Patents

Literature

63results about How to "High product strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

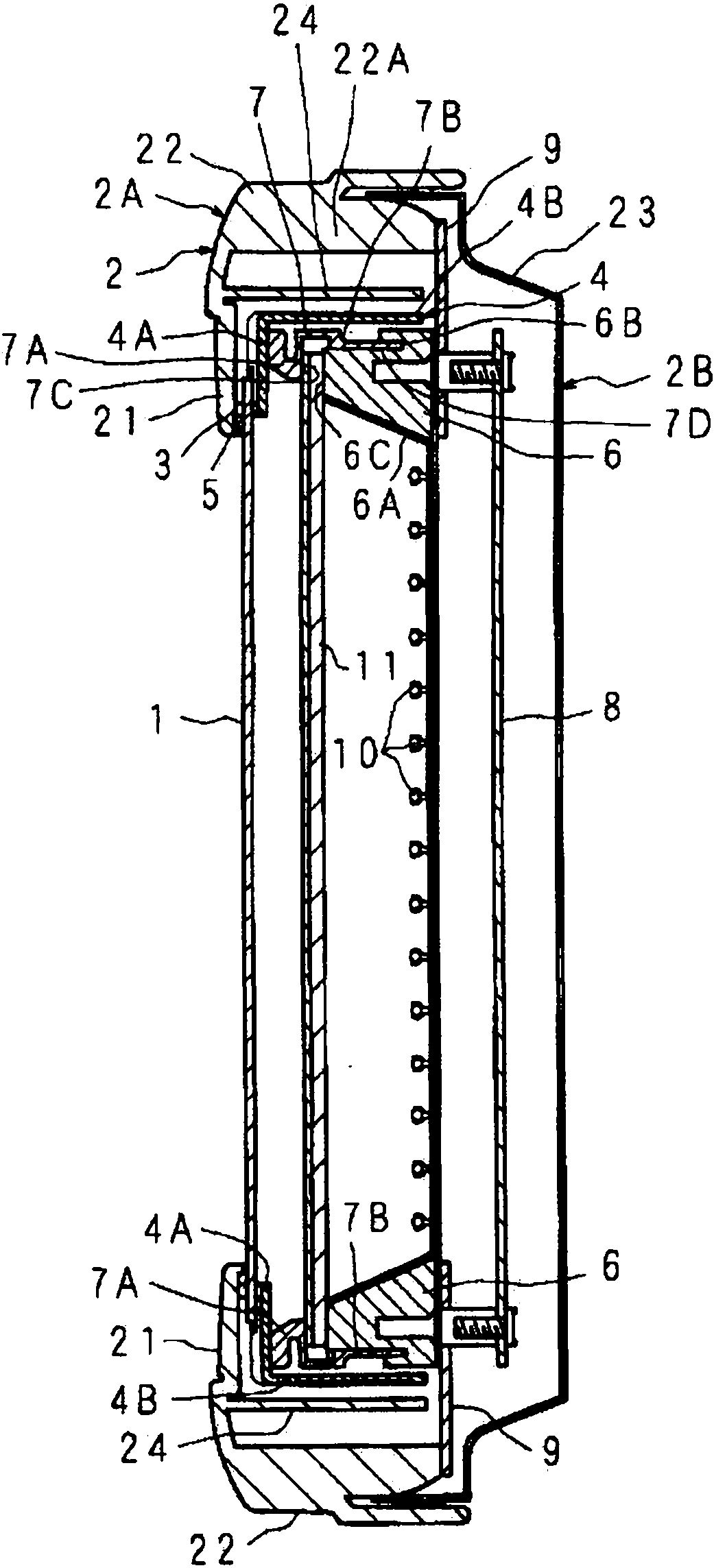

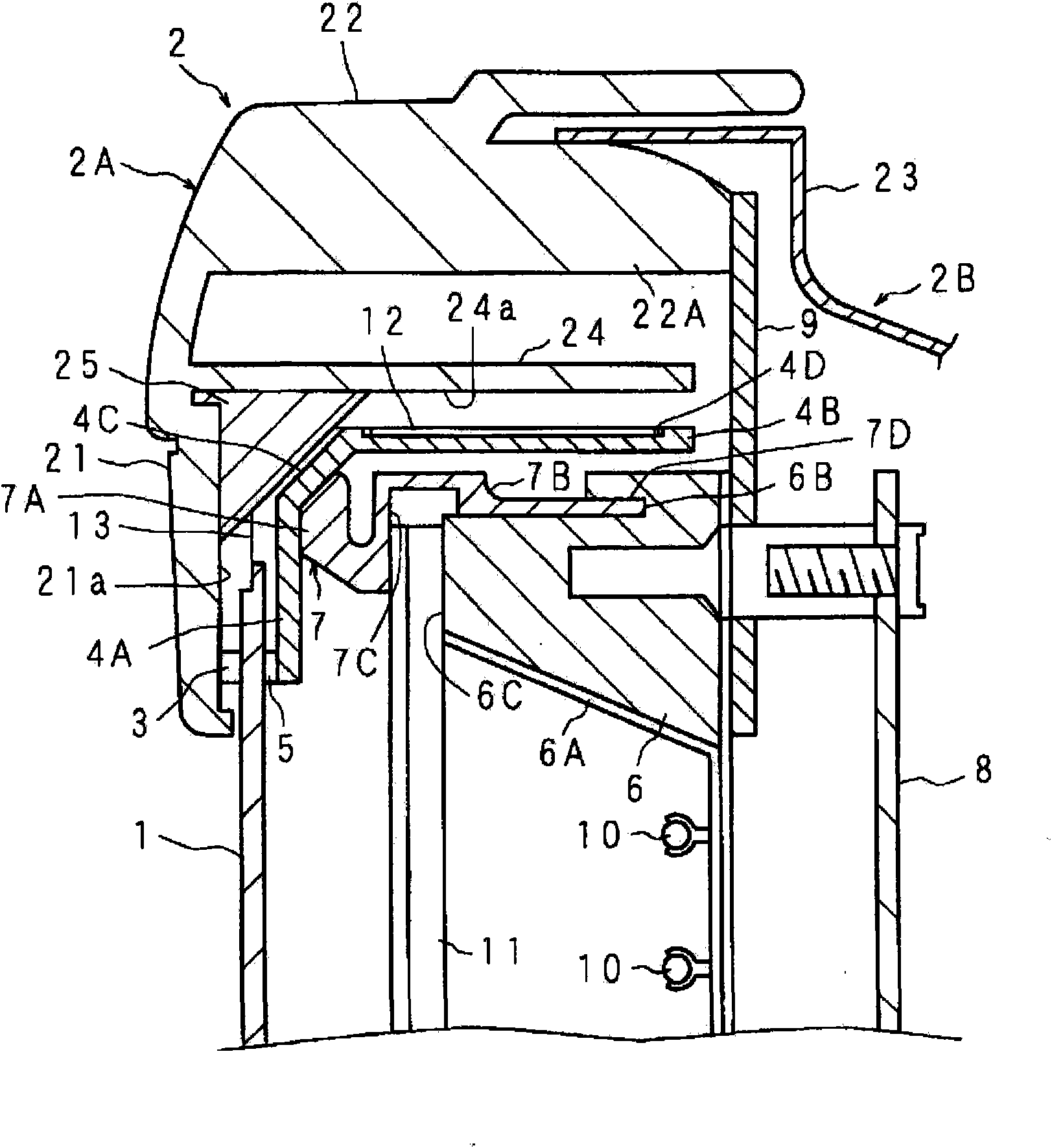

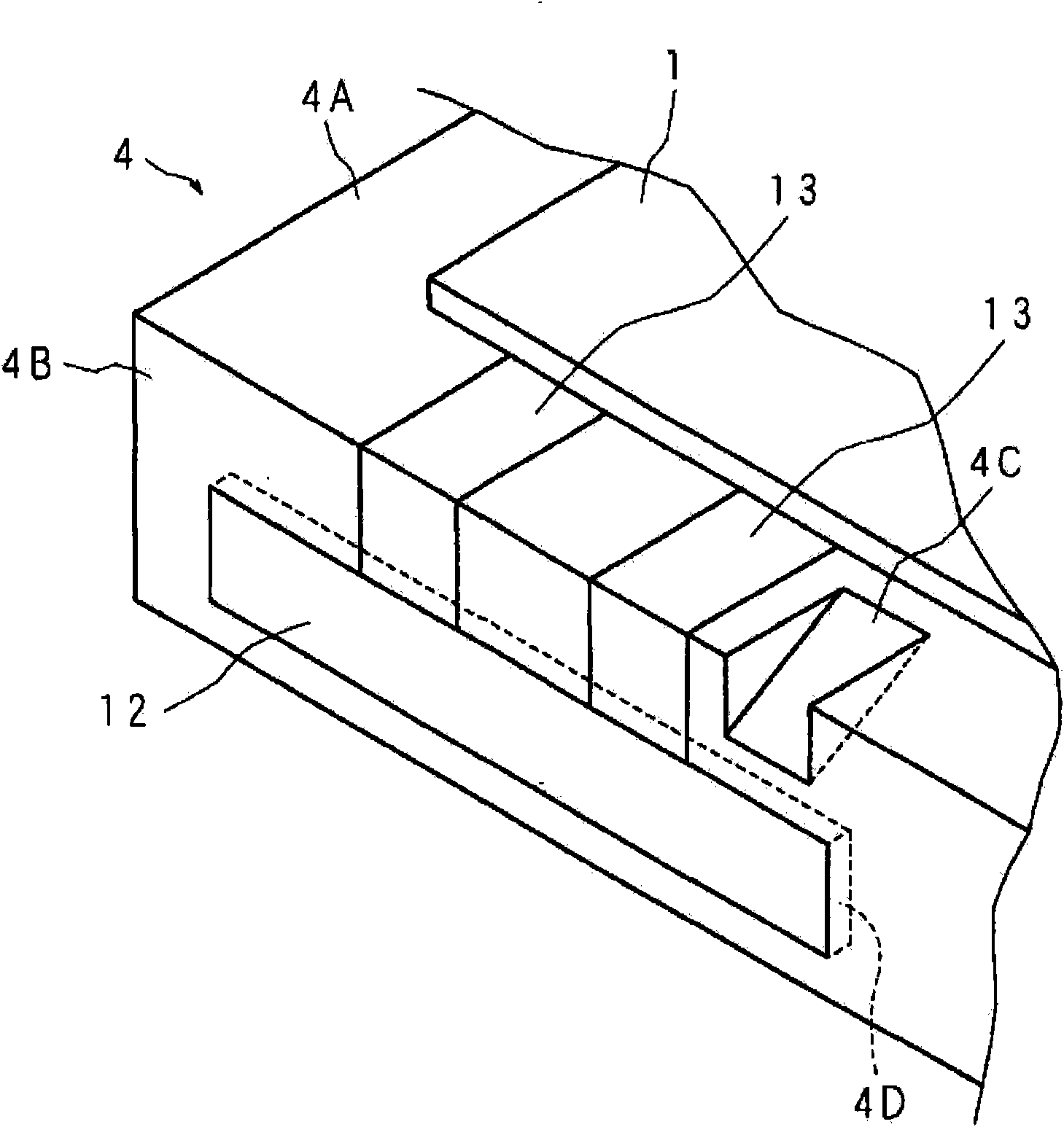

Display device

InactiveCN101842826AImprove rigidityImprove retentionNon-linear opticsIdentification meansDisplay deviceMechanical engineering

Owner:SHARP KK

Flame Retardant Bedding Product

InactiveUS20080254699A1Retain softnessRetains comfortablenessWarp knittingCircular knitting machinesPolyesterPolymer science

A bedding product, such as a pillow or cushion, that satisfactorily drawing out peculiar softness and comfort possessed by an internal filling material, realizes comfort and high flame retardance without detriment to the excellent drape and tactile sensation possessed by a fiber material of flame shielding cloth. There is provided a flame retardant bedding product comprising an internal filling material covered by a flame shielding cloth made of fibers containing 5 to 60 wt. % halogenous fiber (A), 5 to 60 wt. % flame retardant cellulose fiber (B), 0 to 75 wt. % cellulose fiber (C) and 0 to 50 wt. % polyester fiber (D).

Owner:KANEKA CORP

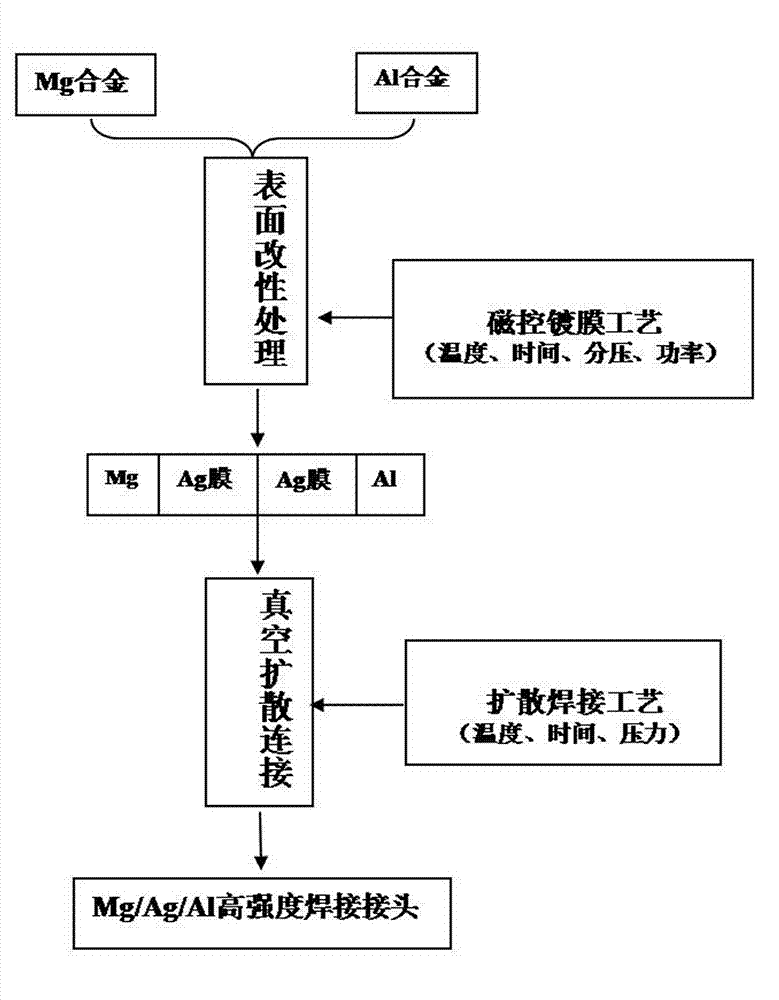

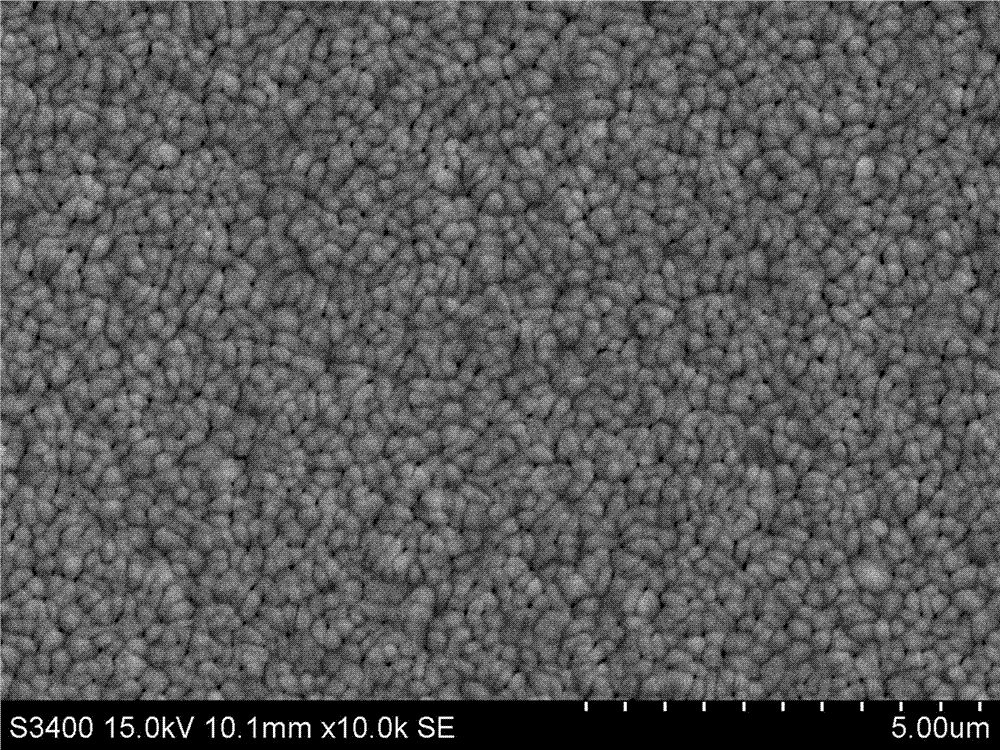

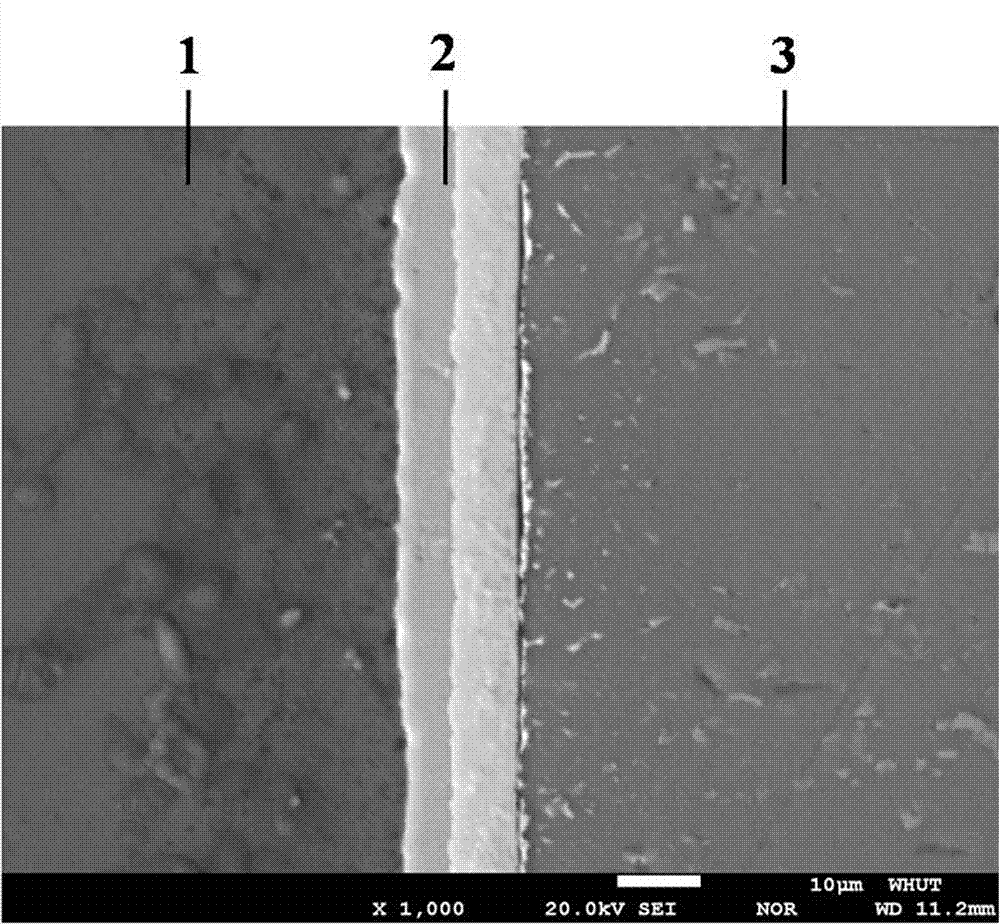

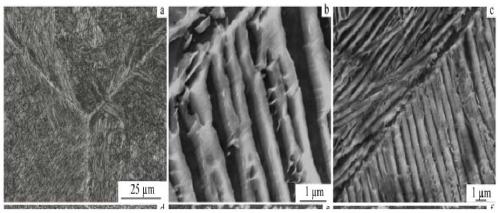

Method for surface modification and high strength connection of magnesium alloy and aluminum alloy

InactiveCN102732849ASolve the problem of low activityPromote interdiffusionVacuum evaporation coatingSputtering coatingSurface oxidationPhase composition

The invention provides a method for surface modification and high strength connection of magnesium alloy and aluminum alloy. The method is as follows: carrying out surface modification on magnesium alloy and aluminum alloy by using the technology of magnetron sputtering and depositing a silver thin layer with micron thickness as a barrier layer and an active layer; and realizing high strength connection of the magnesium alloy and the aluminum alloy at a low temperature by using the technique of vacuum diffusion welding. The invention has the following advantages: coating modification enables surface oxidation resistance of the easily-oxidizable aluminum alloy and magnesium alloy to be improved; diffusion connection of the magnesium alloy and the aluminum alloy at a low temperature is realized for the first time by using the highly active silver thin layer; the silver thin layer changes the phase composition and microstructure of a magnesium / aluminum connection interface and prevents formation of a high-hardness brittle magnesium-aluminum intermetallic compound on the interface, and high strength Mg-Ag and Ag-Al intermetallic transition layers are formed and have a shear strength of 20 to 30 MPa, increased by nearly 4 times compared with a shear strength obtained through direct welding of magnesium aluminum. The method provided in the invention has the advantages of a simple process and high control precision; an obtained connecting piece has small deformation and residual stress.

