Patents

Literature

317results about How to "Improve quenching effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sulfurated hydrogen stress etching-resisting petroleum casing pipe and manufacturing method thereof

InactiveCN101413088AHigh strengthImprove hardenabilityProcess efficiency improvementElectric furnaceHydrogenMartensite

The invention discloses a petroleum casing pipe with sulfurated hydrogen stress corrosion resistance and a producing method thereof, which aims to proceed from improvement on purity and tensile ratio of steel, tempered martensite proportion, grain refinement, remained stress reduction and other aspects, and provide the petroleum casing pipe with high obdurability and sulfurated hydrogen stress corrosion resistance and the production method thereof. The petroleum casing pipe comprises the following compositions in weight percentage: 0.12 to 0.18 percent of C, 0.10 to 0.60 percent of Si, 0.05 to 1.0 percent of Mn, 0.20 to 1.0 percent of Cr, 0.10 to 0.80 percent of Mo, 0.005 to 0.05 percent of Al, 0.005 to 0.02 percent of Ti, 0.05 to 0.15 percent of V, 0.002 to 0.02 percent of Nb, 0.0003 to 0.005 percent of Ca, 0.0003 to 0.005 percent of Mg, 0.0003 to 0.003 percent of B, less than or equal to 0.020 percent of P, less than or equal to 0.005 percent of N, and the balance being Fe, wherein the weight percentages of carbon, manganese, chromium and molybdenum are determined by a comprehensive control formula, that is A is equal to the sum of percentage of C, percentage of Mn divided by 5, percentage of Cr divided by 5, and percentage of Mo divided by 3, and the range of A is between 0.45 and 0.60 percent.

Owner:TIANJIN UNIV OF COMMERCE

High strength and ductility oil casing with hydrogen sulfide corrosion resistance and manufacturing method for oil casing

The invention discloses a high strength and ductility oil casing with hydrogen sulfide corrosion resistance and a manufacturing method for the oil casing, and aims to provide an oil casing with high impact resistance and capable of meeting the requirement for exploiting a deep oil-gas layer containing hydrogen sulfide gas and a manufacturing method for the oil casing. The oil casing consists of the following components in percentage by weight: 0.15 to 0.20 percent of C, 0.1 to 0.2 percent of Si, 0.4 to 0.6 percent of Mn, 0.6 to 0.8 percent of Cr, 1.2 to 1.6 percent of Mo, 0.01 to 0.05 percent of Al, 0.002 to 0.05 percent of Ti, 0.05 to 0.10 percent of V, 0.005 to 0.015 percent of Nb, 0.0003 to 0.005 percent of Ca, less than 0.002 percent of B, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, 0.003 to 0.010 percent of N, and the balance of Fe, wherein the adding amount of Mo, V, Cr and Mn satisfies that 12V+1-Mo is more than or equal to 0 and Mo-(Cr+Mn) is more than or equal to 0. According to the oil casing, the content of manganese, chromium and molybdenum is controlled through a comprehensive control formula, and hydrogen sulfide corrosion resistance and impact ductility are improved by optimizing the content of each component.

Owner:TIANJIN UNIV OF COMMERCE

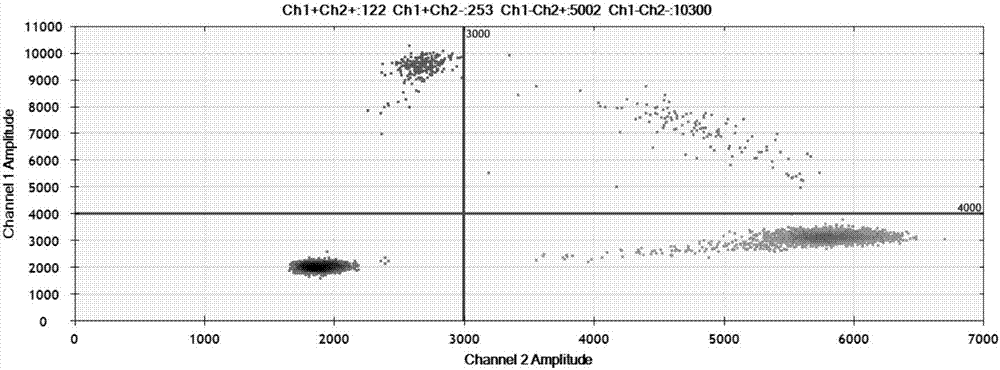

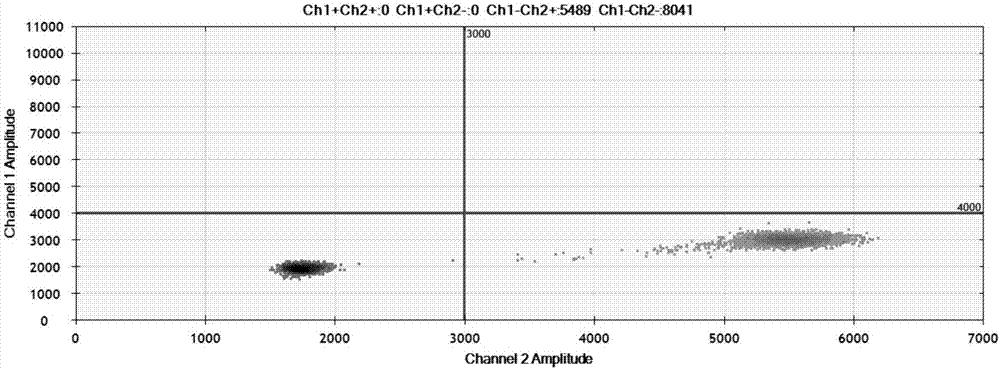

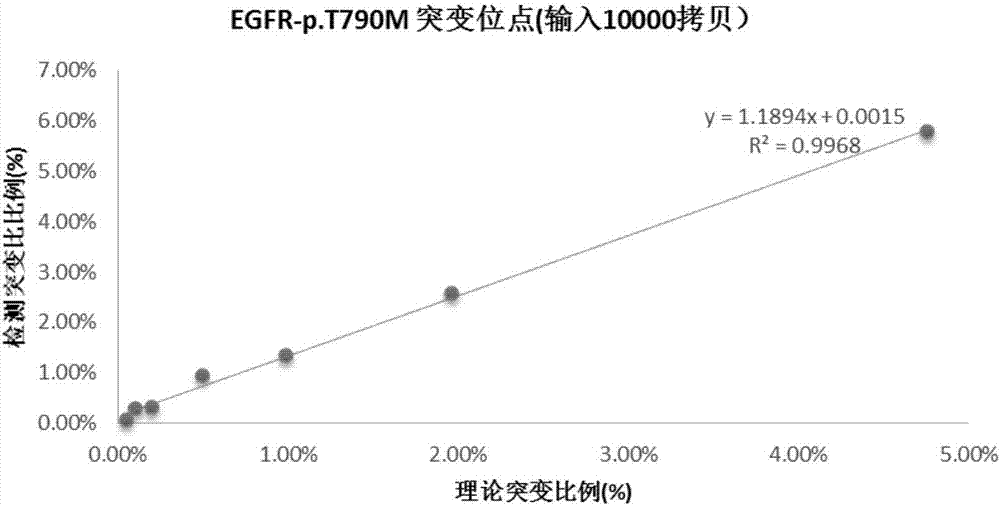

EGFR gene 20 exon T790M and C797S mutation detection primers, probes and method

InactiveCN107083438AReduce distractionsIncrease the Tm valueMicrobiological testing/measurementDNA/RNA fragmentationSpecific detectionMutation detection

The invention discloses a primer pair for specific amplification of EGFR gene 20 exon T790M and C797S loci. The sequence of the primer pair is shown in SEQ ID No:1-2. The invention further discloses a probe set for specific detection of the T790M and C797S loci. The probe set comprises a wild type probe and a mutant type probe, and the sequences are shown in SEQ ID No:3-7. The invention further discloses a reagent kit comprising the primer pair and the probe set, and a method for adopting the primer pair and the detection set for detecting EGFR gene 20 exon T790M and C797S mutation. By designing the specific primers and probes, the 3' end of the probes is connected with a minor groove binder and a non-fluorescent quenching group, the interference of background signals is lowered, hybridization of the probes and a template is stabilized, a Tm value of the probes is increased, and therefore the mutation detection sensitivity is improved.

Owner:上海捷易生物科技有限公司

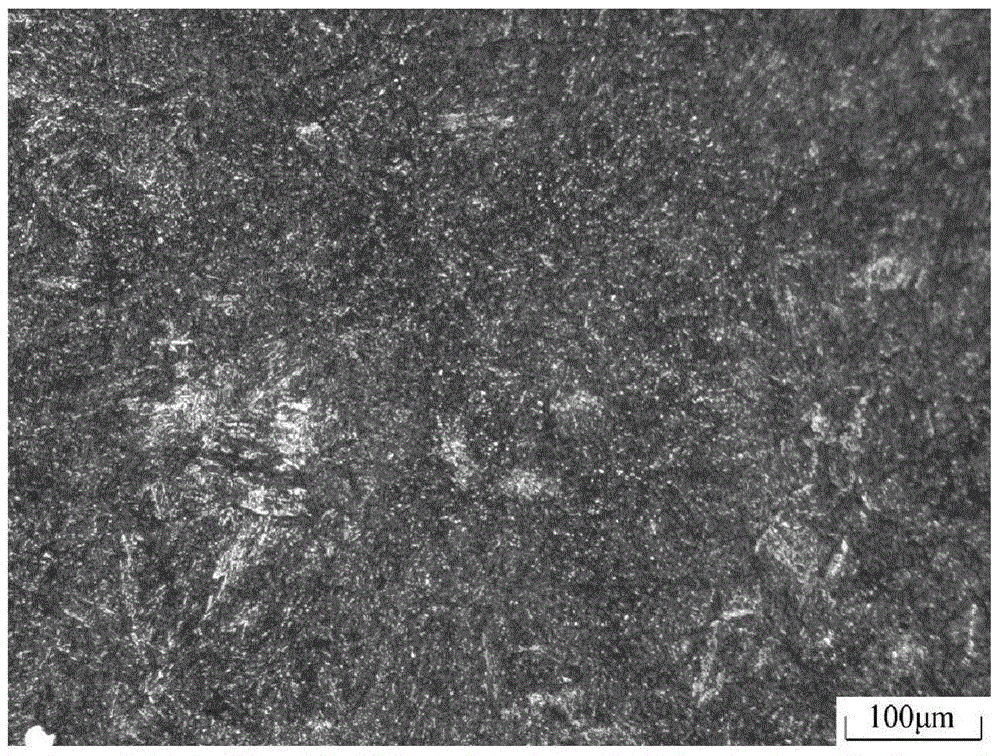

Semi-high speed steel break-down (BD) roller and manufacturing method thereof

ActiveCN105695873AHigh hardnessHigh hardness is controlled at HSD50~70, wear resistanceFurnace typesRollsManufacturing technologyAlloy

The invention discloses a semi-high speed steel break-down (BD) roller and a manufacturing method thereof, particularly relates to a roller applied to a profile steel rail beam BD rolling mill and belongs to the technical field of roller manufacturing. The whole roller is made of semi-high speed steel. The alloy components of the roller comprise, by weight, 0.3-1.5% of C, 0.2-1.4% of Si, 0.2-1.0% of Mn, 1.5-5.0% of Cr, 0-1.0% of Ni, 0.5-2% of Mo, 0.5-1.5% of W, 0-1.5% of V, and the balance Fe and inevitable impurities. The manufacturing method comprises the steps of raw material smelting, integral casting, heat preservation and demolding, heat pretreatment and heat treatment. According to the heat treatment, the high-temperature quenching technique and the high-temperature tempering technique are adopted. According to the structure of the roller, 3% or less of granular carbides are distributed on tempered sorbite, the macro-hardness of the roller is controlled to be HSD50-70, the abrasion resistance is high, the tensile strength is equal to or higher than 800 MPa, the crack extension resistance is high, and the roller is good in roller surface quality under the off-machine condition and small in abrasion under the on-machine condition; and the requirements of rail beam rolling can be well met, and especially the requirements for high strength, high abrasion resistance, high impact resistance and high hot cracking resistance of the roller in the rail beam rolling process can be well met.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

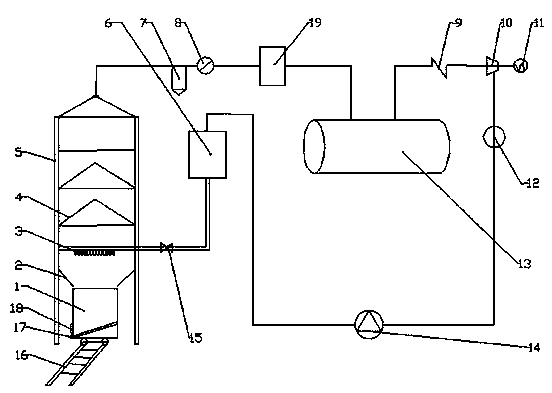

Low-moisture coke quenching and waste heat utilizing device

InactiveCN103759544AReduce pollutionReduce wasteCoke quenchingEnergy inputHigh pressure waterWater circulation

The invention discloses a low-moisture coke quenching and waste heat utilizing device. The low-moisture coke quenching and waste heat utilizing device comprises a coke quenching car, a coke quenching tower, a high-pressure water channel, a waste heat boiler, a steam heat accumulator, a condensing steam turbine, a generator and the like and is characterized in that the high-pressure water channel, the coke quenching tower, the waste heat boiler, the steam heat accumulator and the condensing steam turbine form a water circulation system. The low-moisture coke quenching and waste heat utilizing device respectively integrates low-moisture coke quenching, coke quenching stabilization and dry-method coke quenching, water for coke quenching is saved, the coke quenching effect is good, and atmospheric pollution and heat energy waste are reduced. The device is simple in structure, low in invest cost, convenient to transport, capable of continuously working and good in economical efficiency.

Owner:HENAN SHENGSHI ENERGY SAVING ENVIRONMENTAL PROTECTION ENG

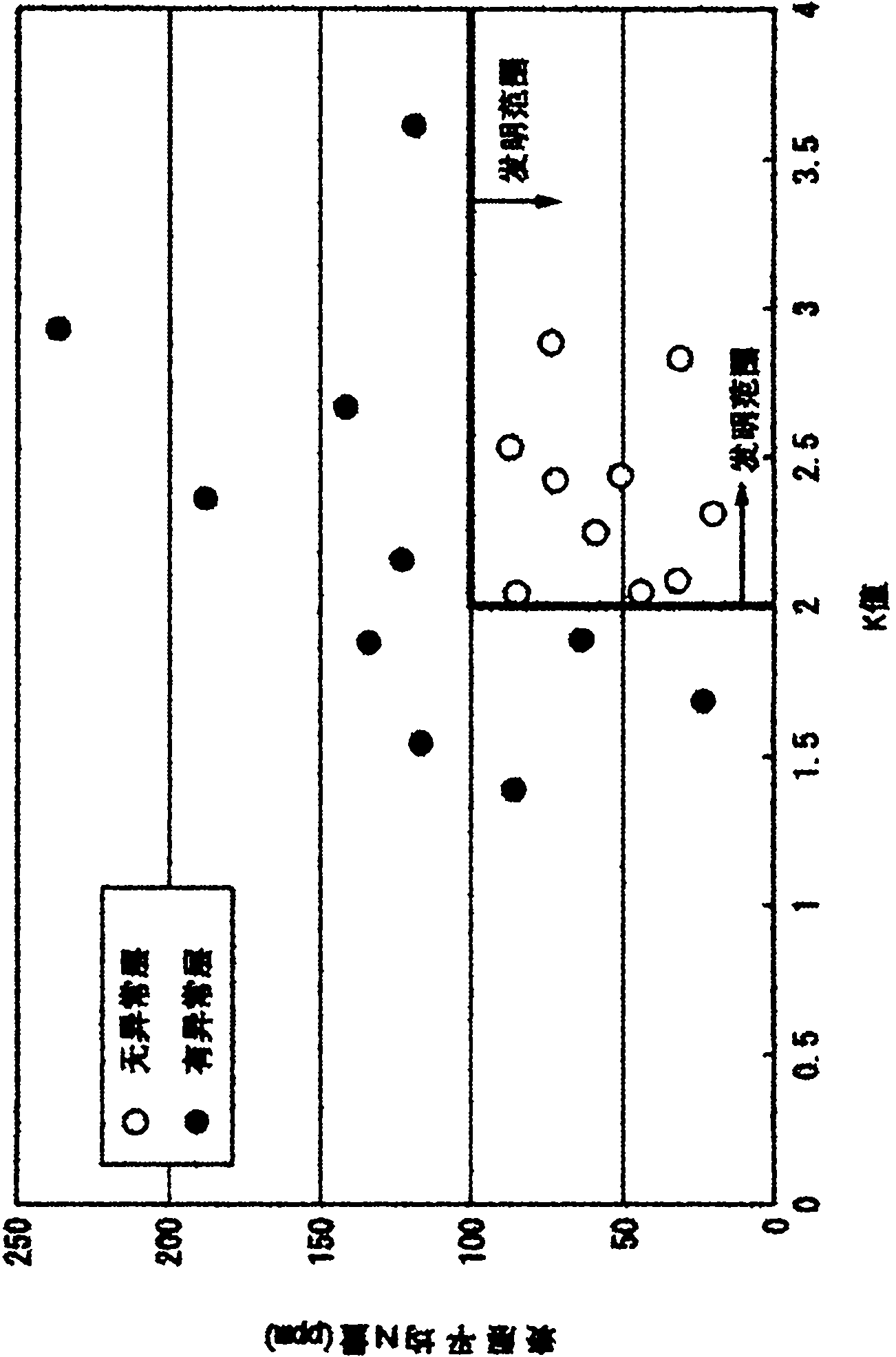

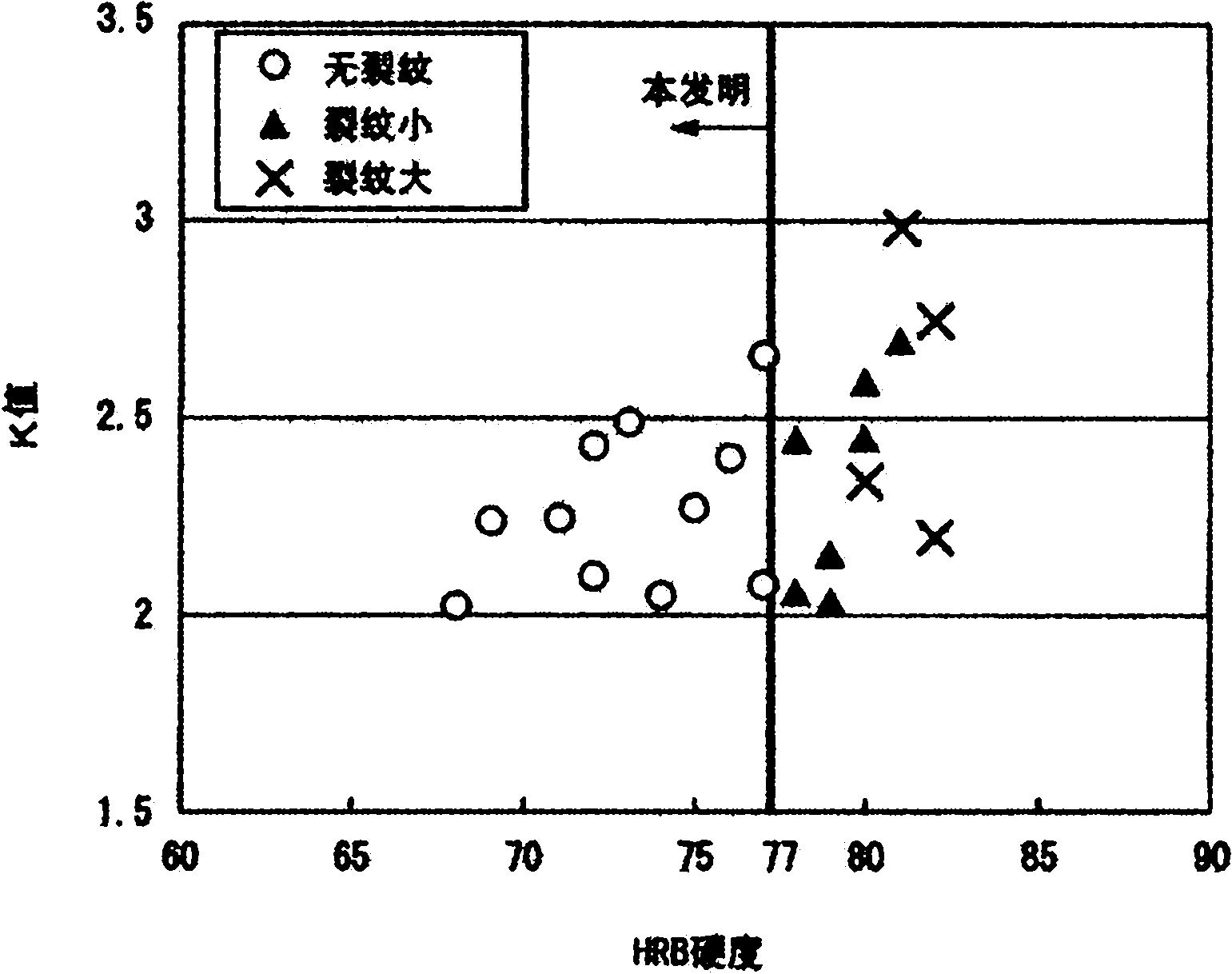

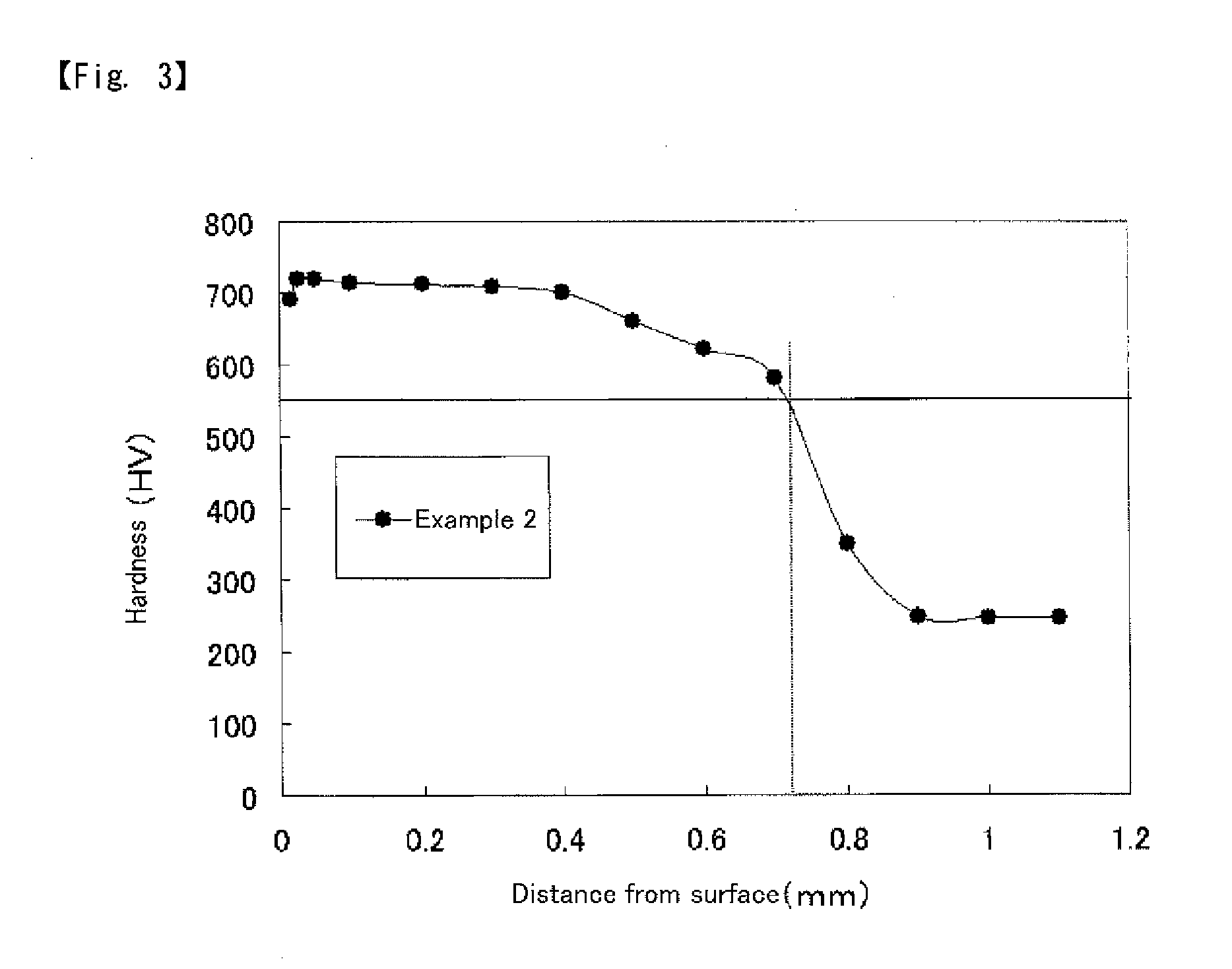

Carbon steel sheet having excellent carburization properties, and method for producing same

