Method for machining sealing rings

A processing method, sealing ring technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., to avoid adverse effects and major losses, good toughness and elasticity, and tight metal fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

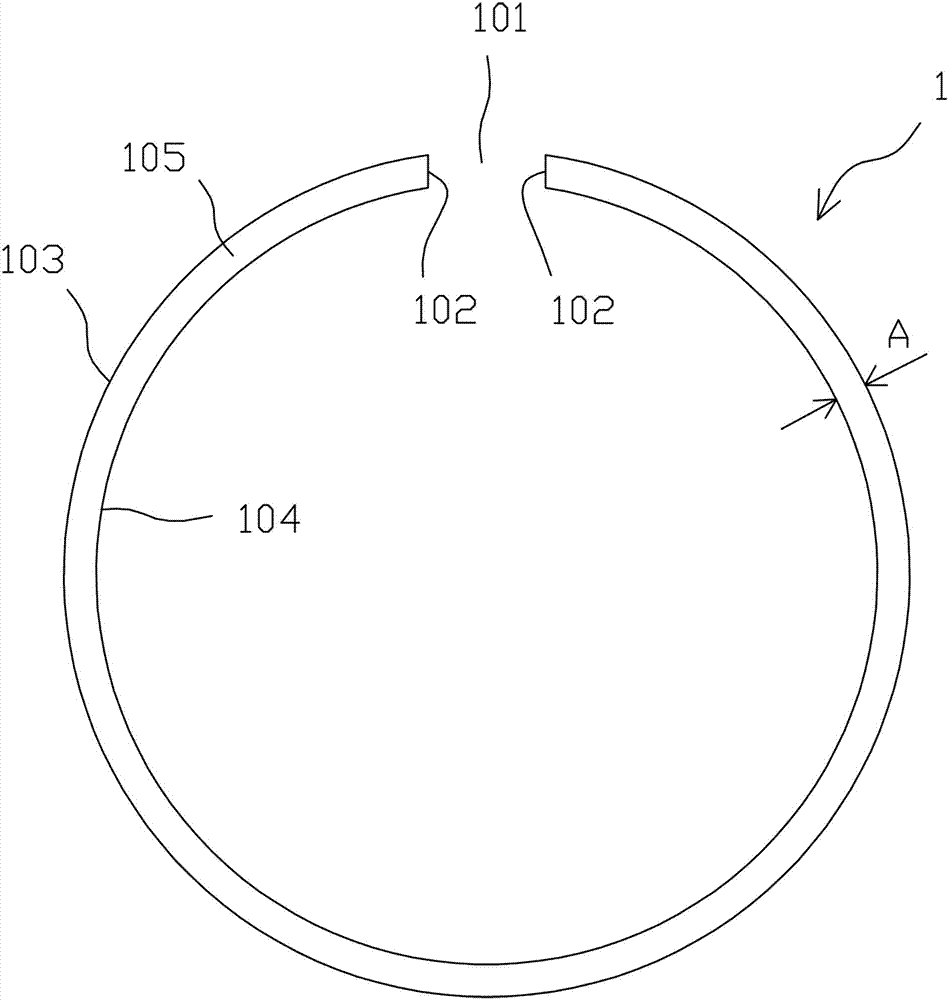

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] The processing method of sealing ring provided by the invention comprises the following steps:

[0033] (1) Four-way extrusion and wire drawing of the metal bar through the mold to obtain filamentous parts;

[0034] (2) Perform tempering heat treatment on the filamentous parts;

[0035] (3) Wind the wire-like parts into a spring shape to obtain the spring-like parts. The above-mentioned wire drawing refers to forcing the metal rod through the mold under the action of external force, the cross-sectional area of the metal rod is compressed, and the required cross-sectional area is obtained. The process of area shape and size, in the present invention, the metal bar is stretched into elongated metal wire by wire drawing, and then the elongated metal wire is wound into a spring shape through a mold;

[0036] (4) Cut the spring-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com