Multi-functional ultrasonic vibration cutting mechanism

An ultrasonic vibration cutting, multi-functional technology, applied in the field of machinery, can solve the problems of inability to meet the requirements of cutting depth, single function, fixed amplitude, etc., and achieve the effect of ingenious structure, multi-function and wide use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

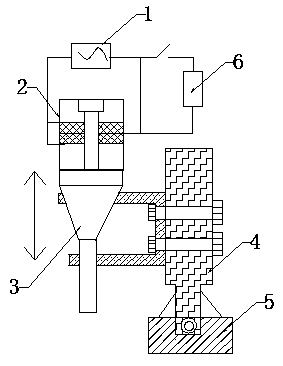

[0020] A multifunctional ultrasonic vibration cutting mechanism, comprising: an ultrasonic signal source 1, a transducer 2, a horn 3, a vibrating tool rest 4 and a cutter 5; the ultrasonic signal source 1 and the transducer 2 pass through The amplifying circuit is connected, the horn 3 is connected with the transducer 2, the vibrating tool rest 4 is fixed on one side of the horn 3 in parallel, and the cutter 5 is installed at the bottom end thereof;

[0021] The amplifying circuit is also connected in parallel with a voltage dividing circuit with a voltage dividing resistor 6 connected in series. The voltage dividing resistor 6 is a digital voltage dividing resistor with an adjustable resistance value, and can also be a plurality of resistors connected in parallel with a fixed resistance value. By adjusting the resistance value on the voltage divider circuit, the voltage value added to the transducer 2 by the amplifying circuit is changed, thereby adjusting the vibration amplit...

Embodiment 2

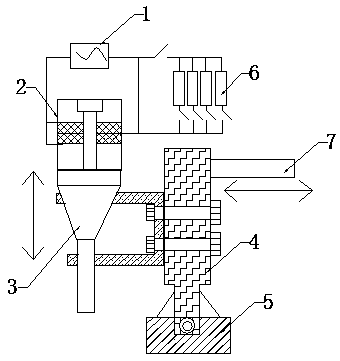

[0023] A multifunctional ultrasonic vibration cutting mechanism, comprising: an ultrasonic signal source 1, a transducer 2, a horn 3, a vibrating tool rest 4, a cutter 5 and a telescopic movement mechanism 7; the ultrasonic signal source 1 and the transducer The amplifiers 2 are connected through an amplifying circuit, the horn 3 is connected to the transducer 2, the vibrating tool holder 4 is fixed on one side of the horn 3 in parallel, and the cutter 5 is installed at the bottom end thereof;

[0024] The amplifying circuit is also connected in parallel with a voltage dividing circuit with a voltage dividing resistor 6 connected in series. The voltage dividing resistor 6 is a digital voltage dividing resistor with an adjustable resistance value, and can also be a plurality of resistors connected in parallel with a fixed resistance value. By adjusting the resistance value on the voltage divider circuit, the voltage value added to the transducer 2 by the amplifying circuit is ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com