ActiveCN102149839AEasy to processImprove quenching effectSolid state diffusion coatingFurnace typesCarbon potentialHardness

Disclosed is a carbon steel sheet which contains not less than 0.20% by mass but not more than 0.45% by mass of C, not less than 0.05% by mass but not more than 0.8% by mass of Si, not less than 0.85% by mass but not more than 2.0% by mass of Mn, not less than 0.001% by mass but not more than 0.04% by mass of P, not less than 0.0001% by mass but not more than 0.006% by mass of S, not less than 0.01% by mass but not more than 0.1% by mass of Al, not less than 0.005% by mass but not more than 0.3% by mass of Ti, not less than 0.0005% by mass but not more than 0.01% by mass of B, and not less than 0.001% by mass but not more than 0.01% by mass of N. The carbon steel sheet has a K value, which is expressed by 3C + Mn + 0.5Si, of not less than 2.0, a surface hardness, namely a Rockwell hardness of not more than 77 on the B scale, and an average N content of not more than 100 ppm in the region from the surface to the depth of 100 [mu]m. The carbon steel sheet is carburized in a carburizing atmosphere having a carbon potential of not more than 0.6.

Owner:NIPPON STEEL CORP

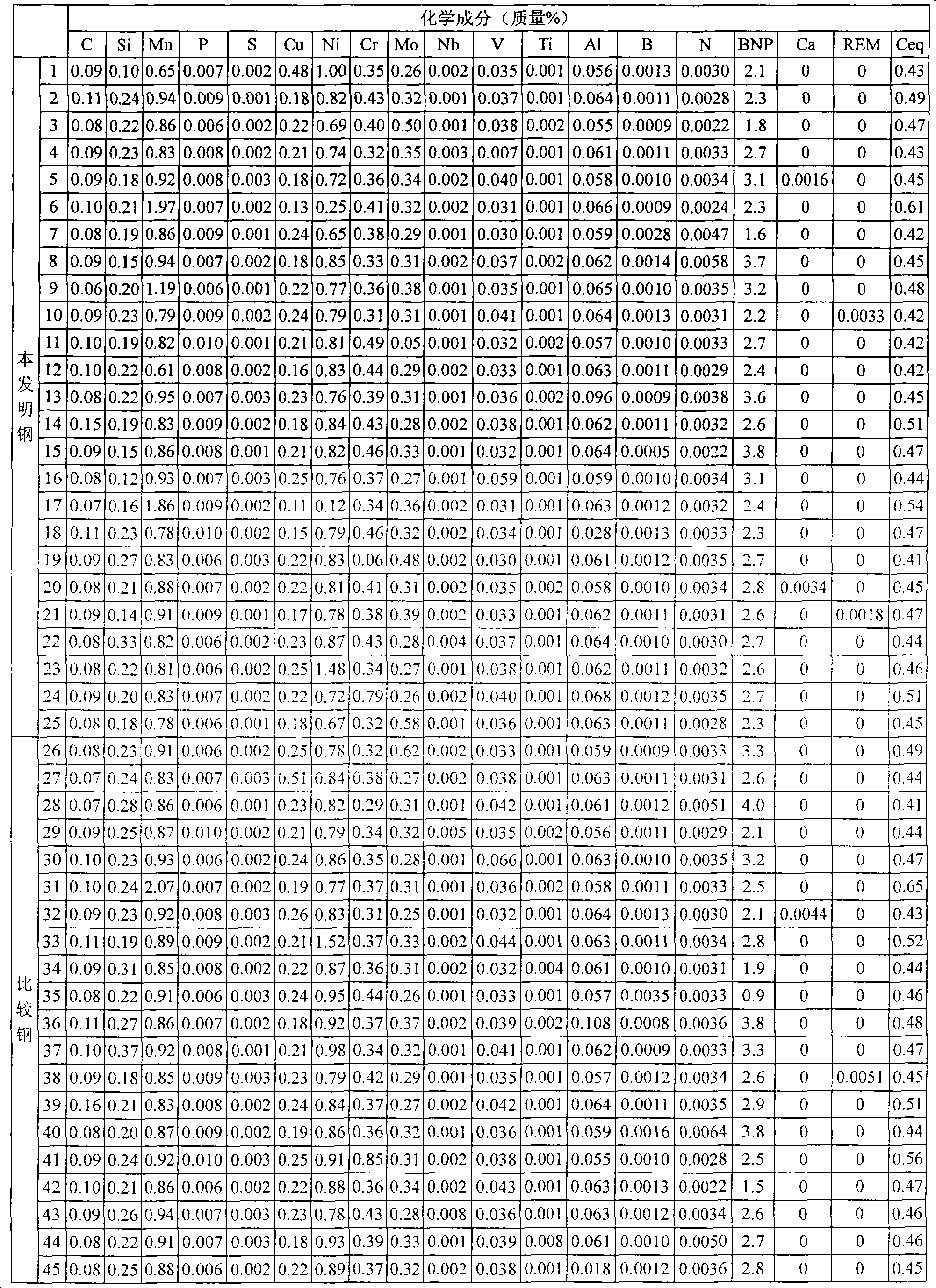

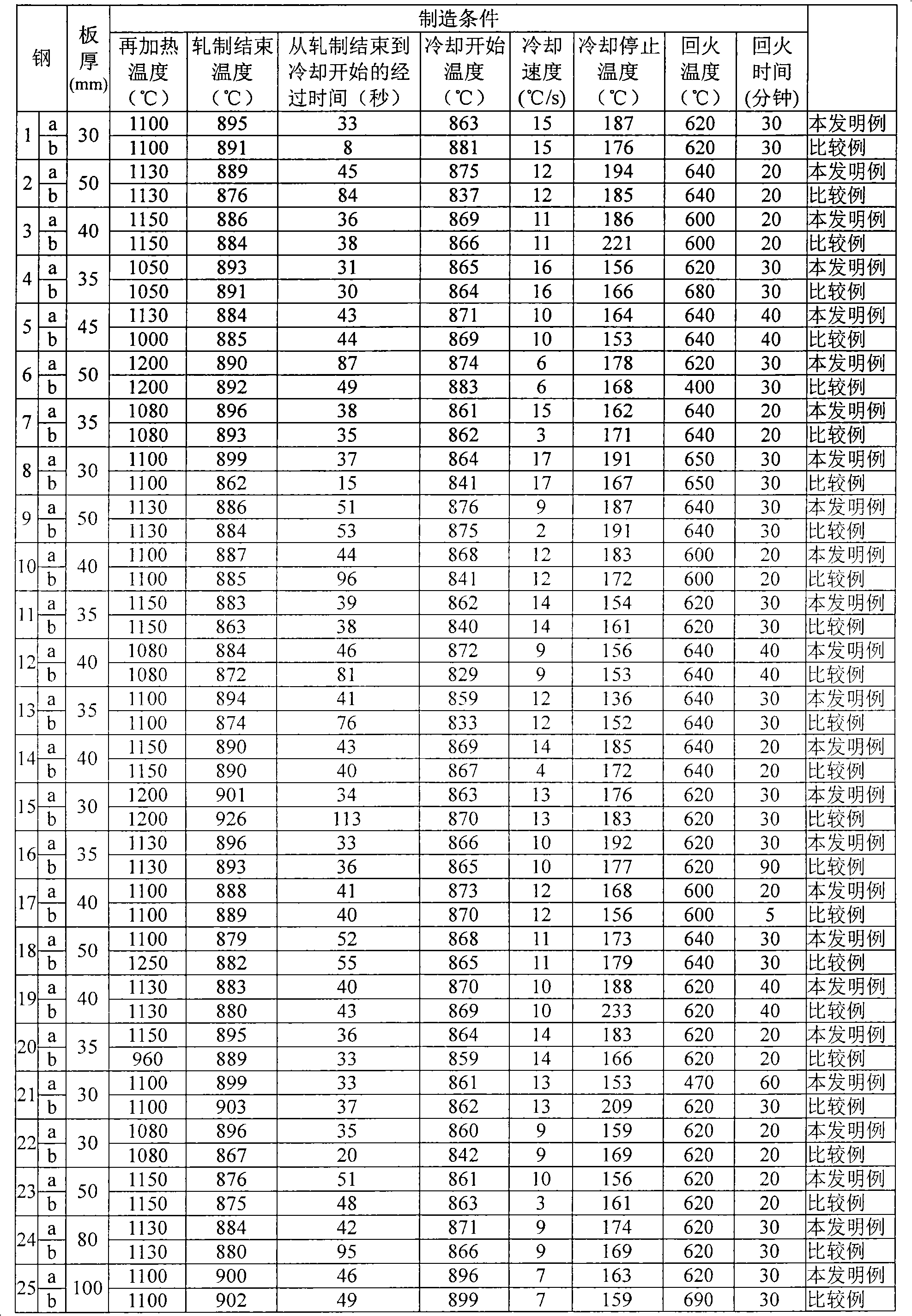

Process for production of 780mpa-grade high-tensile-strength steel plates excellent in low-temperature toughness

A process for the production of 780PMa-grade high-tensile -strength steel plates excellent in low-temperature toughness, which comprises heating a steel bloom which contains by mass C: 0.06 to 0.15%,Si: 0.05 to 0.35%, Mn: 0.60 to 2.00%, P: 0.015% or less, S: 0.015% or less, Cu: 0.1 to 0.5%, Ni: 0.1 to 1.5%, Cr: 0.05 to 0.8%, Mo: 0.05 to 0.6%, Nb: less than 0.005%, V: 0.005 to 0.060%, Ti: less than 0.003%, Al: 0.02 to 0.10%, B: 0.0005 to 0.003%, and N: 0.002 to 0.006% to a temperature of 1050 to 1200 DEG C; completing the hot rolling of the bloom at 870 DEG C or above; cooling, after a lapse of 10 to 90 seconds, the obtained plate at a cooling rate of 5 DEG C / s or above from a temperature of 840 DEG C or above to a temperature of 200 DEG C or below; and then tempering the resulting plate at a temperature of 450 to 650 DEG C for 20 to 60 minutes.

Owner:NIPPON STEEL CORP

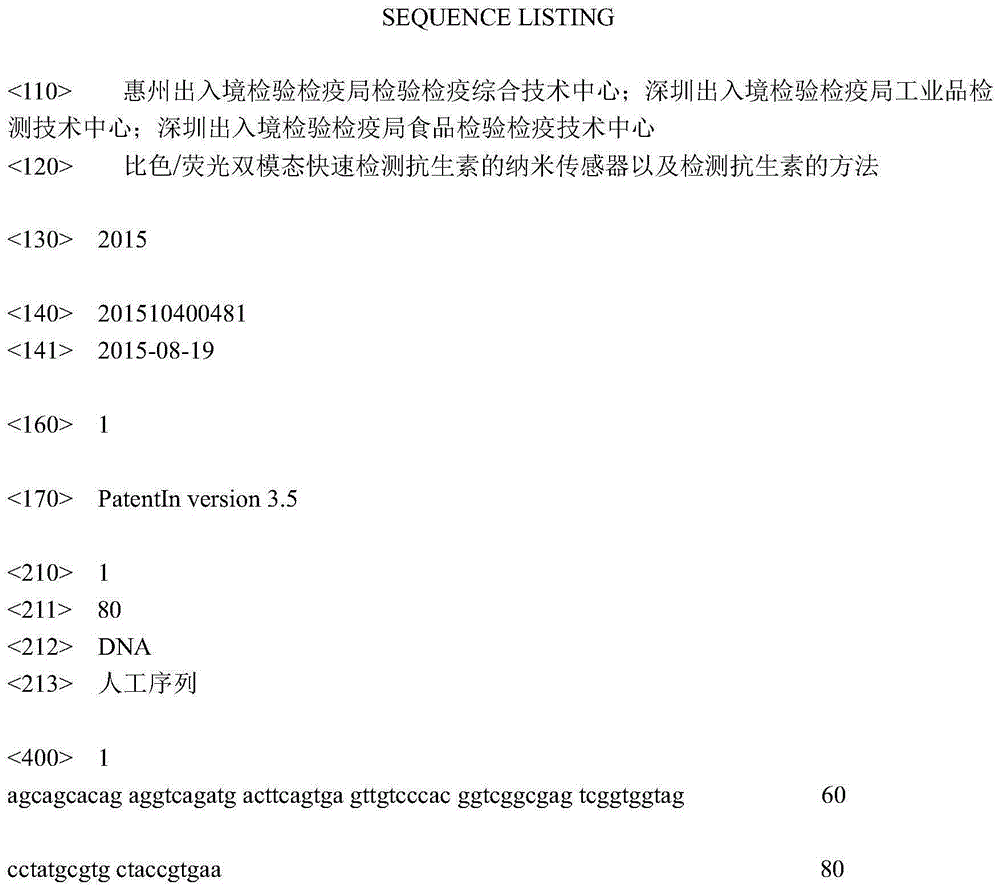

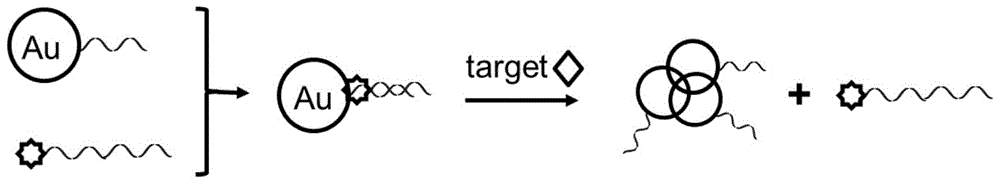

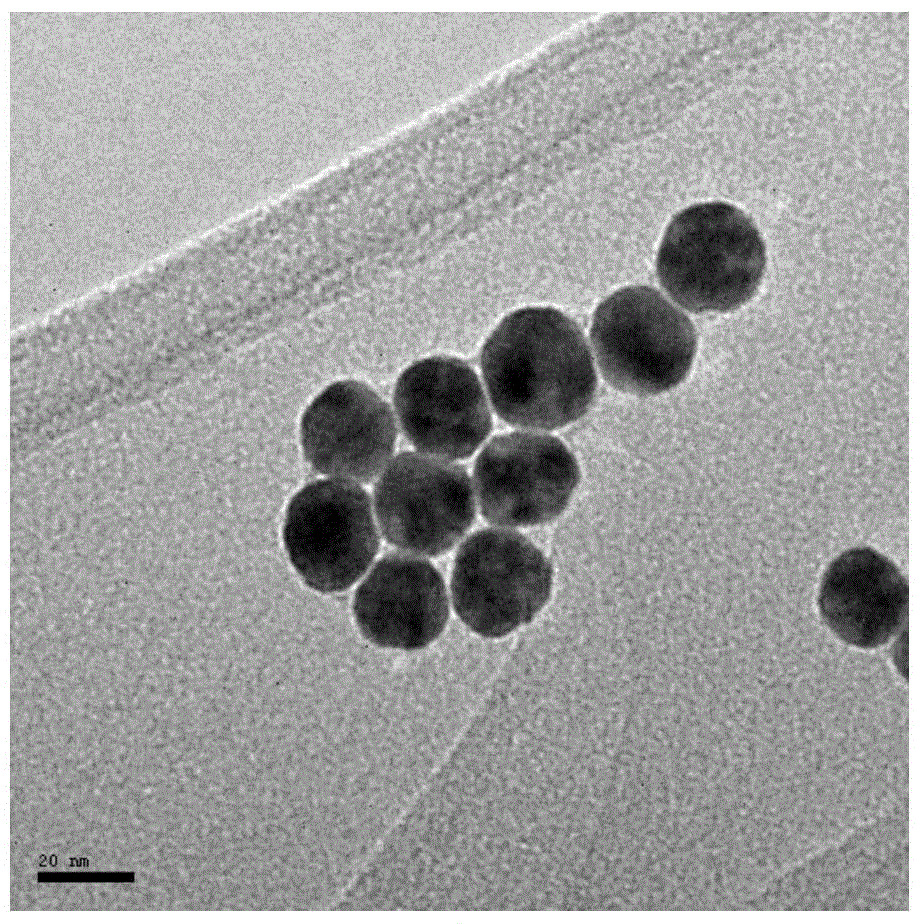

Nano-sensor for colorimetric/fluorescence dual-mode rapid detection of antibiotics and antibiotic detection method

PendingCN105044003AHigh precisionSolve the detection speed is slowColor/spectral properties measurementsFluorescence/phosphorescenceNanoparticleFluorescence

The invention provides a nano-sensor for colorimetric / fluorescence dual-mode rapid detection of antibiotics. The nano-sensor includes gold nanoparticles, by means of electrostatic adsorption, the surfaces of the gold nanoparticles are adsorbed with aptamer able to specifically bind with specific antibiotic, and the aptamer is marked with a fluorescent dye. The invention aims to provide the nano-sensor for colorimetric / fluorescence dual-mode rapid detection of antibiotics with short detection time and high detection precision, and also provides a method for colorimetric / fluorescence dual-mode rapid detection of antibiotics.

Owner:惠州出入境检验检疫局检验检疫综合技术中心 +2

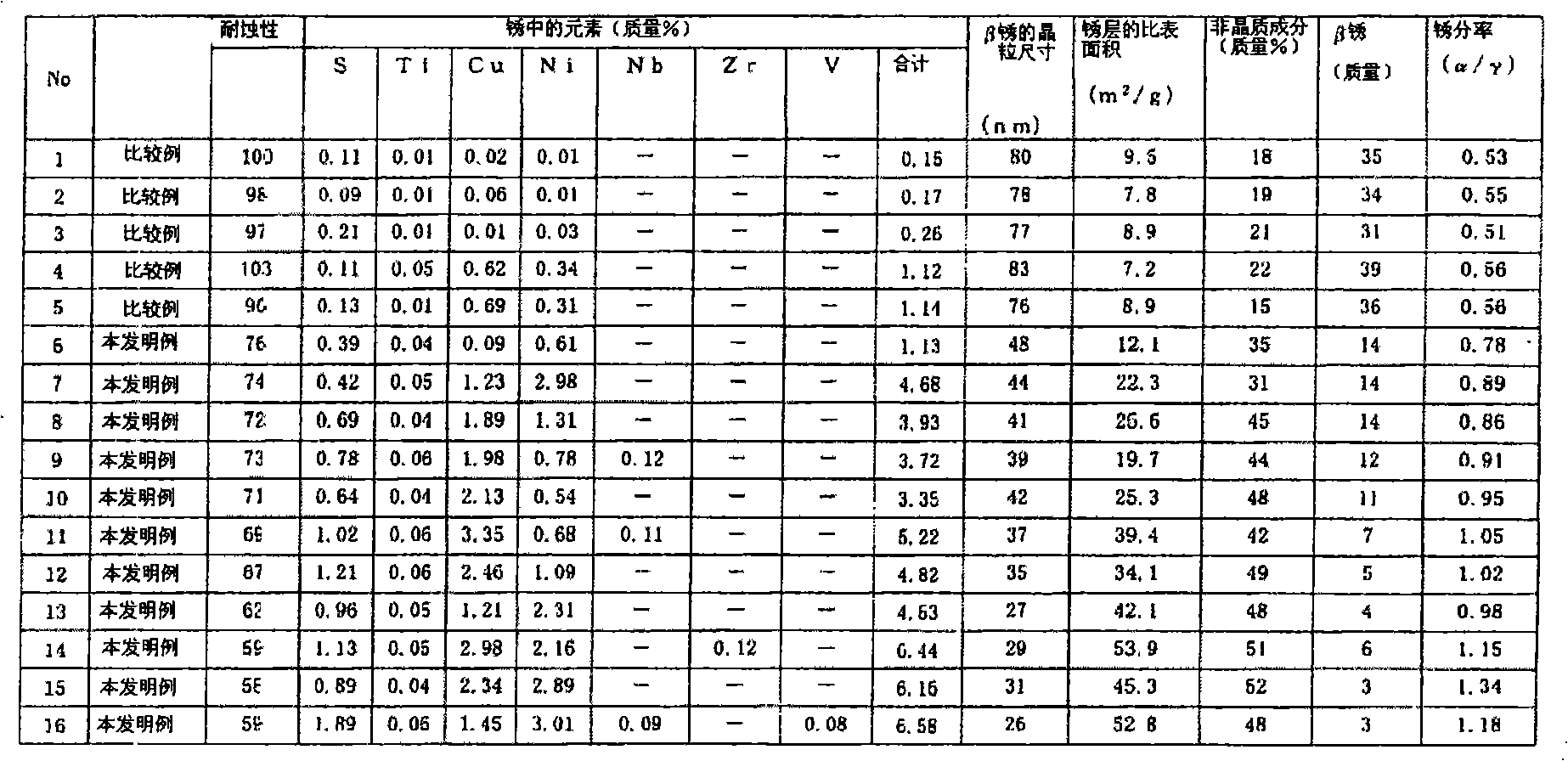

Steel material having excellent corrosion resistance

Disclosed is a steel material having excellent corrosion resistance, which is characterized by the following properties (A) to (C); (A) the steel material comprises the following components (by mass) as essential components: C: 0.02-0.15%, Si: 0.10-1.0%, Mn: 0.1-1.5%, S: 0.02-0.5%, Ti: 0.02-0.15%, Ca: 0.0001-0.01% and Al: 0.01-0.50%, and contains at least one component selected from Cu in an amount of 0.05-3.0% and Ni in an amount of 0.05-6.0%, with the remainder being Fe and unavoidable impurities, wherein the contents of Ni, Cu, S and Ti have the relationship represented by the following formula: [(Ni+4.5xCu)xSx2500xTi>5]; (B) the surface of the steel material is covered with a rust containing S in an amount of 0.3-5.0% by mass and further containing at least one element selected from Ti, Cu, Ni, Nb, Zr and V in the total amount of 0.5-10.0% by mass; and (C) a rust layer is formed on the surface of the steel material, wherein the crystallite size of a ss-FeOOH component in the rust layer is less than 50 nm as measured by the X-ray diffraction method, and the rust layer has a specific surface area of 10 m / g or greater as measured by the molecular adsorption method.