Owner:WUHAN UNIV OF TECH

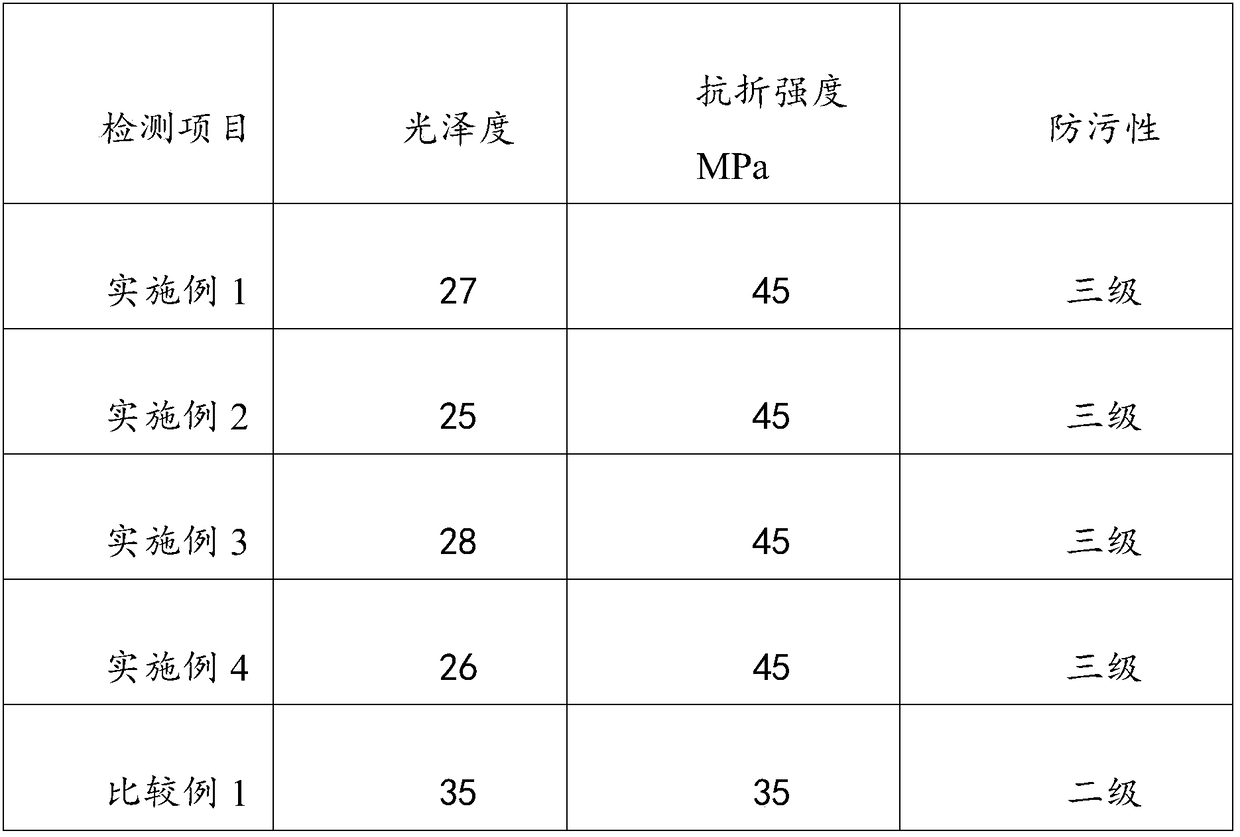

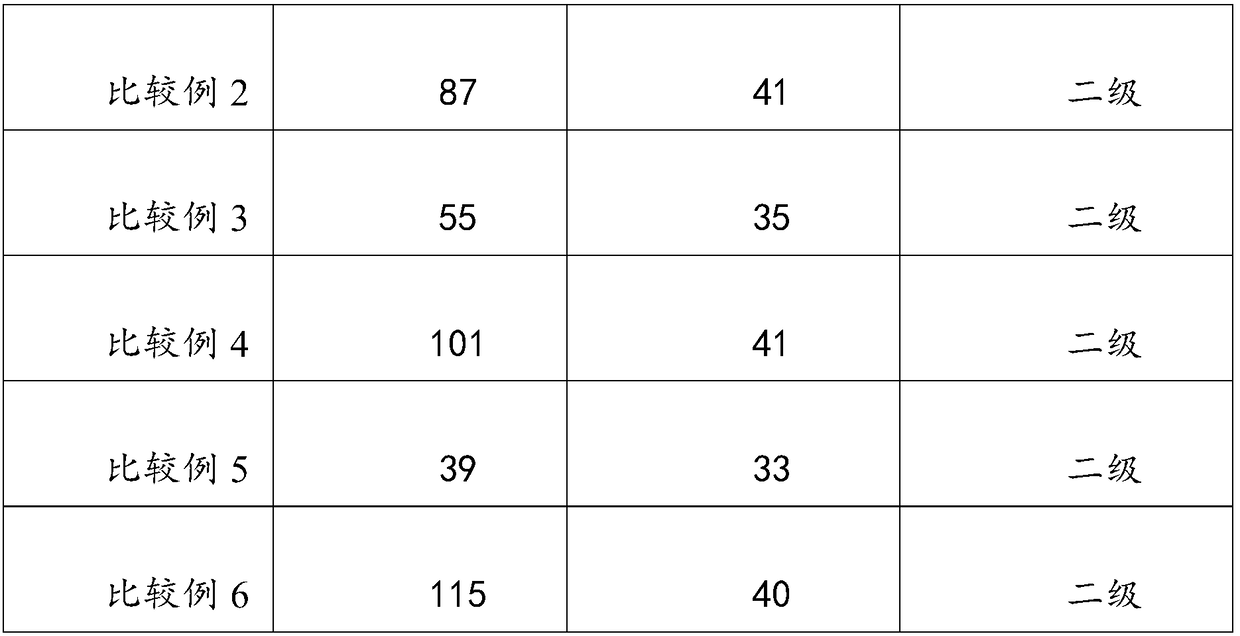

Method for preparing matte dry granular glazed brick

Owner:HEYUAN DONGYUAN EAGLE CERAMICS CO LTD

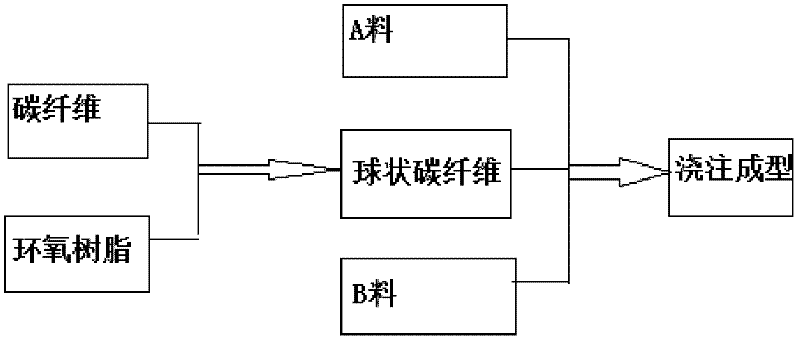

Carbon-fiber-reinforced polyurethane foamed plastic and preparation method thereof

The invention relates to a carbon-fiber reinforced polyurethane foamed plastic which is characterized by comprising the following components: component A: 100 parts of polyether glycol, 5-15 parts of flame retardant, 7-15 parts of foaming agent, 1.5-2.5 parts of foam stabilizer, 5-15 parts of carbon fiber, 1.5-2.5 parts of catalyst, 0.01-0.15 part of water, and epoxy resin; and component B: 20-30 parts of isocyanate (crude MDI (methylenediphenyl diisocyanate)) of which the index is 100-105. The flame retardant is a mixture of aluminum hydroxide and TCPP (trichloropropylphosphate); the foaming agent is CFC-11 or pentane; the catalyst is a mixture of tertiary ammonium salt catalyst and organotin; and the foam stabilizer is organosilicon ketone. The preparation method comprises the following steps: mixing carbon fiber and epoxy resin, evenly mixing to form quasispheric carbon fibers, mixing the carbon fibers with the component A and the component B, and carrying out primary cast molding. The density of the polyurethane material is 0.49g.cm<-3>, the compression modulus is 550MPa, the impact strength is 1.5kJ.m<-2>, and the density, compression modulus, impact strength and other physical and chemical parameter reach the standard at the same time.

Owner:WUJIANG MINGFENG POLYURETHANE PROD

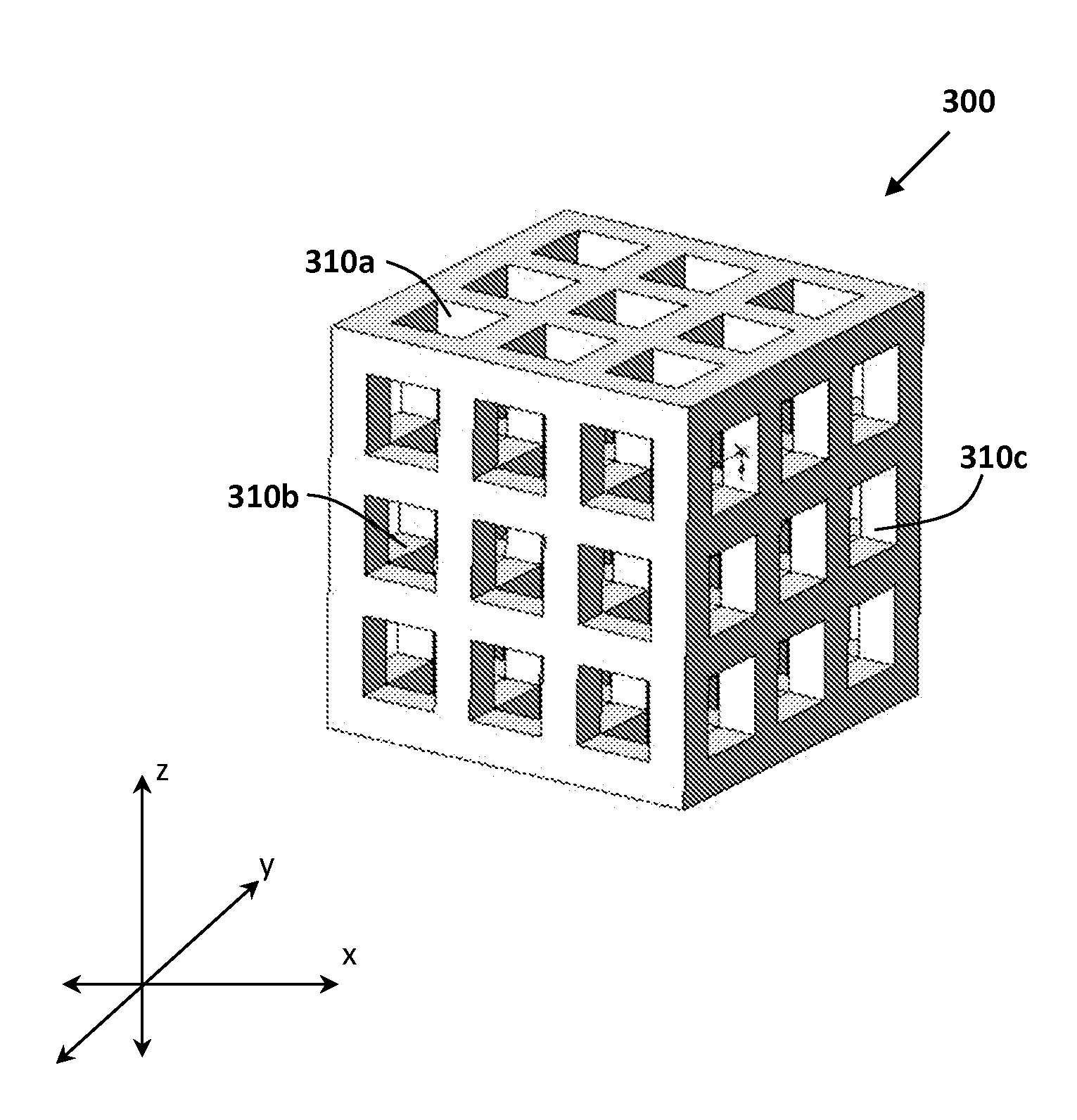

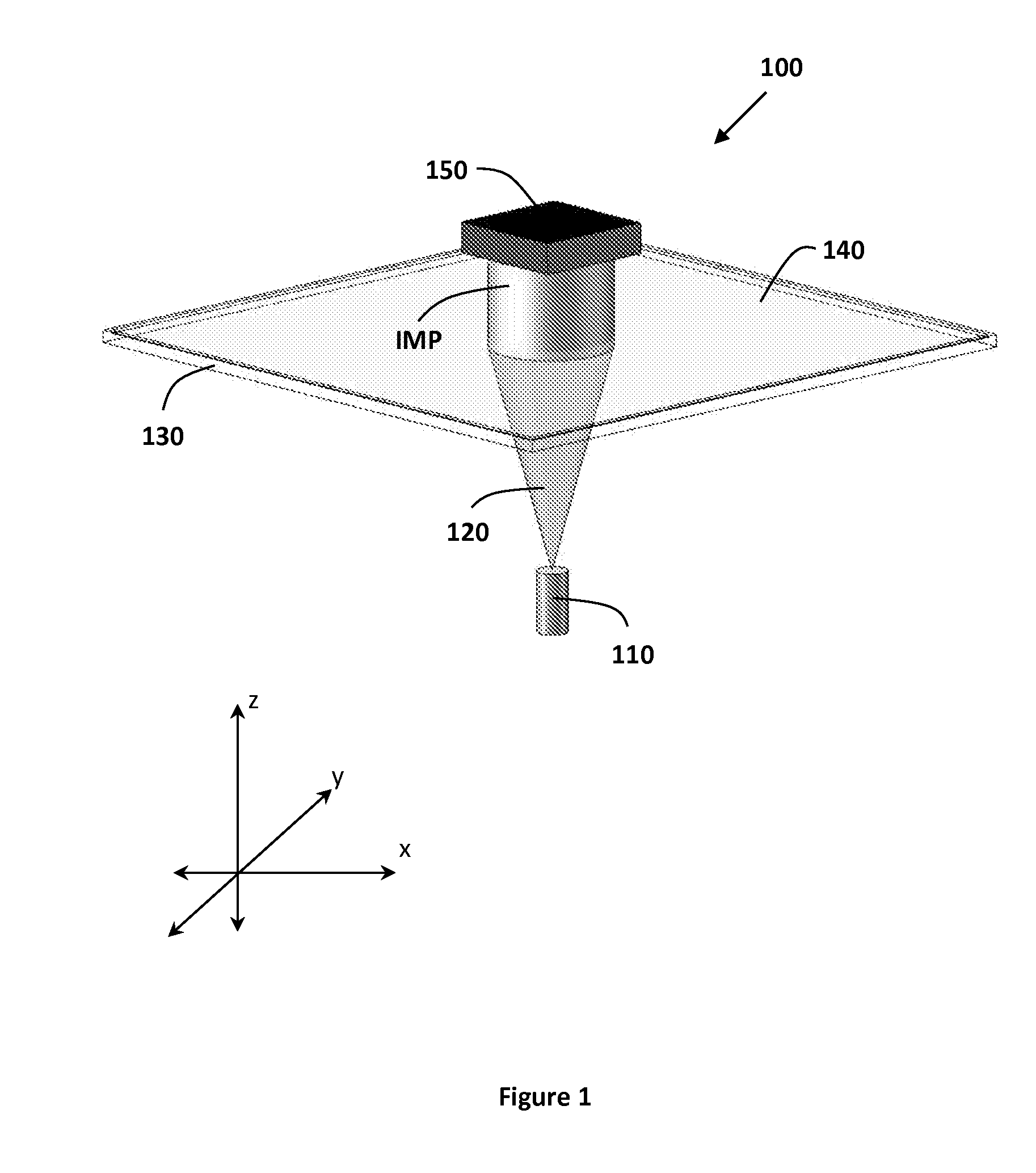

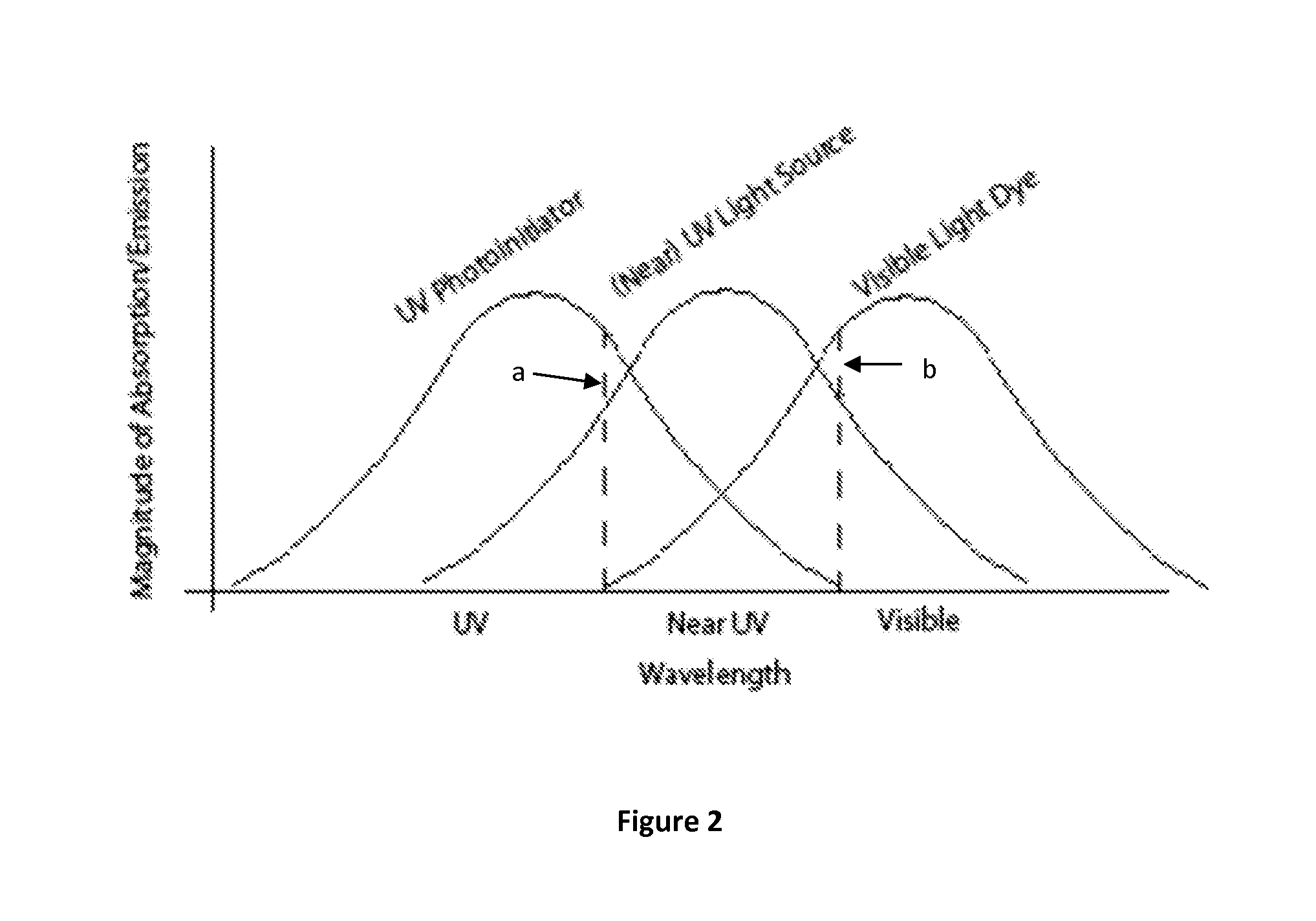

Absorbant and reflecting biocompatible dyes for highly accurate medical implants

ActiveUS20150314039A1High strengthHigh product strengthAdditive manufacturing apparatusImpression capsImage resolutionLight absorber

A light-polymerizable composition for additive manufacturing of resorbable scaffolds and implants comprising a biocompatible resin. The biocompatible resin includes a combination of photo-initiators or a dye-initiator package tailored to manufacture implants with the desired physical and chemical properties. A dye or other constituent controls between layer (z) resolution of the manufactured part built in an additive manufacturing device. A light absorber or other constituent controls within layer (x-y) resolution of the manufactured part.

