High-strength steel, high-strength plastic seamless steel pipe for automotive driver shafts and manufacturing method of high-strength plastic seamless steel pip

A technology of high-strength steel and a manufacturing method, which is applied in the field of steel materials, seamless steel pipes and their manufacturing, can solve the problems of machinability limiting tensile performance and improvement of torsional fatigue performance, etc., achieve excellent quenching performance, avoid pipe bending , the effect of high strength and strong plastic product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

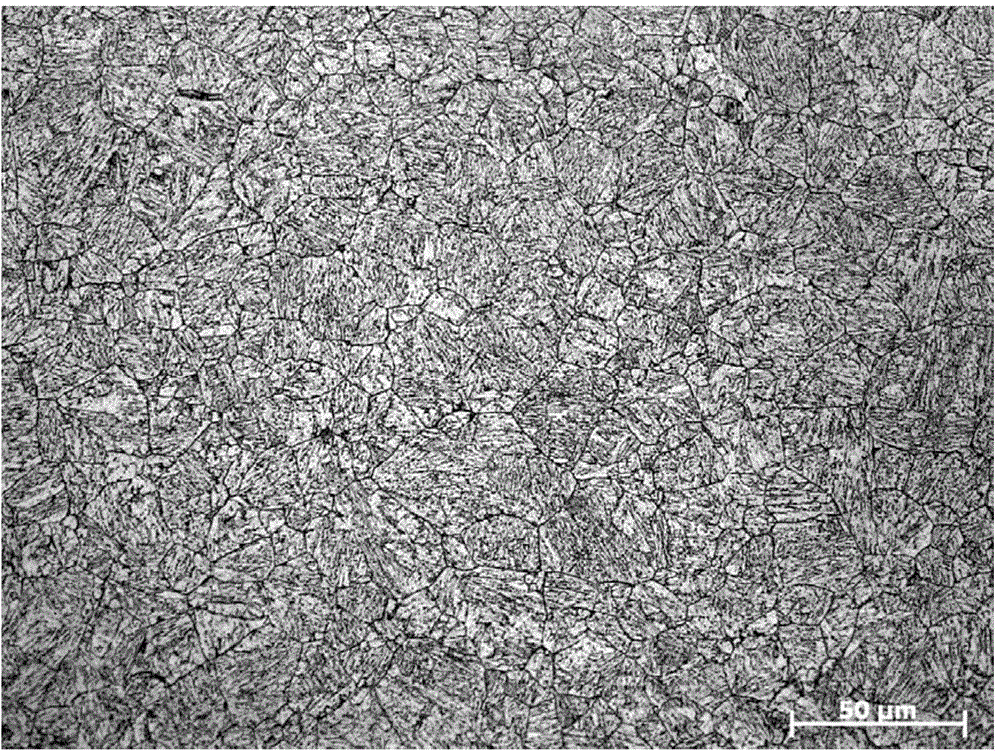

Image

Examples

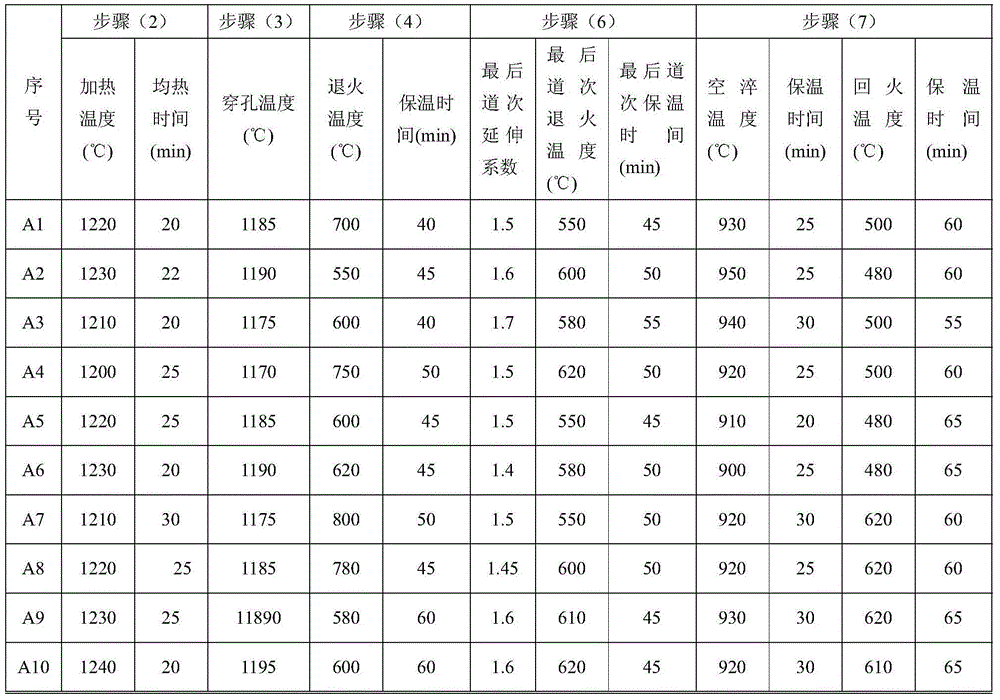

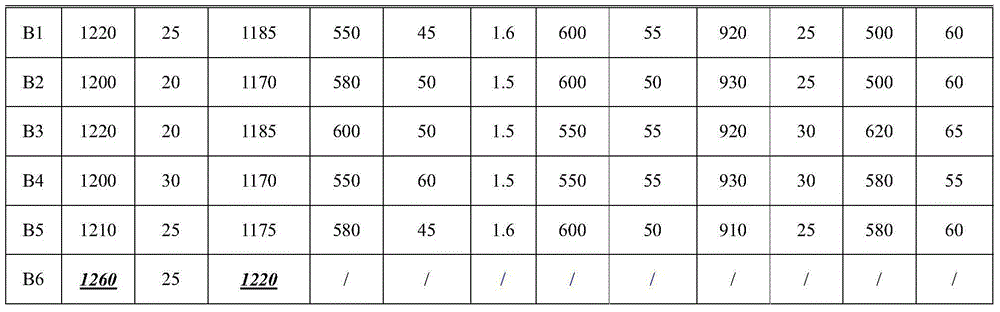

Embodiment A1-A10 and comparative example B1-B6

[0069] According to the following steps, high-strength plastic seamless steel pipes A1-A10 and comparative examples B1-B6 for automobile transmission half shafts according to the present invention are manufactured, and the steps are as follows:

[0070] (1) Manufacture tube blank, control its chemical element mass percentage distribution ratio as shown in Table 1;

[0071] (2) Heat the tube billet to 1200°C-1250°C in an annular heating furnace, and soak for 20-30min;

[0072] (3) Use a vertical conical hot piercer for hot piercing, with a piercing temperature of 1170-1200°C and continuous rolling;

[0073] (4) After reheating, use a three-roll tension reducer to reduce the diameter and wall thickness of the tube billet. The cooling bed is cooled by natural cooling without air cooling, and it is annealed in time at 550-850 ° C for 30-60 minutes;

[0074] (5) Phosphating and saponification after pickling;

[0075] (6) Use cold drawing or cold rolling to carry out cold processi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Strong plastic product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com