Owner:KOBE STEEL LTD

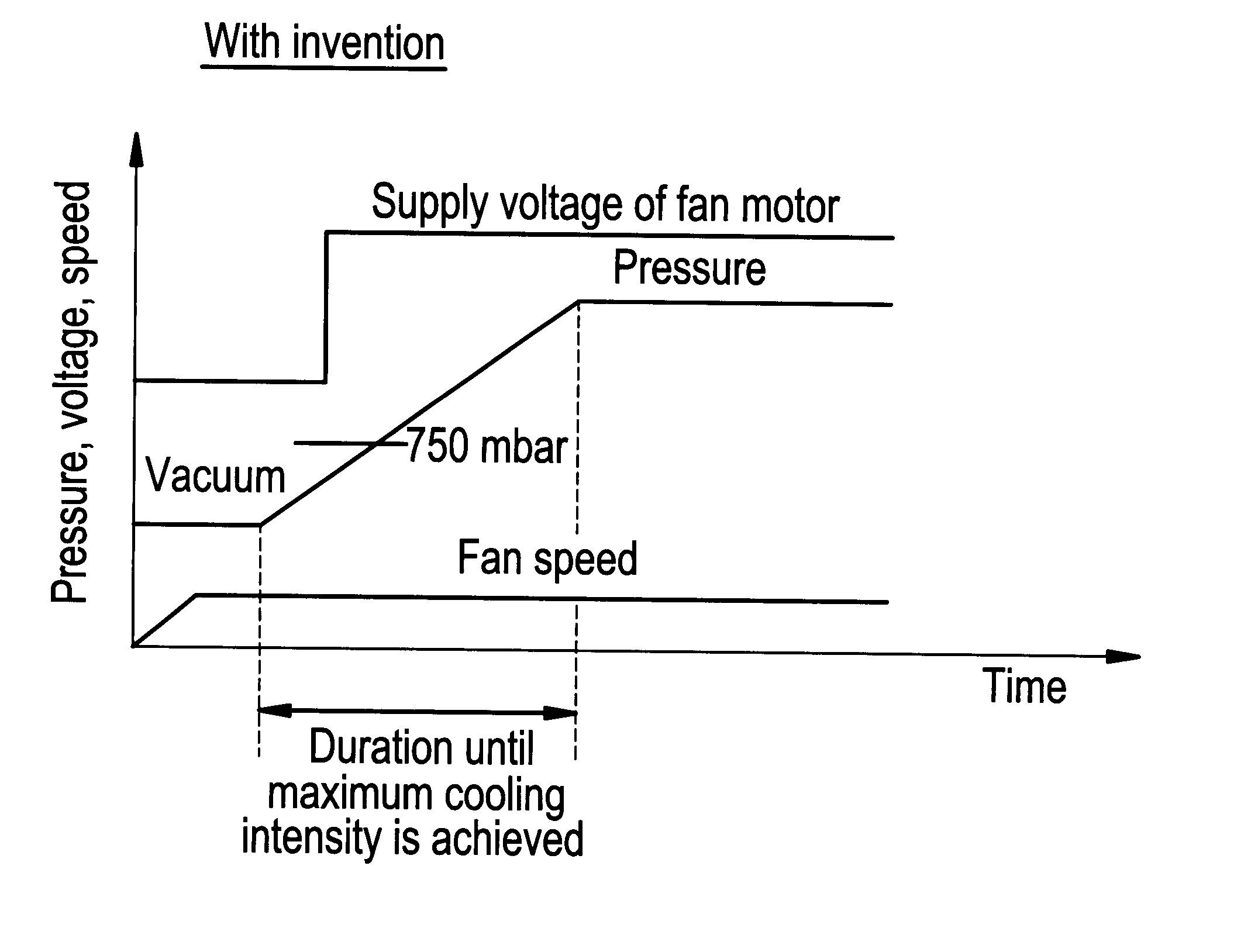

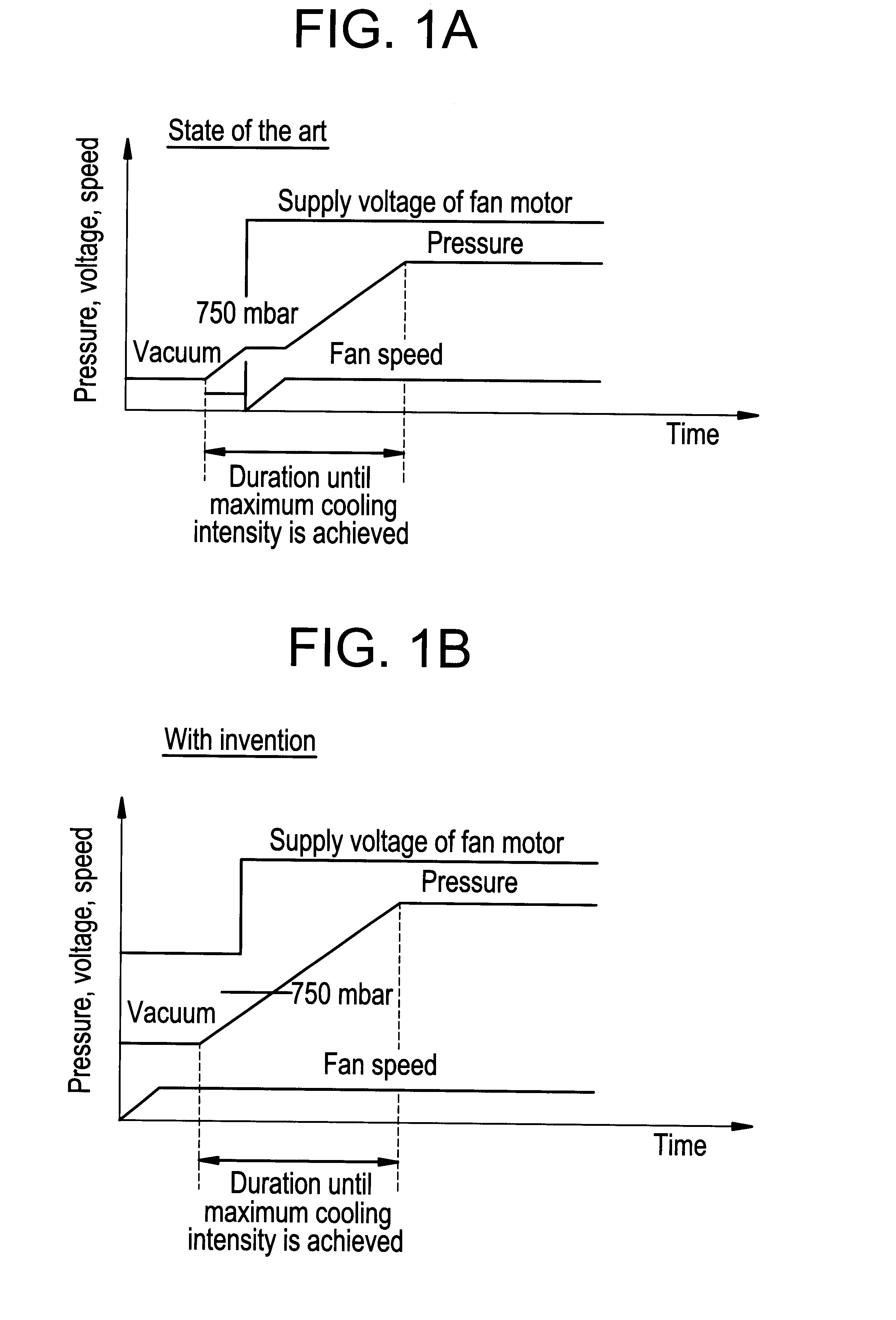

Method for heat-treating metallic workpieces

InactiveUS6428742B1Improve quenching effectShort timeSolid state diffusion coatingFurnace typesPower flowEngineering

A method for heat-treating metallic workpieces, in which a flow of cooling gas is generated in a vacuum furnace by a fan in order to quench the workpieces, with the fan being driven by a rotary current motor that is operated with a predetermined supply voltage above a minimum pressure in the vacuum furnace which is determined with regard to the motor power of the rotary current motor. In order to additionally develop this method such that a simple and inexpensive improvement of the quenching effect is achieved, the fan is started at a pressure in the vacuum furnace which is lower than the minimum pressure, with the rotary current motor being operated with a second, lower supply voltage until the minimum pressure in the vacuum furnace is reached.

Owner:IPSEN INT

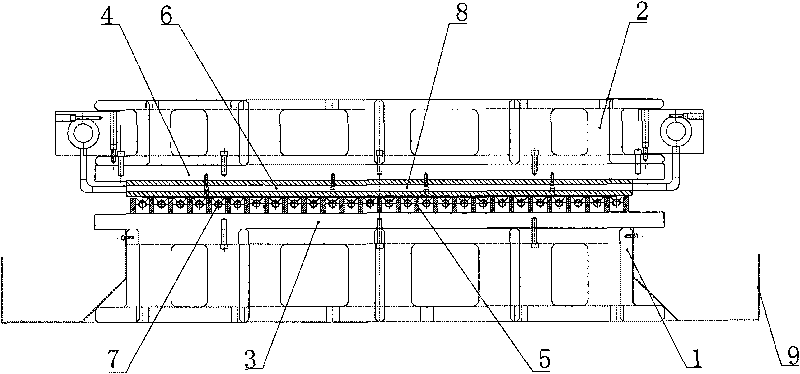

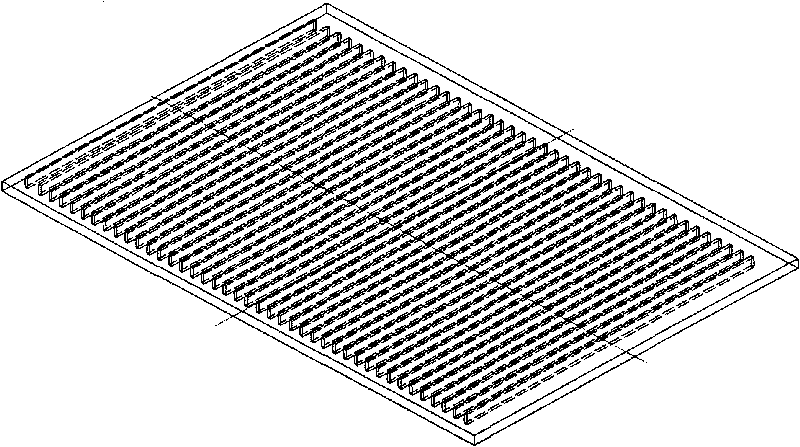

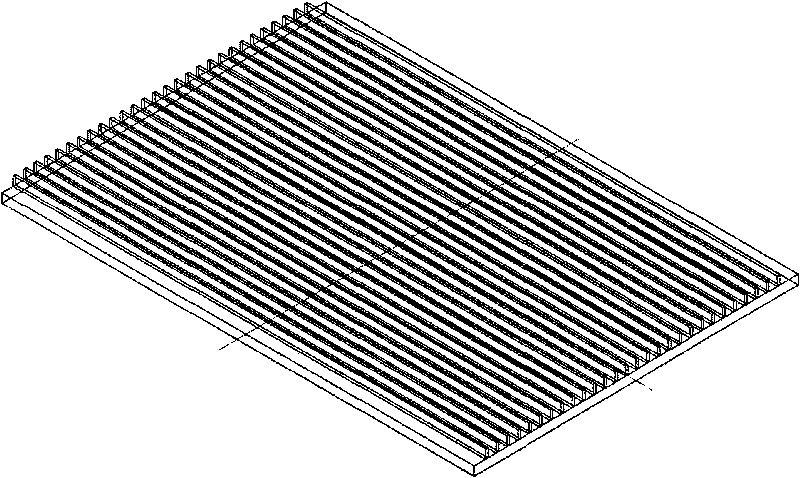

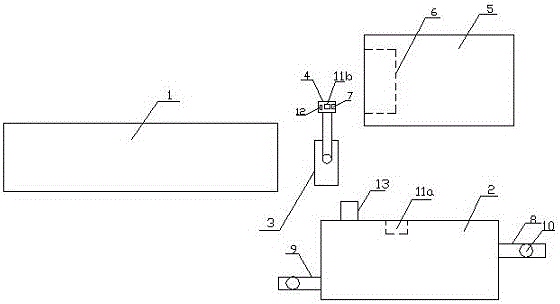

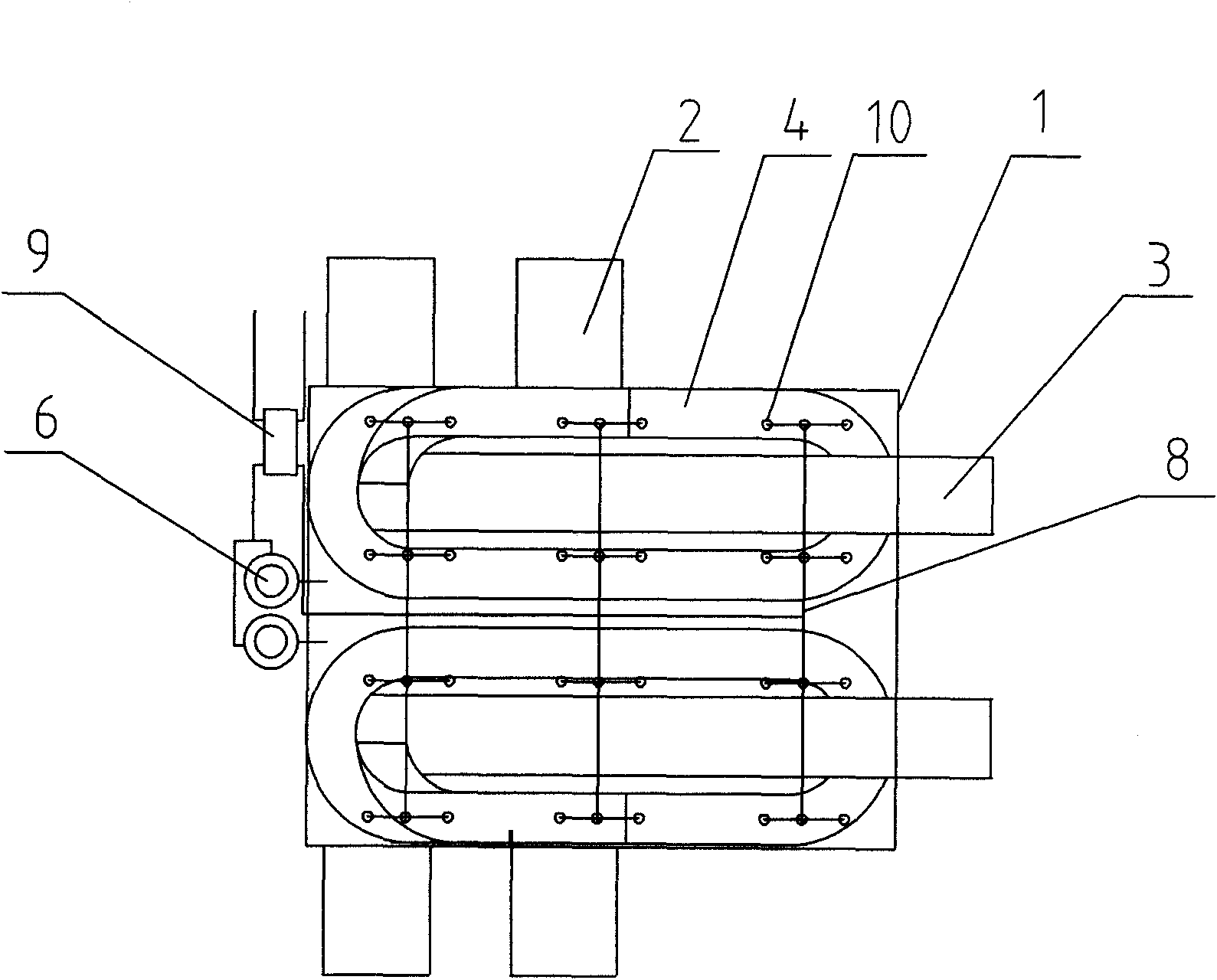

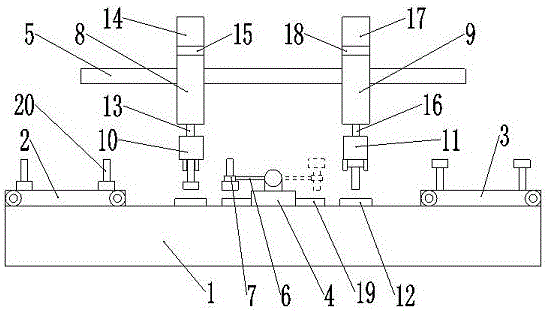

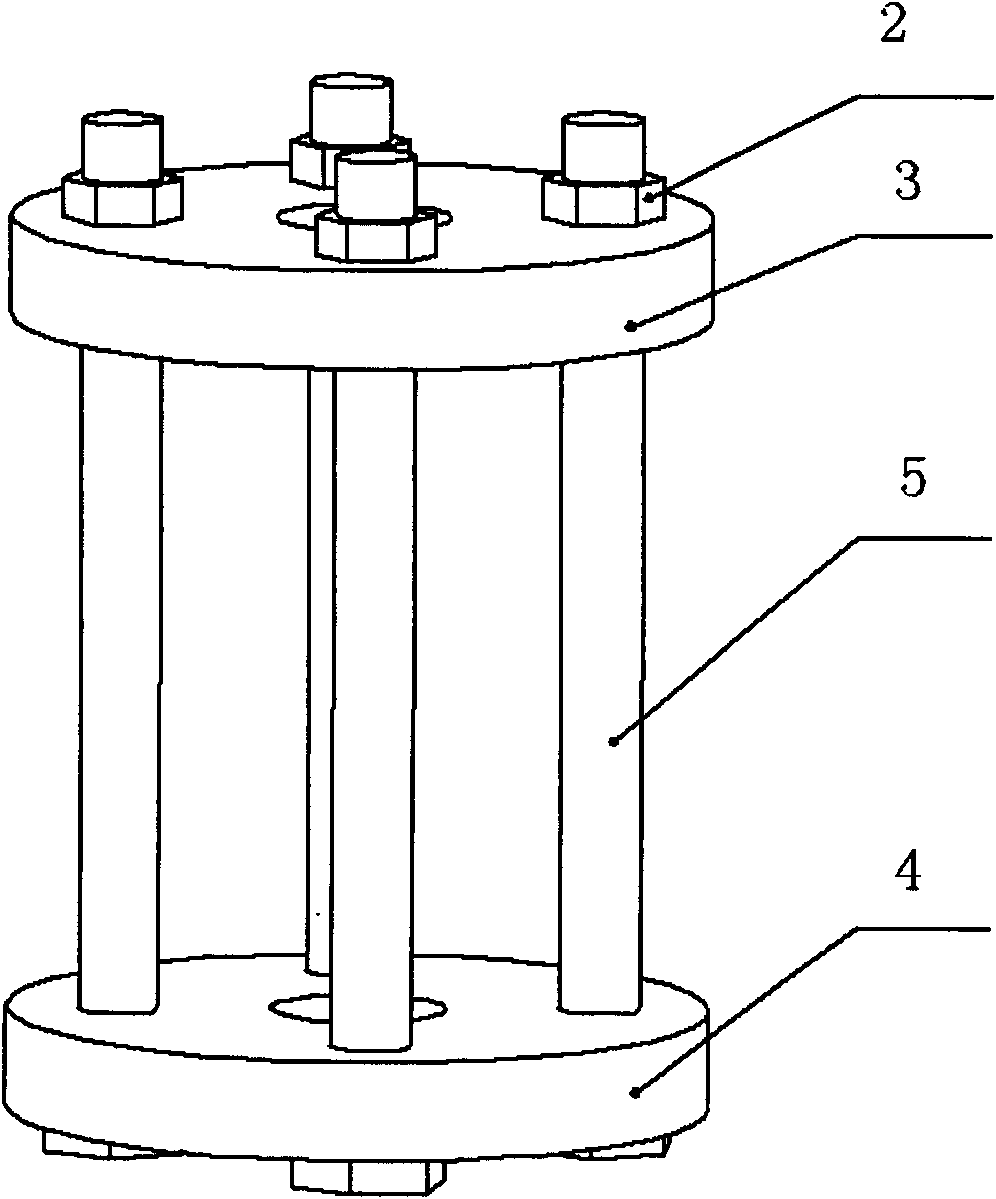

Pressure quenching mold for obtaining quality-controllable intensified heat-treated superhigh intensity steel plate

ActiveCN101736137AImprove flatnessSmall thermal deformationProcess efficiency improvementQuenching devicesQuenchingSpray cooling

A pressure quenching mold for obtaining a quality-controllable intensified heat-treated superhigh intensity steel plate belongs to the technical field of heat treatment. The mold comprises an upper mold and a lower mold, wherein the lower mold consists of a lower platform, a lower mold mounting plate, a lower vertical rib plate, a lower mold water inlet pipe and a water tank; the lower vertical rib plate, the lower mold water inlet pipe and the water tank are arranged on the lower mold mounting plate, and then the lower mold mounting plate is fixed on the lower platform through a fastening screw; the upper mold consists of an upper platform, an upper mold mounting plate, an upper vertical rib plate and an upper mold water inlet pipe; and the upper vertical rib plate and the upper mold water inlet pipe are arranged on the upper mold mounting plate, and then the upper mold mounting plate is fixed on the upper platform through the fastening screw. When pressure quenching operation is performed, a slide block on a pressure machine moves downwards to drive the upper mold to be enclosed with the lower mold, and cooling water sprayed from the lower mold water inlet pipe and the upper mold water inlet pipe circularly flows in a water passage to perform pressure quenching on the steel plate. The water tank reclaims the sprayed cooling water for later cycle use. The mold has the advantage that: the intensified heat-treated superhigh intensity steel plate produced by the mold has controllable quality and excellent performance.