Owner:RICE UNIV

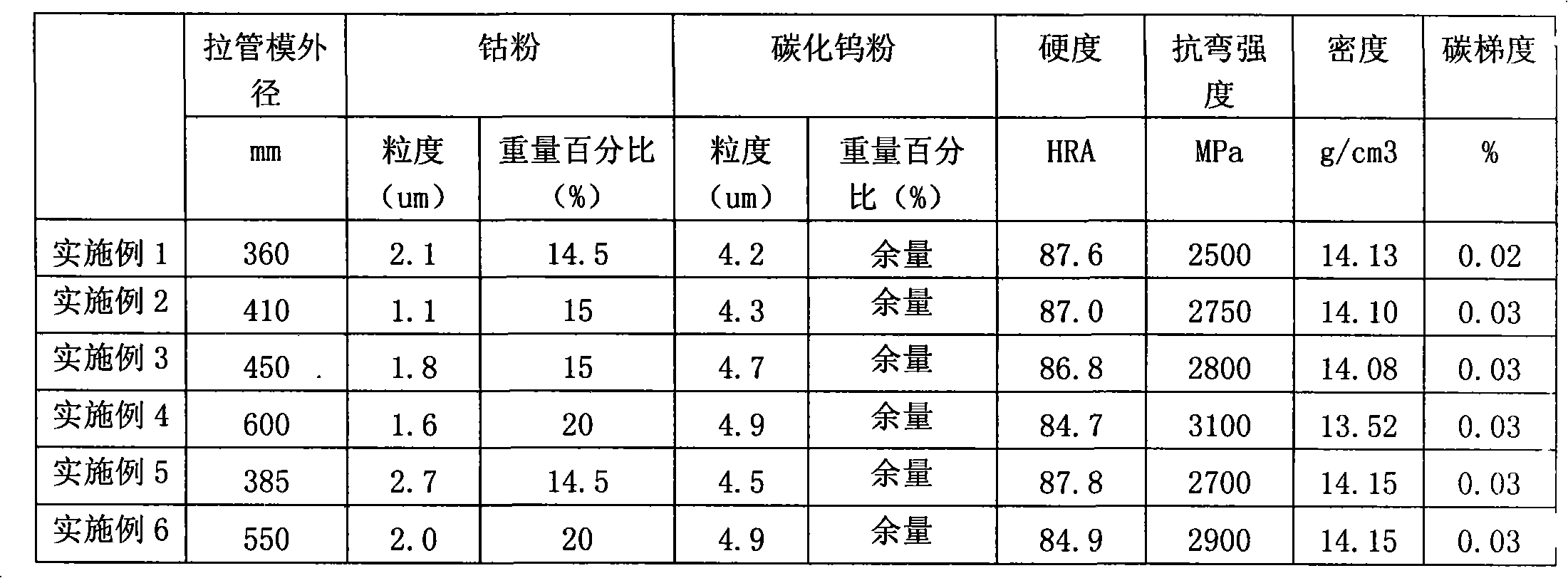

Hard alloy large pipe drawing mold and preparation method

InactiveCN101892408AHigh product strengthGuaranteed hardness and wear resistanceDrawing profiling toolsWaxCemented carbide

The invention provides a hard alloy large pipe drawing mold and a preparation method. The hard alloy large pipe drawing mold comprises the following raw material ingredients in percentage by weight: 14 to 20 percent of cobalt with a particle size of 1.0 to 3.0mu m, and the balance of tungsten carbide with a particle size of 4 to 5mu m. The preparation method comprises: raw material preparation, wet milling, drying, pressing, forming agent removal and sintering, wherein in the drying step, wax or butadiene rubber is used as the forming agent; the drying with the wax as the forming agent is spray drying; the forming agent remove is performed in a dewaxing and sintering integrated furnace or bell-type furnace; and the sintering is pressure sintering, and during the sintering, the temperature is raised within 11 to 13 hours till a liquid phase of the product appears, then about 40 mbars of high-purity argon is introduced into the furnace till the final sintering temperature of 1,390 to 1,400 DEG C, the temperature is kept for 50 to 60 minutes, then about 50 to 60 bars of high-purity argon is introduced, the temperature is kept continuously for 50 to 60 minutes, and the product is cooled to room temperature. The Rockwell hardness of the hard alloy large pipe drawing mold of the invention is more than or equal to 83HRA, the bending strength of the hard alloy large pipe drawing mold is more than or equal to 2,200MPa, and the density of the hard alloy large pipe drawing mold is 13.40 to 14.20g / cm<3>. And the hard alloy large pipe drawing mold has the advantages of high hardness, high wear resistance, uniform product performance, fragmentation resistance and long service life.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

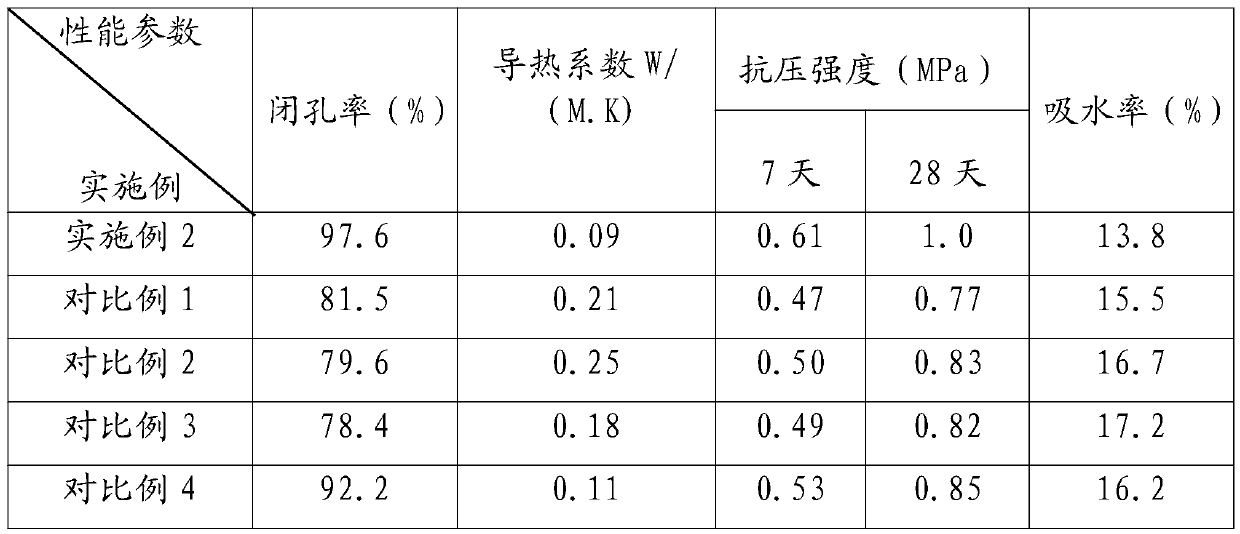

Microporous structure foam light soil and preparation method thereof

InactiveCN110128073AImprove and enhance the pore structurePore structure highCeramicwareUltimate tensile strengthAbsorption rate

The invention discloses micro-pore structure foam light soil which is prepared from the following raw materials: a cementing material, foaming foam, micro-silicon powder, a modifier and water, whereinthe mass ratio of the components is 100:(0.51-30.3):(0-10):(0-8):(61-80). The method can effectively improve and improve the pore structure in the foam light soil. The micro-pore structure foam lightsoil is uniform and round in pores, thick and compact in pore wall, few in capillary pores, high in pore closing rate, good in pore closing effect, high in strength, capable of remarkably improving heat preservation and heat insulation and low in water permeability and water absorption rate. According to the technical scheme, the utilization rate of industrial solid waste and tailings can be effectively increased, the cement utilization amount is reduced, and the production cost is reduced. The product can be widely applied to road and bridge filling, roof heat preservation, pipeline backfilling, large-scale filling engineering, building component preparation and the like.

Owner:河南华泰新材科技股份有限公司

Preparation method of micro-capsule fly ash floating bead toughened and reinforced phenolic foam

The invention discloses a preparation method of micro-capsule fly ash floating bead toughened and reinforced phenolic foam. The method comprises the following steps: treating a fly ash floating bead by using a silane coupling agent, and then wrapping the fly ash floating bead by using a polyurethane prepolymer to obtain a micro-capsule fly ash floating bead; then performing foaming reaction with raw materials such as A-stage phenolic resin, a surfactant, a foaming agent and a catalyst to obtain the toughened and reinforced phenolic foam. The surface of the prepared micro-capsule fly ash floating bead disclosed by the invention contains relatively more isocyanate active groups, thus the micro-capsule fly ash floating bead can be used for reacting with matrix resin in the foaming process to improve the compatibility with the phenolic foam; the micro-capsule fly ash floating bead has an reinforcement effect on the phenolic foam; the introduction of flexible long chains in the polyurethane prepolymer can be used for improving a friable structure of the phenolic foam and improving the toughness, and only can influence the excellent combustion characteristics of the phenolic foam to the lowest extent.

Owner:HEFEI GENIUS NEW MATERIALS

Efficient and energy-saving type high temperature mortar for cement rotary kilns, and preparation method thereof

The present invention discloses an efficient and energy-saving type high temperature mortar for cement rotary kilns, wherein the components in the formula comprise, by weight, 40-55 parts of fused mullite, 6-15 parts of corundum fine powder, 2-10 parts of active alumina micro-powder, 2-10 parts of andalusite fine powder, 3-6 parts of kyanite fine powder, 0.5-3 parts of Y2O3, 0.5-2 parts of carboxymethyl cellulose, 0.1-1 part of sodium tripolyphosphate, 0.1-1 part of sodium hexametaphosphate, and 20-35 parts of a silicon-aluminum sol. The present invention further relates to a preparation method of the high temperature mortar. According to the present invention, the efficient compounding of the silicon-aluminum sol is used, and the mullite is easily generated during the high temperature sintering process, such that the structure is compact, the performance is stable, the adhesion strength is continuously improved along with the temperature increase, and the high temperature resistance and the thermal shock resistance are good; and the high adhesion strength is provided at the low temperature, and the adhesion strength is greater than the brick strength, such that the sufficient adhesion strength is provide so as to ensure no generation of bricking lining distortion, brick falling and other phenomena during the drying on the cement rotary kiln.

Owner:PINGXIANG KEXING FURNACE MATERIAL

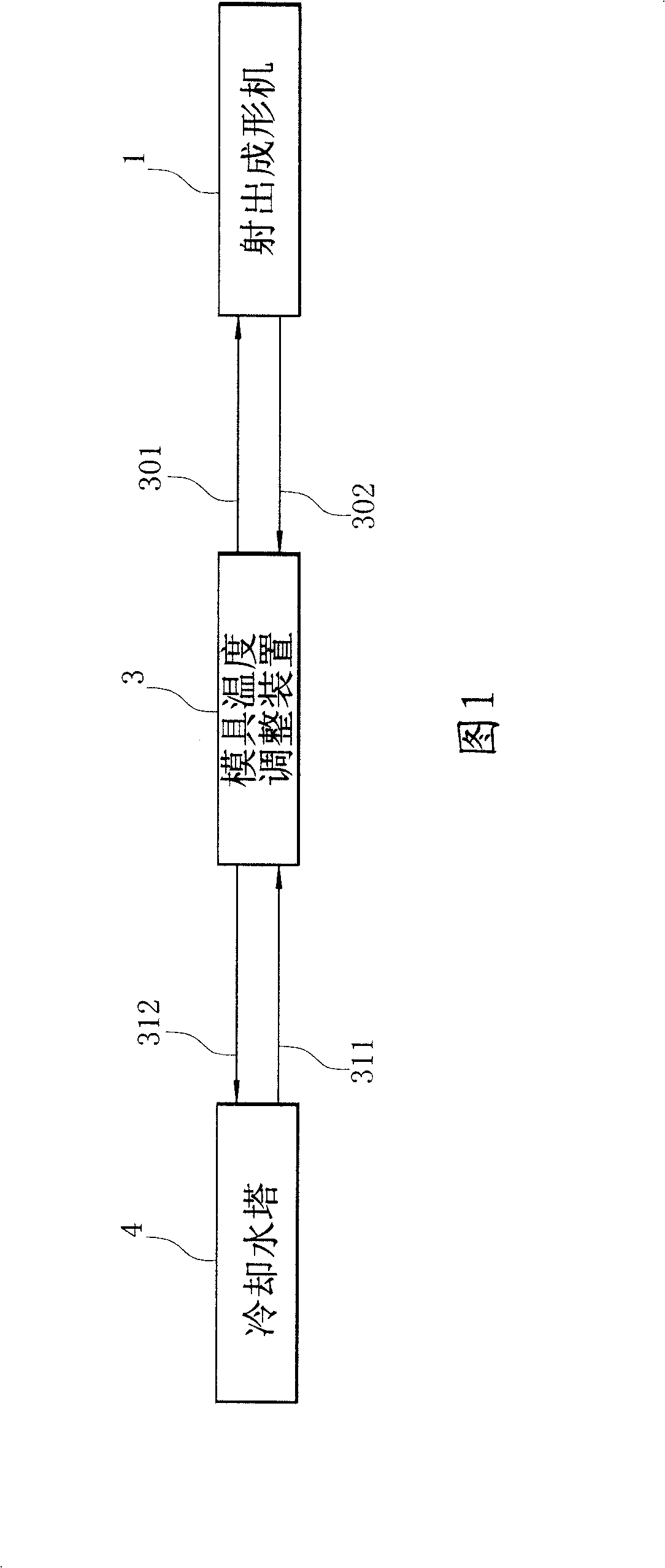

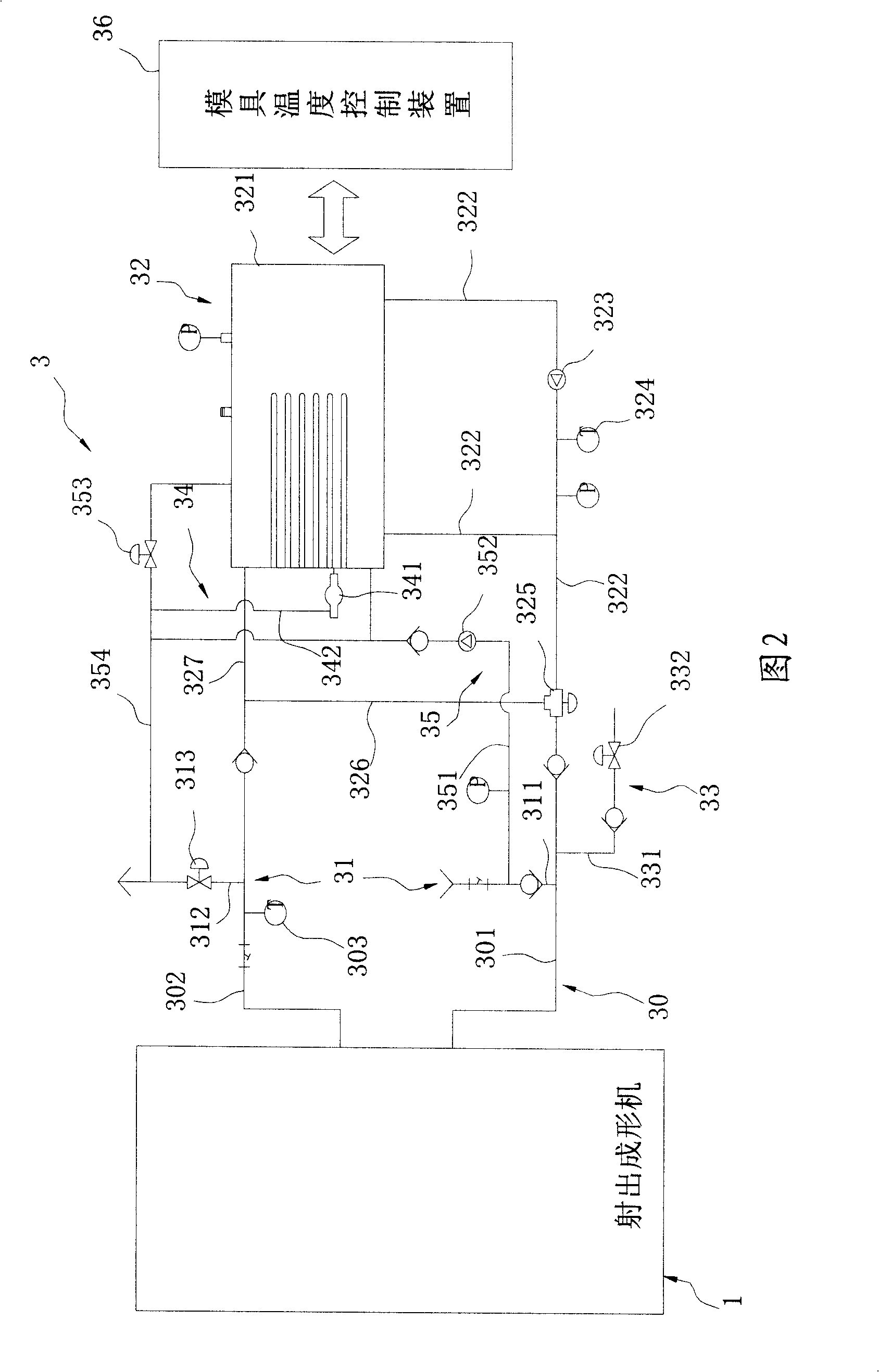

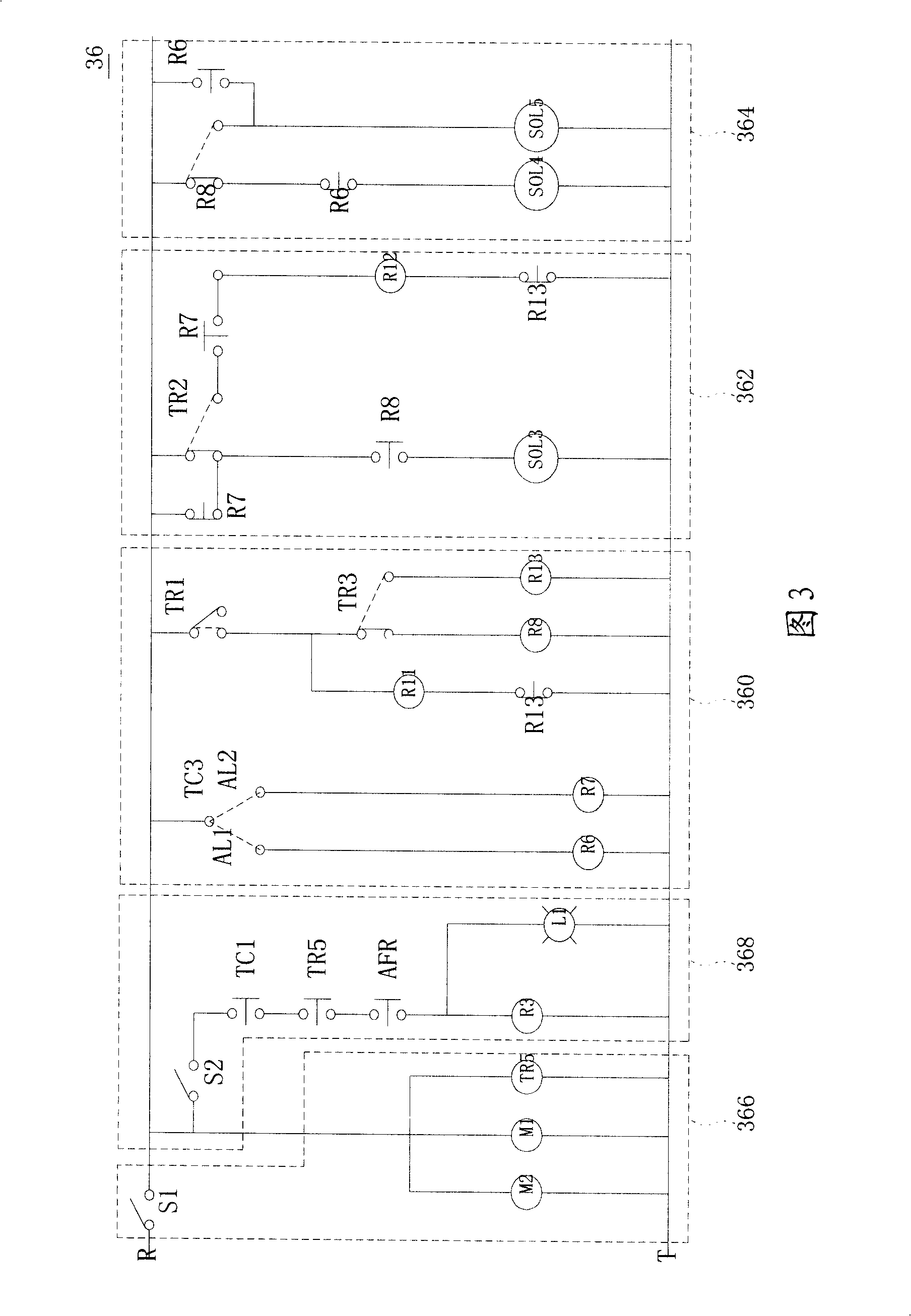

Die temperature control device and control method thereof

The invention provides a mould temperature control device and a control method thereof; wherein, the control device comprises a driving circuit of an ice water valve, a driving circuit of a triple valve and a temperature judgment circuit; wherein, the temperature judgment circuit can judge the mould temperature of the injection molding machine. The mould temperature control device is characterized in that when the temperature reaches the first design temperature, the control circuit of the triple valve drives the triple valve to move, stops the circulating hot fluid from flowing to the mould of the injection molding machine and controls the driving circuit of the ice water valve to drive the movement of the ice water valve; when the temperature reaches the second design temperature, the temperature judgment circuit can control the driving circuit of the triple valve to drive the movement of the triple valve, control the circulating hot fluid to the mould of the injection molding machine and control the driving circuit of the ice water valve to stop the movement of the ice water valve.

Owner:暐立实业有限公司

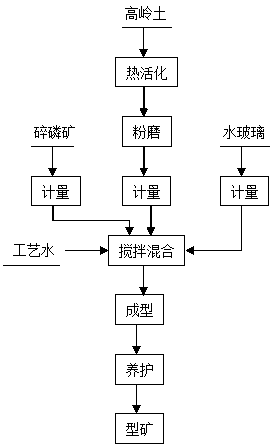

Method for molding phosphate detritus

ActiveCN103864036AReduce the amount addedRaise the gradeRaw phosphate material treatmentMineral SourcesHeat stability

The invention relates to a method for molding and solidifying phosphate detritus, belonging to the technical field of comprehensive utilization of mineral resources. The method comprises steps of adding activated kaolin accounting for 2-4% of the mass of dry matrix of the phosphate detritus, water glass accounting for 4-5% of the mass of dry matrix of the phosphate detritus, and process water accounting for 10-12% of the mass of dry matrix of the phosphate detritus into phosphate detritus, then stirring, mixing and homogenizing the mixture, after molding, standing and curing so as to obtain the finished product. The method has characteristics of simple production process, mature equipment, less investment, convenience in operation, low energy consumption, high strength molded mineral, and good high temperature heat stability, can reduce the serpentine consumption in production of yellow phosphorus by an electric furnace method, and can be used as the raw material for producing yellow phosphorus by the electric furnace method.

