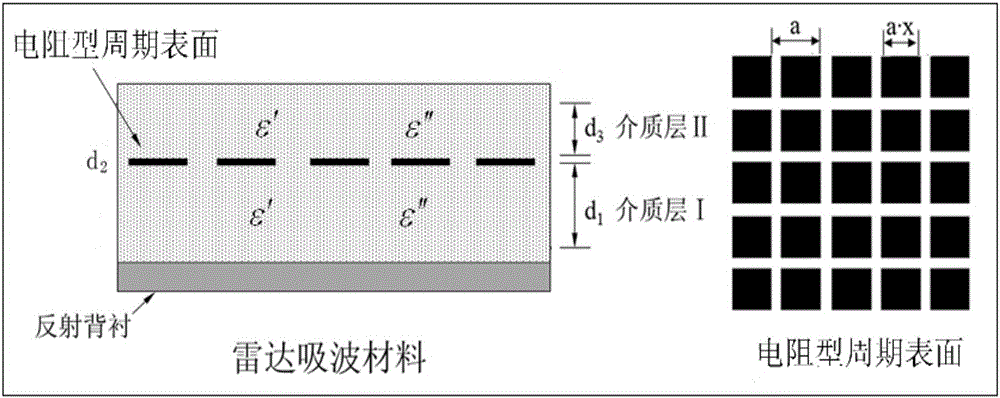

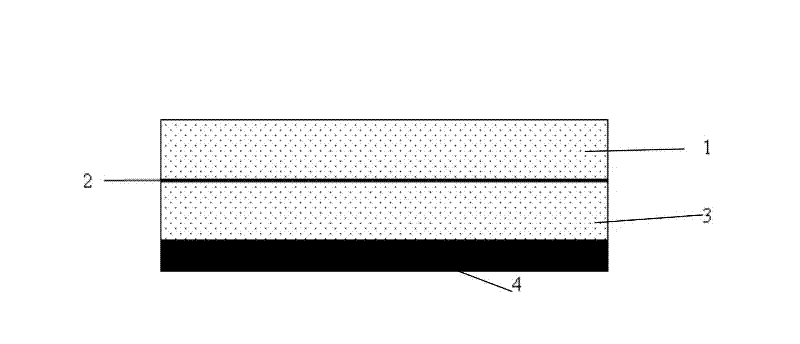

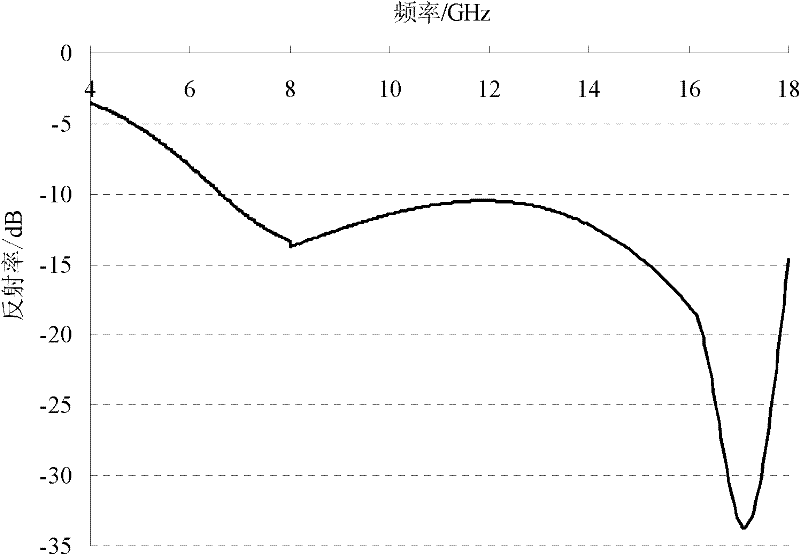

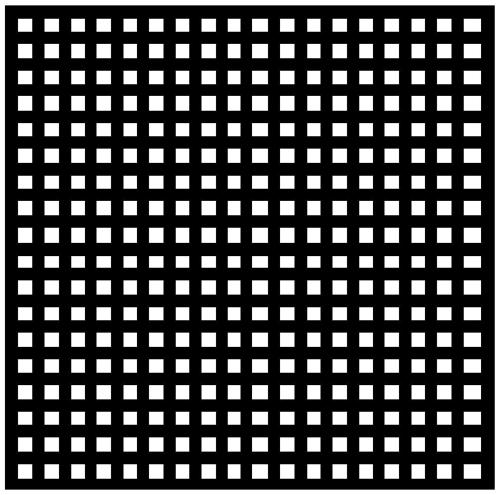

Sandwich-structure high-temperature-resistant radar wave-absorbing material and preparation method thereof

ActiveCN106042515AImprove high temperature resistanceImprove antioxidant capacityLaminationLamination apparatusFiberScreen printing

The invention discloses a sandwich-structure high-temperature-resistant radar wave-absorbing material which sequentially comprises a dielectric layer I, a resistance-type periodic surface layer and a dielectric layer II from inside to outside, wherein the dielectric layer I and the dielectric layer II are made of an oxide fiber reinforced oxide based composite material; and the resistance-type periodical surface layer is composed of a high-temperature-resistant resistance coating with a periodic pattern. A preparation method comprises the following steps: preparing the composite material of the dielectric layer I and the high-temperature-resistant resistance coating; printing the high-temperature-resistant resistance coating on the composite material of the dielectric layer I by a screen printing technique, conducting drying and sintering to form the resistance-type periodic surface layer on the surface of the composite material of the dielectric layer I; and laying the composite material of the dielectric layer II on the surface of the resistance-type periodic surface layer to prepare the high-temperature-resistant radar wave-absorbing material. The high-temperature-resistant radar wave-absorbing material can resist the high temperature of at least 1000 DEG C, and has the advantages of favorable high-temperature resistance and excellent oxidation resistance.

Owner:NAT UNIV OF DEFENSE TECH +1

Hybrid fiber reinforced resin matrix sandwich structural absorbing material and its preparation method

ActiveCN102229267AImprove toughnessHigh strengthSynthetic resin layered productsGlass/slag layered productsGlass fiberCarbide silicon

The invention discloses a hybrid fiber reinforced resin matrix sandwich structural absorbing material and its preparation method. The absorbing material has a multifunctional laminated structure from the outside to the inside comprising a first dielectric layer, an absorbed layer, a second dielectric layer and a reflecting layer, wherein the first dielectric layer and the second dielectric layer are both composed of a glass fiber reinforced resin matrix composite material; the absorbed layer is composed of a continuous silicon carbide fiber reinforced resin matrix composite material; and the reflecting layer is composed of a carbon fiber reinforced resin matrix composite material. The preparation method of the absorbing material comprises the following steps of: firstly, each kind of fiber that satisfies each functional layer is selected; secondly, with the resin as the matrix, according to the laminated order and thickness of each functional layer, the absorbing material provided by the invention is prepared by the resin matrix composite material molding technology. The absorbing material provided by the invention has advantages of simple structure, good parameter tolerance, excellent wave absorbing function and low material cost, and furthermore is easy to mold.

Owner:NAT UNIV OF DEFENSE TECH

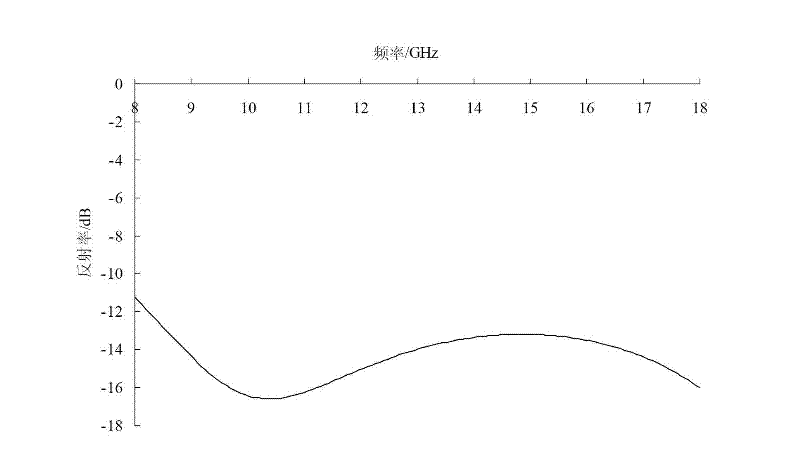

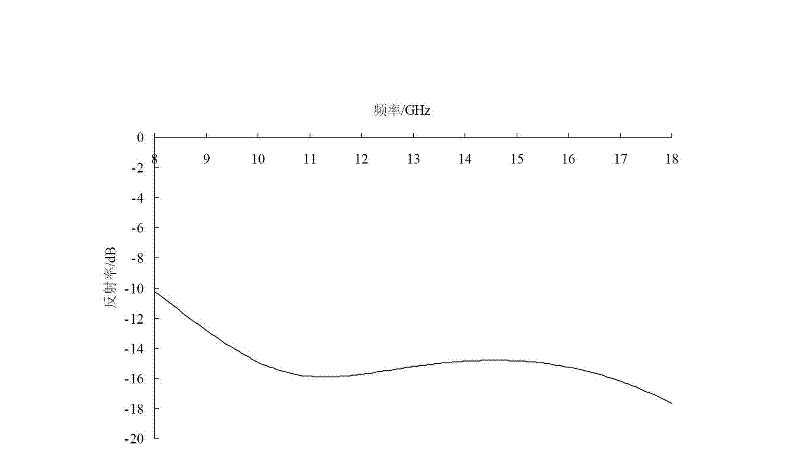

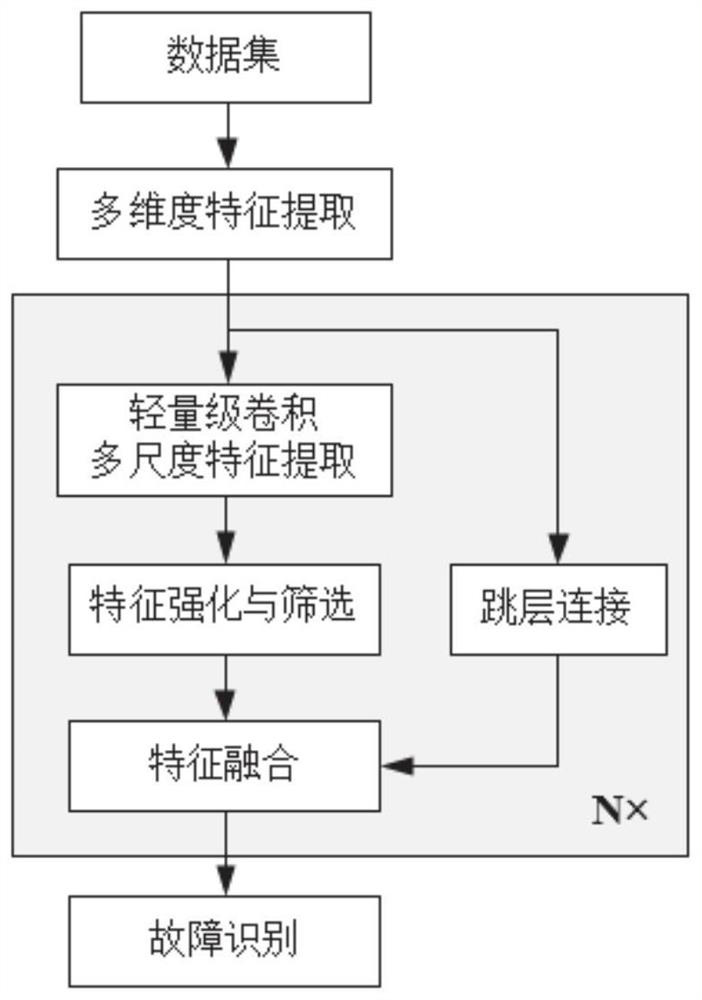

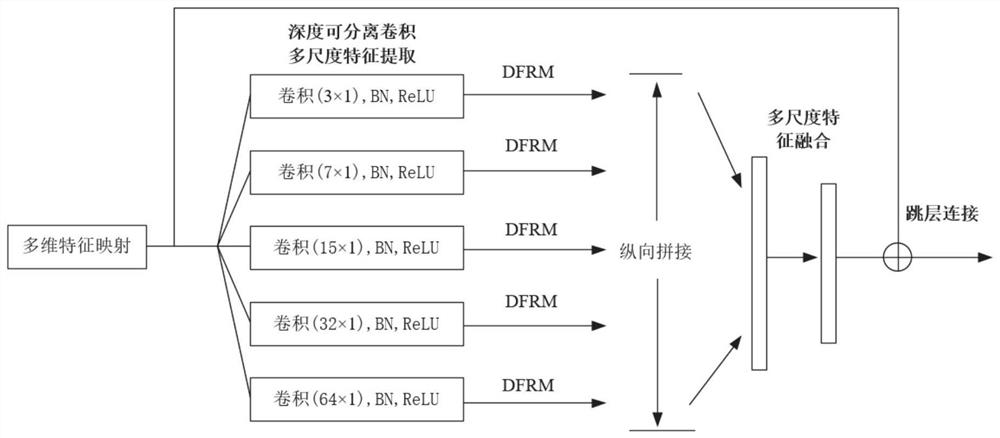

Rolling bearing fault diagnosis method based on enhanced lightweight multi-scale CNN

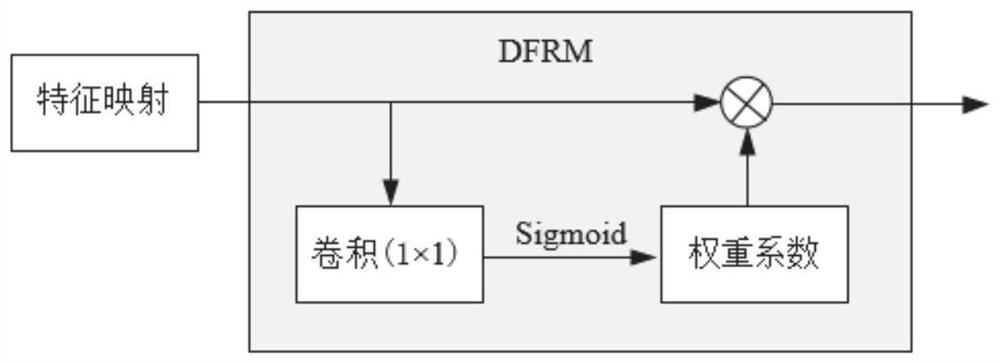

PendingCN112577748AAchieve lightweightOvercoming Suboptimal Diagnostic PerformanceMachine part testingCharacter and pattern recognitionFeature extractionAlgorithm

The invention provides a rolling bearing fault diagnosis method based on an enhanced lightweight multi-scale CNN. The method comprises the steps of: firstly carrying out multi-dimensional feature extraction on original vibration signals through a built CNN model; then inputting the original vibration signals into a lightweight multi-scale feature learning network to extract multi-scale features; carrying out selective enhancement on the learned multi-scale features by utilizing a discriminative fault feature enhancement mechanism (DFRM) so as to enhance fault features and weaken general features; fusing the enhanced multi-scale features; repeating the above steps for several times, mapping and inputting finally obtained high-level abstract features into a classifier for training; and finally performing fault identification on a to-be-detected sample according to the trained CNN model, thereby realizing fault diagnosis of a rolling bearing.; According to the method, the defect that a traditional CNN algorithm is insufficient in discriminative fault feature extraction capacity under the conditions of complex working conditions and strong noise interference is overcome, and the lightweight requirement of the industrial Internet of Things for a deep learning model is met.

