Patents

Literature

162results about How to "Change depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

electrical connector

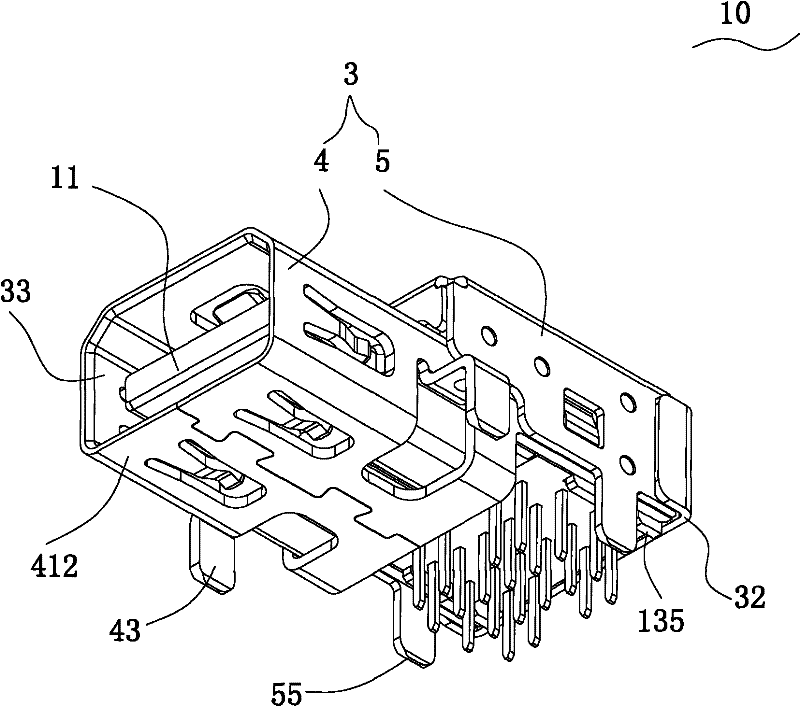

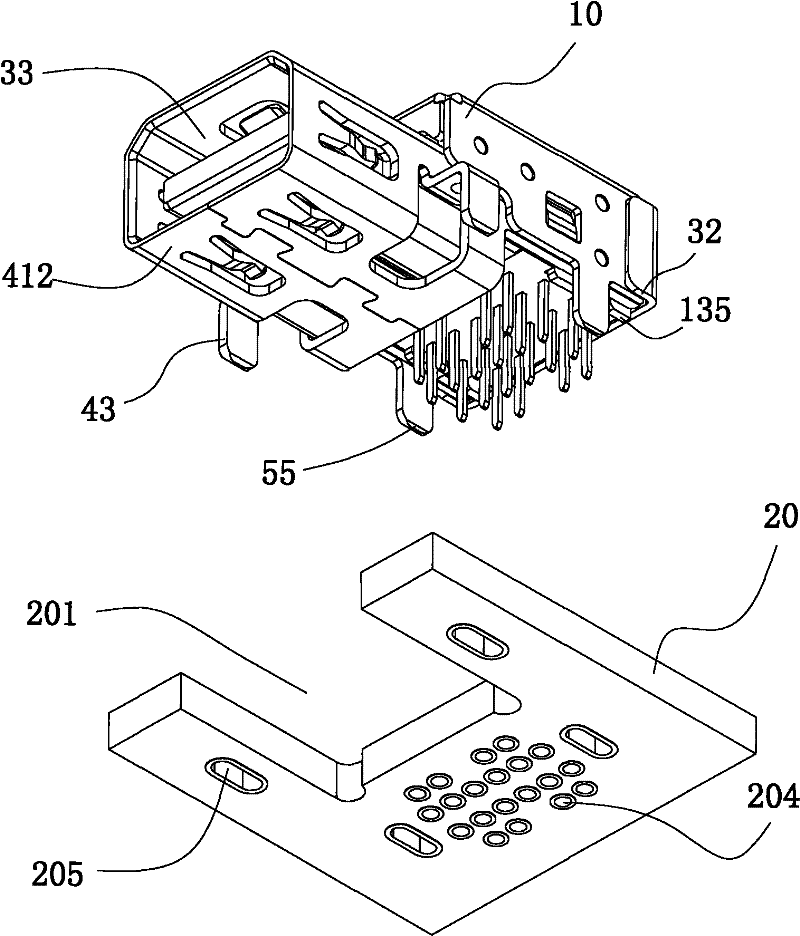

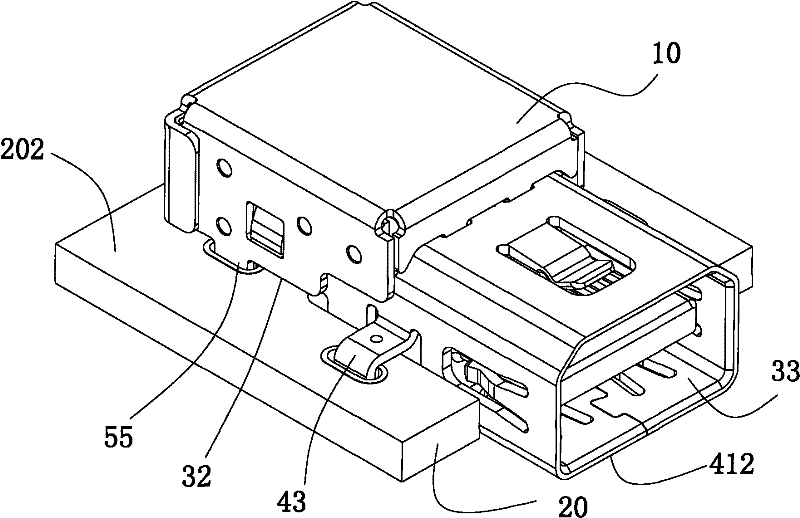

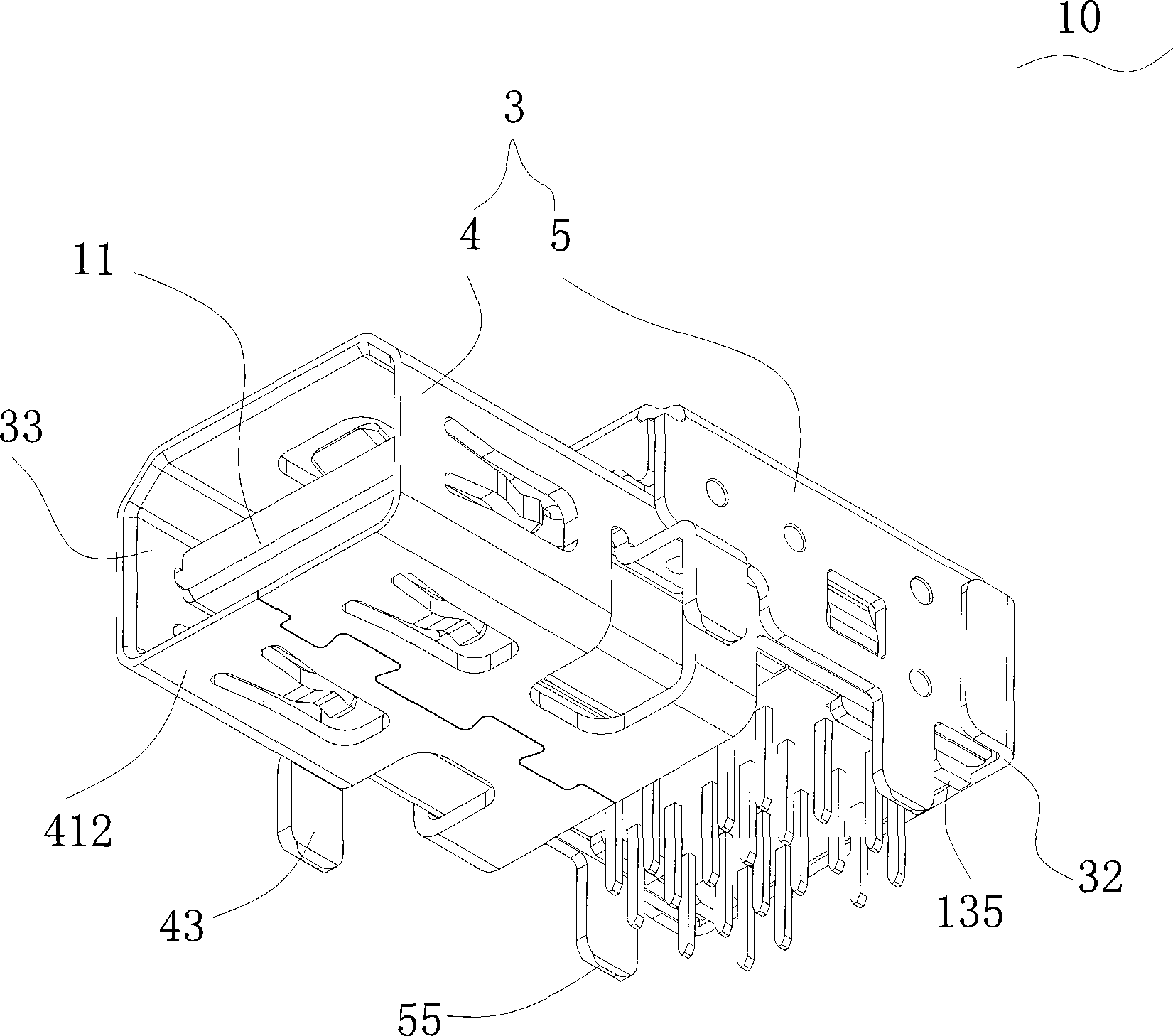

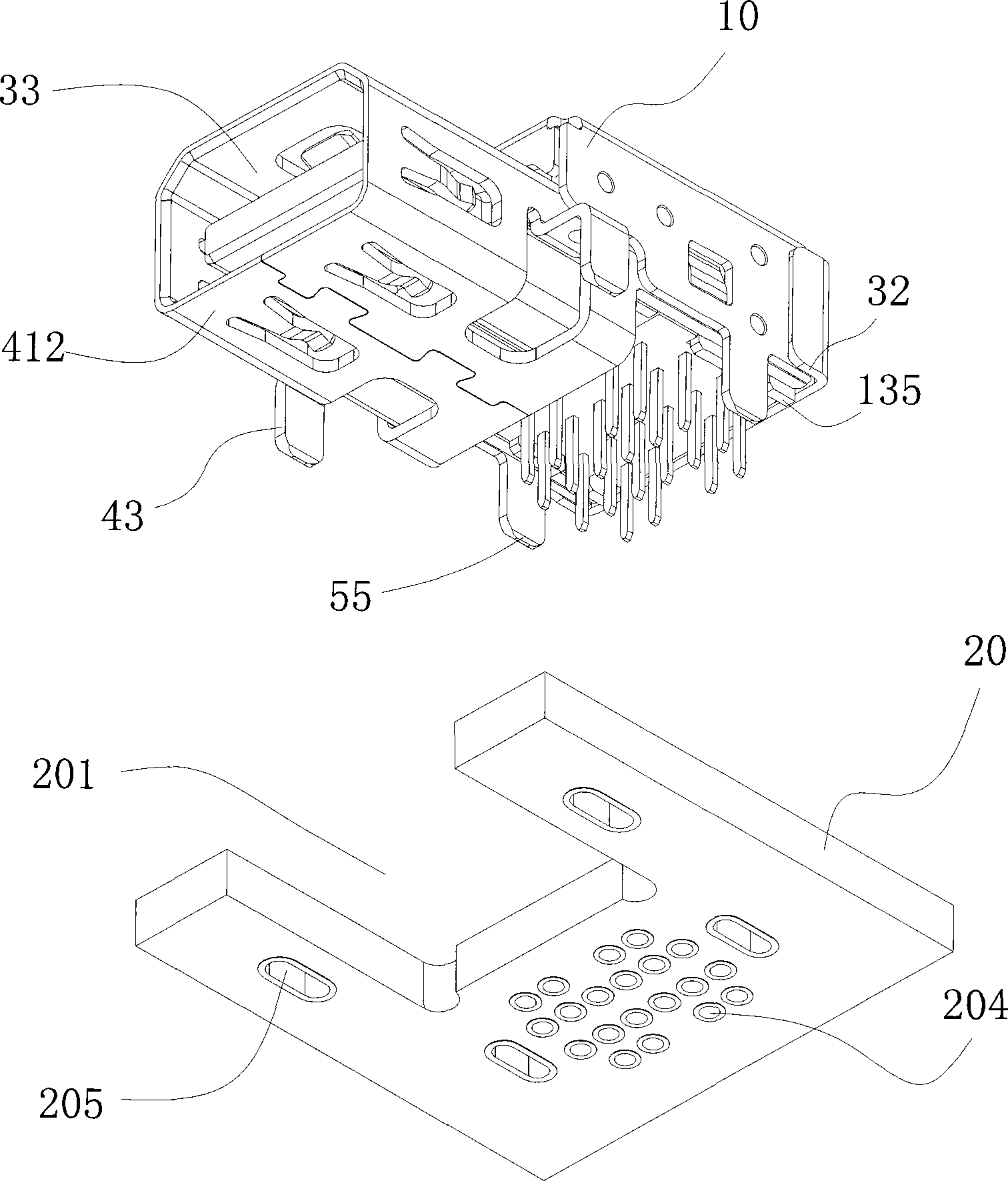

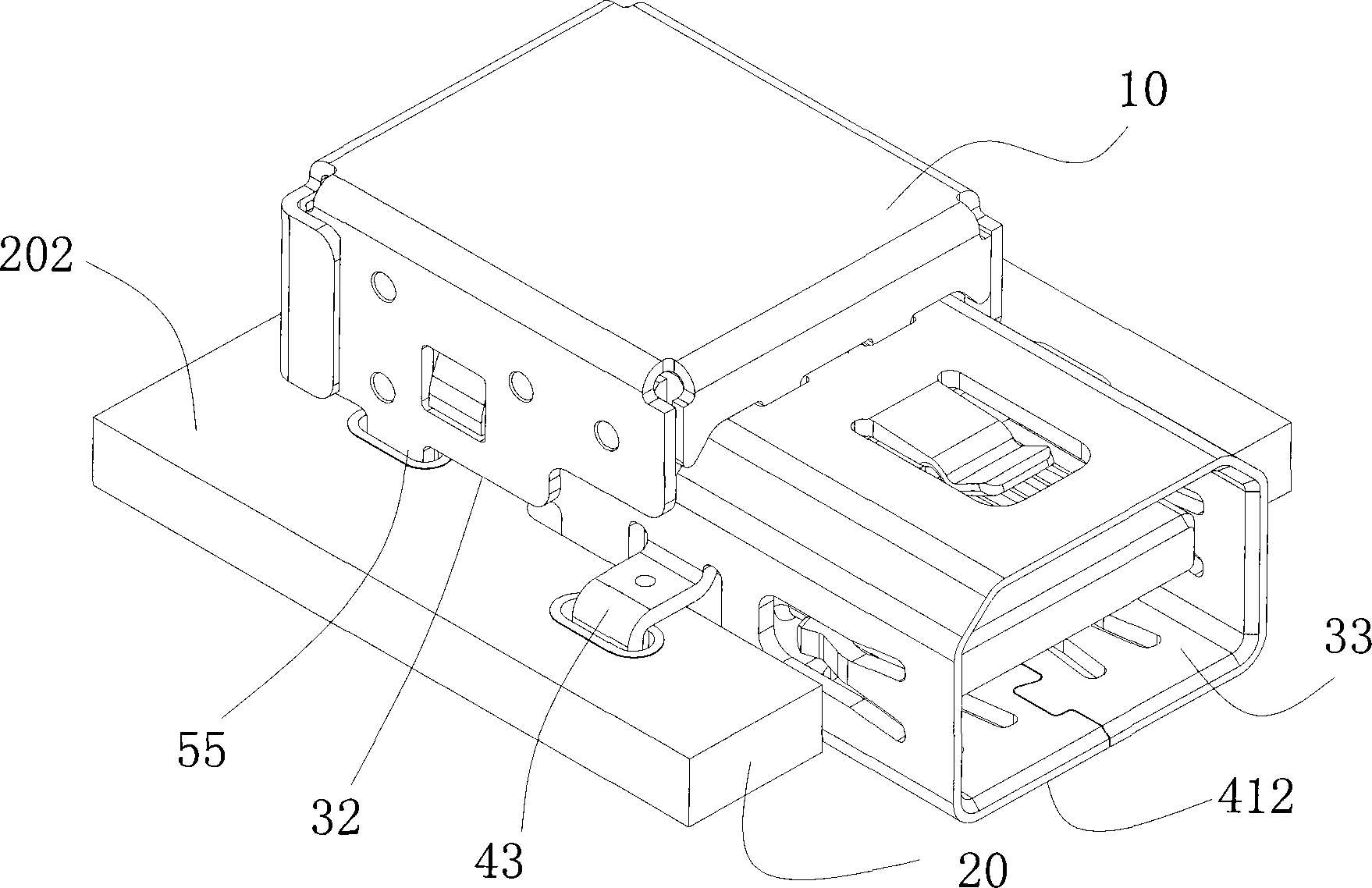

InactiveCN102280732AFixed uniformLower the altitudeSecuring/insulating coupling contact membersCoupling contact membersEffective heightEngineering

An electrical connector includes a body with a tongue and the body supports a terminal module, the terminal module including a first row of terminals and a second row of terminals. Each terminal includes a contact portion and a soldering portion, the contact portions of the first and second row of terminals being disposed on an upper side and a lower side of the tongue, respectively, and the soldering portions of the first and second row of terminals each being arranged in a front column and a back column. A first and second positioning element can support the first and second rows of terminals, respectively. A shield that envelopes a periphery of the insulating body forms a contact chamber for accommodating the tongue. The front portion of the shield can be recessed into the circuit board to reduce the effective height of the connector and circuit board.