Owner:KUNMING UNIV OF SCI & TECH

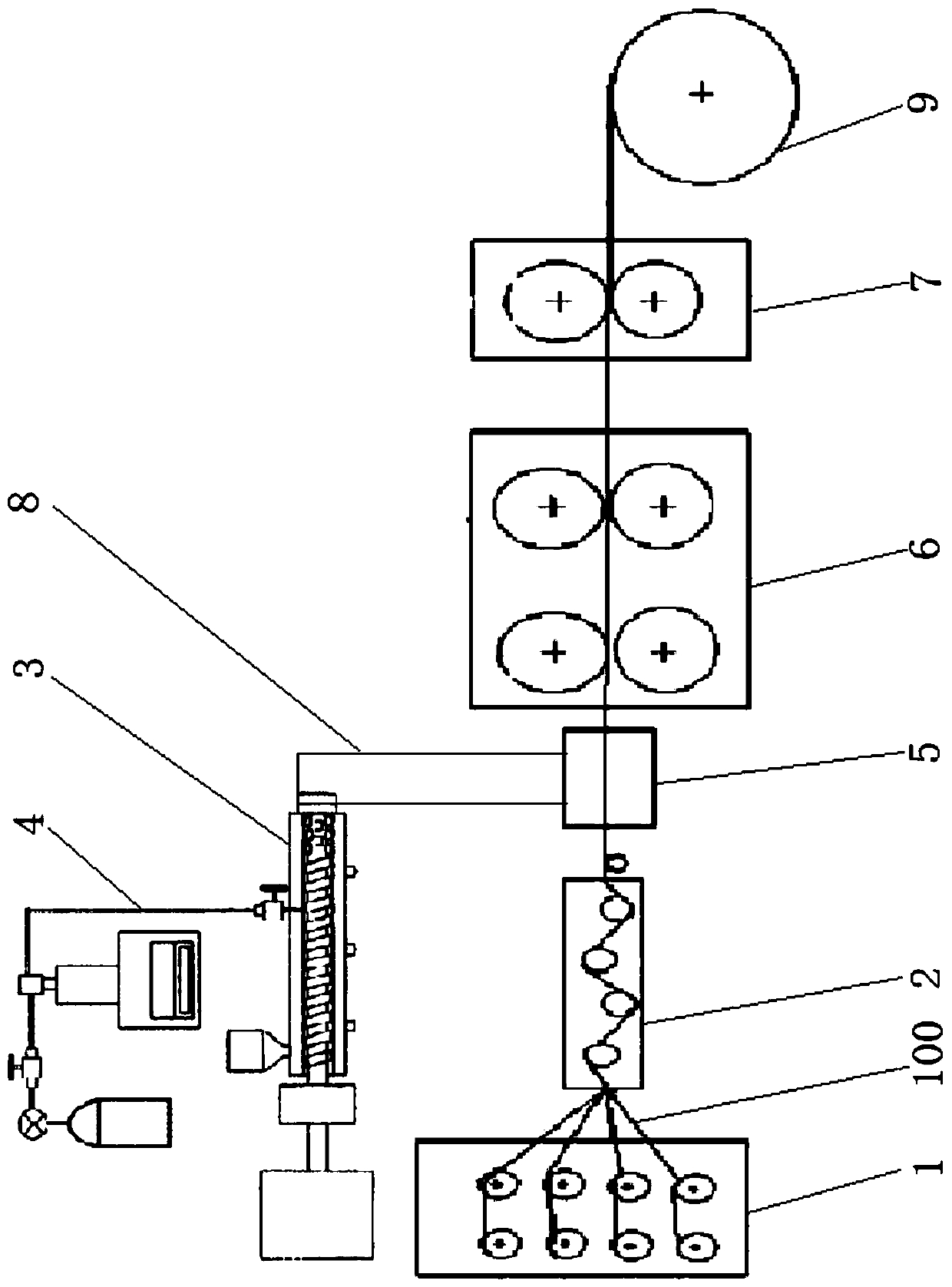

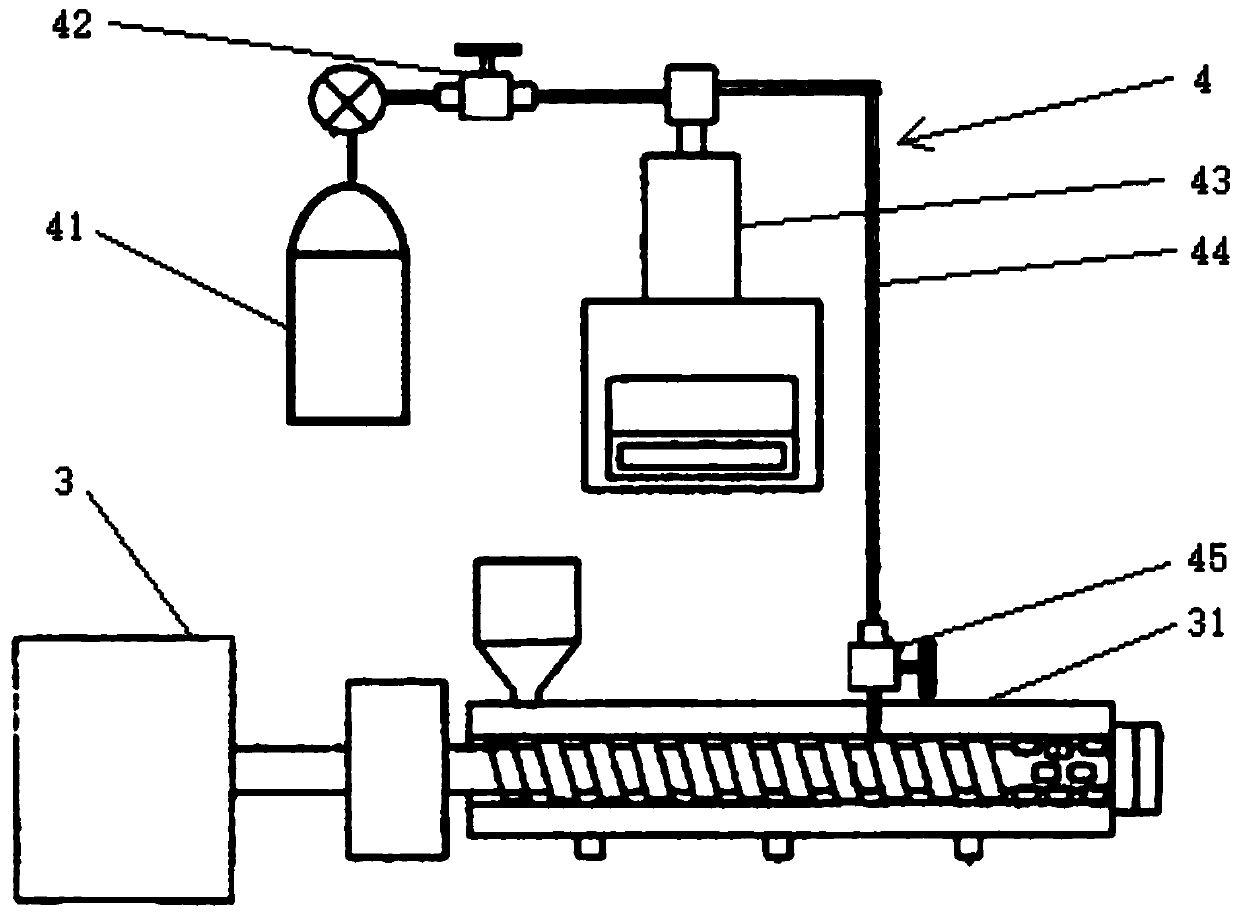

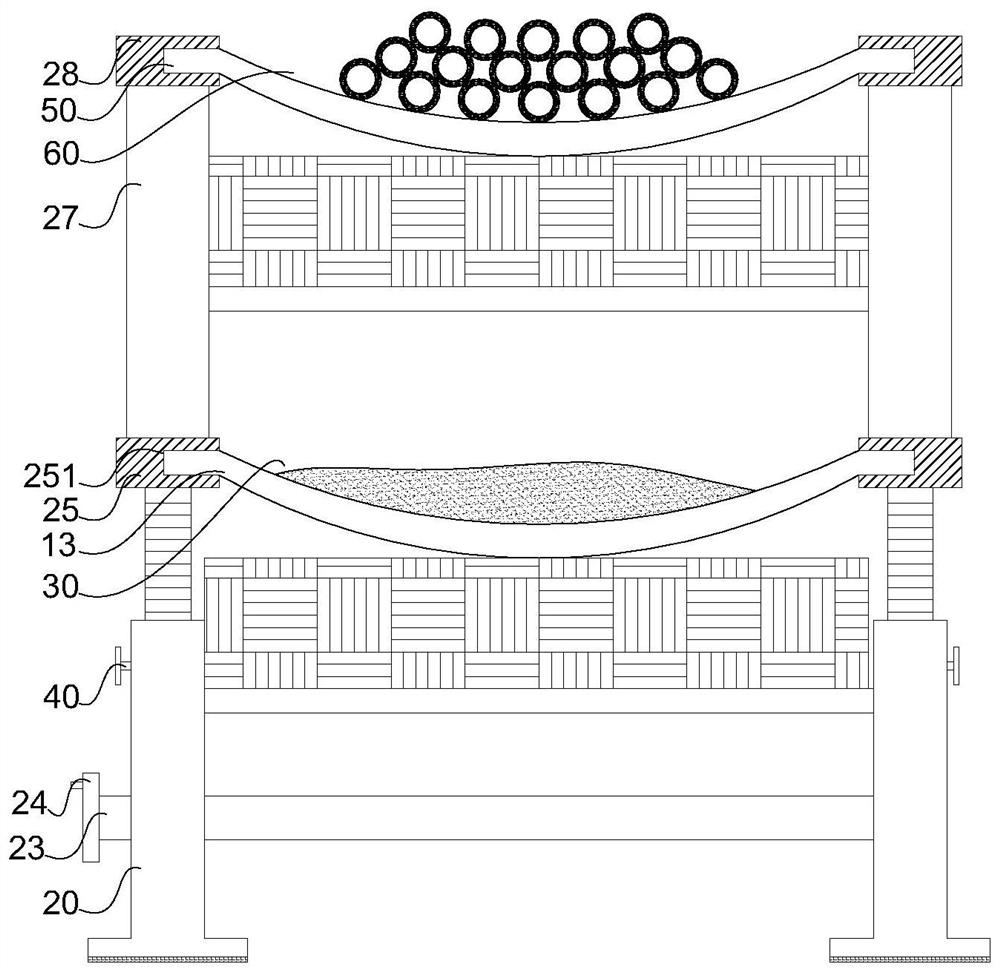

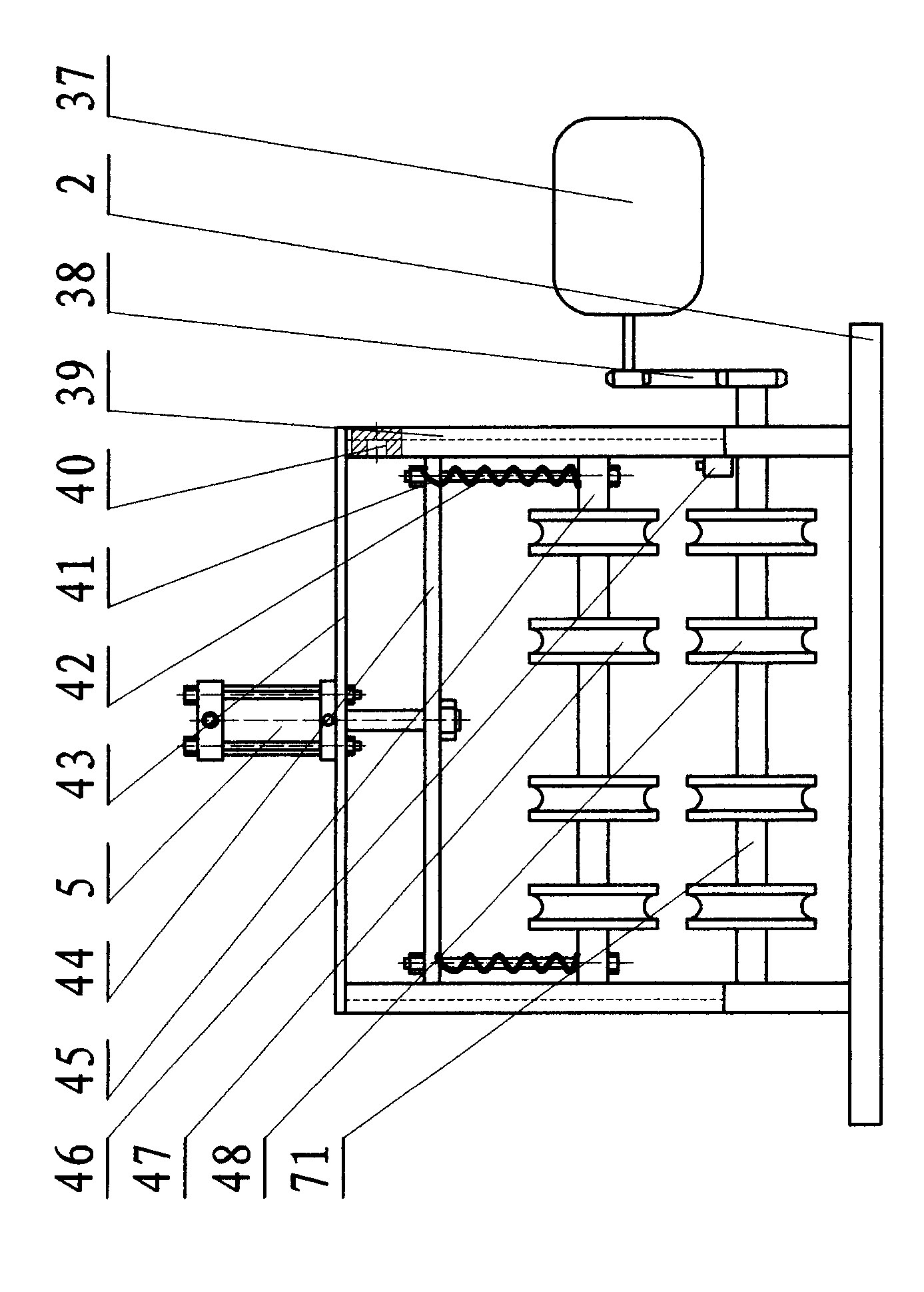

Production device and production method of continuous fiber reinforced thermoplastic composite

The invention discloses a production device and production method of a continuous fiber reinforced thermoplastic composite. The production device of the continuous fiber reinforced thermoplastic composite comprises a yarn frame, a tension filament spreading device, a screw extruder, a supercritical carbon dioxide generation device, a fiber impregnation structure, a cooling pressure roller device and a traction device; the screw extruder communicates with the fiber impregnation structure, the supercritical carbon dioxide generation device communicates into a screw machine cylinder of the screwextruder, and supercritical carbon dioxide is injected into molten thermoplastic resin in the screw machine cylinder. The production device has the advantages that due to the fact that the supercritical carbon dioxide generation device is arranged, the supercritical carbon dioxide is injected to the molten thermoplastic resin in the screw machine cylinder, the viscosity of the molten thermoplasticresin is reduced, the molten thermoplastic resin can completely impregnate a continuous fiber bundle, after impregnation, the supercritical carbon dioxide reaches the normal pressure, the carbon dioxide is released into the air, the whole product property is not affected, and product quality is ensured.

Owner:江苏苏能新材料科技有限公司

Consumer electronic panel machining process based on sapphire technology

InactiveCN106163178AImprove thermal stressHigh product strengthCasings/cabinets/drawers detailsL&D processSurface finishing

The invention discloses a consumer electronic panel machining process based on a sapphire technology. A consumer electronic panel is machined using a cutting process, a tree process and a surface treatment process. Consumer electronic panels comprise mobile phone panels and tablet computer panels. The machining process comprises the following steps: cutting sapphire after quality inspection into a block, finishing blank allowance of 0.15-0.2mm according to the single-side size of a consumer electronic panel, and rounding the edges of the block corresponding to the four corners of the panel, wherein the fillet dimension is 4.5-8R; and then, cutting the block into a piece through linear cutting equipment. In view of the defects of the existing large-screen sapphire panel, such as high processing difficult, low efficiency and poor yield, a novel machining process is provided, which can be used to machine a 2.5D consumer electronic panel with a wear-resistant and scratch-resistant arc edge contour.

Owner:成都市思卡利科技有限公司

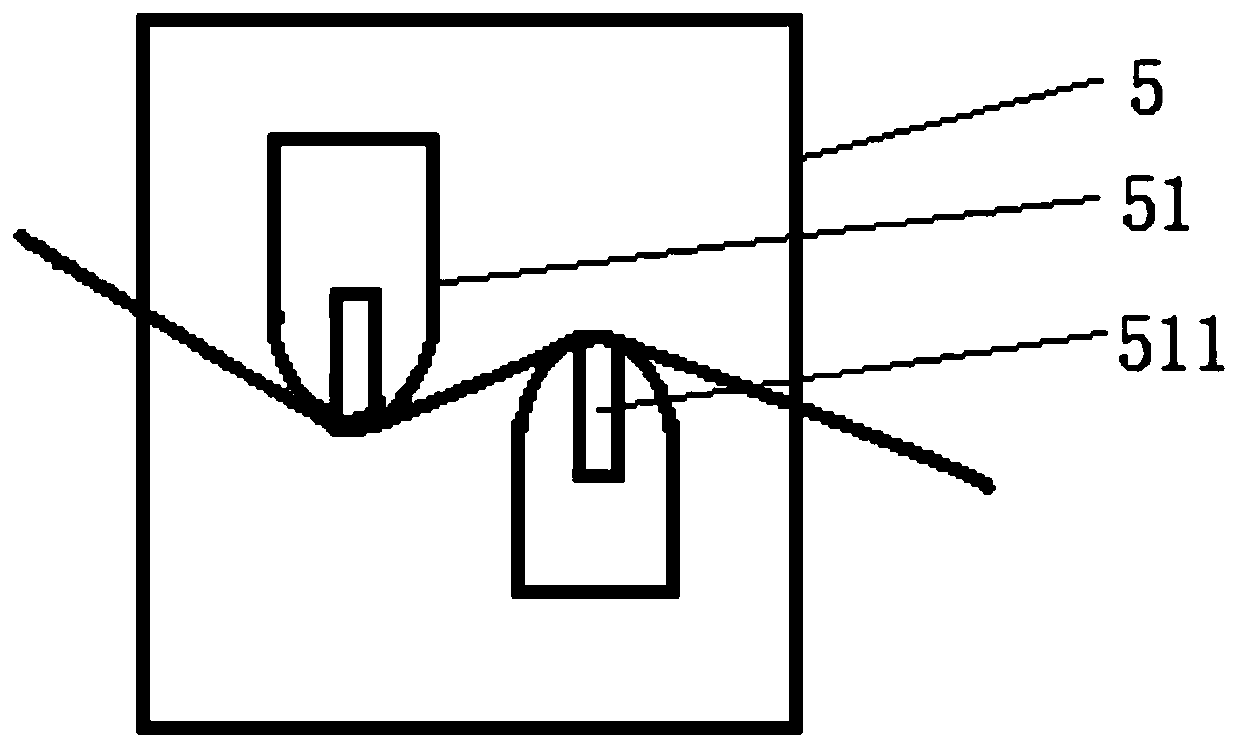

Preparation process of high-performance precoated sand for complex casting and compression molding system thereof

ActiveCN112139442AImprove toughnessReduce crosslink densityFoundry mouldsMould handling/dressing devicesCrazingAlkali free

The invention discloses a high-performance precoated sand for complex castings and a compression molding system thereof. According to the high-performance precoated sand for the complex castings and the compression molding system thereof, a binder is bisphenol A epoxy resin modified phenolic resin, meanwhile, nitrile rubber is added, the mechanical property, the bonding strength and the thermal stability of the obtained modified phenolic resin are greatly improved, and the dimensional stability of a cured product is excellent; the precoated sand prepared from the phenolic resin is high in strength and excellent in thermal stability, and when the sand is used for casting a high-precision casting with a complex structure, due to the high strength, the thermal stability and the dimensional stability, thermal stress generated by sand core expansion can be resisted, and casting cracks are prevented from being generated; montmorillonite, calcium stearate and alkali-free glass fibers are usedas a composite collapsing agent, so that the collapsibility, gas evolution, strength and thermal toughness of the precoated sand are remarkably improved, the compactness of the sand core is improved,the strength of a mold core is improved, and the casting is prevented from deforming and cracking; and in addition, the compression molding system utilizes sand mold preheating to preheat the precoated sand, so that the precoated sand is easier to press.

