Low-density and low-diffusivity polypropylene material and preparation method thereof

A polypropylene material, low emission technology, applied in the field of modified polypropylene materials for automotive interiors, can solve the problem of not being able to meet the requirements at the same time, and achieve the effect of meeting the requirements of lightweight, avoiding brittle cracks and low VOC characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

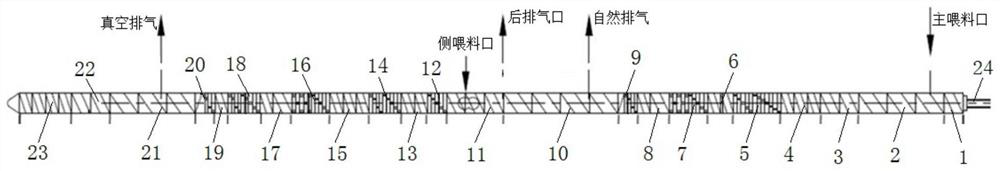

[0030] Embodiment one, a kind of preparation method of low-density, low emission polypropylene material, it comprises the steps:

[0031] S1, preparing materials, weighing a sufficient amount of polypropylene resin, elastomer, deodorant, additive masterbatch and filler for standby;

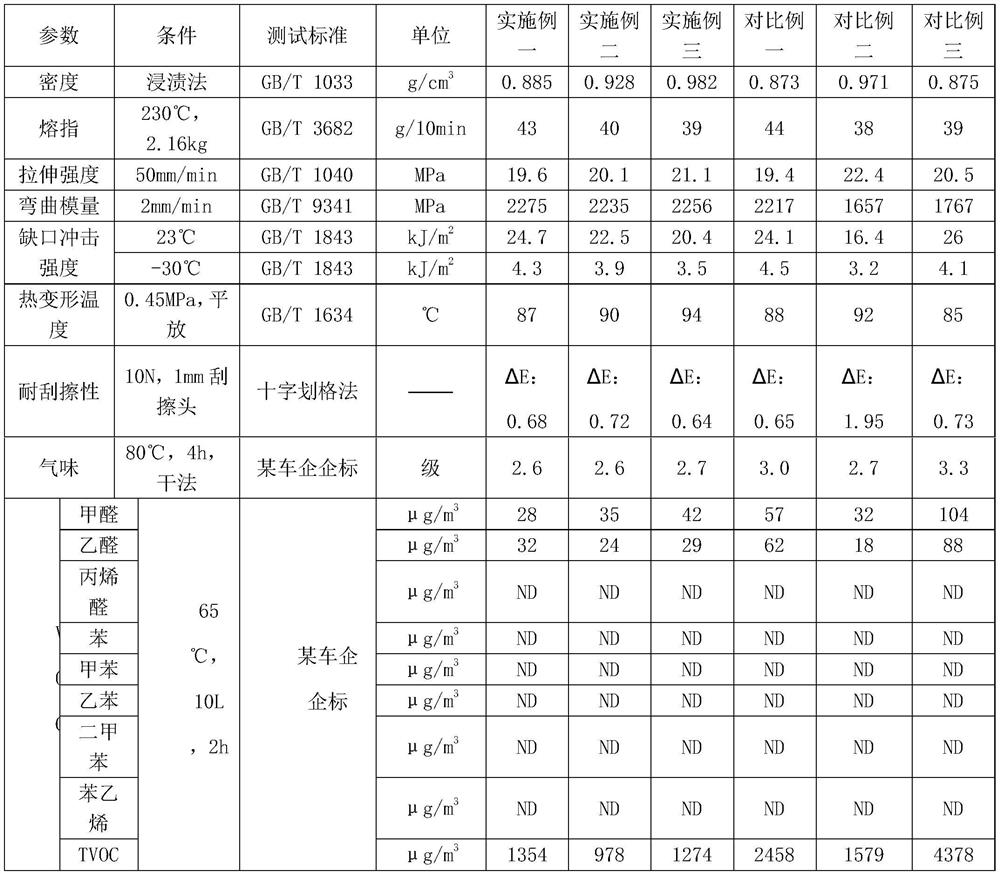

[0032] S2, the polypropylene resin and elastomer are conveyed to the twin-screw extruder through the main feeding assembly from the main feeding port, and the deodorant and additive masterbatch are evenly mixed through the auxiliary feeding assembly from the auxiliary feeding port Transported to the twin-screw extruder, the filler is delivered to the twin-screw extruder from the side feed port through the side feed assembly. Set automatic feeding system parameter in proportion, make automatic feeding system by the polypropylene resin of 83 parts by weight, the basic magnesium sulfate whisker of 5 parts by weight, the hollow glass microsphere of 3 parts by weight, the auxiliary agent of 2 parts by ...

Embodiment 2

[0035] Embodiment two, select the twin-screw extruder identical with embodiment one, set automatic feeding system parameter in proportion, make automatic feeding system press the polypropylene resin of 79 parts by weight, the talcum powder of 3 parts by weight, the talcum powder of 5 parts by weight The basic magnesium sulfate whisker of 6 parts, the hollow glass microsphere of 3 parts by weight, the additive masterbatch of 2 parts by weight, the deodorant of 2 parts by weight, the elastomer POE ratio feeding of 6 parts by weight, all the other processing parameters Same as Example 1, a low-density, low-emission polypropylene material was obtained.

Embodiment 3

[0036] Embodiment three, select the twin-screw extruder identical with embodiment one, set automatic feeding system parameter in proportion, make automatic feeding system press the polypropylene resin of 76 parts by weight, the talcum powder of 6 parts by weight, the talcum powder of 5 parts by weight The basic magnesium sulfate whisker of 6 parts, the hollow glass microsphere of 3 parts by weight, the additive masterbatch of 2 parts by weight, the deodorant of 2 parts by weight, the elastomer POE ratio feeding of 6 parts by weight, all the other processing parameters Same as Example 1, a low-density, low-emission polypropylene material was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluidity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com