Workpiece quenching machine tool and quenching machine thereof

A technology for quenching machine tools and workpieces, applied in the field of workpiece quenching, can solve the problems of poor quenching process effect, inability to meet different hardness requirements, unreasonable structural design of quenching devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further elaborated below in conjunction with the accompanying drawings.

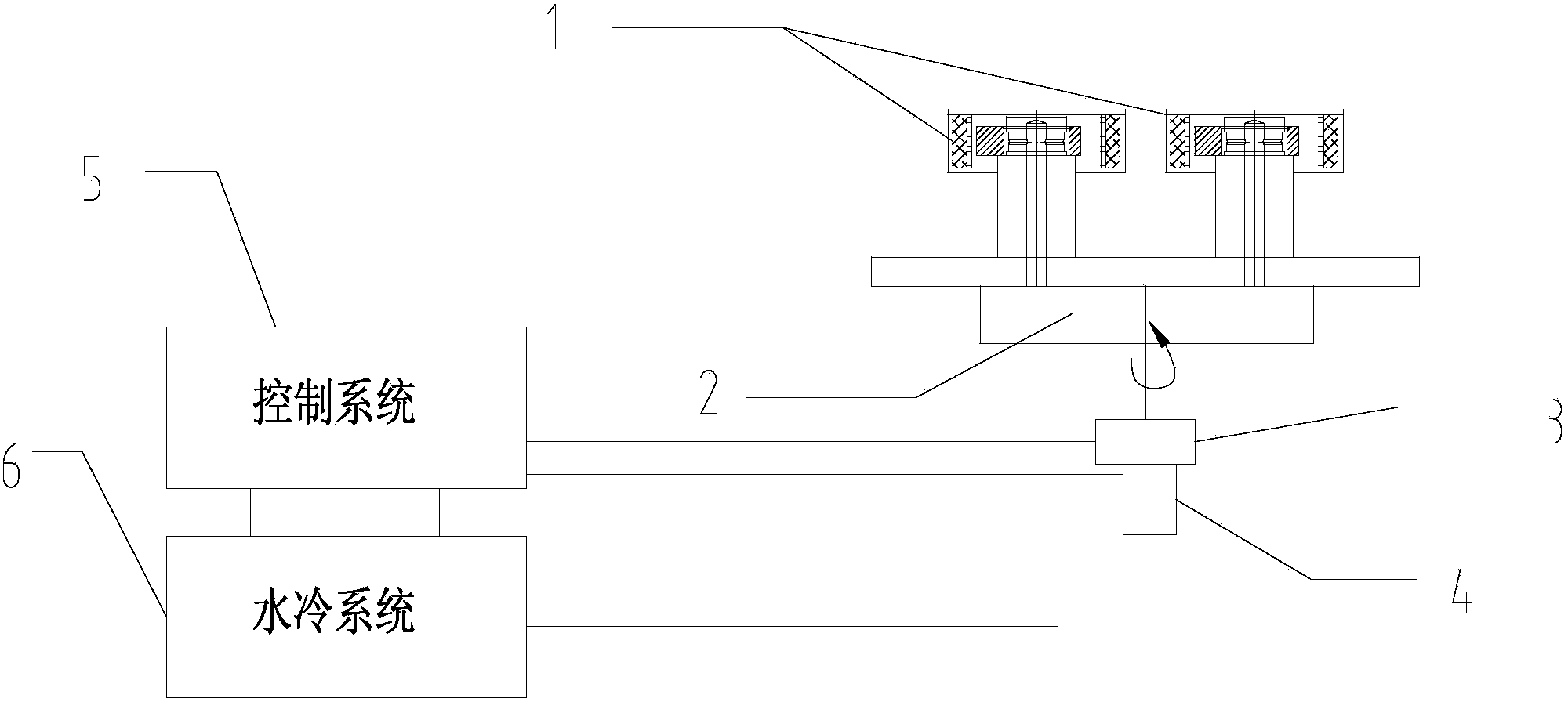

[0018] Such as figure 1 as shown, figure 1 A schematic structural diagram of an embodiment of the present invention is shown. The workpiece quenching machine tool of the present invention includes a bed body; the bed body is the connecting body of each component, and the structure of the bed body is designed in a form in which a moving fixture system can control the lifting as required. In this embodiment, a quenching system is provided on the bed; the quenching system includes a high-frequency power supply and a quenching coil 1, and the high-frequency power supply is connected to the quenching coil. The number of quenching coils can be determined according to the number of workpieces such as cam pieces that need to be quenched at a time. One cam piece can be quenched at a time, or two cam pieces can be quenched at the same time, or three, four or More cam pieces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com