Metal coating-based high temperature-resistant structural wave absorbing material and preparation method thereof

A wave-absorbing material and metal coating technology, which is applied in the field of wave-absorbing materials, can solve the problem that the wave-absorbing performance changes greatly with temperature rise, and achieve the effects of impedance matching design, high temperature resistance, and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

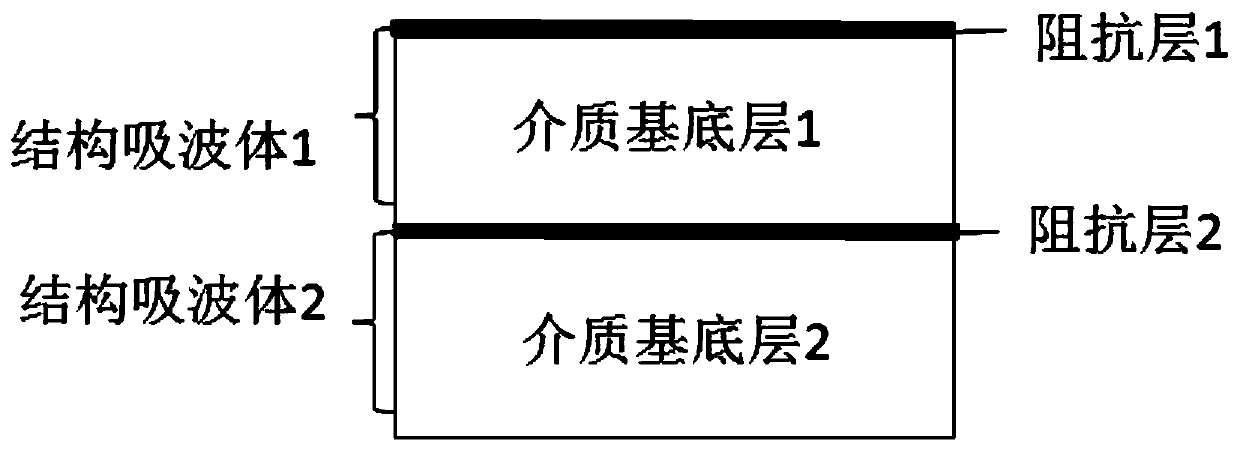

[0037] A kind of high temperature resistant structural wave absorbing material based on metal coating of the present invention, such as figure 1 As shown, it is composed of two sets of structural absorbers. The structural absorber includes a dielectric base layer and an impedance layer from bottom to top. The dielectric base layer is a silica fiber reinforced silica airgel composite material. The resistance layer is quartz fiber cloth coated with nickel-chromium alloy. Its preparation method comprises the following steps:

[0038] (1) Preparation of medium substrate: select quartz fiber reinforced silica airgel composite material according to the design requirements, prepare quartz fiber reinforced silica airgel composite material by sol-gel process, and finally, use mechanical processing method to make the composite The material is processed to 7.5mm to make 7.5mm thick dielectric base layer 1 and dielectric base layer 2;

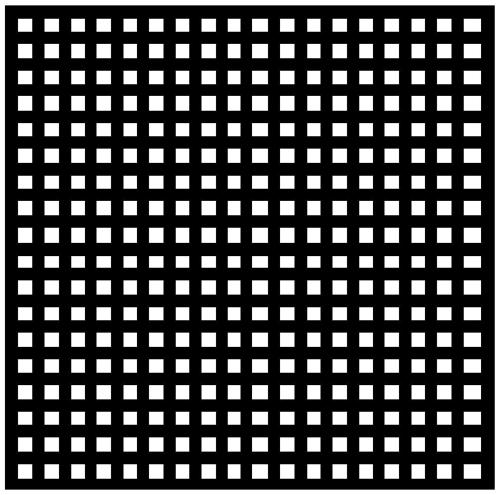

[0039] (2) Preparation of impedance layer: Using ...

Embodiment 2

[0045] A metal coating-based high-temperature-resistant structural wave-absorbing material of the present invention is composed of a group of structural wave-absorbing bodies, and the structural wave-absorbing body includes a dielectric base layer and an impedance layer from bottom to top, and the dielectric base layer It is a continuous mullite fiber reinforced silicon oxide airgel composite material, and the resistance layer is a boron nitride fiber cloth coated with nickel-chromium-iron alloy. Its preparation method comprises the following steps:

[0046] (1) Preparation of medium substrate: Select quartz fiber-reinforced silica airgel composite material according to the design requirements, and prepare continuous mullite fiber-reinforced silica airgel composite material by sol-gel process, and finally, adopt mechanical processing method , process the composite material to 7.5mm to make a 7.5mm thick dielectric base layer;

[0047] (2) Preparation of impedance layer: The mag...

Embodiment 3

[0052] A kind of high temperature resistant structural wave absorbing material based on metal coating of the present invention, such as figure 1 As shown, it is composed of two sets of structural absorbers. The structural absorber includes a dielectric base layer and an impedance layer from bottom to top. The dielectric base layer is a silica fiber reinforced silica airgel composite material. The resistive layer is silicon carbide fiber cloth coated with Ni-Cr-Nd alloy. Its preparation method comprises the following steps:

[0053] (1) Preparation of medium substrate: select quartz fiber reinforced silica airgel composite material according to the design requirements, prepare quartz fiber reinforced silica airgel composite material by sol-gel process, and finally, use mechanical processing method to make the composite The material is processed to 5mm to make a dielectric base layer 1 and a dielectric base layer 2 with a thickness of 5 mm;

[0054] (2) Preparation of impedan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com