Owner:SOUTHEAST UNIV

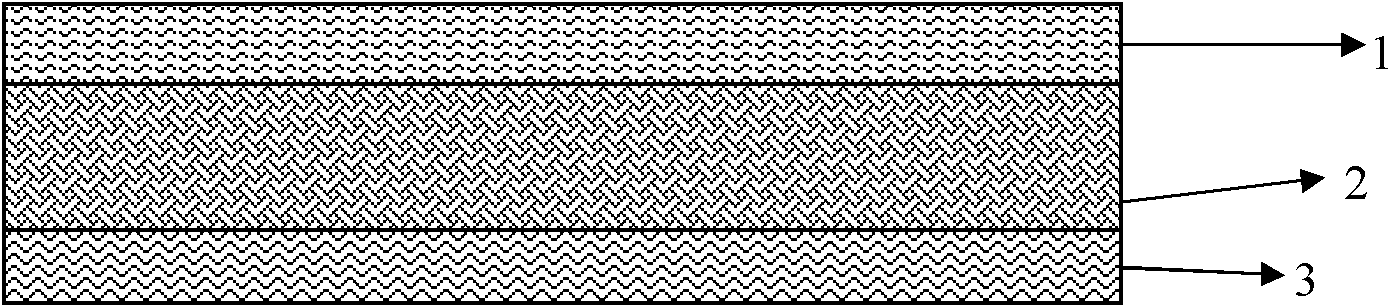

Wave-absorbing material for silicon carbide fibre reinforced resin base sandwich structure and preparation method thereof

ActiveCN102218868AImprove toughnessHigh strengthSynthetic resin layered productsResin-Based CompositeMedia layer

The invention discloses a wave-absorbing material for a silicon carbide fibre reinforced resin base sandwich structure and a preparation method thereof. The wave-absorbing material has a multi-functional layer laminated structure. The structure comprises a first medium layer, an absorbing layer, a second medium layer and a reflection layer; all the functional layers consist of a continuous silicon carbide fibre reinforced resin base composite material; and the continuous silicon carbide fibres serving as the reinforcing materials in each functional layer have different specific resistances. The preparation method for the wave-absorbing material comprises the steps as follows: the continuous silicon carbide fibres are selected firstly and woven into plain cloth; and then the resin is used as a basal body and the wave-absorbing material is manufactured by adopting a resin base composite material forming technique according to the laminated sequence and thickness of each functional layer. The wave-absorbing material has the advantages of simple structure, good parameter tolerance level, easy forming, excellent wave-absorbing functions, etc.

Owner:NAT UNIV OF DEFENSE TECH

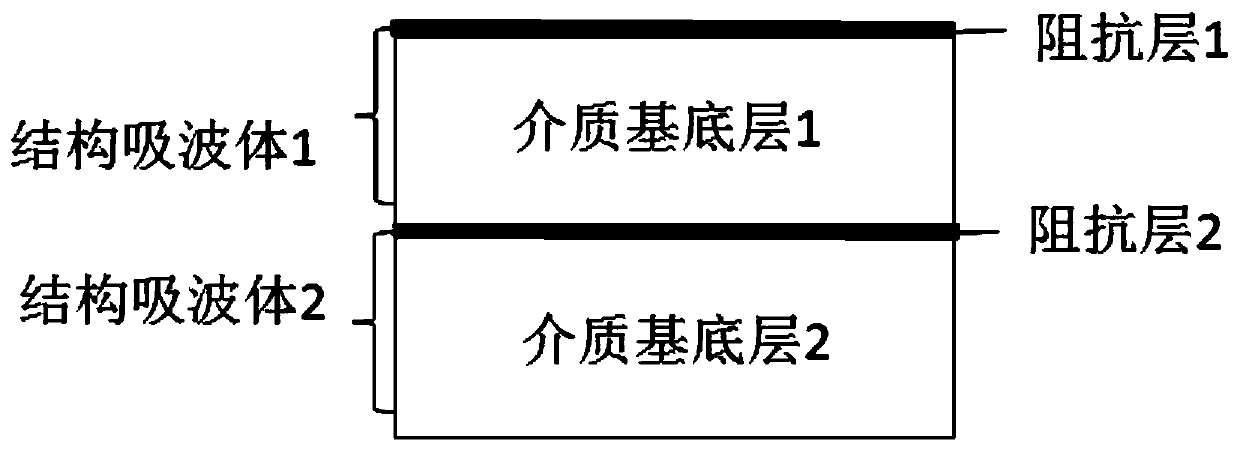

Metal coating-based high temperature-resistant structural wave absorbing material and preparation method thereof

ActiveCN109720027AImprove high temperature resistanceImprove antioxidant capacityVacuum evaporation coatingSputtering coatingFiberMetal coating

The invention discloses a metal coating-based high temperature-resistant structural wave absorbing material and a preparation method thereof. The high temperature-resistant structural wave absorbing material is formed by coating a structural wave absorbing body with a high temperature-resistant fiber cloth; the structural wave absorbing body is formed by a group of structural wave absorbing body units or is formed by laminating two or more structural wave absorbing body units; and every structural wave absorbing body unit comprises a dielectric substrate layer and an impedance layer on the surface of the dielectric substrate layer. The preparation method comprises the following steps: sputtering a high temperature-resistant metal material onto the surface of the high temperature-resistantfiber cloth by using a magnetron sputtering process to obtain the impedance layer; covering the surface of the dielectric substrate layer with the impedance layer to obtain the group of structural wave absorbing units; and coating the group of structural wave absorbing body units or the plurality of laminated structural wave absorbing body units with the high temperature-resistant fiber cloth, andperforming stitching to obtain the high temperature-resistant structural wave absorbing material being able to withstand a high temperature of 700 DEG C or above, having good resistance to the high temperature and oxidation and having a wide wave absorbing bandwidth.

Owner:CENT SOUTH UNIV

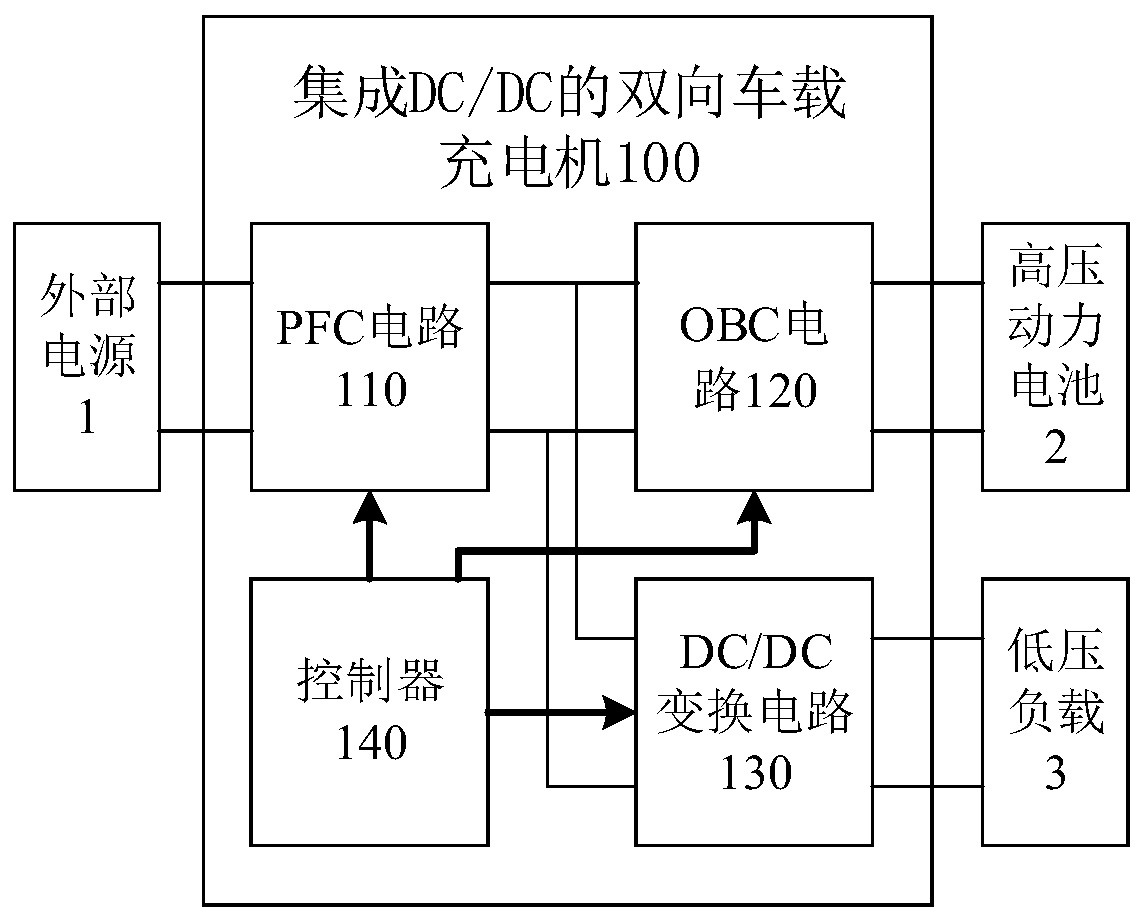

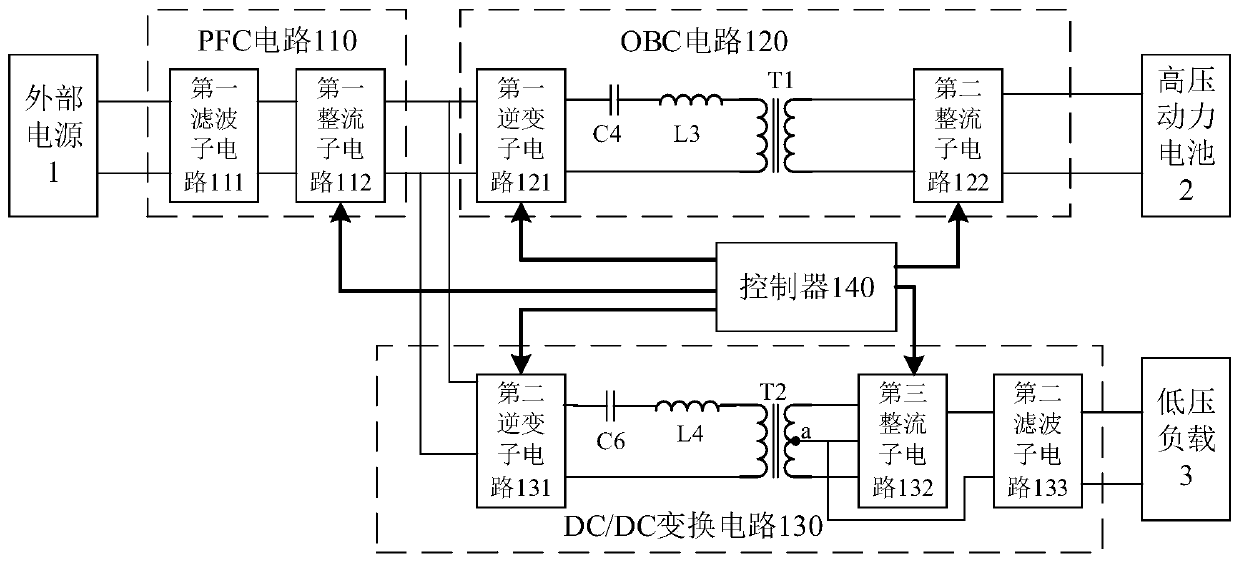

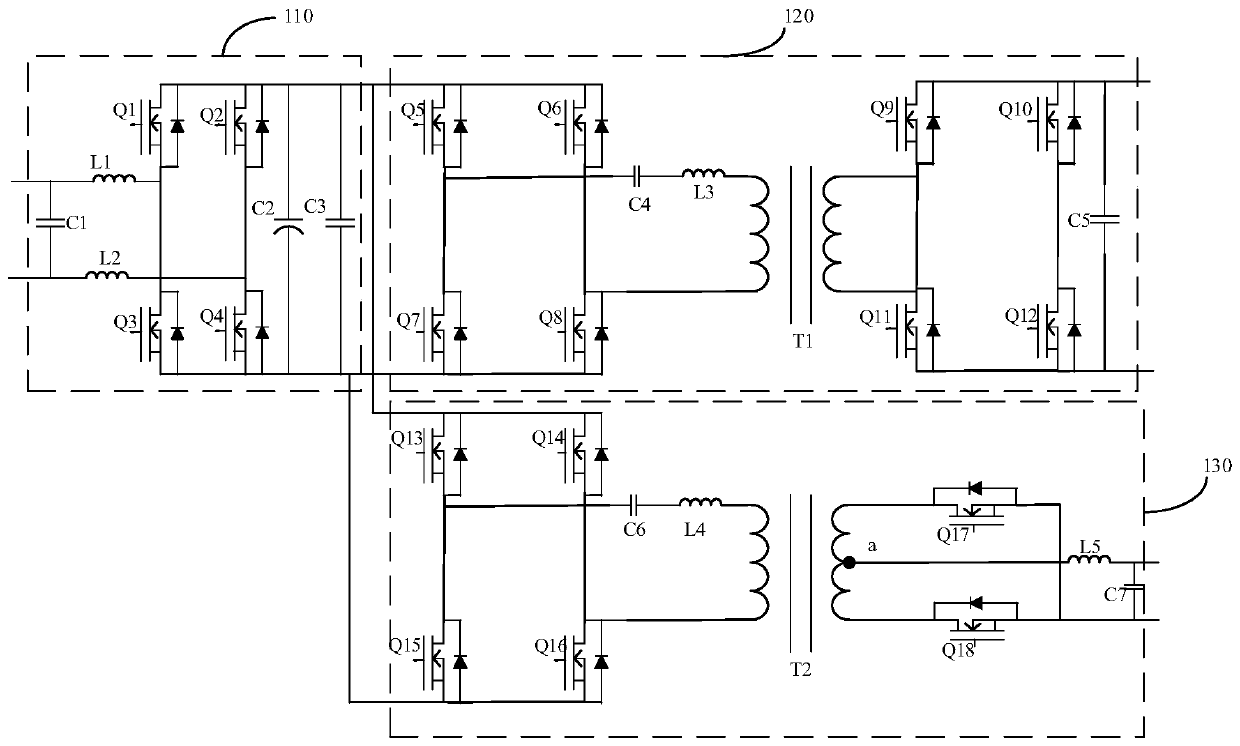

Bidirectional vehicle-mounted battery charger integrated with DC/DC and electric vehicle

