Sandwich-structure high-temperature-resistant radar wave-absorbing material and preparation method thereof

A radar absorbing material and interlayer structure technology, applied in the field of radar absorbing materials, can solve the problems of poor controllability of dielectric constant, small design space, and high process requirements, so as to meet the needs of lightweight, easy expansion, The effect of easy absorbing bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

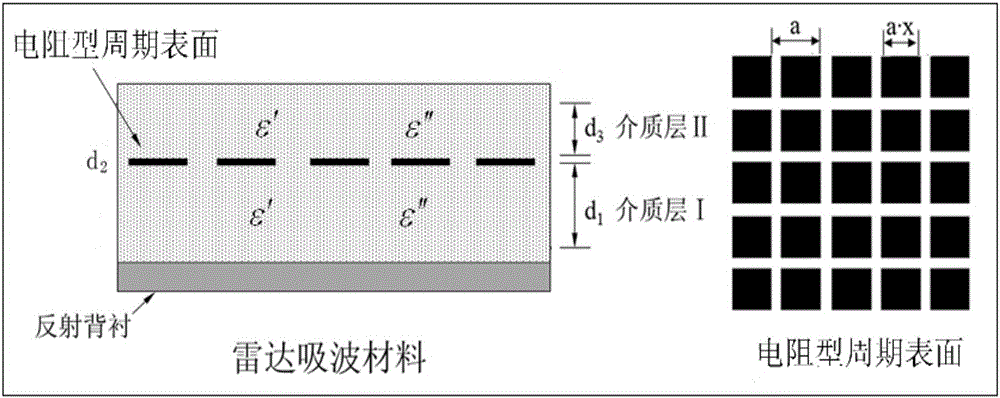

[0044] a kind of like figure 1 The high-temperature-resistant radar wave-absorbing material of the present invention shown in the present invention sequentially includes a sandwich structure formed by a dielectric layer I, a resistive periodic surface layer and a dielectric layer II, wherein the dielectric layer I is located on the reflective lining, and the dielectric layer I Both the medium layer and the medium layer II are mullite fiber reinforced mullite-based composite materials, with a thickness of d1=d3=2.5mm; the resistive periodic surface layer is composed of a high-temperature resistant coating with a thickness of d2=0.02mm and a periodic pattern (ruthenium dioxide-based glass-based resistance coating), the periodic pattern is a square patch pattern distributed in a matrix, the side length of the matrix unit where the square patch is located is a=12.24mm, the side length of the square patch is the same as the matrix unit The ratio of side lengths x=0.82.

[0045] Th...

Embodiment 2

[0056] a kind of like figure 1 The high-temperature-resistant radar wave-absorbing material of the present invention shown includes a sandwich structure formed by a dielectric layer I, a resistive periodic surface layer and a dielectric layer II in sequence from the inside to the outside, wherein the dielectric layer I is located on the reflective lining, and the dielectric layer Both the Ⅰ and the medium layer Ⅱ are alumina fiber alumina matrix composite materials, and the thicknesses of the medium layer Ⅰ and the medium layer Ⅱ are d1=2.53mm and d3=2.47mm respectively; the resistive periodic surface layer consists of thickness d2=0.02mm, and Composed of high temperature resistant coating (ruthenium dioxide-based glass-based resistance coating) in a periodic pattern, the periodic pattern is a square patch pattern distributed in a matrix, and the side length of the matrix unit where the square patch is located is a=15.20mm, The ratio of the side length of the square patch to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com