Matte low-density spraying-free material for automotive interiors and preparation method thereof

An automotive interior, low-density technology, applied in the field of automotive interior materials, can solve the problem of not being able to meet the requirements at the same time, and achieve the effect of meeting the requirements of lightweight, good mechanical properties, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

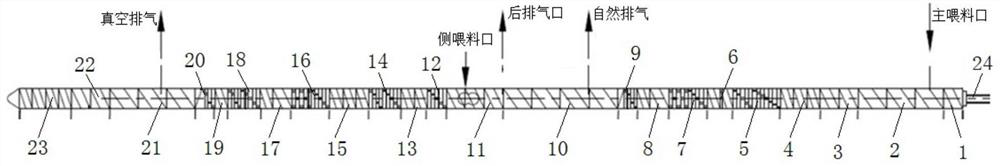

Method used

Image

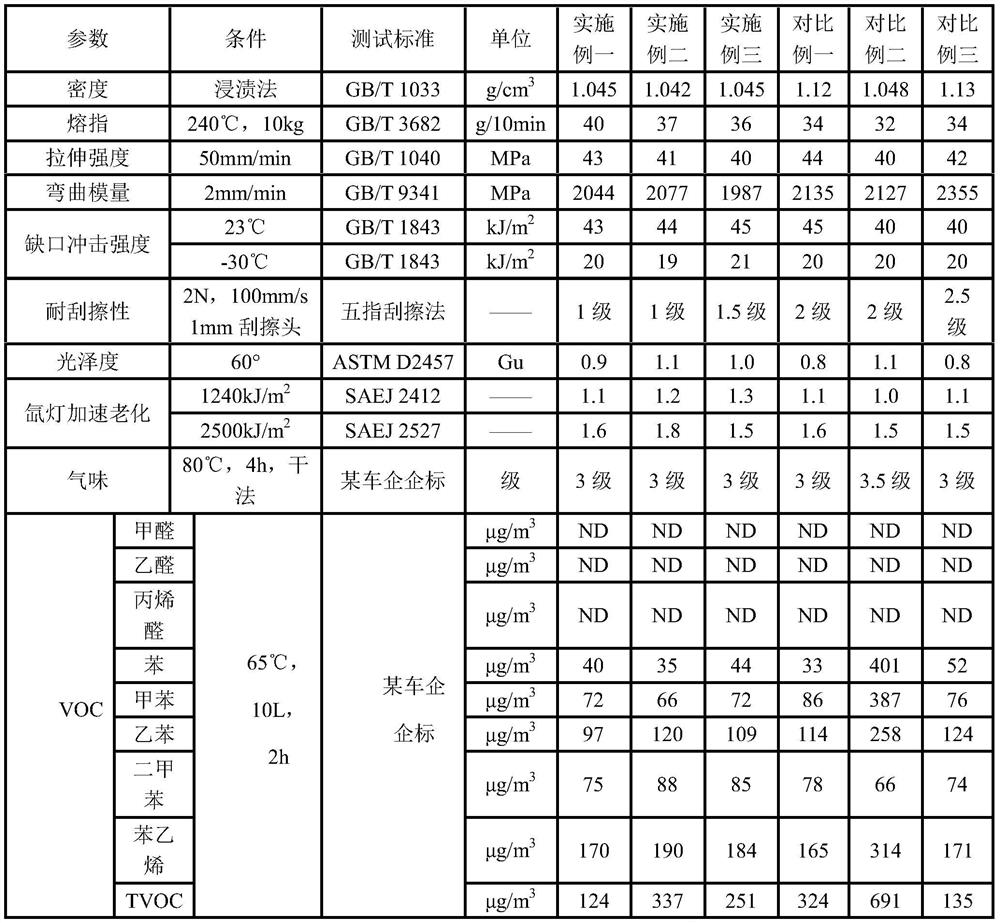

Examples

Embodiment 1

[0033] Embodiment one, a kind of preparation method of matte low-density spray-free material for automobile interior decoration, it comprises the steps:

[0034] S1, prepare materials, weigh enough ASA high rubber powder, polyamide resin, SAN resin, ASA-g-GMA resin, silane modified filler, hollow glass microspheres, additive masterbatch, deodorant, scratch resistance Auxiliary. The diameter of the hollow glass microsphere is 50 μm, and its surface is treated with a silane coupling agent.

[0035] The auxiliary agent masterbatch is made by extrusion granulation of carrier, weather-resistant agent, lubricant and antioxidant, and the carrier is polyamide resin, wherein the weight ratio of carrier, weather-resistant agent, lubricant and antioxidant is according to Reasonable adjustments to material requirements.

[0036] ASA-g-GMA resin, additive master batch, deodorant and anti-scratch additive are mixed uniformly to obtain a premix, which includes 40% ASA-g-GMA resin, 15% deo...

Embodiment 2

[0042] Embodiment 2, a kind of preparation method of matte low-density spray-free material for automobile interior decoration, feed parameters are set by automatic feeding system: by weight percentage, according to 24% ASA high rubber powder, 30% poly Amide resin, 20% SAN resin, 4% silane-modified filler, 3% hollow glass microspheres and 19% premix are fed in proportion. All the other steps and process parameters are the same as in Example 1.

Embodiment 3

[0043] Embodiment three, a kind of preparation method of matte low-density spray-free material for automobile interior decoration, feed parameters are set by automatic feeding system: by weight percentage, according to 17% ASA high rubber powder, 33% poly Amide resin, 24% SAN resin, 4% silane-modified filler, 3% hollow glass microspheres and 19% premix are fed in proportion. All the other steps and process parameters are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com