Owner:MOLEX INTERCONNECT SHANGHAI +1

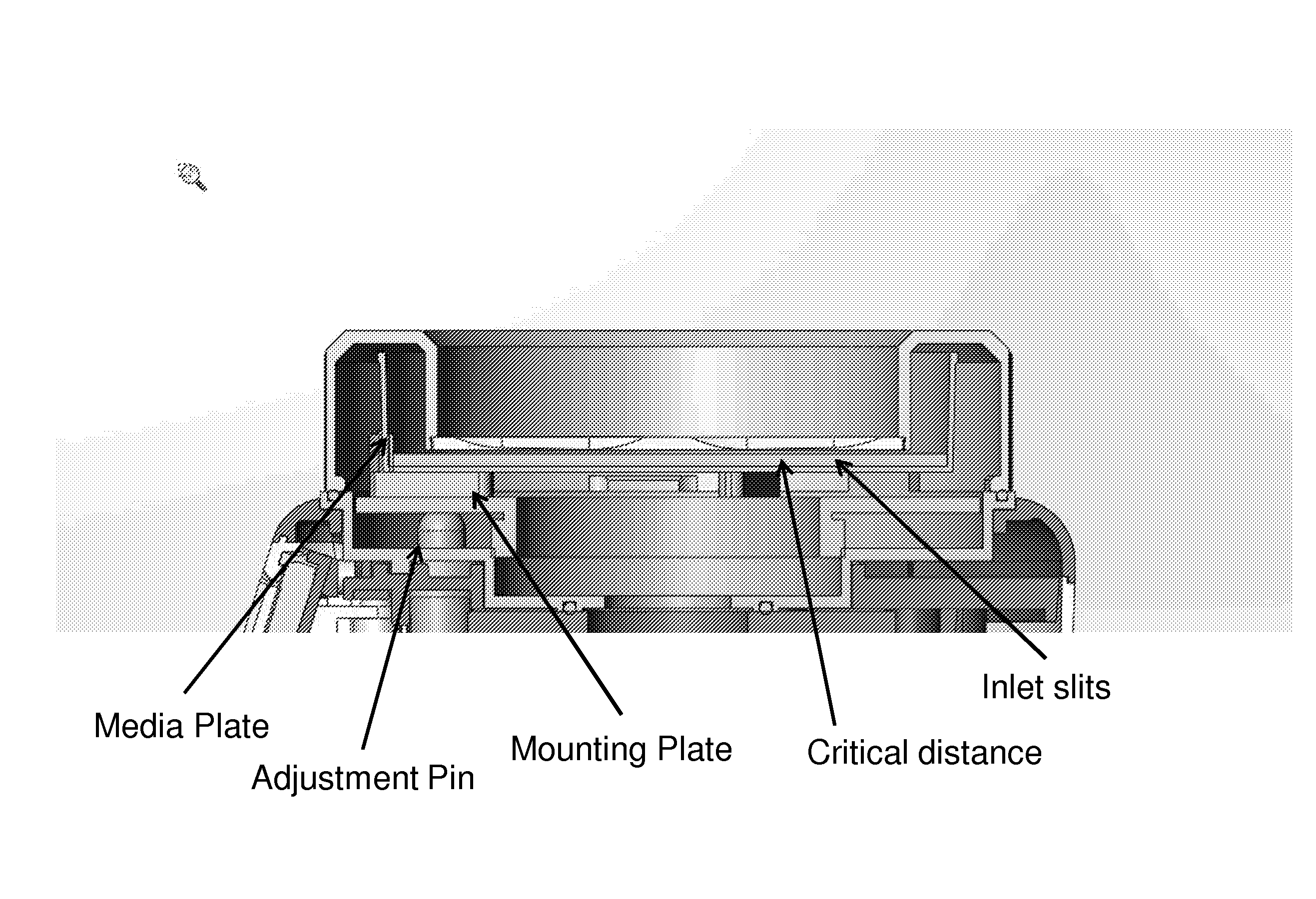

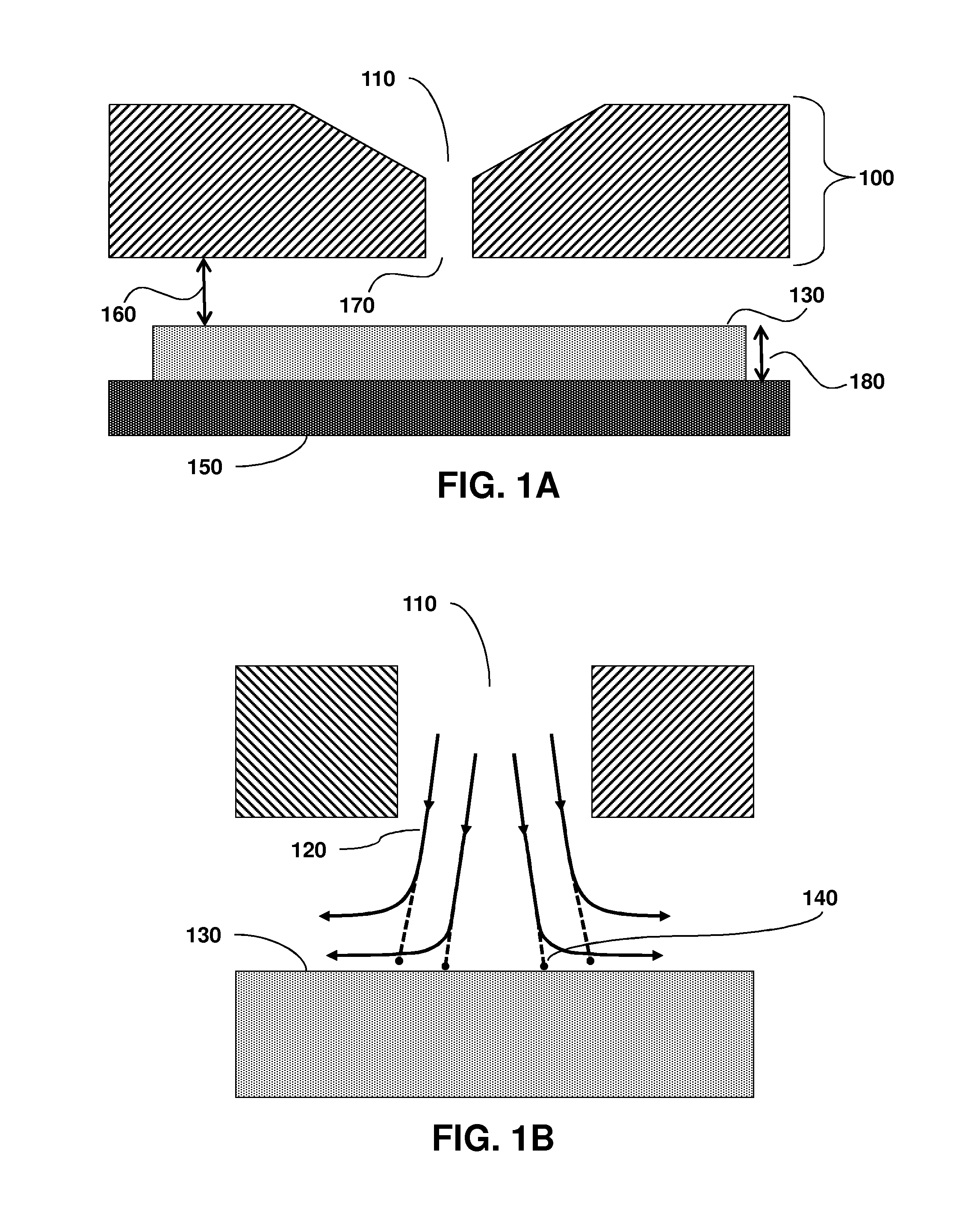

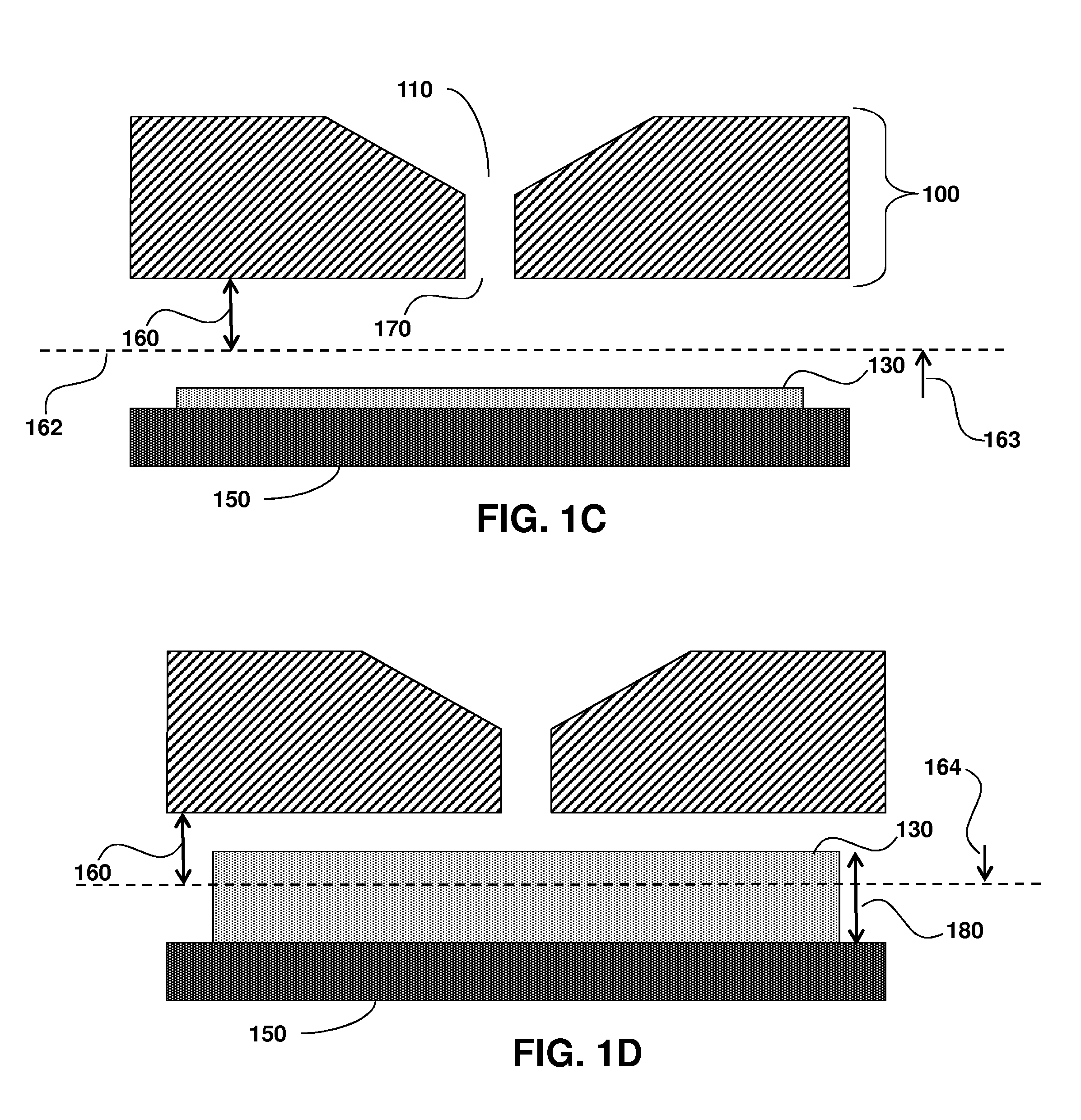

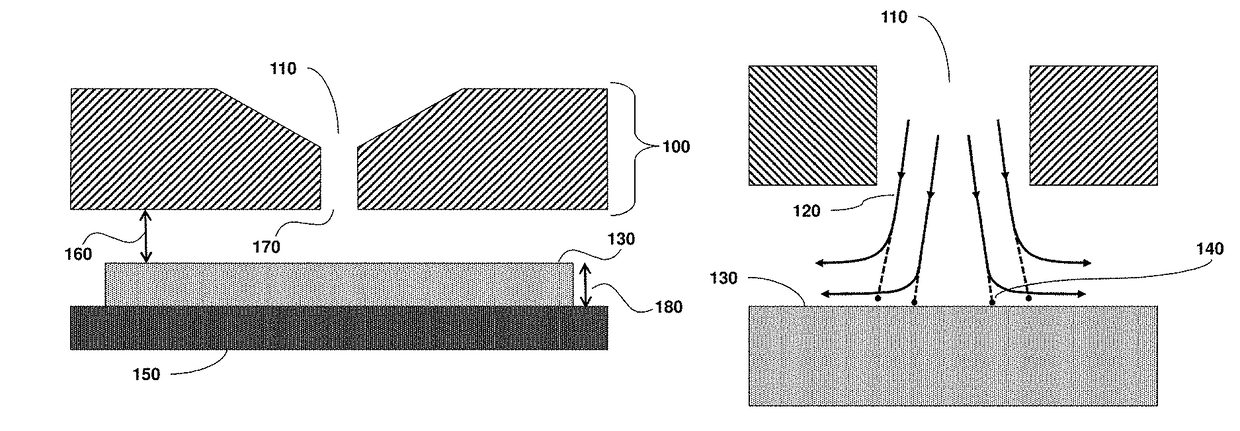

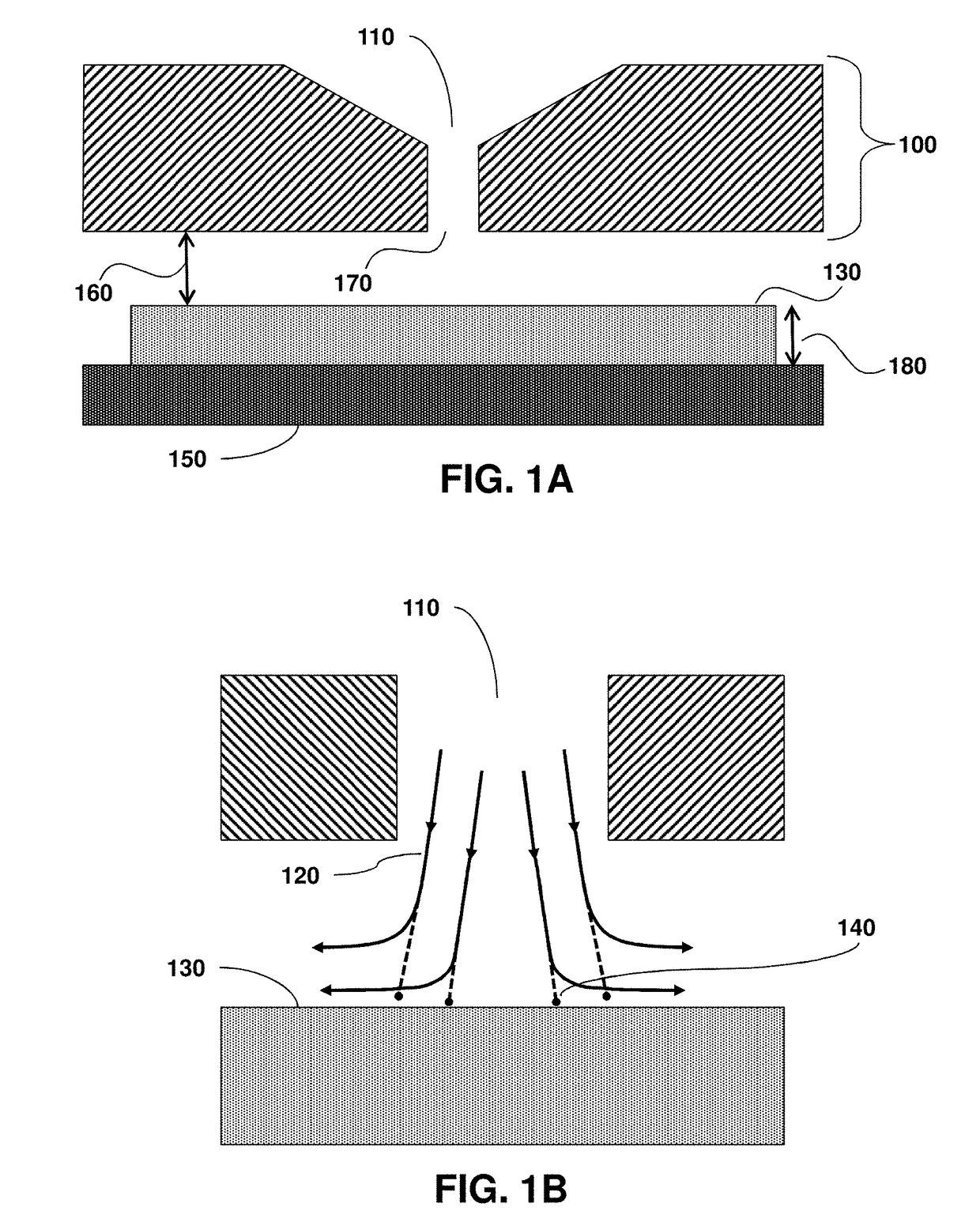

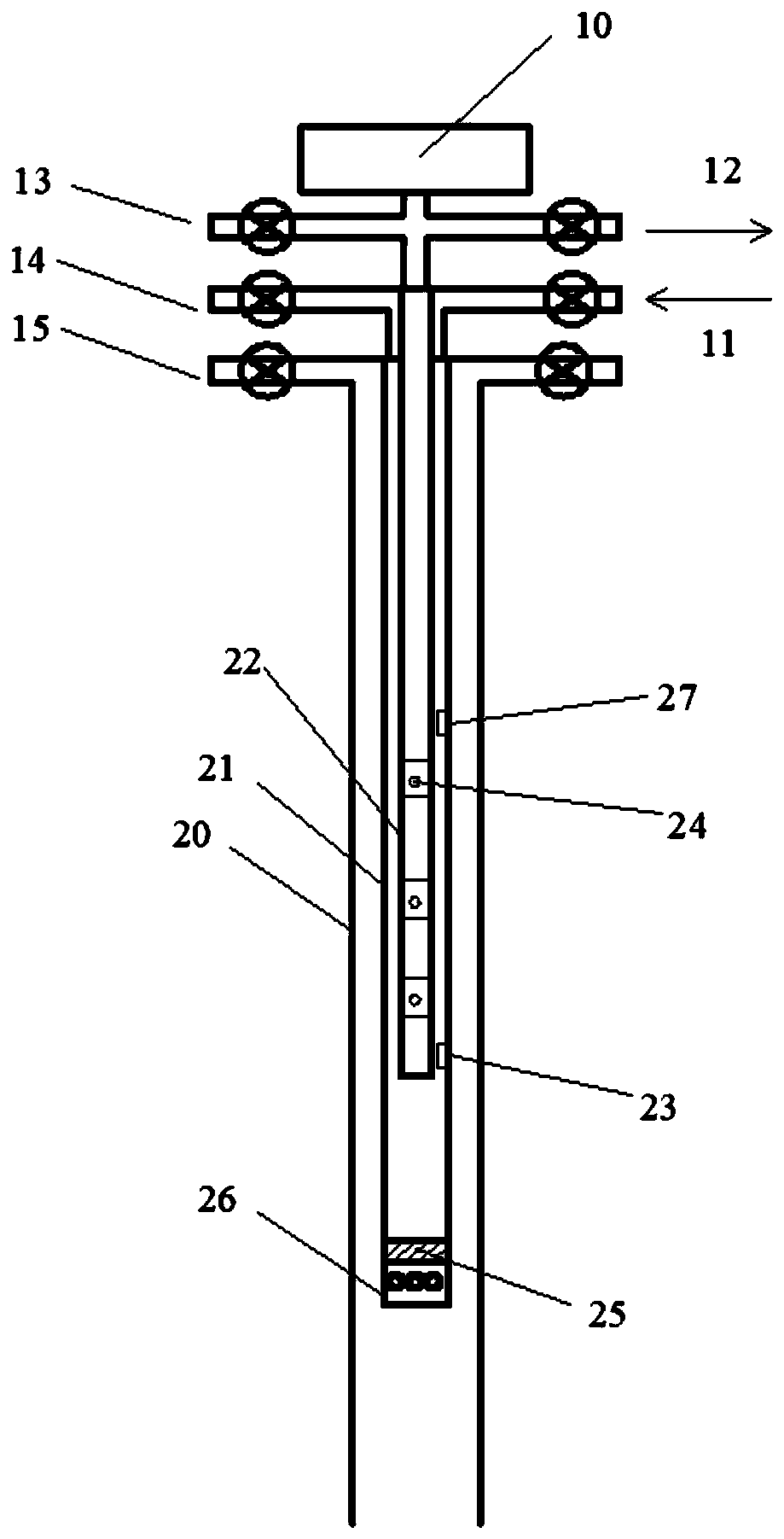

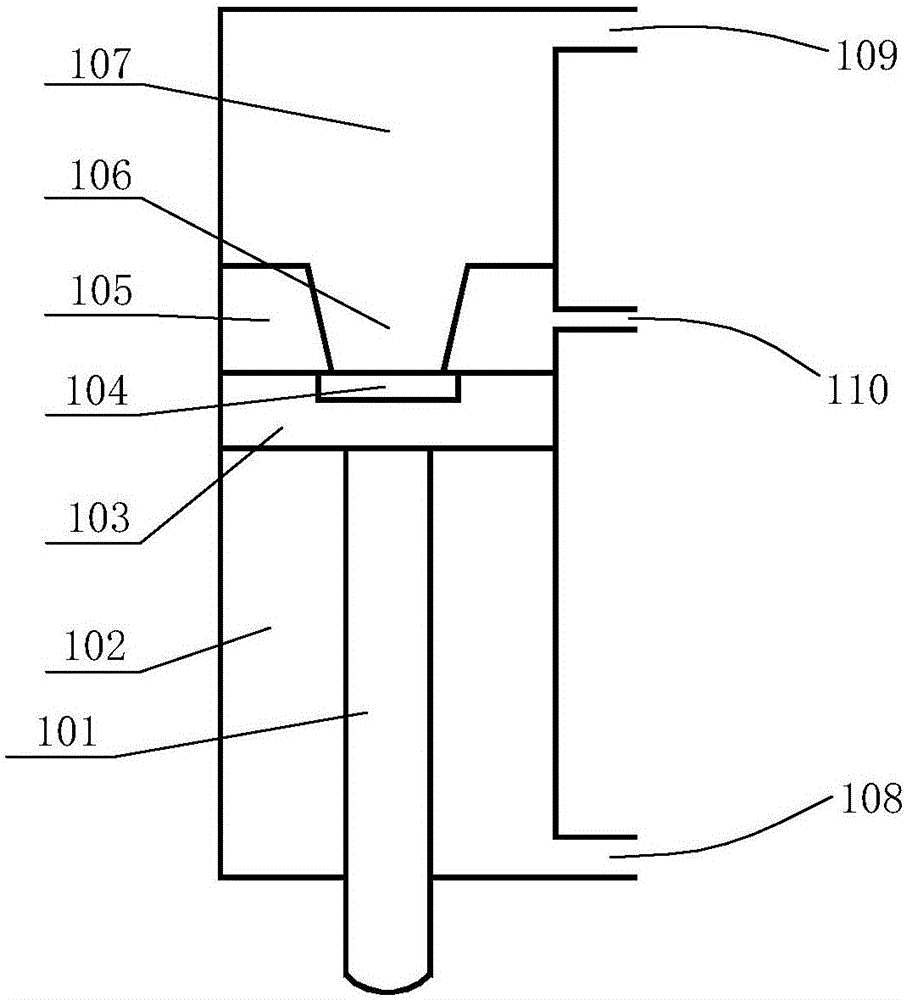

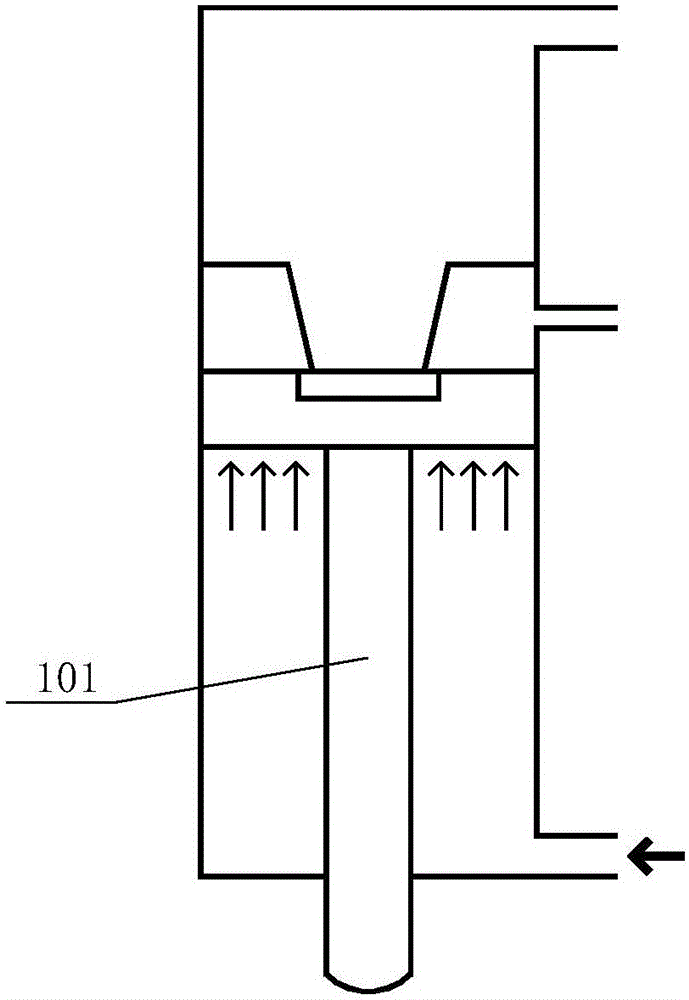

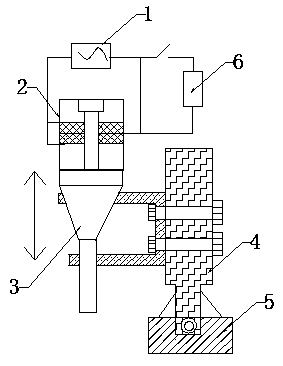

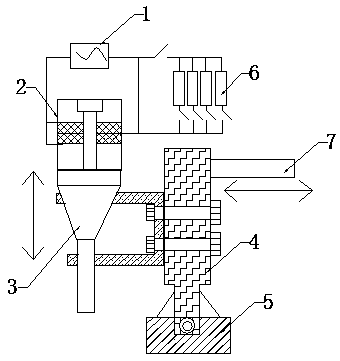

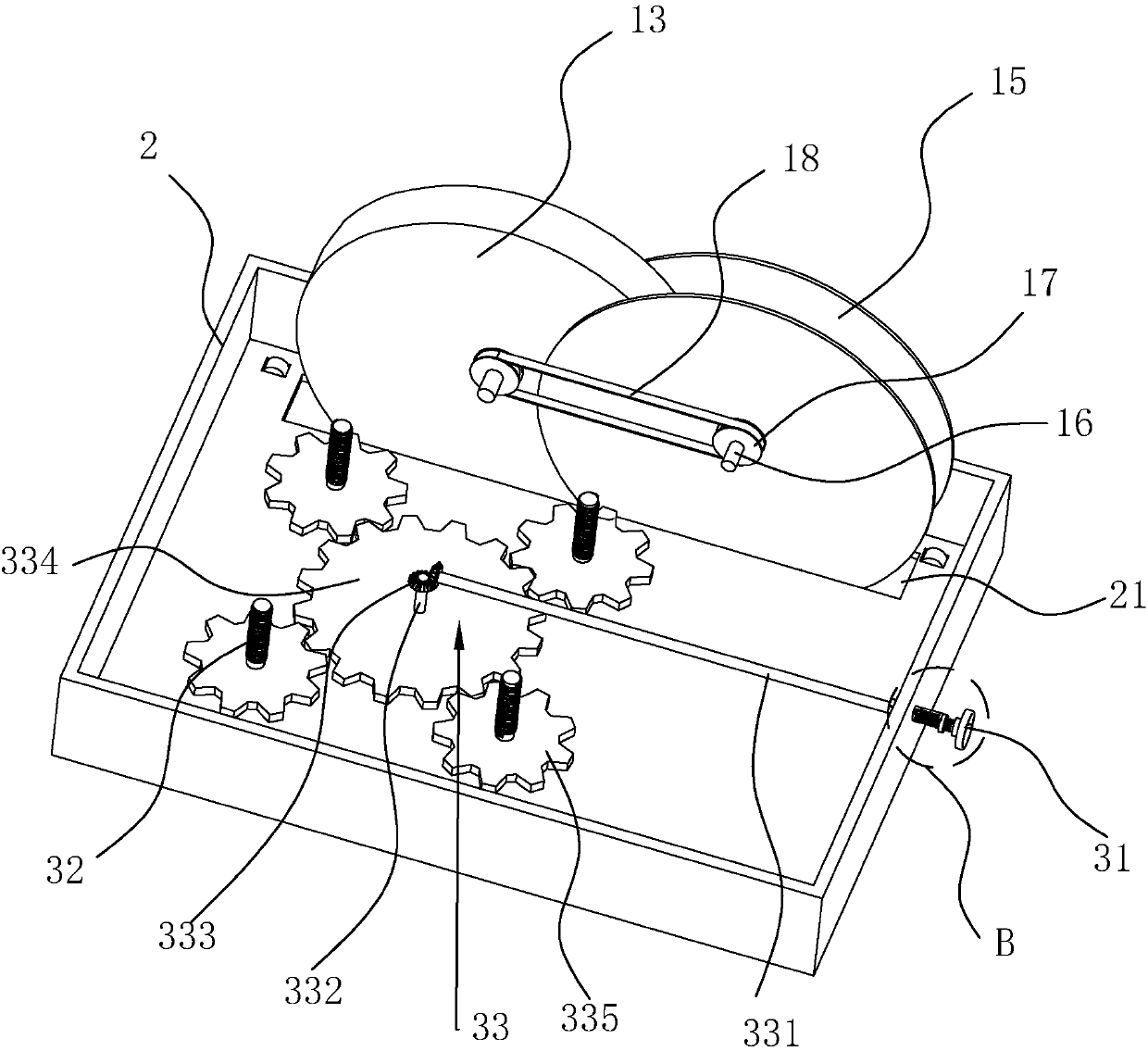

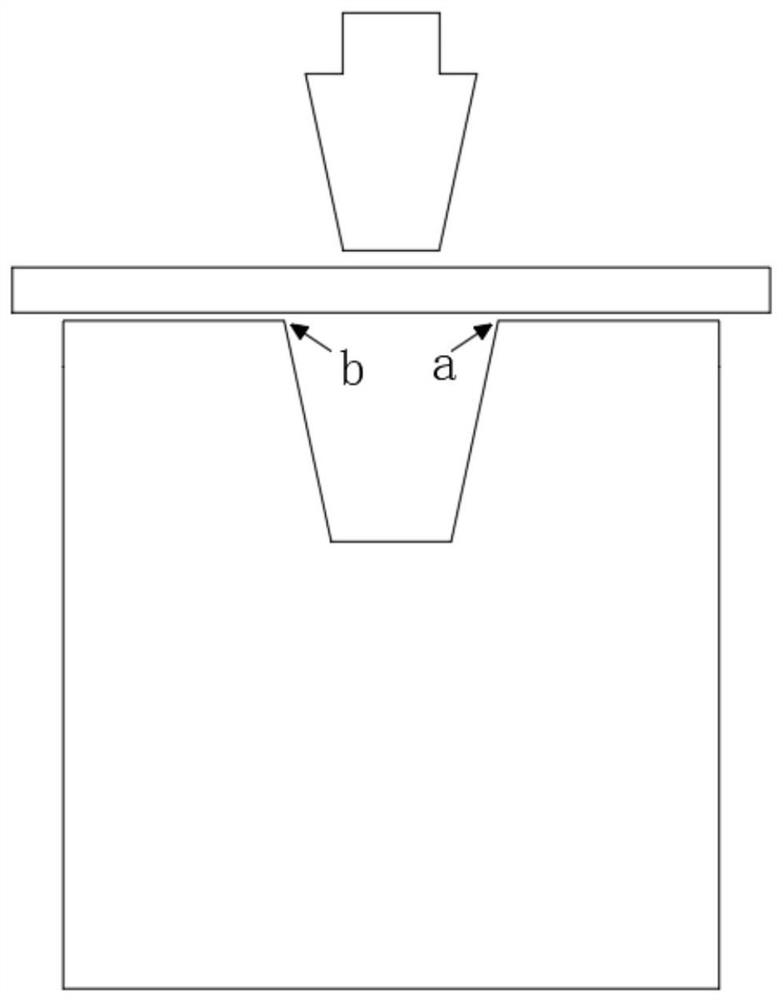

Particle impactor with selective height adjustment

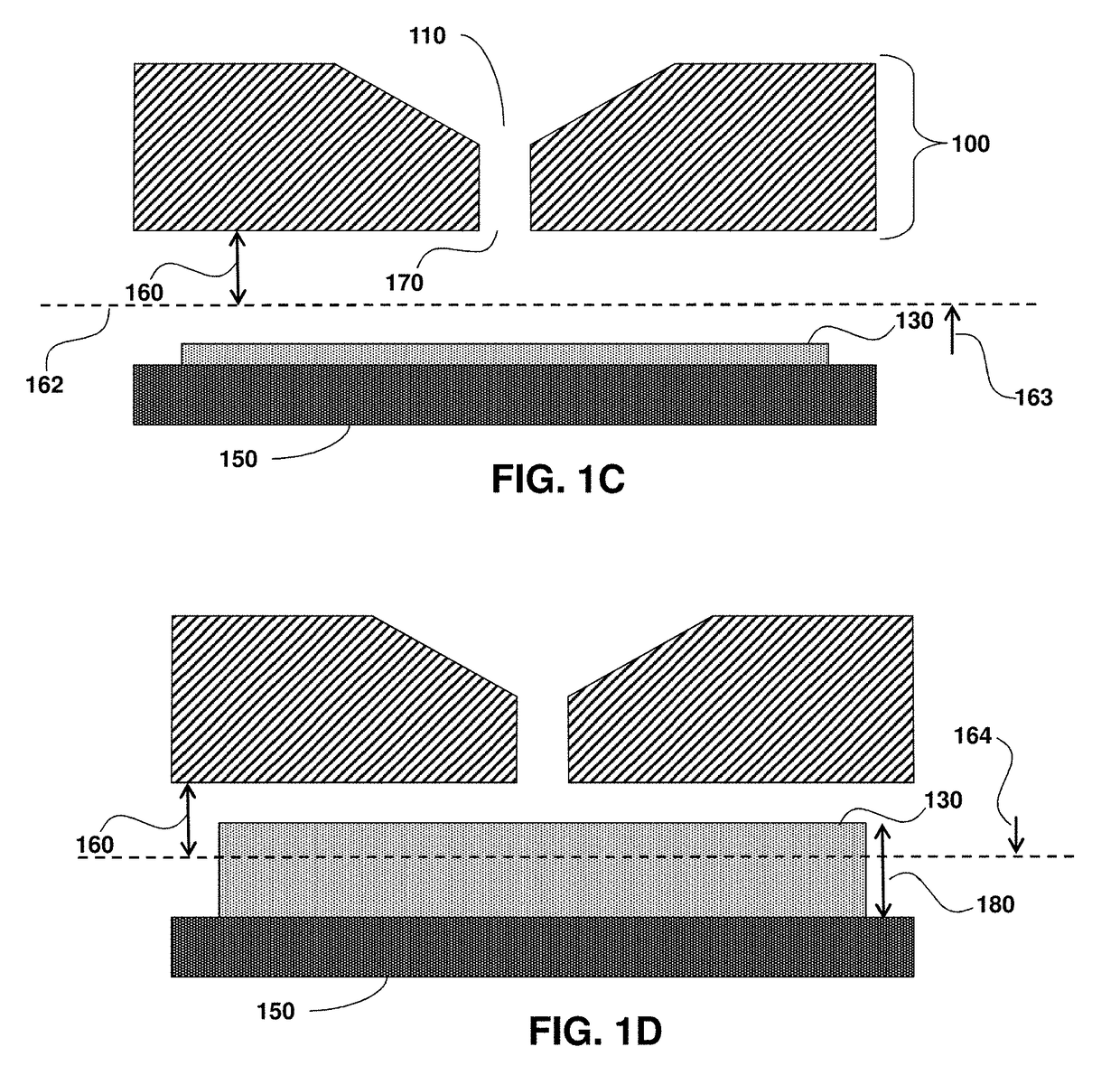

ActiveUS20150260617A1Continuous regulationHelp positioningWithdrawing sample devicesBiological particle analysisEngineeringGround level

Provided are impactors for detecting biologics having an adjustable separation distance between an impact surface and the intake aperture, including the exit of the intake aperture. The impactor has a sampling head having at least one intake aperture and an exit, an impactor base comprising an impact surface, wherein the impact surface opposibly faces the sampling head exit and is separated from the exit by a separation distance. The separation distance is continuously adjustable between a minimum separation distance and a maximum separation distance and can accommodate impact surfaces having different heights by positioning the impact surface, irrespective of height of the impact surface, at an optimal separation distance from the sample intake aperture, such as by a rotation-type mechanism with a change in distance indication provided to a user by a separation distance step indicator.

Owner:PARTICLE MEASURING SYST

Particle impactor with selective height adjustment

ActiveUS9885640B2Help positioningConvenient distanceWithdrawing sample devicesBiological particle analysisEngineering

Provided are impactors for detecting biologics having an adjustable separation distance between an impact surface and the intake aperture, including the exit of the intake aperture. The impactor has a sampling head having at least one intake aperture and an exit, an impactor base comprising an impact surface, wherein the impact surface opposibly faces the sampling head exit and is separated from the exit by a separation distance. The separation distance is continuously adjustable between a minimum separation distance and a maximum separation distance and can accommodate impact surfaces having different heights by positioning the impact surface, irrespective of height of the impact surface, at an optimal separation distance from the sample intake aperture, such as by a rotation-type mechanism with a change in distance indication provided to a user by a separation distance step indicator.

Owner:PARTICLE MEASURING SYST

Electric connector

InactiveCN102280732BFixed uniformLower the altitudeSecuring/insulating coupling contact membersCoupling contact membersElectrical connectionEngineering

An electrical connector includes a body with a tongue and the body supports a terminal module, the terminal module including a first row of terminals and a second row of terminals. Each terminal includes a contact portion and a soldering portion, the contact portions of the first and second row of terminals being disposed on an upper side and a lower side of the tongue, respectively, and the soldering portions of the first and second row of terminals each being arranged in a front column and a back column. A first and second positioning element can support the first and second rows of terminals, respectively. A shield that envelopes a periphery of the insulating body forms a contact chamber for accommodating the tongue. The front portion of the shield can be recessed into the circuit board to reduce the effective height of the connector and circuit board.

