Patents

Literature

90results about How to "Eliminate processing stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Annealing method of sapphire wafer

InactiveCN102634850AUniform annealingEliminate processing stressPolycrystalline material growthAfter-treatment detailsWaferingCrystalline materials

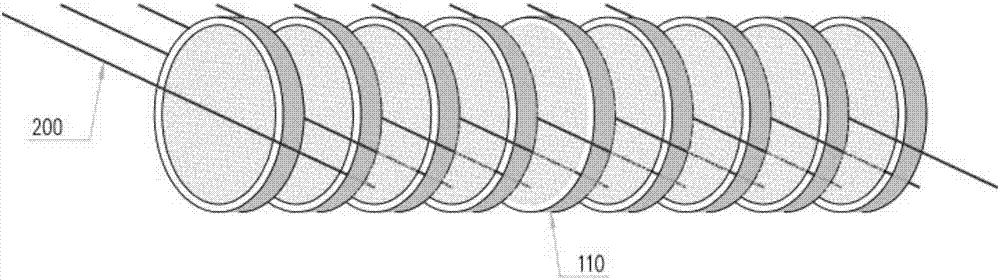

The invention relates to an annealing method of a sapphire wafer, belonging to the technical field of the machining of a crystalline material. The invention provides the annealing method of the high-quality sapphire wafer, comprising the following steps of: raising the temperature on the sapphire wafer which is cut, milled or polished by sections and keeping the heat for a period of time at 900-1600 DEG C; carrying out annealing treatment on the sapphire wafer so as to eliminate machining stress for cutting, milling or polishing; and rotating the wafer at a heat-preservation phase to uniformly anneal the whole wafer, so as to eliminate the influence that a temperature field of an annealing furnace is not uniform. The machining stress of the wafer annealed by the method is basically eliminated and the whole wafer is uniformly annealed; and the warping degree of the annealed wafer is small.

Owner:CHANGZHOU TONGTAI PHOTOELECTRIC

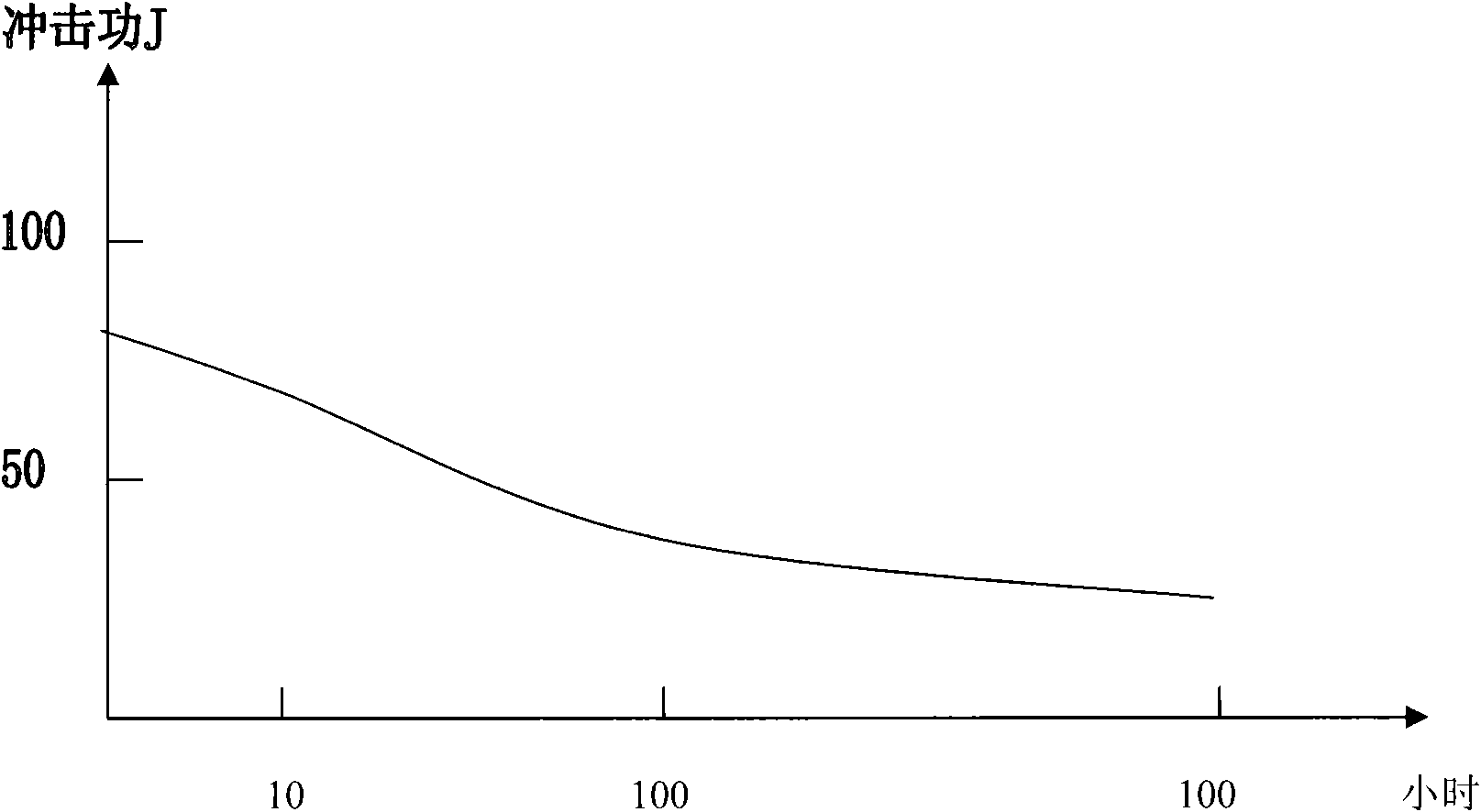

2Cr13 heat treatment process

InactiveCN101608252AHigh surface hardnessImprove surface wear resistanceFurnace typesQuenching agentsLong axisMechanical equipment

The invention belongs to the field of a heat treatment process for reciprocating-compressor 2Cr13 piston-rods, and is applicable to all reciprocating compressors adopting a 2Cr13 piston-rod heat treatment process and mechanical equipment which requires high toughness and needs post-order surface heat treatment. The process can solve the problem that the prior heat treatment adopted for 2Cr13 piston rods is low in impact toughness, large in high-frequency quenching deformation of long-axis parts, large in hardening cracks and workpiece residual stress, and the like. The process comprises the forging molding of 2Cr13 piston rods, annealing, quenching-tempering, stabilizing, medium-frequency or high-frequency quenching and low-temperature tempering. The 2Cr13 heat treatment process can completely overcome the disadvantages of the prior heat treatment process such as incapability of eliminating residual stress and serious high-frequency quenching workpiece distortion, and is an ideal heat treatment process for long-axis workpieces.

Owner:SHENYANG BLOWER WORKS GROUP CORP

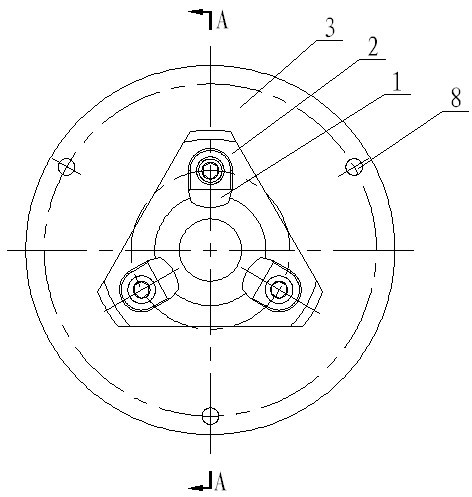

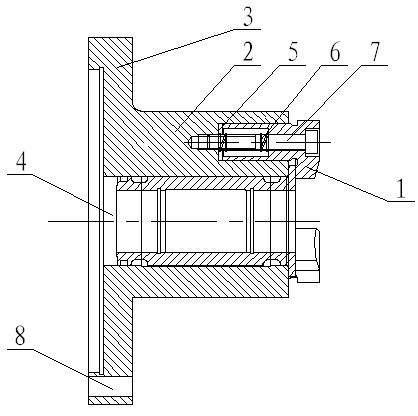

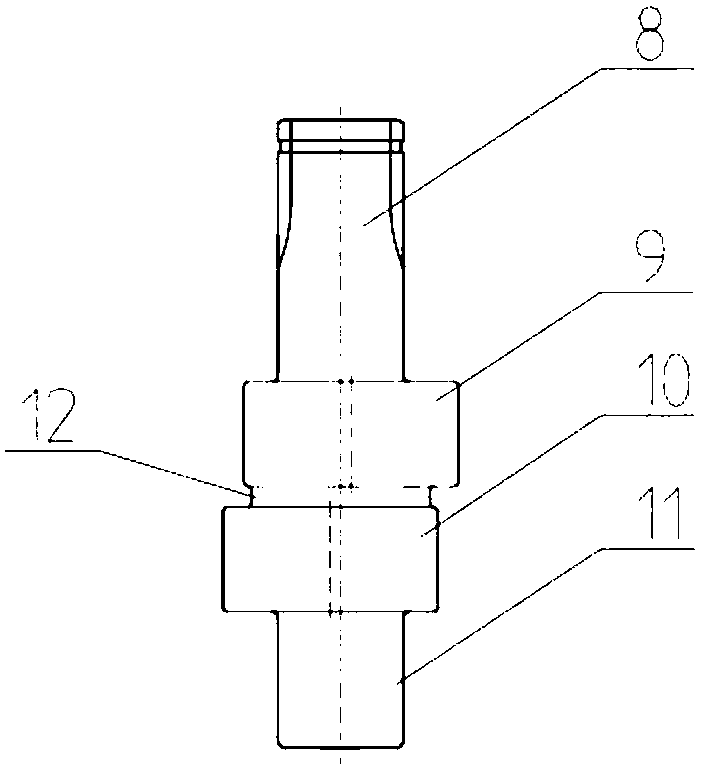

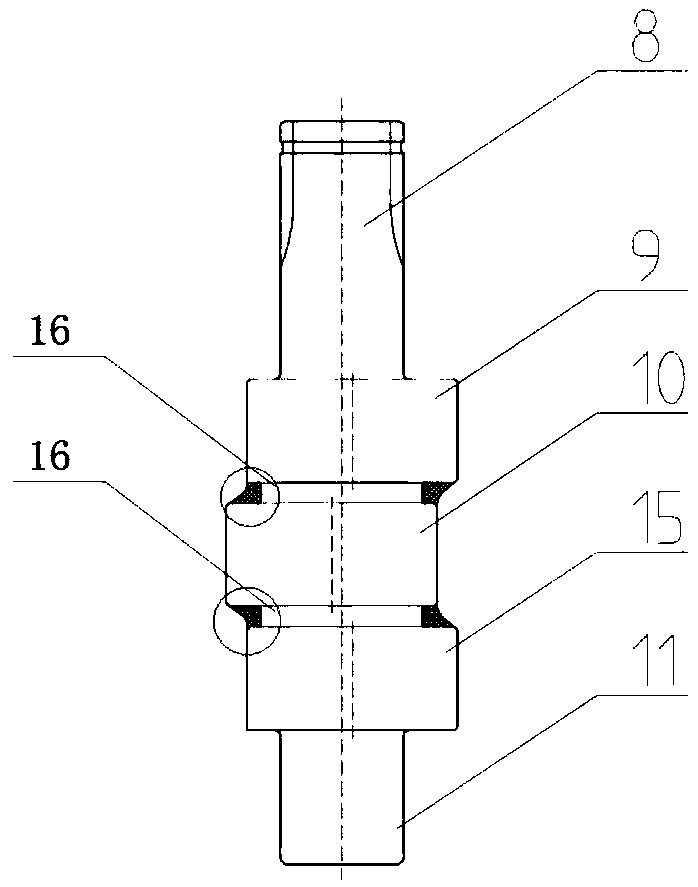

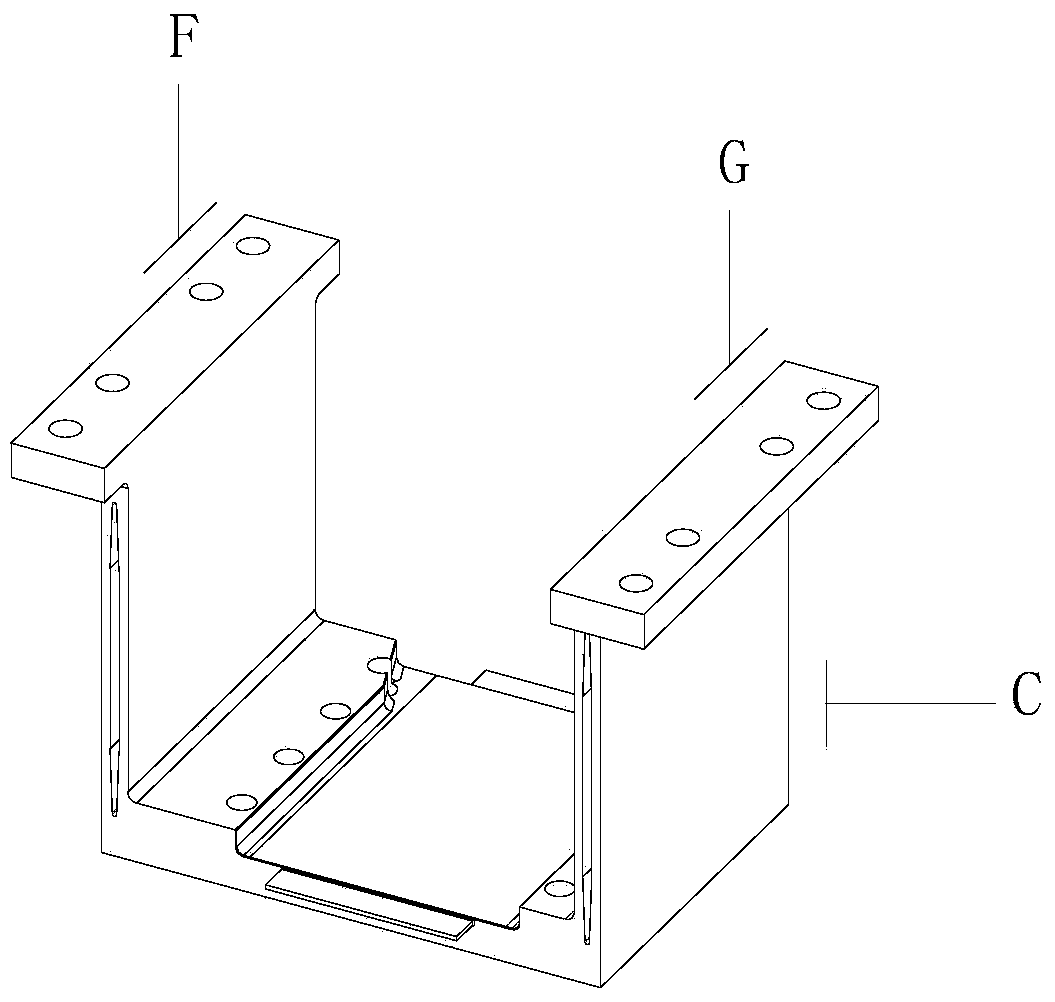

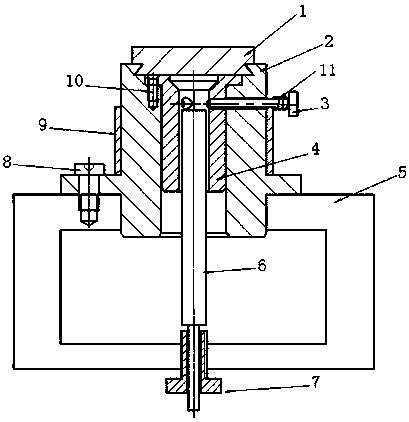

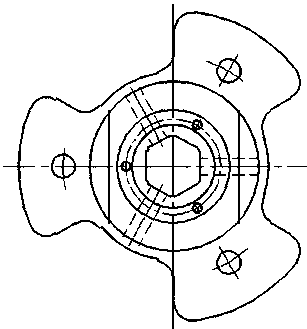

Manufacturing method of pedestal bearing for turbocharger and positioning tool for same

ActiveCN102658458AStress reliefEliminate processing stressGrinding work supportsTurbochargerEngineering