InactiveCN110356269AImprove conversion efficiencyRealize energy transferCharging stationsDc-dc conversionPower batteryElectrical battery

The invention provides a bidirectional vehicle-mounted battery charger integrated with DC / DC and an electric vehicle. The bidirectional vehicle-mounted battery charger integrated with the DC / DC comprises a PFC circuit, a OBC circuit, a DC / DC conversion circuit and a controller, wherein the input end of the PFC circuit is used for being connected with an external power supply, the input end of theOBC circuit is connected with the output end of the PFC circuit, the output end of the PFC circuit is used for being connected with a high-voltage power battery of the electric vehicle, the input endof the DC / DC conversion circuit is connected with the output end of the PFC circuit, the output end of the DC / DC conversion circuit is used for being connected with the low-voltage load of the electric vehicle, the controller is correspondingly connected with the PFC circuit, the OBC circuit and the DC / DC conversion circuit, and is used for correspondingly controls the PFC circuit, the OBC circuitand the DC / DC conversion circuit to achieve energy transmission among the external power supply, and the high-voltage power battery and the low-voltage load. The bidirectional vehicle-mounted batterycharger integrated with the DC / DC is light in weight, high in DC / DC conversion efficiency, and an inverter discharging function is achieved.

Owner:宝能(广州)汽车研究院有限公司

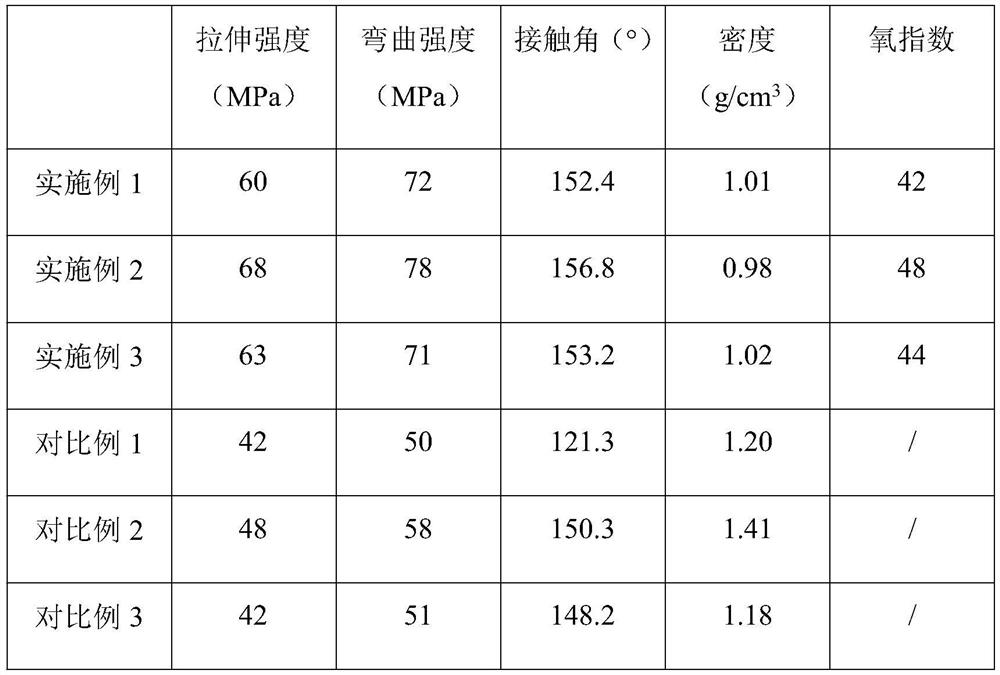

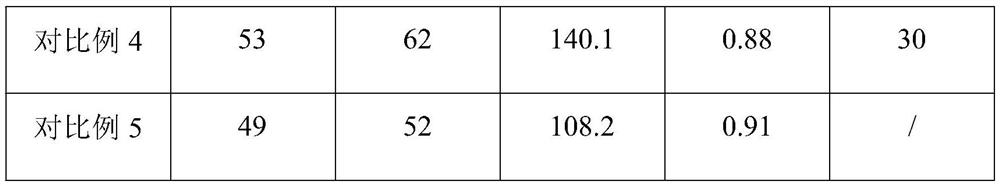

High-strength wear-resistant composite fender and processing technology thereof

ActiveCN114395166AHigh product strengthStrong waterproof and antifouling abilityClimate change adaptationInksLow-density polyethylenePolymer science

According to the high-strength wear-resistant composite fender and the processing technology thereof provided by the invention, the weight of the high-strength wear-resistant composite fender is reduced through limited added components and technological design, and the composite fender with high strength, good wear resistance and strong waterproof and anti-pollution capabilities is prepared; hydroxyl groups on the surface of the cellulose nanocrystal react with para-isocyanato of caprolactam to modify the cellulose nanocrystal, and caprolactam is adopted for end capping; the interface compatibility among the anionic polymerization nylon 6, the polypropylene and the hollow glass beads is improved through the modified cellulose nanocrystals, and the modified PP layer is prepared through a microcellular foaming injection molding process; the adding amount of the hollow glass beads is limited; low-density polyethylene, a fluorine-containing hyperbranched polymer, modified cellulose nanocrystals and polyphenylene sulfide are blended and extruded to obtain protective slurry, the two sides of the modified PP layer are coated with the protective slurry to form protective layers, the surface hydrophobicity of the composite fender is improved, the composite fender has the anti-fouling and waterproof functions, and the service life of the composite fender is greatly prolonged.

Owner:CHANGZHOU NANGUA VEHICLE PARTS

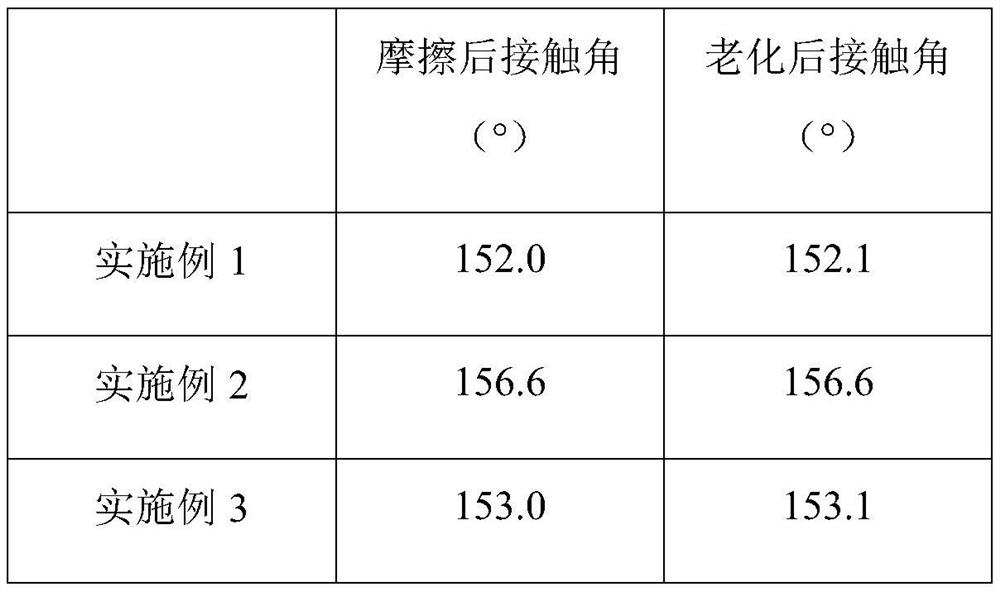

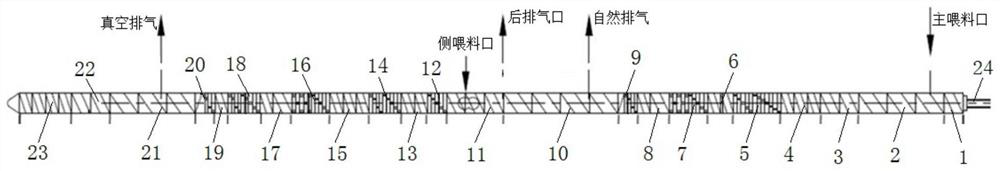

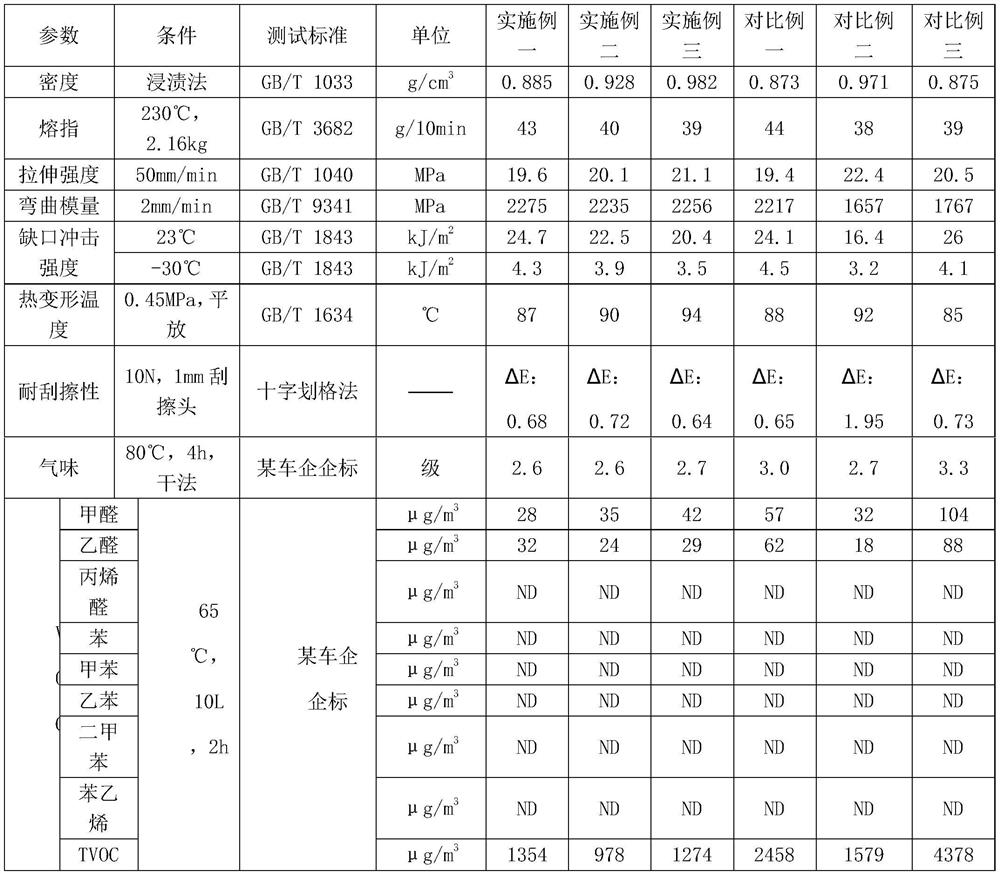

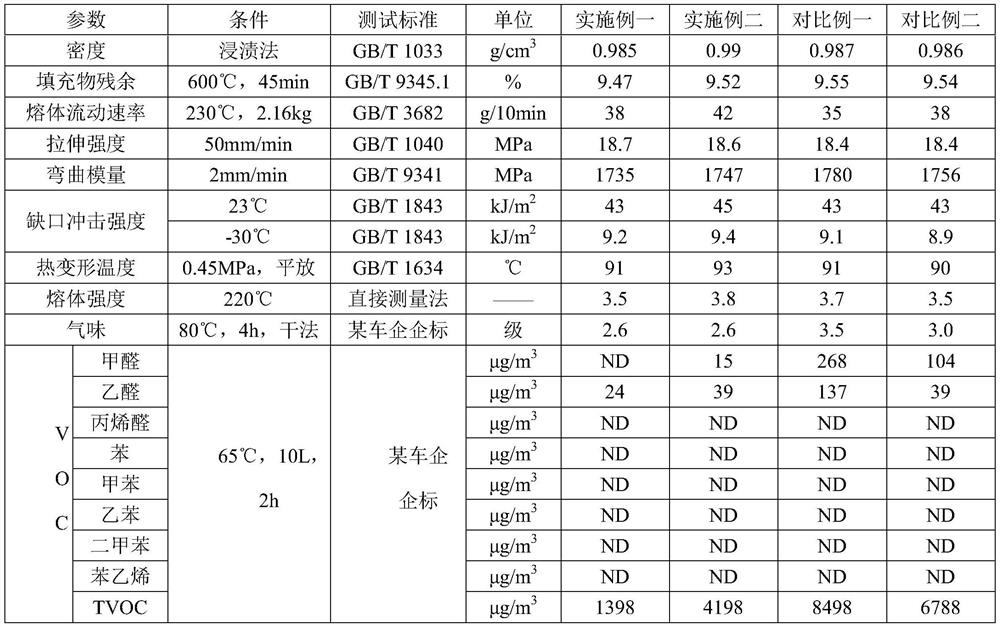

Low-density and low-diffusivity polypropylene material and preparation method thereof