Owner:MOLEX INTERCONNECT SHANGHAI +1

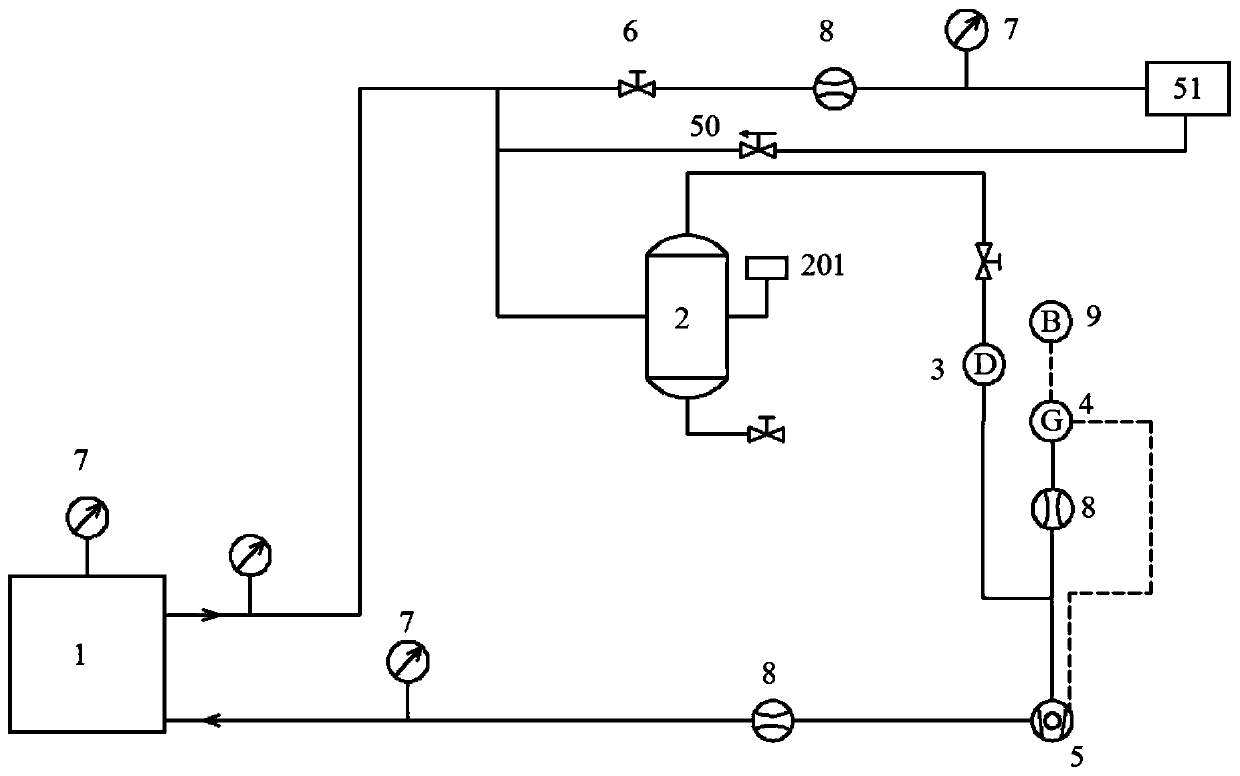

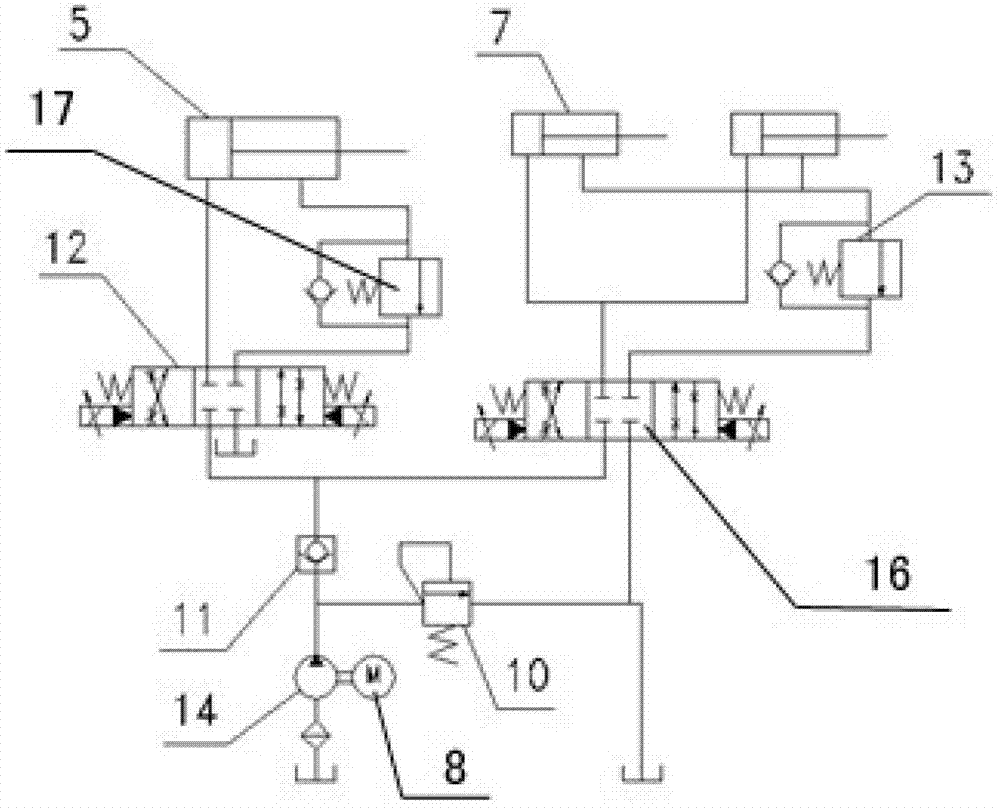

Water production gas well full-life-circle drainage gas recovery method and system

The invention relates to a water production gas well full-life-circle drainage gas recovery method and system. The system comprises drainage gas recovery equipment, a gas-water shunting device, dryingequipment, a gas power generator and a compressor. A first branch of an outlet pipeline of the drainage gas recovery equipment is connected to an outer conveying pipe network. A second branch is connected with the gas-water shunting device. Gas flowing out of the top of the gas-water shunting device passes through an adjusting valve and is dried through the drying equipment, then the gas is divided into two branches, one branch flows into the gas power generator through a flow adjuster, the other branch flows into the compressor, and the gas power generator provides electric energy for the compressor by burning natural gas. The natural gas is pressurized through the compressor, multiple stages of pressure adjusters are started by the natural gas, shaft accumulated liquid is removed section by section, and continuous production of a gas well is guaranteed. The method and system can be suitable for water production gas well full-life-circle drainage gas recovery, one-time construction is effective for a long time, the gas lift starting pressure is low, the energy consumption is low, external electric energy does not need to be used, and the method and system are safe, reliable, capable of being reused, easy to manage and low in maintenance cost.

Owner:西安诚科石油工程技术服务有限公司

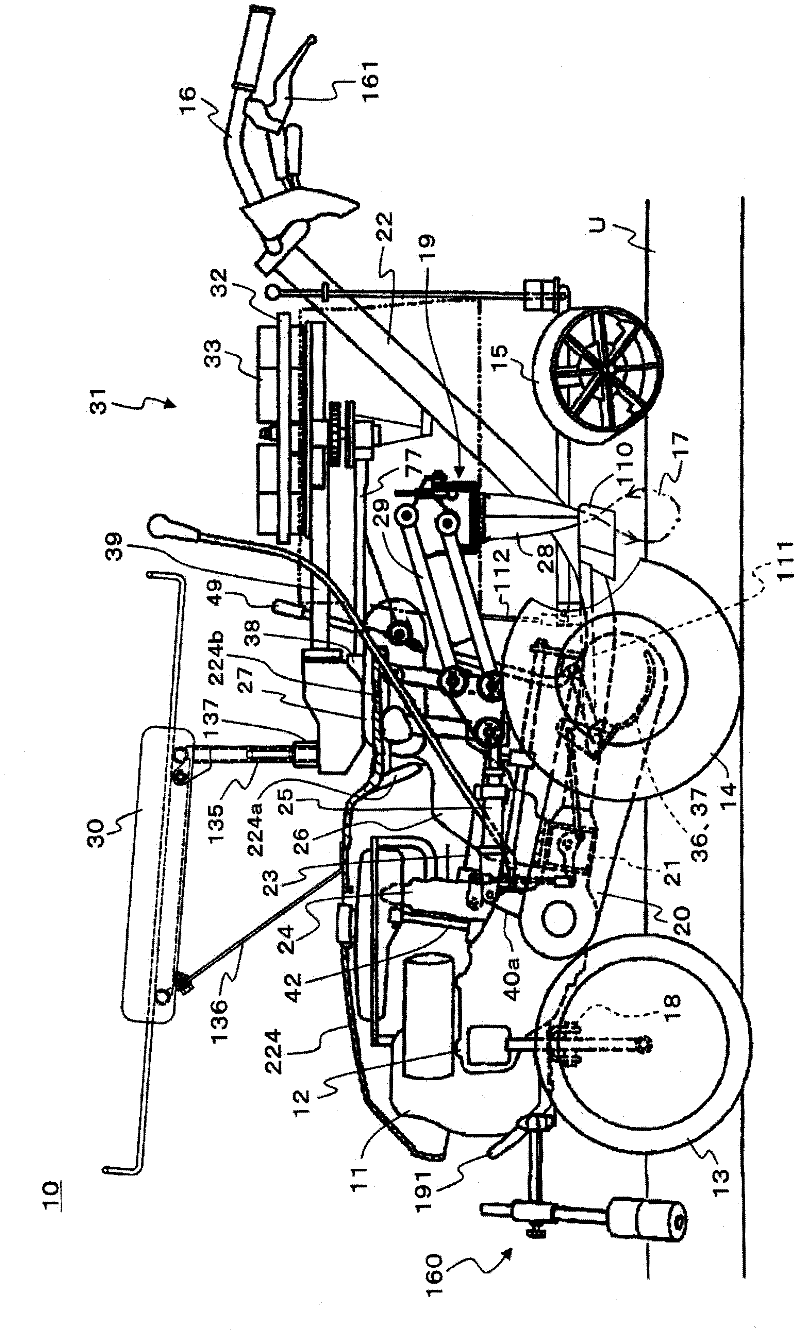

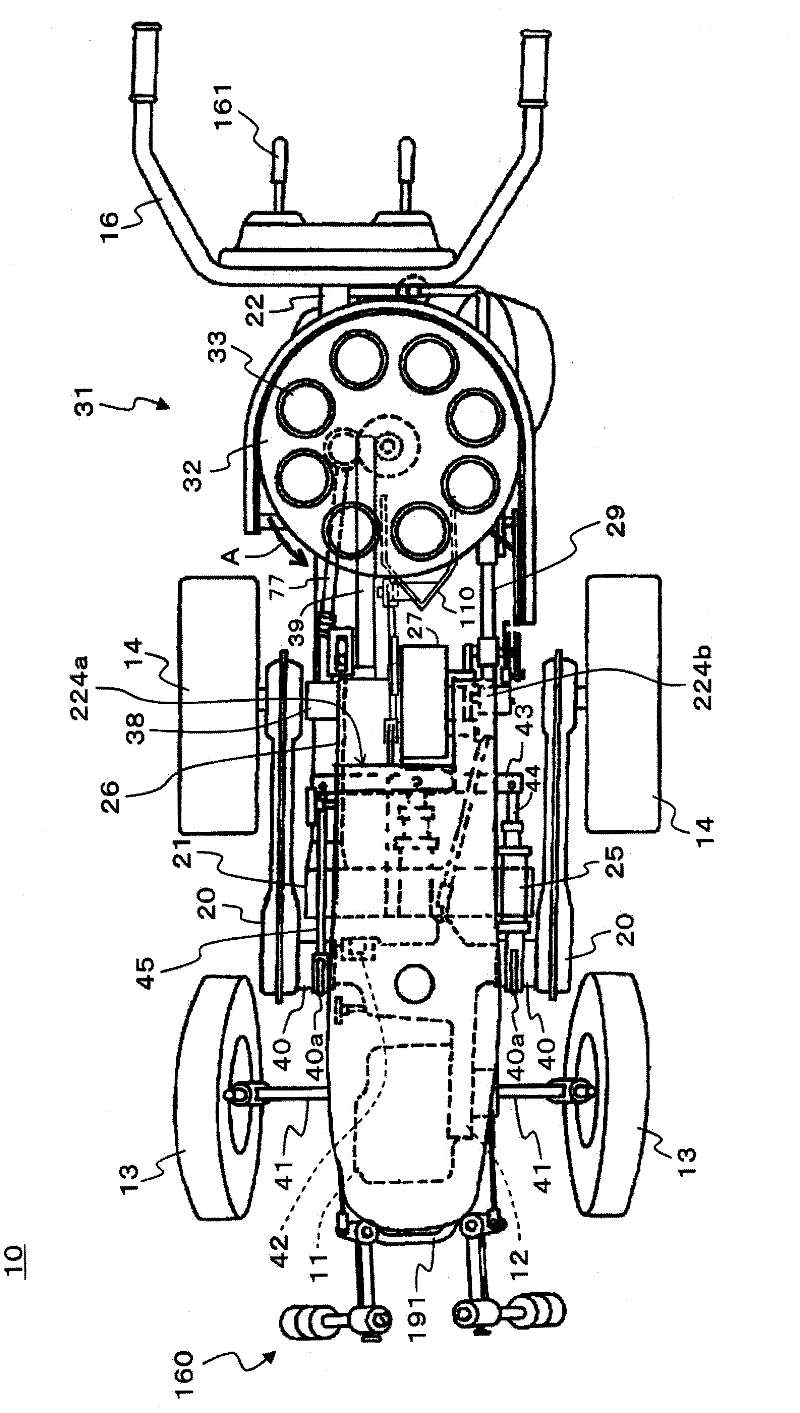

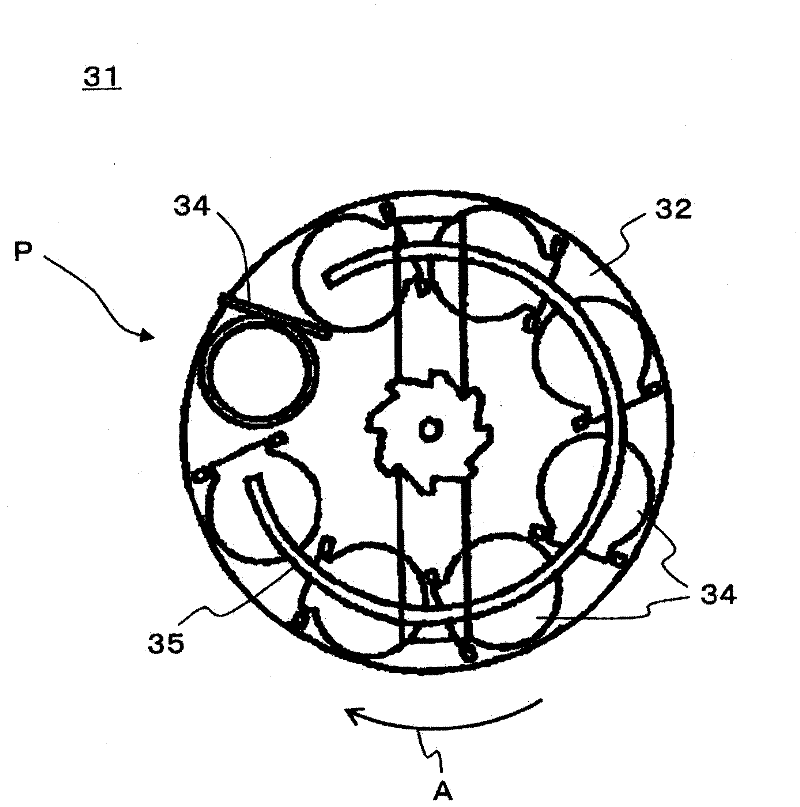

Transplanter

The present invention provides a transplanter which is provided with a planting tool (28) that receives transplanting object from a feeding part that is supported on a driving body and moves to a lower farmland surface for planting. The transplanter is provided with the following components: a pit digging member (110) which forms pits at the periphery of the planting according to driving of the body, and an interlocking lifting mechanism which causes the pit digging member (110) to be interlocked with the planting tool (28) and lifts. The transplanter of the invention is provided with a simple-structure planting part which can form a pit for storing water at the periphery of each planting object which is planted by the planting device.

Owner:ISEKI & CO LTD

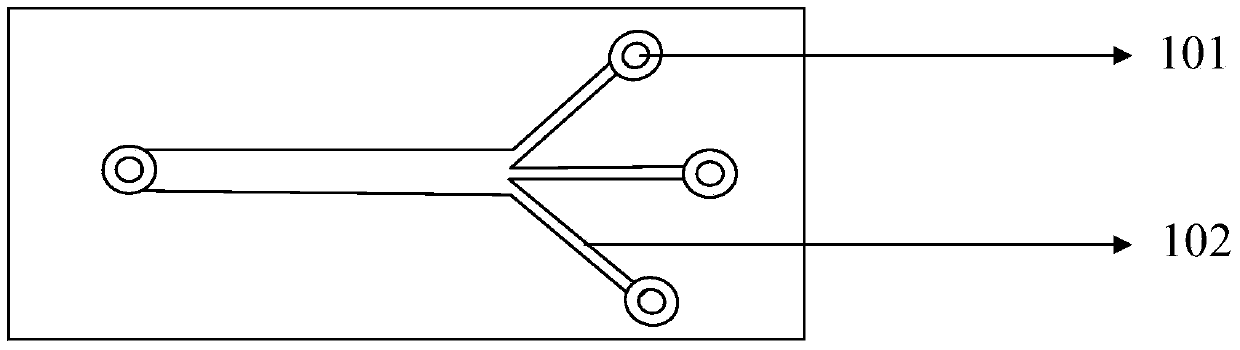

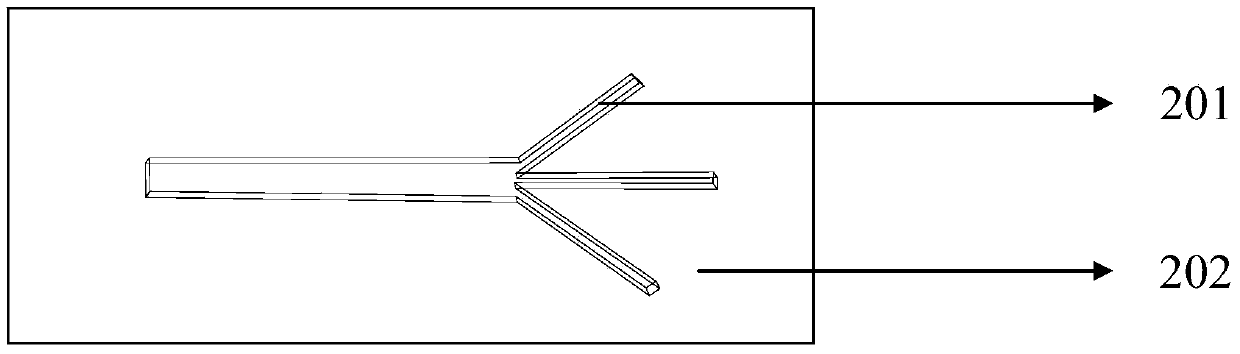

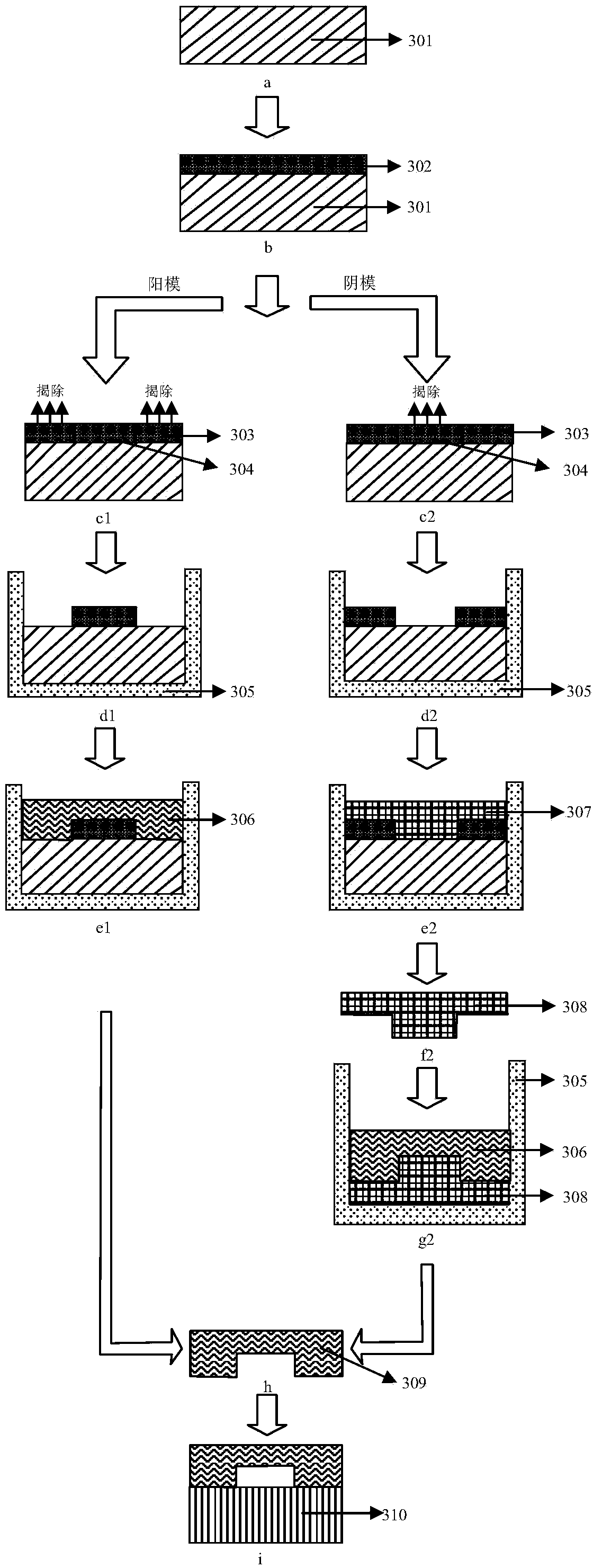

Quick preparation method of die of transparent adhesive tape-carved micro-fluidic chip

The invention aims at providing a quick preparation method of a die formed by carving a transparent adhesive tape by a micron-scale depth and used for manufacturing a PDMS micro-fluidic chip. The transparent adhesive tape is caved by use of a scalpel to form a female die and a male die, and the female die and the male die are further used for manufacturing the micro-fluidic chip die; the channel depth of a micro-fluidic chip can be controlled by changing the number of types and the number of layers of the pasted transparent adhesive tapes; the channel depth and the channel width of the die both can be in the range of 20 microns to 10000 microns; besides, the channel shape, the channel width and the channel depth all can be changed in design according to requirements. The male die formed by carving the transparent adhesive tape can be directly applied to forming the desired PDMS finished products by casting; while the female die formed by use of the transparent adhesive tape needs to be cast by use of an epoxy resin firstly, and after the epoxy resin is cured and dried, an epoxy resin female die which can be repeatedly used for a plurality of times is obtained. The quick preparation method of the die of the transparent adhesive tape-carved micro-fluidic chip is simple to operate and low in cost, is expected to be popularized in general laboratories and is capable of promoting the manufacture and design of the micro-fluidic chips.

Owner:QILU UNIV OF TECH

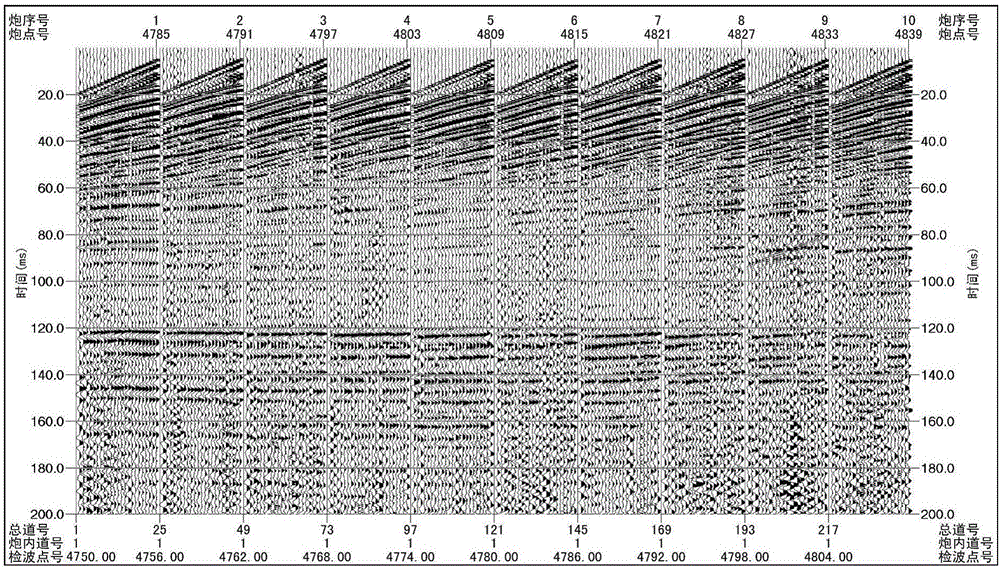

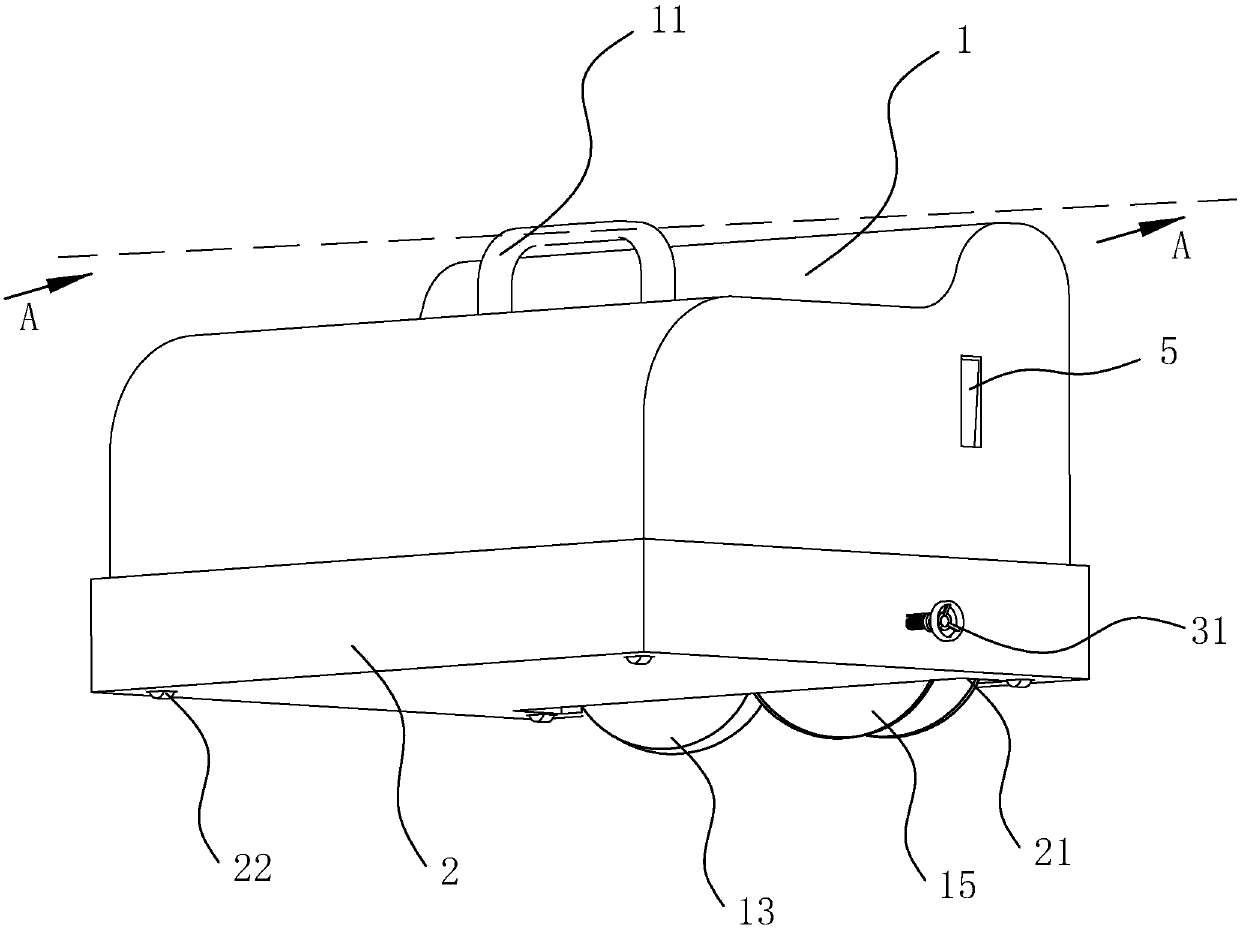

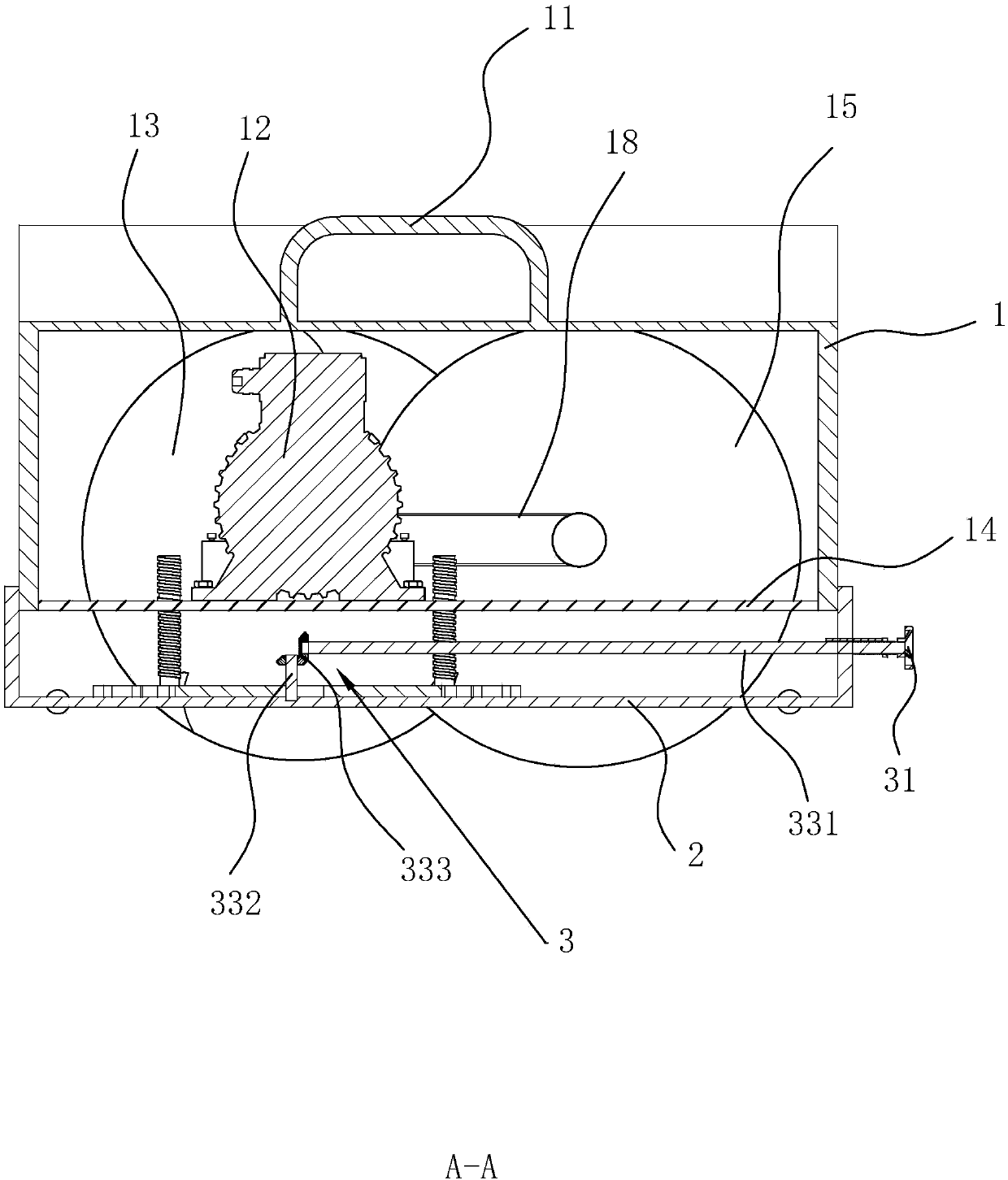

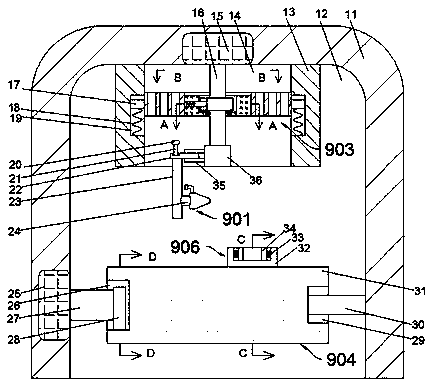

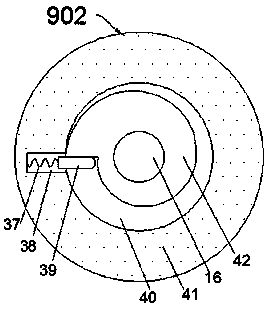

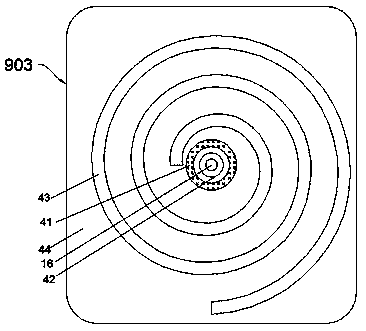

Compressed air energy seismic source apparatus for seismic exploration in waters

ActiveCN106199685ALarge output energyLarge excitation energySeismology for water-covered areasEngineeringFlange

The invention discloses a compressed air energy seismic source apparatus for seismic exploration in waters. The apparatus includes a housing, a compressed air source, an impact cylinder, a flange, a stainless steel base plate, a cylinder bottom pad plate and a vibration plate. The housing is a vertically arranged hollow canister body. The impact cylinder is disposed inside the housing. The flange is horizontally and fixedly installed at the bottom part of the housing. The stainless steel base plate and the vibration plate are horizontally arranged. The stainless steel plate is an annular plate having a center hole. The stainless steel plate is arranged under the flange. The vibration plate is arranged under the stainless steel base plate. The flange, the stainless steel base plate ad the vibration plate are connected through external fastening bolts which vertically penetrates. The cylinder bottom pad plate is an annular plate which is arranged between the impact cylinder and the stainless steel plate and has a center hole. An internal fastening bolt vertically penetrates the stainless steel base plate and the cylinder bottom pad plate, and then is connected to the bottom part of the impact cylinder so as to fix the impact cylinder to the stainless steel base plate in a suspension manner. The apparatus can be used in seismic exploration in waters.