Owner:济南市平阴县玛钢厂

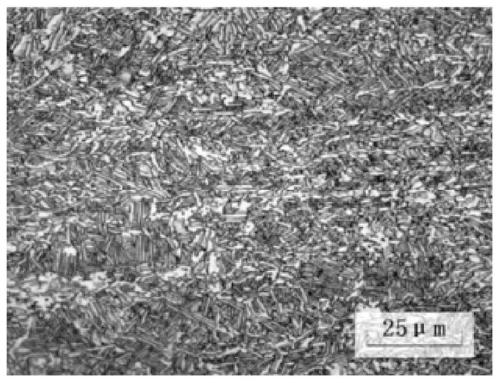

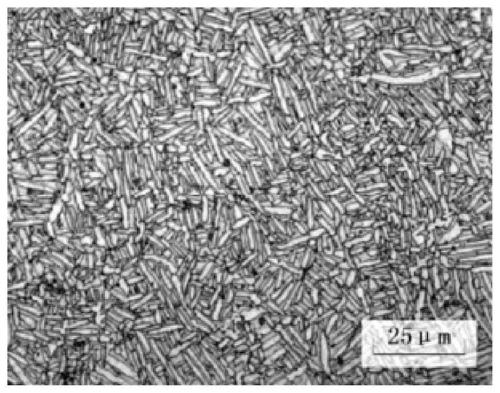

Preparation method of high-strength and high-toughness titanium alloy material cutter

InactiveCN110129700AHigh strengthImprove corrosion resistanceVacuum evaporation coatingSputtering coatingFine structurePunching

The invention relates to the technical field of cutters, in particular to a preparation method of a high-strength and high-toughness titanium alloy material cutter. The preparation method comprises the following steps that S1, raw materials are prepared; S2, punching is carried out, wherein the prepared titanium alloy materials are fed into a punching workshop for cutting, and a cutter blank is cut according to the size of the cutter, and the size and the thickness of a cutter sample; S3, heat treatment is carried out, and specifically heat treatment is carried out on the cut cutter blank; S4,surface hydrogen permeation is carried out; and S5, film coating is carried out, wherein a Ti-DLC film is plated on the surface of the cutter blank by using a magnetron sputtering method, microporesin the DLC film layer are plugged through fluorine-containing acrylate monomers, so that the wear resistance of the cutter is improved, the toughness of a substrate is not reduced, the coating has a fine structure, so that the compressive stress is produced inside the coating, the anti-crack propagation capability is high, and the service performance of the cutter is improved.

Owner:阳江十八子刀剪制品有限公司

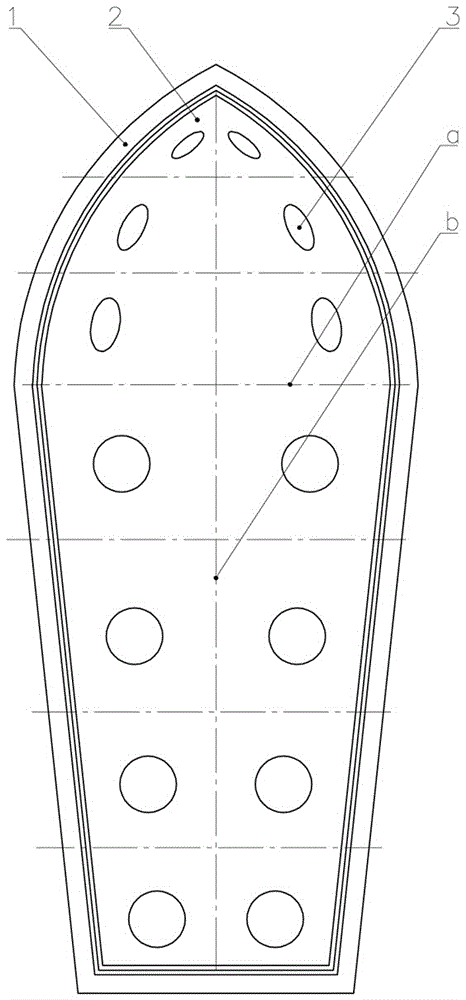

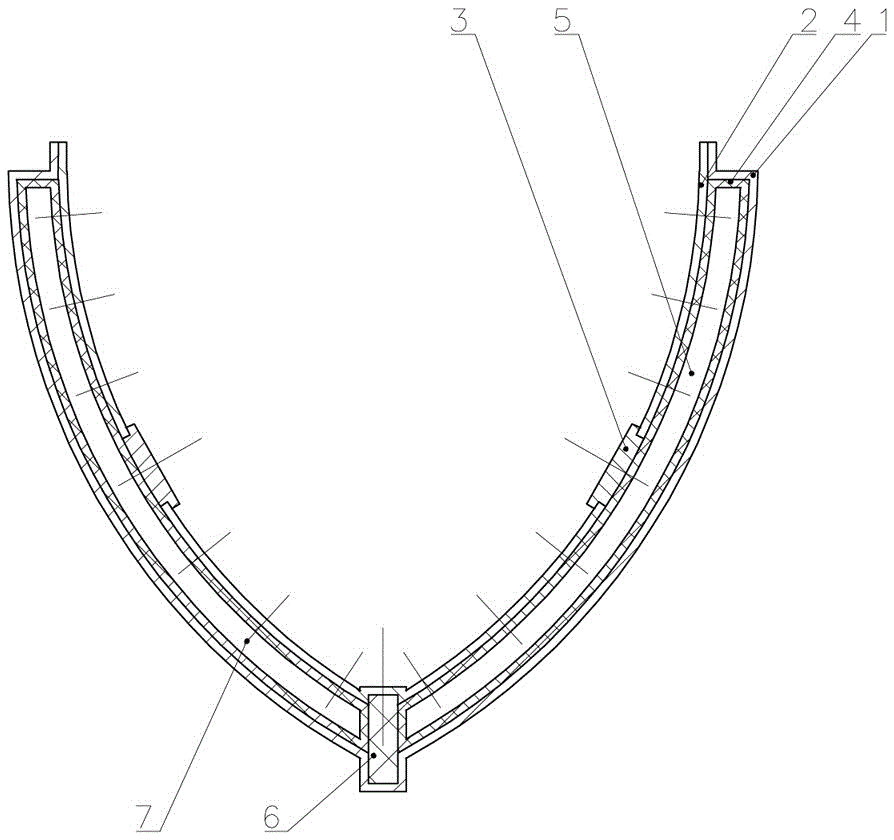

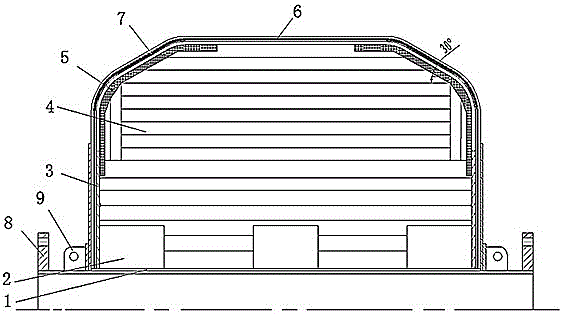

Rotational molding manufacturing method for double-layer all-plastic ship

The invention provides a rotational molding manufacturing method for a double-layer all-plastic ship. The method includes the process that after an inner mold body and an outer mold body are combined, plastic and other raw materials are added through a feed port, the mold bodies are heated and rolled, the plastic and other raw materials are melted, mixed and arranged on the inner walls of the mold bodies in a coating mode, and finally cooling and demolding are conducted; before the inner mold body and the outer mold body are combined, a supporting frame is fixed between the inner mold body and the outer mold body through a supporting frame fixing device, and the distance between the surface of the supporting frame and the inner walls of the inner mold body and the outer mold body is within the design thickness of a hull shell. Compared with the prior art, the supporting frame is arranged between the inner layer and the outer layer of the hull shell, the defects that no keel is arranged, and a rib hull is insufficient in strength are overcome, the hull is firm and stable and is not prone to deformation, re-modification worries are avoided, and the defects that labor and materials are wasted due to the fact that reinforcing ribs are additionally welded or a hollow interlayer is filled with foam materials are overcome.

Owner:王海平

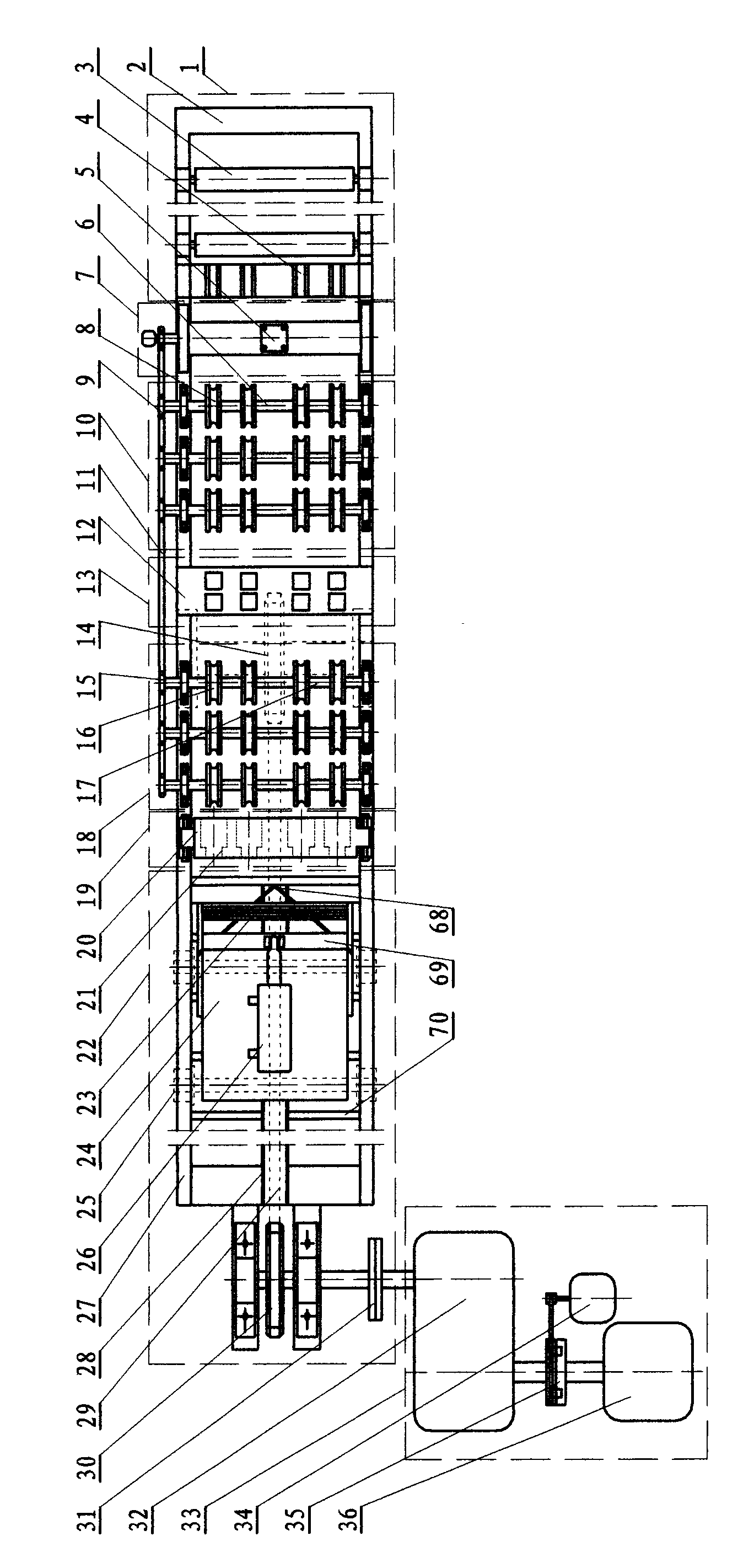

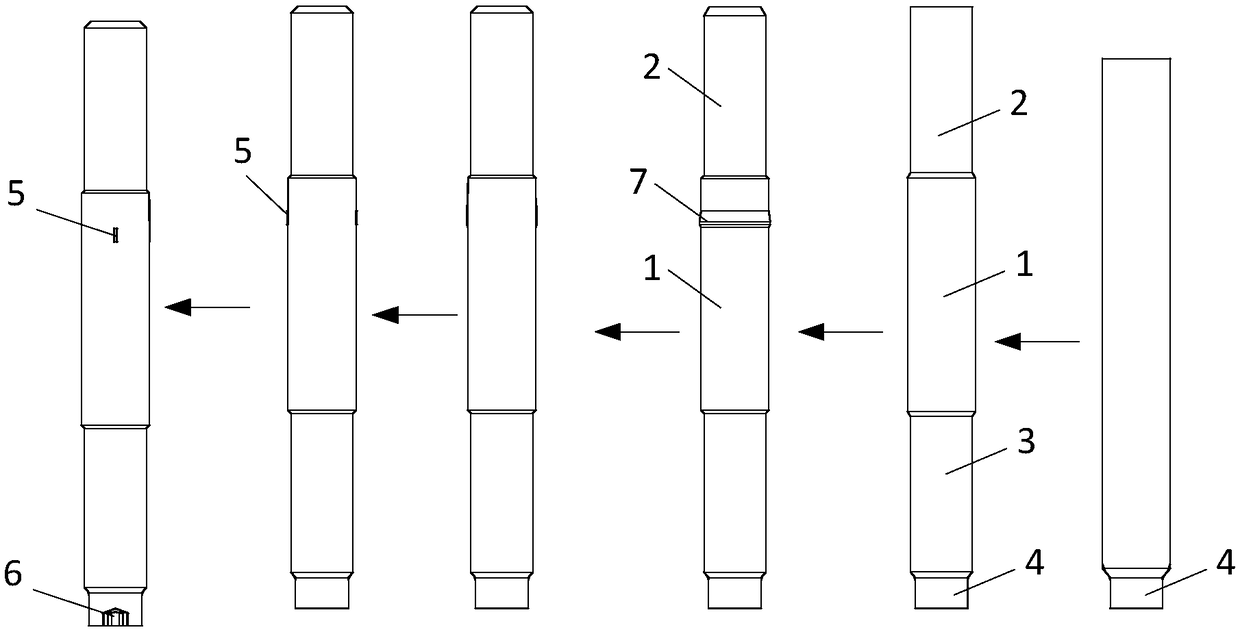

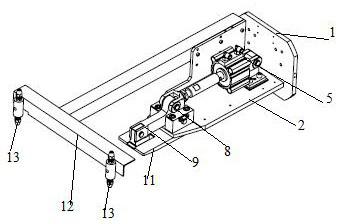

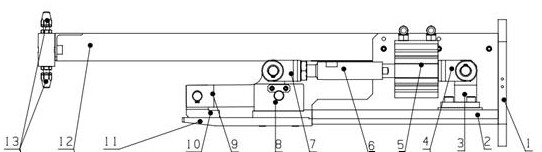

Novel automatic cold drawing process for colored metal tube and automatic cold drawing machine of colored metal tube

ActiveCN102240686AReduce labor intensityIncrease lock speedDrawing diesEngineeringUltimate tensile strength

The invention discloses a automatic cold drawing process for a colored metal tube, and relates to the technical field of colored metal tube processing. The process comprises the following steps of: feeding material tube, conveying the material tube at the first time, locking the opening of the material tube, conveying the material tube at the second time, clamping the material tube, drawing the material tube and resetting the material tube. The automatic cold drawing machine has the characteristics of reducing the labor intensity, improving the production efficiency, reducing the energy consumption, improving the product quality, realizing automatic and continuous production and the like, and is suitable for all types of colored metal tubes, such as a cold drawing aluminum tube, a cold drawing copper tube and the like.

Owner:QIYANG HONGTAI ALUMINUM IND

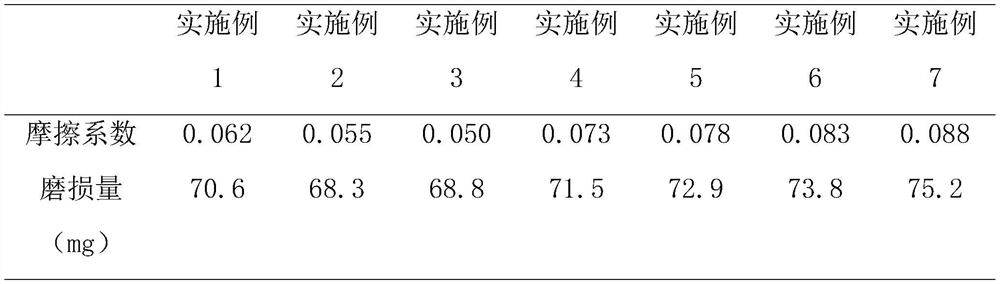

Polytetrafluoroethylene sealing friction material for hydraulic oil cylinder and preparation method thereof

The invention discloses a polytetrafluoroethylene sealing friction material for a hydraulic oil cylinder and a preparation method thereof and belongs to the field of sealing friction materials. The prepared material is resistant to pressure, oil and abrasion, low in friction coefficient and suitable for a reciprocating hydraulic sealing system with the pressure being 28 MPa and the reciprocating speed being 0.2 m / s or below. The preparation method comprises the steps of high-speed mixing, cold press molding, slow heating, high-temperature sintering and slow cooling. Through matching of the wear-resistant phase filler and the antifriction phase filler, slow heating and slow cooling, stress in a blank is reduced, the crystallinity of PTFE is improved, and the sealing material with high strength, good toughness, high wear resistance and low friction is prepared; and the sealing material is suitable for a reciprocating hydraulic sealing system with the pressure being 28 MPa and the reciprocating speed being 0.2 m / s or below, and the service life and reliability of a sealing piece are guaranteed.

