Preparation method of high-strength and high-toughness titanium alloy material cutter

A technology of tough titanium alloy and titanium alloy, which is applied in the field of preparation of high-strength and high-toughness titanium alloy material cutting tools, can solve the problems such as the decrease of bending strength and impact toughness of cutting tool materials, the inapplicability of high-efficiency processing of difficult-to-machine materials, and the impact on the performance of cutting tools. , to achieve the effect of eliminating harmful elements, reducing friction coefficient and strong crack growth resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Prepare the raw materials first, the density of the raw material is titanium alloy material, the prepared titanium alloy material is sent to the stamping workshop to cut the material according to the size of the knife, the size and thickness of the knife sample, and the knife blank is opened, and then the knife blank is heat treated, usually The annealing temperature of α alloy and (α+β) alloy is selected at 120-200°C below the (α+β)-→β phase transformation point; solid solution and aging treatment are rapidly cooled from the high temperature zone to obtain martensitic α′ phase and the metastable β phase, and then keep warm in the middle temperature zone to decompose these metastable phases to obtain finely dispersed second phase particles such as the α phase or compounds. Usually (α+β) alloys are quenched at (α+β)-→ It is carried out at 40-100°C below the β-phase transformation point, and the metastable β-alloy is quenched at 40-80°C above the (α+β)-→β-phase transformat...

Embodiment 2

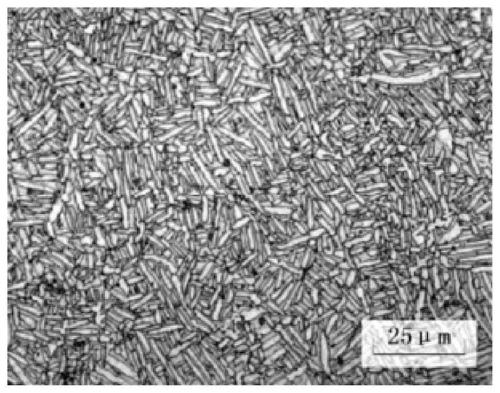

[0029] S1: Prepare raw materials; prepare BT16 alloy, the blanking temperature is 1150°C, the final temperature is controlled at about 800°C, heat preservation for 2 hours, air cooling for 2 hours, 500°C heat preservation for 6 hours, air cooling, the obtained titanium alloy is composed of primary α, intergranular β phase and phase The needle-like secondary α phase precipitated in the composition;

[0030] S2: Stamping: Send the prepared titanium alloy material into the stamping workshop to cut the material according to the size of the knife, the size and thickness of the knife sample, and cut out the blank;

[0031] S3: Heat treatment: heat-treat the knife blank by double heat treatment; the titanium alloy sample obtained after double heat treatment contains 70-80% primary α, 10-20% intergranular β phase and 5-10% The needle-like secondary α phase;

[0032] S4: Surface hydrogen infiltration: In the high-temperature furnace, the knife blank is subjected to hydrogen infiltrati...

Embodiment 3

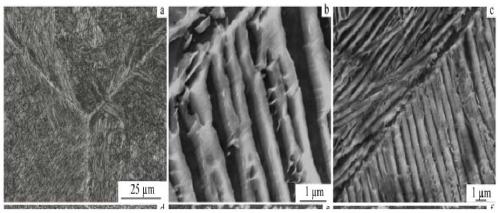

[0042] Microscopic observation, titanium alloy is a coarse α+β two-phase structure, see figure 1 As shown in a, under a 20,000-fold electron microscope, part of the α phase in the crystal is observed side by side with dendritic vertical β grain boundary crystals, such as figure 1 As shown in b, part of the α phases are crystallized side by side in the form of columnar crystals vertically or parallel to the β grain boundaries, such as figure 1 as shown in c.

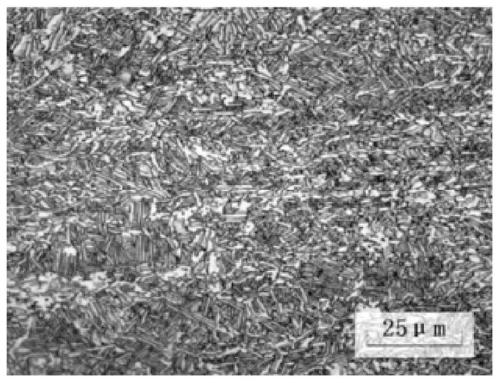

[0043] BT16 titanium alloy supply state organization such as figure 2 As shown, its basic feature is that a thin layer of black β phase is surrounded by a white α phase. The whole structure can be roughly divided into two types of regions, one is the lamellar α+β phase region, and in this phase region, α The length of the sheet is about 4 μm to 12 μm, and the thickness is about 0.5 μm to 0.6 μm. The α sheets in a microregion are parallel to each other, and the number is about 2 to 5; the other type of region is the equ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com