Owner:广东省地质物探工程勘察院

Multi-functional ultrasonic vibration cutting mechanism

InactiveCN104308628ACleverly structuredVersatileMechanical vibrations separationFeeding apparatusTool holderDividing circuits

The invention discloses a multi-functional ultrasonic vibration cutting mechanism comprising an ultrasonic signal source, a transducer, an amplitude amplifier pole, a vibration tool holder and a tool. The ultrasonic signal source is connected with the transducer through an amplifying circuit; a voltage dividing circuit in series connection with a voltage dividing resistor is in parallel connection on the amplifying circuit; a telescopic movement mechanism is disposed between the vibration tool holder and a connection device of a machine tool provided with the ultrasonic vibration cutting mechanism; the telescopic movement mechanism is controlled by a power plant operating independently; movement direction of the telescopic movement mechanism is perpendicular to that of the amplitude amplifier pole. With the design of the voltage dividing circuit, amplitude magnitude of the tool is adjusted, depth of a cutting tool workpiece is changed, and requirements of different cutting depth are met. With the design of the telescopic movement mechanism operating independently, the tool has two cutting movement performance of linear motion and elliptical motion, and needs of different cutting process are met. Furthermore, the multi-functional ultrasonic vibration cutting mechanism is multi-functional, widely used, applicable to different processing requirements and more practical.

Owner:SUZHOU HUACHONG PRECISION MACHINERY

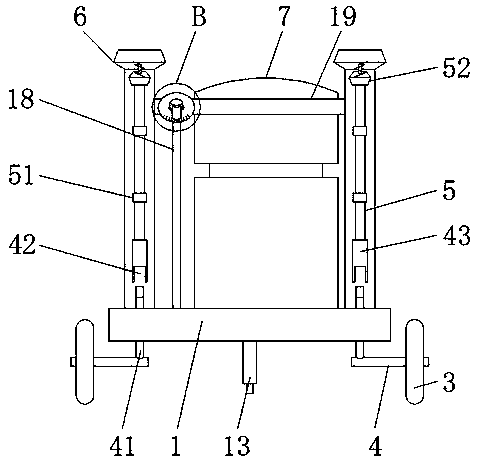

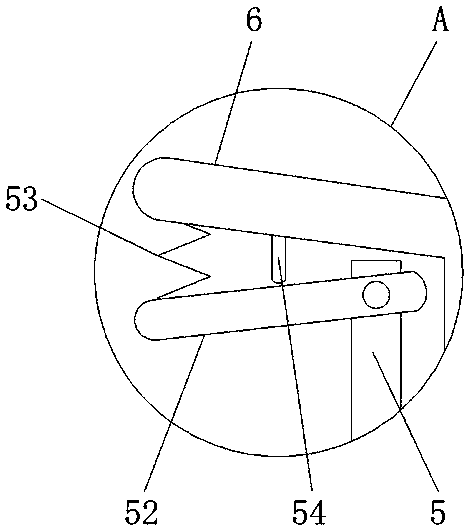

Grooving machine

ActiveCN109773976AAvoid damageImprove flatnessWorking accessoriesStone-like material working toolsMechanical engineeringEngineering

The invention relates to a grooving machine which comprises a machine shell. A motor is arranged in the machine shell. A groove cutter is arranged at the end of a rotating shaft of the motor. Groovingsaw blades are arranged on the two sides of the groove cutter correspondingly. The two saw blades are connected with the inner side wall of the machine shell through two first rotating rods correspondingly. One end of each first rotating rod is fixedly connected with the corresponding saw blade, and the other ends of the first rotating rods are rotationally connected with the inner side wall of the machine shell. The first rotating rods are parallel to the rotating shaft of the motor. A drive part used for driving the saw blades to rotate in the direction the same as that of the groove cutteris arranged in the machine shell. According to the principle that the smaller the thickness of a cutting cutter is, the smaller the stress damage generated to cutting objects is, the grooving saw blades are arranged on the two sides of the groove cutter, and therefore when a wall is grooved, the saw blades firstly form grooves in the wall, then the groove cutter is utilized for crushing the position, between the two grooves, of the wall along with movement of the grooving machine, operation that a groove cutter with the width conforming to that of a channel is utilized for direct grooving isavoided, and therefore the flatness of the positions, on the two sides of the channel, of the wall can be improved obviously, and then damage to the positions, on the two sides of the channel, of thewall in the grooving process is reduced.

Owner:TIANJIN ERJIAN WATER & ELECTRICAL INSTALLATION ENG

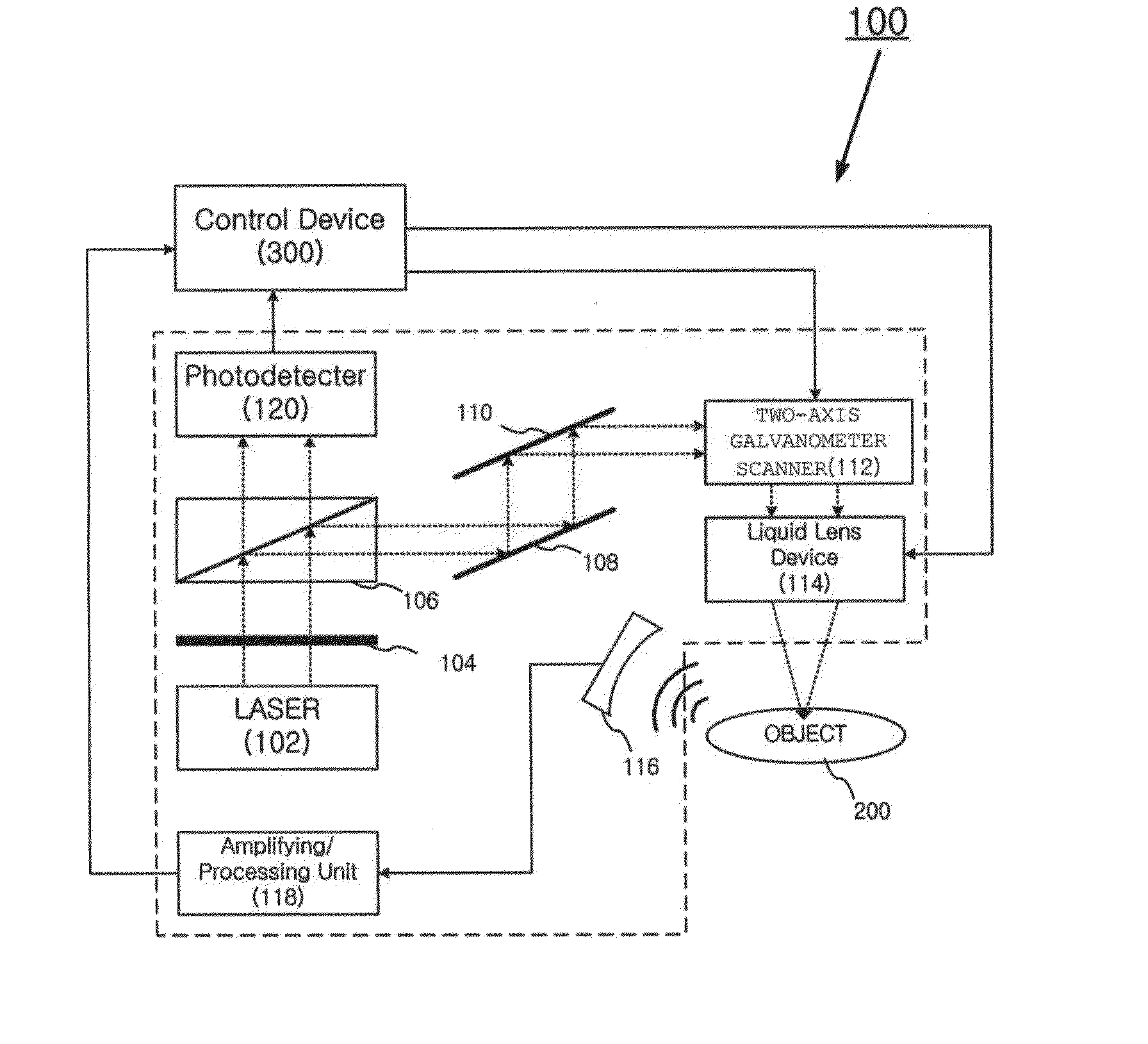

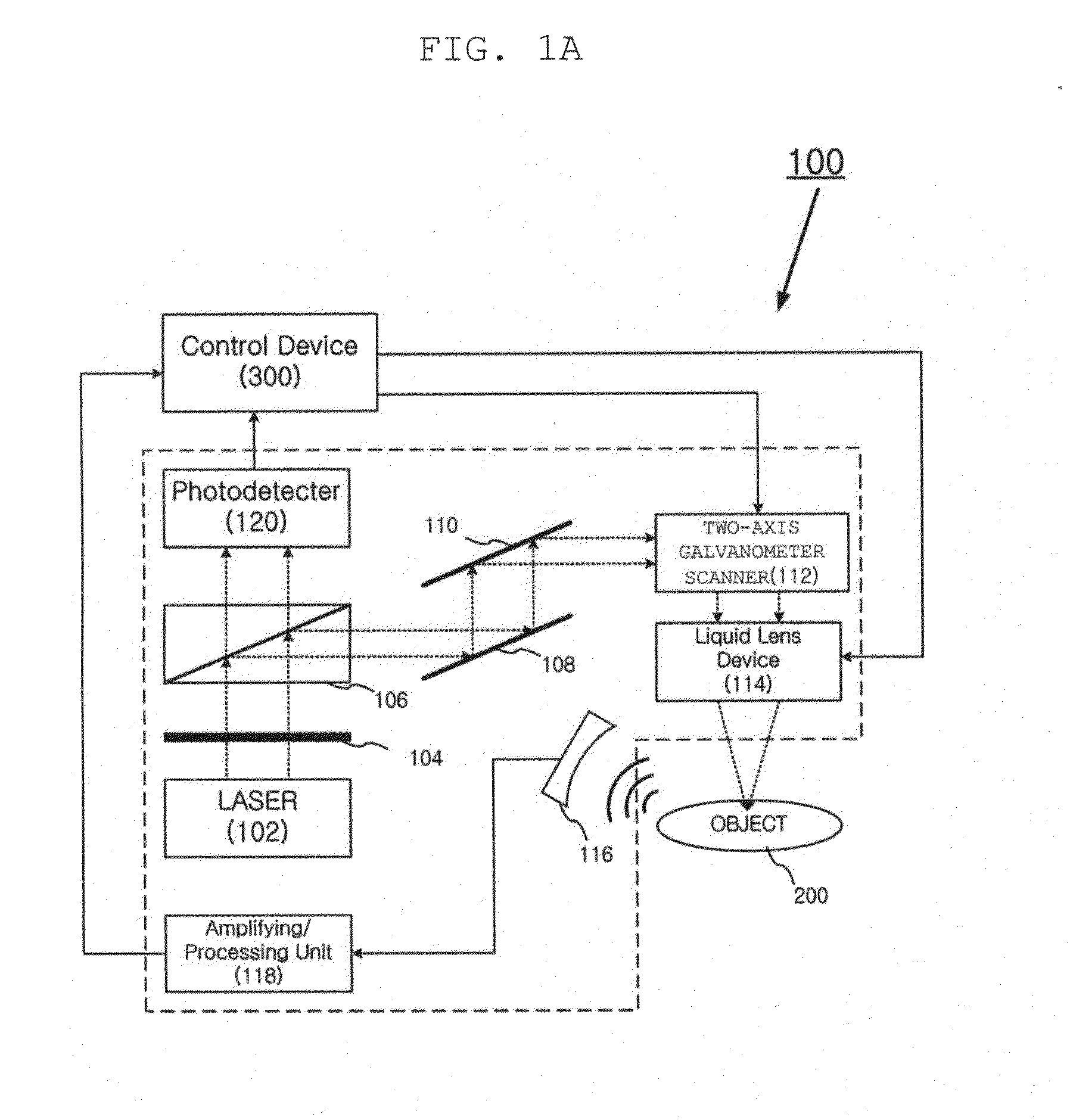

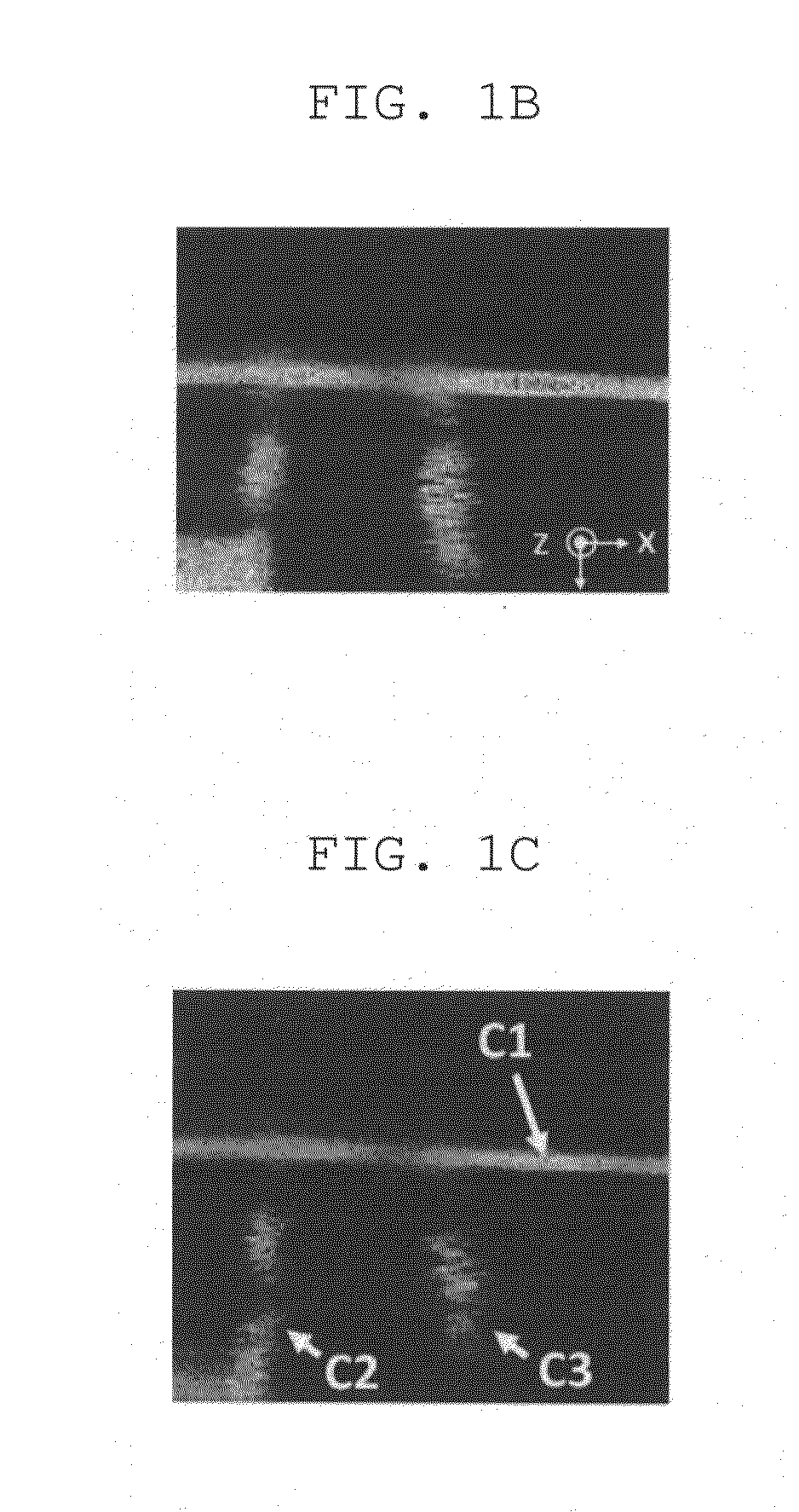

Optical imaging apparatus for multi-depth image

InactiveUS20160220120A1Change depthSimple controlMaterial analysis using sonic/ultrasonic/infrasonic wavesMaterial analysis by optical meansFluorescenceImage system

Provided are an optical imaging apparatus for multi-depth image and an imaging system having the same, where an optical lens of a sample stage of an optical imaging apparatus is used as a liquid lens, so that it is possible to acquire an optical image such as a photoacoustic image, an optical coherence tomography image, or a fluorescent image while finely and speedily changing a depth, and it is possible to acquire optical images having various depths by only user's simple control.

Owner:POSTECH ACAD IND FOUND

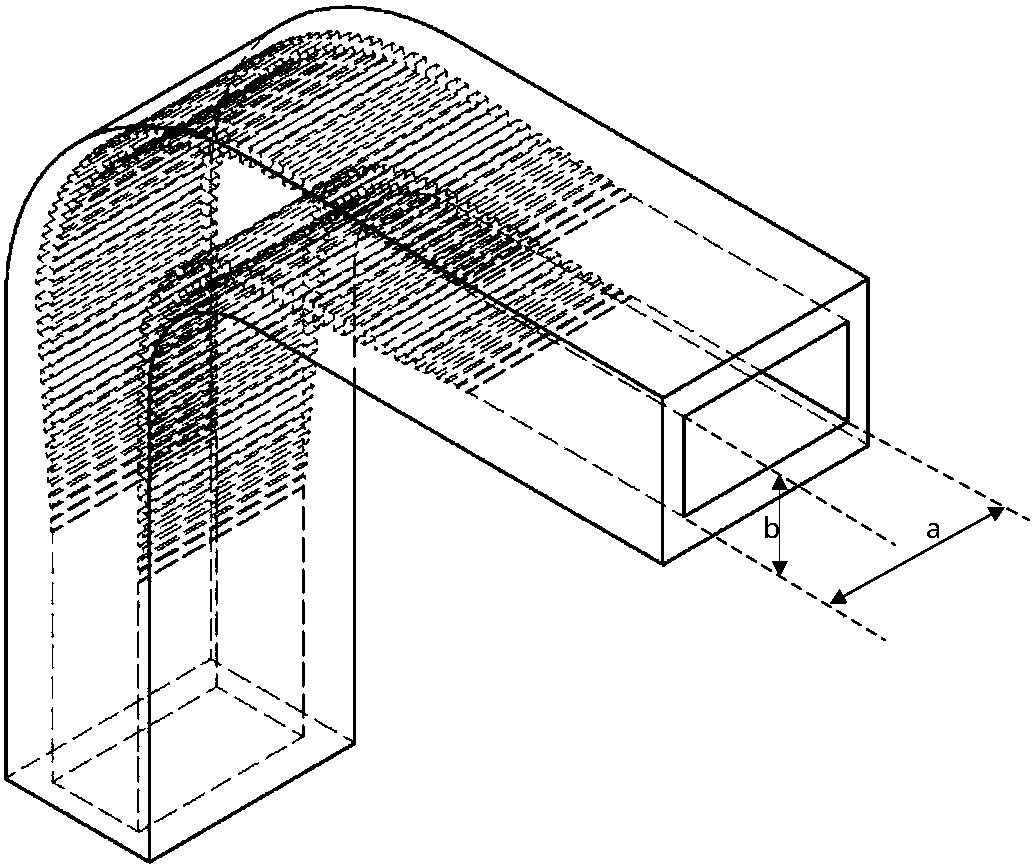

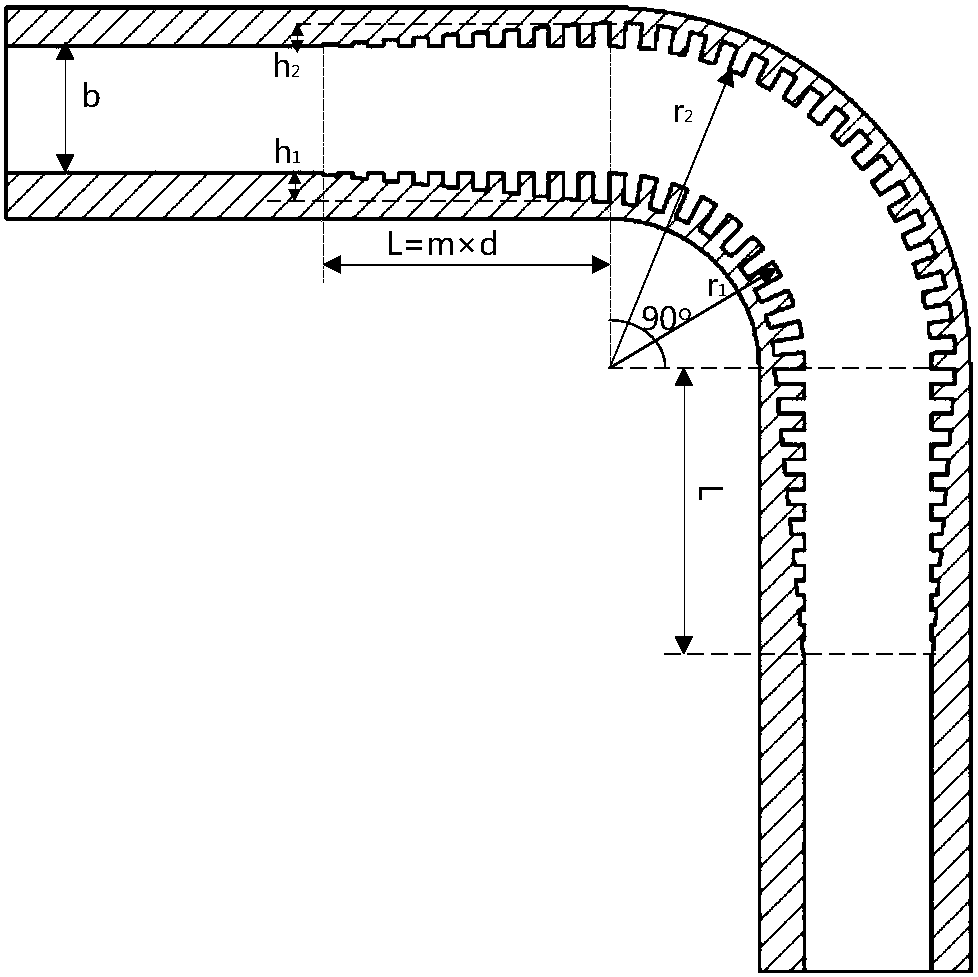

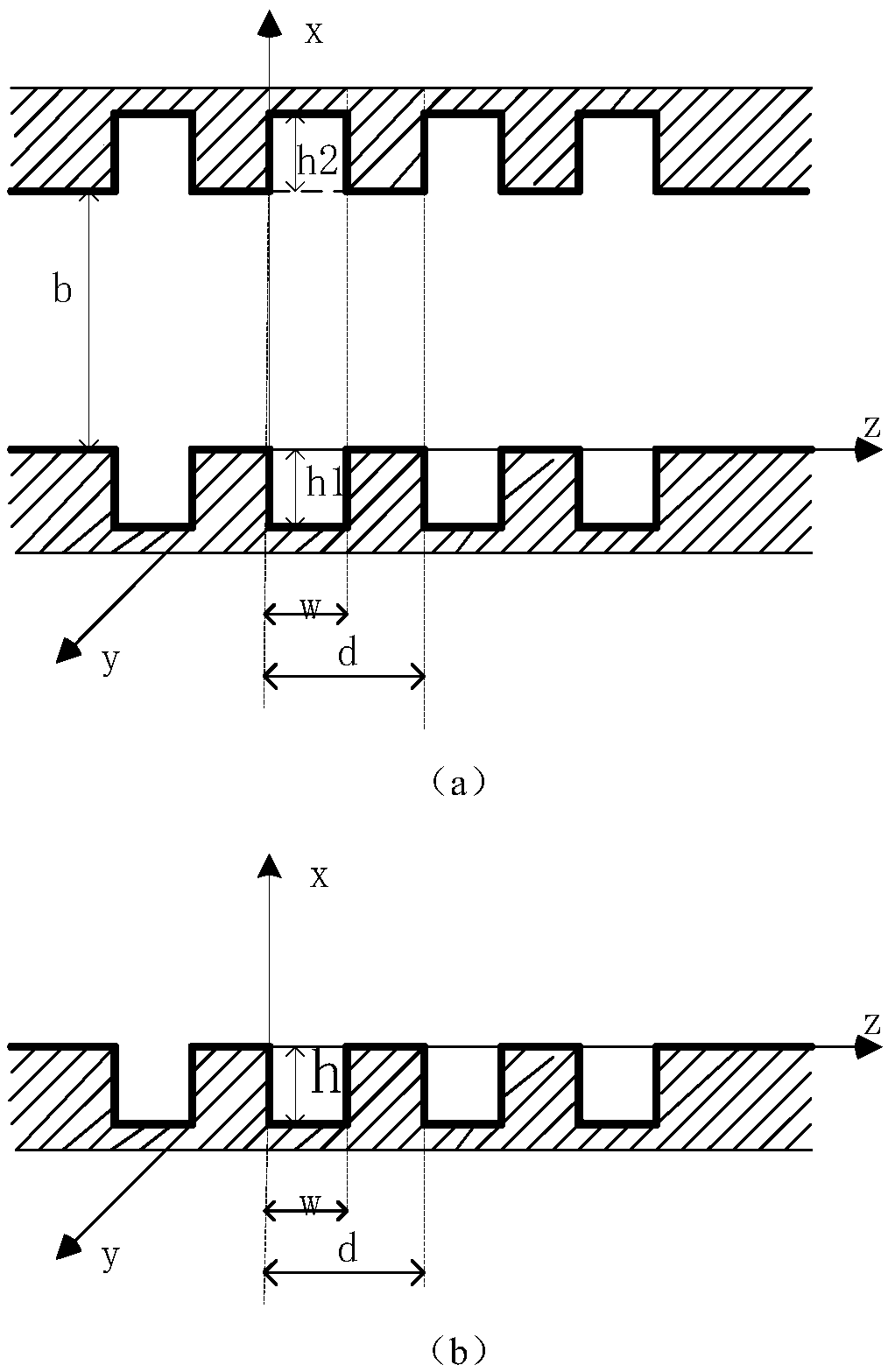

Curved waveguide mode converter based on surface plosmon polaritons and implementation method thereof

The present invention discloses a curved waveguide mode converter based on surface plosmon polaritons and an implementation method thereof. Gratings with the uniform depth are respectively arranged at the inner concave surface and the outer concave surface of an arc waveguide, the inner walls of two sections of straight waveguides connected with the inner concave surface and the outer concave surface are respectively provided with gratings with gradually varied depths, when electromagnetic waves pass through the arc waveguide, a surface wave mode is aroused at the gratings with the uniform depth so as to constrain the electromagnetic waves at the surface, and the grating with gradually varied depths can realizes the wave vector matching between the waveguide mode and the surface wave mode. The curved waveguide mode converter based on the surface plosmon polaritons and the implementation method thereof are compact in structure with no need for other transition parts; compared to a traditional method, through adoption of the lithography technology, the processing is easy, the curved waveguide mode converter based on the surface plosmon polaritons and the implementation method thereof change the depths of the gratings and is also taken as a curved waveguide for usage; the curved waveguide is big in curvature and small in occupied space compared to the curved waveguide having the same functions in the prior art; and moreover, the method provided by the invention is high in mode conversion efficiency can reduce the reflection and other parasitic modes to the lowest.