Owner:SHENYANG POLYTECHNIC UNIV

Building concrete prefabricated part and machining method thereof

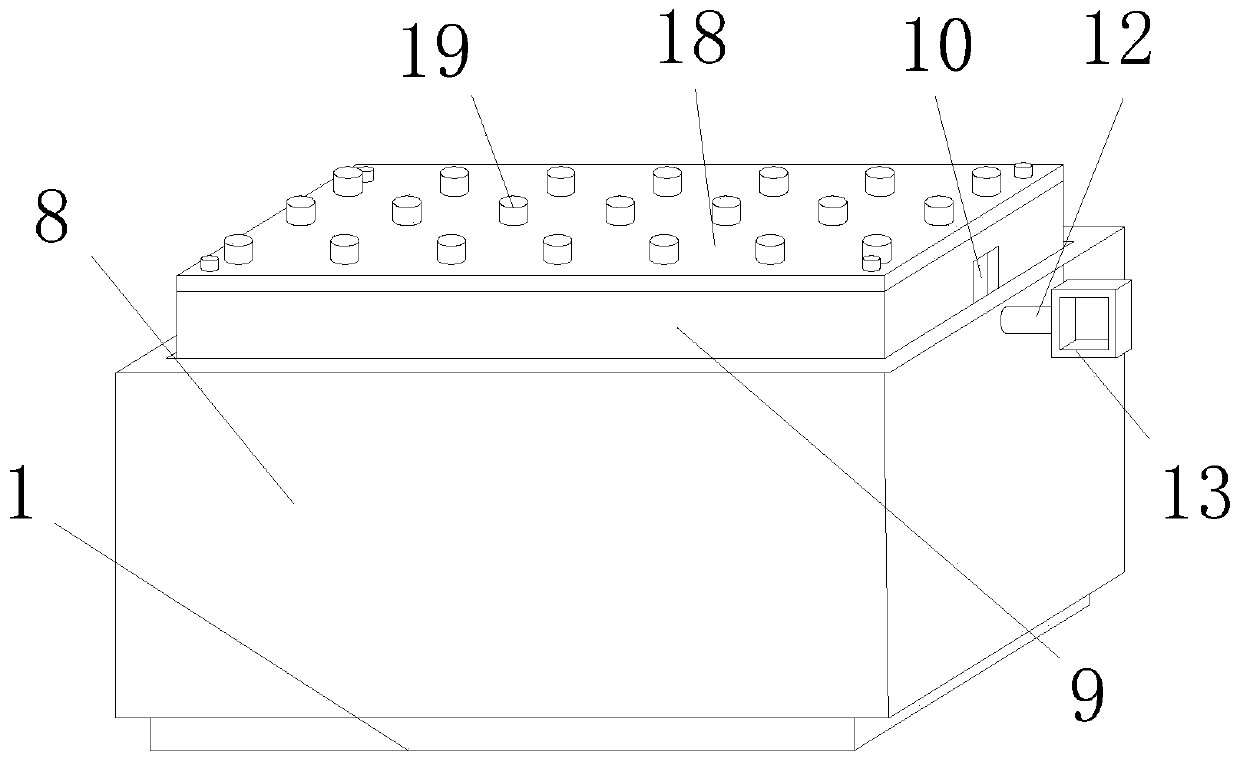

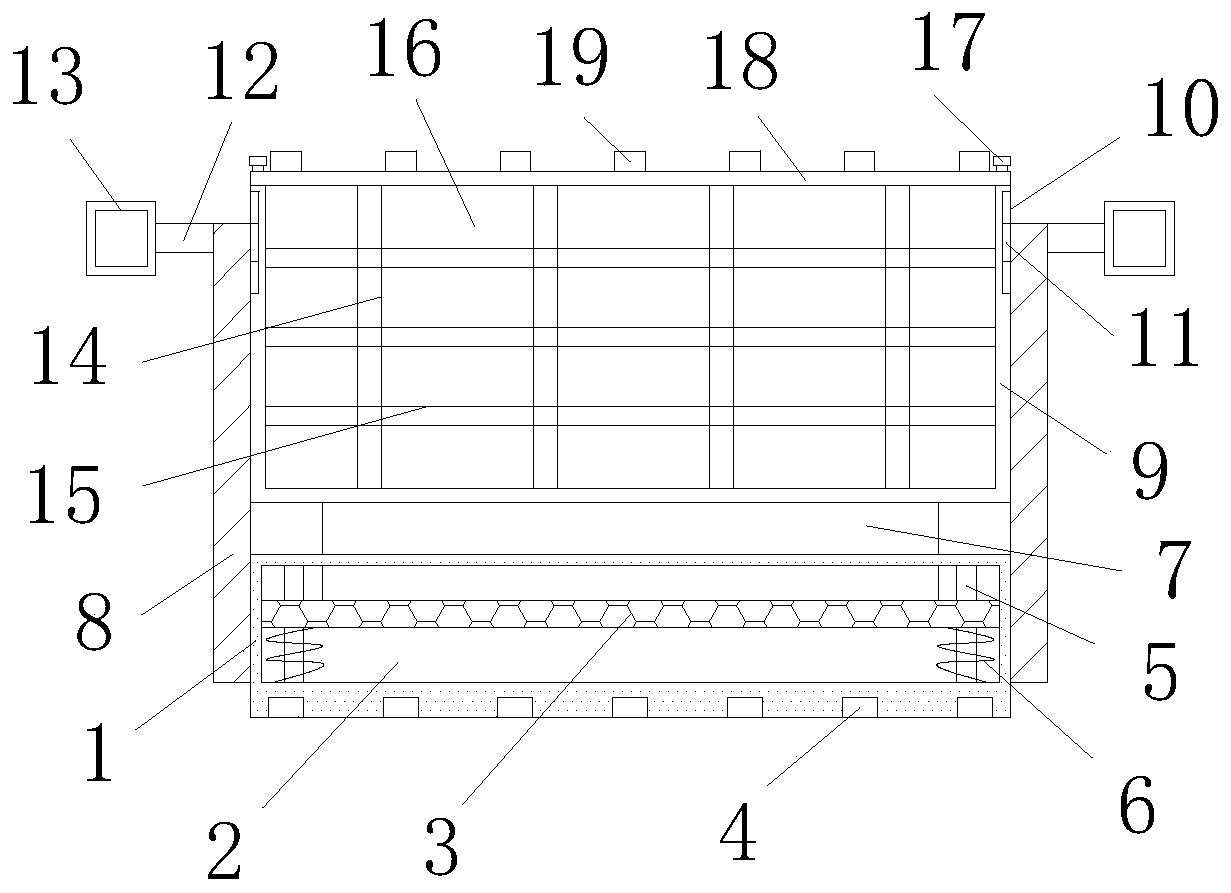

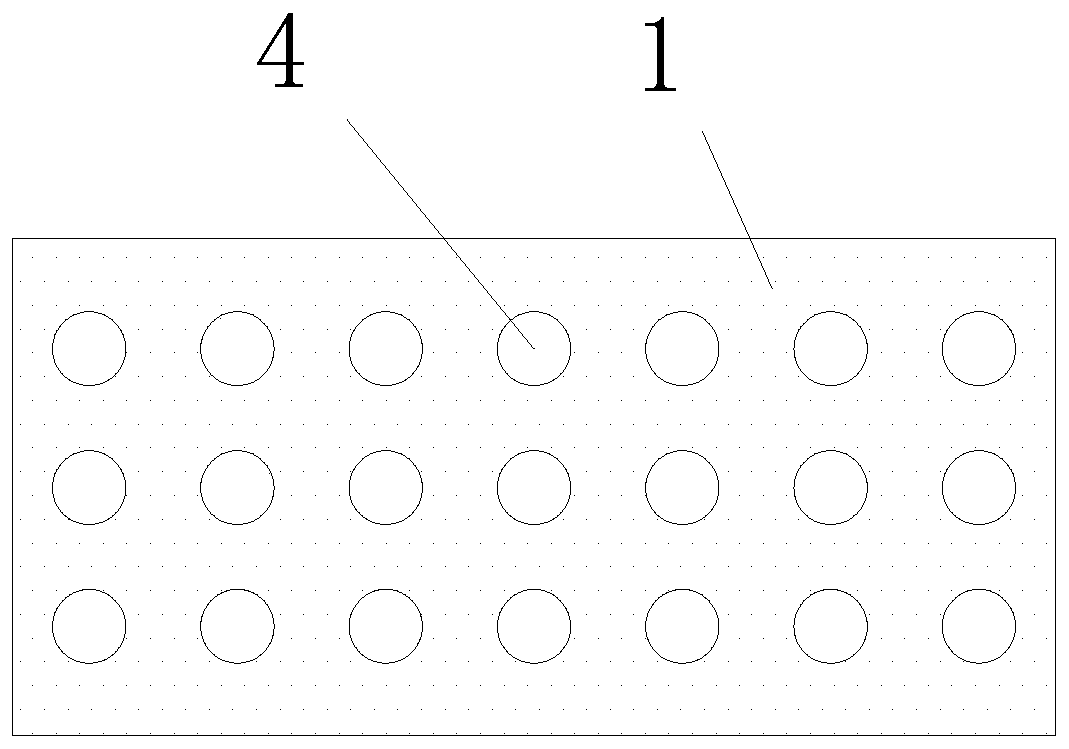

PendingCN111483053AImprove shock absorption performanceEasy to operateCeramic shaping apparatusProtective buildings/sheltersSlide plateArchitectural engineering

The invention discloses a building concrete prefabricated part and a machining method thereof. The building concrete prefabricated part comprises a base, a sliding cavity, a sliding plate, a limitinggroove, a sliding rod, a spring, a connecting plate, a connecting shell, an embedded shell, a sliding groove, a sliding block, a connecting rod, a fixed block, a first reinforcing rib, a second reinforcing rib, a filling cavity, a fixed bolt, a top plate and a limiting column. According to the building concrete prefabricated part and the machining method thereof, the structure is simple, the design is novel, under the action of an arranged damping mechanism, the overall damping effect of the device is improved, stable use of the prefabricated part is guaranteed, the use requirements of workersare met, and the operation is convenient; in use, under the action of an arranged concrete prefabricated mechanism, concrete can be conveniently filled, the overall manufacturing strength of the prefabricated part is improved, the overall practicability of the prefabricated part is improved, the prefabricated part is convenient for the workers to use, two prefabricated parts can be conveniently and stably placed under the action of an arranged placing mechanism, the mounting efficiency of the prefabricated part is improved, the mounting convenience is improved, and the practical value is high.

Owner:张家港市永茂住宅工业有限公司

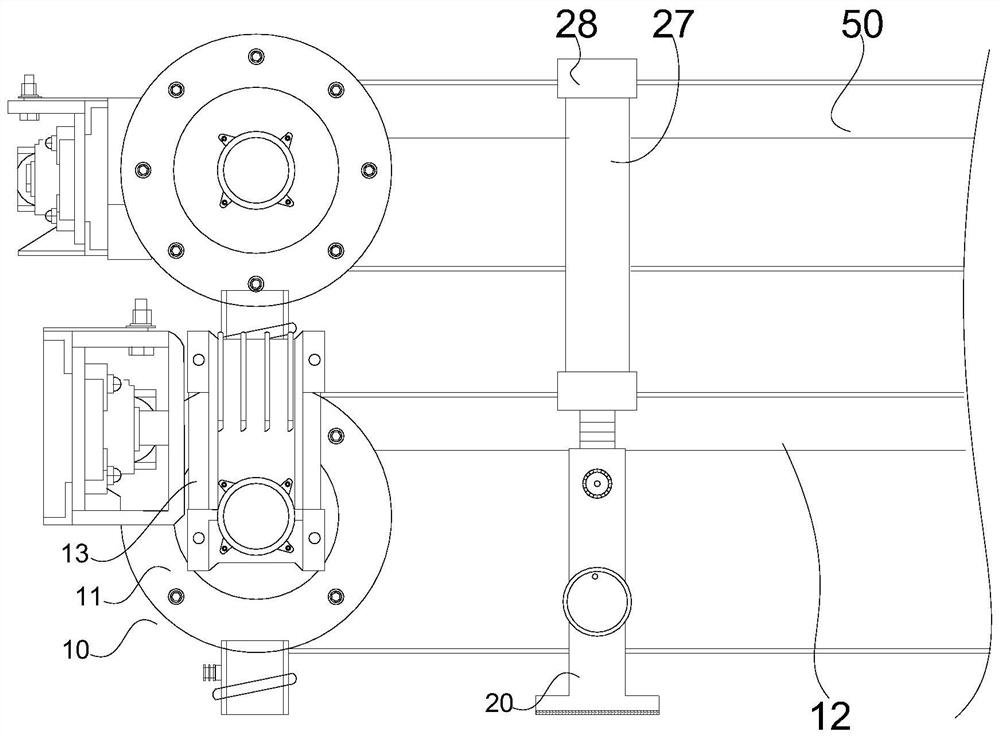

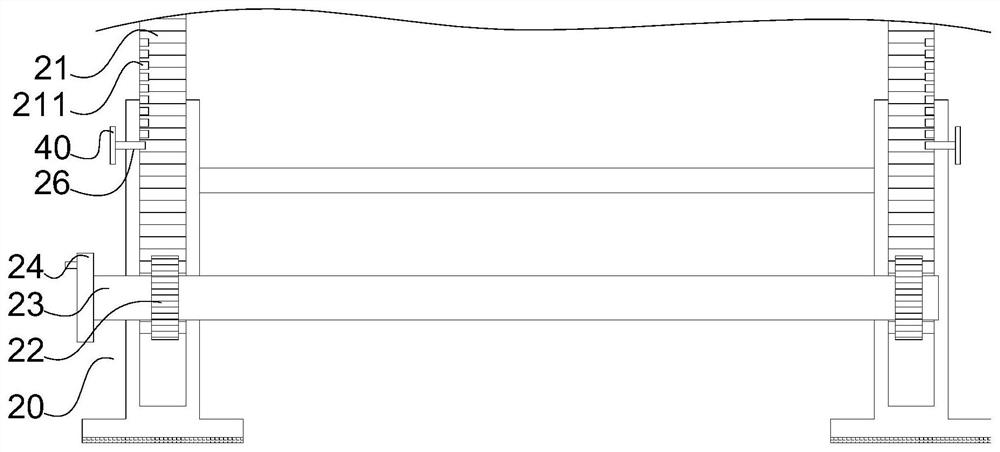

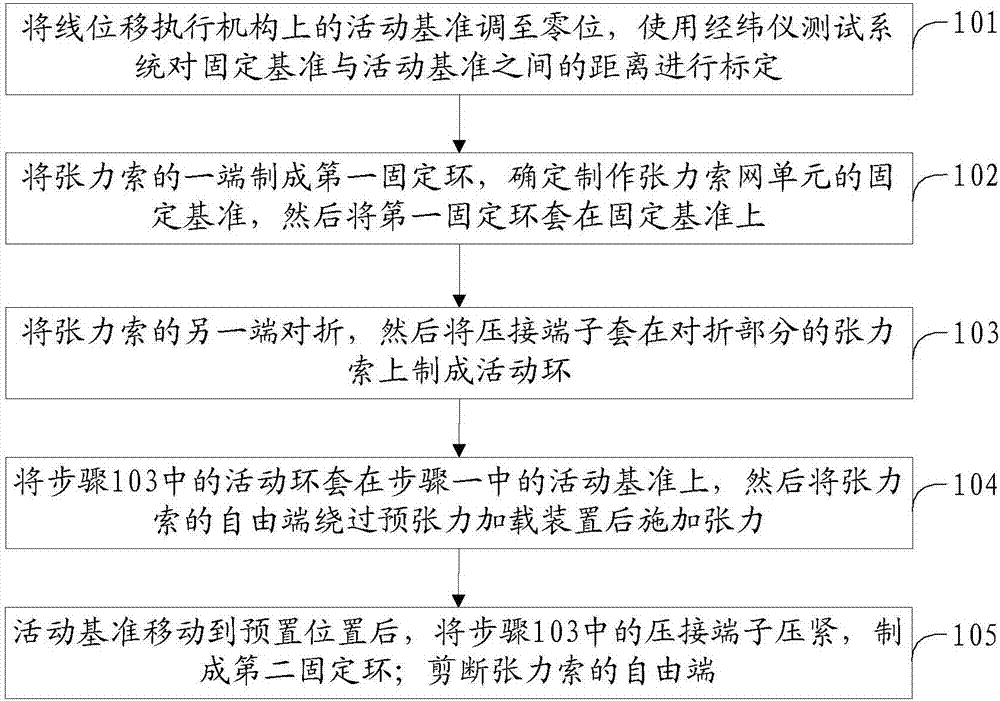

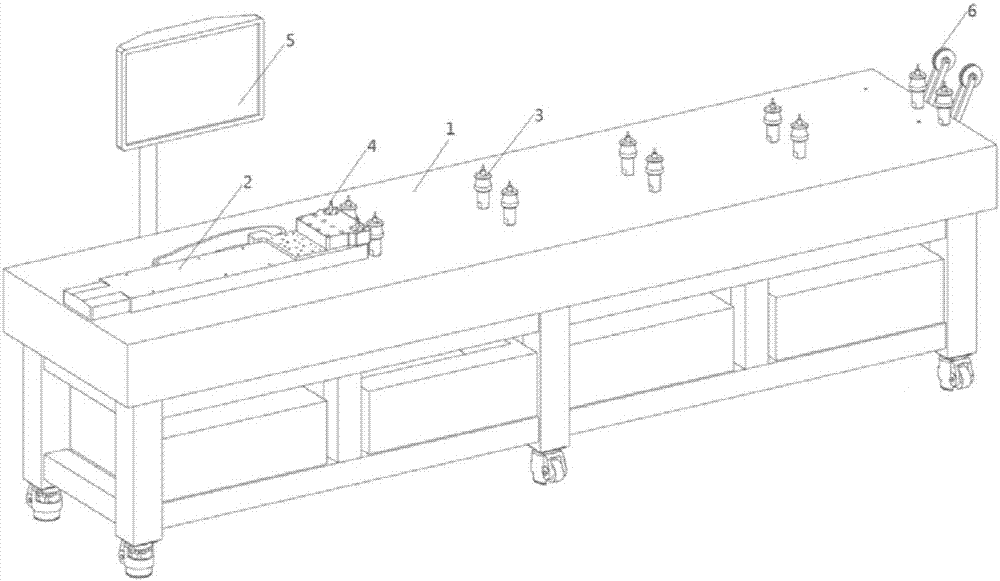

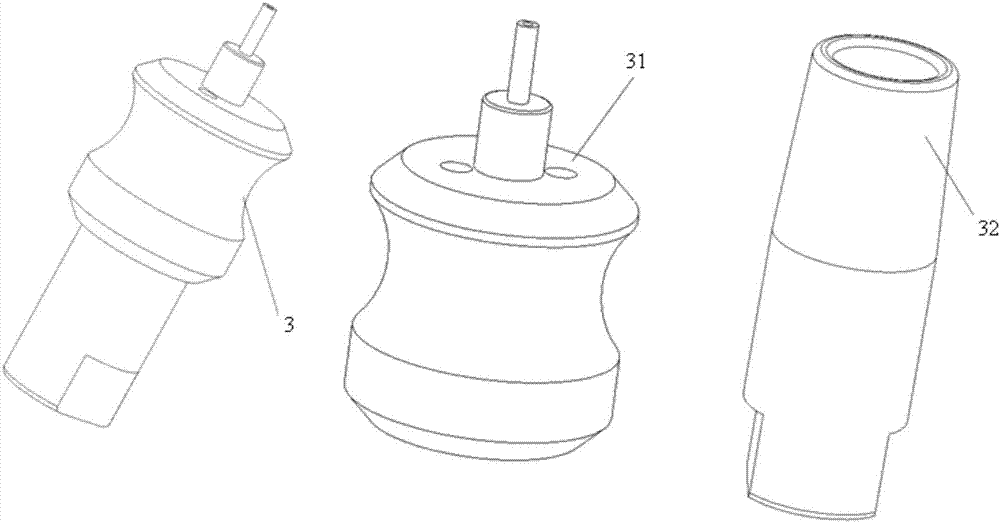

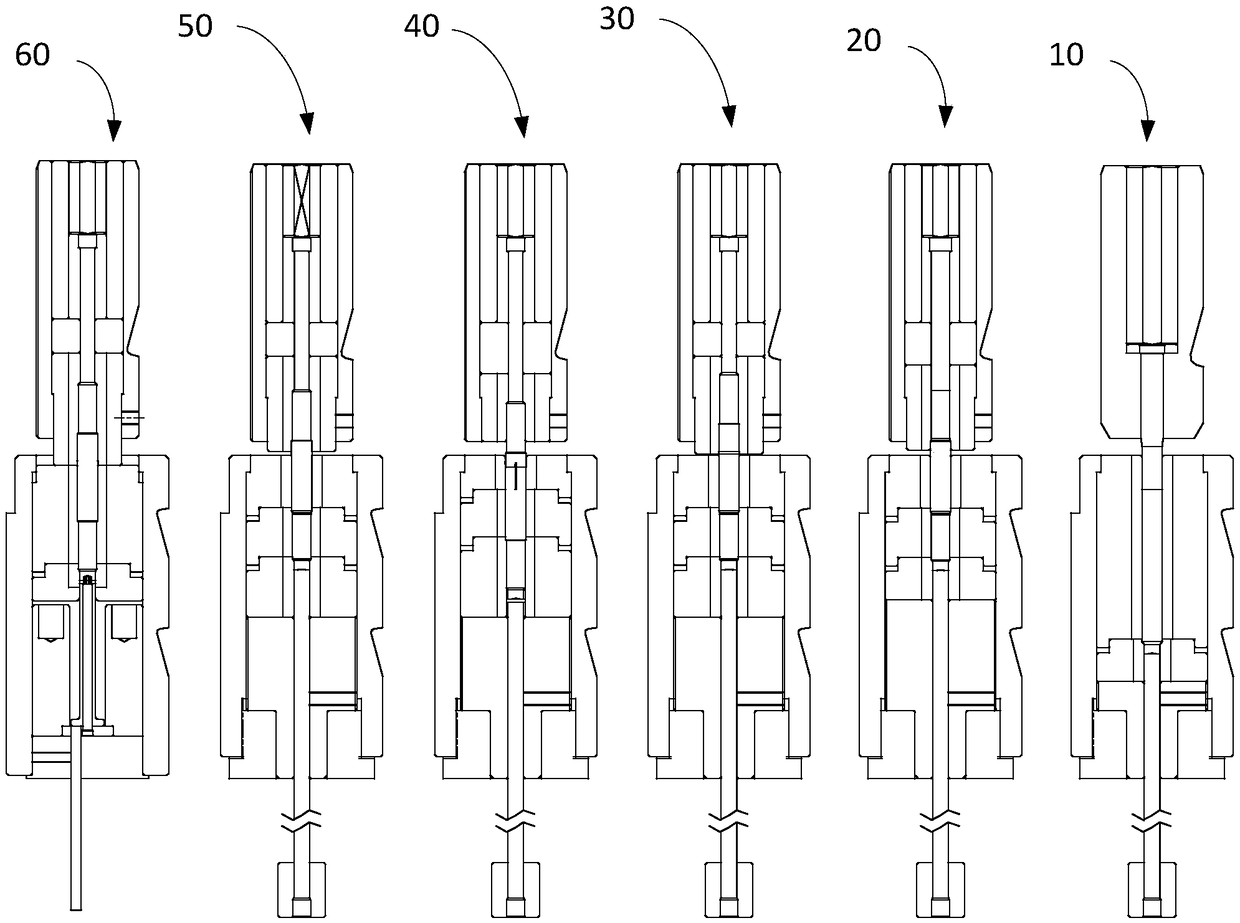

Manufacturing method of high-precision tension cable net unit of mesh antenna

ActiveCN107986115AEasy to makeGood operation consistencyAntenna supports/mountingsWire toolsLinear displacementTheodolite

A manufacturing method of a high-precision tension cable net unit of a mesh antenna comprises the following steps that firstly, a moving datum (4) on a linear displacement executing mechanism (2) is adjusted to be zero, and the distance between a fixed datum (3) and the moving datum (4) is calibrated through a theodolite test system; secondly, one end of a tension cable is manufactured to be a first fixed ring, and the fixed datum (3) is sleeved with the first fixed ring; thirdly, after the other end of the tension cable is used as a free end and folded in two, the part, folded in two, of thetension cable is sleeved with a compression connection terminal, and a moving ring is manufactured; fourthly, the moving datum (4) obtained in the first step is sleeved with the moving ring obtained in the third step, the free end of the tension cable is wound around a pretension loading device (6), and then tension is applied; fifthly, the linear displacement executing mechanism (2) is controlledto move, after the linear displacement executing mechanism (2) drives the moving datum (4) to move to a preset position, the compression connection terminal in the third step is tightly pressed, anda second fixed ring is manufactured.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