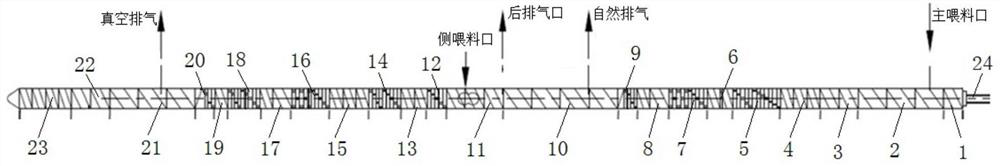

The invention discloses a polypropylene material with low density and low diffusivity. The polypropylene material comprises the following components in parts by weight: 70-90 parts of polypropylene resin, 0.1-10 parts of elastomer, 3-10 parts of filler, 1-5 parts of deodorant, 1-5 parts of assistant master batch and 1-2 parts of foaming agent, the alloy material has the advantages of favorable flowability, low density and higher rigidity and toughness, and can satisfy the performance requirements for thin-walled automotive upholstery. The invention also discloses a preparation method of the material. The preparation method comprises the following steps: S1, weighing raw materials; S2, conveying polypropylene resin and an elastomer into a double-screw extruder through a main feeding assembly, uniformly mixing a deodorant and the auxiliary master batch, conveying the mixture into the double-screw extruder through an auxiliary feeding assembly, conveying a filler into the double-screw extruder through a side feeding assembly, mixing, melting, extruding, bracing, cooling and pelletizing to obtain an intermediate product; and S3, performing devolatilization treatment on the intermediateproduct to obtain the low-density and low-emission polypropylene material, and the preparation method is simple in process, easy in condition control and suitable for large-scale production.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

High-silicon aluminum alloy adapter plate and preparation method thereof

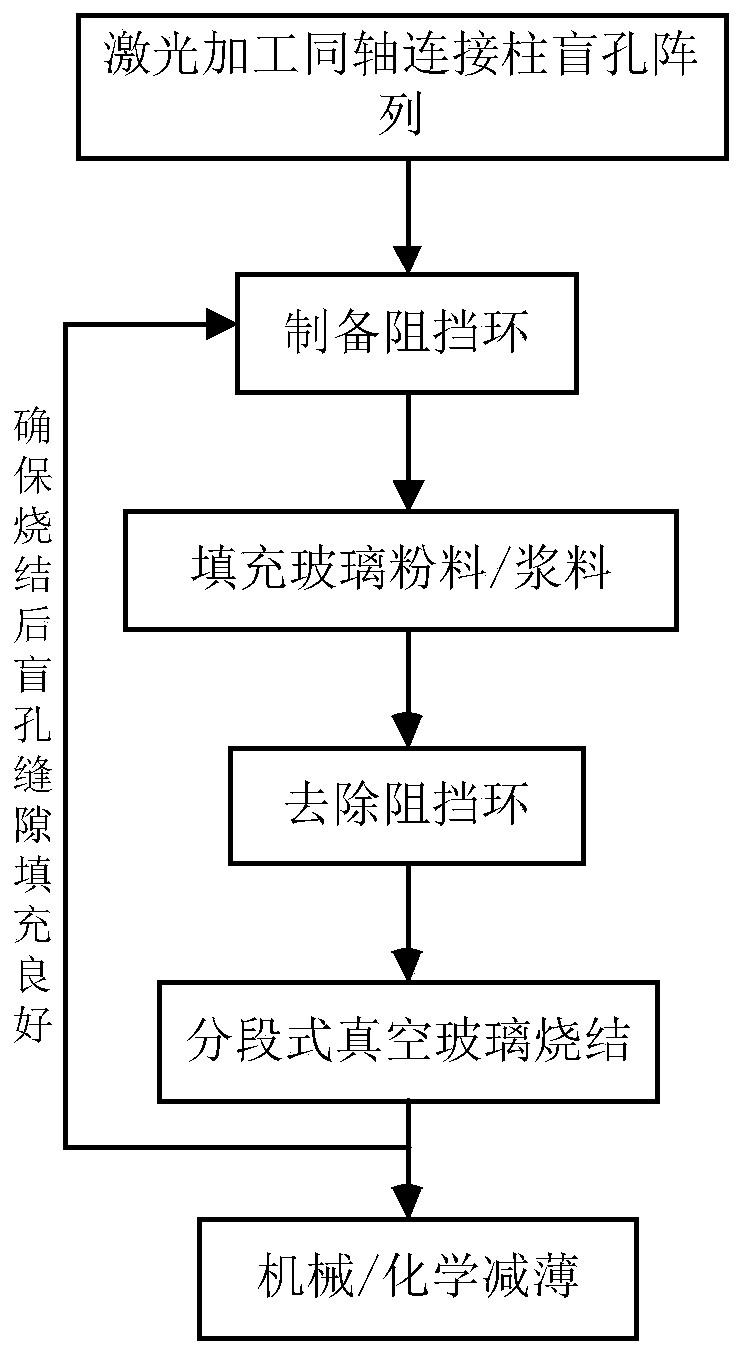

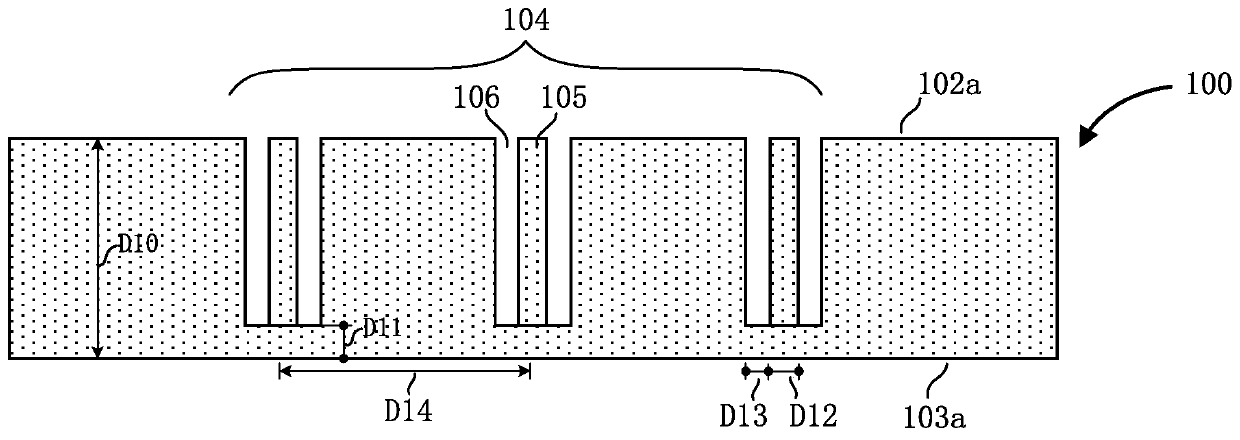

ActiveCN111081674AThe preparation process is simpleShorten production timeSemiconductor/solid-state device detailsSolid-state devicesAir tightnessDielectric layer

The invention discloses a high-silicon aluminum alloy adapter plate and a preparation method thereof. The adapter plate comprises a substrate, a connecting column array and an insulating dielectric layer filled in a gap between the connecting column array and the substrate, the connecting column array is formed by processing the substrate through a laser vertical through hole technology; the substrate and the connecting column array are made of high-silicon aluminum alloy, the insulating dielectric layer is made of a glass dielectric, connecting columns of the connecting column array are coaxial with the insulating dielectric layer, and the connecting columns, the glass dielectric and the substrate have the same height. The adapter plate prepared by adopting the method provided by the invention is firm and reliable in bonding interface and high in air tightness, and the blind hole center connecting column has electrical conductivity and can be directly used for electrical interconnection, so that a through hole metallization process can be omitted, the adapter plate preparation process flow is simplified, and the adapter plate preparation time and cost are reduced.

Owner:SHANGHAI SPACEFLIGHT ELECTRONICS & COMM EQUIP RES INST

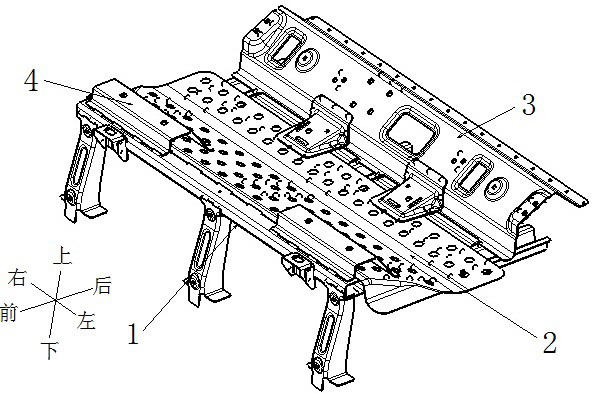

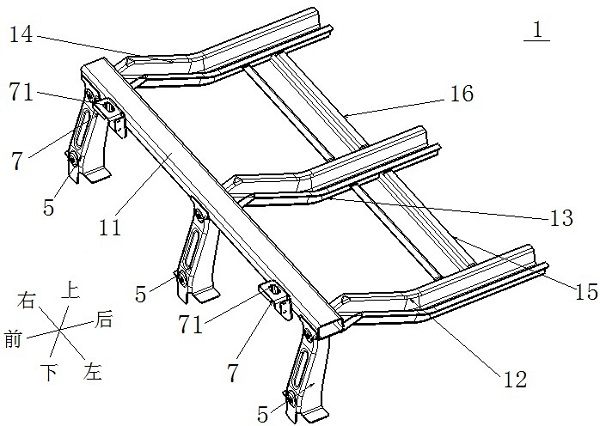

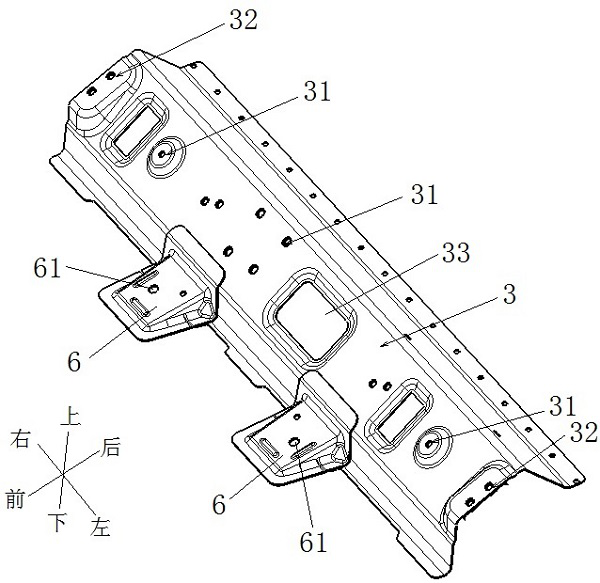

Light-weight rear-row seat mounting structure and vehicle

The invention discloses a light-weight rear-row seat mounting structure and a vehicle, and the structure comprises an aluminum alloy frame, a supporting panel, a reinforcing plate and an anti-descending support; the supporting panel is fixed to the surface of the aluminum alloy frame, the front end of the aluminum alloy frame is fixedly connected with the top ends of a plurality of supporting beams, and the bottom ends of the supporting beams are fixedly connected with a middle floor cross beam; the front edge of the reinforcing plate is fixedly connected with the rear portion of the aluminum alloy frame, the rear edge of the reinforcing plate is fixedly connected with the rear floor beam, and the reinforcing plate is provided with a plurality of first installation holes used for fixing a seat assembly; and the anti-descending support is fixedly connected with the upper side of the front edge of the aluminum alloy frame. Rigidity, strength and modality of a seat mounting point can be guaranteed, the weight of a mounting structure is greatly reduced, and universality is good.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD +1

Wave-transmitting material with broadband resin matrix interlayer structure and preparation method of wave-transmitting material

ActiveCN102303441BImprove toughnessHigh strengthSynthetic resin layered productsPolymer scienceResin matrix

Owner:NAT UNIV OF DEFENSE TECH

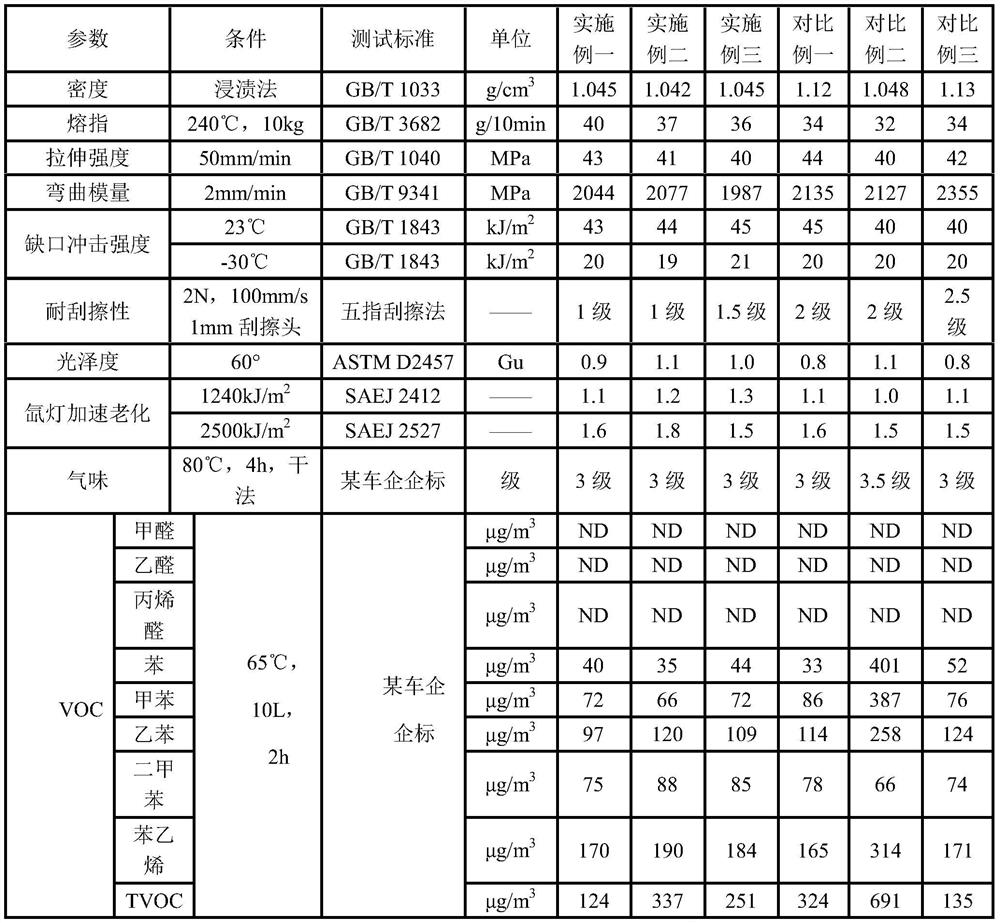

Matte low-density spraying-free material for automotive interiors and preparation method thereof