Owner:PEKING UNIV

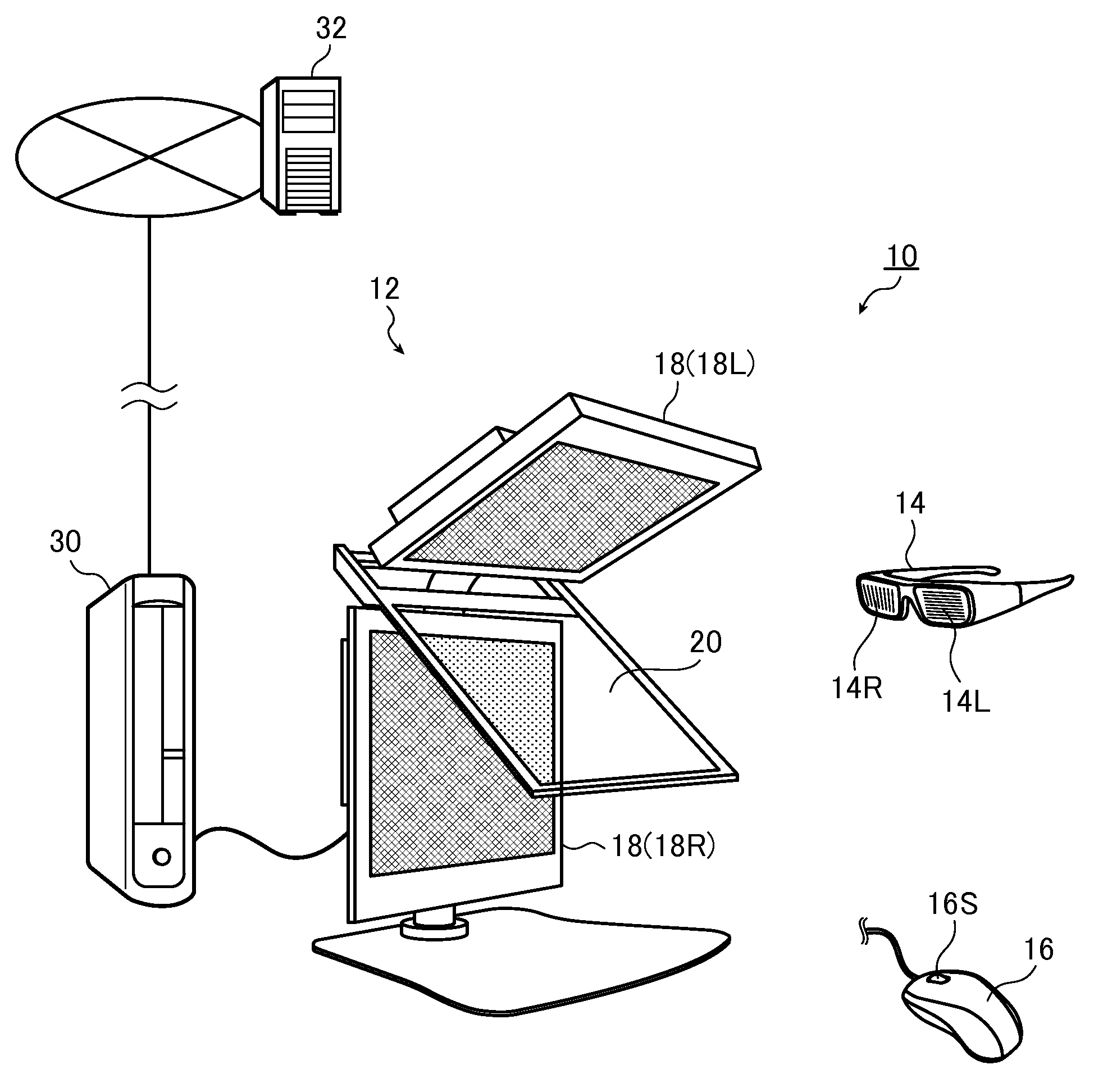

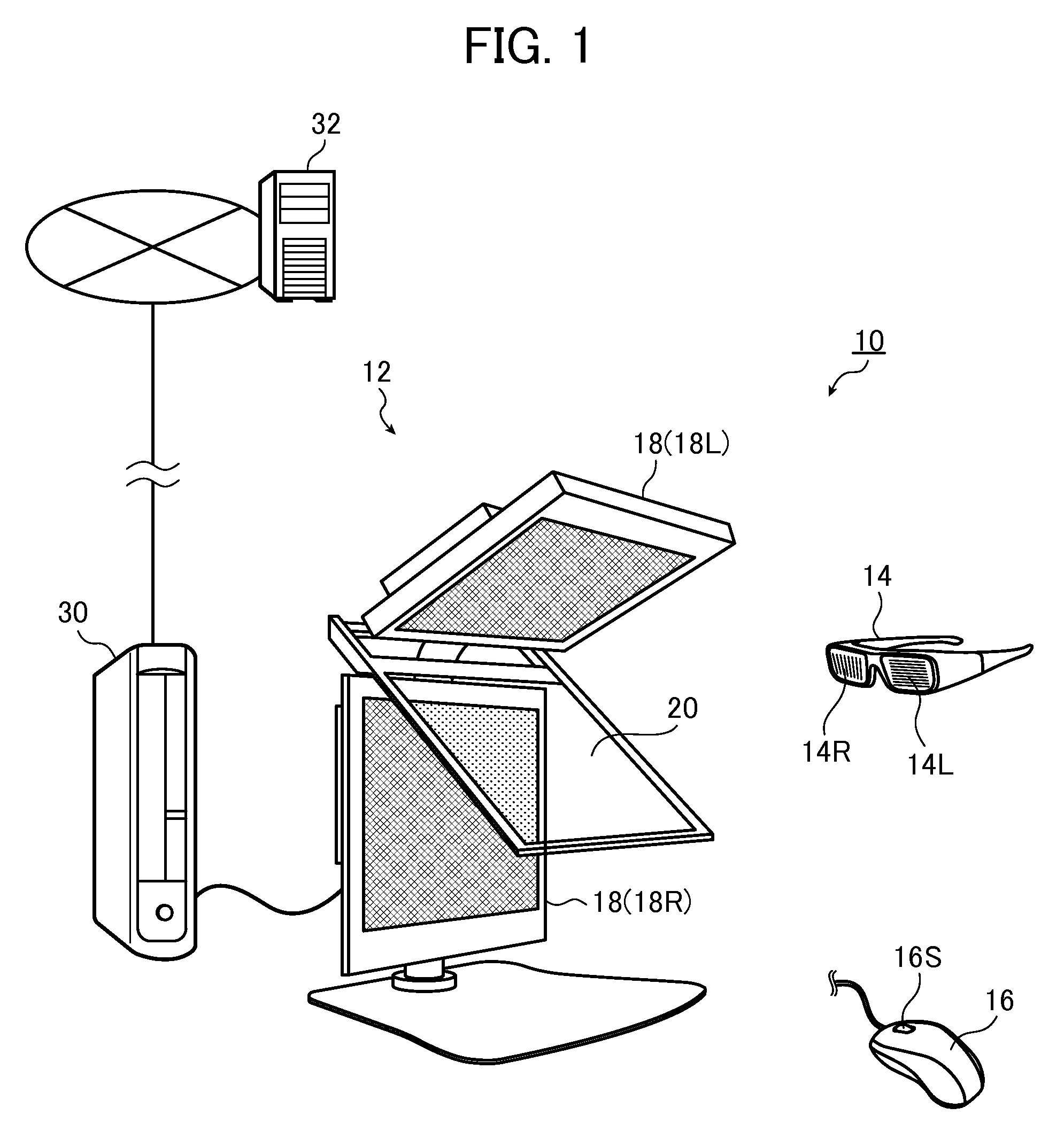

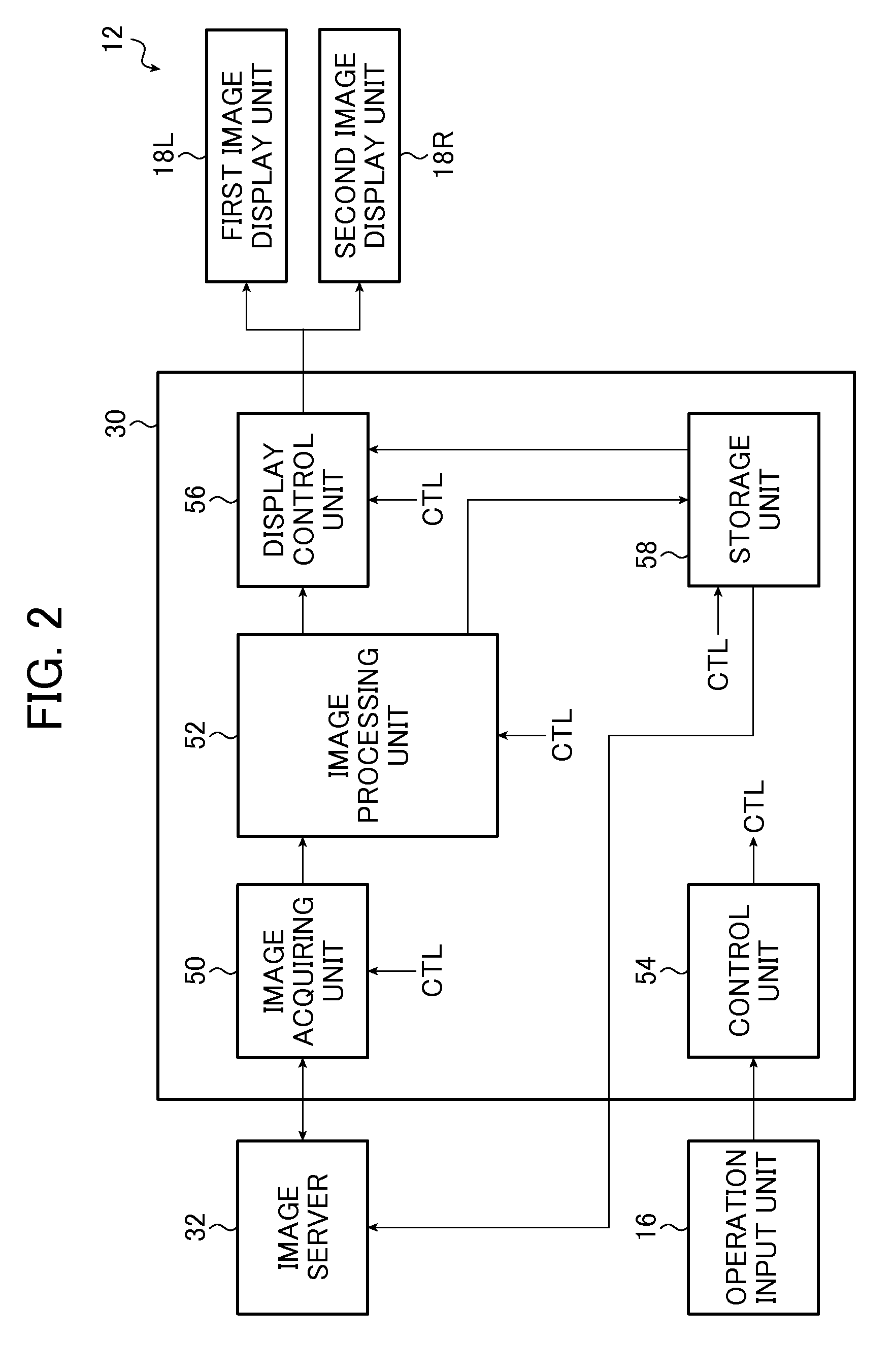

Stereoscopic display apparatus

InactiveUS20120249534A1Reduce burdenPrevent erroneous diagnosisSterographic imagingSteroscopic systemsRadiationImage display

A stereoscopic display apparatus that performs a stereoscopic display using a right-eye image and a left-eye image acquired by radiographing a subject plural times while changing an incidence angle of radiation on the subject, includes a display unit that stereoscopically displays the right-eye image and the left-eye image, and a changing unit that shifts at least one of the right-eye image and the left-eye image displayed on the display unit to change an inter-image distance being a distance between the right-eye image and the left-eye image in a direction parallel to a straight line connecting the right eye and the left eye of an observer.

Owner:FUJIFILM CORP

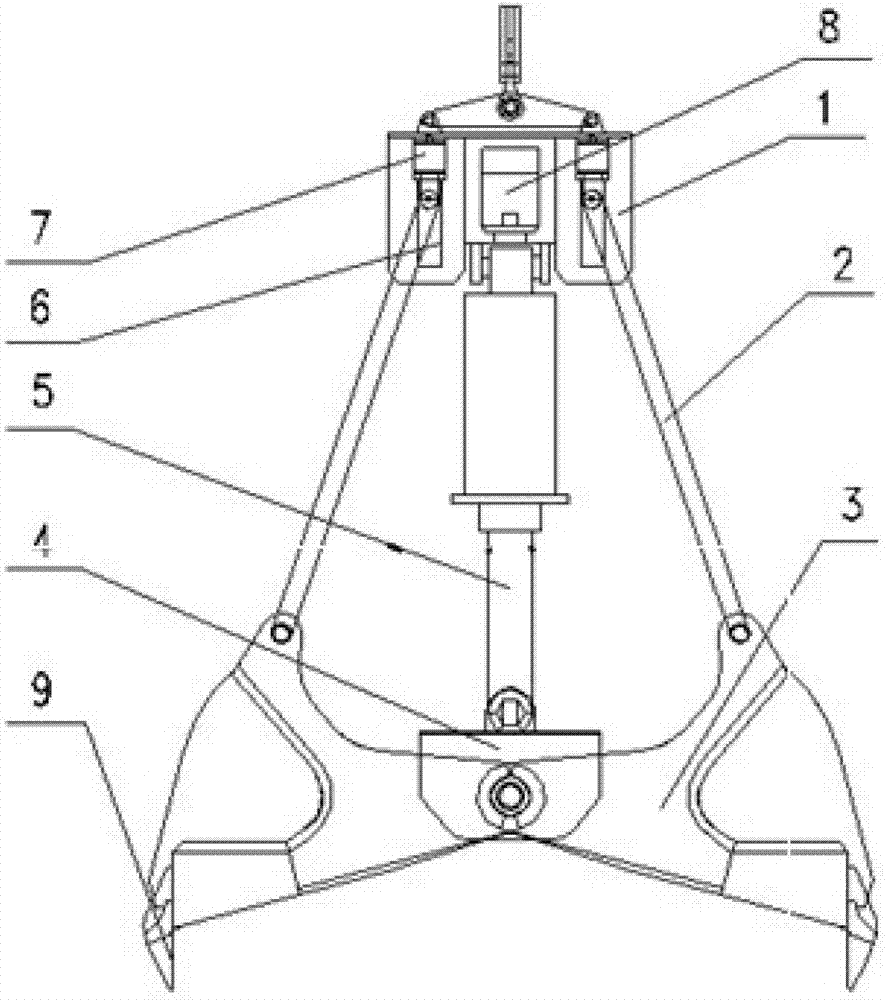

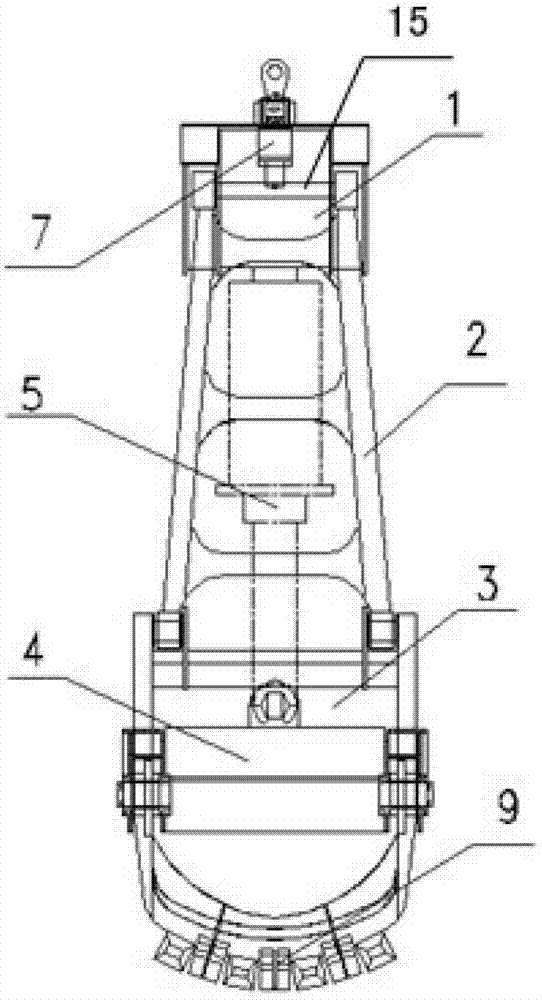

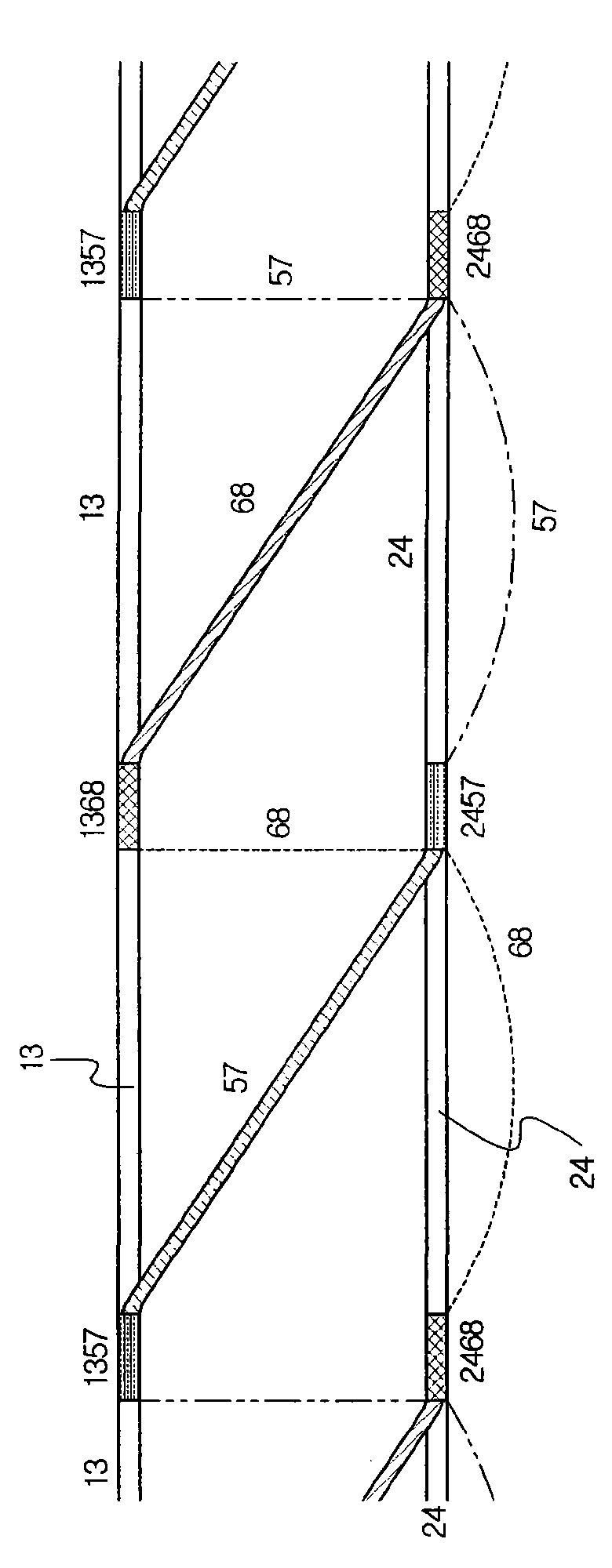

Brace rod sliding groove type hydraulic flat digging grab bucket

The invention relates to a brace rod sliding groove type hydraulic flat digging grab bucket which comprises an upper bearing beam, a lower bearing beam and a bucket body. The upper bearing beam is connected with the lower bearing beam through an open and closed bucket oil cylinder, the bucket body is hinged to the lower bearing beam, the upper bearing beam is provided with a brace rod sliding unit, the brace rod sliding unit comprises a brace rod sliding oil cylinder and a brace rod, one end of the brace rod is hinged to the bucket body, and the other end of the brace rod is connected with the brace rod sliding oil cylinder. The brace rod sliding groove type hydraulic flat digging grab bucket further comprises a hydraulic control device, and the hydraulic control device controls work of the open and closed bucket oil cylinder and the brace rod sliding oil cylinder. The brace rod sliding groove type hydraulic flat digging grab bucket has the advantages that the brace rod sliding groove type hydraulic flat digging grab bucket is simple in structure and convenient to operate, an excavated seabed or river bed can be flattened so as to meet the flatness requirements in engineering operation, the maximum opening and the maximum excavating depth of the grab bucket can be changed conveniently, the operation requirements of different working conditions can be met, and popularization and application values are large.

Owner:WUHAN UNIV OF TECH

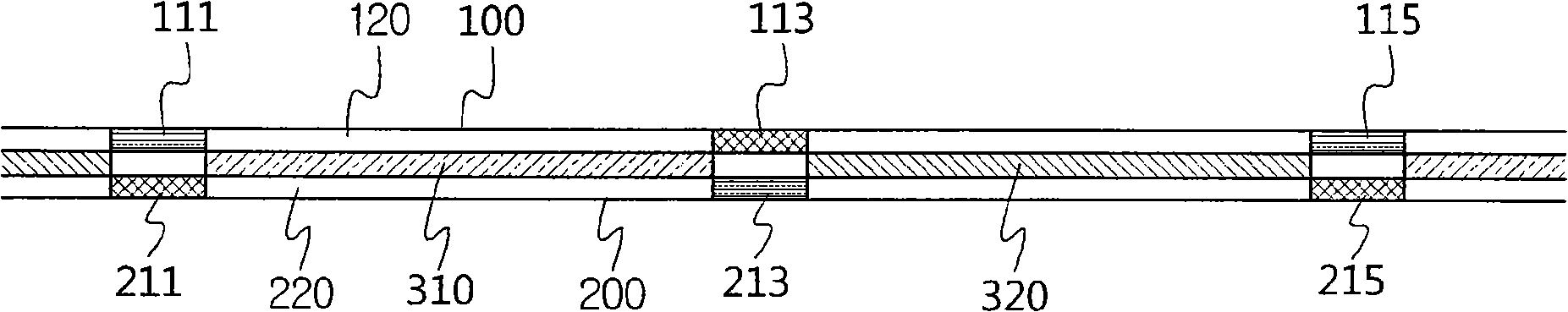

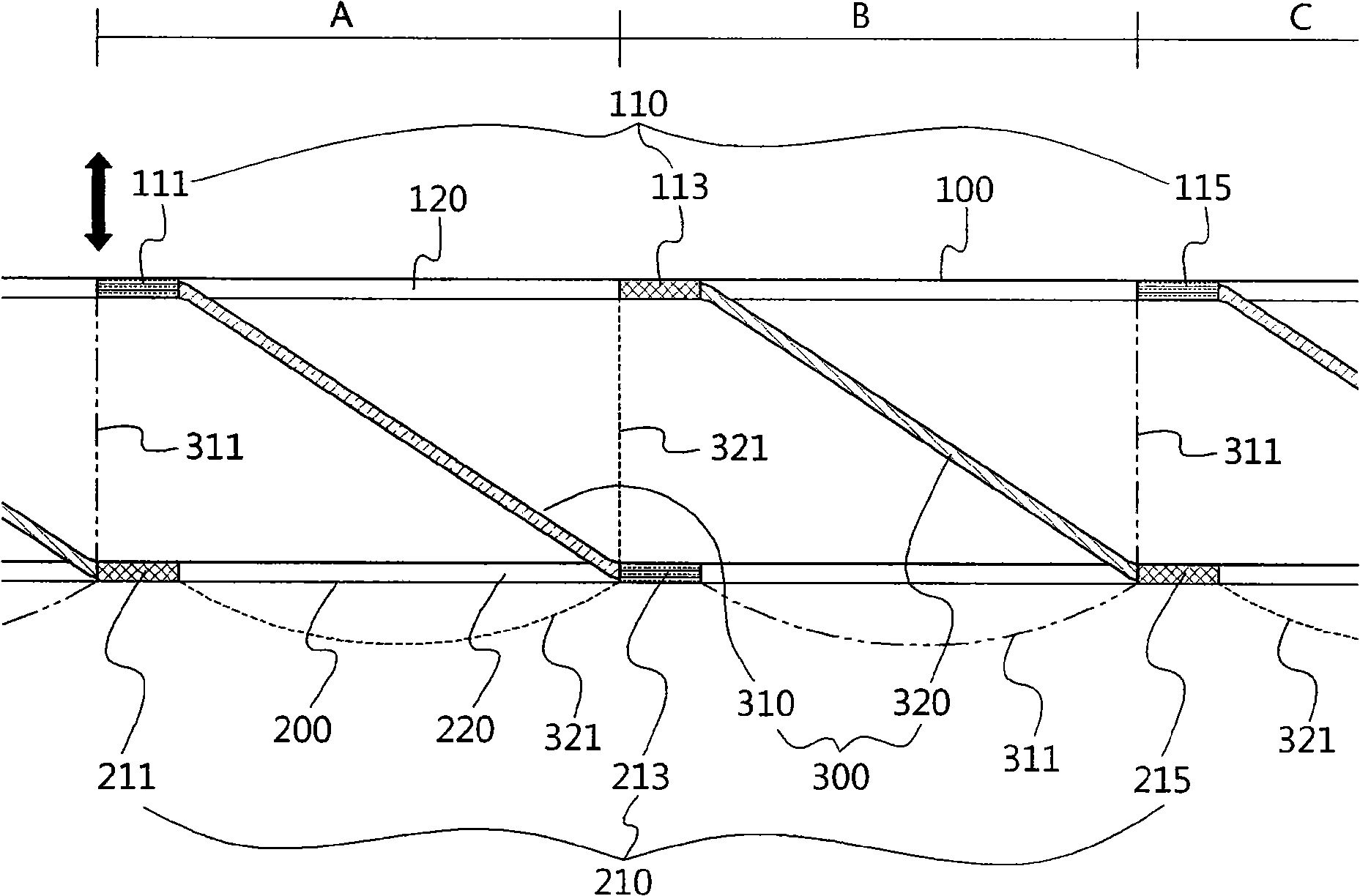

3d fabric and preparing thereof

ActiveCN101558191AChange designChange depthOrnamental textile articlesLight protection screensSurface layerRepeat pattern

A three-dimensional multilayer fabric is provided. The fabric comprises a surface layer, a backing layer, and an intermediate layer connecting the surface layer and the backing layer. The surface layer includes sequential unstitched surface portions and sequential stitched surface portions formed in an alternating and repeating pattern. The unstitched surface portions of the surface layer are essentially composed of surface warp threads only, and the stitched surface portions of the surface layer are composed of the surface warp threads and intermediate warp threads. The backing layer includes sequential unstitched backing portions and sequential stitched backing portions formed in an alternating and repeating pattern. The unstitched backing portions of the backing layer are essentially composed of backing warp threads only, and the stitched backing portions of the backing layer are composed of the backing warp threads and the intermediate warp threads. The intermediate warp threads are woven without interlacing with weft threads on the surfaces of the unstitched backing portions. The intermediate layer includes sequential intermediate portions composed of the intermediate warp threads only. Each of the in not termediate portions consists of a first intermediate portion and a second intermediate portion connected to the stitched surface portions and the stitched backing portions in an alternating and repeating pattern. The connecting warp threads of the intermediate layer exposed to the outside of the backing layer are sheared. Further provided is a method for the production of the fabric.