Owner:CENT IRON & STEEL RES INST

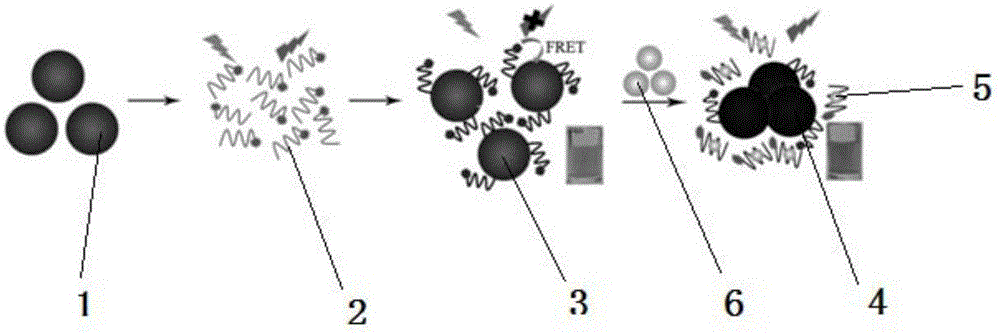

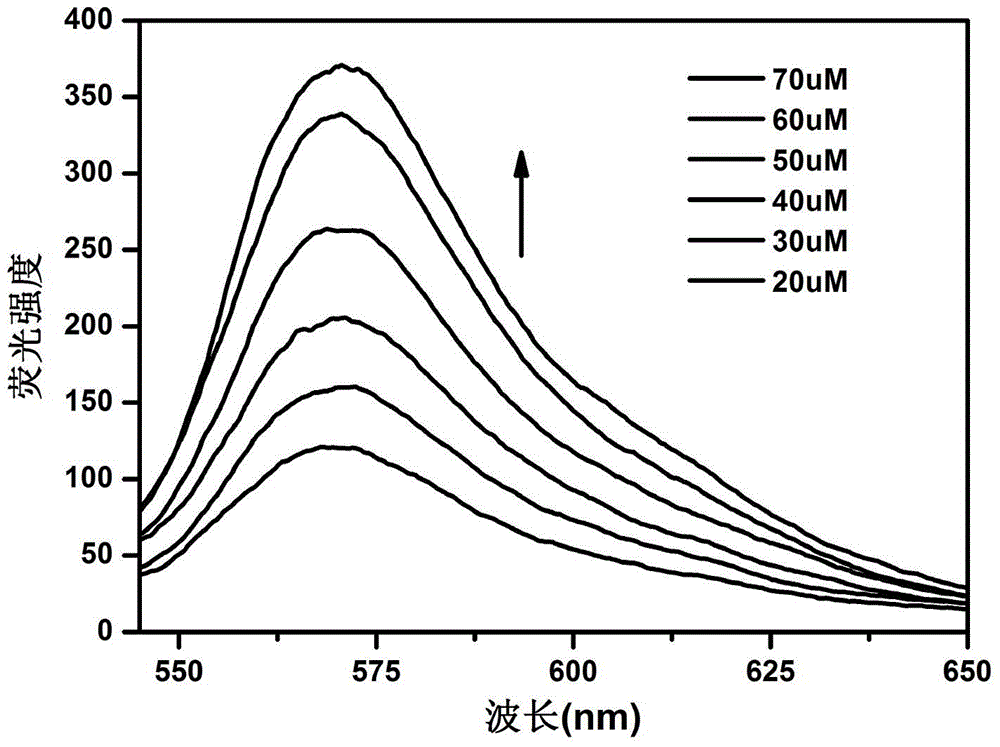

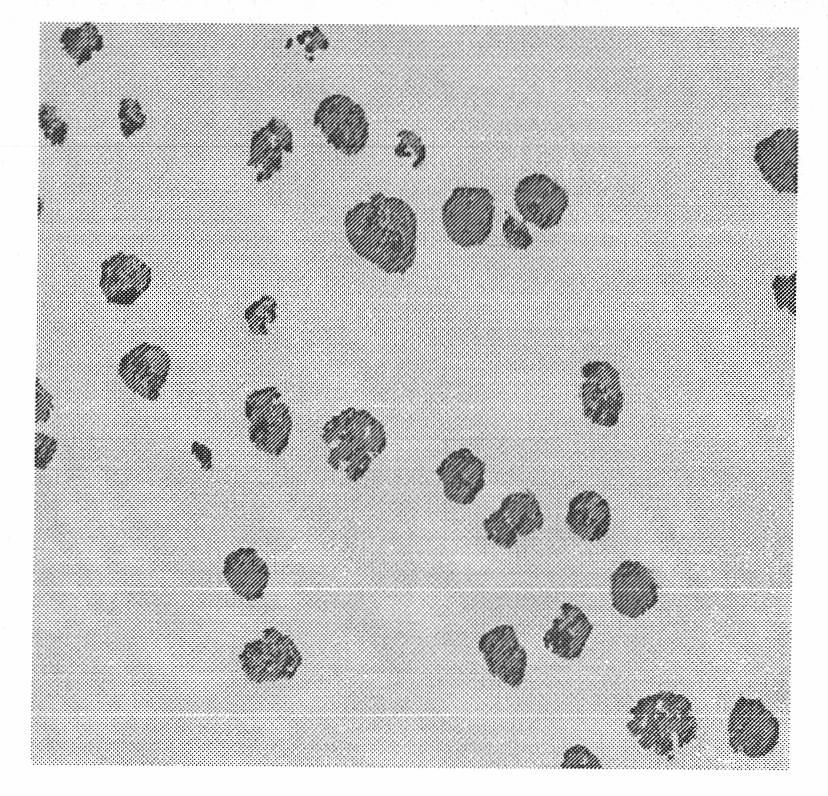

Adenosine determination method based on fluorescent and colorimetric dual detection system

ActiveCN104155273AReduce background fluorescenceGood quenching effectMaterial analysis by observing effect on chemical indicatorFluorescence/phosphorescenceAdenosineSulfur

The invention discloses an adenosine determination method based on a fluorescent and colorimetric dual detection system, and belongs to the technical field of analytical chemistry. By gold-sulfur bonds, sulfydryl DNAs are connected to gold nanoparticles, and the sulfydryl DNAs can hybridize with adenosine aptamers modified by fluorescent dye; because of fluorescence quenching in high-salt solution, the detection system is free of fluorescence or very low in fluorescence intensity and the stable gold nanoparticles keep the solution in a wine red color; addition of adenosine causes changes in the structures of the aptamers, so that the adenosine aptamers modified by the fluorescent dye are dissociated from the gold nanoparticles and the fluorescence of the fluorescent dye recovers; at the moment, the gold nanoparticles cannot exist stably, the color of the solution changes from red to blue. By the adenosine determination method, through changes in fluorescence intensity and solution color of the detection system, qualitative and quantitative adenosine determination is achieved; the adenosine determination method has the advantages of high sensitivity, good selectivity and the like.

Owner:UNIV OF SCI & TECH BEIJING

High-strength and high-tenacity nodular cast iron and working roll of wide thick plate

ActiveCN101775533AEnhanced quenching performanceImprove anti-globularization and prevent recessionPearliteSilicon iron

The invention relates to the improvement of nodular cast iron, which is characterized in that 3.0-3.5 wt% of C, 2.0-2.8 wt% of Si, 0.5-0.8 wt% of Mn, not more than 0.08 wt% of P, not more than 0.02 wt% of S, 0.5-1.2 wt% of Cu, 0.2-0.6 wt% of Mo, 0.05-0.1 wt% of Mg, 0.01-0.03 wt% of Ca, 0.01-0.015 wt% of Re, 0.001-0.003 wt% of Sb, 0.01-0.05 wt% of Ba and the balance of Fe and impurity elements are smelted, then added into yttrium-based heavy rare earth magnesium for nodulizing by using a pour-over process; after nodulizing, a long-acting yttrium-based inoculant and silicon iron are utilized to carry out compound inoculation. The obtained nodular cast iron has both high strength and high tenacity, wherein the tensile strength of as-cast nodular cast iron is not less than 500MPa, and the tenacity is not less than 9J / cm2; by metallographic analysis, the as-cast nodular cast iron has a structure with part of fine pearlites and globular graphite, and the graphite globuring ratio can be improved by more than 2 levels. The invention is especially suitable for the high-strength nodular cast iron used for the core of the working roll of a wide thick plate, thereby greatly prolonging the service life of the working roll.

Owner:JIANGSU GONGCHANG ROLL

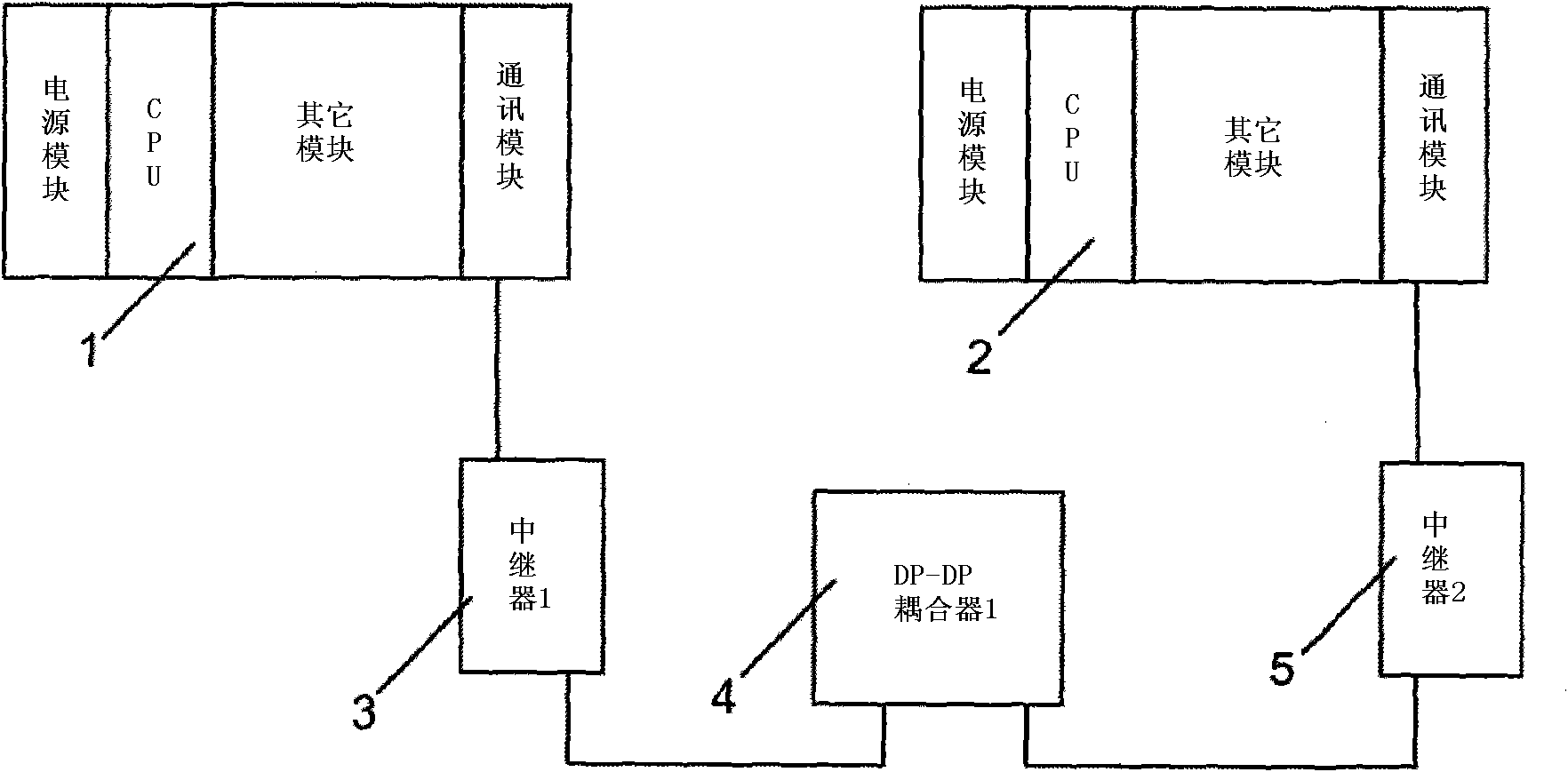

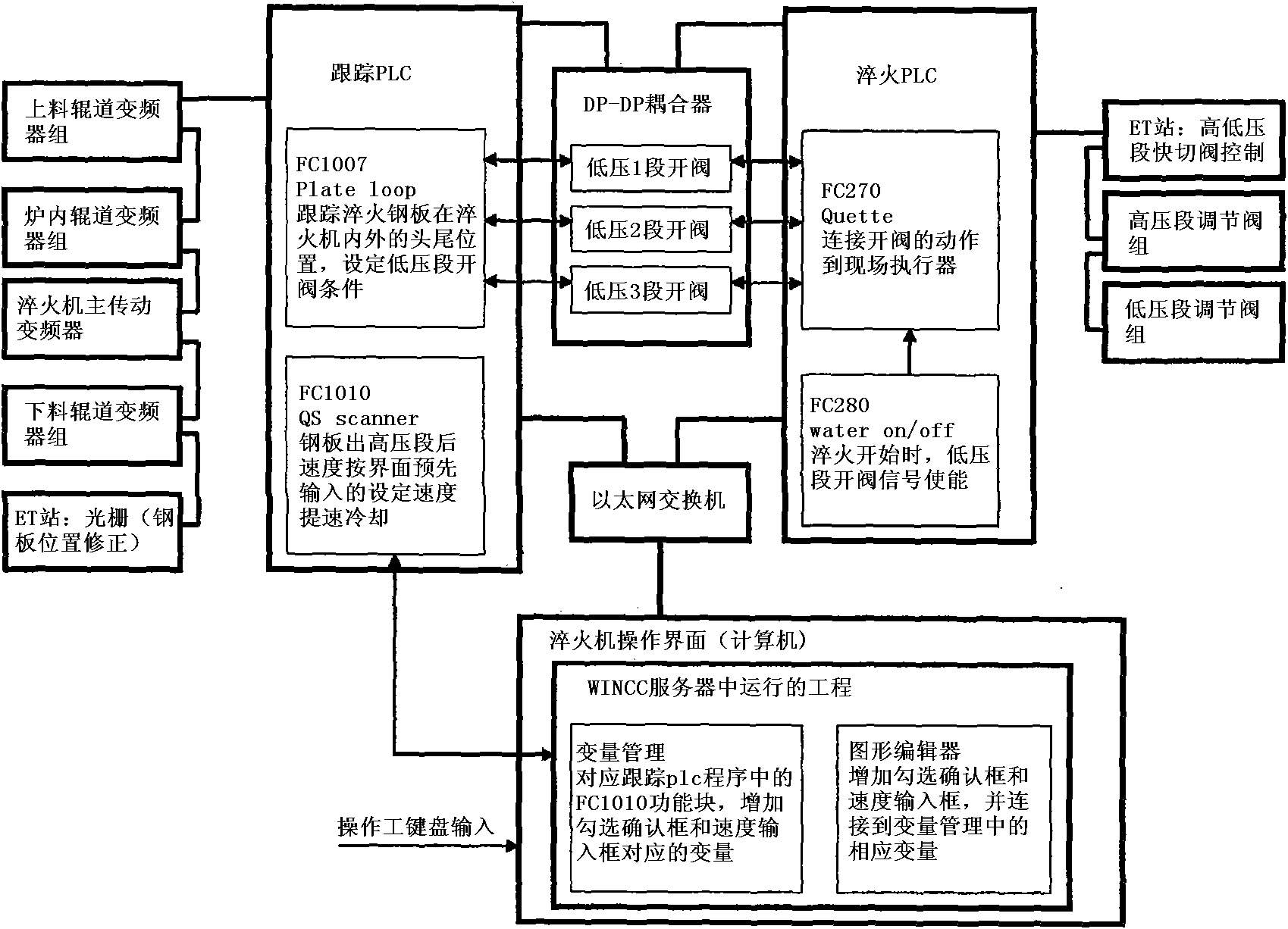

Method for controlling water cooling process of quenching machine

The invention discloses a method for controlling a water cooling process of a quenching machine, and belongs to the technical field of quenching control. Based on an automatic network constructed by siemens S7-400 PLC, a DP-DP coupler is added in the aspect of hardware, and the DP-DP coupler is connected to a PROFIBUS-DP network through an idle channel of a DP network relay; then, corresponding hardware configuration is carried out in a PLC program and used for signal switching between a steel plate tracking PLC and a quenching PLC; three switching variables are established in the tracking PLC and quenching machine PLC programs respectively, and the three switching variables in the tracking PLC are output variables; the three switching variables in the quenching PLC are input variables; and the on-off states of the three switching variables are sent to the quenching machine PLC by the steel plate tracking PLC through a DP-DP coupler module to control the quenching machine to open corresponding quick switching valves at a low pressure section. The method is applied to controlling the water cooling process of the quenching machine, and greatly relieves the problems that the water supply at the low pressure section is insufficient when the steel plate is quenched at a low speed and the pressure continually declines to influence the surface quality of the quenched steel plate.

Owner:SHOUGANG CORPORATION

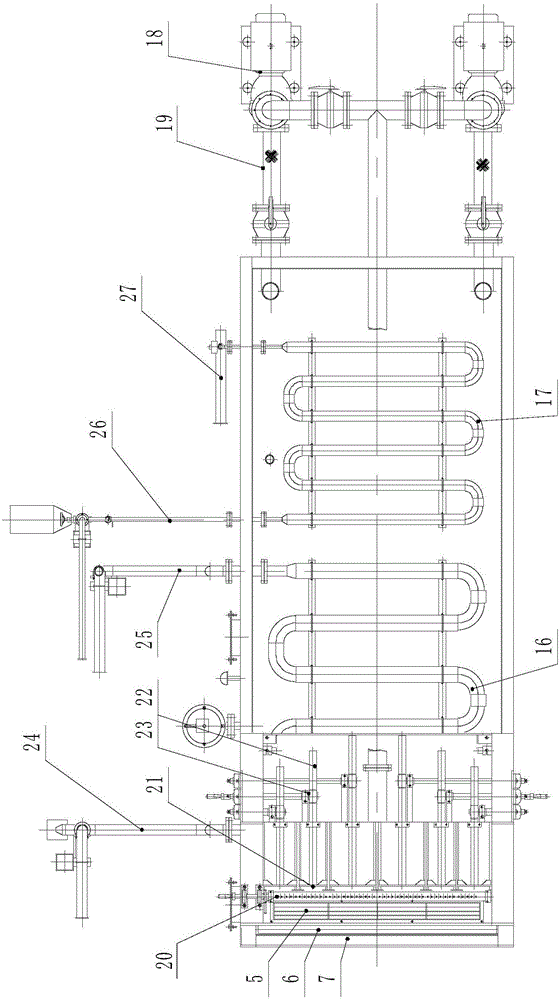

Quenching device of shaft lever

InactiveCN106086336AHigh precisionGood effectFurnace typesHeat treatment furnacesEngineeringManipulator

The invention discloses a quenching device of a shaft lever. The quenching device comprises a conveying belt and a cooling pond, wherein the conveying belt is used for conveying the shaft lever, the cooling pond is installed on one side of the conveying belt, a manipulator is arranged between the cooling pond and the conveying belt, a fixture which is used for grabbing the shaft lever is arranged on the manipulator, a quenching furnace is further arranged on one side of the cooling pond, a tooling plate is arranged in the quenching furnace, and a position sensor is arranged on the fixture. The manipulator is arranged to transfer the shaft lever, so that the quenching efficiency of the shaft lever is improved. The quenching device has the advantages of simple structure and convenience in operation, the quenching effect is greatly increased, and the input cost is reduced.