The invention discloses a manufacturing method of a pedestal bearing for a turbocharger and a positioning tool for the same. The manufacturing method comprises the following machining procedures of: 1), roughly turning one end surface and a hole of a workpiece; 2), roughly turning the other end surface and an outer circle of the workpiece; 3), annealing the workpiece to remove stress; 4), carrying out finish turning on the end surface and the hole; 5), carrying out the finish turning on the other end surface and the hole; 6), milling a semicircular positioning groove; 7), drilling radial holes at two ends; 8), milling the flat and square parts of the outer circle; 9), removing burrs by a bench worker; 12), milling an oil applying wedge surface of a thrust surface; 13), carrying out flaw detection; 14), removing the burrs by the bench worker and cleaning a part; and 15), carrying out comprehensive detection. The procedure 3) is adopted between the procedure 2) and the procedure 4) to anneal the workpiece to remove the stress; a procedure 10) and a procedure 11) are adopted between the procedure 9) and the procedure 12); the procedure 10) comprises the following steps of: adopting the positioning tool, positioning the outer circle of the workpiece by utilizing a tool hole, compacting the thrust surface of the workpiece, and accurately grinding the holes; and the procedure 11) comprises the following steps of: positioning the holes by utilizing a taper shaft, and accurately grinding the outer circle and the thrust surface. The manufacturing method and the positioning tool have the advantages that the procedures are arranged reasonably, and the machining quality and the machining efficiency can be effectively improved.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

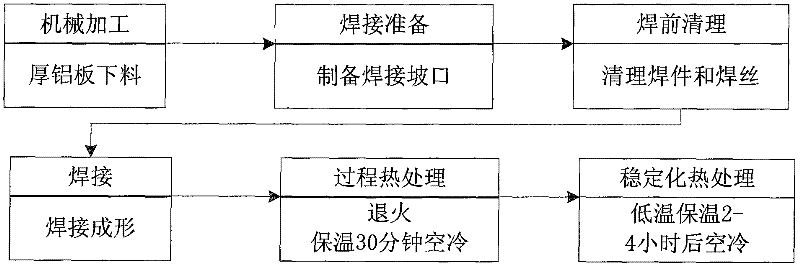

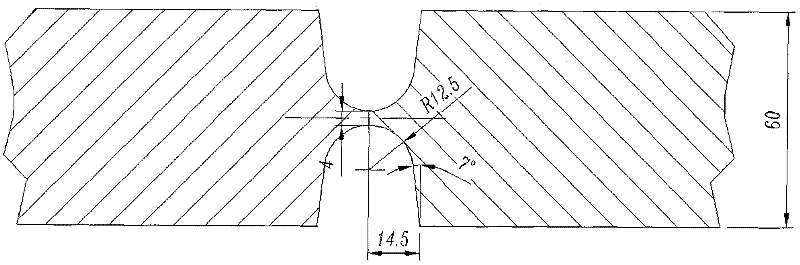

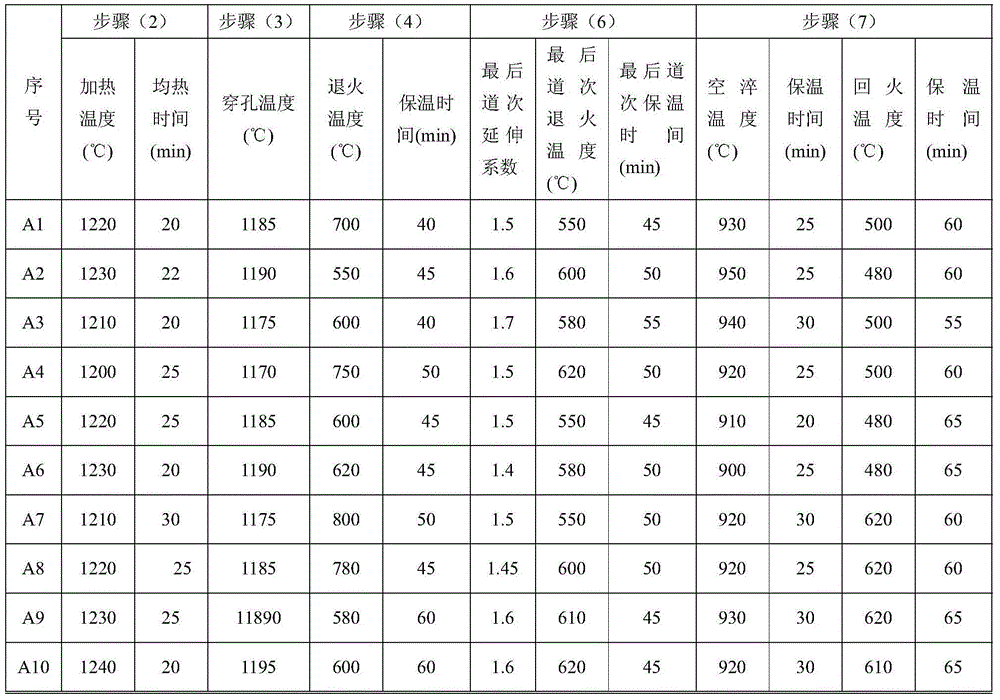

Method for welding thick aluminum alloy plate

InactiveCN102363237AEliminate welding residual stressEliminate processing stressArc welding apparatusWelding/soldering/cutting articlesMachining processWeld strength

The invention discloses a method for welding a thick aluminum alloy plate. The method comprises the following steps of: blanking from a large aluminum plate according to a specified size: butting two opposite edges to be welded and forming two U-shaped welding grooves on the upper surface and the lower surface of the thick aluminum alloy plate; washing an aluminum alloy and a welding wire with acetone, removing oxidation films on the surfaces of the U-shaped welding grooves, and wiping; and welding the U-shaped welding grooves by using an inverted consumable electrode argon arc welding machine of which the maximum output current is 500 A, welding, annealing, and performing relief annealing in a subsequent further machining process. In the method, preheating is not required before welding, so that the labor intensity is effectively lowered, the mechanical property of a welding joint is improved, the internal quality of a weld seam of a thick aluminum plate is improved, and the welding strength is required to be over 90 percent of parent substrate strength.

Owner:中国航天科工集团第二研究院二一〇所

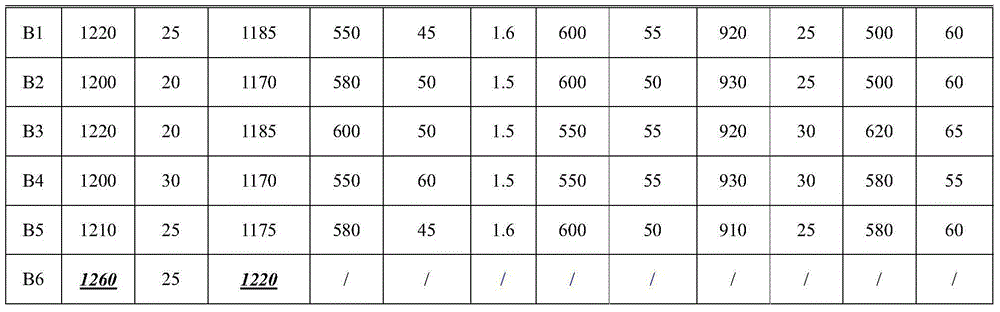

High-strength steel, high-strength plastic seamless steel pipe for automotive driver shafts and manufacturing method of high-strength plastic seamless steel pip

The invention discloses high-strength steel. The high-strength steel comprises the following chemical elements in percentage by mass: 0.07% to 0.15% of C, 0.1% to 1.0% of Si, 2.0% to 2.6% of Mn, 0.05% to 0.6% of Ni, 0.2% to 1.0% of Cr, 0.1% to 0.6% of Mo, 0.001% to 0.006% of B, 0.05% to 0.50% of Cu, 0.015% to 0.060% of Al, 0.02% to 0.1% of Nb, 0.02% to 0.15% of V, and the balance Fe and unavoidable impurities. Correspondingly, the invention further discloses a high-strength plastic seamless steel pipe for automotive driver shafts. The high-strength plastic seamless steel pipe for the automotive driver shafts is manufactured by the high-strength steel. In addition, the invention further discloses a manufacturing method of the high-strength plastic seamless steel pipe for the automotive driver shafts. The high-strength plastic seamless steel pipe for the automotive driver shafts is high in strength, high in strength and ductility product and good in anti-torsion fatigue performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Machining process for large spring pieces

InactiveCN104668907AEliminate processing stressReduce thermal stressFurnace typesHeat treatment furnacesSurface stressPunching

The invention relates to processes for springs, in particular to a machining process for large spring pieces. The machining process includes the following steps of blanking of a 3mm plate, punching, finishing, rough grinding, thermal treatment, accurate grinding, oxidation treatment and packaging, wherein the step of thermal treatment includes high-temperature tempering, quenching and intermediate-temperature tempering. The large spring pieces produced by the machining process are stable in quality, free of saw blade cracking and basically free of workpiece cracking; a shaping die is adopted for tempering, so that uniformity in surface stress is realized, warping of the spring pieces is ensured to be slight, and the machining process is a mature thermal treatment process.