Owner:YOUIL

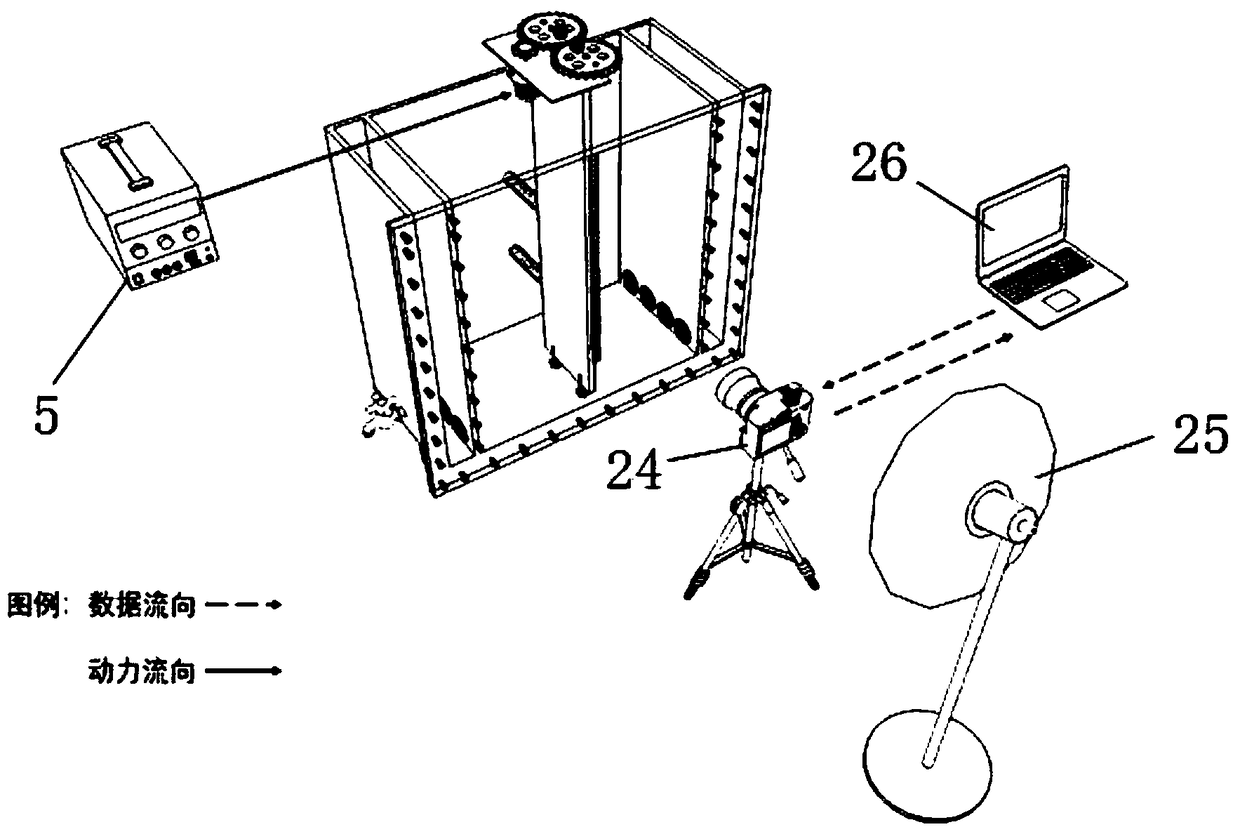

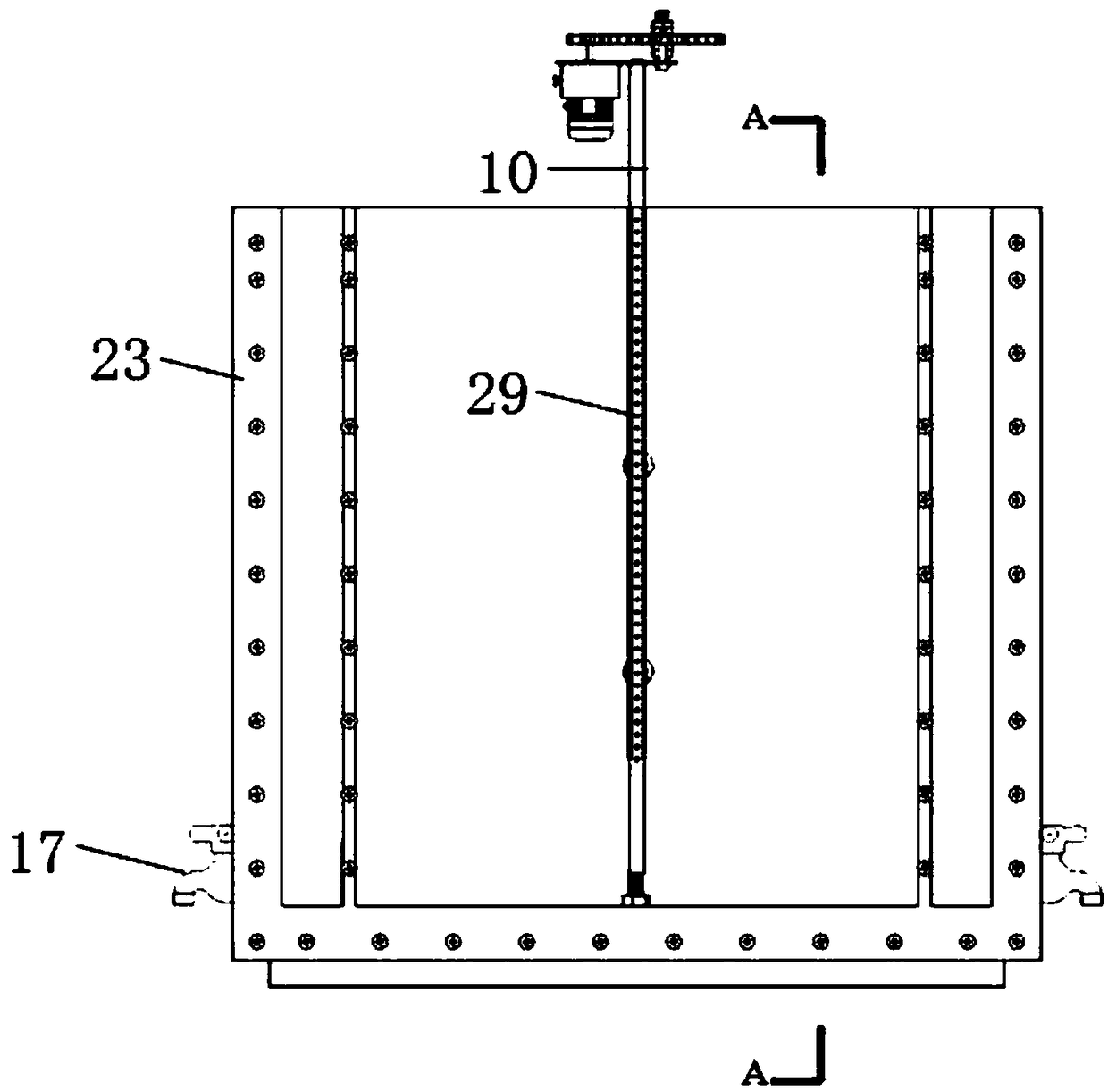

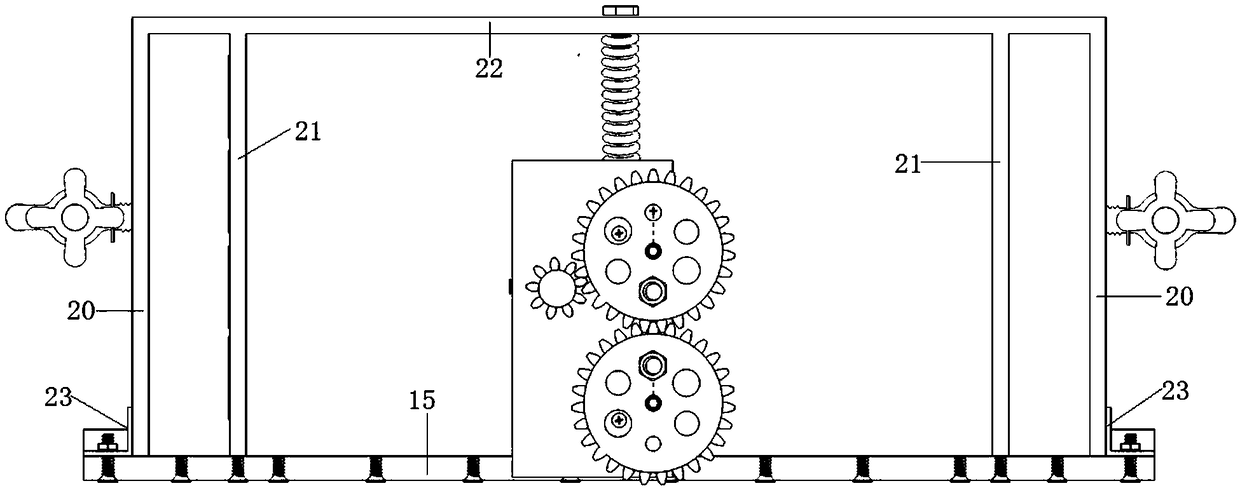

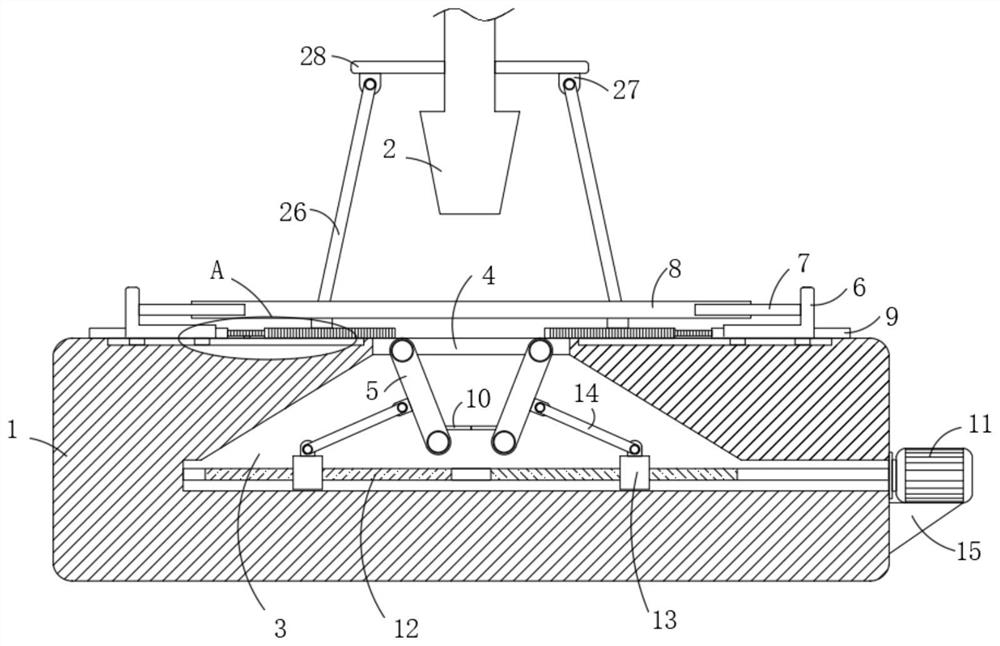

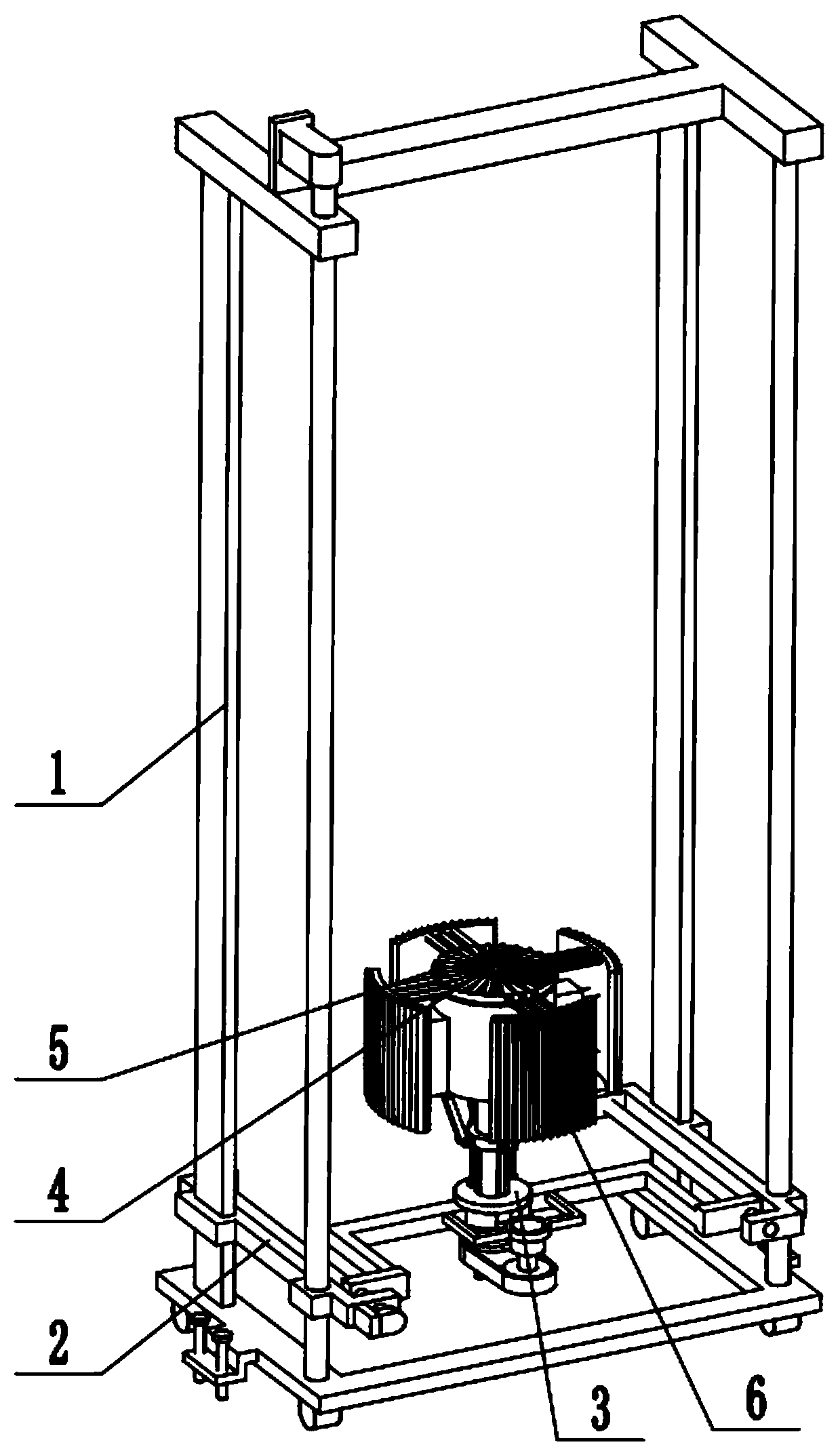

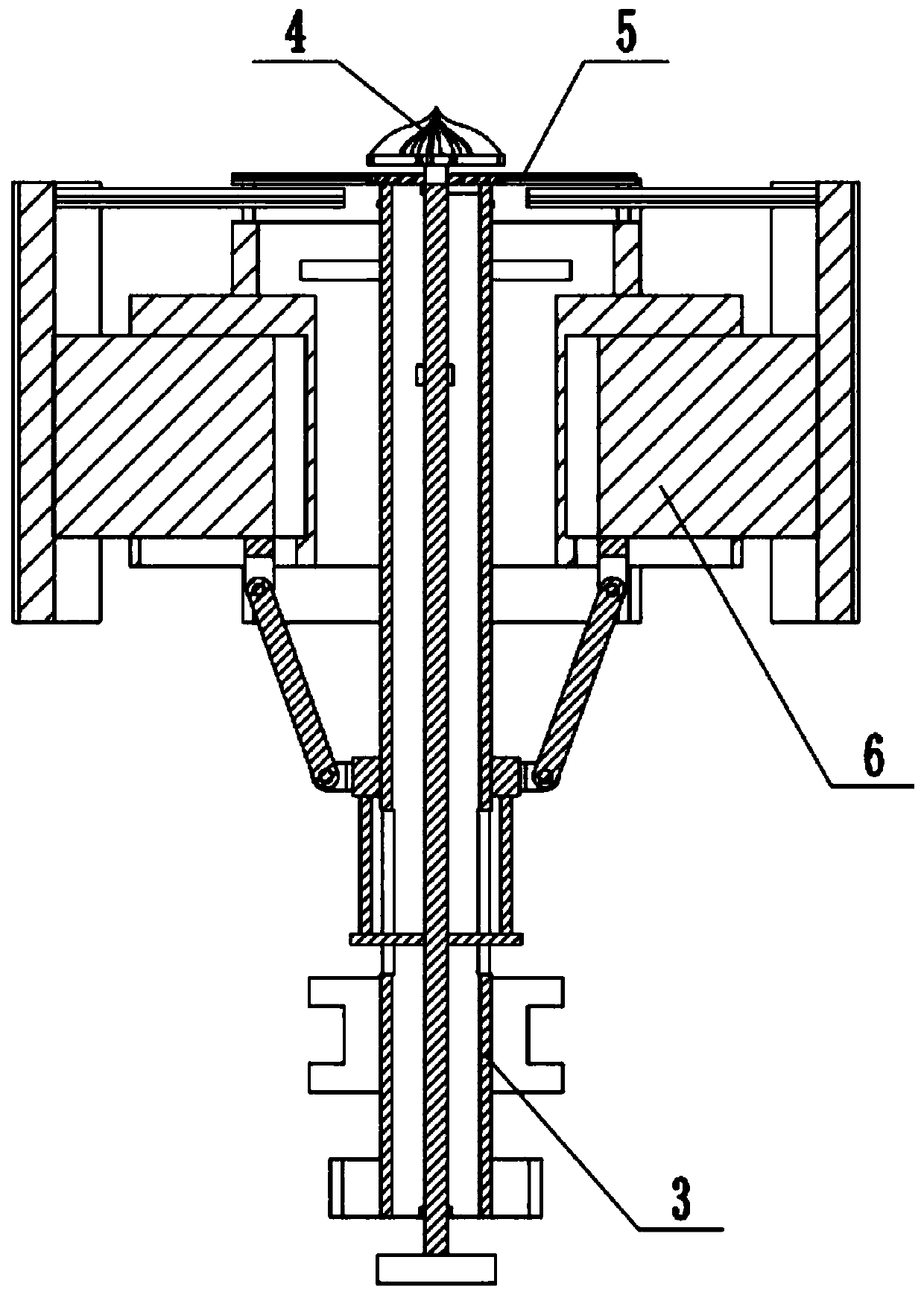

Two-dimensional pile soil interaction experiment system based on PIV technology and experiment method

ActiveCN109490111AChange the stiffnessChange depthMaterial strength using repeated/pulsating forcesEngineeringData collecting

The invention relates to a two-dimensional pile soil interaction experiment system based on PIV technology and an experiment method. The system comprises a two-dimensional vibration generating structure capable of controlling vibration force amplitude and vibration frequency, and the two-dimensional vibration generating structure is arranged on a plane; the system further comprises a data collecting and processing module applying PIV technology and in communication connection with the two-dimensional vibration generating structure through a data line. By the system and the method, vibration frequency, force amplitude, pile foundation rigidity, pile foundation buried depth, soil saturation and uniformity can be changed directly or indirectly, and impact of the above factors on soil movementcan be researched; soil particle movement process can be measured by adopting a noncontact way without damaging undisturbed soil.

Owner:HOHAI UNIV

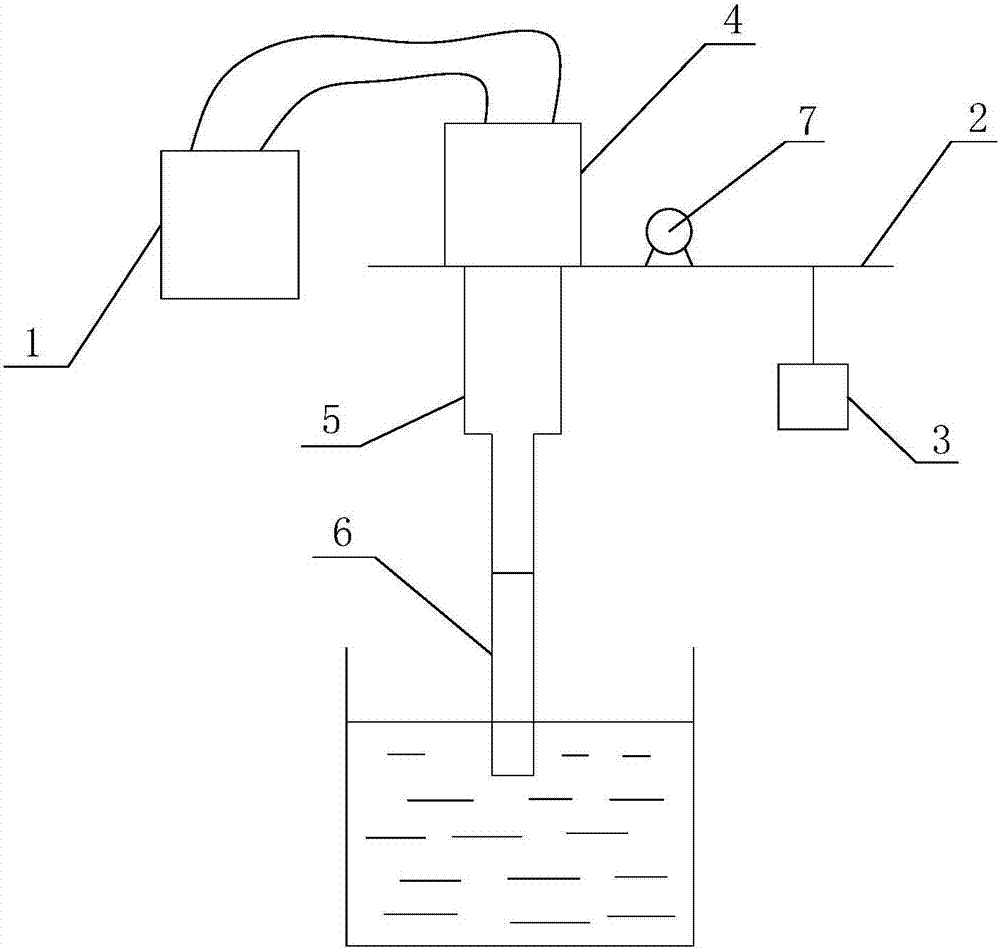

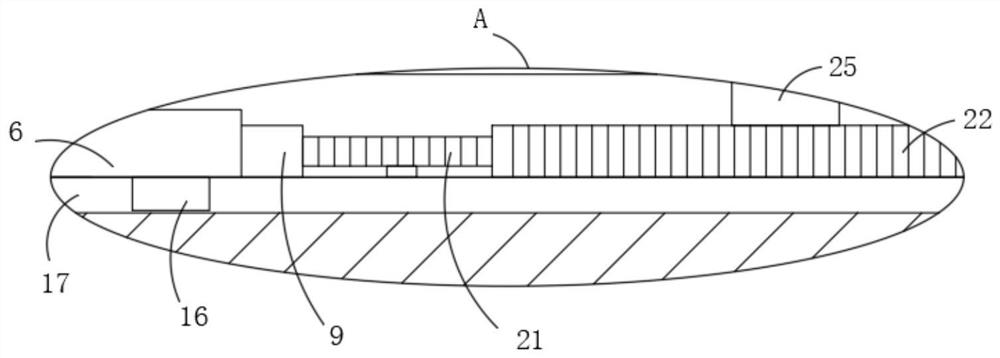

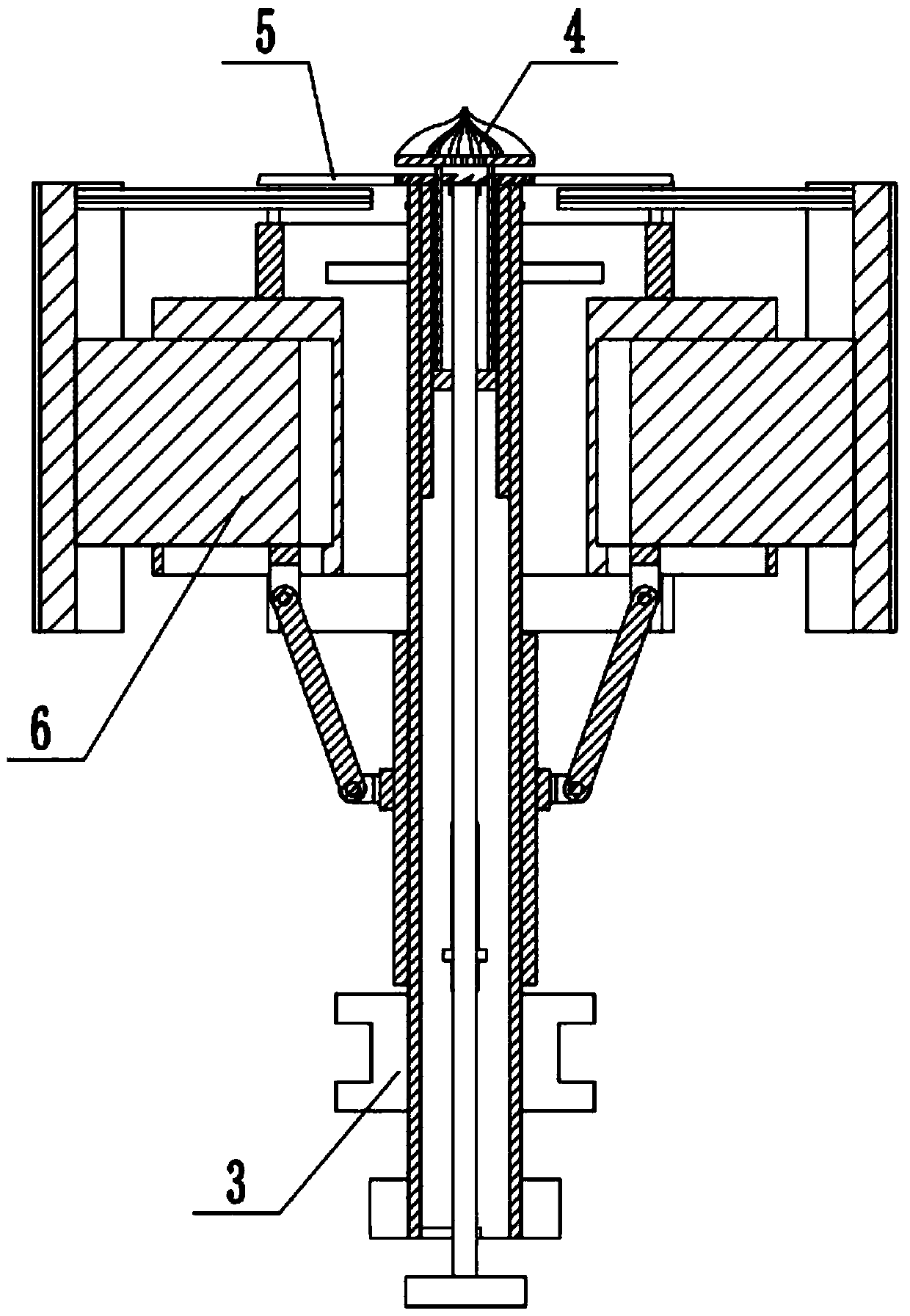

Ultrasonic wave vibration device for aluminum alloy casting

InactiveCN107363245ALower working temperatureAdjust depth in real timeTransducerUltrasonic vibration

The invention relates to the field of casting technology, in particular to an ultrasonic vibration device for aluminum alloy casting, which includes an ultrasonic generator, a mobile control platform, a power device, and an ultrasonic vibration system. The ultrasonic vibration system includes ultrasonic transducers connected in sequence The ultrasonic generator is connected with the ultrasonic transducer, the ultrasonic transducer is connected with the mobile control platform, and the power device is used to drive the mobile control platform to move up and down. Through the device, the forming effect of the aluminum alloy in the casting process can be improved, and the quality of the finished product can be improved. Set up a mobile control platform, which can adjust the height of the device in real time, thereby changing the depth of the tool rod in the aluminum alloy solution, avoiding too close contact with the high-temperature aluminum alloy solution, and ensuring the safety of the device.

Owner:CHENGDU XINGYU PRECISION CASTING

Nondestructive metal plate bending machining device

PendingCN111842560AReduce frictionGuaranteed aestheticsMetal-working feeding devicesPositioning devicesStructural engineeringManufacturing engineering

The invention discloses a nondestructive metal plate bending machining device. The nondestructive metal plate bending machining device comprises a mounting base and a bending head arranged above the mounting base, wherein a mounting cavity is formed in the mounting base; a bending hole is formed in the top in the mounting cavity; the inner side wall of the mounting cavity is rotationally connectedwith two symmetrically-arranged rotating supporting plates; the opposite sides of the two rotating supporting plates are fixedly connected with jacking supporting plates; and an adjusting device matched with the rotating supporting plates is arranged in the mounting cavity. According to the nondestructive metal plate bending machining device, two limiting mechanisms are utilized for cooperation,the position of a metal plate machining piece body can be fixed, meanwhile, when the bending head moves downwards, the two limiting mechanisms can be driven to synchronously move towards the middle, then the bending work of the metal plate machining piece body is completed, friction between the metal plate machining piece body and the inner wall of the top of the bending hole can be effectively reduced, generation of scratches and dents is reduced, and the attractiveness and quality of a machined workpiece are guaranteed.