Owner:NEXTEER LINGYUN DRIVELINE WUHU

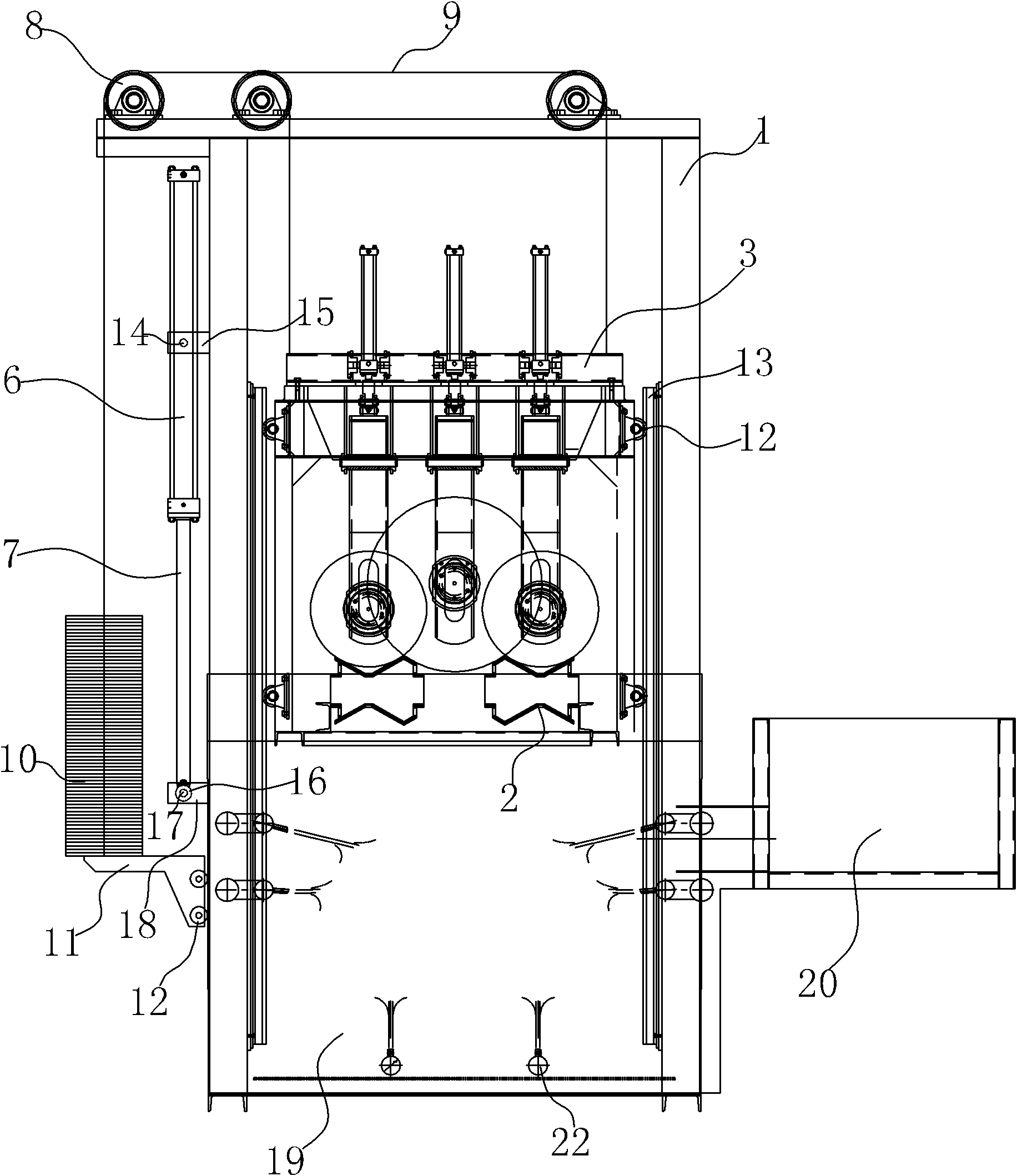

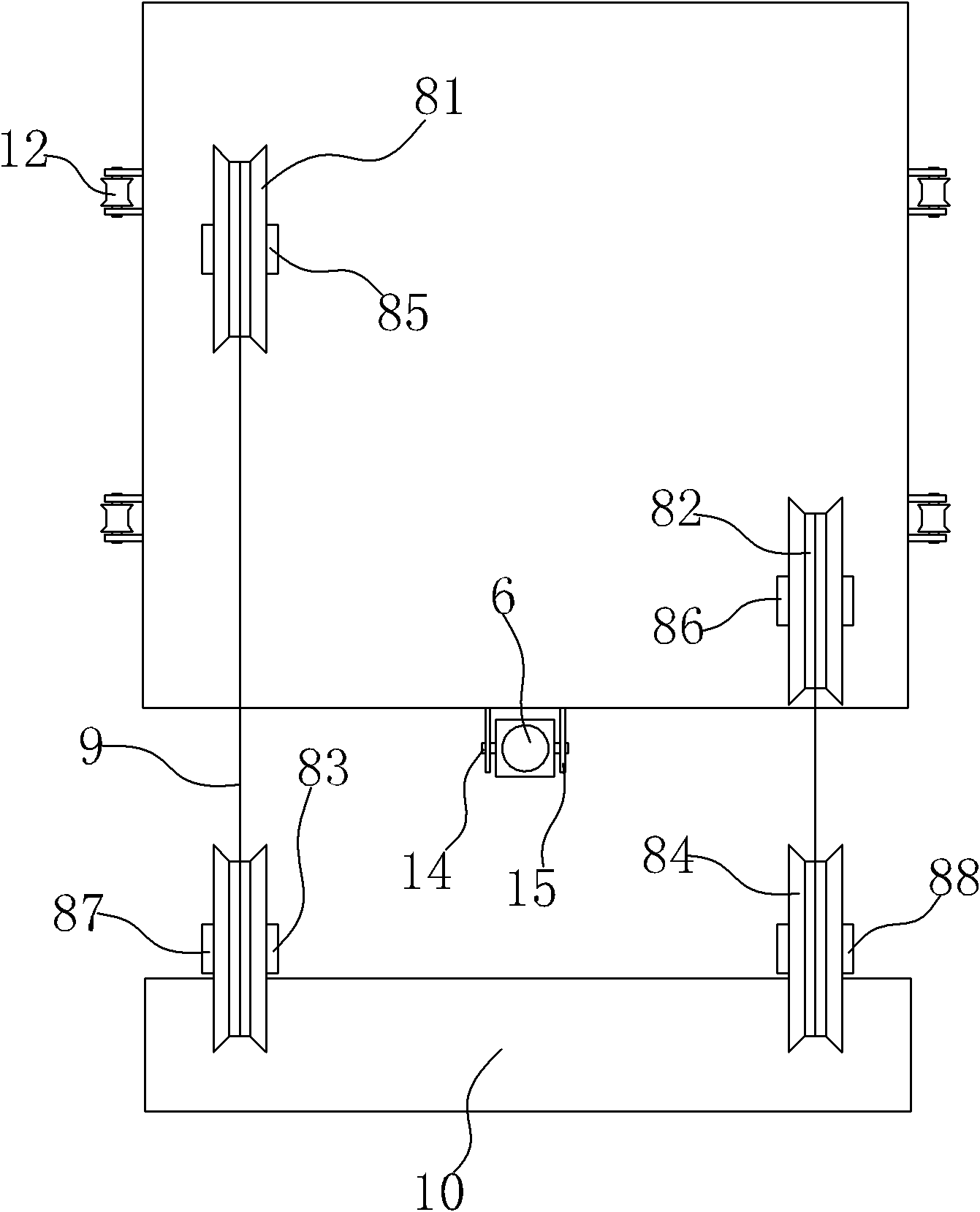

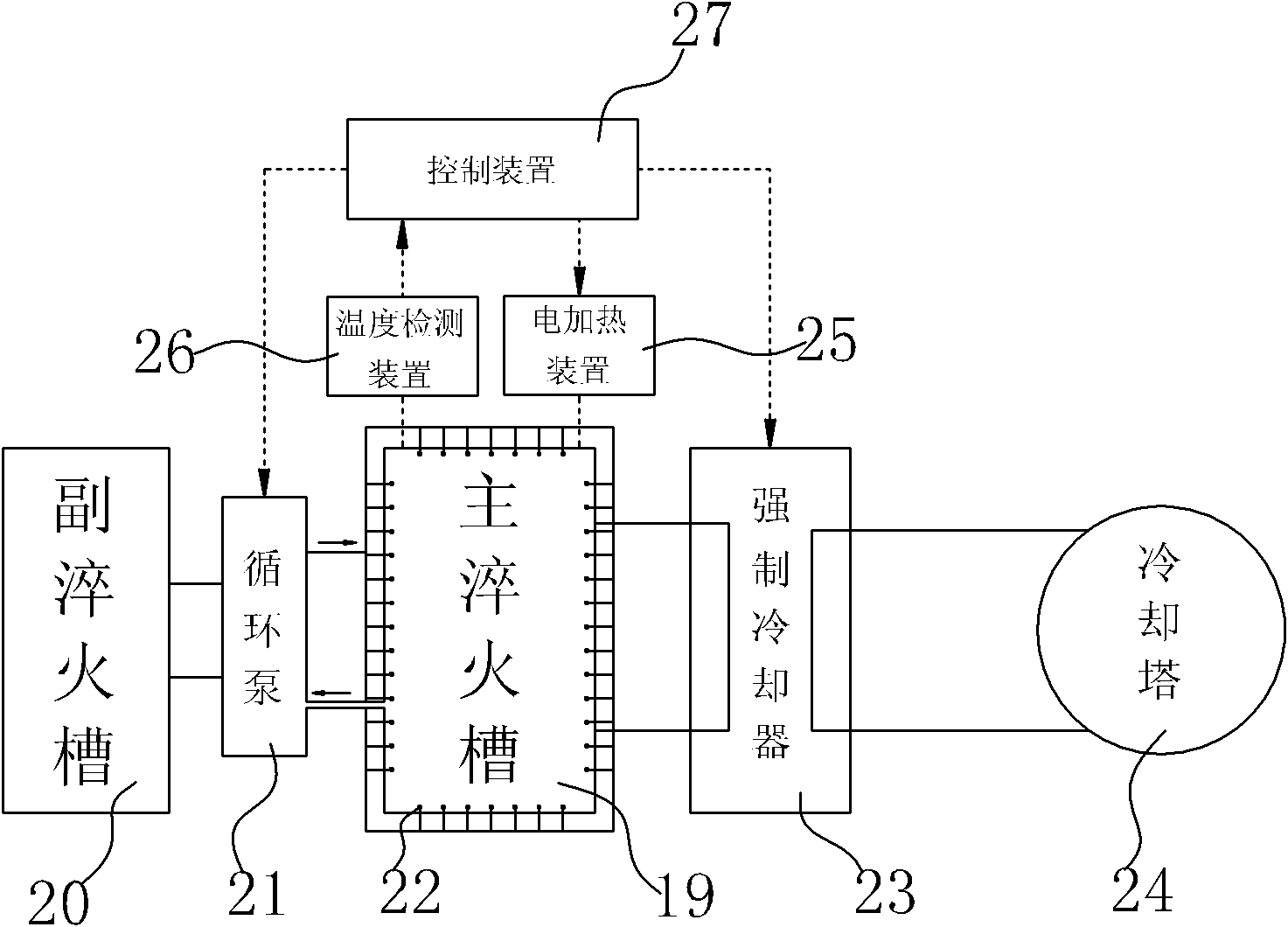

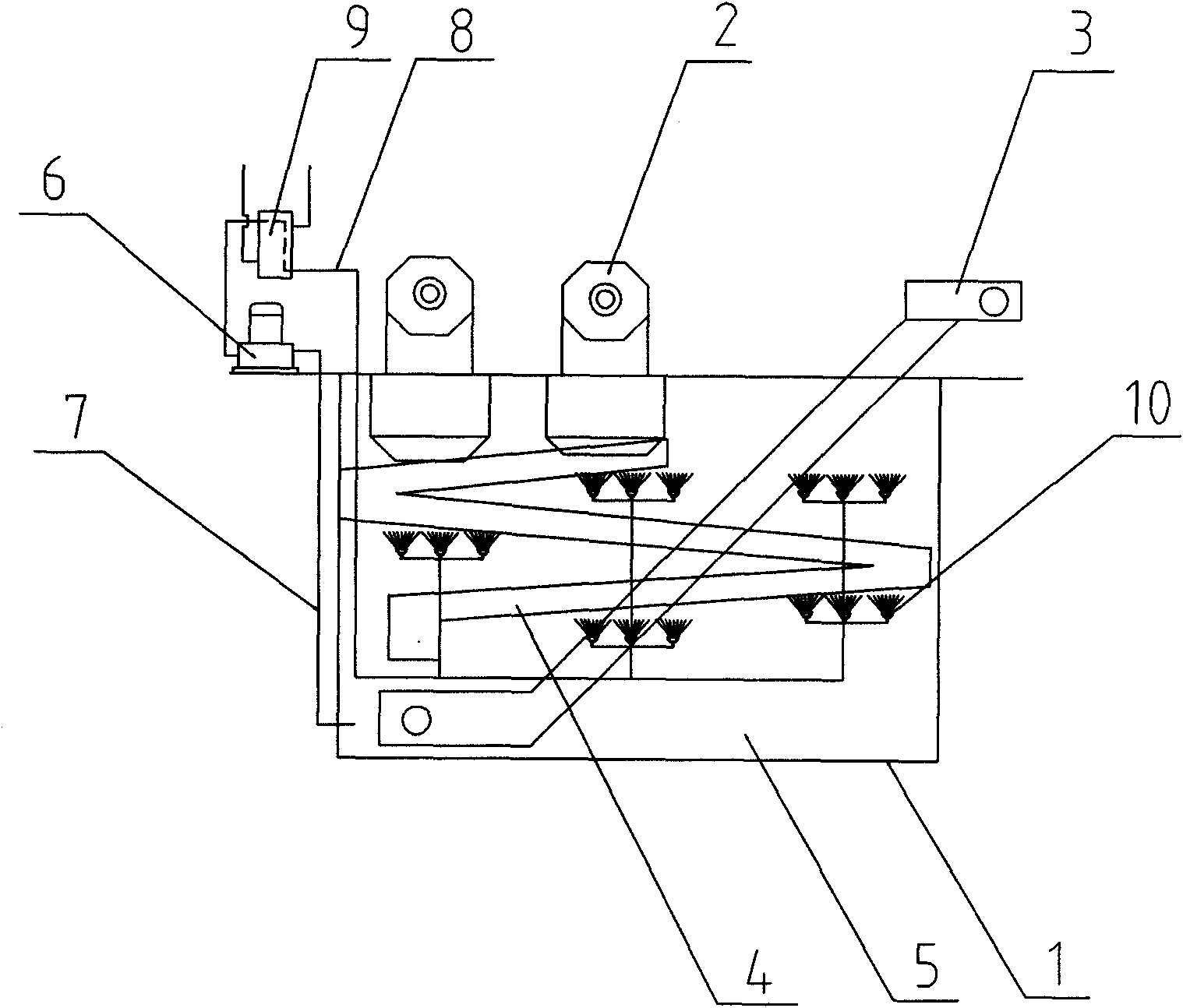

Integrated immersion quenching device of steel bottle quenching-and-tempering line

InactiveCN101984090ASimple structureRun smoothlyFurnace typesHeat treatment furnacesHydraulic ramSprocket

The invention discloses an integrated immersion quenching device of a steel bottle quenching-and-tempering line, comprising a main rack, a quenching rack provided with a steel bottle holding mechanism and a quenching groove containing a quenching liquid. Each side of the quenching rack is provided with a quenching rack roller. The main rack is provided with a first guide rail matched with the quenching rack roller. The quenching rack is fixedly connected with a hydraulic cylinder. The front end of a hydraulic push rod matched with the hydraulic cylinder is fixed on the main rack. The main rack is further provided with a sprocket assembly. One end of a chain matched with the sprocket assembly is fixedly connected with the top of the quenching rack, while the other end of the chain is fixedly connected with a balancing weight. The quenching groove comprises a primary quenching groove and a secondary quenching groove between which a circulation pump is arranged. The circulation pump is respectively connected with the primary quenching groove and the secondary quenching groove through a two-way pipeline. The invention has the benefits of simple structure, stable operation, rapid immersion of the quenching rack into the quenching liquid, improved quenching intensity, increased balancing weight and reduced driving burden of the hydraulic cylinder.

Owner:ZHEJIANG JUHONG MECHANICAL TECH

Wind power generation steel ball thermal treatment and quenching combined device

ActiveCN101928820AAvoid collision damageImprove quenching effectFurnace typesHeat treatment furnacesContact timeSteel ball

The invention relates to a wind power generation steel ball thermal treatment and quenching combined device which comprises a cooling pool, a feeding hole and a lifting mechanism, wherein the top side of the cooling pool is connected with the feeding hole, the bottom is provided with the lifting mechanism, cooling liquid is filled in the cooling pool; the cooling pool is internally provided with a spiral rail connected with the feeding hole and the lifting mechanism; and one side of the cooling pool is provided with a cooling liquid cooling and circulating device. The invention has the advantages of having large heat radiation area and little impaction because a steel ball slides along the spiral rail, avoiding the collision damage of the steel ball during the falling, and prolonging the contact time of the steel ball and the cooling liquid. One side of the cooling pool is connected with the cooling liquid cooling and circulating device, and spraying holes are uniformly arranged under the spiral rail to ensure that the cooled cooling liquid is uniformly distributed in the cooling pool, therefore, the quenching effect of the steel ball is improved.