Owner:NANTONG HONGFENG ELECTRO MECHANIC

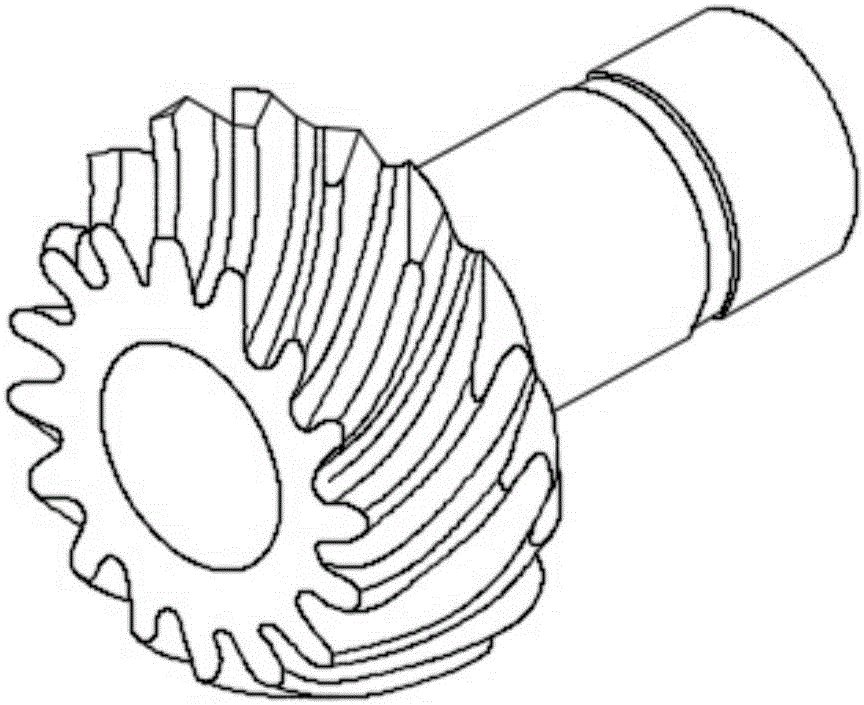

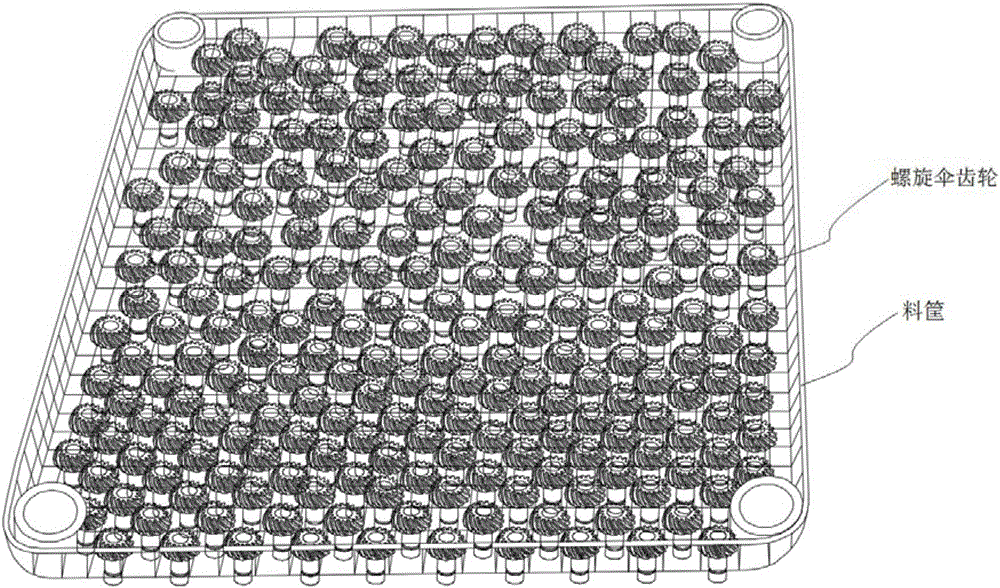

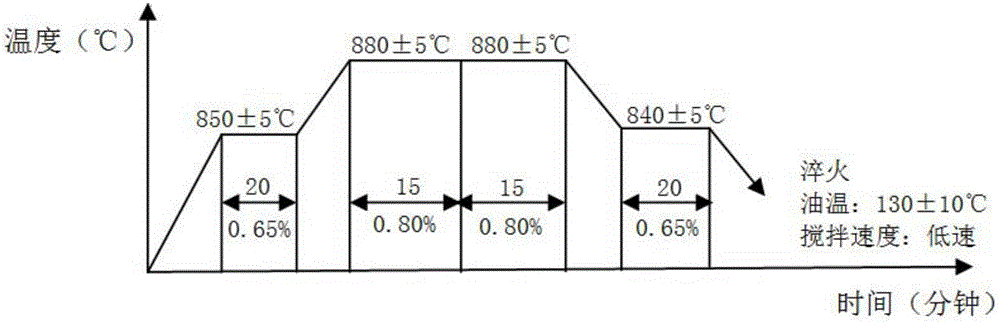

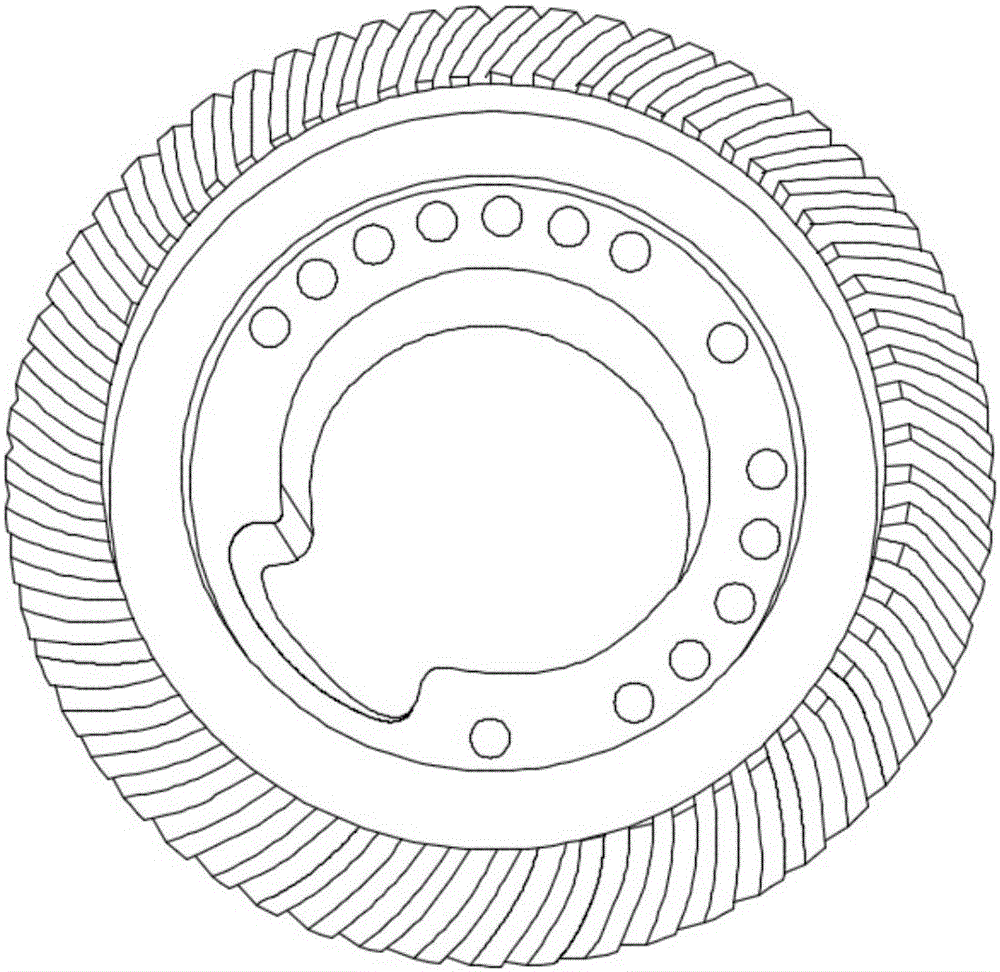

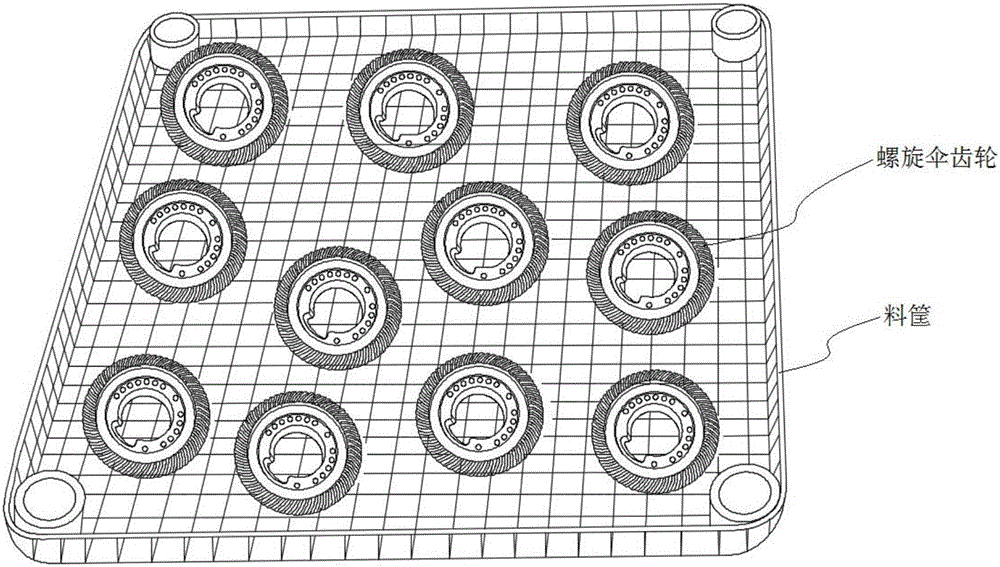

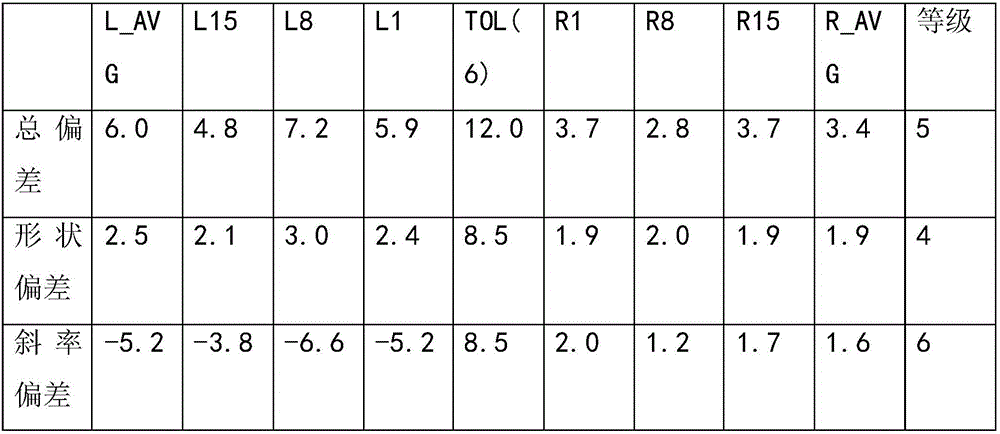

Heat treatment technology for reducing deformation of spiral bevel gear for hay mower

ActiveCN106048192AReduce distortionSmall temperature differenceFurnace typesHeat treatment furnacesCarbon potentialThermal insulation

The invention discloses a heat treatment technology for reducing deformation of a spiral bevel gear for a hay mower and belongs to the field of heat treatment technology. The technology comprises the following steps: 1) preparation of the spiral bevel gear by the adoption of a SCM415 blank; 2) crating; 3) front cleaning; 4) carburizing and quenching: temperature equilibrium at 850 + / - 5 DEG C for 20 + / - 1 min, and carbon potential is 0.65 + / - 0.025%; intensive carburizing and thermal insulation at 880 + / - 5 DEG C for 15 + / - 1 min, and carbon potential is 0.8 + / - 0.025%; diffusion and thermal insulation at 880 + / - 50 DEG C for 15 + / - 1 min, and carbon potential is 0.8 + / - 0.025%; quenching and temperature equilibrium at 840 + / - 5 DEG C for 20 + / - 1 min, and carbon potential is 0.65 + / - 0.025%; and cooling in 130 + / - 10 DEG C of quenching oil; 5) post cleaning; and 6) tempering at the temperature of 175 + / - 5 DEG C for 150 + / - 10 min. According to the invention, deformation of the spiral bevel gear after heat treatment is reduced, and first pass yield for heat treatment can reach 100%.

Owner:常州新区河海热处理工程有限公司

Preparing method for molybdenum and molybdenum alloy pipe

ActiveCN105964721AImprove hot working plasticityUniform wall thicknessRoll mill control devicesMetal rolling arrangementsAlloyPipe

The invention belongs to the technical field of powder metallurgy machining, and particularly relates to a preparing method for a molybdenum and molybdenum alloy pipe. The technology steps of molybdenum and molybdenum alloy pipe blank preparing, molybdenum pipe hot rolling, molybdenum pipe warm rolling and surface treatment and control over the technology conditions are adopted, and the super-long and thin-wall seamless molybdenum and molybdenum alloy pipe is prepared. Due to the comprehensive effects of hot rolling and warm rolling, the molybdenum and molybdenum alloy pipe prepared through the method achieves the beneficial effects that the molybdenum pipe is super long, thin in wall and seamless, the yield is high, and the comprehensive utilization rate of materials is high. The large deformation rate is achieved when molybdenum and a molybdenum alloy are used for preparing the pipe, an inner structure of the molybdenum pipe is refined and homogenized, and the mechanical performance is excellent; and an existing molybdenum pipe preparing technology is simplified, the materials are saved, and implementation is easy.

Owner:JINDUICHENG MOLYBDENUM CO LTD +1

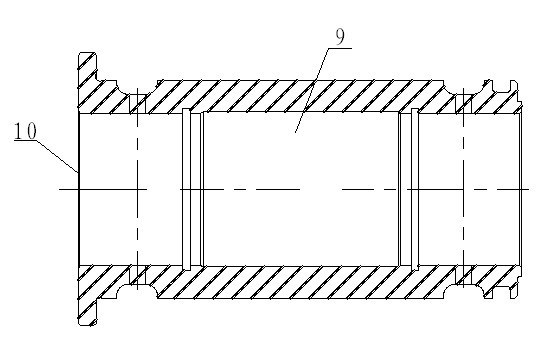

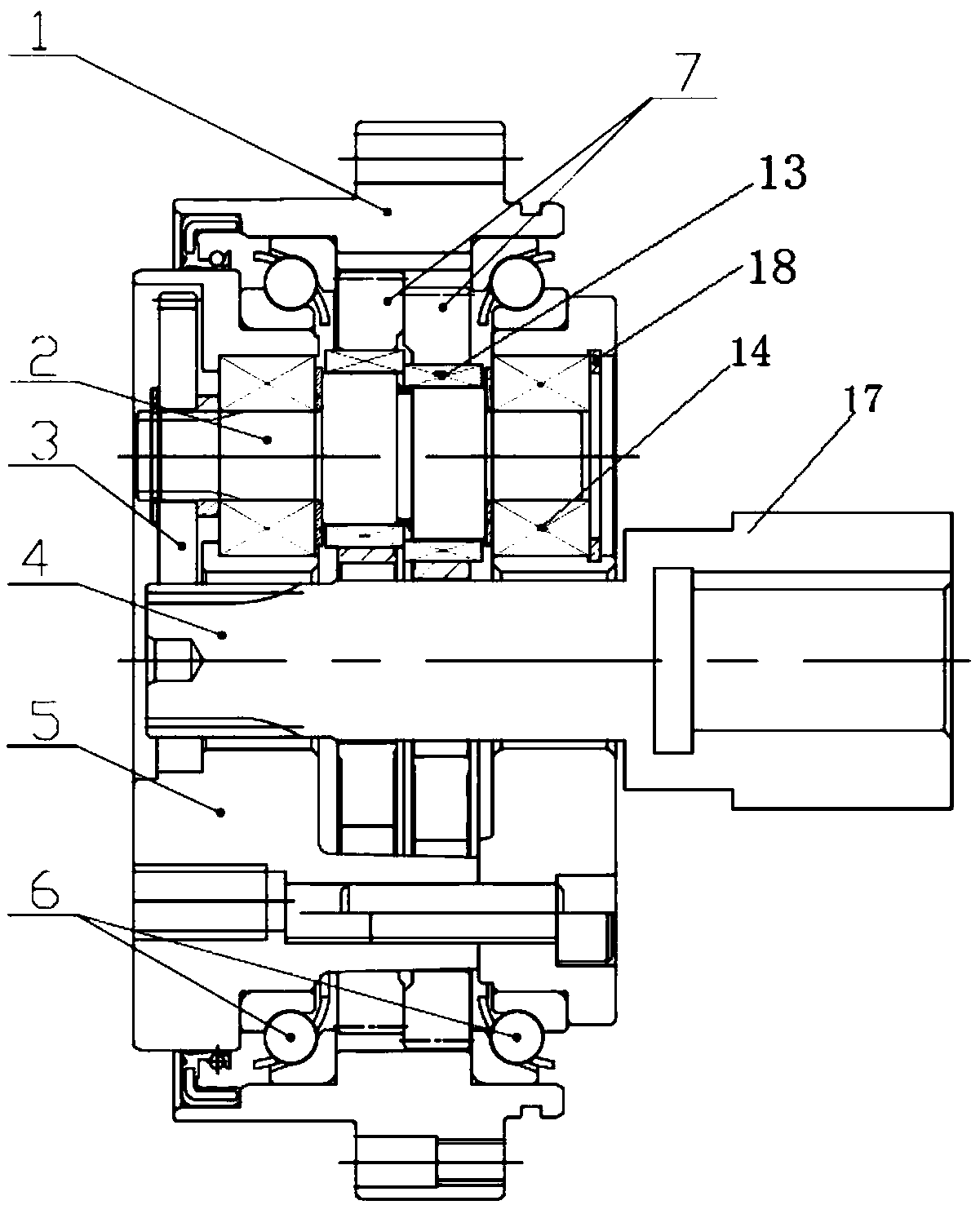

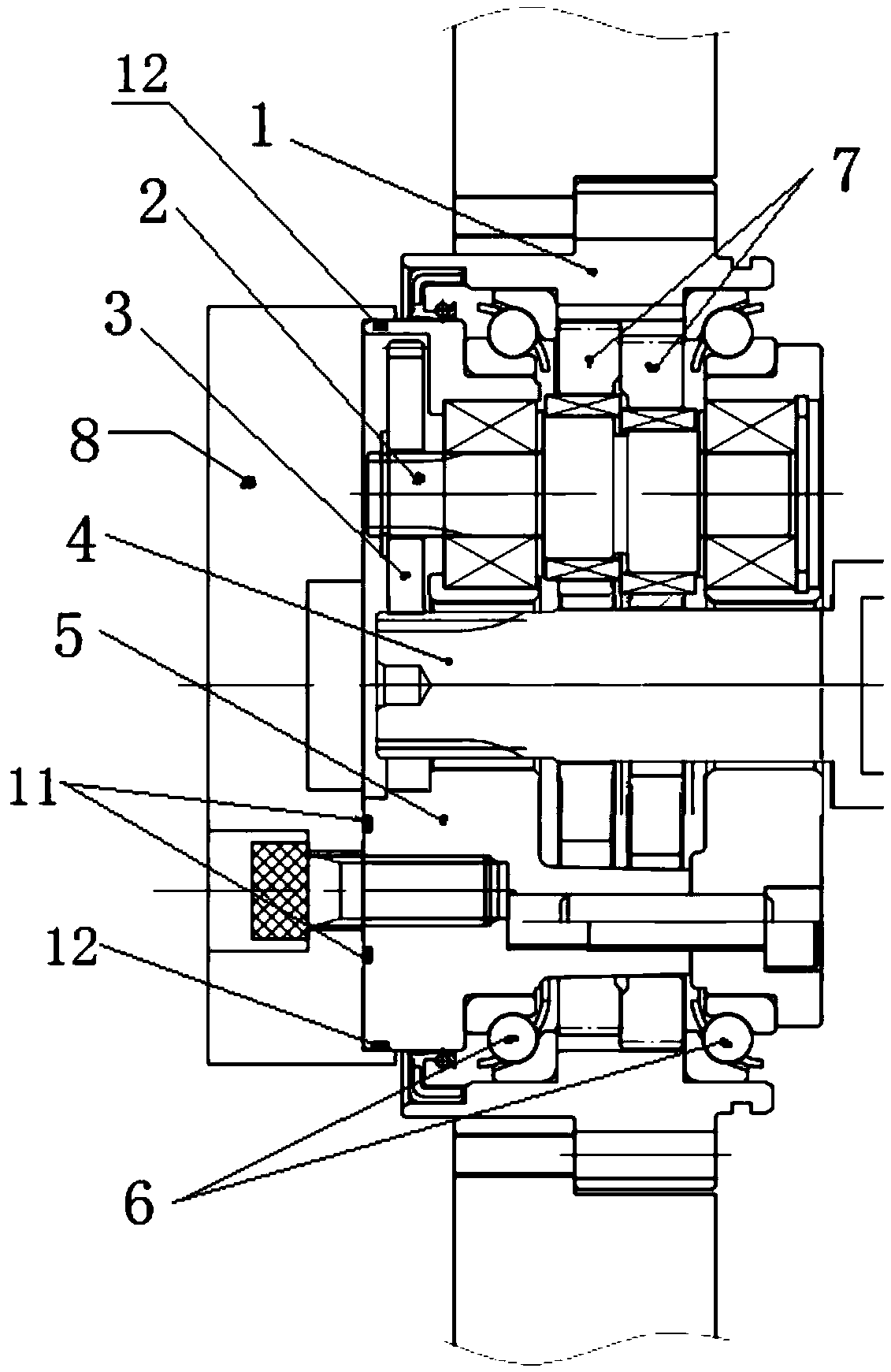

RV precise speed reducer eccentric shaft and precise speed reducer

ActiveCN108799316AIncrease load capacityImprove impact resistanceEccentric-shaftsToothed gearingsBall bearingAgricultural engineering

The invention provides a RV precise speed reducer eccentric shaft and a precise speed reducer. An annular reinforcement block is arranged in a sunken groove between two adjacent cams of the eccentricshaft; the precise speed reducer comprises a pin wheel housing, the eccentric shaft, a planet wheel, an input shaft, an output plate rack, an angular contact ball bearing and a cycloidal wheel; the planet wheel is arranged at one end of the eccentric shaft; the input shaft is located in the center of the pin wheel housing; one end of the input shaft is connected with a motor; a center gear is arranged at the other end of the input shaft; the center gear and the planet wheel are in mesh connection on the same rotation plane so as to form a first-stage planet speed reduction mechanism; and the angular contact ball bearing is arranged between the pin wheel housing and the output plate rack. According to the RV precise speed reducer provided by the invention, through increasing the diameter ofa cam connecting part, the impact resistance of the RV precise speed reducer eccentric shaft is greatly improved, the fatigue life of the RV precise speed reducer eccentric shaft is greatly prolonged, and the carrying capacity, the impact resistance, the service life and the running precision of the RV speed reducer are further improved.

Owner:NANTONG ZHENKANG WELDING ELECTROMACHINERY +1

Forming process of nickel-based bimetal composite tube

InactiveCN107774737AImprove the bonding strength of the interfaceHigh yieldFurnace typesHeat treatment furnacesSolution treatmentIron oxide

The invention discloses a forming process of a nickel-based bimetal composite tube, comprising the steps of pretreating, forming by cold pushing, performing solution treatment, and tempering; the stepof forming by cold pushing includes placing a nickel-based bimetal composite tube in a die of a cold-extrusion former, and allowing a punch of the cold-extrusion former to act on the nickel-based bimetal composite tube through a forming hole arranged in the die so as to finish forming by cold pushing; the forming by cold pushing, solution treatment and tempering are performed sequentially repeatedly until the nickel-based bimetal composite tube reaches finish specifications; ends of the nickel-based bimetal composite tube are cut off by flame cutting, sawing, toothless saw cutting or plasma cutting, and the finished composite tube is obtained; iron oxide skin on the inner and outer surfaces of the finished composite tube is removed by chemical or mechanical means. The forming process of the nickel-based bimetal composite tube can provide reduced production cost and improved production efficiency.