Owner:潘礼萍

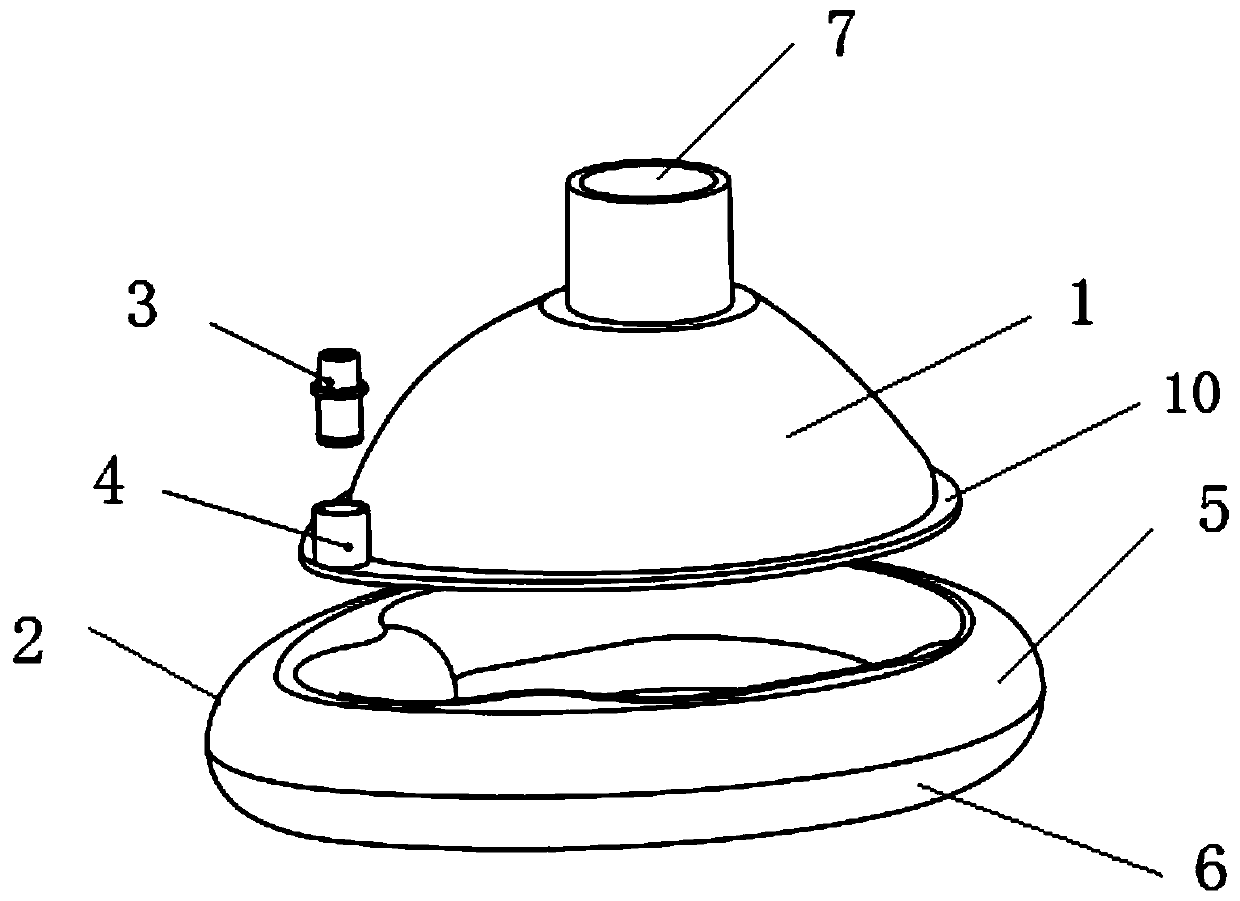

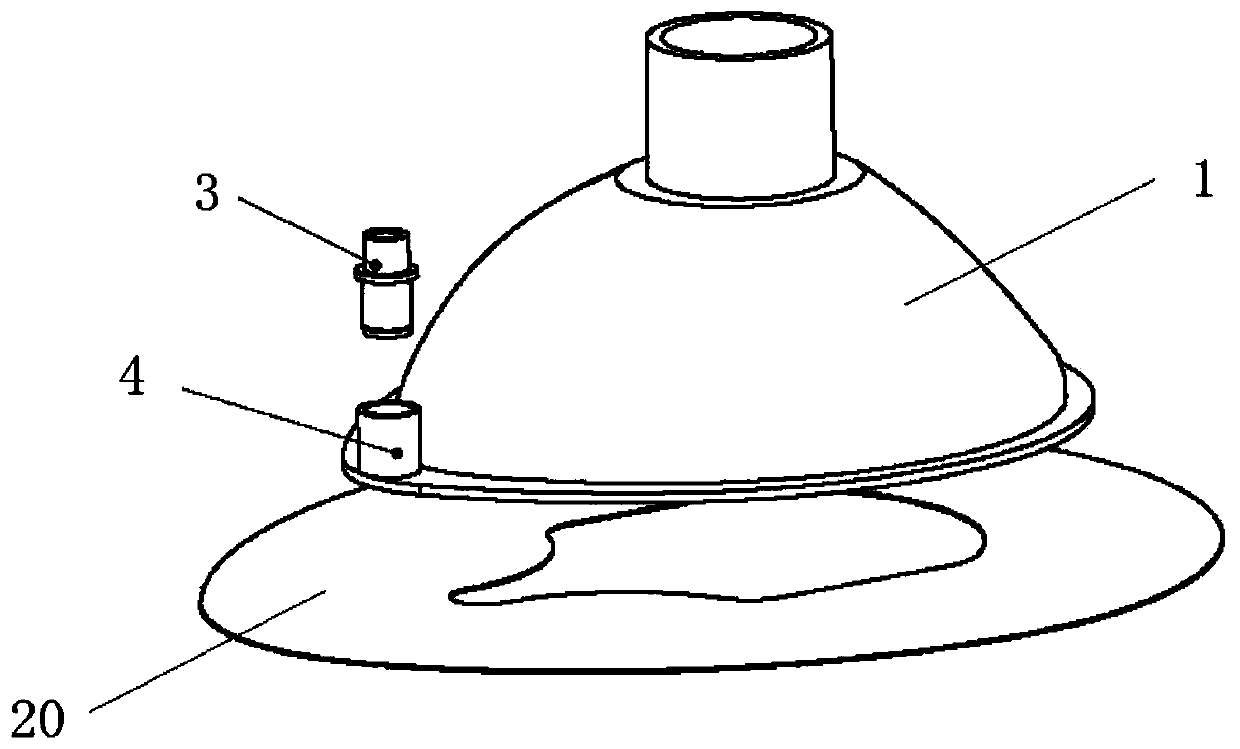

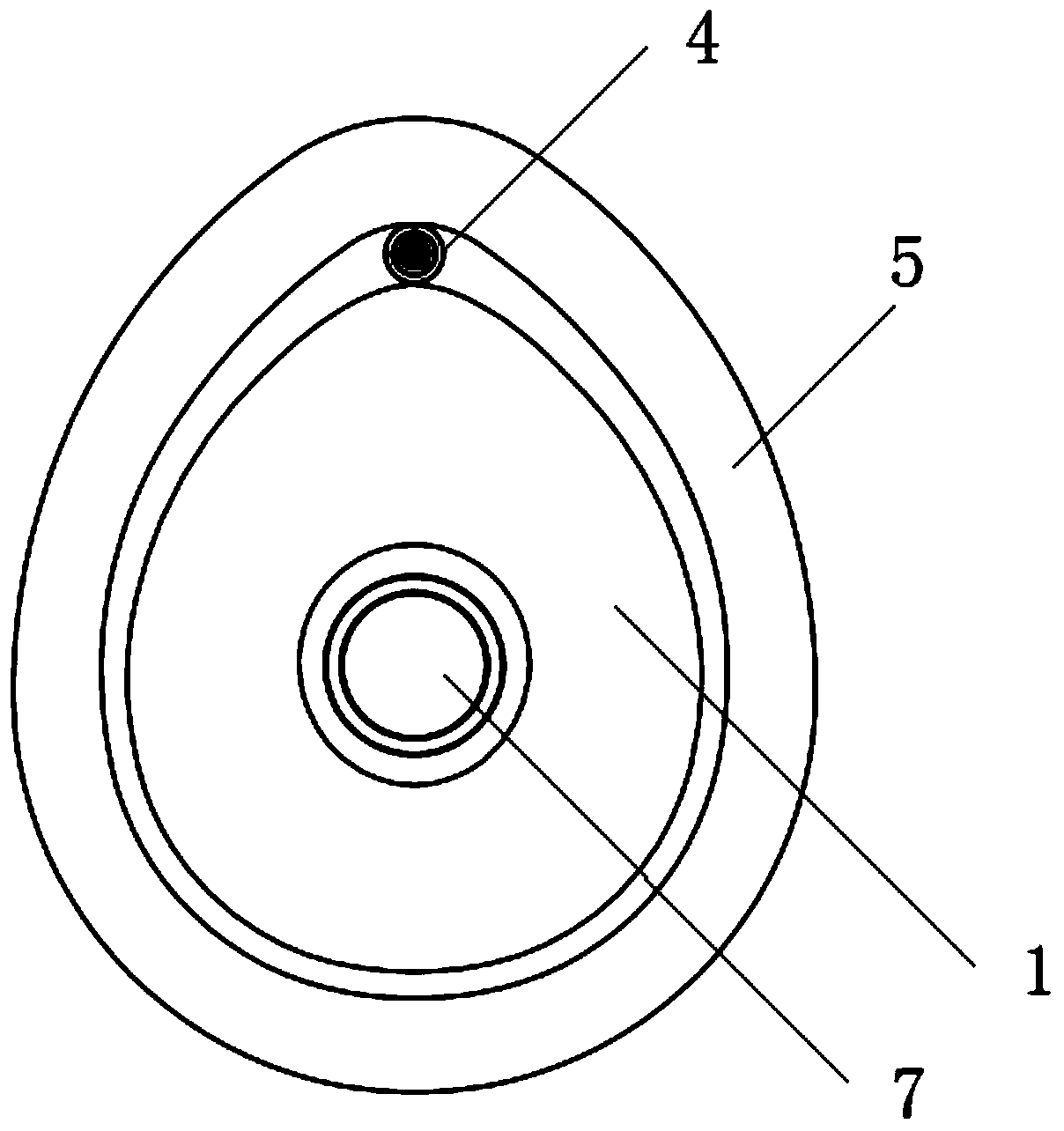

Anaesthetic mask adopting air bag manufactured by unique method as air cushion and manufacturing method thereof

ActiveCN110448778AControl thicknessMulti-intensityRespiratory masksMedical devicesPlastic filmEngineering

The invention discloses an anaesthetic mask adopting an air bag manufactured by a unique method as an air cushion and a manufacturing method of the anaesthetic mask. The anaesthetic mask comprises anupper cover, the air cushion and an air valve, the air cushion is formed by superposing a thin and soft plastic film A and a thin and soft plastic film B which are manufactured by a blow molding process, welding the film A and the film B together by using a prefabricated irregular annular air cushion mold of which the inner ring outline is consistent with the outline of the mouth and the nose of ahuman face to form the annular air bag, and then inflating the annular air bag. The section shape of an air cushion mold is designed and manufactured according to the shape of the annular air bag, and the inner ring outline of the annular air bag is designed according to the face, mouth and nose outline. The upper surface of the A film is bonded with the bottom of the upper cover, the air valve is installed in an air valve installation hole of the upper cover, and the A film is provided with a small hole communicated with the air valve. An annular ring air cushion is formed after the annularair bag is inflated, and the circle, making contact with a patient, of the annular ring air cushion can be tightly attached to the face of the patient. The anaesthetic mask has the characteristics ofhigh air tightness, quick installation, high comfort and high economy.

Owner:KOO MEDICAL EQUIP SHANGHAI CO LTD

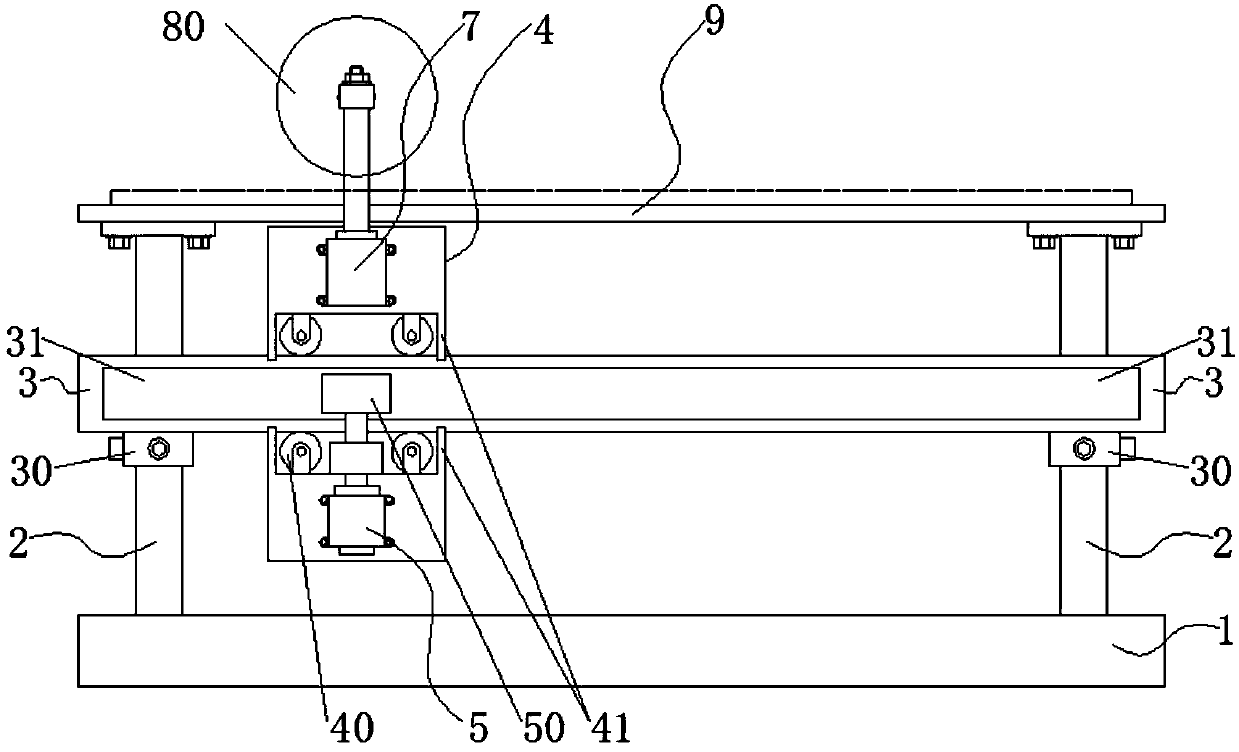

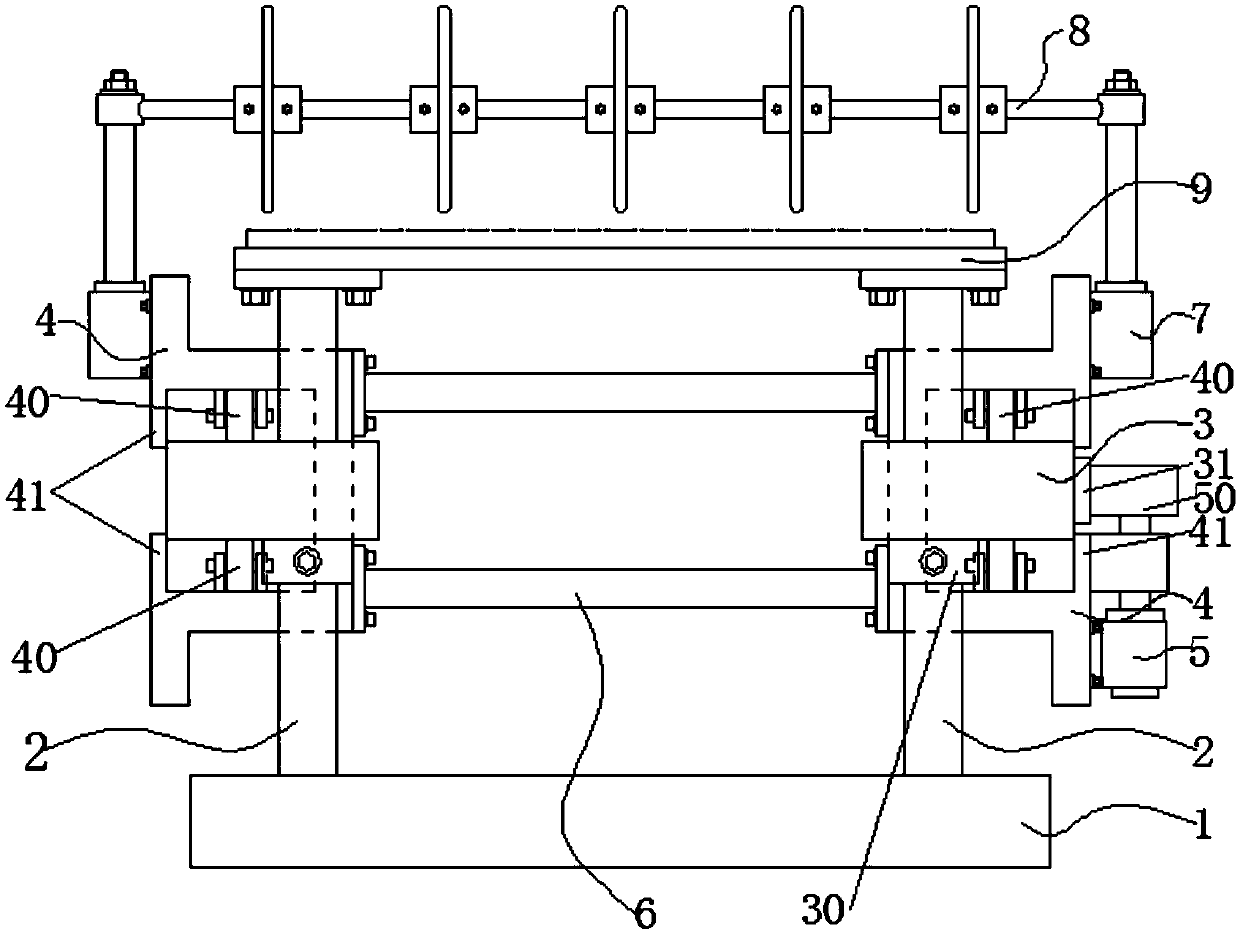

Paperboard folding-line making device

InactiveCN109834989ARealize indentation operationChange depthBox making operationsPaper-makingProduction linePaperboard

The invention discloses a paperboard folding-line making device. The paperboard folding-line making device comprises a base, stand columns, sliding tables, sliding bases, a servo motor, supporting rods, air cylinders, a folding-line making shaft and a workbench, wherein four stand columns and four supporting rods are arranged, two sliding tables, two sliding bases and two air cylinders are arranged, the lower ends of the stand columns are fixedly connected with the base, connecting sleeves are arranged at the lower ends of the sliding tables, the sliding tables are connected with the middles of the stand columns in a locking mode through the connecting sleeves, racks are arranged on the side faces of the sliding tables, a pair of rollers are arranged in each sliding base, the sliding basesare in rolling connection with the sliding tables through the rollers, the servo motor is connected with the side faces of the lower ends of the sliding bases, a gear is arranged on an output shaft of the servo motor, the gear is meshed with the racks, the two sliding bases are connected into a whole through the supporting rods, the air cylinders are connected with the side face of the upper endsof the sliding bases, the two ends of the folding-line making shaft are respectively connected with the end parts of piston rods of the two air cylinders, and the worktable is connected with the topsof the stand columns, so that the folding-line making operation of a paperboard on a production line of the paperboard is realized, the traditional manual rolling and pressing operation is avoided, and the requirements of an automatic production line are met.

Owner:安徽祥欣新材料科技有限公司

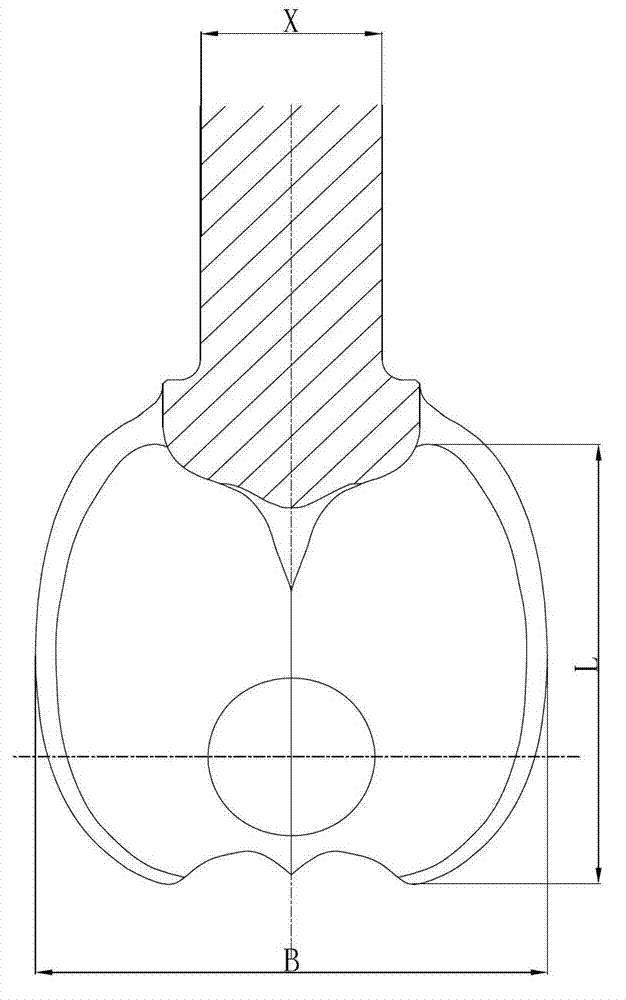

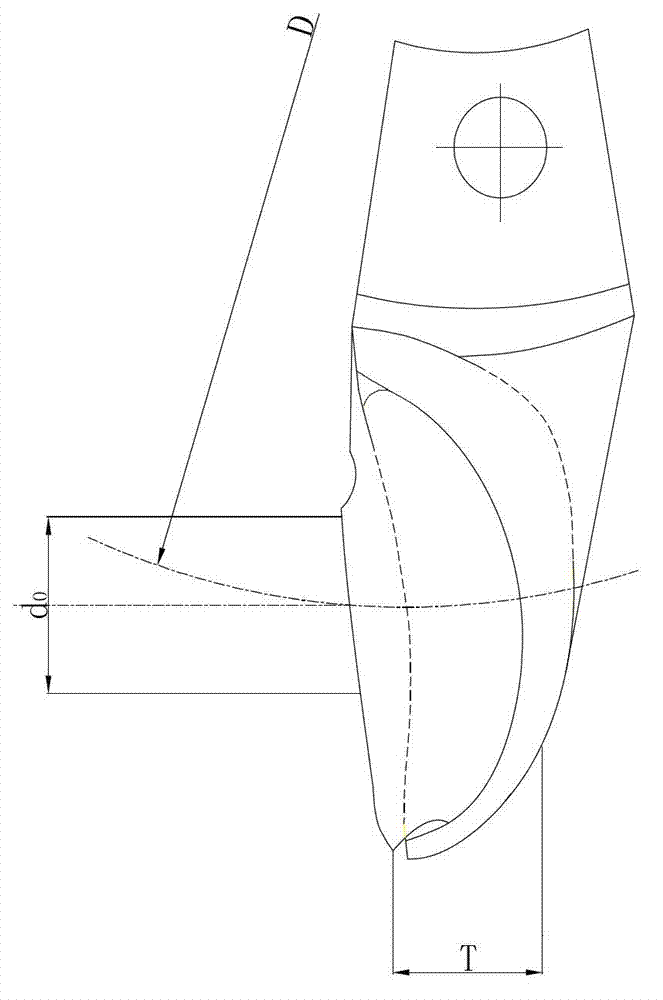

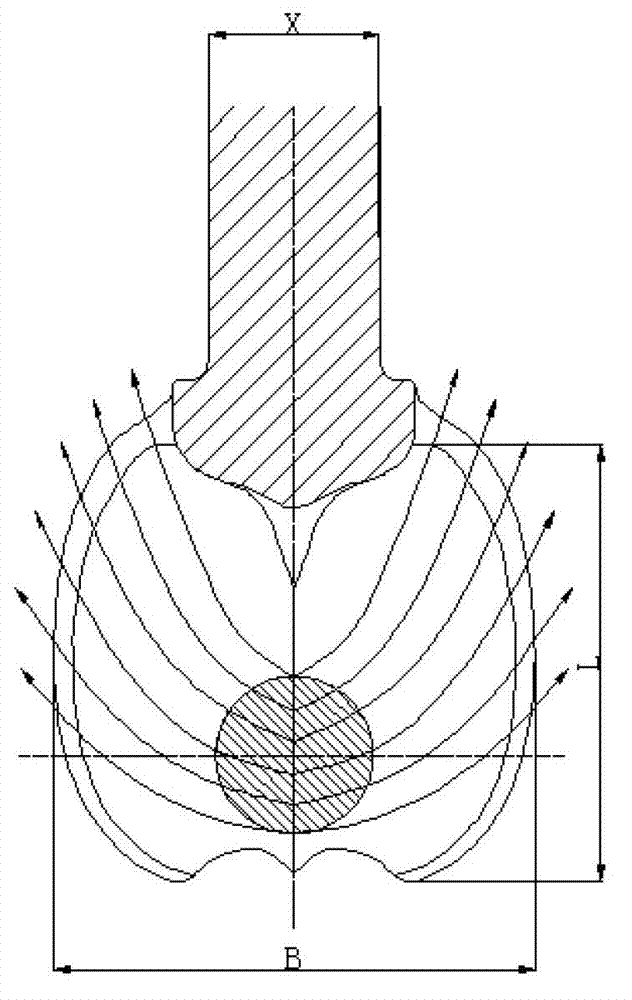

Tangential turbine runner

InactiveCN102734041AChange radial lengthChange widthHydro energy generationImpulse enginesJet flowMaximum efficiency

The invention discloses a tangential turbine runner comprising a runner shaft and bucket blades which are uniformly arranged on the circumference of the runner shaft. The quantity of the bucket blades is obtained by the formula that the radial length L of each bucket blade is equal to (2.2-2.5)d0 and is reduced by 10%-15% compared with the radial length of the regular bucket blade; the width B of each bucket blade is equal to (2.8-3.2)d0 and is increased by 9%-11% compared with the width of the regular bucket blade; the depth T of each bucket blade is equal to (0.95-1.15)d0 and is increased by 4%-6% compared with the depth of the regular bucket blade; and the root thickness X of each bucket blade is equal to (0.5-0.8)B. According to the tangential turbine runner disclosed by the invention, parameters of the radial length, the width and the depth of each blade bucket are changed, the root thickness of each bucket blade is increased, and the quantity of the bucket blades is calculated according to the researched bucket blade quantity determining formula, so that the nozzle quantity, the jet flow and the flowing inside the runner do not interfere with one another, and reflowing does not exist in the root part region of each bucket blade. The hydraulic loss is greatly reduced and the output power of a set is greatly improved; and the model hydraulic efficiency of the tangential turbine runner with the bucket blade structure is detected to reach 91.66%, which the highest efficiency value of the current same-type runners at home and abroad.

Owner:XIHUA UNIV

Composite carbon tool steel/plain carbon steel metallurgical lining board with high resistance, high uniformity and long service life

InactiveCN102154537AHigh hardnessImprove uniformityIncreasing energy efficiencyFurnace typesHigh resistanceWear resistant

The invention discloses a composite carbon tool steel / plain carbon steel metallurgical lining board with high resistance, high uniformity and long service life. Aiming at characteristics of an explosive composite wear-resistant material and operating requirements of a metallurgical wear-resistant lining board, the surface induction heating principle and the metal phase transformation theory are used for controlling the depth of heat penetration, the hardness of an appropriate layer interface, and the depth and uniformity of a quench hardening layer so that the hardness of the composite layer is distributed in gradient, and the complete martensite phase change is avoided from occuring in the composite interface layer during quenching so to reduce the structure stress formed on the interface and keep the original combination state of the composite board to the greatest extend. The composite metallurgical lining board with high resistance, high uniformity and long service life has surface hardness of larger than 61HRC (rockwell hardness) and uniformity of hardness of less than 3 HRC (rockwell hardness); A 5mm place of the composite layer in the thickness direction has a hardness value of larger than 50HRC (rockwell hardness); and the three fifth to four fifth place of the composite layer thickness has the hardness value of less than 35HRC (rockwell hardness).