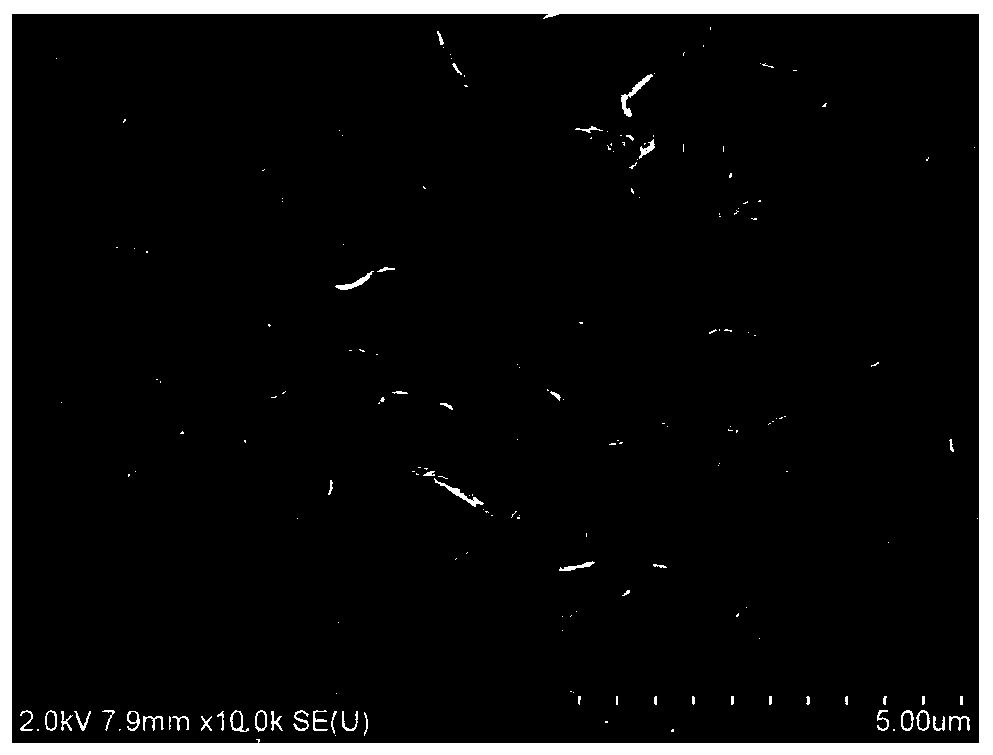

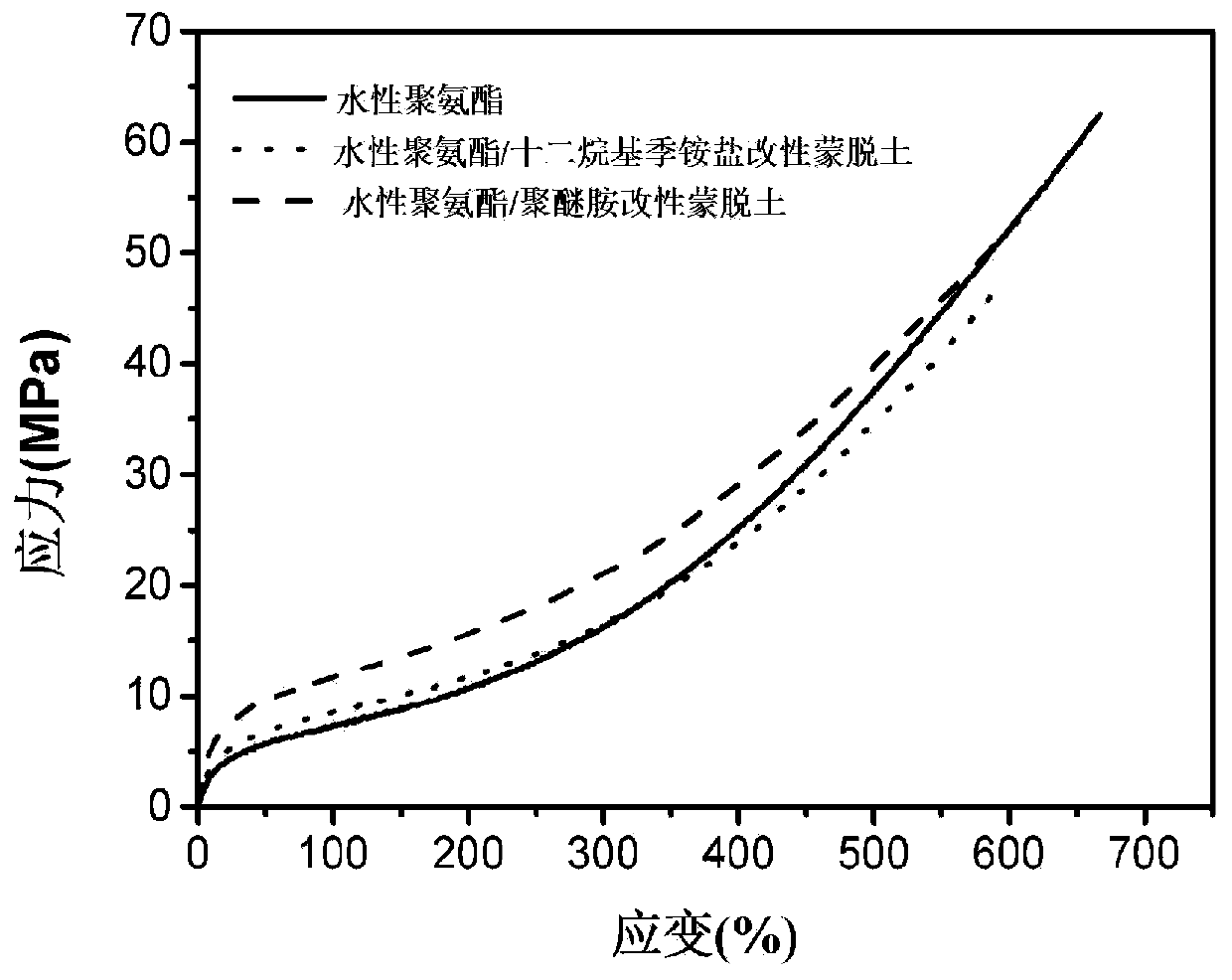

A highly water-resistant waterborne polyurethane modified montmorillonite nanocomposite emulsion

The invention discloses waterborne polyurethane modified montmorillonite nanometer composite emulsion with high water resistance, and belongs to the field of organic-inorganic nanometer composite emulsion. Intercalation modification is carried out on montmorillonite by the aid of acid dissociation polyether amine. Interlayer sodium ions in the montmorillonite are substituted by ammonium ions, andaccordingly the interlayer spacing of the montmorillonite can be increased; groups with isocyanate reaction activity are led into the montmorillonite, then reaction is carried out on formed intercalation-modified organic montmorillonite solution and polyurethane to prepare the waterborne polyurethane modified montmorillonite nanometer composite emulsion which is waterborne polyurethane and montmorillonite nanometer composite emulsion. The waterborne polyurethane modified montmorillonite nanometer composite emulsion has the advantages that the waterborne polyurethane modified montmorillonite nanometer composite emulsion prepared by the aid of methods is good in dispersion stability, inorganic nanometer particles are led into the waterborne polyurethane modified montmorillonite nanometer composite emulsion, accordingly, the thermal and mechanical properties of waterborne polyurethane coatings can be obviously improved, and the barrier properties can be enhanced by montmorillonite lamellar structures; dispersion can be widely applied to the field of high-temperature-resistant food and medicine packages with excellent barrier properties.

Owner:JIANGNAN UNIV

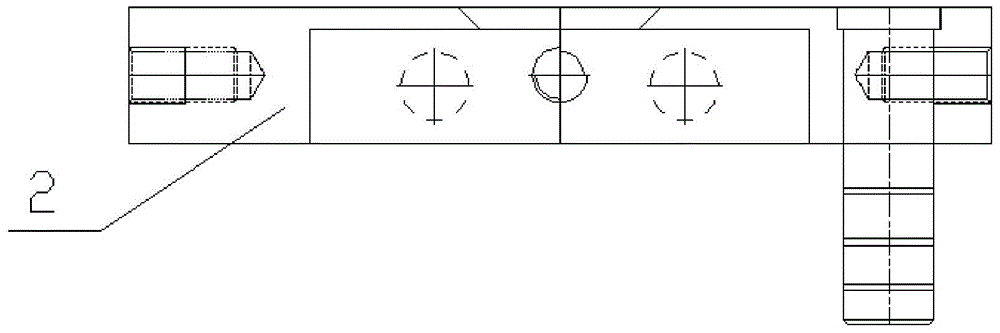

Shaping structure and method of special-shaped dual-head bolt

The invention discloses a shaping structure and method of a special-shaped dual-head bolt. The shaping structure of the special-shaped dual-head bolt includes a cold heading machine, a washing machine, a thread rolling machine, a heating device and an electroplating device, wherein the cold heading machine is used for shaping the special-shaped dual-head bolt, the washing machine is used for washing the special-shaped dual-head bolt, the thread rolling machine is used for conducting thread rolling on the special-shaped dual-head bolt, the heating device is used for heating the special-shaped dual-head bolt after thread rolling, and the electroplating device is used for electroplating the special-shaped dual-head bolt. According to the special-shaped dual-head bolt, bumps and a quincuncialhole are directly formed in a cold heading mode, no materials can be cut off during shaping, the utilization rate of the materials is high, the overall metal flow line of the interior of a product isensured, and the strength of the prepared product is high. No subsequent machining is needed, the production efficiency is improved, and the production cost is reduced.

Owner:BINKE AUTOMOBILE FASTENER KUNSHAN

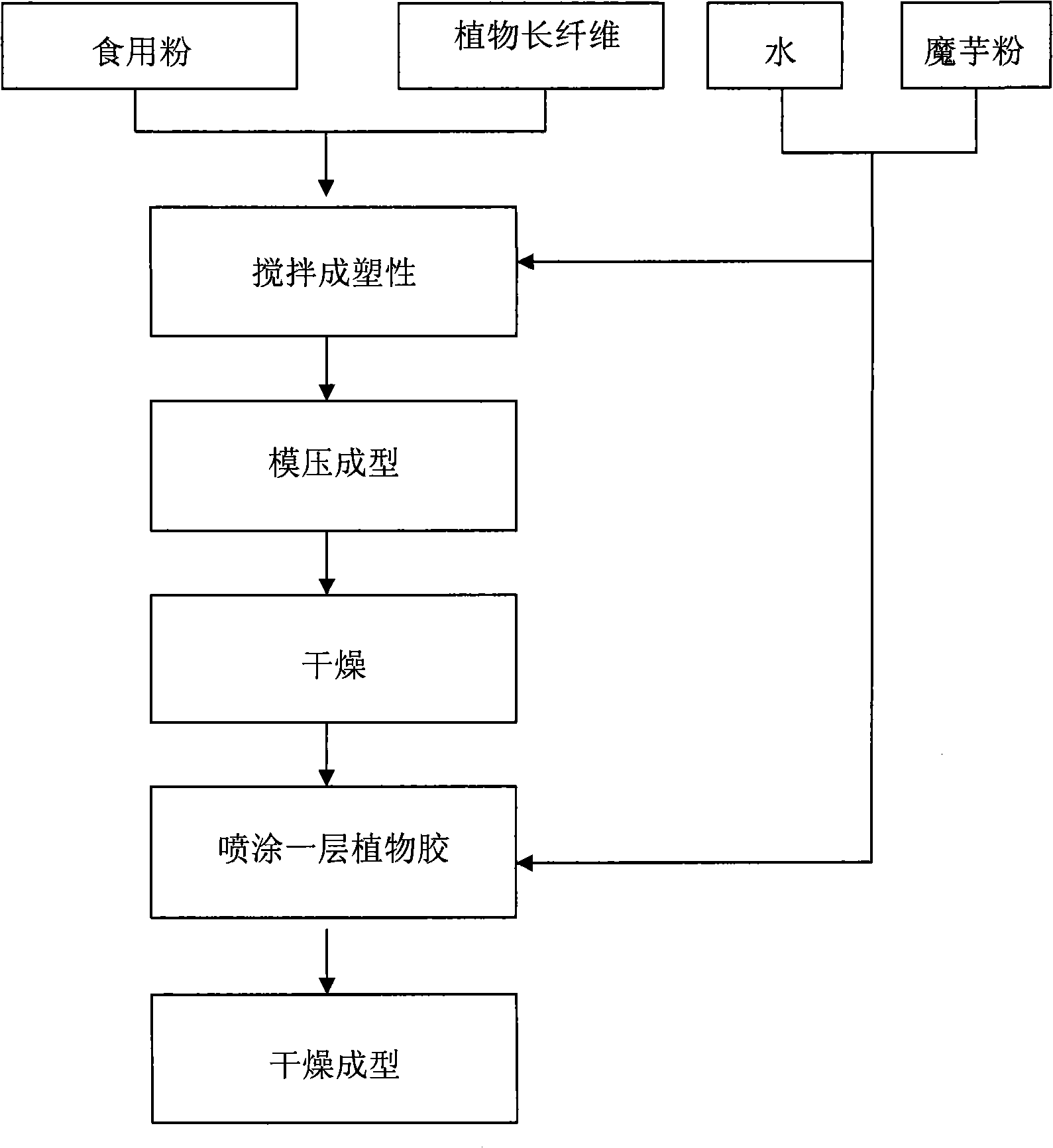

Whole plant material environment friendly dishware and the process for making the same

Whole plant material environment friendly dishware and the process for making the same are disclosed in the invention, which aims to solve the problem of chemical substances existing in the prior environment friendly dishware. The whole plant material environment friendly dishware of the invention is made by the following raw materials based on weight percentages: 80%-85% of food flour, 10%-15% of plant long fiber with the length of 1cm-3cm, and 5%-10% of vegetable gum. The process for making the whole plant material environment friendly dishware includes the following steps: (1) adding the plant long fiber into the food flour; (2) adding water and konjaku flour into the above mixture and agitating into plasticity substances; (3) compression molding; and (4) drying. According to the materials and the making process, the product strength is increased, the fragility is improved, the cost is reduced; in addition, the invention is convenient to produce, high in yield of finished product and is low in energy consumption during drying.

Owner:哈秋舲

Cellulose wear-resisting wire

InactiveCN105256562AThe process is simpleHigh product strengthFibre treatmentCelluloseFire retardant

The invention discloses a cellulose wear-resisting wire. The cellulose wear-resisting wire is prepared from the following raw materials in parts by weight: 20-30 parts of basic cellulose, 3-5 parts of binding agent, 8-10 parts of initiator, 20-30 parts of carbon cellulose, 10-12 parts of hydroxyethyl cellulose, 3-5 parts of fire retardant, 6-10 parts of butadiene vinyl-pyridine rubber latex, 4-6 parts of ceramic powder, 5-9 parts of impregnation liquid and 4-6 parts of formaldehyde solution. The cellulose wear-resisting wire has the advantages of simple proportion, damage resistance and abrasion resistance, nonflammable property and low cost.

