Die temperature control device and control method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] For further elaborating the technical means and effects that the present invention adopts to achieve the intended purpose, please refer to the following detailed description and accompanying drawings of the present invention. It is believed that the purpose, features and characteristics of the present invention can be obtained from this in-depth and specific It should be understood that, however, the attached drawings are only for reference and illustration, and are not intended to limit the present invention.

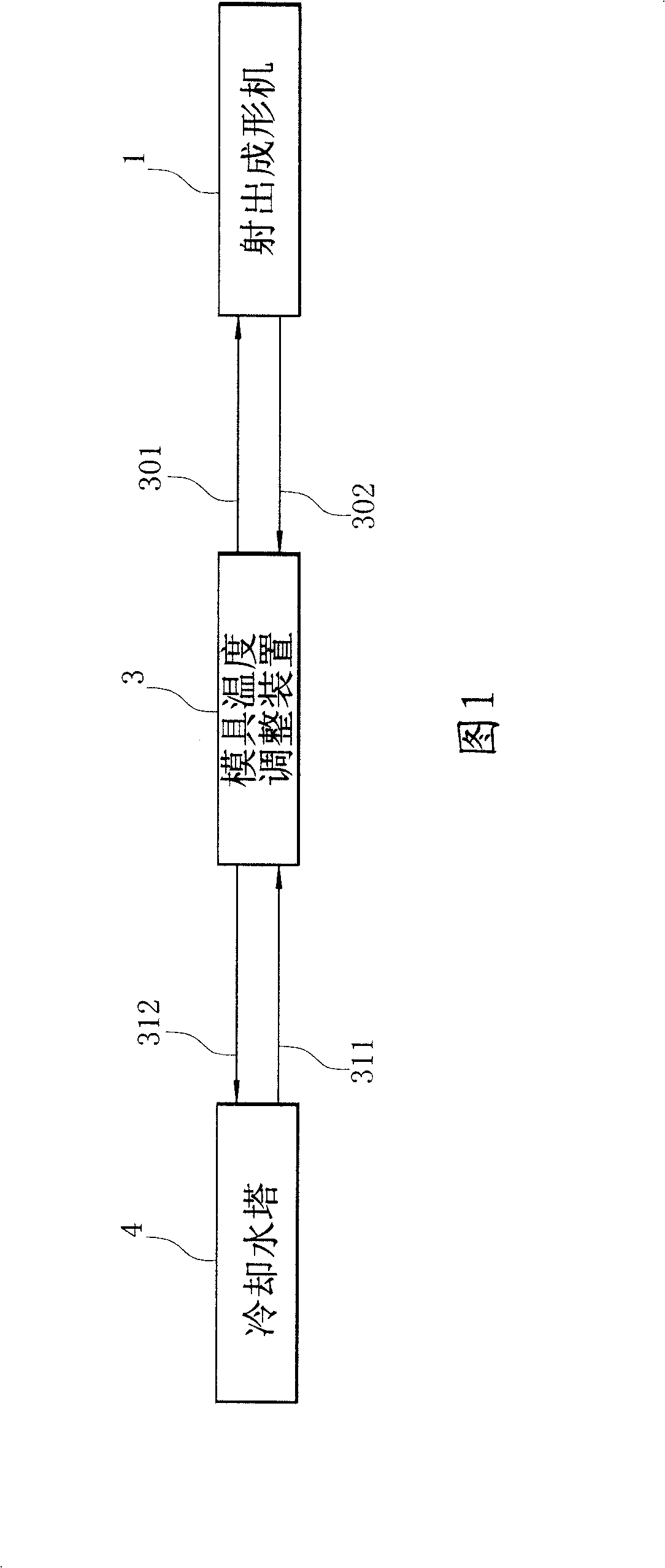

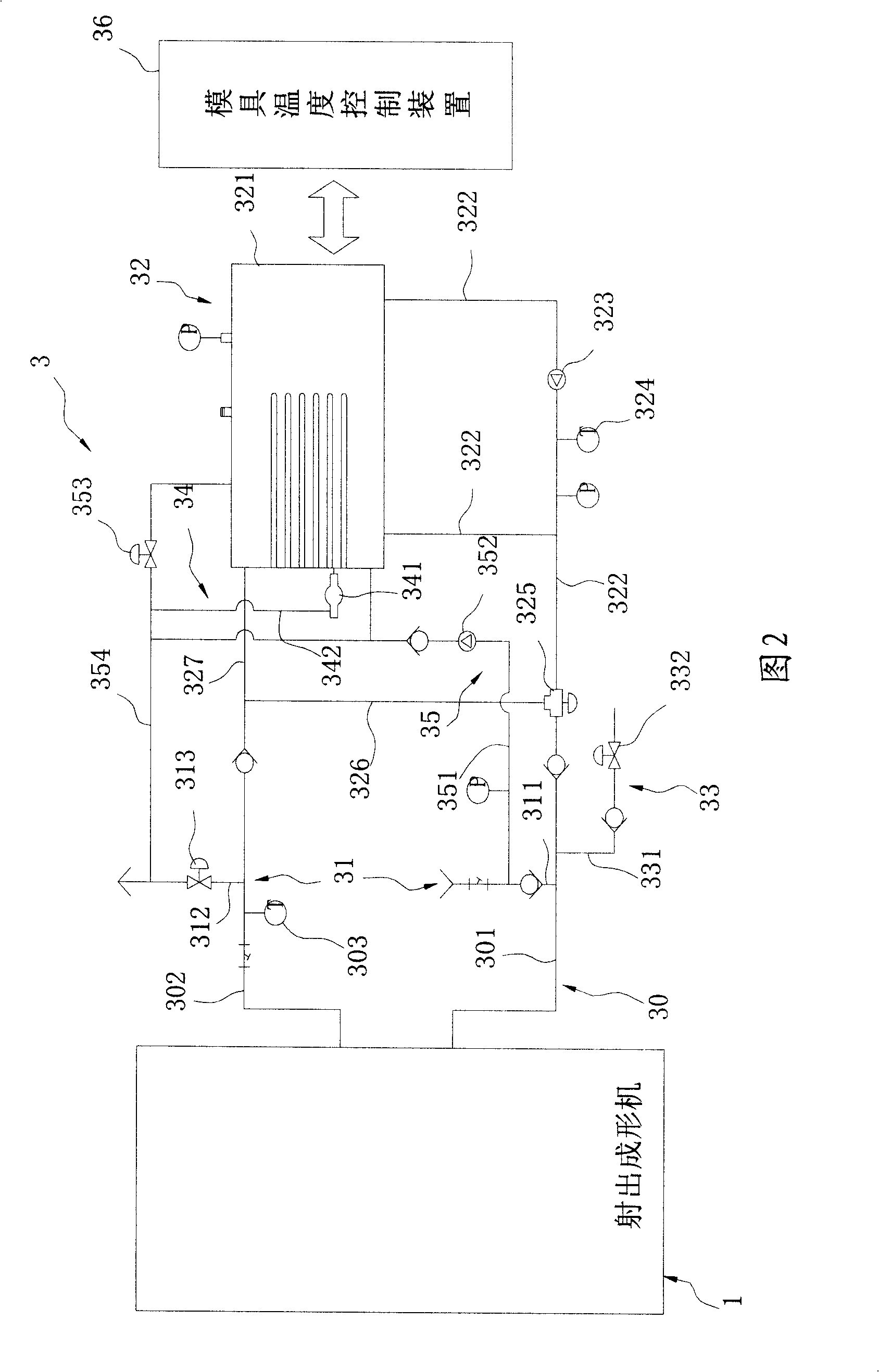

[0040] Please refer to FIG. 1 , which is an injection molding system using the present invention. The injection molding system includes an injection molding machine 1 , a mold temperature regulating device 3 and a cooling water tower 4 . The mold temperature regulating device 3 is connected to the cooling water tower 4 through a cold fluid input pipeline 311 and a cold fluid output pipeline 312 to obtain a circulating cold fluid, and through a first temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com