The invention discloses a matte low-density spraying-free material for automotive interiors. The matte low-density spraying-free material comprises the following components in percentage by weight: 10-40% of ASA high glue powder, 20-50% of polyamide resin, 5-25% of SAN resin, 5-10% of ASA-g-GMA resin, 3-10% of composite filler, 5-15% of auxiliary master batch, 1-5% of deodorant and 1-5% of anti-scratch additive. The composite filler comprises a silane modified filler and hollow glass beads; the diameter of the hollow glass beads is 15-100 microns, and the surfaces of the hollow glass beads aretreated by a silane coupling agent so that the hollow glass beads have relatively low odor and VOC, relatively low gloss, relatively good scratch resistance, weather resistance and processability andrelatively low material density. The invention further discloses a preparation method of the matte low-density spraying-free material for the automotive interiors, the process is simple, and large-scale production can be achieved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

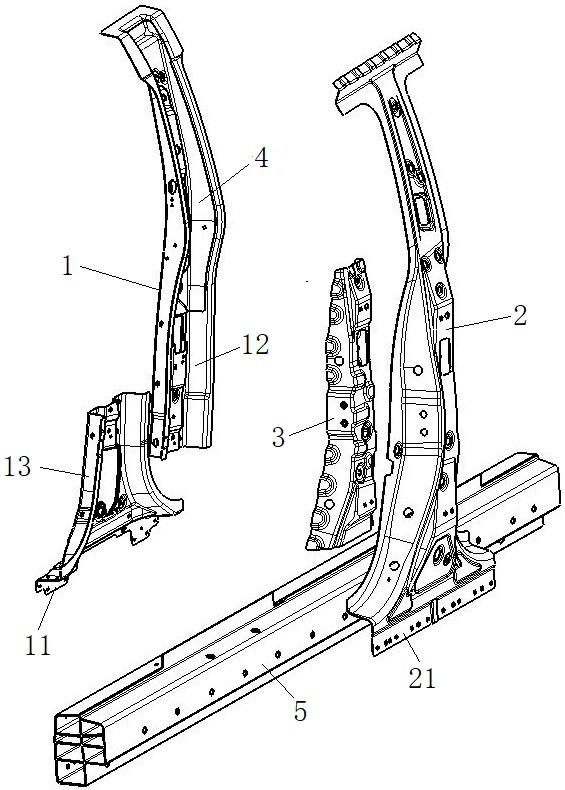

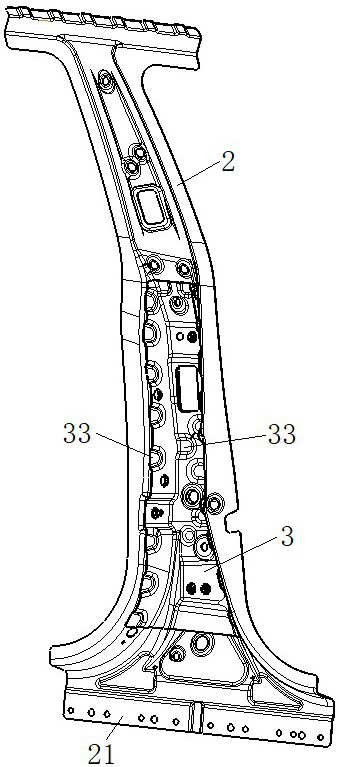

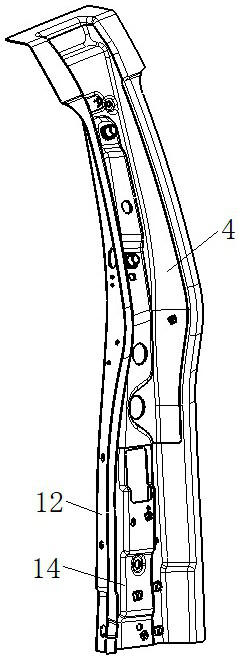

B-pillar structure of frameless vehicle door and vehicle

ActiveCN112896324AGuaranteed structural strengthGuaranteed energy absorptionSuperstructure subunitsSuperstructure connectionsSide impactCar door

The invention discloses a B-pillar structure of a frameless vehicle door and a vehicle, and the structure comprises a B-pillar body; the B-pillar body comprises a B-pillar inner plate and a B-pillar reinforcing piece, the transverse section of the B-pillar inner plate is in an n shape, an opening faces the B-pillar reinforcing piece, and the B-pillar inner plate and the B-pillar reinforcing piece define a cavity; a thermal forming patch plate is arranged on the side wall, close to the B-pillar reinforcing piece, of the upper portion of the B-pillar inner plate, the side wall, close to the B-pillar inner plate, of the lower portion of the B-pillar reinforcing piece is fixedly connected with a hinge reinforcing piece, and the upper portion of the hinge reinforcing piece and the lower portion of the thermal forming patch plate are partially overlapped in the radial direction. And the lower end of the B column body is riveted and fixed with an aluminum alloy doorsill boundary beam. The side impact performance of the B-pillar structure can be guaranteed, the problems that when a traditional B-pillar structure is applied to a frameless vehicle door, the strength is poor, the invasion amount of a B-pillar is large, and the B-pillar is bent are solved, and the safety performance of the whole vehicle is effectively improved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

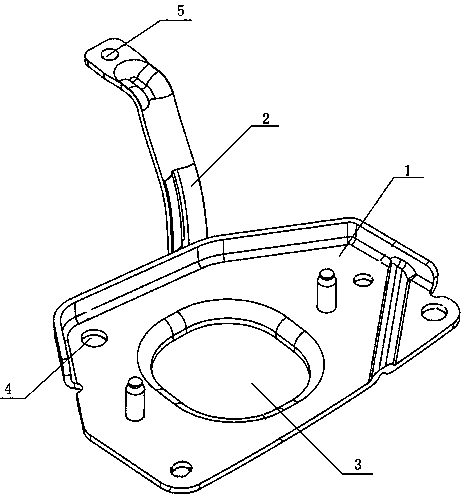

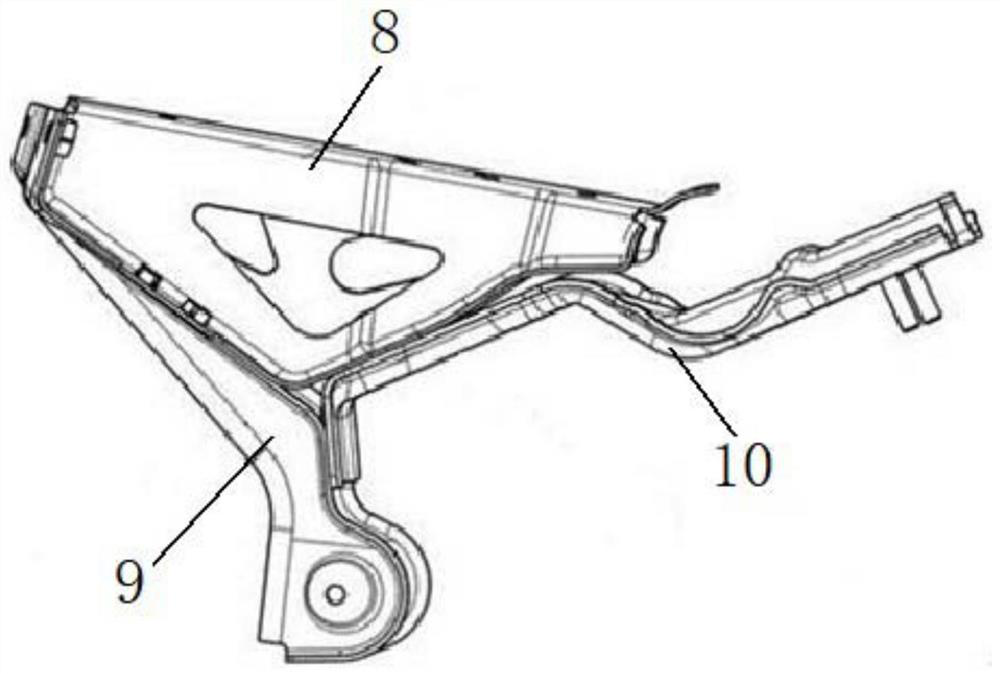

Lightweight stamping and welding type automobile engine suspension support

InactiveCN103448524AStable NVH characteristicsSimple structureJet propulsion mountingInternal combustion mountingNickel alloyUltimate tensile strength

The invention discloses a lightweight stamping and welding type automobile engine suspension support. The lightweight stamping and welding type automobile engine suspension support comprises a flat support body and an auxiliary support which is connected with the side edge of the support body by adopting stamping and welding, wherein the support body is provided with a hole which can be used for suspending an engine on the support body; the auxiliary support is divided into an upper section, a bending part and a lower section, the upper section and the lower section are connected through the bending part, and the bending angle of the auxiliary support is 90-135 degrees. According to the lightweight stamping and welding type automobile engine suspension support disclosed by the invention, stamping and welding of plates is adopted, compared with conventional cast iron manufacturing, the design, the disassembly and the assembly are convenient; lightweight requirements are met as the automobile engine suspension support is manufactured by adopting stamping and welding of metal plates of aluminum alloy, nickel alloy and the like which are in less mass and enough strength; low-cost development requirements of the automobile engine suspension support can be met on the premise that the load of weight of the engine is ensured to be borne by adjusting the size of the auxiliary support if the type of the engine is changed, NVH (Noise, Vibration and Harshness) characteristics of an automobile are facilitated to be stabilized, and dynamic / static state strength and fatigue life of the lightweight stamping and welding type automobile engine suspension support are prolonged.

Owner:奇昊汽车系统(苏州)有限公司

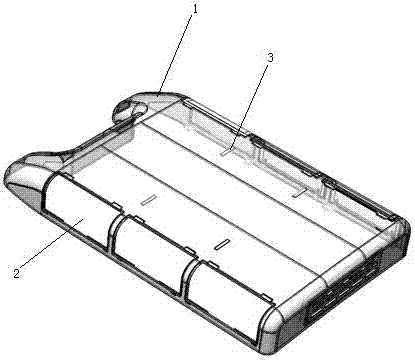

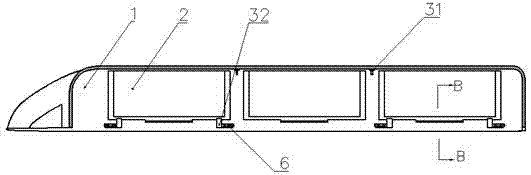

Lightening method of battery protective cover for electric buses and battery protective cover

InactiveCN107284217AReduce weightReduce manufacturing costElectric propulsion mountingSecondary cellsPolyvinyl chlorideElectrical and Electronics engineering

A lightening method of a battery protective cover for electric buses is provided. The battery protective cover includes a protective cover body, a maintenance door mounted on the protective cover body, and a connector for mounting and connecting the battery protective cover. The battery protective cover is characterized in that both the protective cover body and the maintenance door are made of a heat-insulating sandwich material, the heat-insulating sandwich material is composed of two fiber-reinforced plastic layers and a PVC (polyvinyl chloride) foam layer pasted between the two fiber-reinforced plastic layers, and the connector is embedded in the protective cover body. The lightening method of the invention has the advantages that the weight and manufacture cost of the battery protective cover for electric buses are effectively decreased, the lightening requirement of electric buses is met, and the overall appearance effect of the battery protective cover is improved. The invention also provides a battery protective cover.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

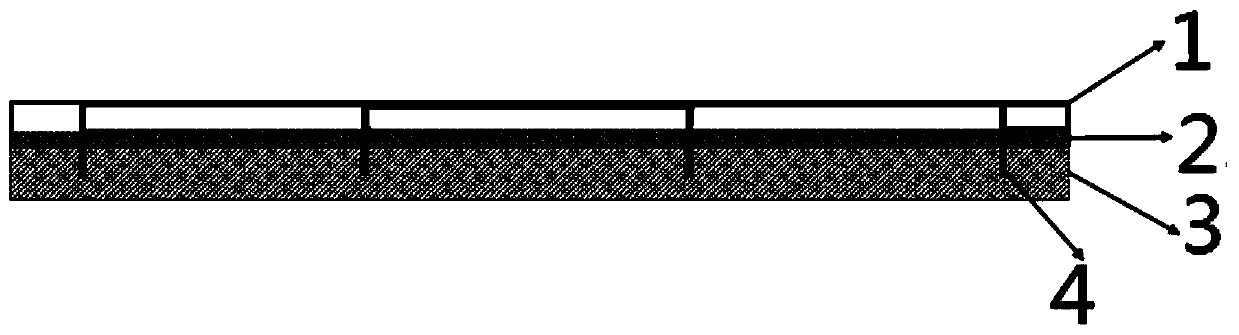

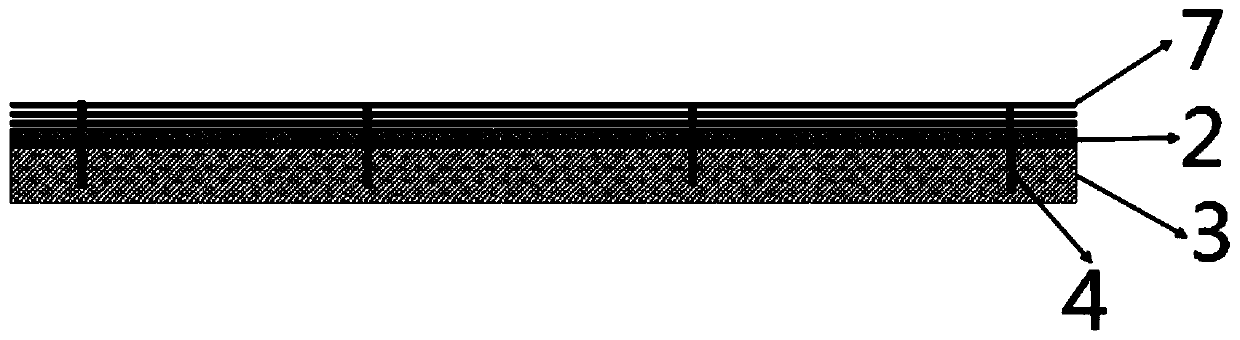

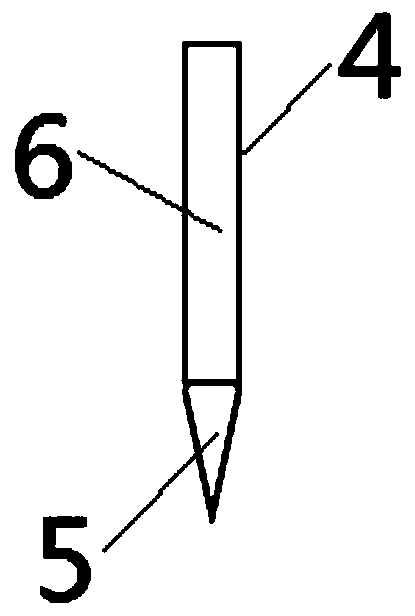

Connecting method and structure of carbon fiber reinforced composite part and metal part and automobile

InactiveCN110315784AAvoid damageAchieve connectionFiber-reinforced compositeCarbon fiber reinforced composite

The invention provides a connecting method and structure of a carbon fiber reinforced composite part and a metal part. The connecting method of the carbon fiber reinforced composite part and the metalpart includes the steps that an adhesive film layer (2) is laid on the surface of the metal part (3), and multiple carbon fiber reinforced composite prepreg layers (7) are laid on the adhesive film layer (2); each metal rod (4) penetrates through the multiple carbon fiber reinforced composite prepreg layers (7), the adhesive film layer (2) and the metal part (3); and the structures of the carbonfiber reinforced composite part and the metal part are transferred into a forming die to be heat-cured, and the multiple carbon fiber reinforced composite prepreg layers (7) are heat-cured to form thecarbon fiber reinforced composite part (1). According to the connecting method of the carbon fiber reinforced composite part and the metal part, the interlayer strength of a carbon fiber reinforced composite can be improved, the stripping-resistant capacity of the adhesive film layer for connecting the carbon fiber reinforced composite with the metal part is improved, and the bearing capacity isimproved.