Owner:JIANGSU LIXING GENERAL STEEL BALL

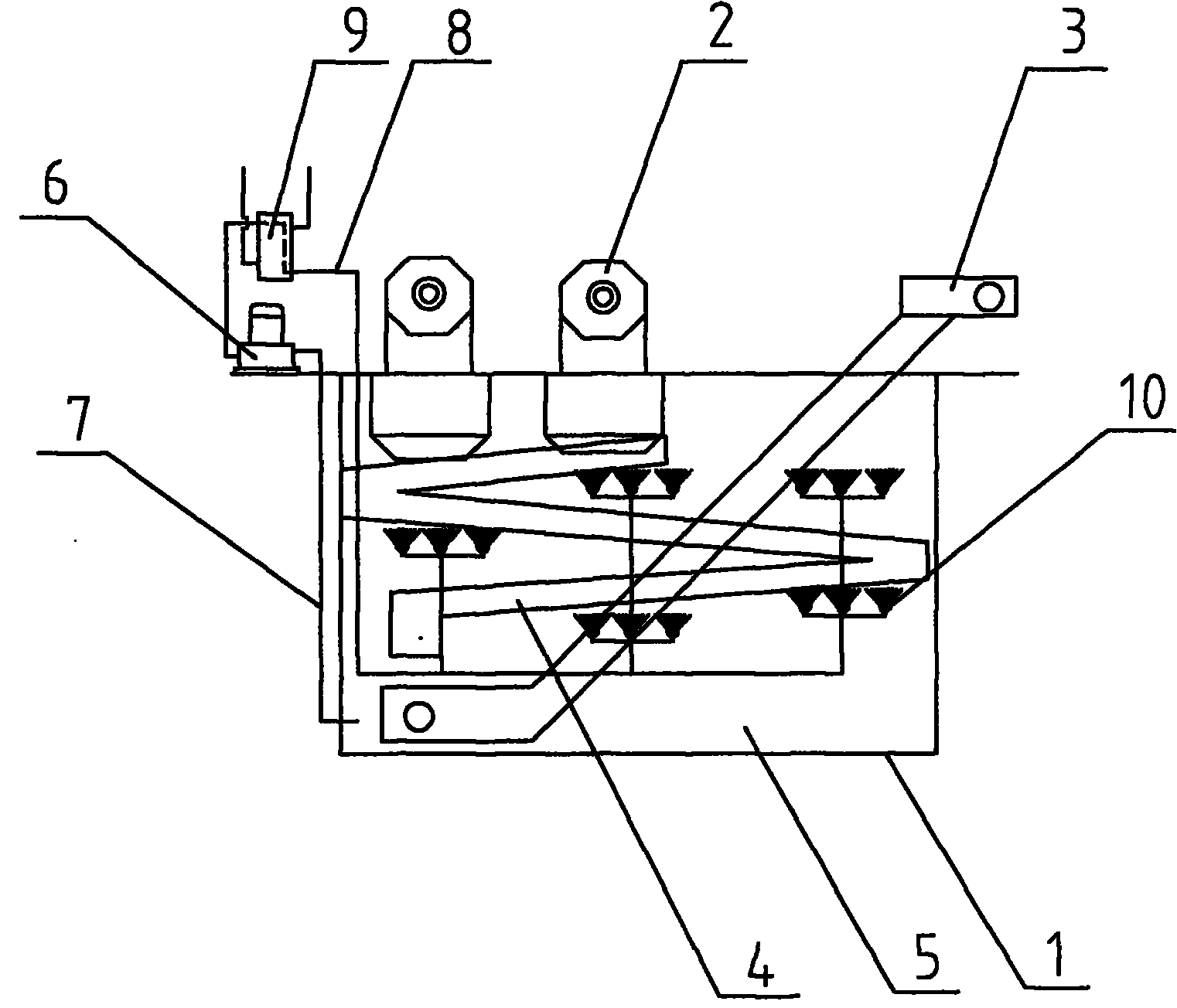

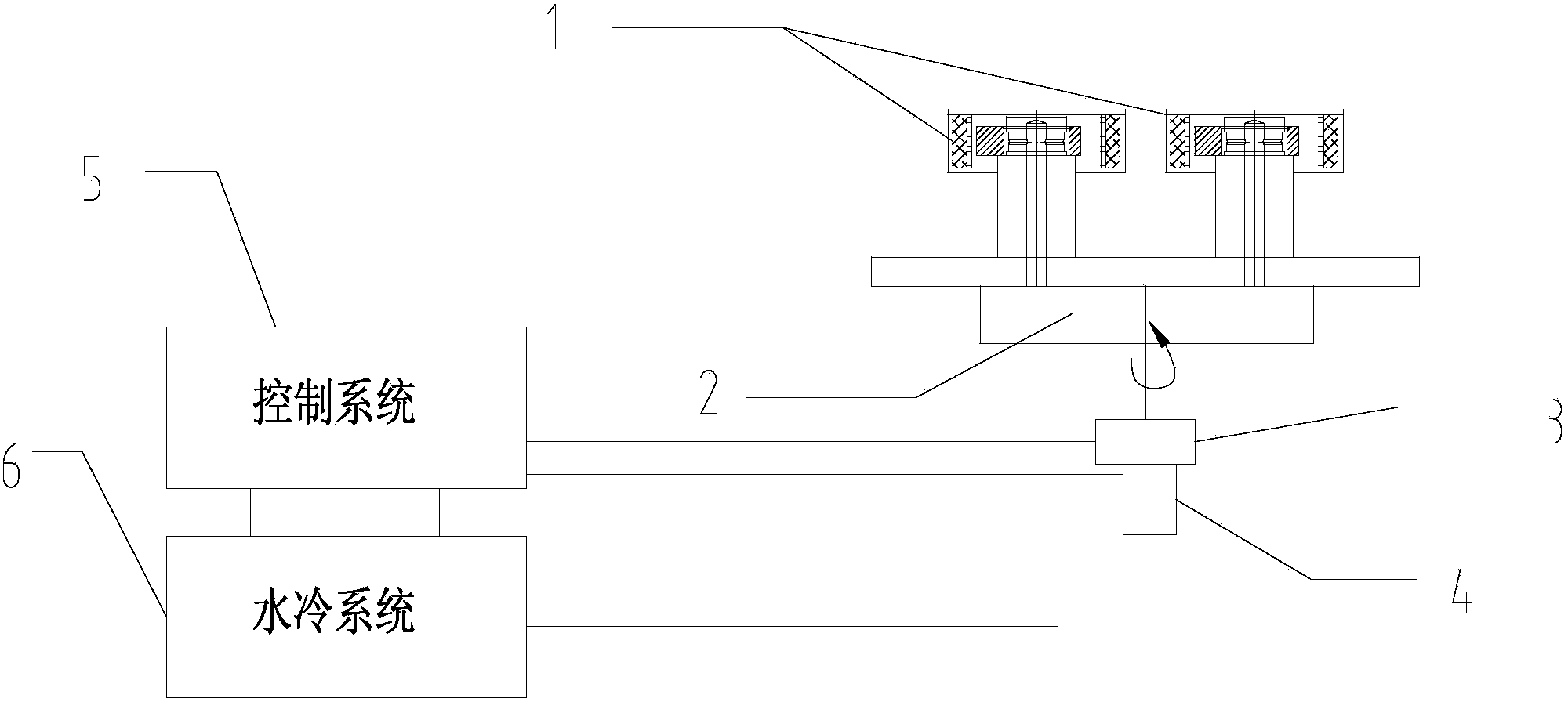

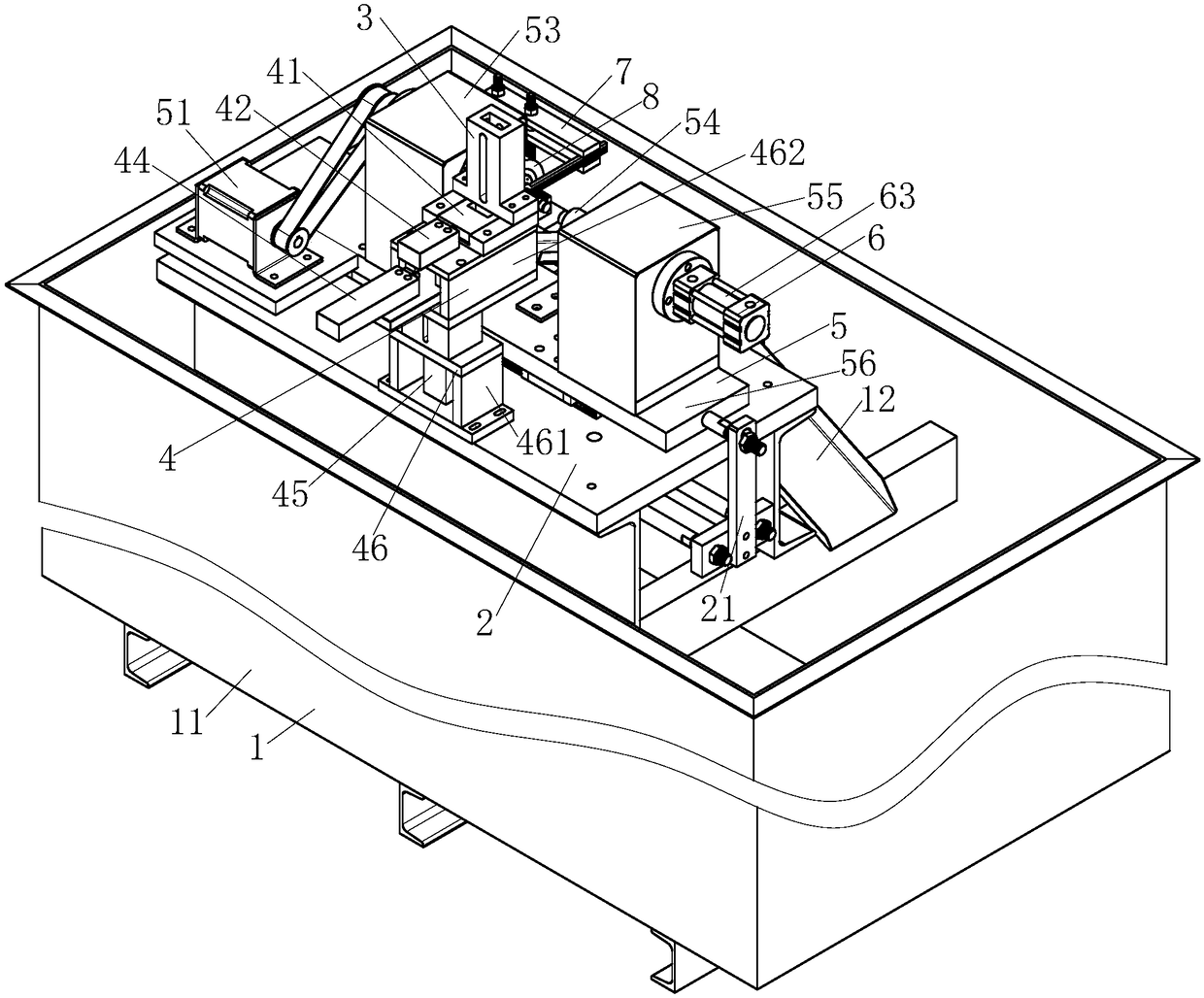

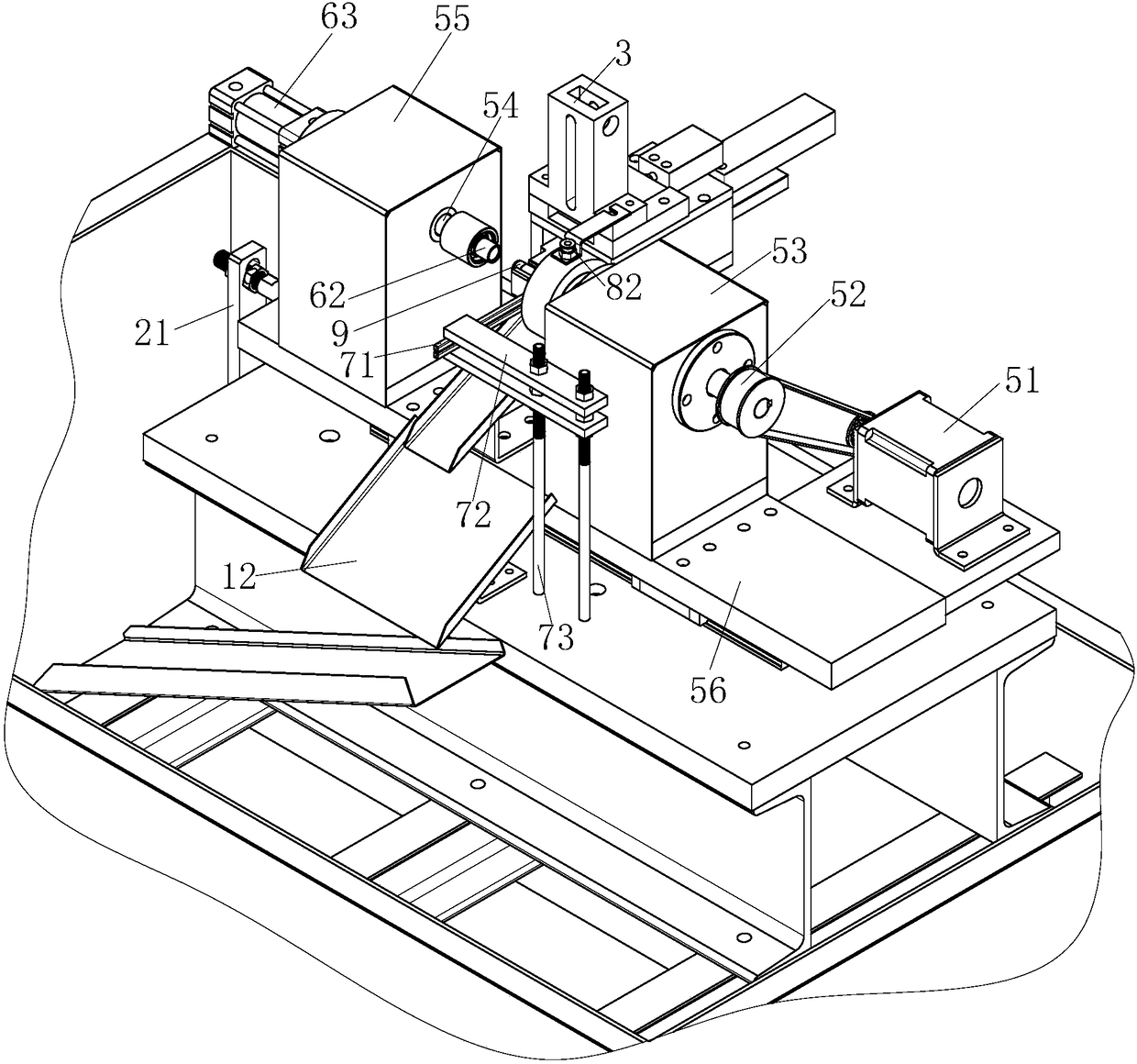

Workpiece quenching machine tool and quenching machine thereof

ActiveCN103409600ACleverly structuredMeet different hardness requirementsQuenching devicesHigh frequency powerControl system

The invention discloses a workpiece quenching machine tool and a quenching method thereof. The workpiece quenching machine tool comprises a bed piece body, wherein a quenching system is arranged on the bed piece body; a moving fixture system is arranged on the bed piece body; a water cooling system is further arranged on the bed piece body, a control system is further arranged on the bed piece body for automatically operating the machine tool according to steps, and the control system is connected with the quenching system; the control system is connected with the moving fixture system; the control system is connected with the water cooling system. The quenching method comprises the following steps that a workpiece is arranged on the moving fixture system; the moving fixture system drives the workpiece to move to a quenching position; the control system controls the water cooling system to spray water onto the middle position of the workpiece; the control system controls a high-frequency power supply to heat a quenching coil; the control system controls the water cooling system to spray water to the quenching coil so as to cool the quenching coil and the workpiece. The quenching device is smart in structure, and a better quenching effect is achieved by the quenching method.

Owner:MIANYANG BRILLIANCE RUIAN AUTOMOTIVE COMPONENTS

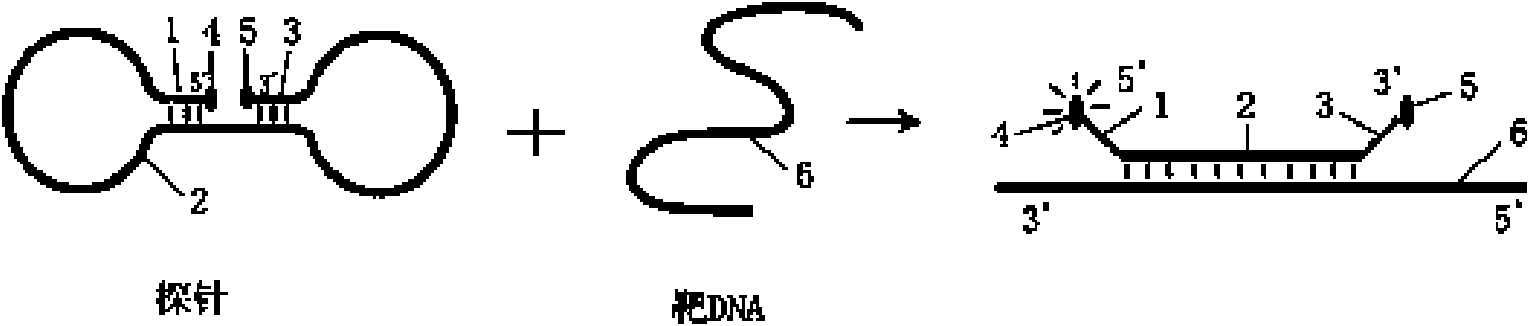

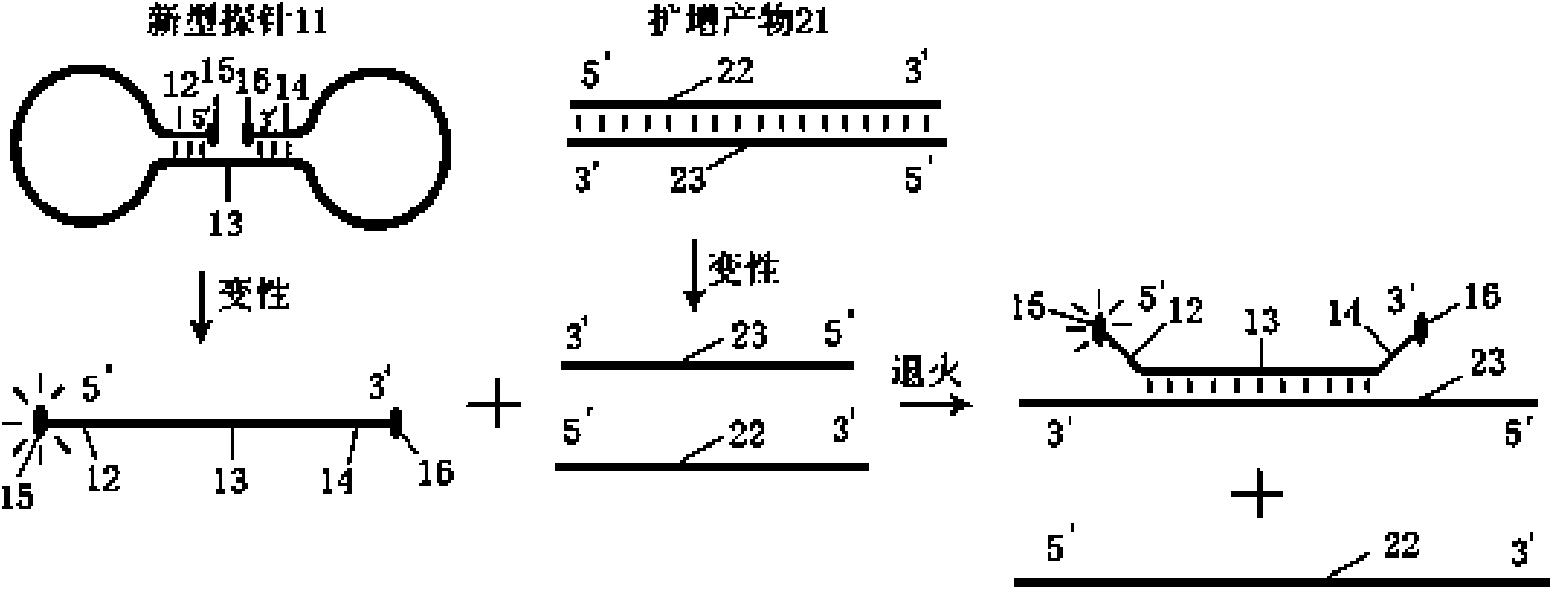

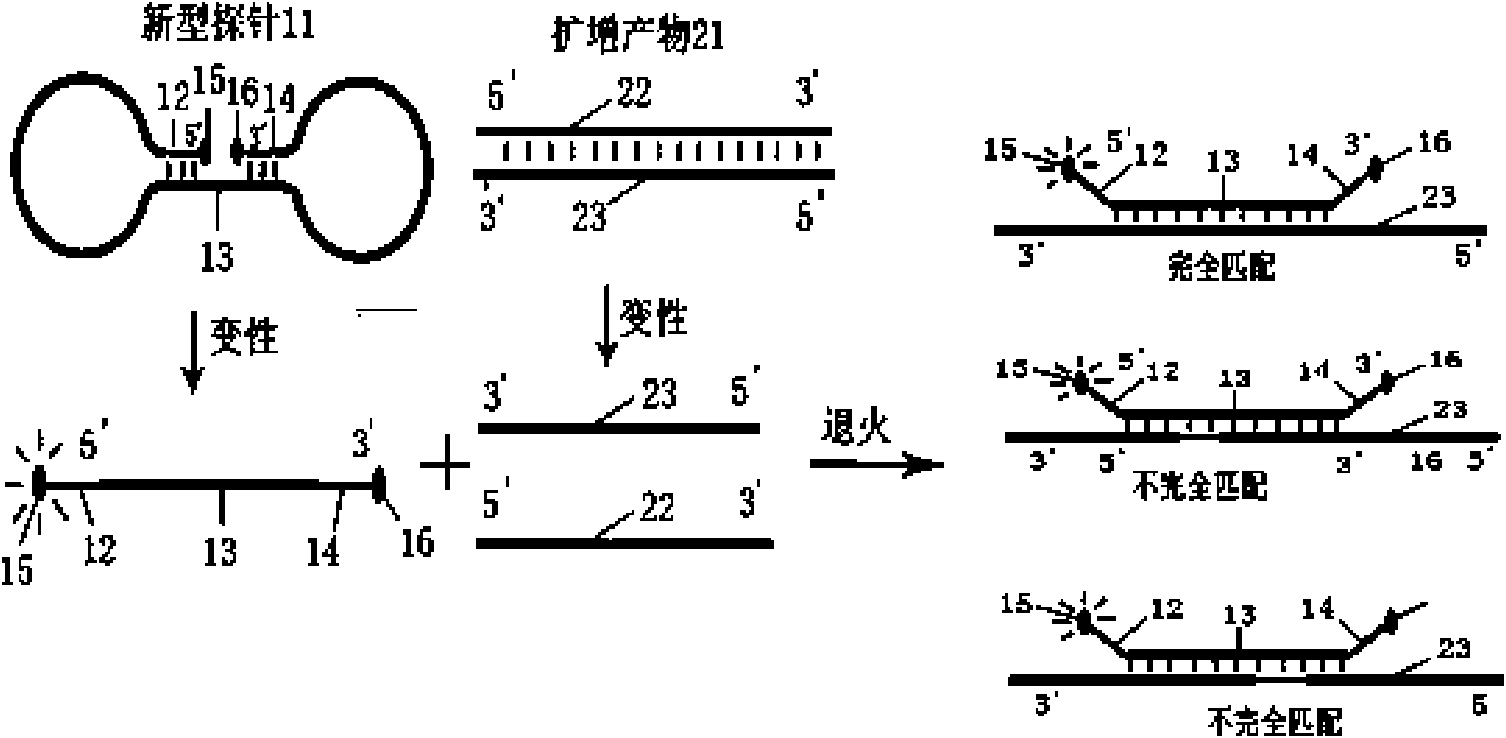

Probe for real-time detection of nucleic acid

InactiveCN101671744ASimple designImprove quenching effectMicrobiological testing/measurementFluorescence/phosphorescenceBinding siteBinding domain

The invention provides a probe for real-time detection of nucleic acid, belonging to the field of molecule detection. The probe comprises a single-chain target sequence binding site which is relatively complemented with a target sequence, a 5' end cyclization binding domain and a 3' end cyclization binding domain, wherein the 5' end cyclization binding domain and the 3' end cyclization binding domain are relatively complemented respectively with a section of sequence in the target sequence binding site to enable the probe to be in two annular structures. As the probe has an inherent complementary double-chain structure in opposite directions, the probe of the invention has strong specificity. In addition, as the probe has the complementary double-chain structure in opposite directions, thelength of a complementary region can be adjusted in the process of design to adjust the specificity of the probe.

Owner:AMOY DIAGNOSTICS CO LTD

Special quenching liquid for preparing large axial forgings from 35CrMo

The invention discloses special quenching liquid for preparing large axial forgings from 35CrMo, and belongs to the technical field of heat treatment quenching. The quenching liquid disclosed by the invention is composed of a mixture of polypropylene-methacrylic acid and polyacrylamide, an ethylene oxide and epoxypropane random copolymer, polyamide polyethylene glycol, a defoaming agent and water. The quenching liquid is mainly suitable for quenching large axial forgings prepared from 35CrMo steel, the process is simple, the traditional double-liquid and triple-liquid quenching processes are changed to effectively avoid quenching crack of the large axial forgings of 35CrMo steel, the quenching effect is good, and the defects of common quick quenching oil that the hardness after quenching is insufficient, the internal organizational form is non-uniform and cracking is liable to produce can be overcome.

Owner:马鞍山金泉工业介质科技有限公司

Steel member having nitrogen compound layer and process for producing same

InactiveUS20120118434A1Easy to slideImprove quenching effectOther chemical processesSolid state diffusion coatingNitrogenInduction hardening

A process for duplex heat treatment of combined nitriding treatment and induction quenching treatment on an iron and steel material includes a chemical conversion treatment step for forming a chemical conversion film on a nitrogen compound layer formed on the iron and steel material by the nitriding treatment, after the nitriding treatment and before the induction quenching treatment. A compound layer formed on a surface of an iron and steel material by nitriding treatment is prevented from being oxidized by induction quenching, so that unevenness in film thickness between different portions of an oxidization-inhibiting film does not easily occur, with the result that a nitrogen-containing compound layer obtained after high-frequency heating remain uniformly.

Owner:NIHON PARKERIZING

Method for preparing quenching liquid

ActiveCN104388643AOvercoming vulnerability to contaminationUniform cooling rate on the surfaceQuenching agentsPolypropyleneEpoxide

The invention discloses a method for preparing a quenching liquid, and belongs to the technical field of thermal treatment quenching. The quenching liquid consists of a mixture of polypropylene-methacrylic acid and polyacrylamide, a random copolymer of ethylene oxide and propylene epoxide, polyamide polyethylene glycol, a defoaming agent and water. The quenching liquid is mainly applicable to quenching of large-size 35CrMo steel forged shaft pieces, the process is simple, the conventional double-liquid / three-liquid quenching process is changed, by adopting the quenching liquid prepared by using the method disclosed by the invention, the large-size 35CrMo steel forged shaft pieces are effectively prevented from being cracked when being quenched, the quenching effect is good, the defects that the large-size 35CrMo steel forged shaft pieces are insufficient in hardness, not uniform in internal tissue form, easy to crack and the like when being quenched by using ordinary rapid quenching oil are overcome, and the prepared quenching liquid has the advantages of good dispersibility and high storage property.