Owner:YANGZHOU PIPE FITTING FACTORY

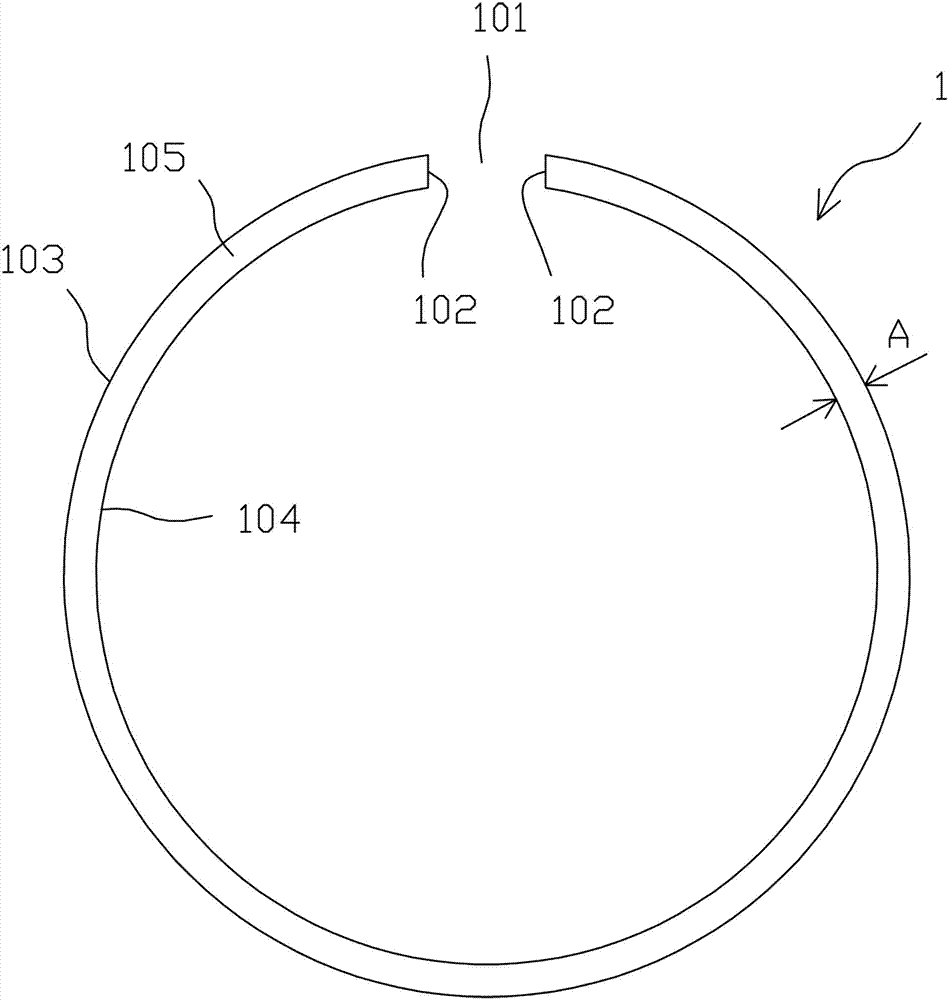

Method for machining sealing rings

InactiveCN104289871AAvoid it happening againSave raw materialsMachines/enginesEngine componentsResidual deformationUltimate tensile strength

The invention discloses a method for machining sealing rings. The method comprises the following steps of (1) carrying wiredrawing on metal bar materials, (2) carrying out heat treatment, (3) winding the wiredrawn metal bar materials into a spring shape, (4) cutting the metal bar materials into multiple twisted ring-shaped components with openings, (5) leveling the ring-shaped components, (6) carrying out quench tempering, (7) grinding the inner circumferential surfaces and the outer circumferential surfaces of the ring-shaped components so that the inner circumferential surfaces and the outer circumferential surfaces of the ring-shaped components can be regular arcs, (8) opening the openings of the ring-shaped components to a preset size and then carrying out heat shaping, (9) obtaining the formed sealing rings. According to the method for machining the sealing rings, material waste is quite low, the machined sealing rings are high in strength, toughness and elasticity and uniform in wall thickness, the thermal elastic loss and the residual deformation of the machined sealing rings are both small, latent defects of the sealing rings can be exposed in the early stage of machining, and the sealing rings with the latent defects can be picked out.

Owner:PINGXIANG DEBO TECH CO LTD

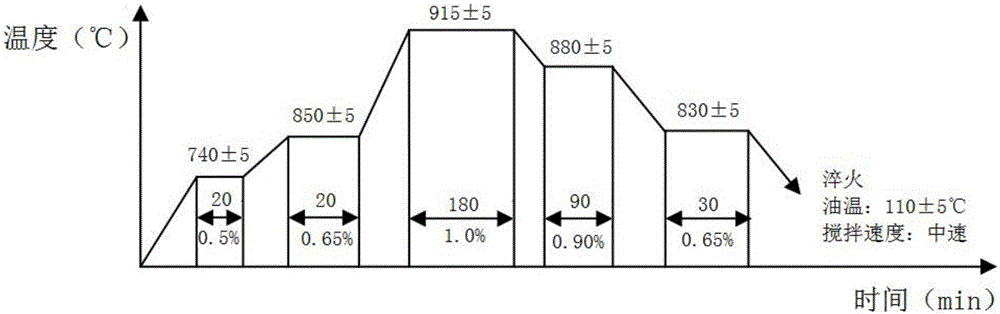

Heat treatment technology for reducing deformation of spiral bevel gear for industrial robot

ActiveCN106048191AReduce distortionSmall amount of deformationFurnace typesHeat treatment furnacesFirst pass yieldEngineering

The invention discloses a heat treatment technology for reducing deformation of a spiral bevel gear for an industrial robot and belongs to the field of heat treatment technology. The technology comprises the following steps: 1) preparation of a spiral bevel gear part; 2) crating; 3) front cleaning; 4) carburizing and quenching: temperature equilibrium at 740 + / - 5 DEG C for 20 + / - 1 min, and carbon potential is 0.50 + / - 0.025%; temperature equilibrium at 850 + / - 5 DEG C for 20 + / - 1 min, and carbon potential is 0.65 + / - 0.025%; intensive carburizing at 915+ / - 5 DEG C for 180 + / - 1 min, and carbon potential is 1.0 + / - 0.025%; diffusion at 880 + / - 5 DEG C for 90 + / - 1 min, and carbon potential is 0.90 + / - 0.025%; quenching and temperature equilibrium at 830 + / - 5 DEG C for 30 + / - 1 min, and carbon potential is 0.65 + / - 0.025%; and cooling in 110 + / - 5 DEG C of quenching oil; 5) post cleaning; and 6) tempering. According to the invention, deformation of the spiral bevel gear after heat treatment is reduced, and first pass yield for heat treatment can reach 100%.

Owner:常州新区河海热处理工程有限公司

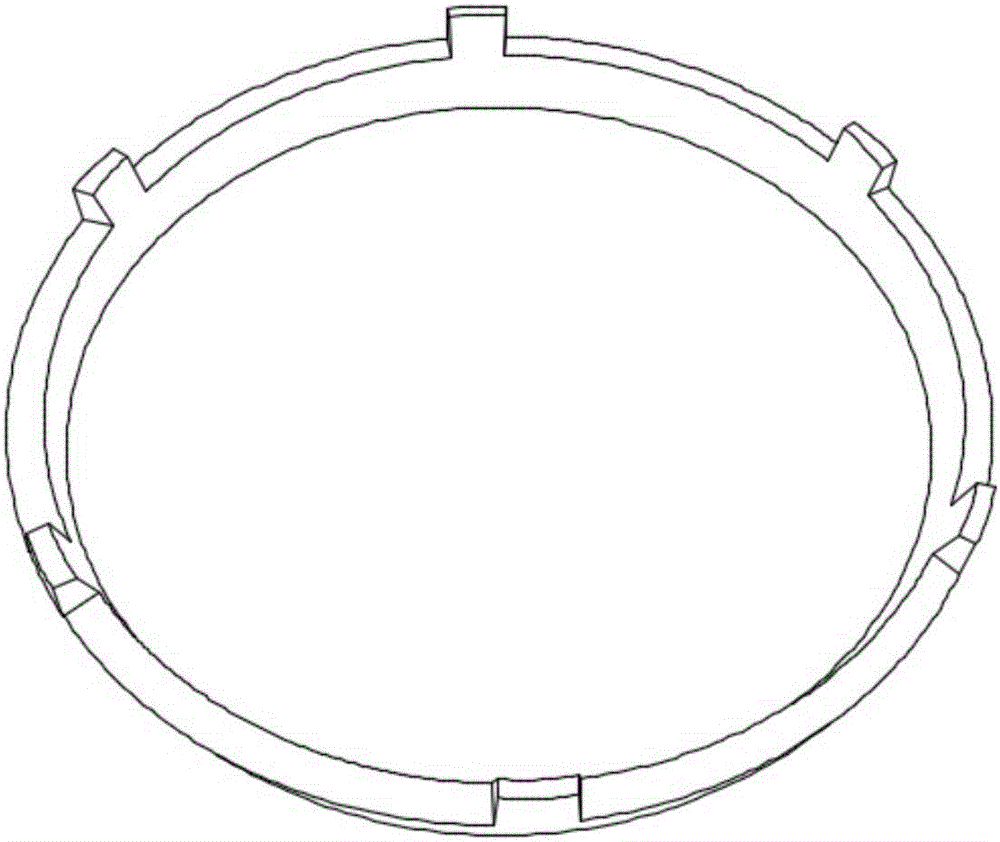

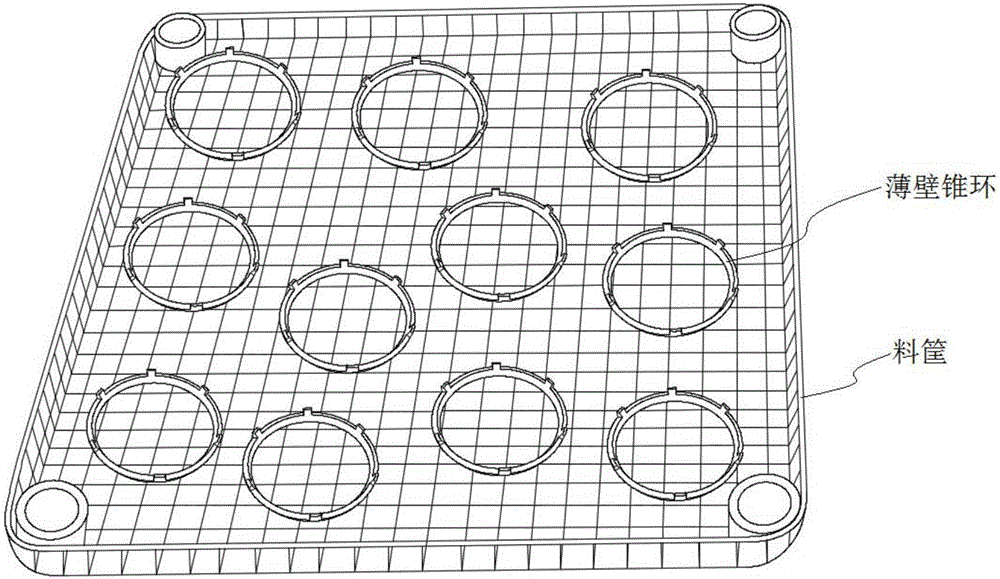

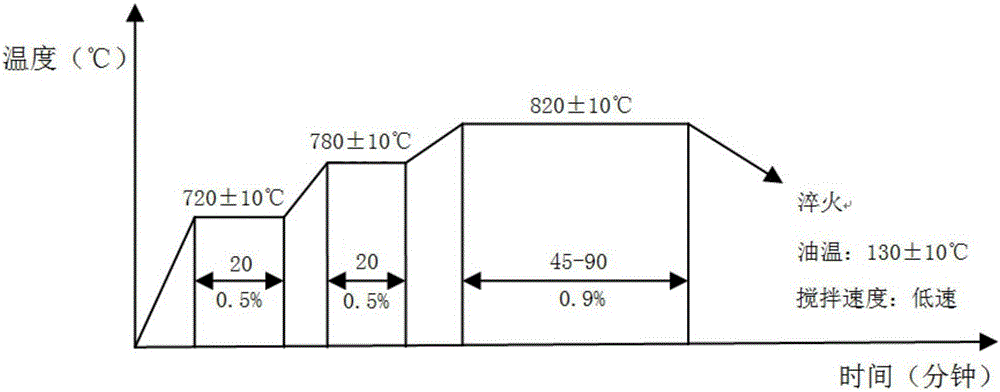

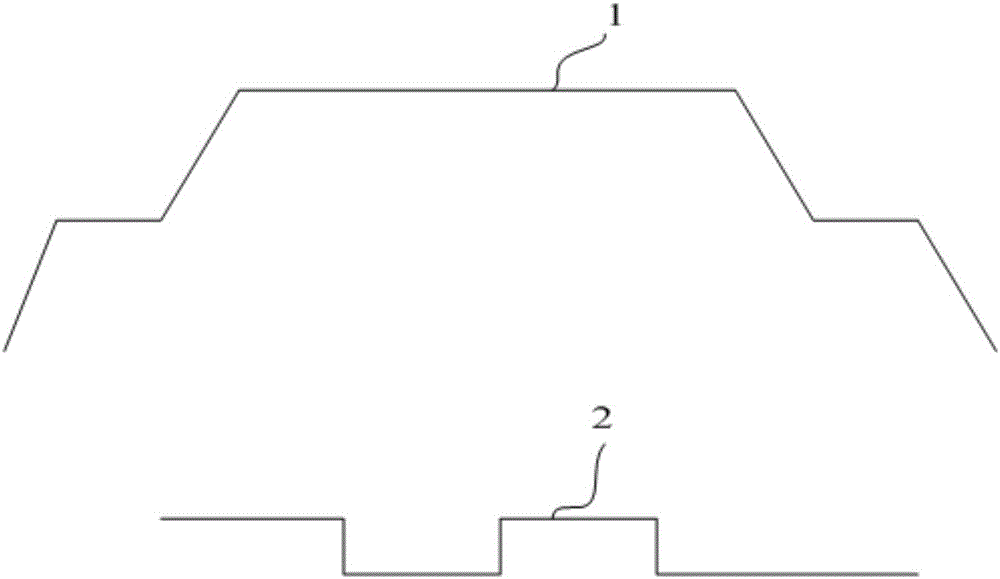

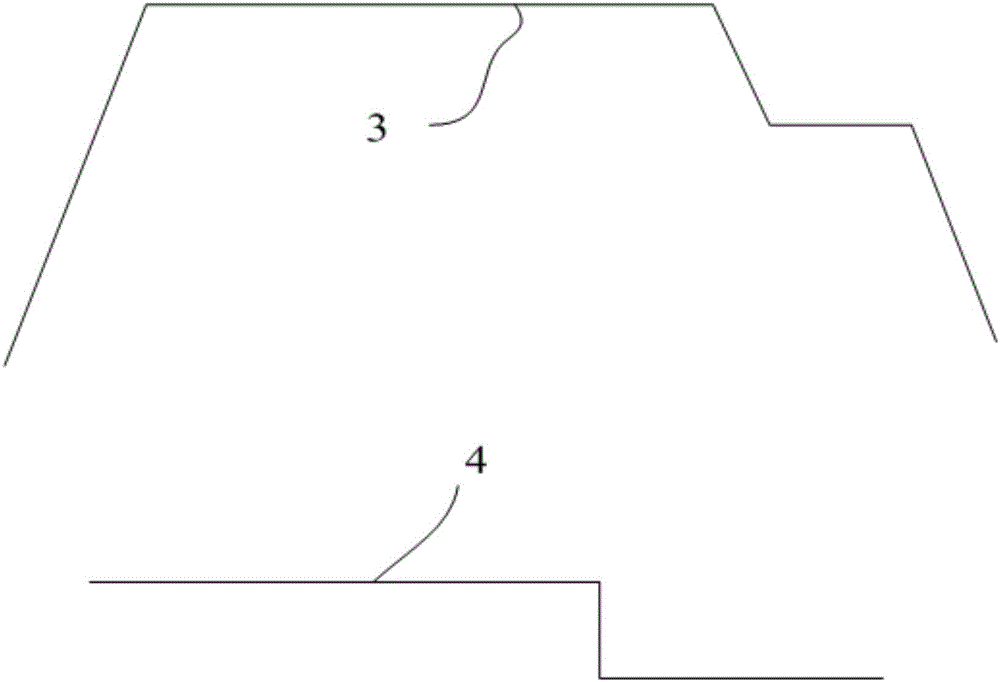

Heat treatment technology for reducing deformation of GCr15 thin-wall conical ring

ActiveCN106048195ASmall amount of deformationReduce grinding allowanceFurnace typesProcess efficiency improvementCarbon potentialThermal insulation

The invention discloses a heat treatment technology for reducing deformation of a GCr15 thin-wall conical ring and belongs to the field of heat treatment technology. The technology comprises the following steps: 1) machining of a spheroidized annealed blank into a thin-wall conical ring part; 2) crating; 3) front cleaning; 4) quenching: thermal insulation at 720 + / - 10 DEG C for 20 + / - 1 min, and carbon potential is 0.5 + / - 0.025%; thermal insulation at 780 + / - 10 DEG C for 20 + / - 1 min, and carbon potential is 0.5 + / - 0.025%; thermal insulation at 820 + / - 10 DEG C for 45-90 min, and carbon potential is 0.9 + / - 0.025%; and cooling in 130 + / - 10 DEG C of quenching oil; 5) post cleaning; and 6) tempering: tempering temperature is 185 + / - 5 DEG C, and time is 150 + / - 10 min. According to the invention, deformation of the thin-wall conical ring part after heat treatment is reduced, grinding allowance after heat treatment is decreased, grinding cost after heat treatment is lowered, and first pass yield for heat treatment reaches 100%.