Owner:ZOTYE INT AUTOMOBILE TRADING CO LTD

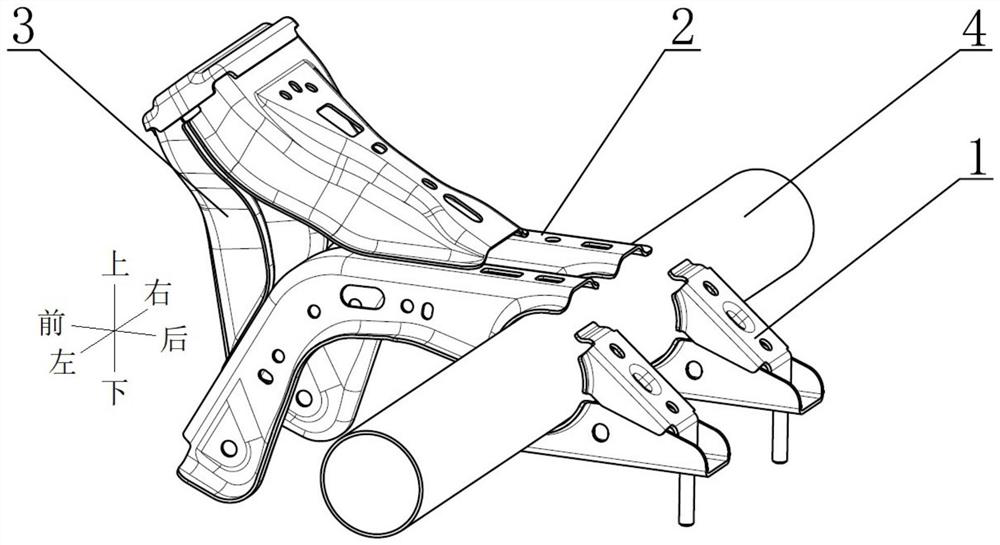

Front auxiliary frame aluminum alloy mounting support and vehicle

The invention discloses a front auxiliary frame aluminum alloy mounting support. The front auxiliary frame aluminum alloy mounting support is arranged between a front auxiliary frame and a cabin boundary beam, and comprises an aluminum alloy support body, and a connecting plate extending upwards is arranged on the edge of the upper end of the support body. The side face, opposite to the connectingplate, of the support body is fixedly connected with a reinforced plate, and the upper portion of the connecting plate and the upper portion of the reinforced plate are fixedly connected with the twoopposite side faces of the cabin boundary beam correspondingly. A vertically through threaded through hole is formed in the support body, and the threaded through hole and a second mounting hole in the cabin boundary beam are coaxially formed. The front auxiliary frame aluminum alloy mounting support can be low in weight, and the connecting problem that an existing mounting support of a steel structure and an aluminum alloy cabin boundary beam must be rivetted is solved, so that the rigidity and strength of an auxiliary frame mounting point meet requirements. The invention further discloses avehicle. The vehicle comprises the front auxiliary frame and the cabin boundary beam. The front auxiliary frame is fixedly connected with the cabin boundary beam through the aluminum alloy mounting support.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

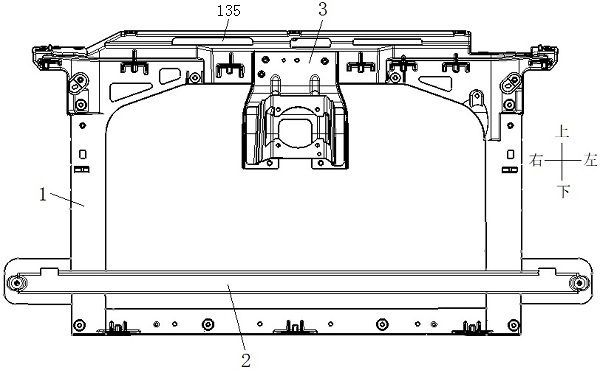

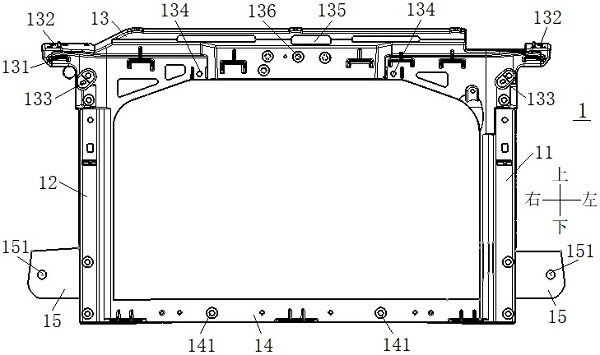

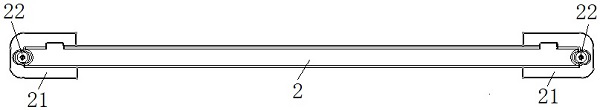

Magnesium alloy front end frame assembly beneficial to pedestrian protection and vehicle

InactiveCN114104109AImprove the collapse energy absorption effectImprove pedestrian protection performancePedestrian/occupant safety arrangementUnderstructuresEnergy absorptionDie casting

The magnesium alloy front end frame assembly facilitating pedestrian protection comprises a frame body and a leg protection cross beam, the frame body is an integrally-formed magnesium alloy die casting, and the left end side and the right end side of the leg protection cross beam are connected with the front end of an energy absorption box. First mounting plates are integrally formed on the left side and the right side of the frame body respectively, and the rear ends of the energy absorption boxes are connected with the front sides of the first mounting plates of the frame body. Pedestrian protection performance in the collision process can be effectively improved, and the requirement for light weight of a vehicle body is met.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Infrared stealth material based on frequency selective surfaces and preparation method of infrared stealth material

ActiveCN107187142AImprove high temperature resistanceImprove antioxidant capacityLaminationLamination apparatusInfraredTarget surface

The invention discloses an infrared stealth composite material based on frequency selective surfaces. The infrared stealth composite material is of a layer structure and sequentially comprises a target surface layer, a first intermediate medium layer, a capacitive frequency selective surface layer, a second intermediate medium layer, a metal capacitive frequency selective surface layer and a resistive capacitive frequency selective surface layer from inside to outside. The high-temperature-resistant infrared stealth composite material can resist the high temperature of at least 1000 DEG C and has good high-temperature resistance and excellent oxidation resistance.

Owner:BEIJING INST OF ENVIRONMENTAL FEATURES

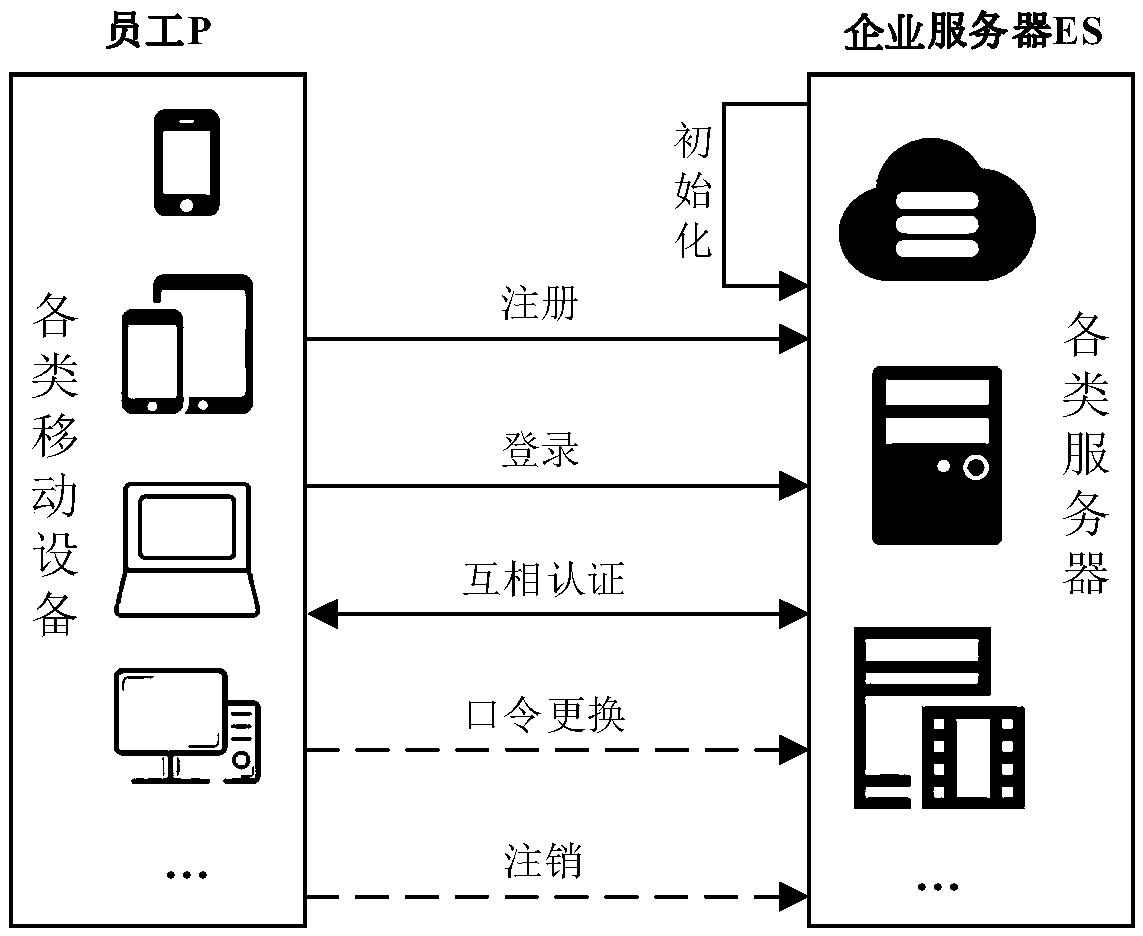

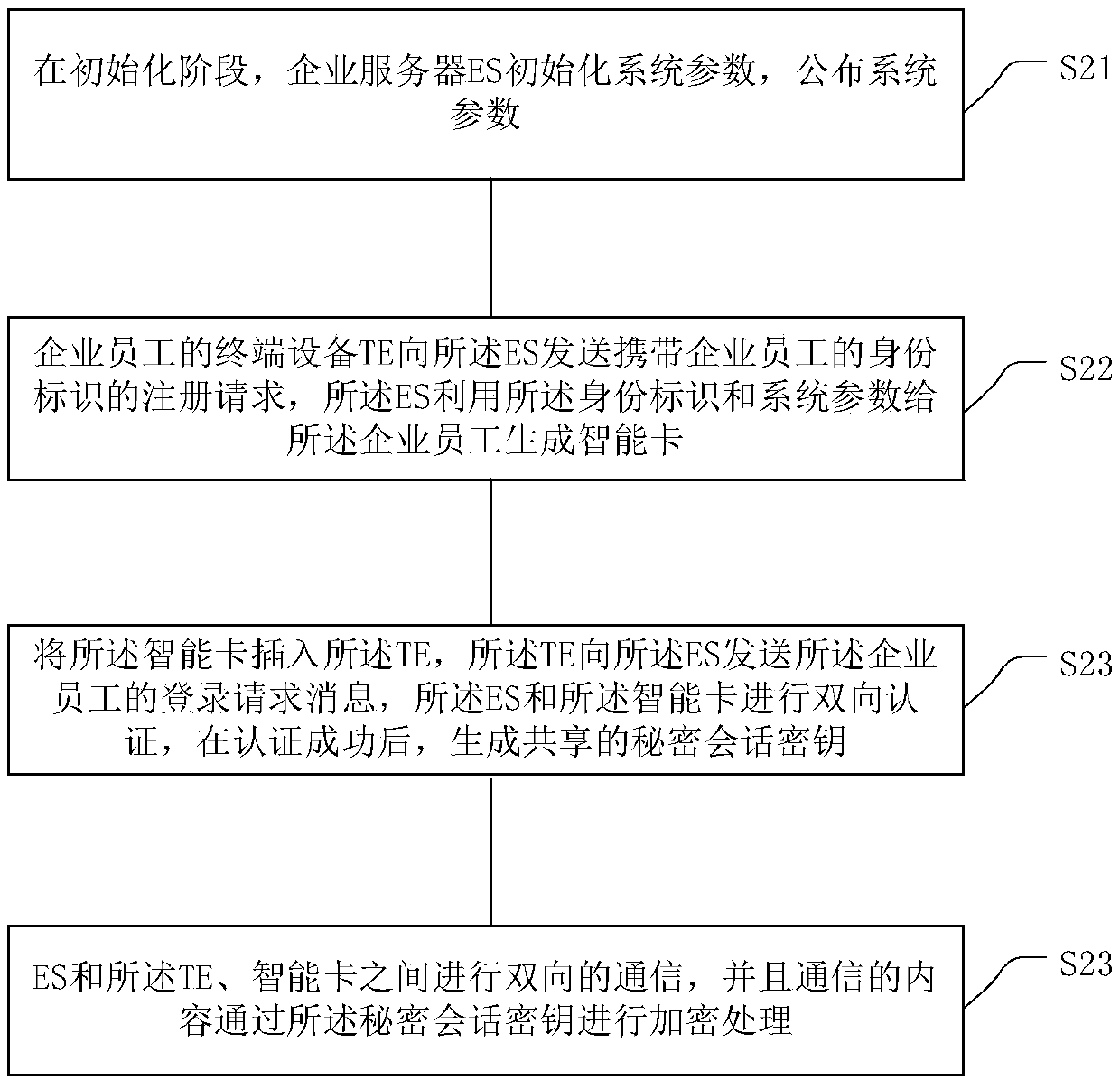

Multi-factor strong identity authentication method in mobile office environment

ActiveCN109522689AEnsure safetyAchieve securityDigital data authenticationTransmissionTerminal equipmentSmart card

The invention provides a multi-factor strong identity authentication method under a mobile office environment. The method comprises the following steps: the terminal equipment TE of an enterprise employee sends a registration request carrying the identity identification of the enterprise employee to the ES, and the ES generates an intelligent card for the enterprise employee by using the identityidentification and the system parameters; the terminal equipment TE of the enterprise employee sends a registration request carrying the identity identification of the enterprise employee to the ES. The smart card is inserted into the TE, the TE sends the logon request message of the enterprise employee to the ES, the ES and the smart card carry out mutual authentication, and after the authentication is successful, the shared secret session key is generated; ES and TE, and the content of the communication is encrypted by the secret session key. The method of the invention can realize safe andefficient two-way authentication between the employee and the enterprise. Forward security, user anonymity, untraceability and session key security can be achieved. While ensuring the authenticity ofthe identity of the user accessing the enterprise information, protect the privacy of the user's information.