Owner:QINGDAO TIPONT CORD

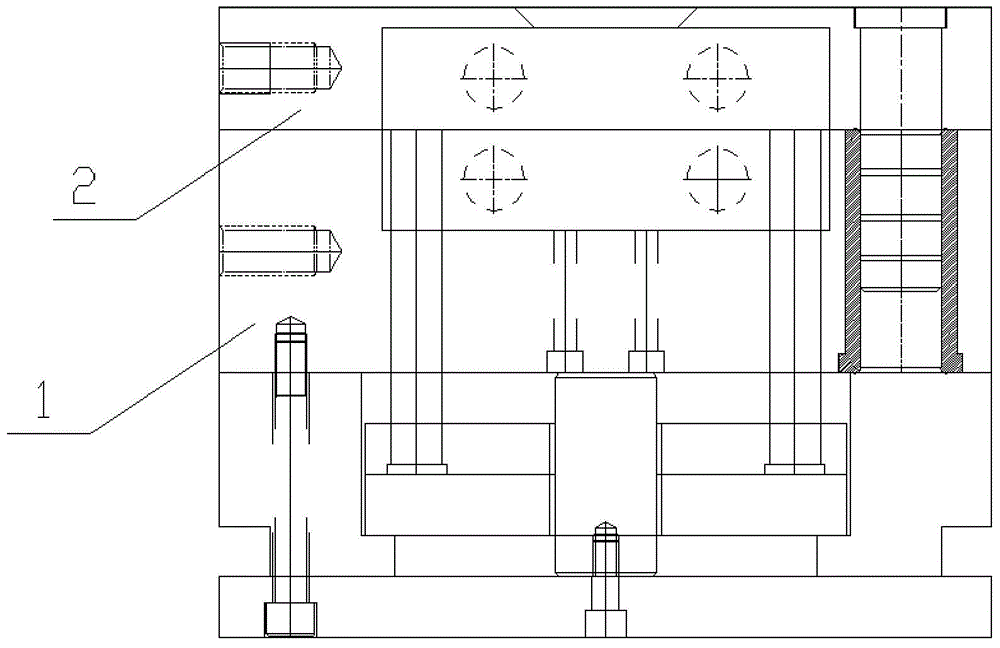

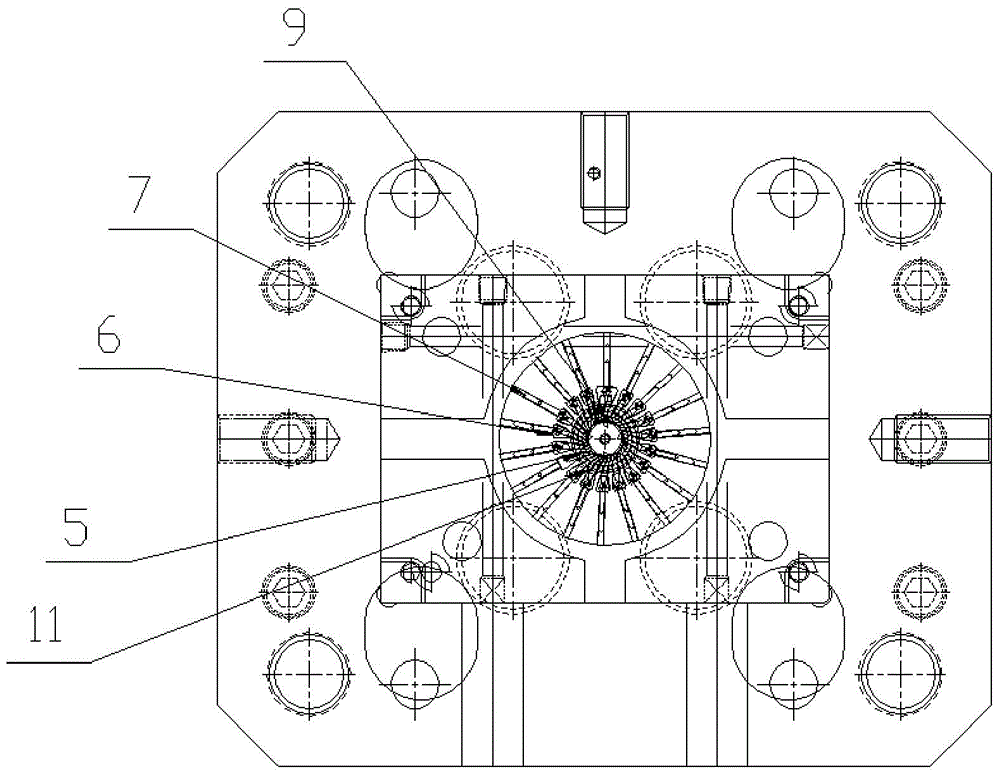

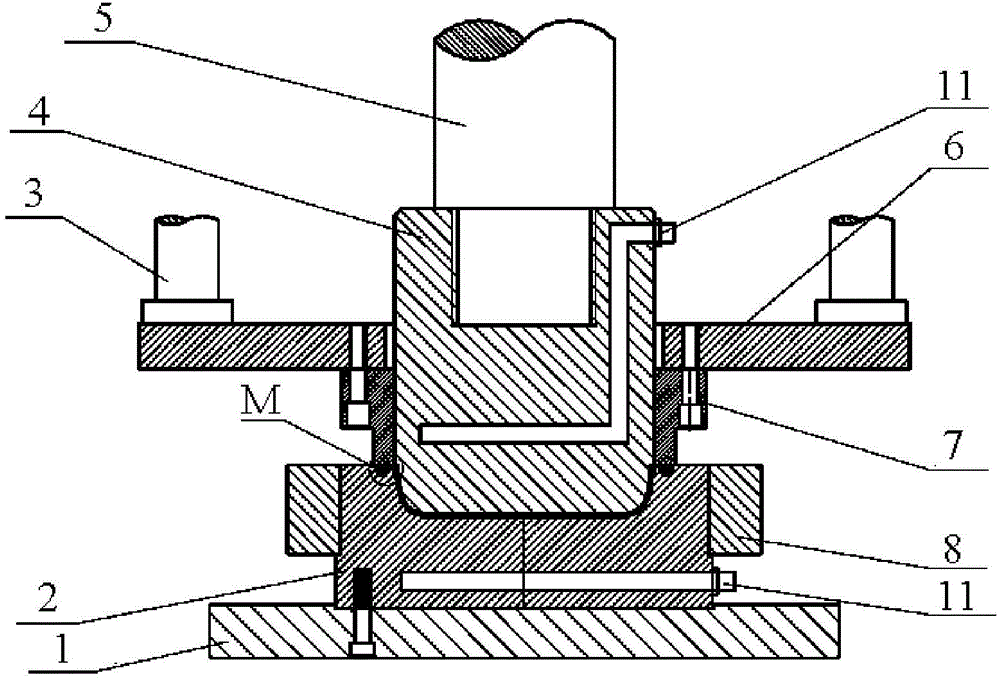

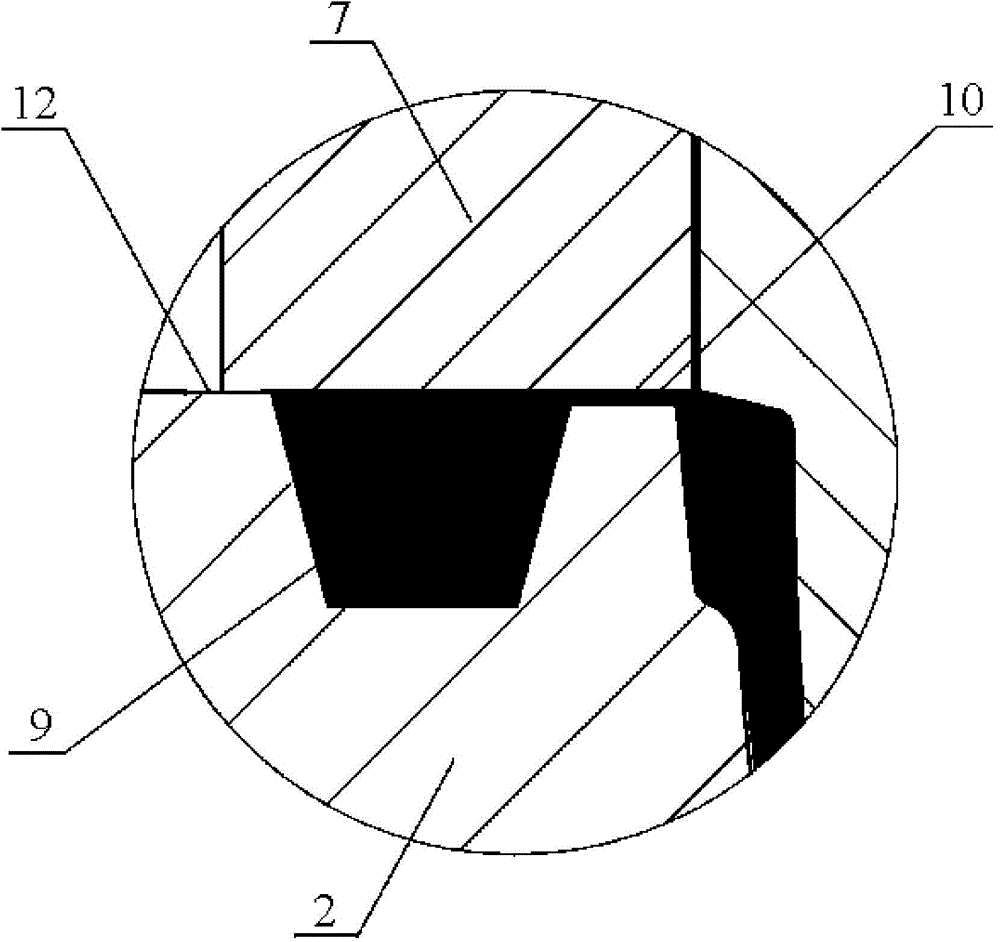

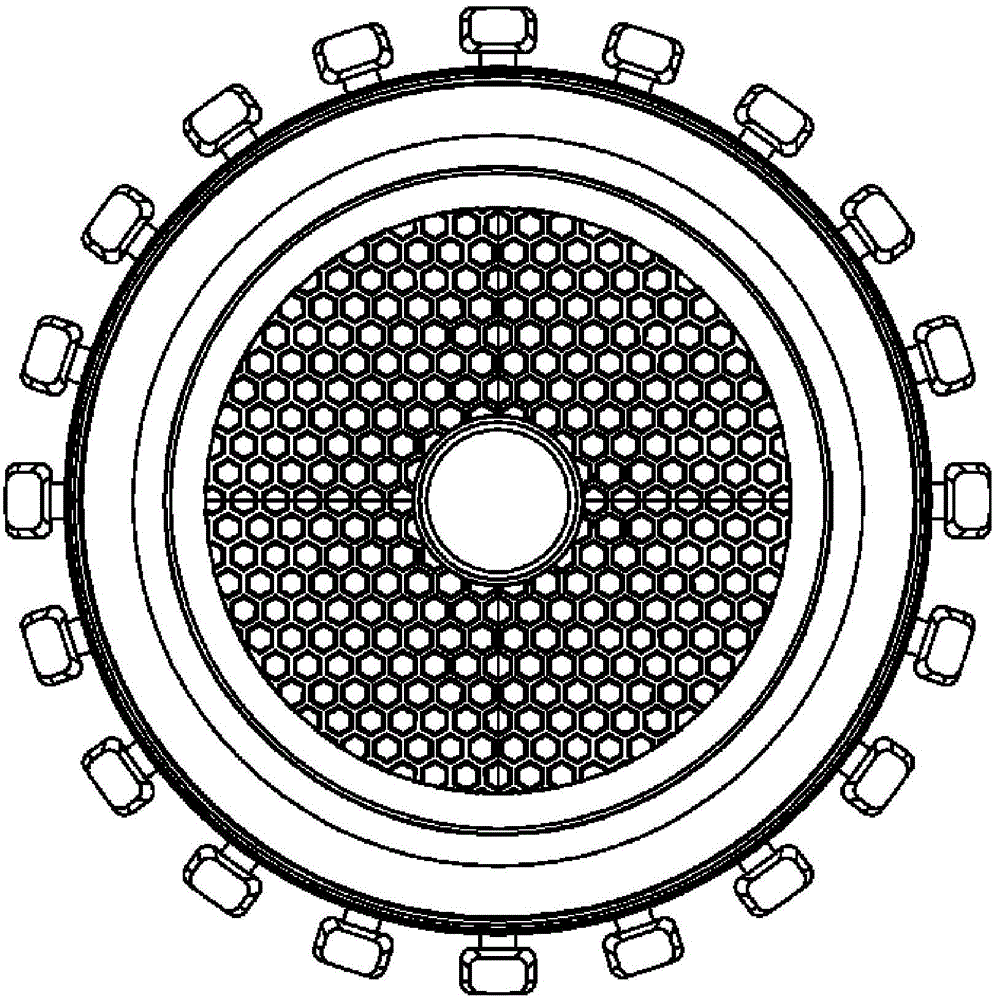

Forming die of light weight and small size magnesium alloy cooling fan and processing method of inserts therefor

The invention discloses a forming die of light weight and small size magnesium alloy cooling fan and a processing method of inserts therefor. A male die of a die is internally provided with a core insert, a female die is internally provided with a cavity insert, and a die-casting cavity is formed between the male die and the female die; a circular thickened inner race forming space is formed in the male die, a plurality of insert grooves corresponding to the positions of fan blades of the fan are uniformly distributed outside the circumference of the thickened inner race forming space, the inserts are respectively embedded in all insert grooves, and blade forming structures are respectively formed at the two sides of each insert; an insert processing method comprises the following steps: cutting all the inserts into inserts of straight structures; processing an auxiliary template; installing the inserts of the straight structures on the auxiliary template to trim the inserts; discharging the processed inserts to be of arc-shaped structures which are consistent with the shapes of the fan blades; taking out the inserts after the completion of the processing. The forming die provided by the invention is beneficial for product forming and de-moulding, is high in fan forming precision and product intensity.

Owner:KUSN GUANGHE ELECTRONICS TECH

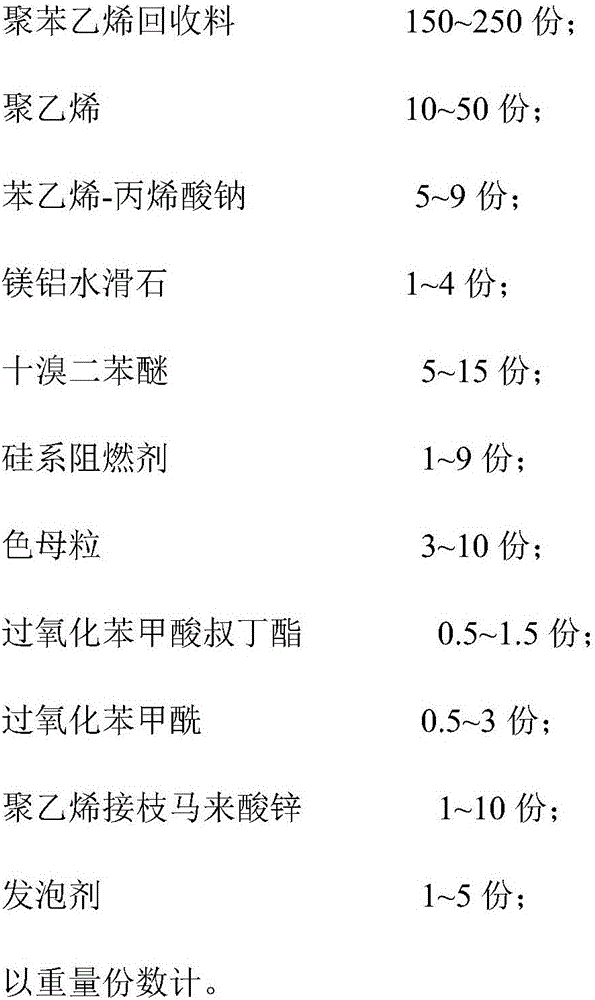

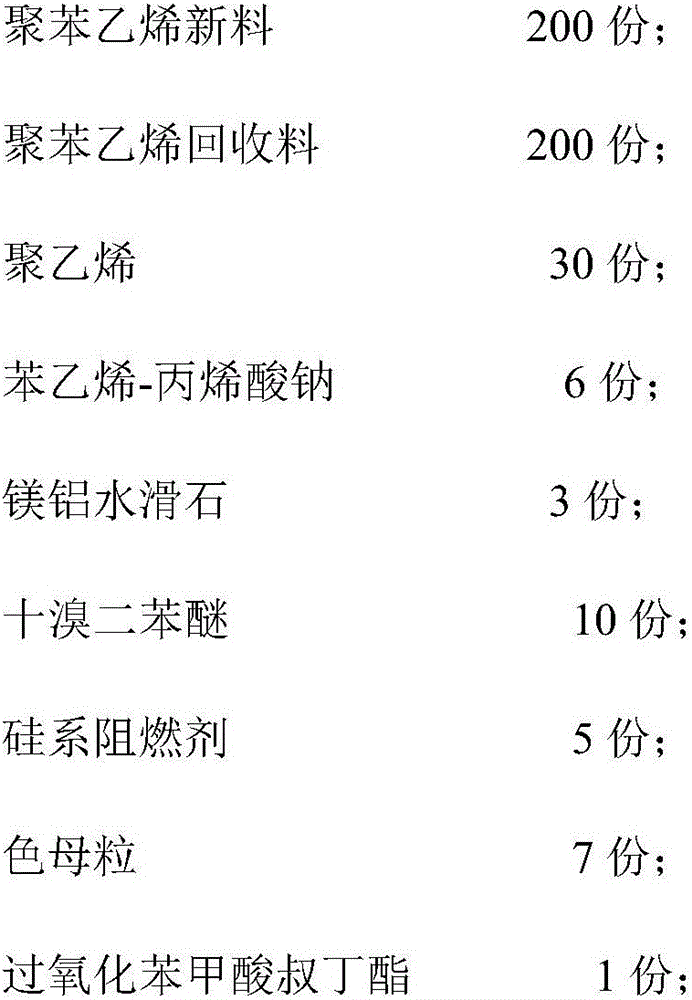

Polystyrene/polyethylene blended high-flame-resistance extruded sheet and production method thereof

The invention discloses a polystyrene / polyethylene blended high-flame-resistance extruded sheet. The polystyrene / polyethylene blended high-flame-resistance extruded sheet comprises a fresh polystyrene material, a recycled polystyrene material, polyethylene, styrene-sodium acrylate, magnalium hydrotalcite, decabromodiphenyl ether, silicon-based fire retardant, color master batch, benzoyl peroxide butyl ester, benzoyl peroxide, polyethylene grafted zinc maleate and foaming agent. The invention provides a production method correspondingly to obtain the extruded sheet with good flame resistance performance. The polystyrene / polyethylene blended high-flame-resistance extruded sheet and the production method thereof have the advantages that the recycled polystyrene material and the fresh polystyrene material are used jointly for producing the high-strength extruded sheet, so that production cost is reduced greatly; by dealing with the chain scission problem of the recycled material, the recycled material has better performance than ordinary waste; through addition of the auxiliary material polyethylene, proper solubilizing agent and other additives, product tenacity is improved, and the problems of embrittlement and easiness in breakage are solved; through addition of the decabromodiphenyl ether and the silicon-based fire retardant according to a certain ratio and combination with other additives, good flame resistance is achieved, and the oxygen resistance index can reach 48.

Owner:南京欧格节能环保科技有限公司

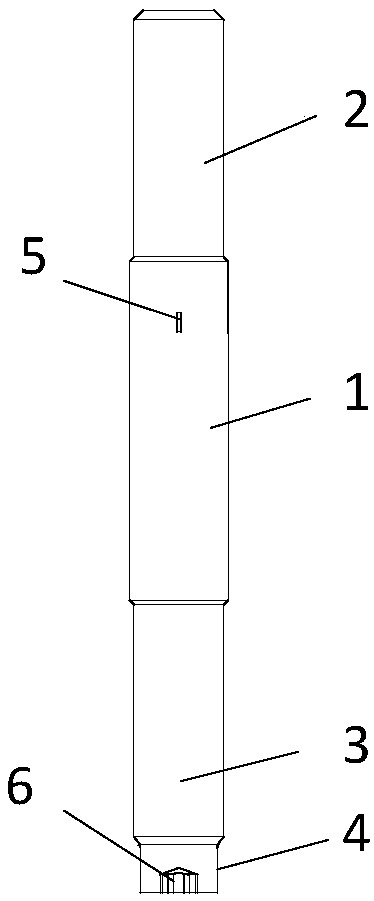

Rubber floater for dredging projects

PendingCN105839688AImprove wear resistanceHigh product strengthSoil-shifting machines/dredgersPolyesterEPDM rubber

The invention provides a rubber floater for dredging projects. The rubber floater for dredging projects is provided with a barrel, an anti-channeling plate, an end flange, a buoyancy layer, a pressure-bearing layer, an aging resisting layer, a flange plate and a suspension lug sequentially from inside to outside. The buoyancy layer is formed by compounding buoyancy EVA foam and pressure-resisting PE foam. The pressure-bearing layer is composed of a shoulder reinforcing plate, a nylon or polyester cord and a nylon mesh, and the nylon or polyester cord and the nylon mesh are integrally wound around and cover the buoyancy layer. The aging resisting layer is made of ethylene-propylene-diene monomer (EPDM) rubber modified by adding rutile type titanium dioxide whiskers. The corrosion resistance, impact resistance and elasticity of the rubber floater for dredging projects are improved, the service life of the rubber floater for dredging projects is prolonged, and the rubber floater for dredging projects is convenient to use, reliable, simple in production process and low in cost. The rubber floater for dredging projects is particularly suitable for connection of quick couplings and a first pipe at the bow portion for dredging projects, the effective operation of dredging projects can be ensured, and the project cost is reduced.

Owner:T RUBBER

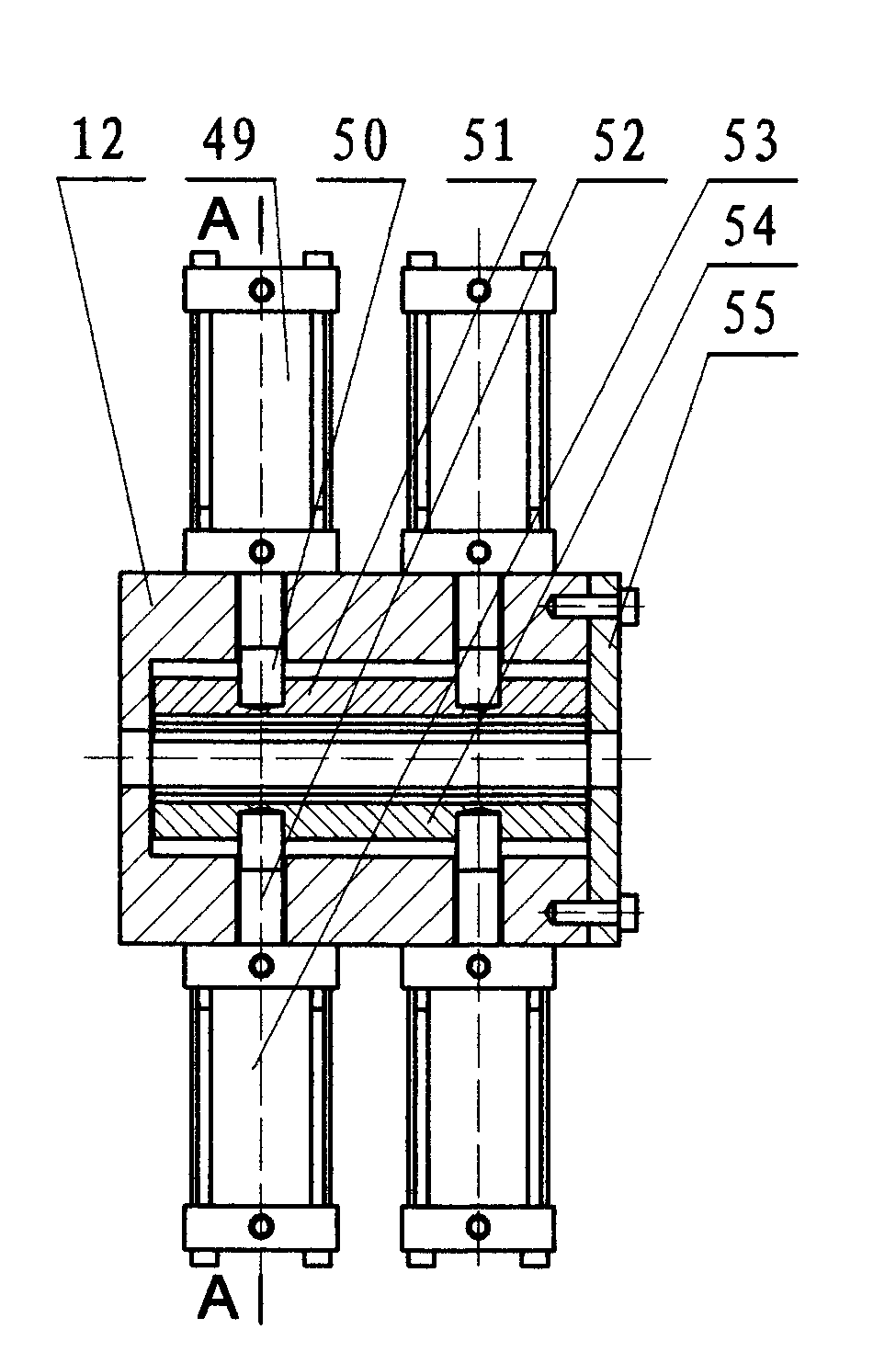

Liquid state extrusion forming apparatus and method

The present invention provides a liquid state extrusion forming apparatus and a method. The liquid state extrusion forming apparatus comprises an upper movable cross beam, a lower movable cross beam, a punching head, a concave mold and an edge pressing gas discharge material discharge ring, wherein one end of the punching head is matched with the mold cavity of the concave mold, the other end of the punching head is connected with the upper movable cross beam, the edge pressing gas discharge material discharge ring is sleeved on the punching head and is matched with the punching head gap, and the edge pressing gas discharge material discharge ring and the concave mold are subjected to mold closing connection when the edge pressing gas discharge material discharge ring moves downward to the concave mold. According to the present invention, the high temperature metal liquid is subjected to extrusion forming through punching head pressing, pressure increasing and pressure maintaining; the work-piece falls down during the return travel of the punching head and the edge pressing gas discharge material discharge ring; and with the technical scheme of the present invention, the easy gas discharge structure is adopted, such that the problems of foaming, low metal liquid utilization rate and high production cost of the cold type die-casting forming are completely solved, the work-piece bottom repair technology can be completed in one time without addition of other bottom repair equipment, and advantages of high yield, high product strength, high production efficiency and the like are provided.

Owner:NINGBO WEISUER IND TECH DEV CO LTD

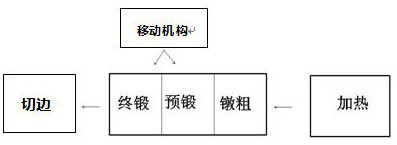

Processing assembly line and processing method of clutch part for vehicle

PendingCN112517832AGuaranteed qualityIncrease productivityRailway componentsForging/hammering/pressing machinesAssembly lineClutch

The invention relates to a processing assembly line and a processing method for a clutch part for a vehicle, and belongs to the technical field of automobile parts. The processing assembly line of theclutch part for the vehicle comprises a heating device, a forging device, a moving device and an edge cutting device, wherein the moving device comprises a moving assembly, a clamping assembly and aspraying assembly, the clamping assembly can clamp a processed product, the processed product can be transferred through the moving assembly, and the spraying assembly can be used for spraying a release agent to the mold. According to the processing assembly line and the processing method for the clutch part for the vehicle, the moving device is designed to be of a T-shaped structure to replace acommon split structure in the prior art, a clamping jaw clamps a product in the middle, nozzles are arranged at the two ends of the clamping jaw respectively and used for spraying a mold, it is implemented that transferring from a pre-forging product to a finish-forging product and painting are carried out synchronously, and the production efficiency is greatly improved; the forging device is of astructure with one mold base and multiple mold cavities, a forge piece only needs to be heated once for repeated forging without being heated again midway, energy consumption is reduced, and meanwhile the working efficiency and the product strength are improved.

Owner:NINGBO XUSHENG AUTO TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com