Owner:常州新区河海热处理工程有限公司

Composite stepped carburizing and quenching technology of gear shaft

InactiveCN106835004AEliminate processing stressReduce the temperature difference between inside and outsideSolid state diffusion coatingFurnace typesTemperature differenceConcentration gradient

The invention belongs to the technical field of heat treatment, in particular to a composite stepped carburizing and quenching technology of a gear shaft. The composite stepped carburizing and quenching technology of the gear shaft includes the steps of entering furnace and heating, preserving heat, reheating, preserving heat of the stepped carburizing and quenching, reducing temperature and preserving heat, outing furnace and quenching, and the like. By adoption the composite stepped carburizing and quenching technology of the gear shaft, a constant temperature is firstly applied at a temperature below the critical point of the transformation before the workpiece is carburized, the temperature of the workpiece tends to be uniform inside and outside the temperature, thus, the internal and external temperature difference, the heating speed, and the thermal stress are reduced; and in carburizing stage, the stepped carburizing is adopted, that is, increase of cyclation and decrease of carbon concentration gradient, thus, the diffusion rate of carbon atoms is increased, the holding time of workpieces at high temperature is reduced, the deformation of heat treatment is reduced, and the requirements of metallurgical structure and mechanical properties are met.

Owner:ZHANGQIU HAILI MACHINERY MFG CO LTD

Post-forging dehydrogenation annealing technology of chromium-containing high-nickel alloy steel forged piece

The invention relates to a post-forging dehydrogenation annealing technology of a chromium-containing high-nickel alloy steel forged piece. The technology comprises the specific steps of after forging, slowly cooling the forged piece to 500 to 700 DEG C, keeping the temperature, increasing the temperature with full power to a temperature 100 to 150 DEG C above a complete austenitizing temperature, keeping the temperature, cooling to a temperature 50 to 100 DEG C below a martensite transformation starting temperature, and keeping the temperature for a short time; increasing the temperature to a high-temperature tempering zone at the speed of 30 to 60 DEG C / h, keeping the temperature, after temperature keeping, carrying out furnace cooling to 400 DEG C at the speed of 30 to 60 DEG C / h, and carrying out furnace cooling to a temperature 10 to 50 DEG C below a martensite transformation ending temperature at the speed of 10 to 30 DEG C / h; and increasing the temperature to the high-temperature tempering zone at the speed of 30 to 60 DEG C / h, keeping the temperature, after temperature keeping, carrying out furnace cooling to 100 to 150 DEG C at the speed of 10 to 30 DEG C / h, taking the forged piece out of a furnace, and carrying out air cooling. According to the post-forging dehydrogenation annealing technology of the chromium-containing high-nickel alloy steel forged piece, the problems that annealing and dehydrogenation are difficult to carry out on the chromium-containing high-nickel alloy steel forged piece through a conventional method, and ultrasonic flaw detection defects are caused by white dots of forged pieces with relatively large specifications are solved better.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

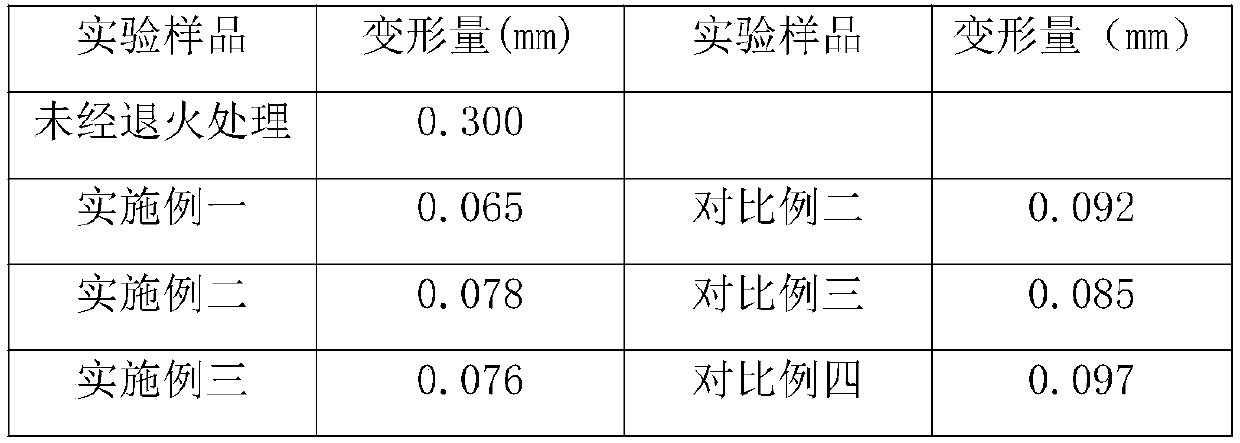

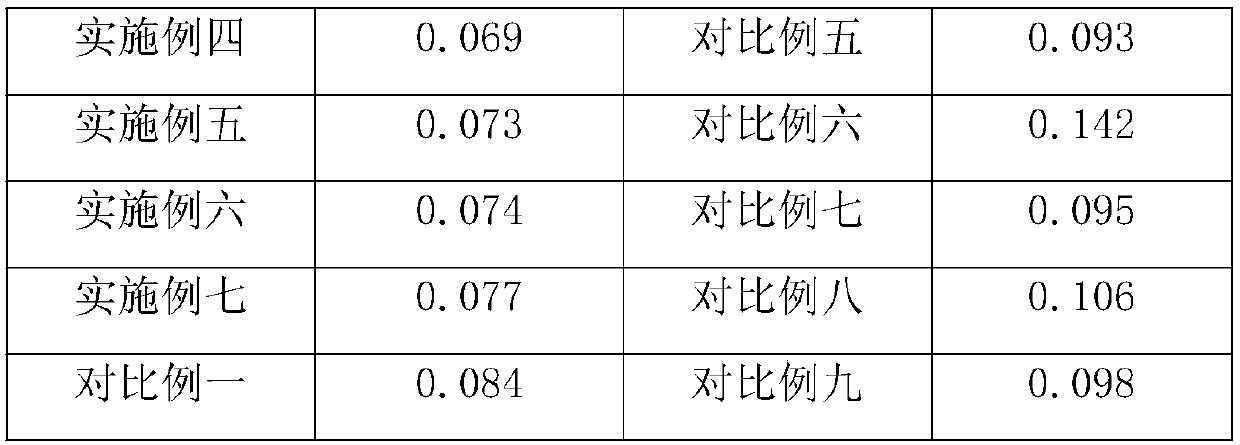

Annealing method of ceramic rear cover

InactiveCN107698278AUniform grain distributionArrangement structure is reasonableTelephone set constructionsInteraction forcesTwo temperature

The invention discloses an annealing method of a ceramic rear cover, and belongs to the field of ceramic rear cover machining. The method comprises the following steps: putting the ceramic rear coverinto an annealing furnace, rising the temperature to a 600 to 800 DEG C medium temperature zone, and performing heat preservation for 1 to 2 hours; rising the temperature to a 1000 to 1200 high temperature zone after heat preservation is performed in the medium temperature zone, and performing heat preservation for 3 to 4 hours in the high temperature zone; reducing the temperature to 800 to 900 DEG C after high temperature preservation is performed, and ensuring that the time is controlled to be 1 to 2 hours; naturally cooling the ceramic rear cover to the room temperature, and then discharging the ceramic rear cover, so as to accomplish annealing. The method has the benefits that a gradient temperature rising and reducing technology is adopted; through twice time rise and twice temperature reduction, the ceramic rear cover is kept in the two temperature zones for a certain period of time, then crystal particles inside the ceramic rear cover are grown by stages, interaction force among the crystal particles is fully released, the crystal particles are more uniformly distributed, and an arrangement structure among the crystal particles is more stable, so that stress produced duringfine carving of the ceramic rear cover is effectively reduced, the fact that the deformation of the ceramic rear cover is below 0.08mm after annealing treatment is ensured, and the assembly requirement of mobile phones is met.

Owner:湖北天宝光电科技有限公司

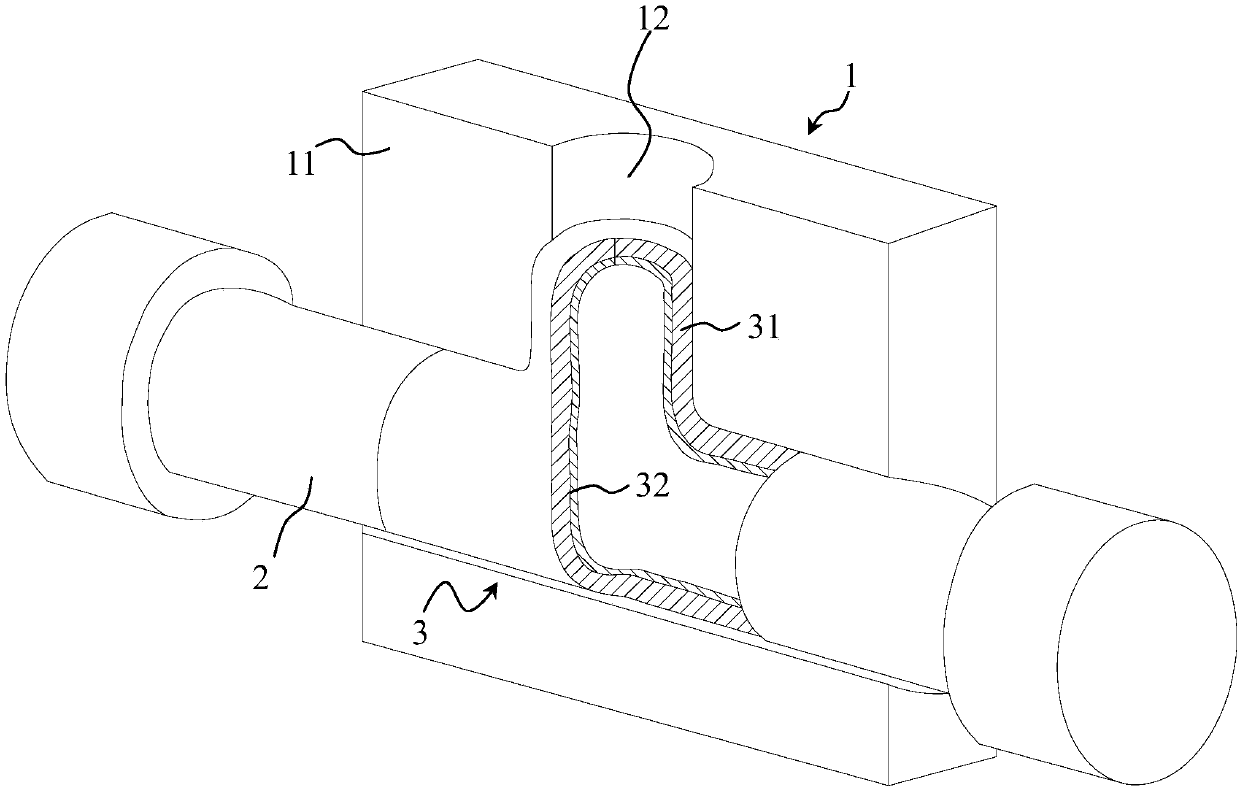

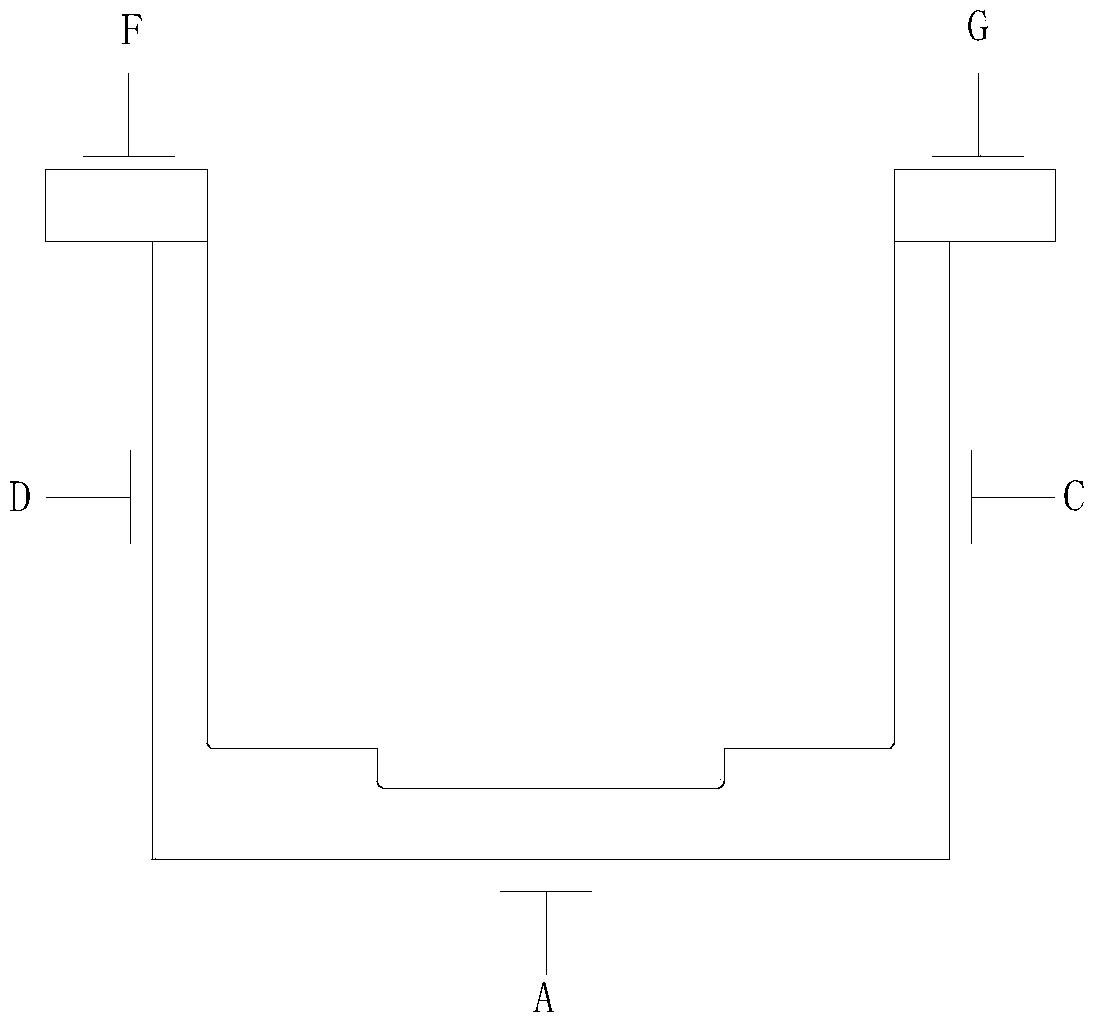

Binaural U-shaped piece welding-free integrated finish machining method for thermonuclear fusion reactor

The invention relates to a machining technology of U-shaped pieces, in particular to a binaural U-shaped piece welding-free integrated finish machining method for a thermonuclear fusion reactor. The binaural U-shaped piece welding-free integrated finish machining method comprises the steps of manufacturing U-shaped blank pieces by using a forming die; carrying out first ultrasonic flaw detection on the U-shaped blank pieces after rough machining is carried out on the U-shaped blank pieces; carrying out rough machining again after heat treatment is carried out, then carrying out second ultrasonic flaw detection, picking out qualified U-shaped pieces, and carrying out a performance test by extracting samples from bodies; machining the U-shaped pieces which are qualified in the performance test into U-shaped pieces with allowance, and then manufacturing the U-shaped pieces into primary semi-finish machining U-shaped pieces by carrying out first artificial aging treatment on the U-shaped pieces; machining the primary semi-finish machining U-shaped pieces into U-shaped pieces with allowance, and then manufacturing the U-shaped pieces into secondary semi-finish machining U-shaped pieces by carrying out second artificial aging treatment on the U-shaped pieces; machining the secondary semi-finish machining U-shaped pieces into finish machining U-shaped pieces, drilling through holes in the end surfaces of side plates of the finish machining U-shaped pieces, and obtaining finished U-shaped pieces through WEDM (Wire Electrical Discharge Machining) after a metal wire is enabled to penetrate through the through holes. The binaural U-shaped piece welding-free integrated finish machining method disclosed by the invention has the advantages that the machining efficiency is high, and the product quality is good.