Owner:BEIJING JIUZHOU YUNTENG TECH CO LTD

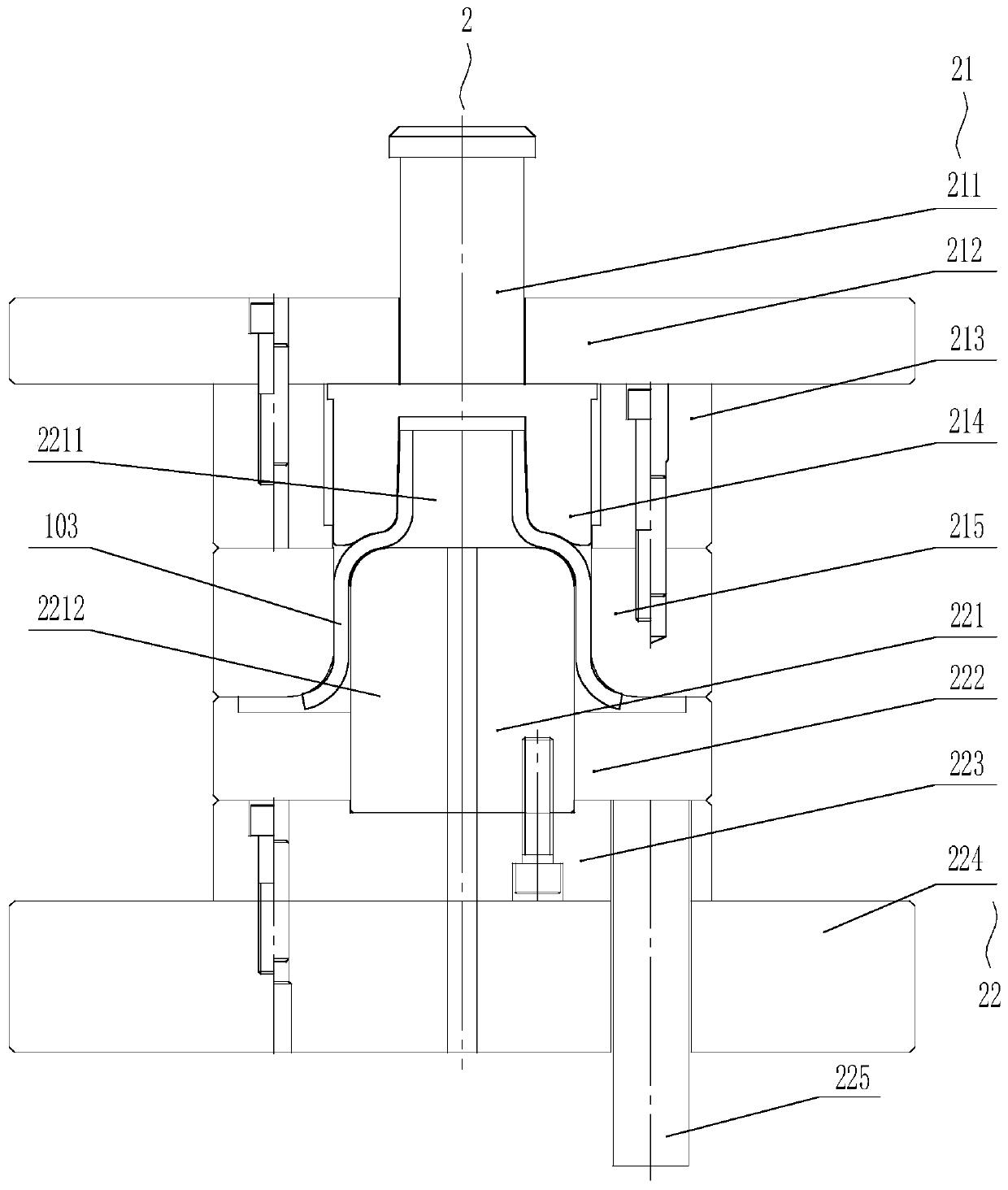

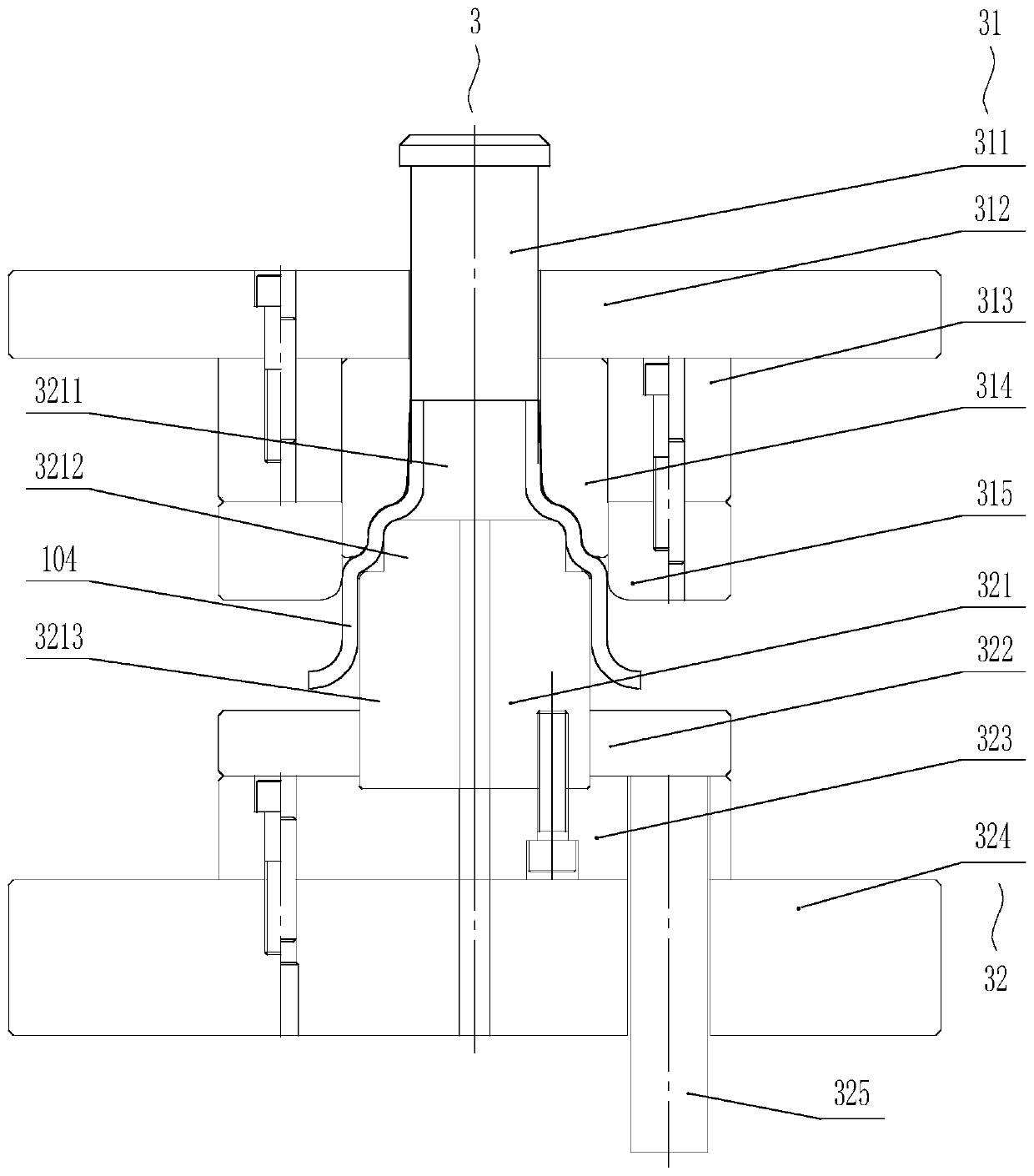

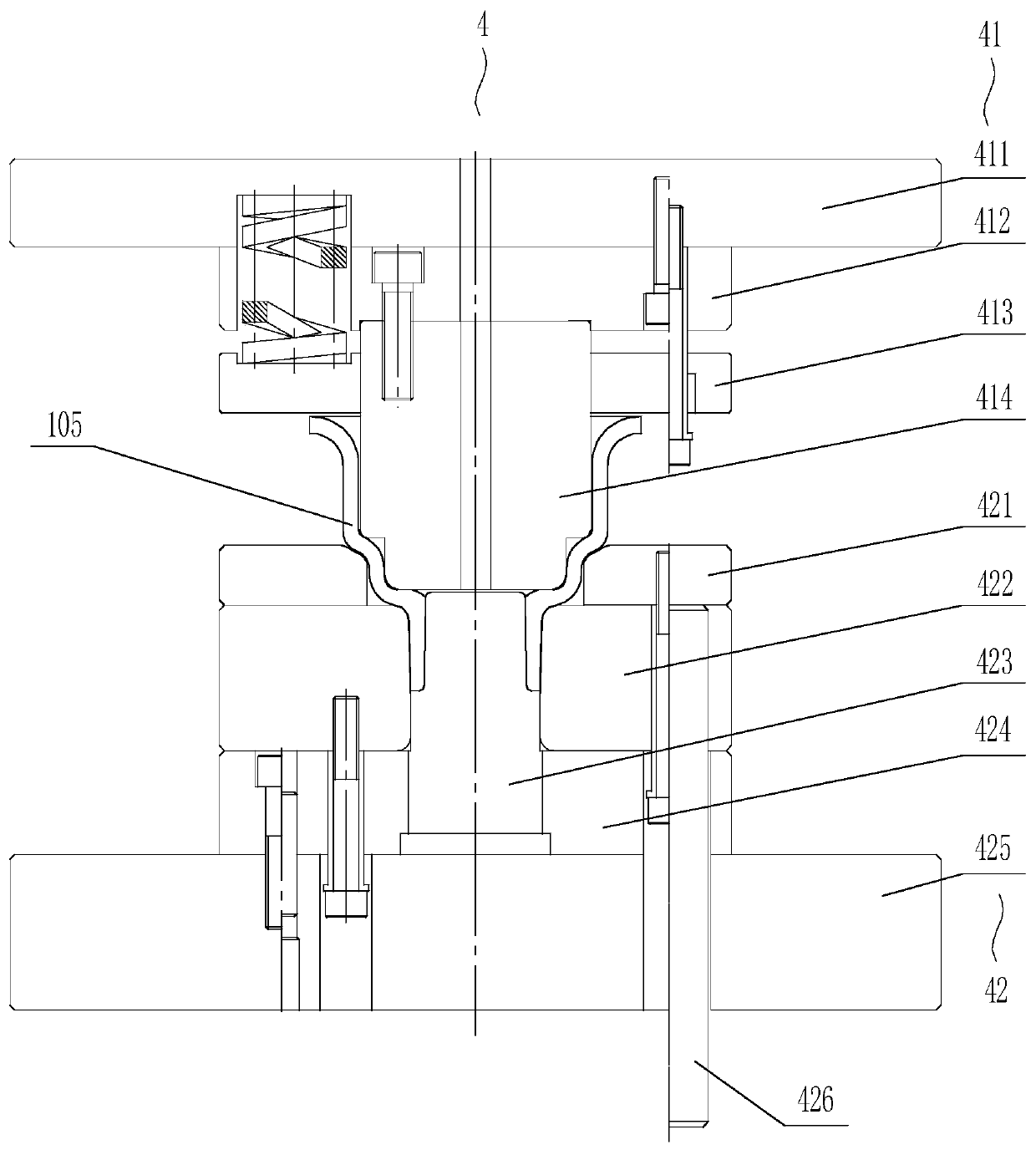

Multi-station forming technology for driven pulley piston of CVT

ActiveCN110038995AMeet strength requirementsGuaranteed liquidityMetal-working apparatusPistonsSheet steelHigh intensity

The invention relates to a multi-station forming technology for a driven pulley piston of a CVT (Continuously Variable Transmission). The multi-station forming technology comprises the steps of S1, shearing a plate, S2, falling, S3, drawing, S4, upsetting and S5, shaping; in the step S1, a high-strength steel plate with a thickness of 5.5-6.5 mm is used as a raw material and subjected to spheroidizing annealing treatment; in the step S3, the drawing coefficient is 0.65-0.85; the step S3 comprises the following steps of S31, inner hole drawing, S32, outer circle drawing, and S33, step drawing;in the S31, a falling blank is subjected to inner hole drawing for many times to form a cap-shaped blank with a center hole; in the S32, the cap-shaped blank with the center hole is subjected to the outer circle drawing to obtain a first-stage stepped inverted cup-shaped blank; and in the S33, the outer circle of the top of a large-end barrel of the first-stage stepped inverted cup-shaped blank isdrawn to form a transition step to obtain a second-stage stepped inverted cup-shaped blank. The multi-station forming technology is suitable for the forming of the driven pulley piston of the CVT, has the characteristics of low material loss, simplicity in machining, reliable quality and light weight, and is easy to popularize and use.

