Low-odor and low-VOC microcellular foaming modified polypropylene material and preparation method thereof

A polypropylene material and microcellular foaming technology, which is applied in the field of low VOC microcellular foaming modified polypropylene material and its preparation, low odor field, can solve the problem that the composite material cannot be foamed and the polypropylene foaming temperature range is narrow. , foaming agent gas is easy to escape and other problems, to meet the needs of lightweight, low VOC characteristics, and enhance the effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

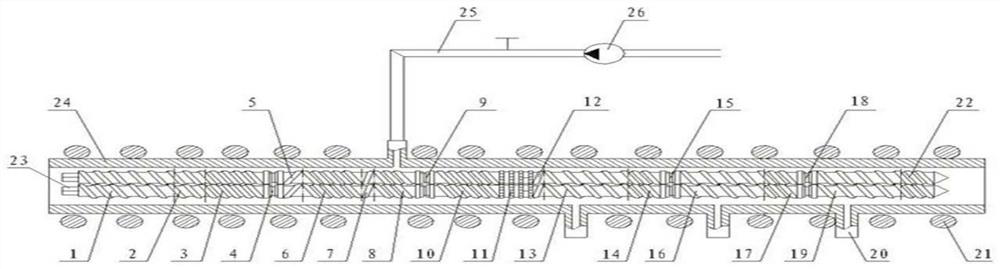

Method used

Image

Examples

Embodiment 1

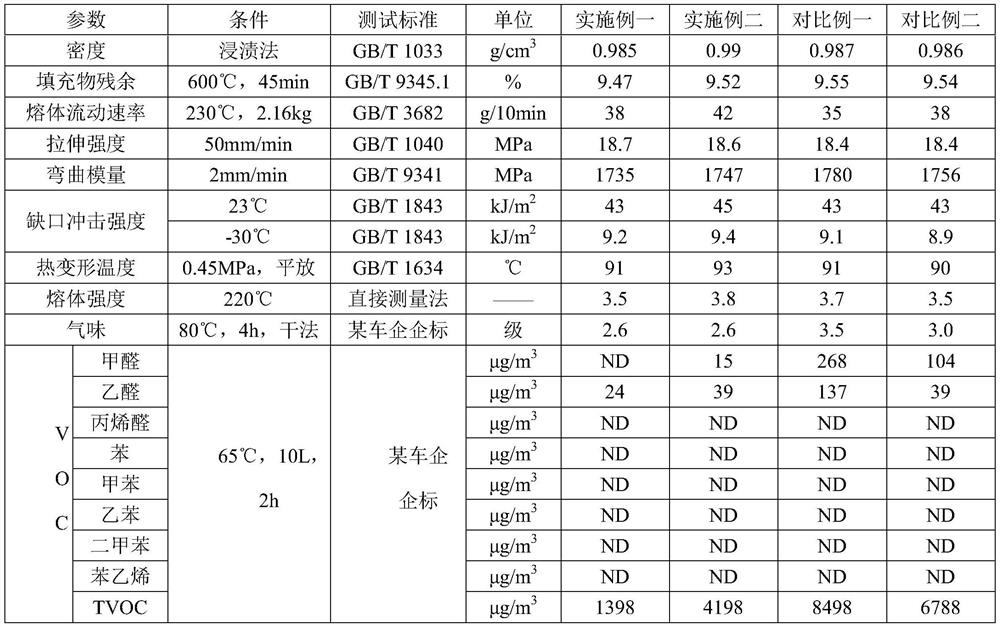

[0032] Example 1, a low-odor, low-VOC microcellular foamed modified polypropylene material includes the following components in parts by weight: 82 parts by weight of polypropylene resin, 4 parts by weight of elastomer, 6 parts by weight of Talc powder, 4 parts by weight of basic magnesium sulfate whiskers, 2 parts by weight of deodorant, 2 parts by weight of auxiliary agent masterbatch and 2 parts by weight of foaming agent. The polypropylene resin is a mixture of high crystallization and high flow copolymerized polypropylene, high melt strength polypropylene and high flow high impact polypropylene, and high crystallization and high flow copolymer polypropylene, high melt strength polypropylene and high flow high impact polypropylene The weight ratio of polypropylene is 24:7:18.

[0033] The preparation method of above-mentioned low smell, low VOC microcellular foaming modified polypropylene material, it comprises the steps:

[0034] S1. Weigh the raw materials according to ...

Embodiment 2

[0038] Example 2, a low-odor, low-VOC microcellular foamed modified polypropylene material, comprising the following components in parts by weight: 83 parts by weight of polypropylene resin, 4 parts by weight of elastomer, 6 parts by weight of Talcum powder, basic magnesium sulfate whiskers of 4 parts by weight, deodorant of 1 part by weight, masterbatch of auxiliary agent of 2 parts by weight and foaming agent of 2 parts by weight; the polypropylene resin is high crystallization and high flow copolymerization A mixture of polypropylene, high melt strength polypropylene and high flow high impact polypropylene, and the weight ratio of high crystalline copolymer polypropylene, high melt strength polypropylene and high flow polypropylene is 25:7:18.

[0039] The preparation method of above-mentioned low smell, low VOC microcellular foaming modified polypropylene material, it comprises the steps:

[0040] S1. Weigh the raw materials according to the above material proportions, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com