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

Machining process of precipitation hardening stainless steel pump shaft

The invention relates to a machining process of a precipitation hardening stainless steel pump shaft. The machining process comprises the steps of: forging, rough turning I, UT inspection, heat treatment, rough turning II, high-temperature aging, semi-finish turning I, semi-finish turning II, low-temperature aging, grinding, finish turning I, polishing I, lineation, milling, polishing II, flaw detection, chromium plating, hydrogen removing treatment, chromium plating protection removal, polishing III, polishing IV, finishing, and obtaining of a finished product. The pump shaft machining process is low in hardening effect and size deformation, excellent in pump shaft machining size precision and high in surface smoothness, controls the size inspection below 40 DEG C after machining, is high in machining efficiency and quality, can guarantee the pump shaft size precision and low shape and position size tolerance deformation, and satisfies the drawing size requirements and the technical requirements.

Owner:SHENYANG SANKE HYDRAULIC MACHINERY MANUFACTORY

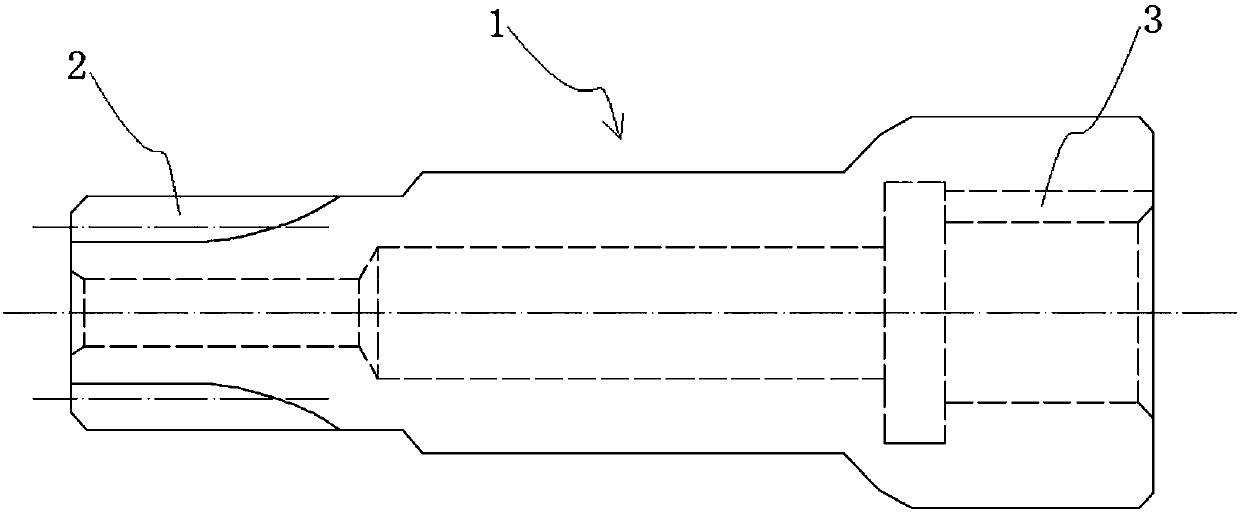

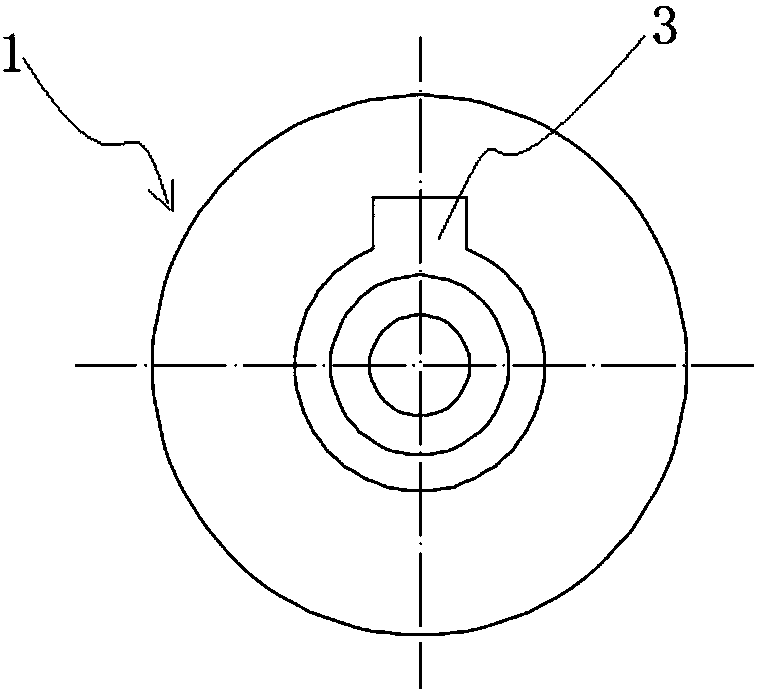

Necking process method and necking tool for titanium alloy self-locking nut

InactiveCN107866476AAvoid crackingEliminate processing stressShaping toolsNutsRoom temperatureSelf locking

The invention discloses a necking process method for a titanium alloy self-locking nut. The method comprises the following steps: S1: performing solid solution heat treatment on a titanium alloy self-locking nut sample prepared by machining to manufacture a sample to be necked; S2: performing necking processing on the sample to be necked at room temperature; and S3 after the necking processing isfinished, performing aging treatment on the titanium alloy self-locking nut, thereby finishing the necking processing of the whole titanium alloy self-locking nut. The possibility that the titanium alloy self-locking nut generates cracks in the process of necking processing process is reduced, the difficult problem that the titanium alloy nut is necked and deformed at room temperature and threadsare cracked is solved, and the necking is realized at the room temperature; and meanwhile, a necking tool is matched, and the tool is more compact in structure, more convenient to operate, more accurate in position and size control, and higher in safety and reliability.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

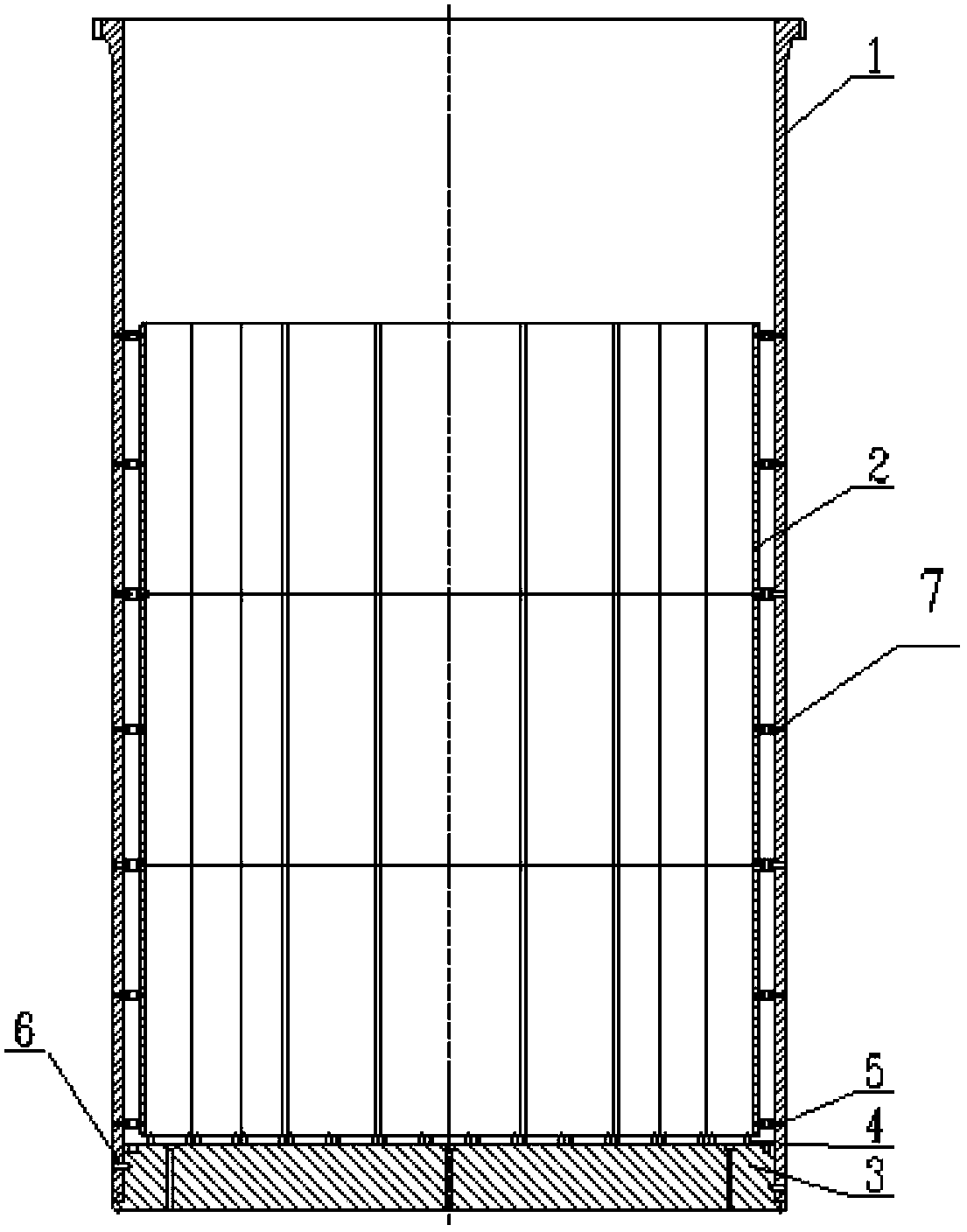

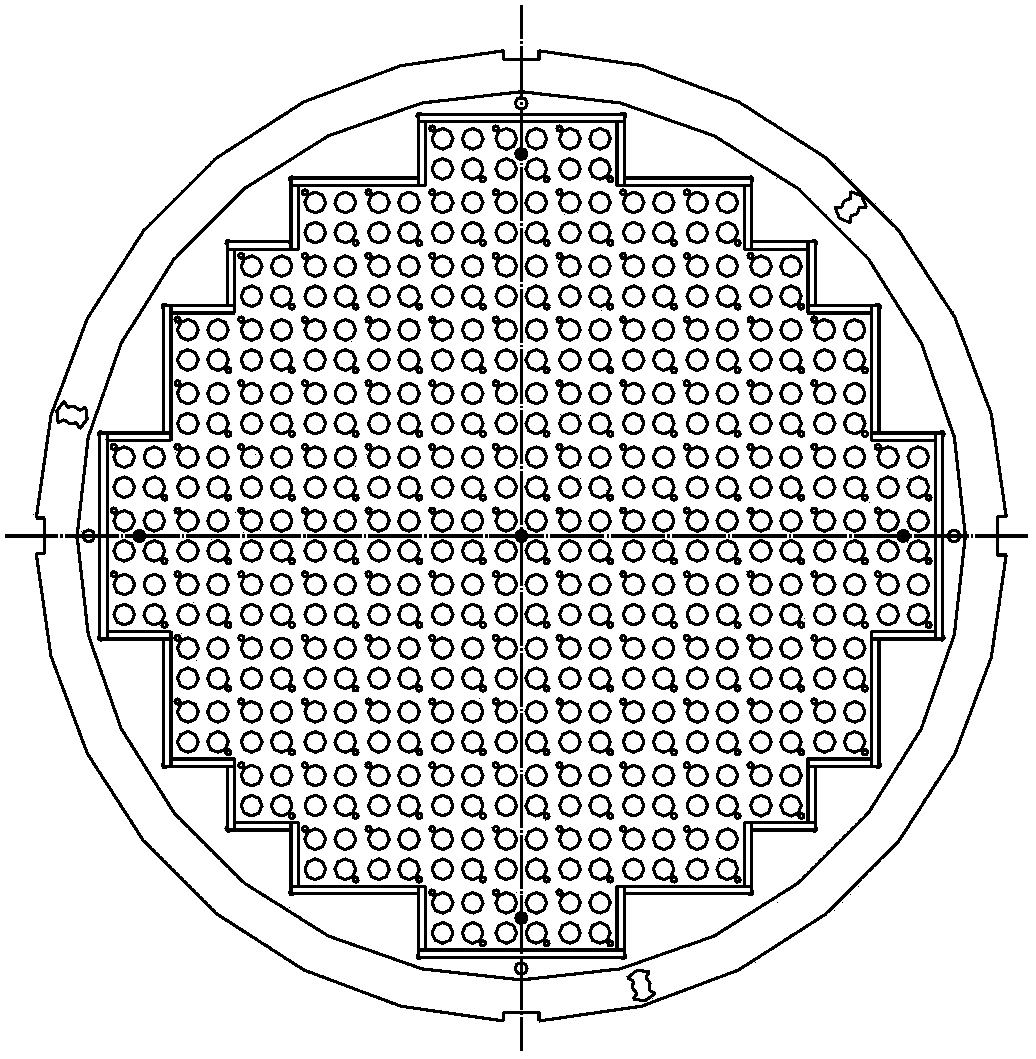

Long-stroke split-type hanging basket assembly capable of controlling deformation

ActiveCN103903655AReduce temperature stressEasy to manufactureNuclear energy generationFuel element assembliesTemperature stressNuclear engineering

The invention relates to the nuclear power technology, and in particular discloses a long-stroke split-type hanging basket assembly capable of controlling deformation. The split-type hanging basket assembly capable of controlling deformation comprises a hanging basket barrel body, a lower reactor core plate which is fixedly connected to the lower end of the hanging basket barrel body, and a baffle which is arranged in the hanging basket barrel body; the baffle is divided into three sections; a forming plate is arranged outside the baffle; by adopting a multi-section short baffle structure, the differential temperature stress of the connection of baffles is effectively reduced and the baffle is convenient to manufacture; by adopting the forming plate, the deformation of the baffle caused by radiation thermal effect is reduced; a cooling agent runner hole corresponding to a fuel assembly is arranged on the lower reactor core plate, and meanwhile, a centering hole for the lower rector core plate and an upper reactor core plate is provided, thus the technical requirement of flow cooling of the cooling agent is met, and meanwhile the centering requirement of the lower reactor core plate and the upper reactor core plate is also met, and besides, the installation becomes more accurate and more reliable.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