Owner:马鞍山金泉工业介质科技有限公司

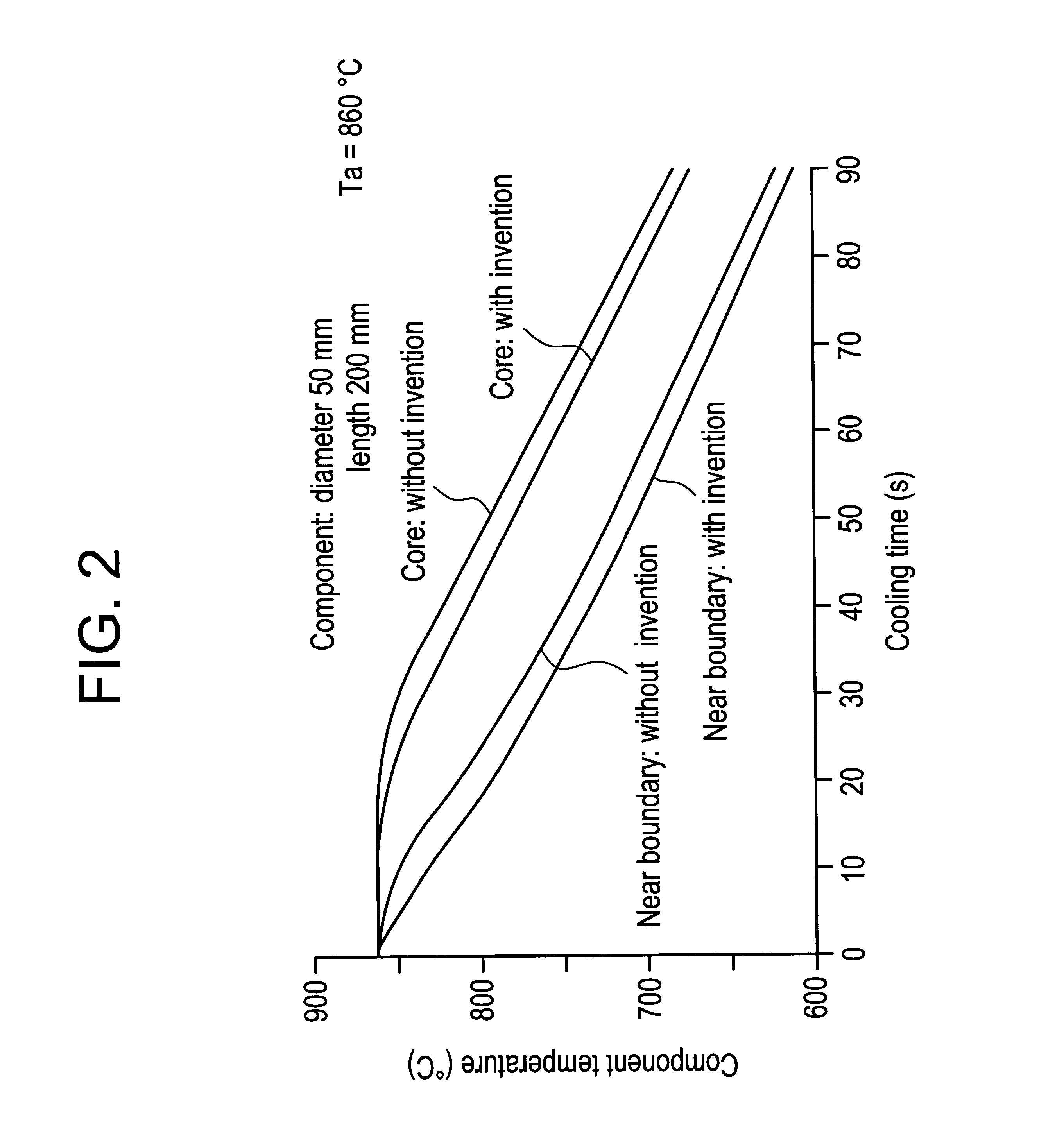

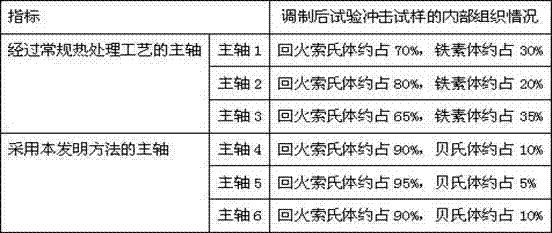

Thermal treatment method for improving low-temperature impact work of air blower main shaft

InactiveCN103173604AReduce the temperatureTemperature drop) significantly shortens theFurnace typesHeat treatment furnacesRoom temperatureEngineering

The invention belongs to the technical field of production of air blower main shafts and in particular relates to a thermal treatment method for greatly improving a low-temperature impact toughness value in the mechanical performances of an air blower main shaft material. The thermal treatment method comprises the following steps of: selecting the air blower main shaft made of a 42CrMoA material, feeding the air blower main shaft to a furnace under a quenching temperature of 840 DEG C to 860 DEG C; heating up and equalizing the temperature, discharging the air blower main shaft out of the furnace after keeping the temperature, wherein the tapping temperature is 840 DEG to 860 DEG C; cooling in the air and placing the cooled air blower main shaft in a quenching station; injecting water for immersing and cooling; re-injecting water for immersing and cooling after cooling in the air; soaking in water or spraying for cooling after cooling in the air, repeating the process for 3 times to 6 times; controlling the outlet water temperature of the workpiece after the cooling to 140 DEG C to 160 DEG C; tempering at 590 DEG C to 630 DEG C after the quenching is finished for preserving the heat; cooling in the air to reach the room temperature after carrying out air-cooling and water-cooling alternatively upon tempering and discharging from the furnace, wherein the impact work value at -30 DEG C can be greatly improved relative to the conventional thermal treatment process.

Owner:ZHONGYUAN SPECIAL STEEL

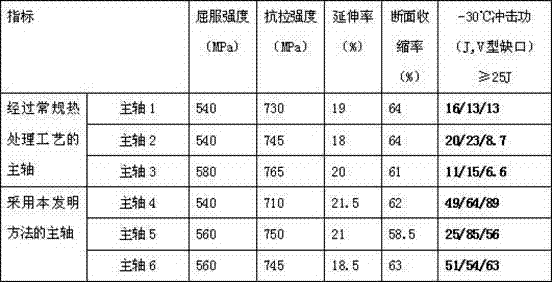

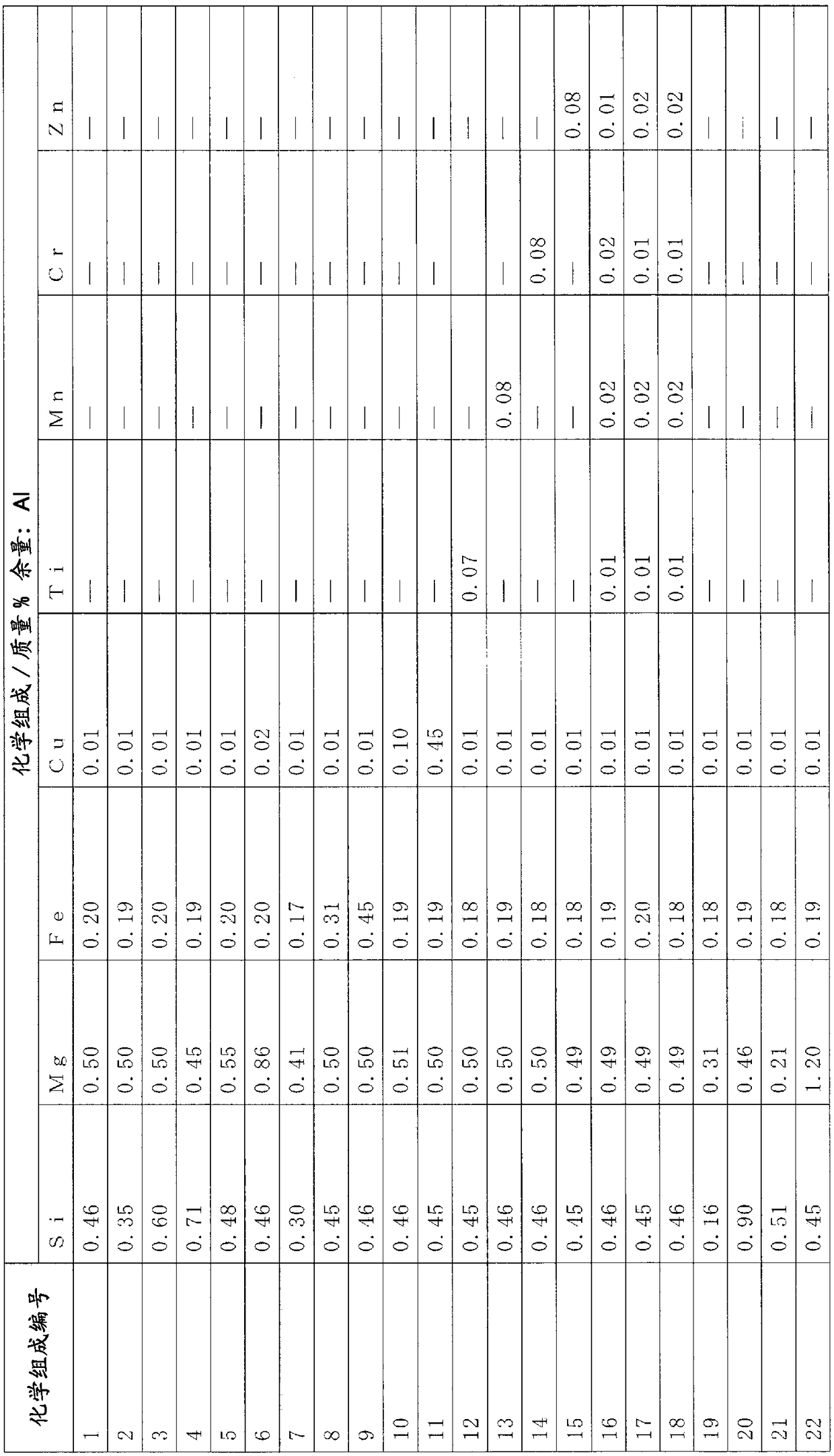

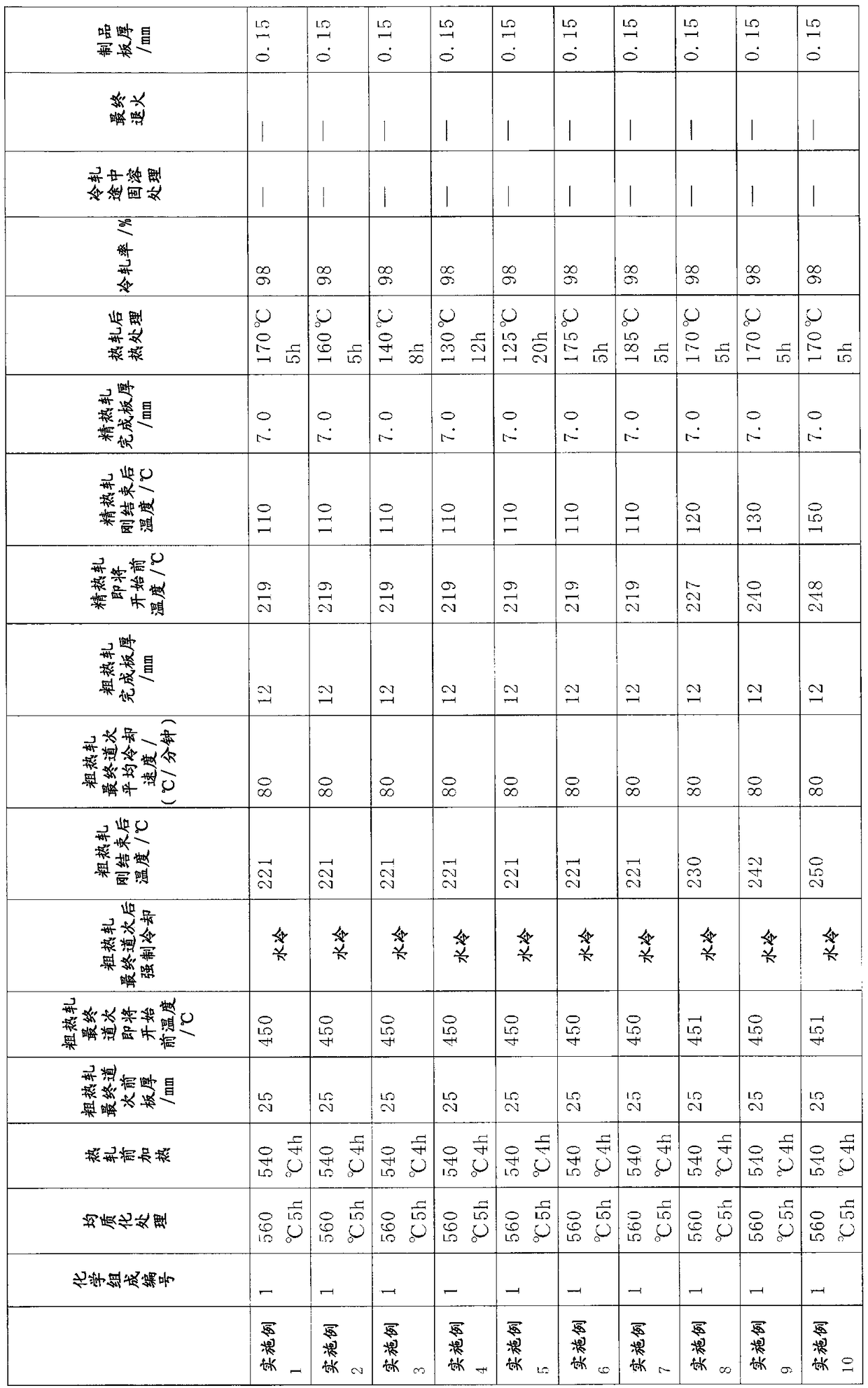

Al-mg-si-based alloy material, al-mg-si-based alloy plate, and method for manufacturing al-mg-si-based alloy plate

Provided is an Al-Mg-Si-based alloy material that has high strength while having high conductivity and good processability. The tensile strength of the Al-Mg-Si-based alloy material, which has a fibrous structure, is set to be equal to or greater than 280 MPa, and the conductivity thereof is set to be equal to or greater than 54 % IACS.

Owner:堺アルミ株式会社

Automatic quenching machine tool

ActiveCN105821188AImprove quenching effectImprove quenching qualityFurnace typesHeat treatment furnacesQuenchingManipulator

The invention discloses an automatic quenching machine tool comprising a machine tool main body, wherein the machine tool main body is provided with a servo system. The automatic quenching machine tool is characterized in that a feeding device is arranged at the left side of the machine tool main body; a discharging device is arranged at the right side of the machine tool main body; a turnover seat controlled by the servo system is arranged in the middle of the machine tool main body; a beam is arranged right above the machine tool main body; the turnover seat is provided with a rotating arm by which turnover manipulators are educed; the beam is provided with a left sliding seat and a right sliding seat which are controlled by the servo system; the lower end of the left sliding seat is provided with a left manipulator adapted to the feeding device; the lower end of the right sliding seat is provided with a right manipulator adapted to the discharging device; and the machine tool main body is provided with a quenching system adapted to the left manipulator and the right manipulator. The automatic quenching machine tool has the very remarkable beneficial effects of high work efficiency, automatic double-station quenching of workpieces, good quenching effect and quality and wide application range.

