Infrared stealth material based on frequency selective surfaces and preparation method of infrared stealth material

A frequency selective surface, infrared technology, applied in the field of infrared stealth materials and their preparation, to achieve the effect of a wide range of materials, excellent oxidation resistance, and meet the needs of lightweight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0049] Unless otherwise specified, various raw materials, reagents, instruments and equipment used in the present invention can be purchased from the market or prepared by existing methods.

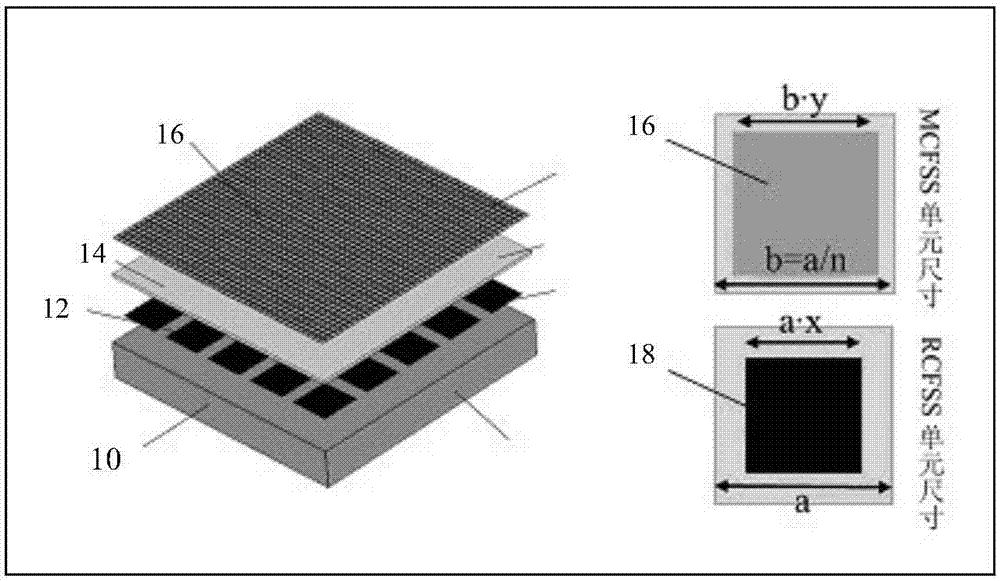

[0050] figure 1 It is a schematic diagram of the combination principle of the infrared stealth material of the present invention. Such as figure 1 As shown, an infrared stealth composite material based on a frequency selective surface, the infrared stealth composite material is a layered structure, which sequentially includes a target surface layer 10, a first intermediate dielectric layer (not shown), a capacitive type A frequency selective surface layer 12, a second intermediate dielectric layer 14, a metal type capacitive frequency selective surface layer 16 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com