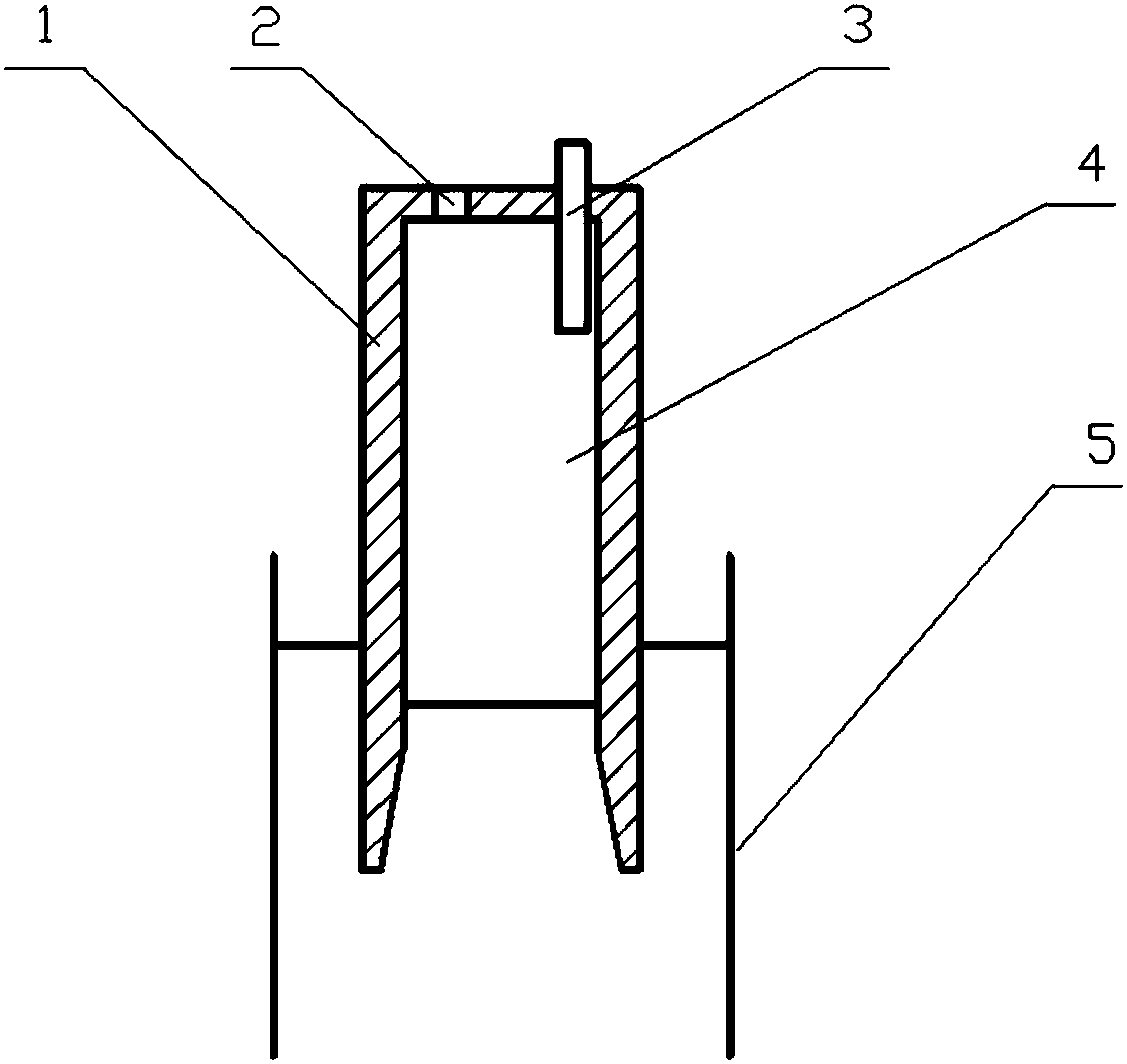

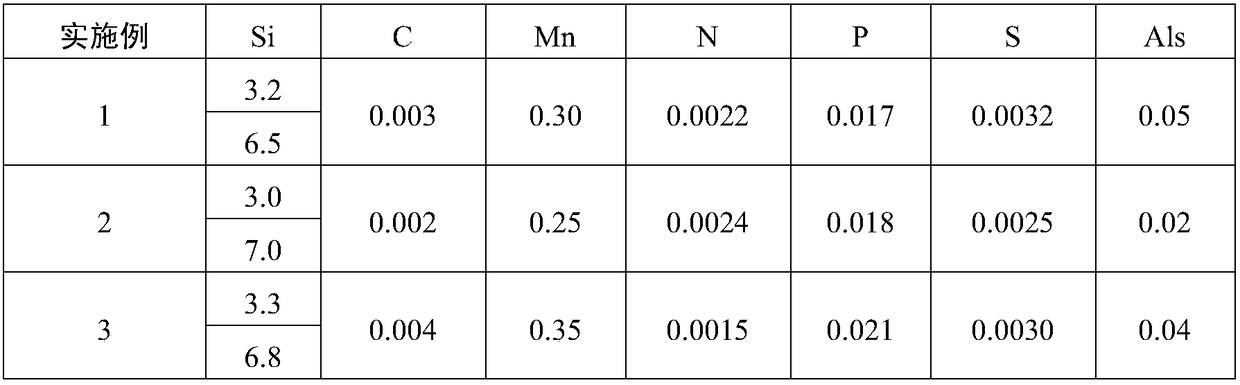

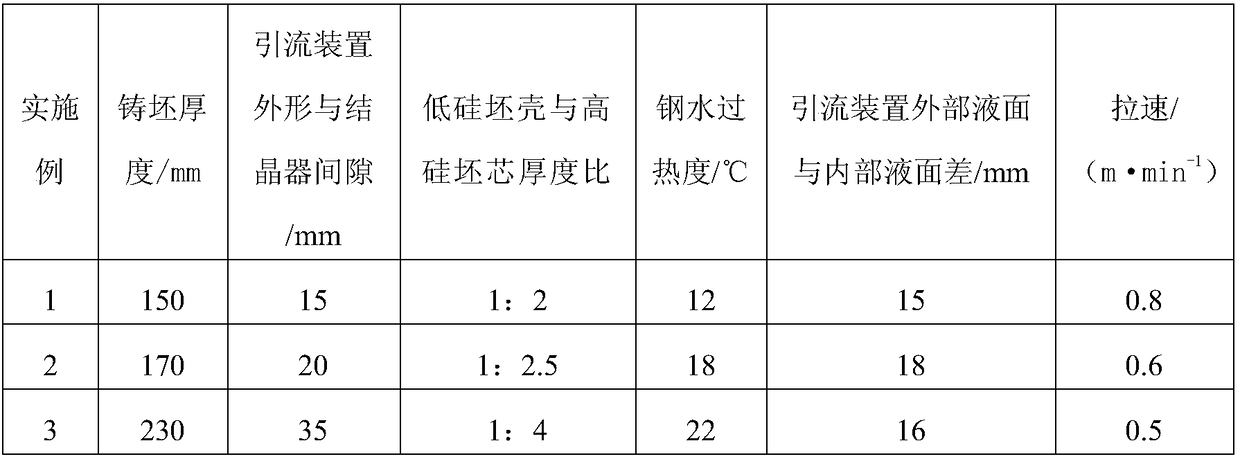

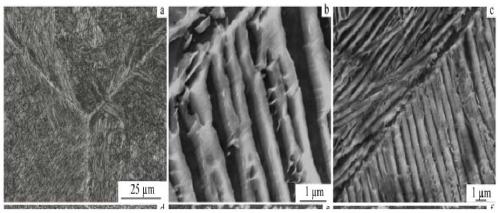

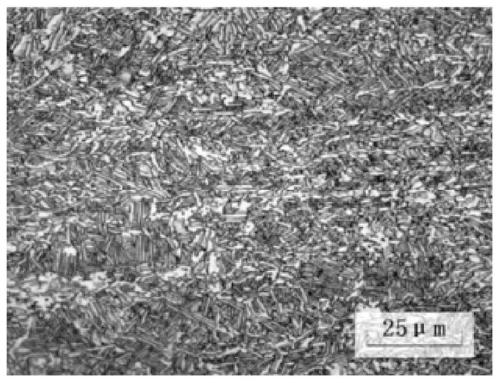

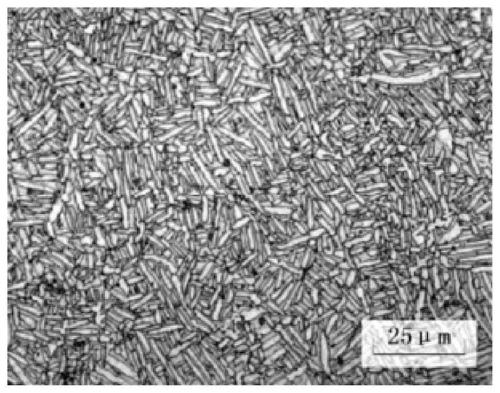

Production method of high-silicon electrical steel

The invention discloses a production method of high-silicon electrical steel. Molten steel with the contents of two kinds of silicon being 2.0%-3.5% and 4.5%-7.0% correspondingly is smelted, and the superheat degree of the molten steel is 10-30 DEG C; a drainage device is arranged in a continuous casting crystallizer, opened downwards and suspended in the molten steel, the gap between the drainagedevice and the crystallizer is 10-40 mm, the high-silicon molten steel is added into the drainage device, low-silicon molten steel flows between the drainage device and the crystallizer, the pullingspeed is 0.4-0.9 m / min, the thickness ratio of a low-silicon blank shell to a high-silicon blank core of a cast blank is 1:2-1:5, inert gas is charged into the drainage device, and thus the internal liquid level of the drainage device is 10-20 mm lower than the external liquid level of the drainage device; the thickness of a hot-rolled roll is 0.8-1.8 mm; and before cold rolling, preheating is carried out to 200-450 DEG C, the annealing temperature is 600-1000 DEG C, and heat-preserving time is 10-200 min. Finished products have good electromagnetic performance and iron loss performance.

Owner:ANGANG STEEL CO LTD

Preparation method of high-strength and high-toughness titanium alloy material cutter

InactiveCN110129700AHigh strengthImprove corrosion resistanceVacuum evaporation coatingSputtering coatingFine structurePunching

The invention relates to the technical field of cutters, in particular to a preparation method of a high-strength and high-toughness titanium alloy material cutter. The preparation method comprises the following steps that S1, raw materials are prepared; S2, punching is carried out, wherein the prepared titanium alloy materials are fed into a punching workshop for cutting, and a cutter blank is cut according to the size of the cutter, and the size and the thickness of a cutter sample; S3, heat treatment is carried out, and specifically heat treatment is carried out on the cut cutter blank; S4,surface hydrogen permeation is carried out; and S5, film coating is carried out, wherein a Ti-DLC film is plated on the surface of the cutter blank by using a magnetron sputtering method, microporesin the DLC film layer are plugged through fluorine-containing acrylate monomers, so that the wear resistance of the cutter is improved, the toughness of a substrate is not reduced, the coating has a fine structure, so that the compressive stress is produced inside the coating, the anti-crack propagation capability is high, and the service performance of the cutter is improved.

Owner:阳江十八子刀剪制品有限公司

Thermal processing method for spiral bevel gear

InactiveCN107034342ASmall temperature differenceReduce distortionSolid state diffusion coatingFurnace typesTemperature differenceQuenching

The invention discloses a thermal processing method for a spiral bevel gear. The method comprises the steps of basket loading operation, cleaning treatment before furnace charging, carburizing treatment, isothermal quenching treatment, cleaning treatment after quenching, tempering treatment, air cooling treatment, and the like. According to the thermal processing method for a spiral bevel gear, the carburizing treatment adopts a heating manner of step temperature rising and temperature preserving, therefore, temperature differences of respective parts of the spiral bevel gear can be reduced, generation of a machining stress is eliminated, and deformation of the spiral bevel gear caused by too fast heating is reduced; since the isothermal quenching treatment is adopted after the carburizing treatment, a constant oil pool temperature ensures uniform cooling of the spiral bevel gear, deformation of the spiral bevel gear is reduced, the thermal processing deformation of the spiral bevel gear is reduced, and a higher thermal processing finished product rate of the spiral bevel gear is ensured.

Owner:燕凌飞

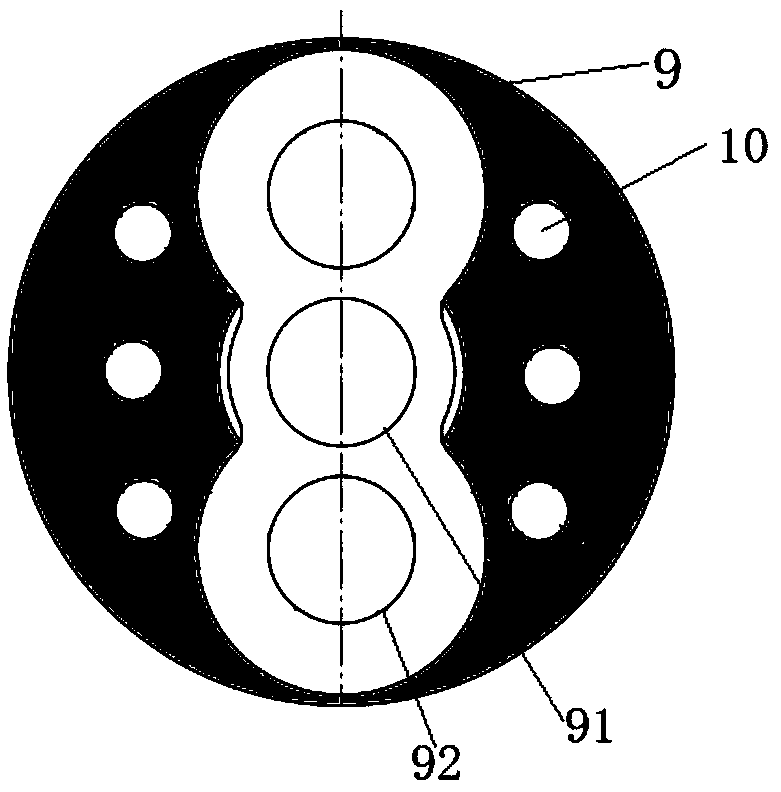

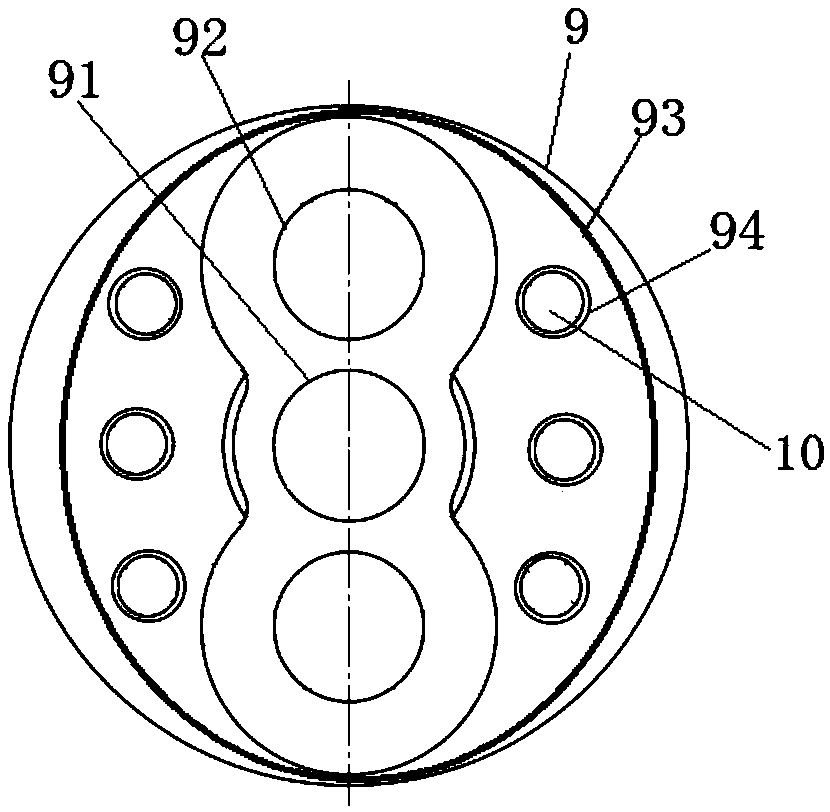

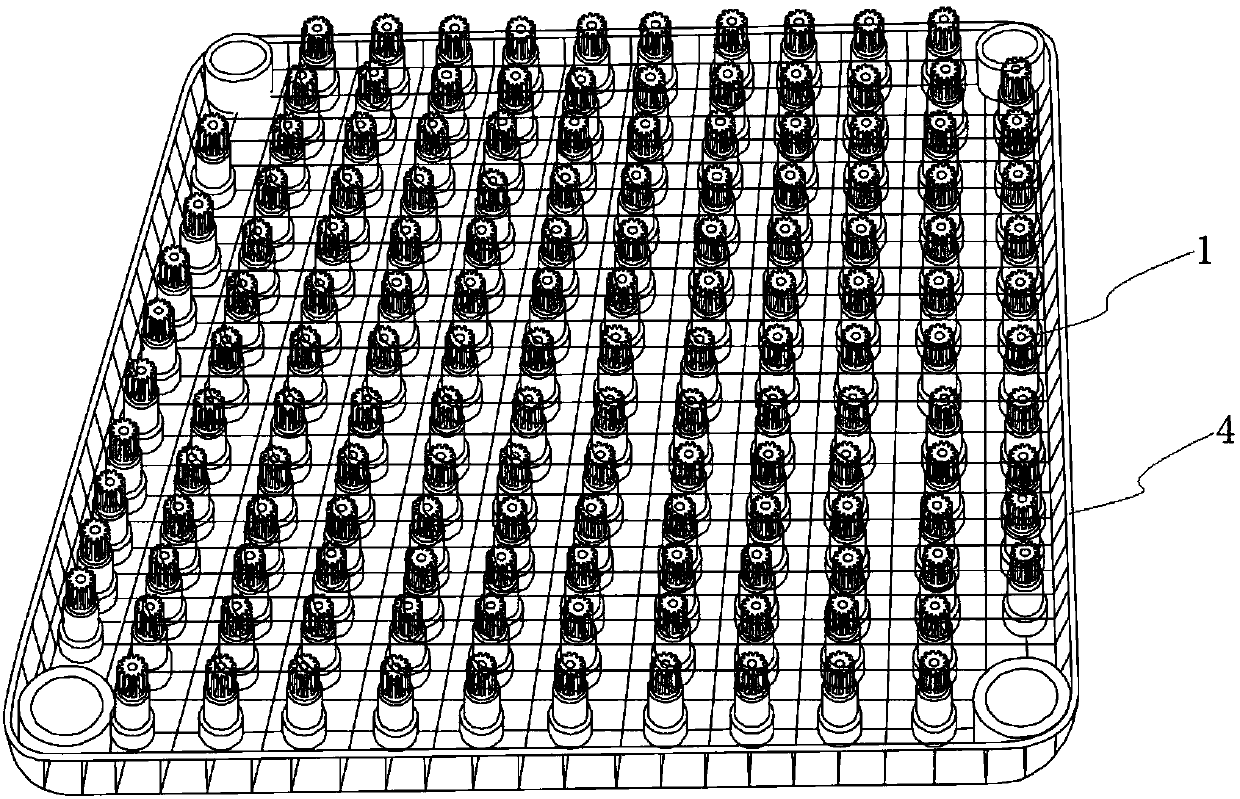

Speed reducer output end sealing structure and RV speed reducer composed of same

The invention provides a speed reducer output end sealing structure and an RV speed reducer composed of the speed reducer output end sealing structure. The speed reducer output end sealing structure is characterized by comprising an output end face flange and an output disc rack; the output disc rack is provided with a smooth output end face, and the center of the output end face is provided witha sun wheel groove and planet wheel grooves distributed around the sun wheel groove in an axially symmetrical or annular manner; the output end face is further provided with threaded holes for fixingthe output disc rack, and the output end face stretches into the output end face flange and is in face sealing or linear sealing with the output end face flange. The RV speed reducer comprises a pin wheel housing, an eccentric shaft, a planet wheel, an input shaft, the output disc rack, angular contact ball bearings, cycloidal gears and the output end face flange. By means of the RV speed reducer,the installation difficulty of the output end face flange of users is greatly lowered, the users do not need to use a plane sealant for sealing, the cost is lowered, and efficiency is improved; and the oil sealing effect is better, and the operation precision is higher.