Owner:柳州市龙杰汽车配件有限责任公司

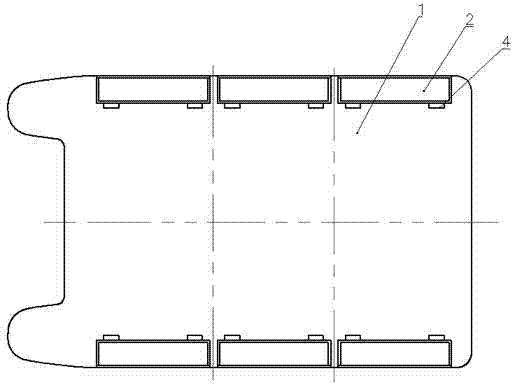

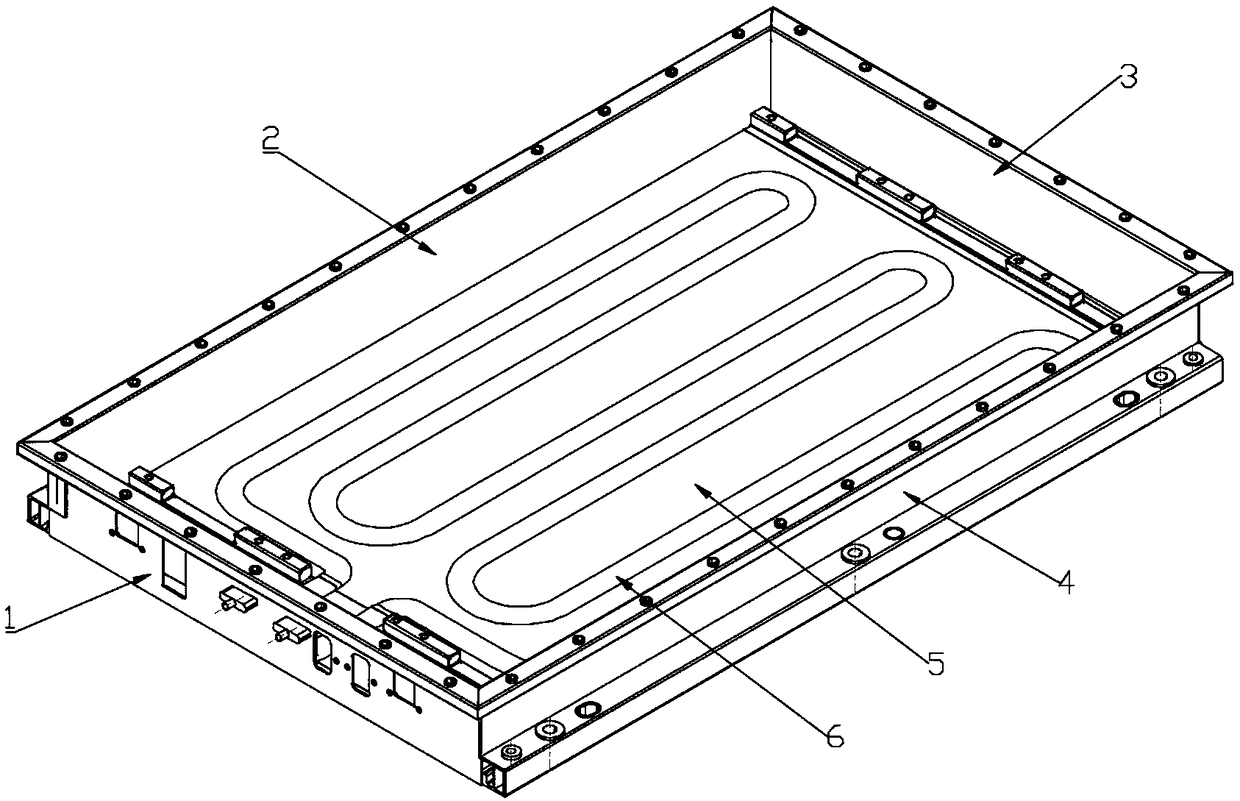

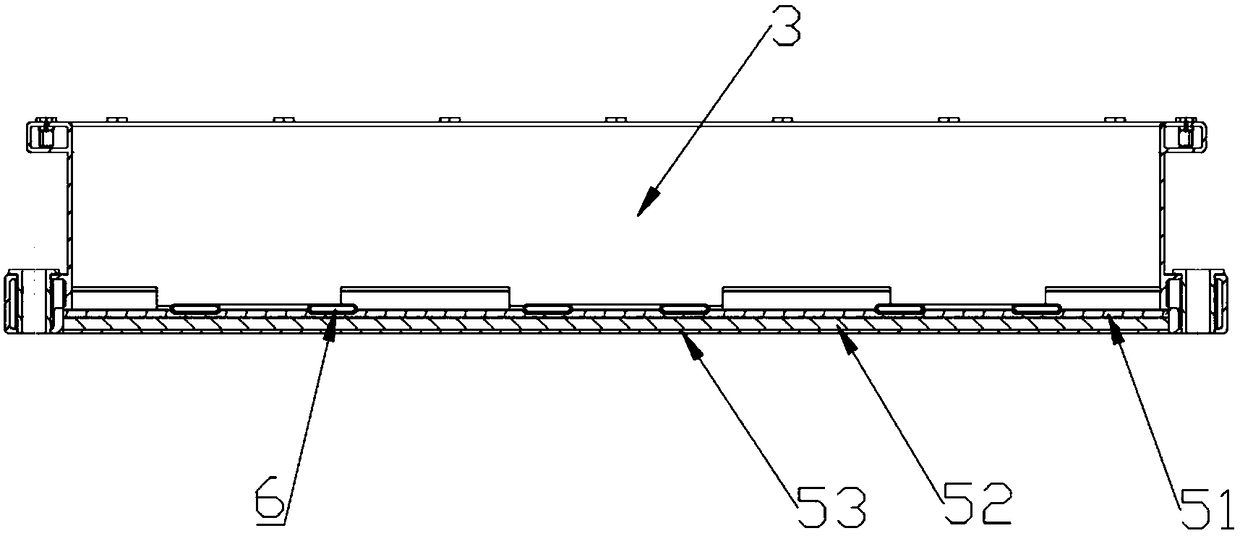

A lightweight battery box

InactiveCN109037529AMeet lightweight needsReduce the risk of fireBattery isolationSecondary cellsFiberCarbon fibers

A lightweight battery box includes a tray main body frame formed by splicing a front border, back border, left border, a right border and a bottom plate, a liquid cooling pipe is laid on the upper surface of the bottom plate, the bottom plate comprises an upper bottom plate, a middle bottom plate and a lower bottom plate, the upper bottom plate and the lower bottom plate are made of carbon fiber materials, The middle bottom plate is a high-strength foam plate, the upper bottom plate, the middle bottom plate and the lower bottom plate are infiltrated by resin and solidified and bonded, and a flame retardant is added to the foam plate material, so that the lightweight battery box can ensure the liquid cooling efficiency, reduce the fire risk caused by the thermal runaway of the battery box,and meet the lightweight demand of the tray.

Owner:江苏奥特帕斯新能源科技有限公司

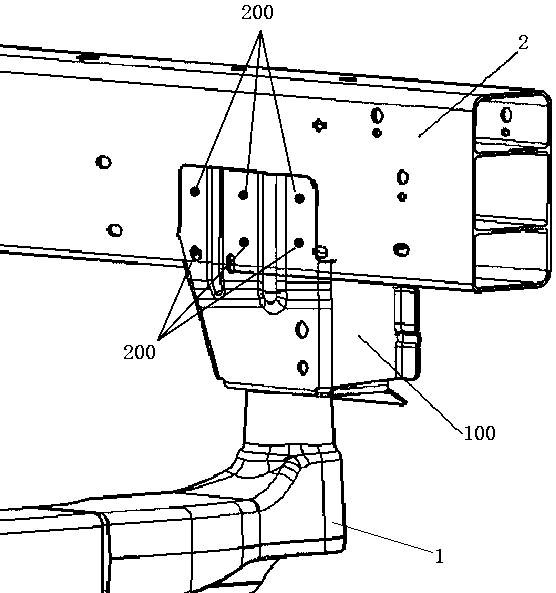

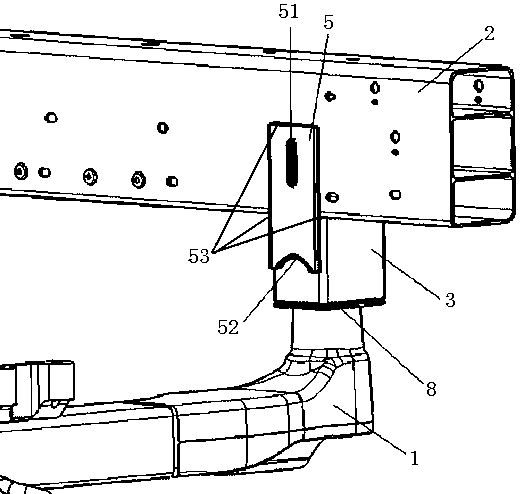

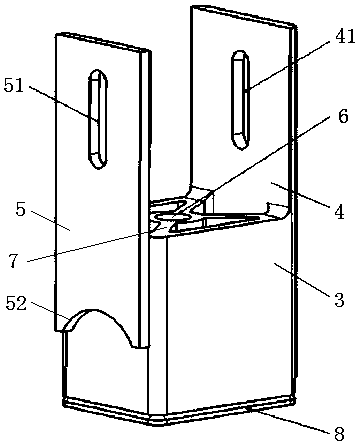

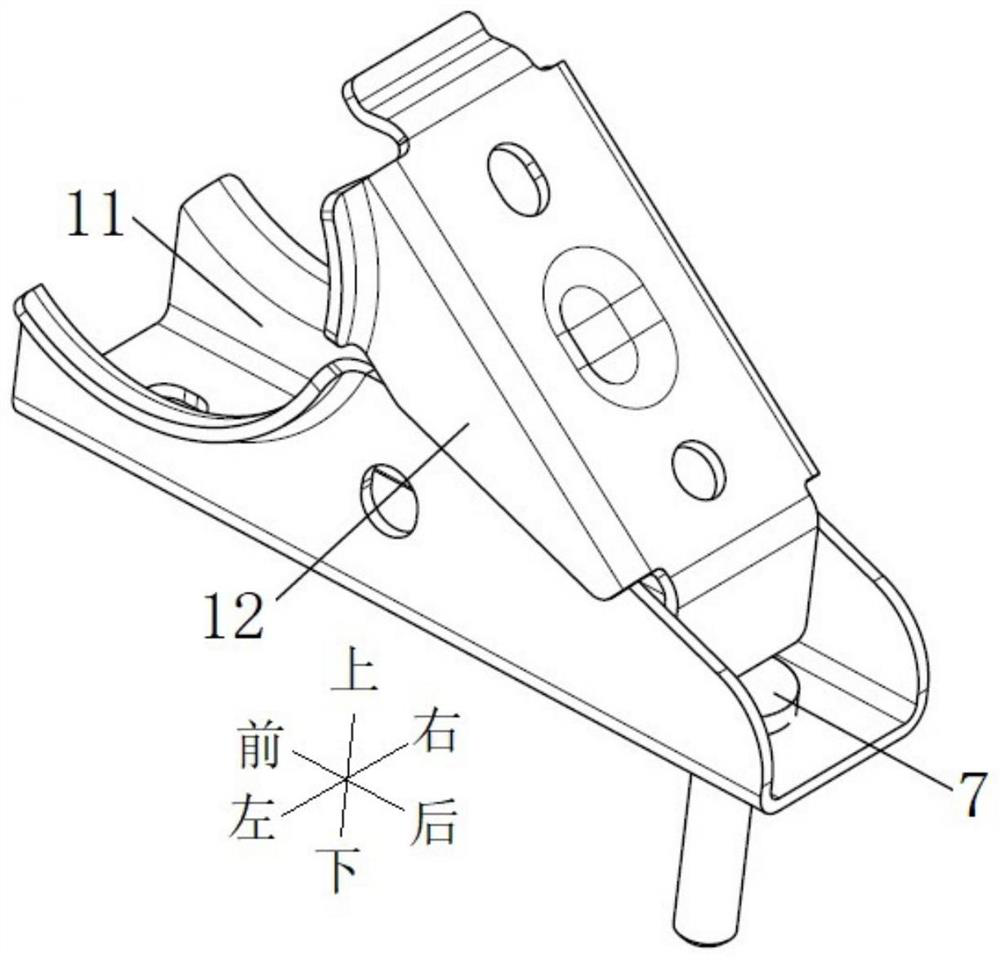

Steering column connecting support assembly and vehicle

ActiveCN112722052AReduce the amount of developmentReduce development costsSteering columnsSteering columnClosed cavity

The invention discloses a steering column connecting support assembly and a vehicle. The steering column connecting support assembly comprises a rear mounting support, a front mounting support and a front wall plate mounting support. The front end edge of the rear mounting support is fixedly connected with a steering support transverse pipe to form a closed cavity, and a steering column rear mounting point is arranged on the lower side of the rear end; the rear end edge of the front mounting support is fixedly connected with the steering support transverse pipe, and a steering column front mounting point is arranged on the lower side of the front end; the lower end of the front wall plate mounting support is fixedly connected with the top surface of the front mounting support to form a closed cavity, and a front wall plate mounting point is arranged at the top end. On the premise that the performance of the mounting points meets the requirement, the weight is reduced, and the universality is good.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Low-odor and low-VOC microcellular foaming modified polypropylene material and preparation method thereof

The invention discloses a low-odor and low-VOC microcellular foaming modified polypropylene material which comprises the following components in parts by weight: 70 to 90 parts of polypropylene resin,0 to 10 parts of elastomer, 0 to 20 parts of filler, 1 to 5 parts of deodorant, 1 to 5 parts of assistant master batch and 2 parts of foaming agent. The polypropylene resin is at least one of high-crystallinity co-polypropylene, high-melt-strength polypropylene and high-fluidity polypropylene. The material has good mechanical strength and rigidity, the characteristics of low odor and low VOC of the material are guaranteed, and the light weight requirement of a microcellular foaming material plastic part of the whole vehicle is met. The invention further discloses a preparation method of the low-odor and low-VOC microcellular foaming modified polypropylene material, raw materials are simple and easy to obtain, the preparation method is simple in process, and large-scale industrial production can be achieved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com