Owner:WONH IND

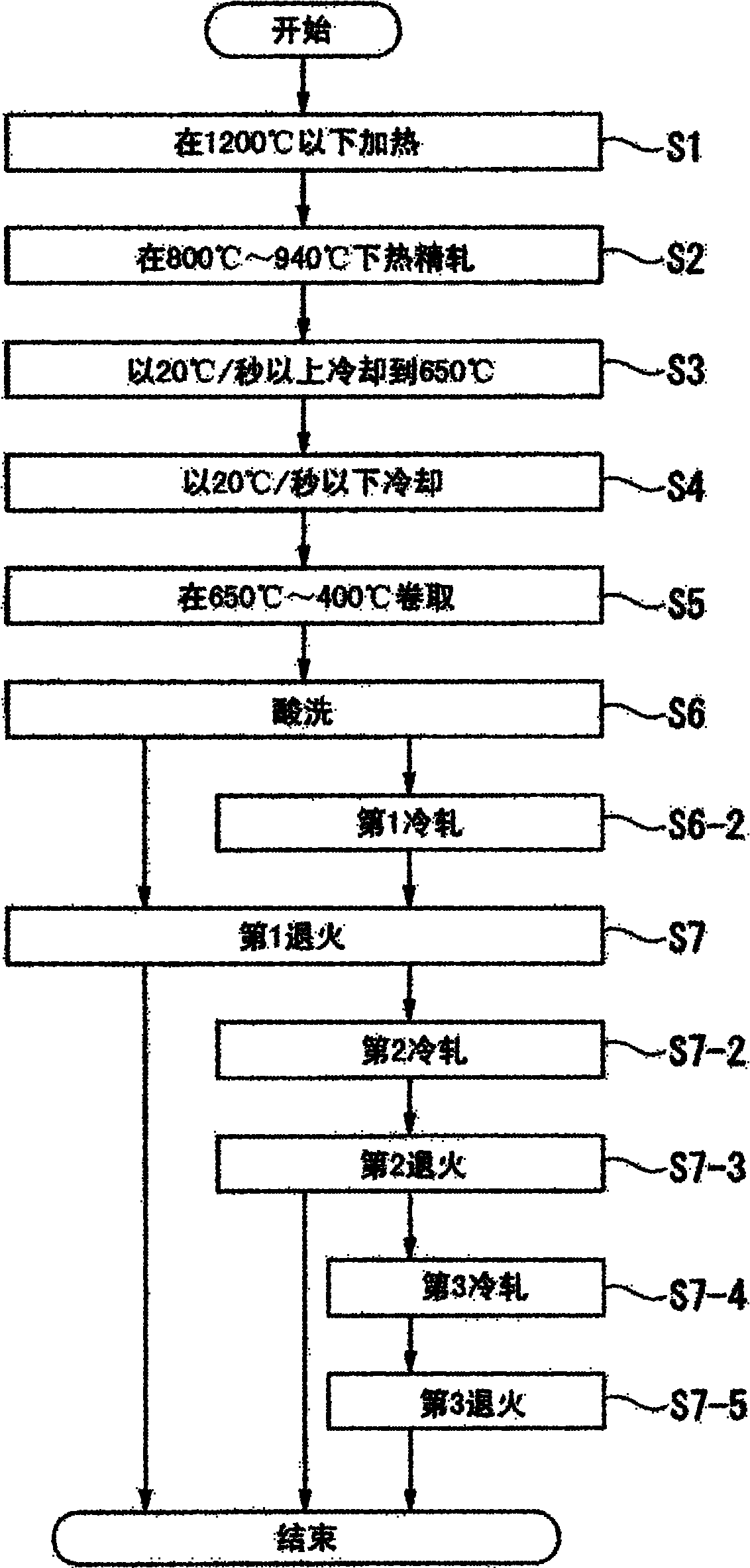

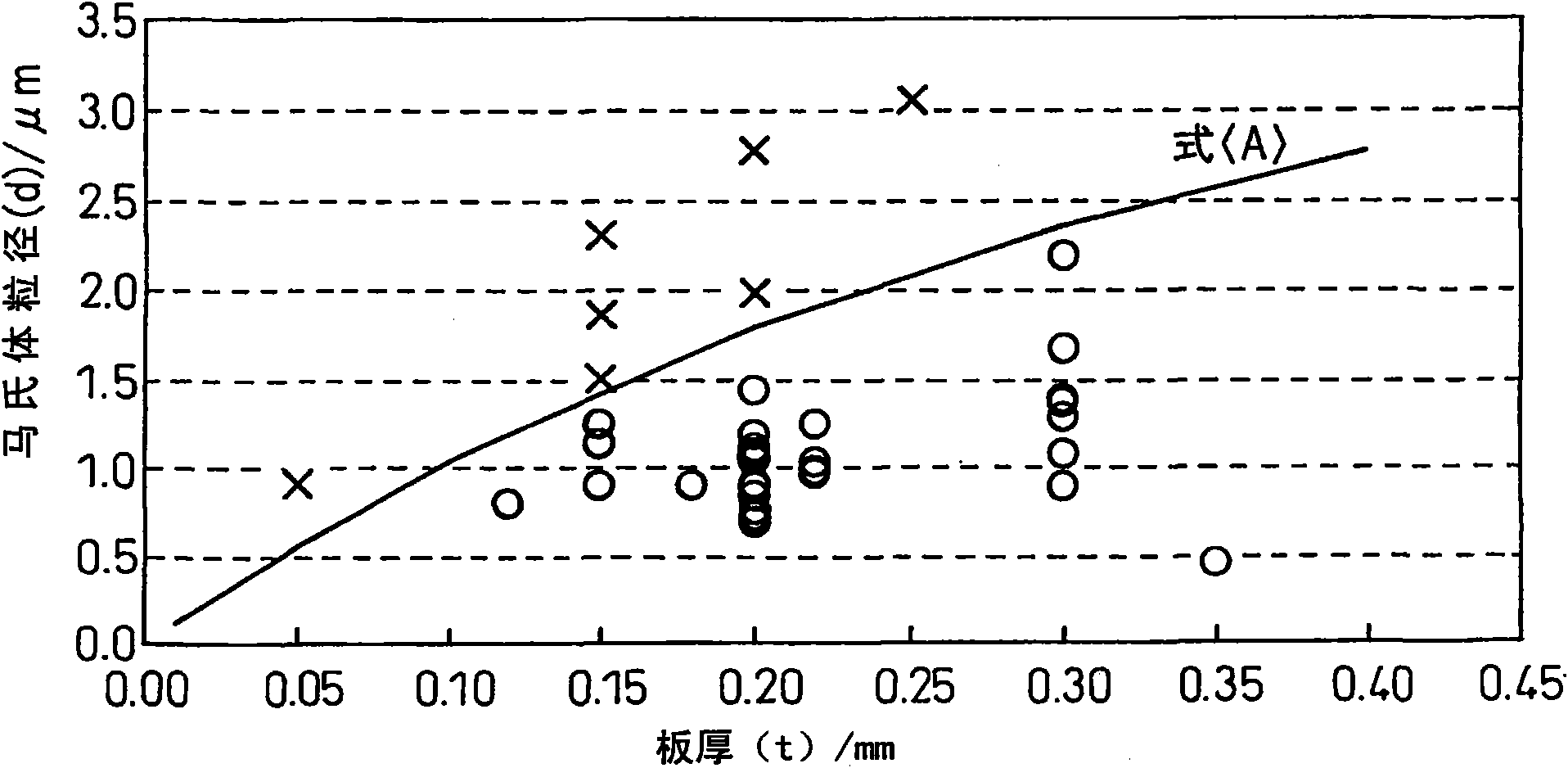

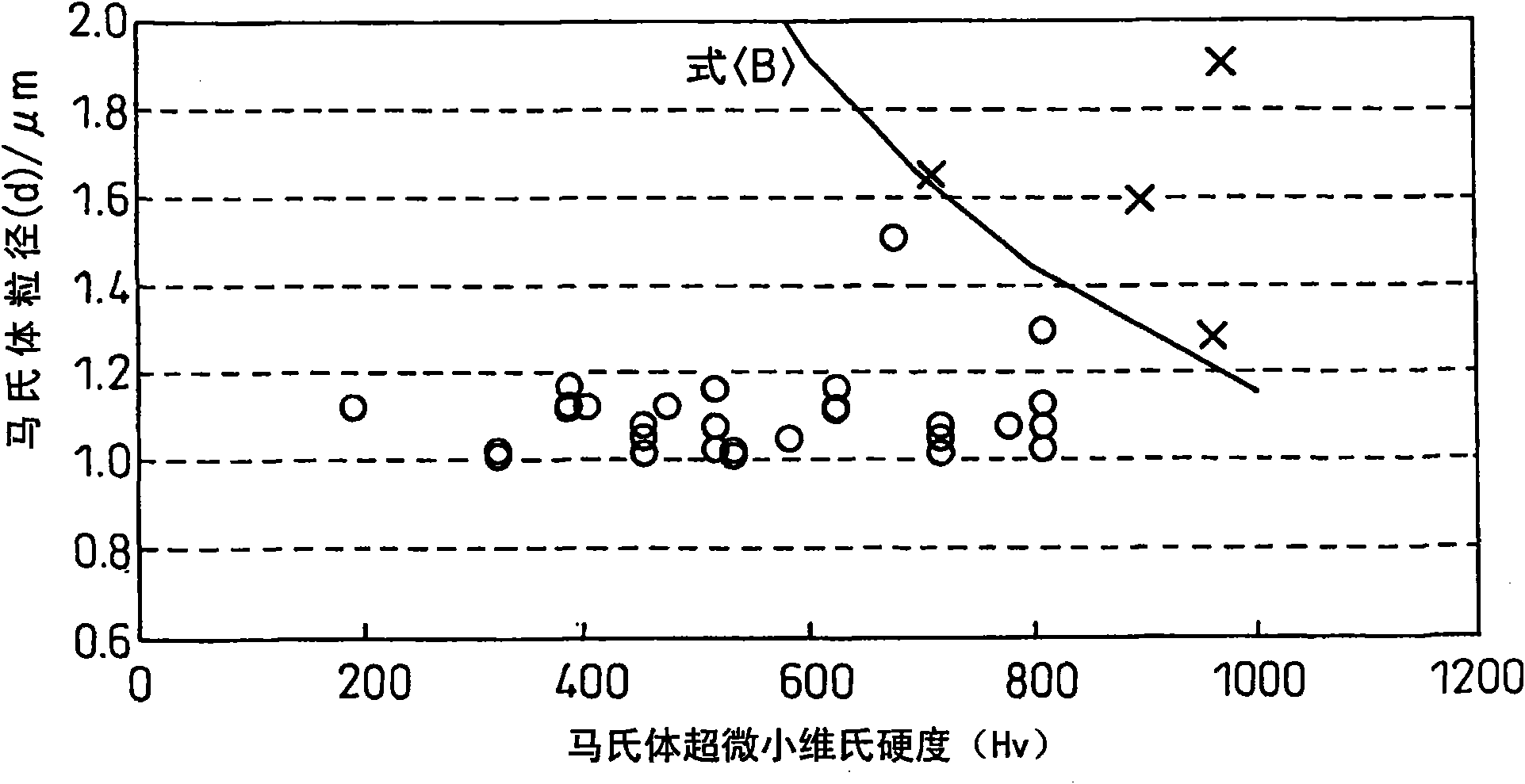

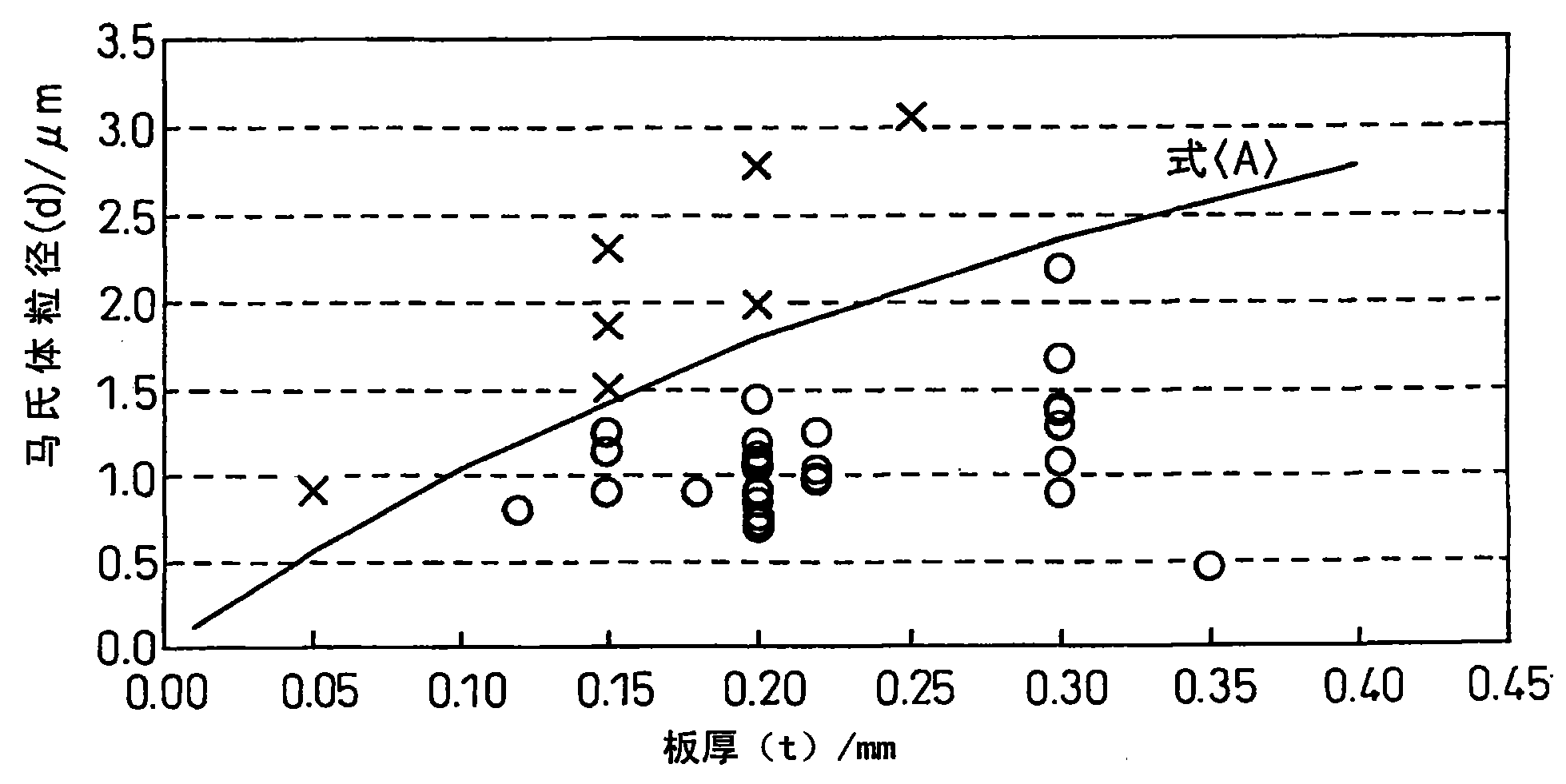

High-strength steel sheet for can manufacturing and process for manufaturing the sheet

ActiveCN101802236AHigh strengthImprove quenching effectFurnace typesHeat treatment furnacesSheet steelHigh intensity

The invention provides a high-strength steel sheet for can manufacturing which is improved in both strength and ductility while clearing the ASTM regulations and is thus excellent in workability. A high-strength steel sheet of 0.1 to 0.5 mm in product sheet thickness (t) for can manufacturing which has a composition containing by mass C: 0.04 to 0.13%, Si: more than 0.01% to 0.03%, Mn: 0.1 to 0.6%, P: 0.02% or below, S: 0.03% or below, Al: 0.01 to 0.2%, and N: 0.001 to 0.02% with the balance consisting of Fe and unavoidable impurities and a ferrite-base ferrite-martensite composite structure, characterized by having a martensite fraction of 5 to less than 30%, satisfying the relationship wherein d is martensite grain diameter ([mu]m) and t is product sheet thickness (mm), and exhibiting a 30T hardness of 60 or above. 1.0 < (1 - EXP(-t x 3.0)) x 4 / d... .

Owner:NIPPON STEEL CORP

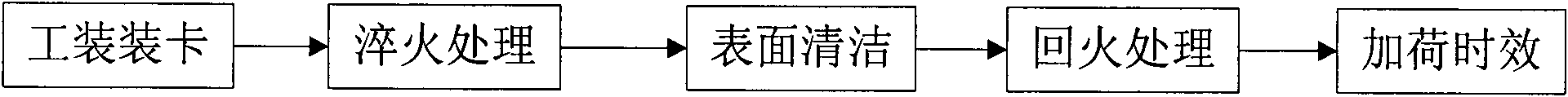

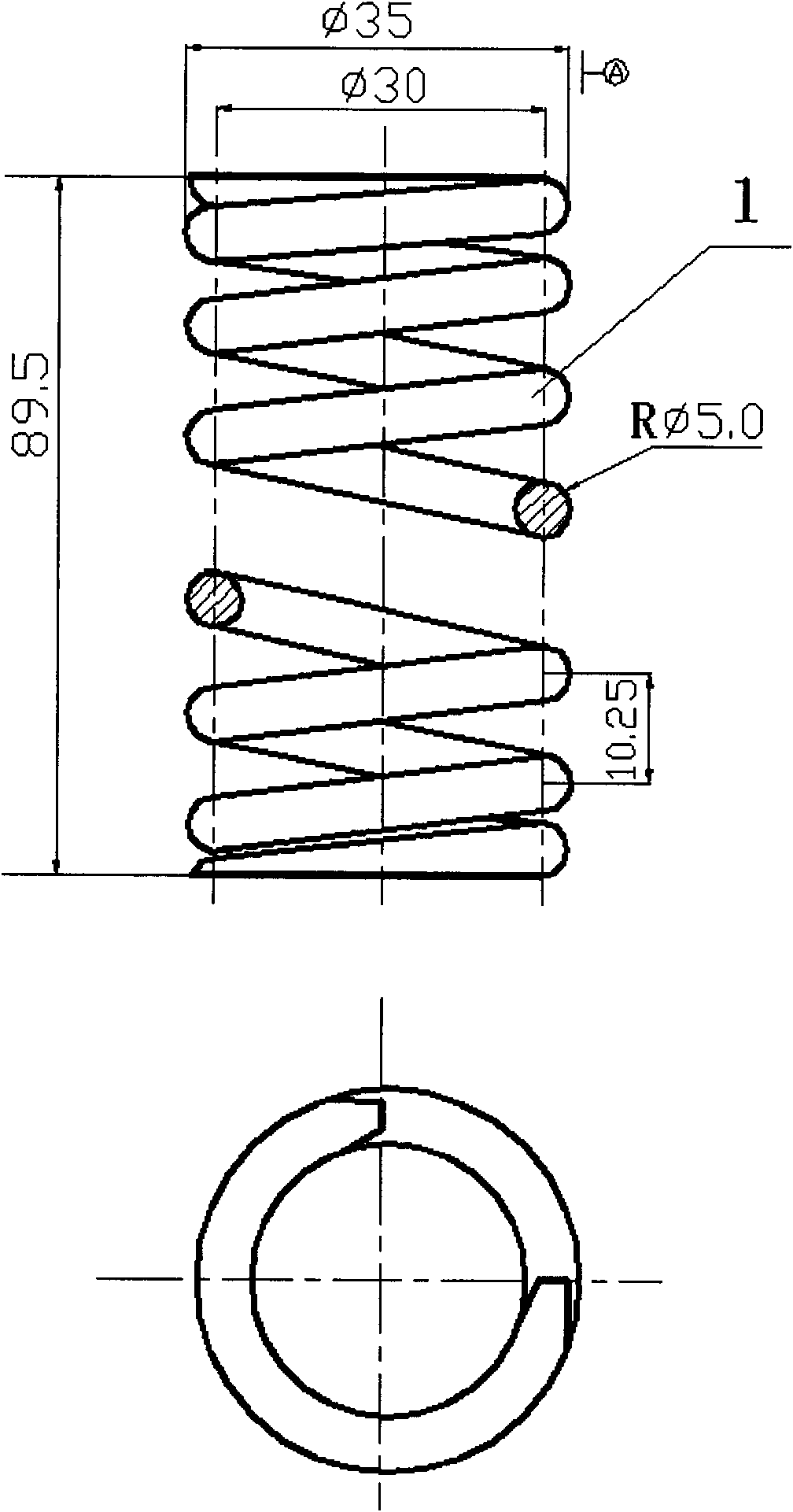

Precise heat treatment method of high-precision elastic element

ActiveCN102134633AAchieve oxidation-free treatmentFull convectionFurnace typesHeat treatment furnacesStress relaxationGraphite particle

The invention relates to a precise heat treatment method of a high-precision elastic element. In the invention, quenching is carried out by adopting a fluidized particle furnace and elastic element quenching treatment equipment, wherein graphite particles are used as a heating medium and optimized design is carried out on the quenching temperature, the heat preservation time and the cooling manner so that the non-oxidation quenching treatment of the high-precision elastic element is realized and the surface quality and the size precision of the high-precision elastic element are improved; according to the quenching rigidity of the high-precision elastic element, proper technological parameters are selected to carry out tempering treatment; and loading ageing treatment is conducted to the element by adopting elastic element loading treatment equipment so that the stress relaxation property of the elastic element is improved, the stress in the winding process is reduced and the micro-yield strength is effectively improved. Through the heat treatment method of the invention, the high-precision elastic element is free of oxidation on the surface, free of deformation on the size and stable in mechanical property after the quenching, and the reliability and the quality of the heat treatment of the high-precision elastic element are improved.

Owner:BEIJING SATELLITE MFG FACTORY

Heat treatment technique for bolts

InactiveCN107435088AThe process steps are simpleEasy to operateSolid state diffusion coatingFurnace typesThreaded fastenerQuenching

The invention discloses a bolt heat treatment process, which comprises the following steps: dephosphorization, pretreatment, quenching, oil cooling, degreasing and tempering steps. The heat treatment process of the bolts of the present invention has simple steps, easy operation, and good quenching effect. The air in the preheating furnace and the quenching furnace can be removed by introducing nitrogen gas, so as to avoid the oxidation reaction between oxygen and the product, thereby avoiding the occurrence of decarburization. The failure of threaded fasteners prolongs the service life of the product, and the staged heating and quenching treatment can make the quenching effect of the product better and improve the quality of the product.

Owner:JIANGSU YONGHAO HIGH STRENGTH BOLT

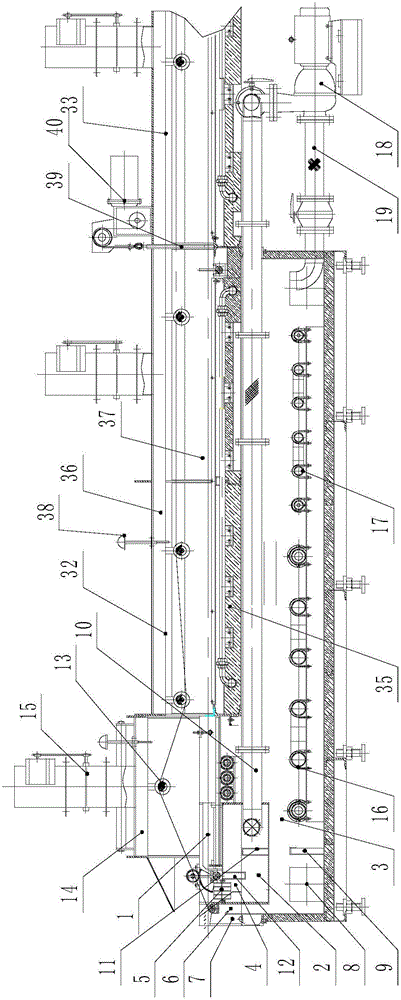

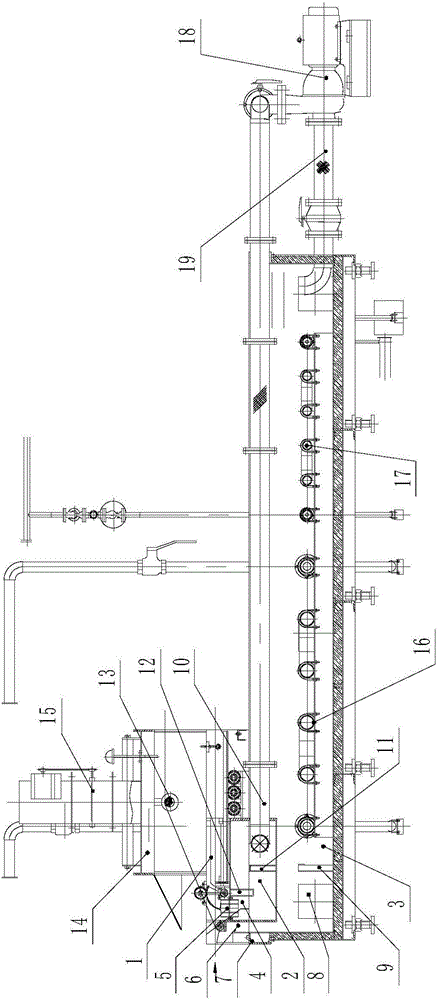

Steel wire water bathing and air cooling quenching unit

ActiveCN105803166AImprove water bath quenching effectImprove stabilityFurnace typesHeat treatment process controlQuenchingAir cooling

The invention discloses a steel wire water bathing and air cooling quenching unit which comprises a water bathing quenching unit body and an air cooling quenching unit body. The air cooling quenching unit body is arranged on the downstream portion of the water bathing quenching unit body, and the air cooling quenching unit body and the water bathing quenching unit body are in mutual linkage. The water bathing quenching unit body is provided with a plurality of water baths, the length of the water baths is controlled through movable baffles capable of moving, and accordingly the water bathing quenching time for steel wires is controlled. The air cooling quenching unit body can control the temperature independently and intelligently, and the influences of the environment temperature on air cooling are reduced. According to the water bathing and air cooling quenching unit, the quenching time and quenching length can be adjusted freely, and products with different specifications and strengths can be produced at the same time; and in addition, the water bathing and air cooling quenching unit can control the temperature independently, so that the steel wires are quenched within the required quenching temperature range all the time, the quenching effect of the steel wires is improved, and the stability of mechanical properties of the steel wires is guaranteed.

Owner:ZHANGJIAGANG DONGHANG MACHINERY

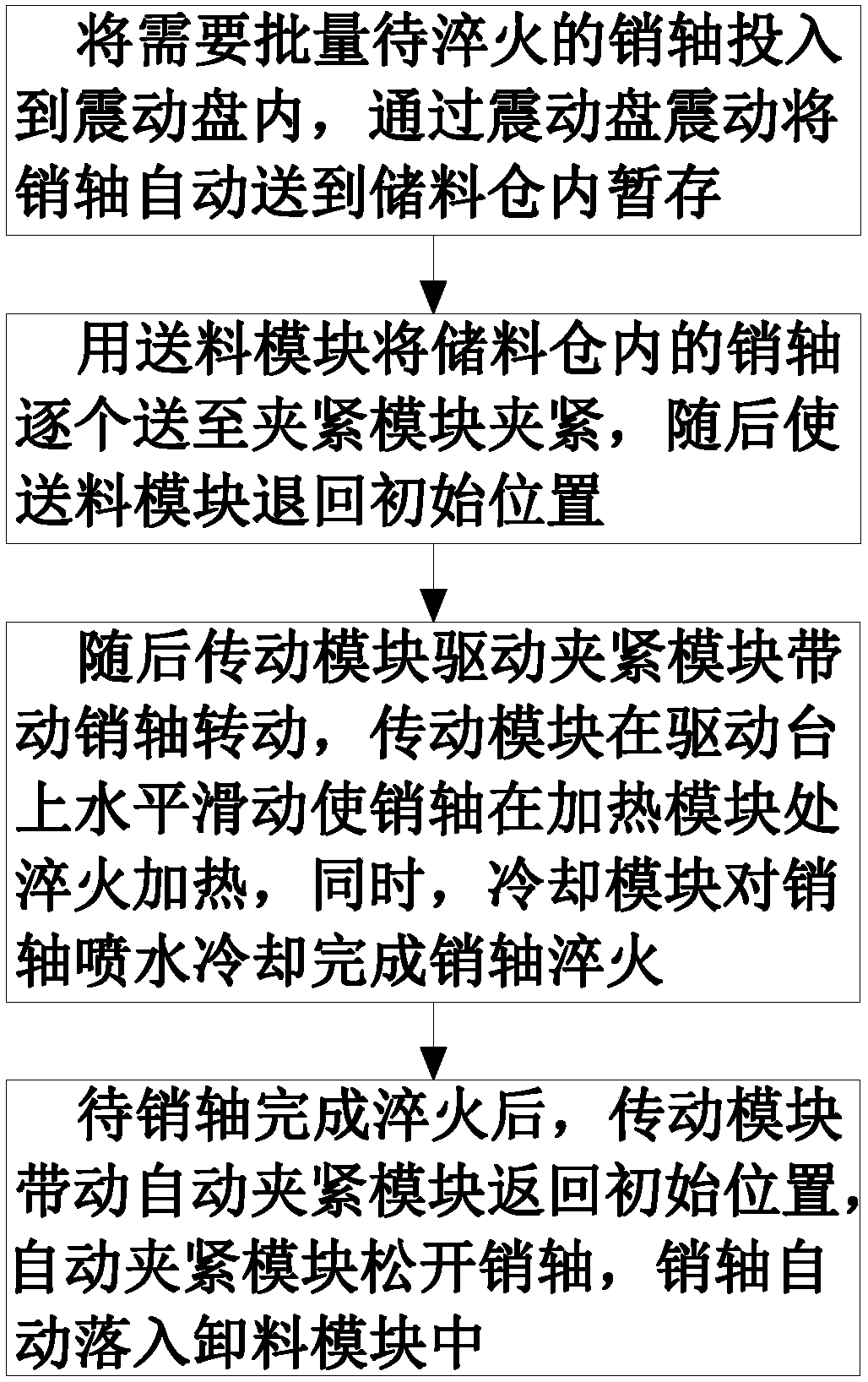

Pin shaft quenching method

ActiveCN108531704AImprove quenching efficiencyContinuous and stable deliveryIncreasing energy efficiencyFurnace typesQuenchingHeat treated

The invention relates to the technical field of pin shaft heat treatment, in particular to a pin shaft quenching method. The pin shaft quenching method comprises the following steps that to-be-quenched pin shafts are put into a storage bin to be temporarily stored, the pin shafts in the storage bin are fed to a clamping module to be clamped one by one through a feeding module, and then the feedingmodule returns back to the initial position; and a transmission module drives the clamping module to drive the pin shafts to rotate, the transmission module horizontally slides on a driving platformto enable the pin shafts to be quenched and heated at a heating module, at the same time, a cooling module sprays water to cool the pin shafts, pin shaft quenching is completed, the transmission module drives the automatic clamping module to return to the initial position, the automatic clamping module loosens the pin shafts, and the pin shafts automatically fall into a discharging module. According to the pin shaft quenching method, the pin shaft quenching method is improved through an automatic induction pin shaft quenching machine, therefore, full automation is achieved in the pin shaft quenching process, manual operation is not needed, and the pin shaft quenching efficiency and the pin shaft overall quality are improved.

Owner:ANHUI JIXI HUISHAN CHAIN TRANSMISSION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com