Owner:NANTONG ZHENKANG WELDING ELECTROMACHINERY +1

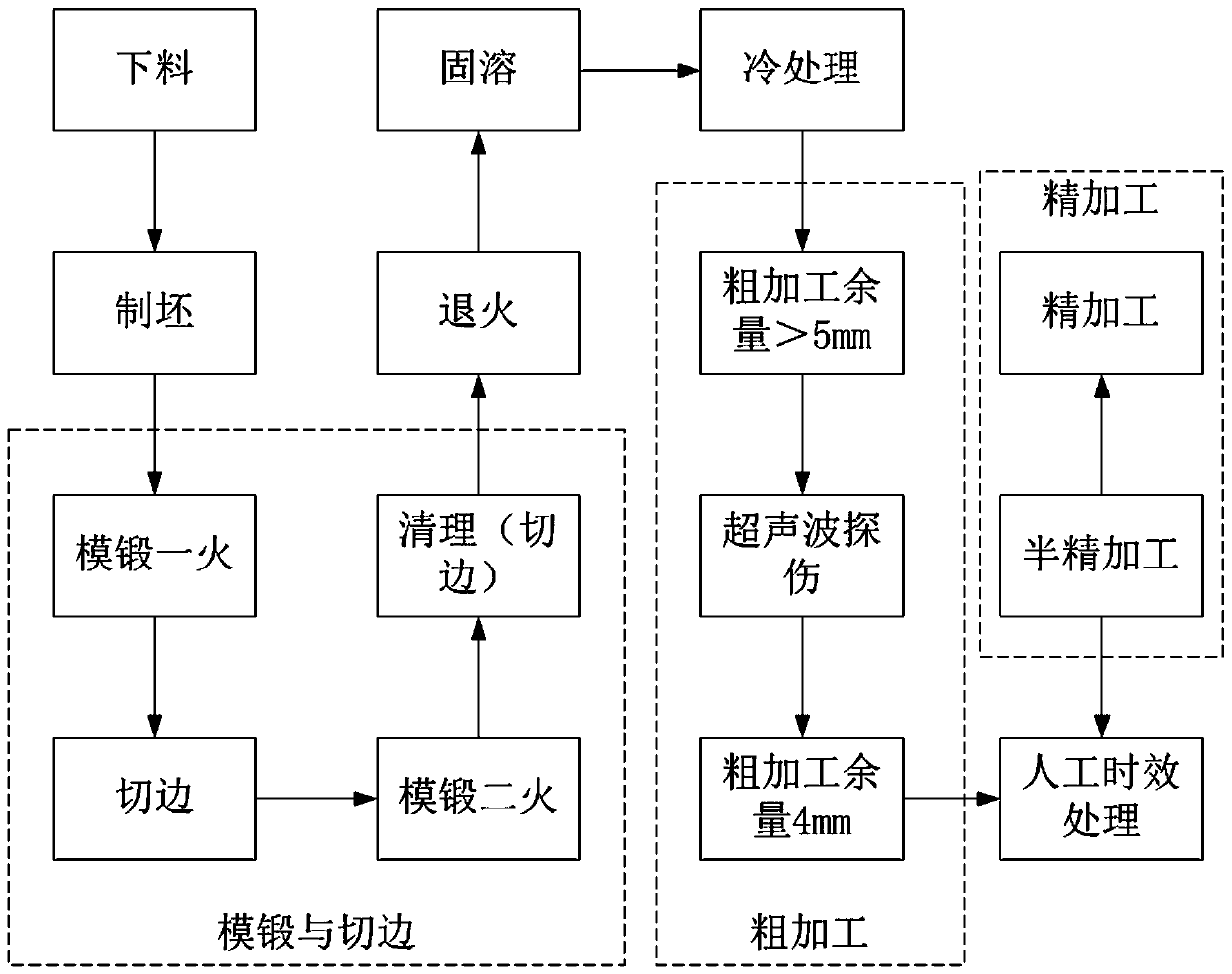

Machining method for PH13-8Mo part used for aviation

ActiveCN110724797AReduce wearImprove processing efficiencyMetal-working apparatusSolution treatmentAviation

The invention discloses a machining method for a PH13-8Mo part used for aviation. The machining method includes the following steps that firstly, a PH13-8Mo bar is subjected to blanking and blank manufacturing and subjected to at least one time of die forging and edge cutting, a forge piece in a certain shape is formed, annealing is conducted at the temperature being 600 DEG C to 760 DEG C, and residual stress in the forging process is eliminated; secondly, the forge piece is subjected to solution treatment; thirdly, the forge piece is subjected to cold treatment; fourthly, after cold treatment is completed, the forge piece is subjected to rough machining, and a blank part is formed initially; fifthly, the manufactured blank part is subjected to manual aging treatment; and sixthly, finishmachining is conducted on the blank part, and a finished product is manufactured. By means of the machining method, a cold and heat combined technology scheme is adopted, the part is subjected to rough machining in a solid solution state, removing work of most of materials is completed under the low hardness, the cutting speed is increased, and the tool loss amount is reduced; and the equivalent thickness of the forge piece obtained after rough machining is reduced, the heating time and energy consumption of subsequent manual aging are reduced, furthermore, heat correction can be conducted onpart deformation, part of machining stress is eliminated, and part deformation is reduced.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

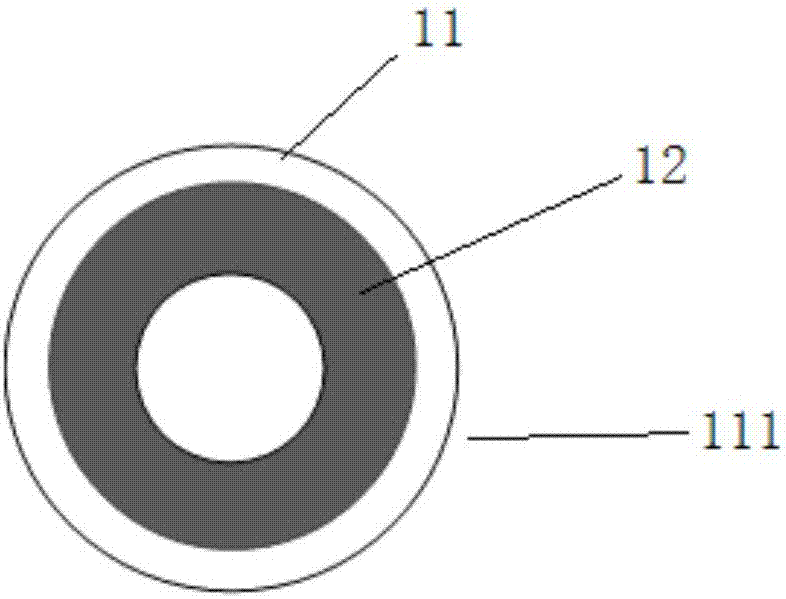

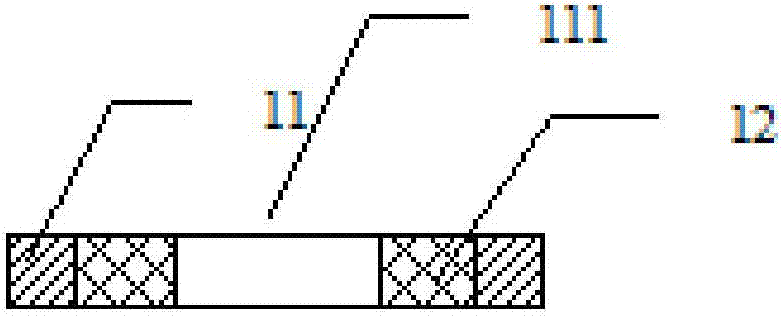

Preparing method for spliced combined structure composite metal sheet and composite metal sheet of preparing method

The invention discloses a preparing method for a spliced combined structure composite metal sheet and the composite metal sheet of the preparing method. At least two kinds of heterogeneous metal materials are subjected to solid-phase composition, and a non-side-face composite structural layered composite initial blank is obtained; the layered composite metal initial blank is subjected to plastic forming machining, straightening and cutting treatment, and a non-side-face composite structural layered composite metal long strip is manufactured; a slicing type cutting technology is adopted on the obtained non-side-face composite structural layered composite metal long strip, and multiple composite metal sheet blanks are manufactured; and the composite metal sheet blanks are subjected to machining and surface treatment, and the composite metal sheet is formed. The manufactured spliced metal sheet is formed in the manner that at least two kinds of metal sheets are tightly combined through mutual contact side faces in a firm physical metallurgy bonding manner. The spliced composite metal sheet has more reliable welding characteristics, and the production cost is obviously reduced while the performance requirements for good electric conduction, heat dissipation, weight reduction, transition connection and the like of overall parts are met.

Owner:徐卓辉 +1

A heat treatment process for reducing the deformation of the gear shaft keyway

ActiveCN106119507BReduce distortionSmall amount of deformationSolid state diffusion coatingFurnace typesCarbon potentialEngineering

The invention discloses a heat treatment process of reducing key slot deformation of a small gear shaft, and belongs to the technical field of heat treatment. The heat treatment process comprises the steps of: 1) machining of a gear shaft part; 2) framing; 3) precleaning; 4) coating of carburization preventing paint at a key slot part of the gear shaft part; 5) carburizing and quenching: temperature homogenization of 830+-5 DEG C by 20+-1 min, and carbon potential of 0.60+-0.025%; strong seepage of 900+-5 DEG C by 60+-1 min, and carbon potential of 0.95+-0.025%; dispersion of 880+-5 DEG C by 40+-1 min, and carbon potential of 0.80+-0.025%; quenching temperature homogenization of 830+-5 DEG C by 35+-1 min, and carbon potential of 0.65+-0.025%; and cooling in quenching oil of 140+-5 DEG C; 6) after cleaning; 7) tempering; and 8) recleaning. The heat treatment method effectively reduces deformation of the key slot of the gear shaft after heat treatment, and can reach 100% of once pass percent of heat treatment.

Owner:常州新区河海热处理工程有限公司

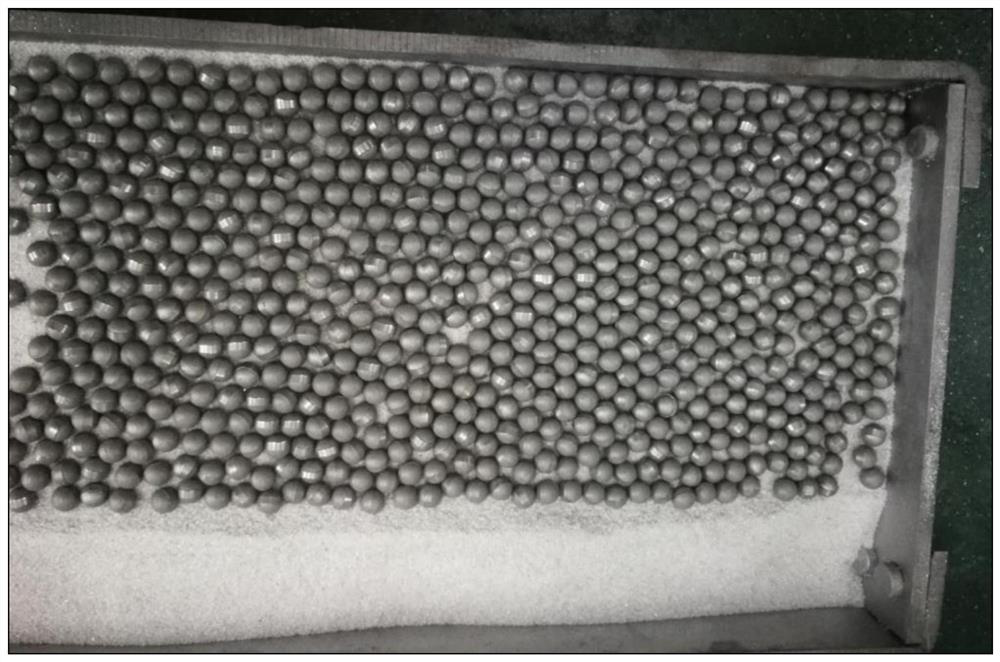

Preparation method of tungsten alloy beads

PendingCN114653948AImprove wettabilityImprove liquidityMetal-working apparatusPackaging by pressurising/gasifyingStress reliefTungsten alloy

The invention discloses a preparation method of tungsten alloy beads, which comprises the following steps of: 1, adding cobalt element into tungsten alloy powder to obtain tungsten alloy bead raw material mixed powder; 2, mixing the tungsten alloy bead raw material mixed powder with glue, granulating, and then screening and grading to obtain granulated materials with different particle size grades; thirdly, the granulation materials of different particle size grades are formed according to the same particle size grade, and tungsten alloy bead pressed blanks are obtained; 4, thermally degreasing the tungsten alloy bead pressed blank; 5, sintering to obtain a tungsten alloy bead sintered blank; and 6, grinding the tungsten alloy bead sintered blank, and carrying out stress relief annealing treatment to obtain the tungsten alloy bead. The cobalt element is added into the tungsten alloy powder, the wettability of tungsten particles is improved, the sintering activity is improved, through glue mixing granulation and screening classification, the flowability of granulation materials is improved, the piece weight and size fluctuation of tungsten alloy bead compacts is reduced, hot degreasing and stress relief annealing are combined, compact damage and performance deterioration are avoided, and the quality of the tungsten alloy beads is improved. And the forming quality and the production efficiency of the tungsten alloy beads are improved.

Owner:XIAN HUASHAN TUNGSTEN PROD CO LTD

Environment-friendly silver metal oxide rivet touch head producing method

InactiveCN101032732ASmall amount of deformationOvercoming low processing plasticityPinsFurnace typesOxideMetal

The process of making environment friendly silver metal oxide rivet contact includes the following steps: pre-upsetting the silver metal oxide wire in a cold upsetting machine to form upset ball, annealing in an air annealing furnace, washing and stoving, punching the upset ball in a rotary rivet forming punch to form the metal oxide rivet contact, and high temperature annealing to obtain soft environment friendly silver metal oxide rivet contact without cracking.

Owner:FUDA ALLOY MATERIALS

Manufacturing method of thin-walled large-diameter pipe with high-pressure copper-nickel alloy for marine engineering

The invention relates to a manufacturing method of a thin-walled large-diameter pipe with high-pressure copper-nickel alloy for marine engineering. The manufacturing method comprises the following steps: (1), performing semi-continuous casting on copper and nickle as raw materials to obtain a copper-nickel alloy solid round billet; (2), performing boring: boring in the center of the copper-nickelalloy solid round billet to obtain an inner hole which can penetrate through the center of the copper-nickel alloy solid round billet in the axial direction; (3), performing reaming: heating a billetmaterial, controlling the outside diameter to be invariable, and reaming the inner hole by 3.5 times to 7 times; (4), performing hot extrusion: carrying out water sealing and extrusion on the billet material into hot extrusion pipe in a way of matching with an extrusion module and extruding a steel pipe in the radial direction and in the axial direction, enabling a discharging end of the extrusionmodule to be directly in abutting joint with a water sealing tank, and directly immersing a pipe billet subjected to hot extrusion molding into water to ensure that the pipe billet is isolated from the air so as to prevent oxidation, removing a surface layer of the pipe billet subjected to hot extrusion, and eliminating surface defects; (5), performing straightening: straightening the pipe billetsubjected to hot extrusion; (6), stretching or cold-rolling the pipe billet in several times until a final specification of the pipe billet is obtained, and carrying out annealing after stretching orcold rolling is performed every time; (7) shaping; and (8) performing formation and thermal treatment.

Owner:江阴和宏精工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com