Owner:JIANGSU RUNBANG NEW MATERIAL GRP CO LTD

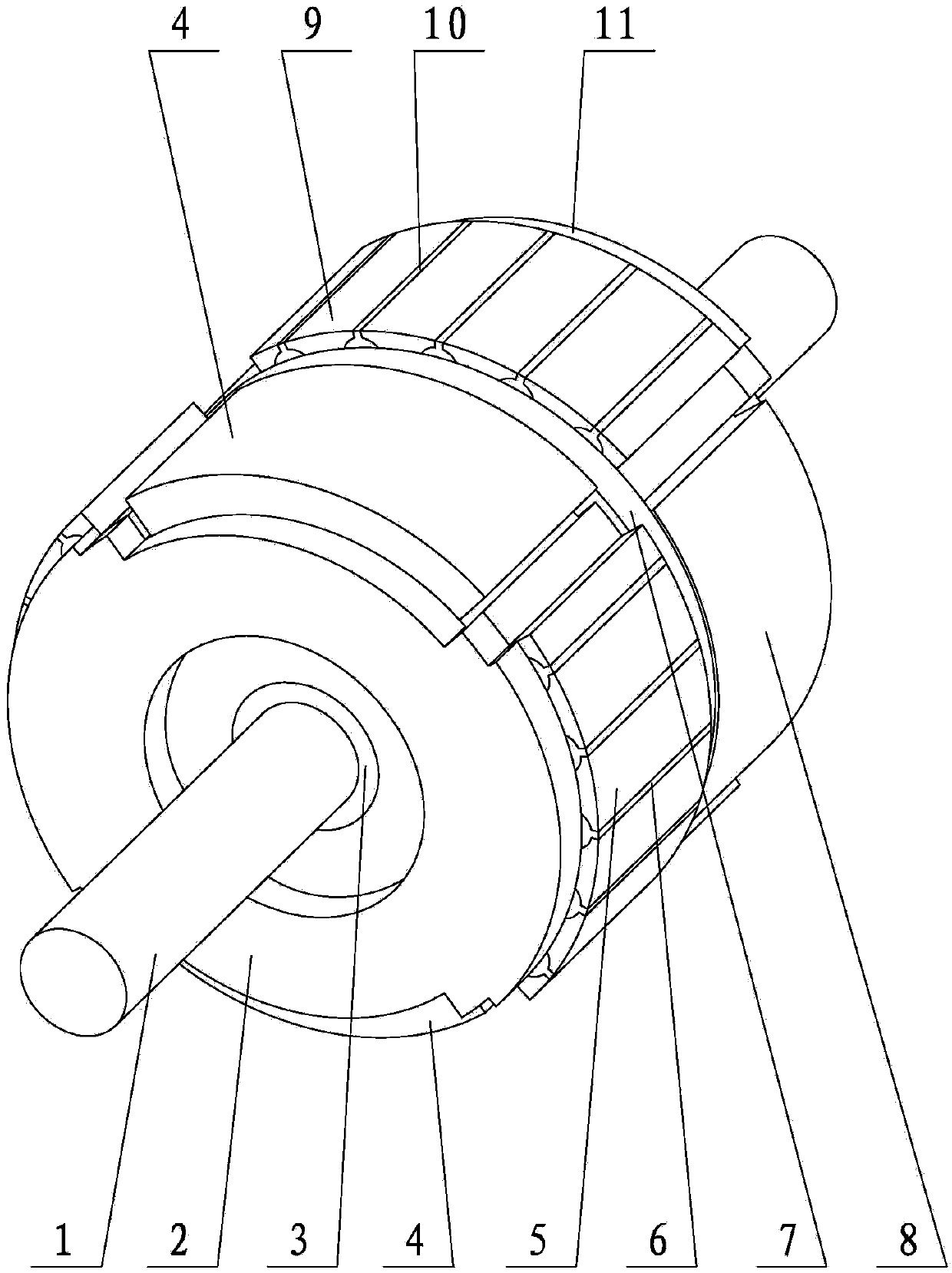

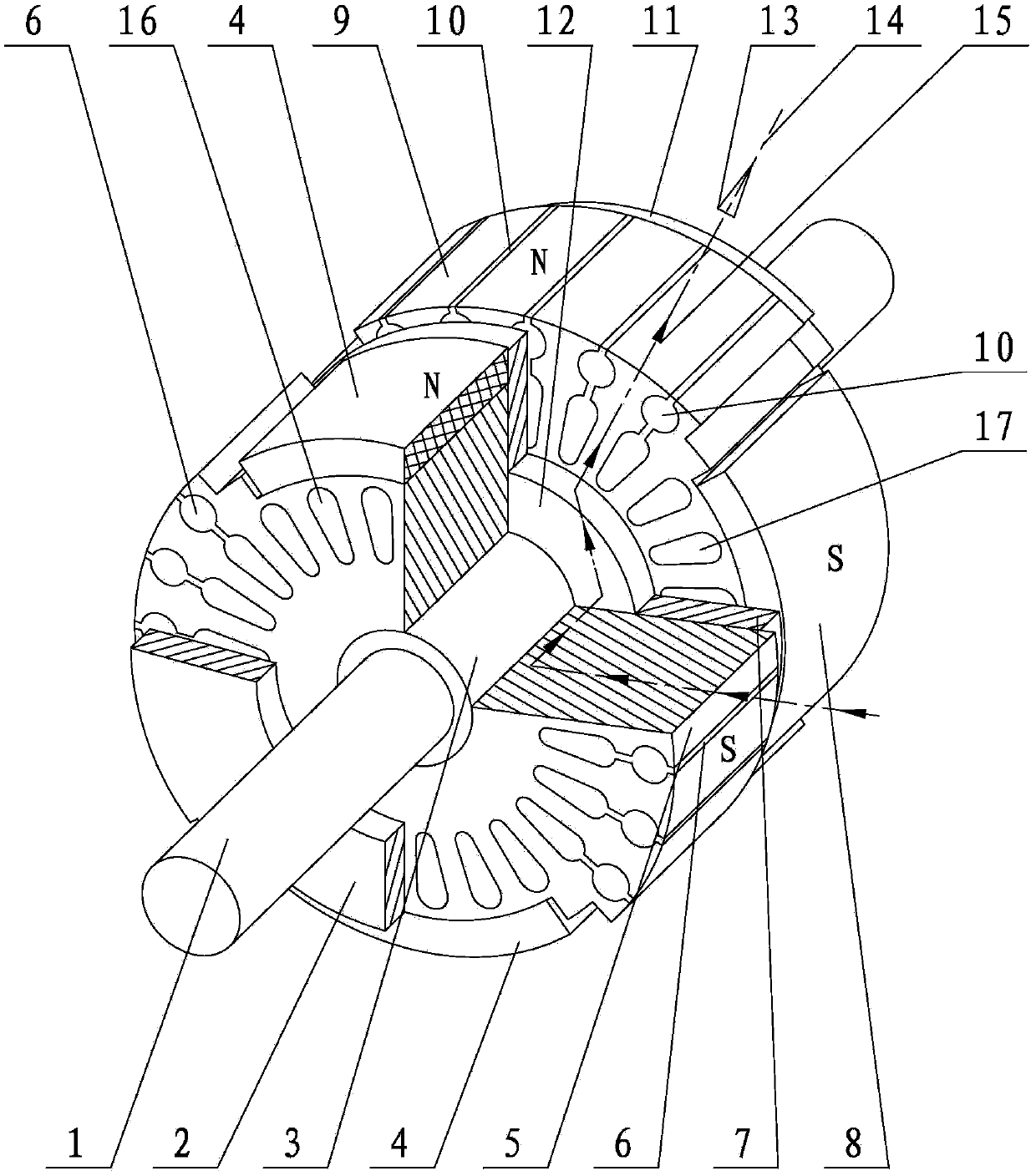

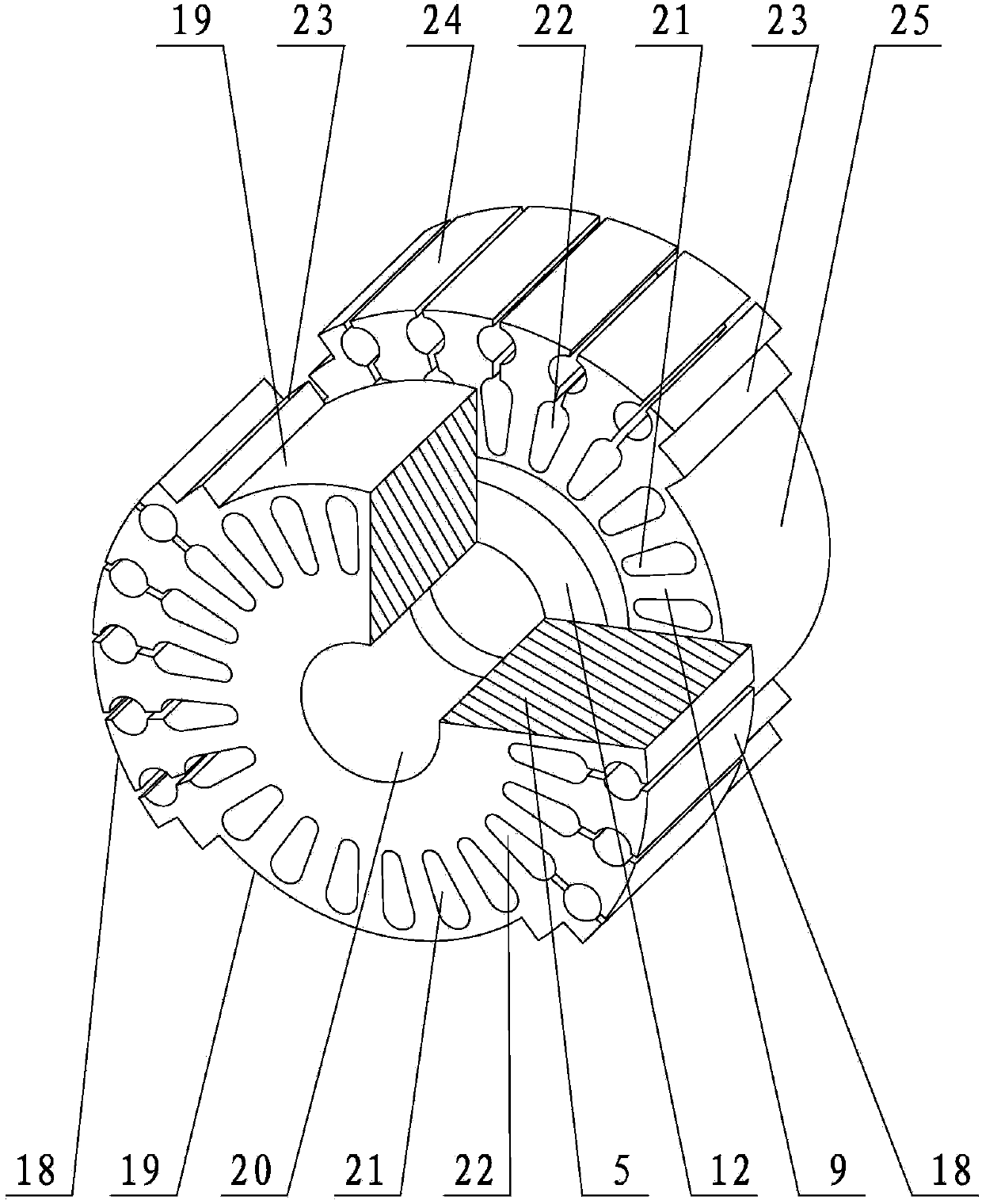

Double-magnetic-circuit asynchronous-starting permanent magnet synchronous motor rotor

ActiveCN104184284AAvoid mutual interferenceChange depthDynamo-electric machinesForce linesRotor magnets

The invention provides a double-magnetic-circuit asynchronous-starting permanent magnet synchronous motor rotor and relates to a rotor applied to a permanent magnet synchronous motor. The rotor is provided with two rotor iron cores. The two rotor iron cores are coaxial and staggered with a certain angle to form two rotor permanent magnet magnetic-circuits. In a pair of opposite magnetic poles of each rotor iron core, only one permanent magnet is used as a magnetic pole, and a rotor iron core salient pole is used as the other magnetic pole. A rotor magnet yoke is arranged between the two rotor iron cores, and the rotor magnet yoke enables a pair of opposite magnetic poles of a stator to be connected through stator magnetic field magnetic circuits of the two rotor iron core salient poles. At any moment of the starting process of the rotor, stator rotating magnetic field magnetic force line path cut by core mouse cage guide bars at the inner side of each rotor iron core salient pole passes through a salient pole air gap twice, magnetic resistance of the stator rotating magnetic field magnetic circuit is minimum, and the double-magnetic-circuit asynchronous-starting permanent magnet synchronous motor rotor is allowed to generate the maximum starting torque.

Owner:HEPING CHANGSHENG MOTOR CO LTD

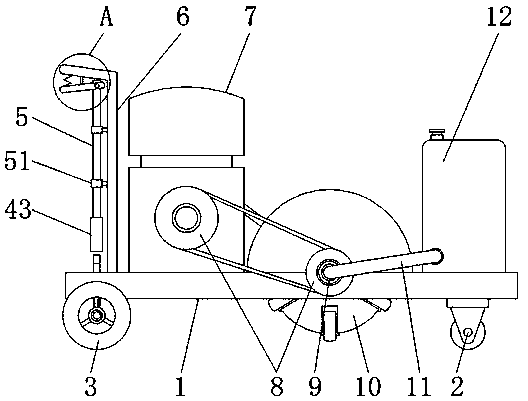

Road surface grooving machine with groove depth adjusting mechanism

InactiveCN109778654AGuaranteed straightnessExtended service lifeRoads maintainenceWater tanksDiesel engine

The invention discloses a road surface grooving machine with a groove depth adjusting mechanism. The road surface grooving machine comprises a machine frame, idler wheels are installed at one end of the machine frame, adjusting rods are arranged at the end of the machine frame, a diesel engine and a sleeve spindle are installed on the machine frame, the sleeve spindle is connected with a water tank through a water pipe, the water tank is installed on the machine frame, a grooving plate is installed on the edge of a grooving wheel, a drive rod is horizontally distributed on the side of the grooving wheel, the right end of the drive rod is installed in a sleeve, a sleeve plate is arranged inside the machine frame, and the sleeve is rotatably installed on the machine frame. Through the road surface grooving machine with the groove depth adjusting mechanism, it is ensured that a worker can change the walking mode of the grooving machine while pushing the grooving machine; by designing thestructure of the grooving wheel again, it is ensured that the worker can conveniently adjust the depth of grooving while grooving work is conducted, and meanwhile the functions of conducting cooling on the grooving wheel and dust falling on a grooving position are realized.

Owner:黄益艺

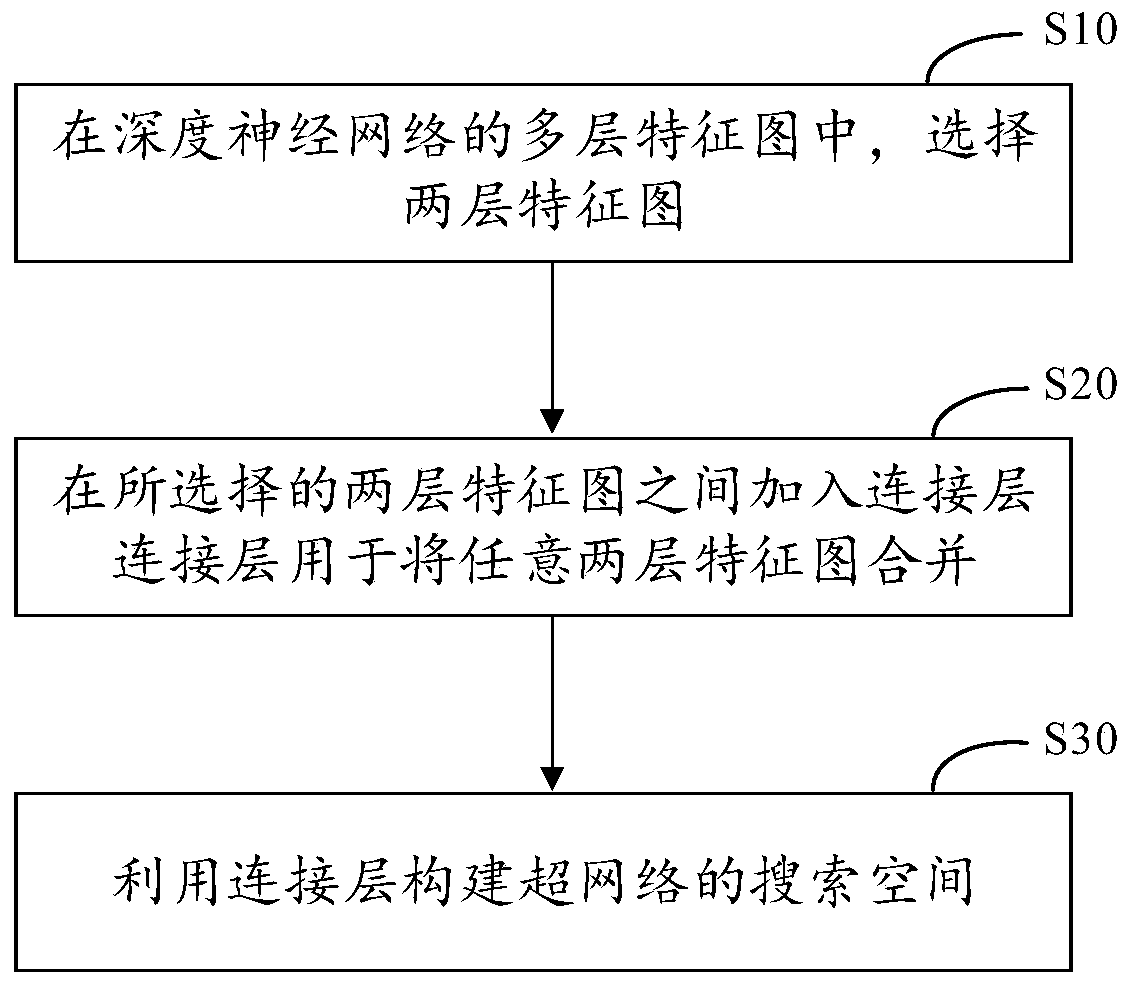

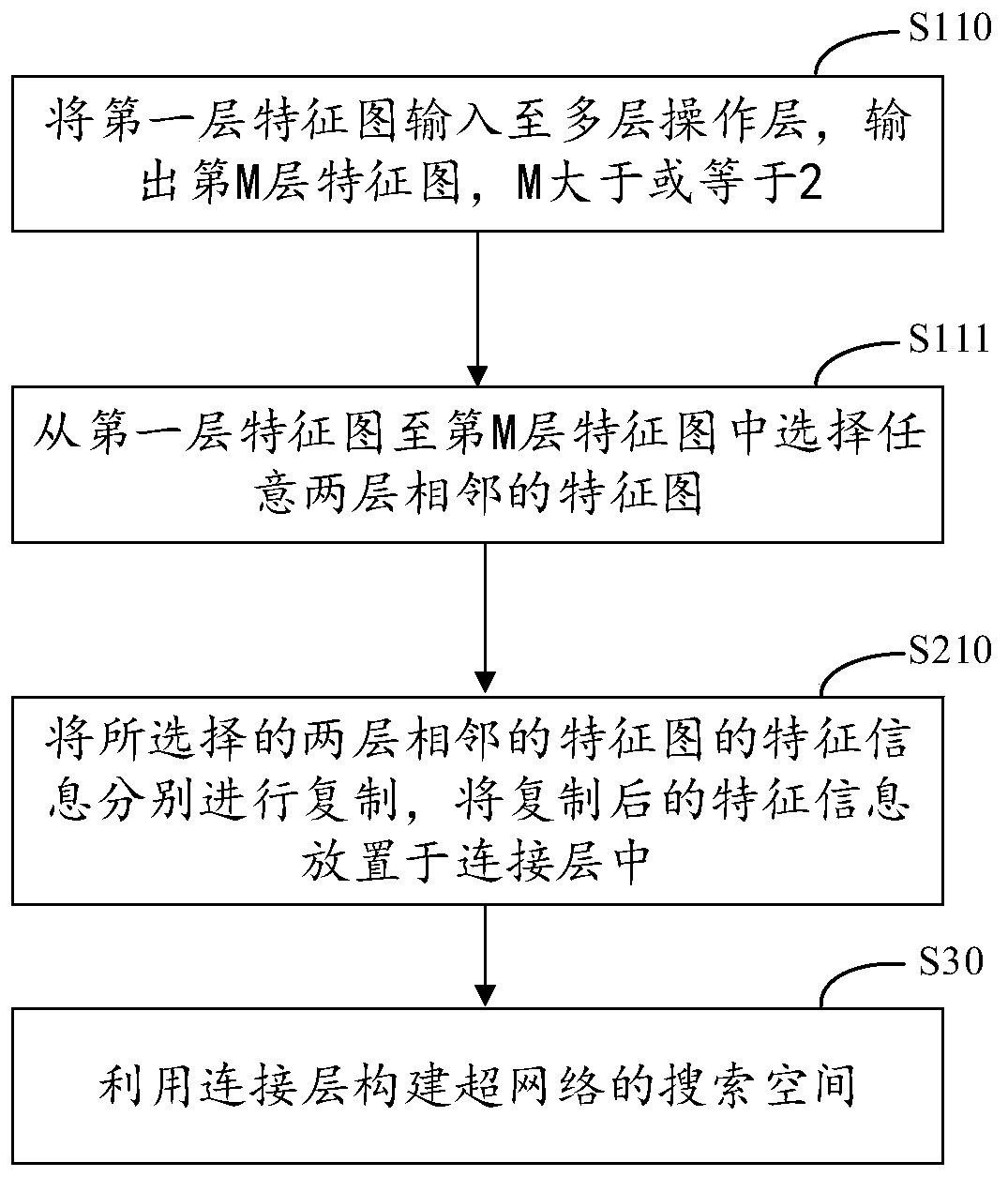

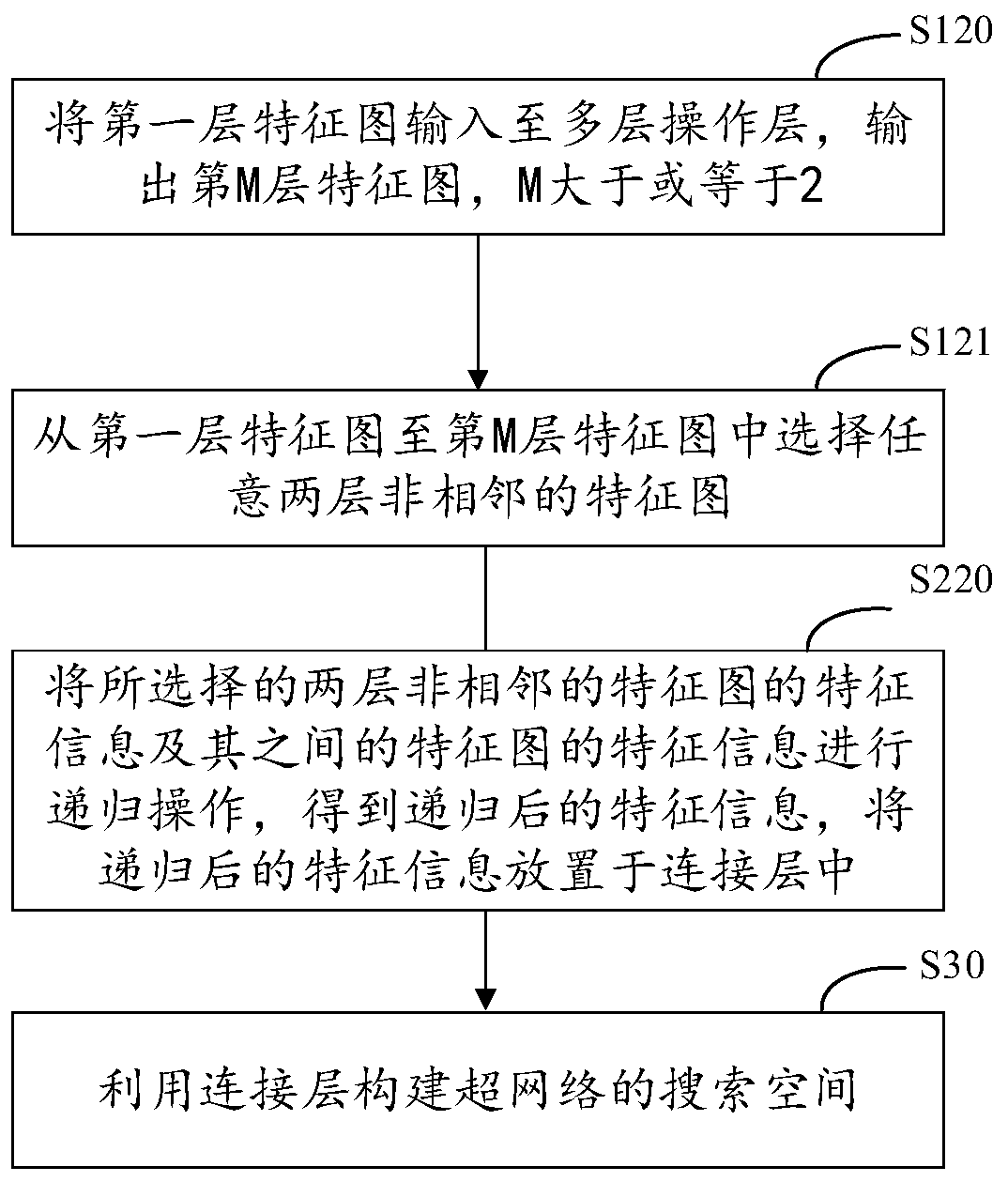

Super-network search space construction method and device and electronic equipment

ActiveCN110598629AChange depthImprove search efficiencyScene recognitionEnergy efficient computingMachine learningMultiple layer

The invention discloses a super-network search space construction method and device and electronic equipment, and relates to the field of neural network search. According to the specific implementation scheme, two layers of feature maps are selected from multiple layers of feature maps of a deep neural network; a connecting layer is added between the two layers of selected feature maps, wherein the connecting layer is used for combining the two layers of selected feature maps; and a search space of the super network is built by utilizing the connection layer. The number of the feature layers is changed by adding the connecting layers, and the depth of the deep neural network is also changed. A new search space is constructed by using a connection layer, so that a deep neural network of anydepth can be obtained under the constraint conditions of any model size and model speed and precision.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

Multi-axis laser cutting device

ActiveCN110238543AImproved adjustment modeAdd depthWelding/cutting auxillary devicesAuxillary welding devicesCouplingLaser cutting

The invention discloses a multi-axis laser cutting device. The multi-axis laser cutting device comprises a supporting frame, wherein a front-back through cutting cavity is formed in the supporting frame. According to the multi-axis laser cutting device, the requirements of machining precision are met by adjusting the positions of X, Y and Z directions on an original lathe, the transmission between a spiral groove and a sliding rod is adopted, the depth of a laser cutting workpiece is changed, a one-way coupling structure controlled by a curvature wheel is arranged on a coaxial shaft, the X-axis direction adjustment and the cutting process are ensured not to interfere with each other, one power source is common, the cost is saved, the operation is simplified, and the machining precision can be controlled when a spiral cutting requirement is guaranteed by utilizing the matching change of the rotation and the height.

Owner:JIANGSU DNCON LASER TECH

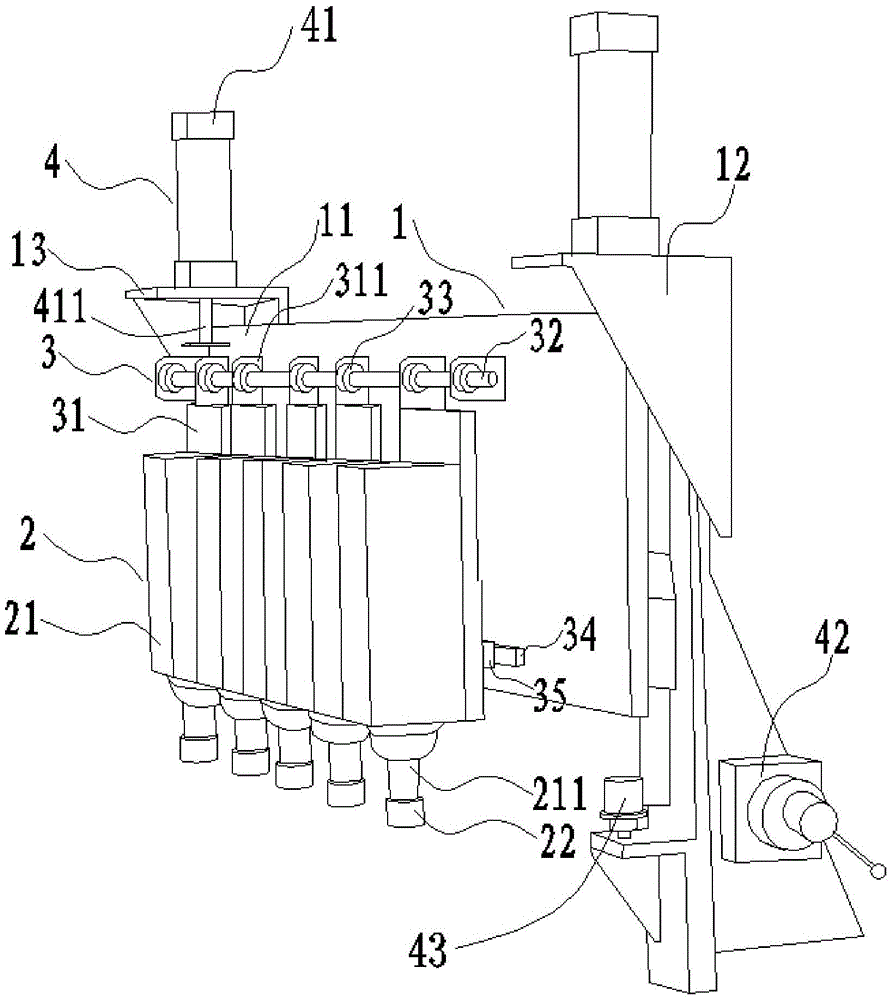

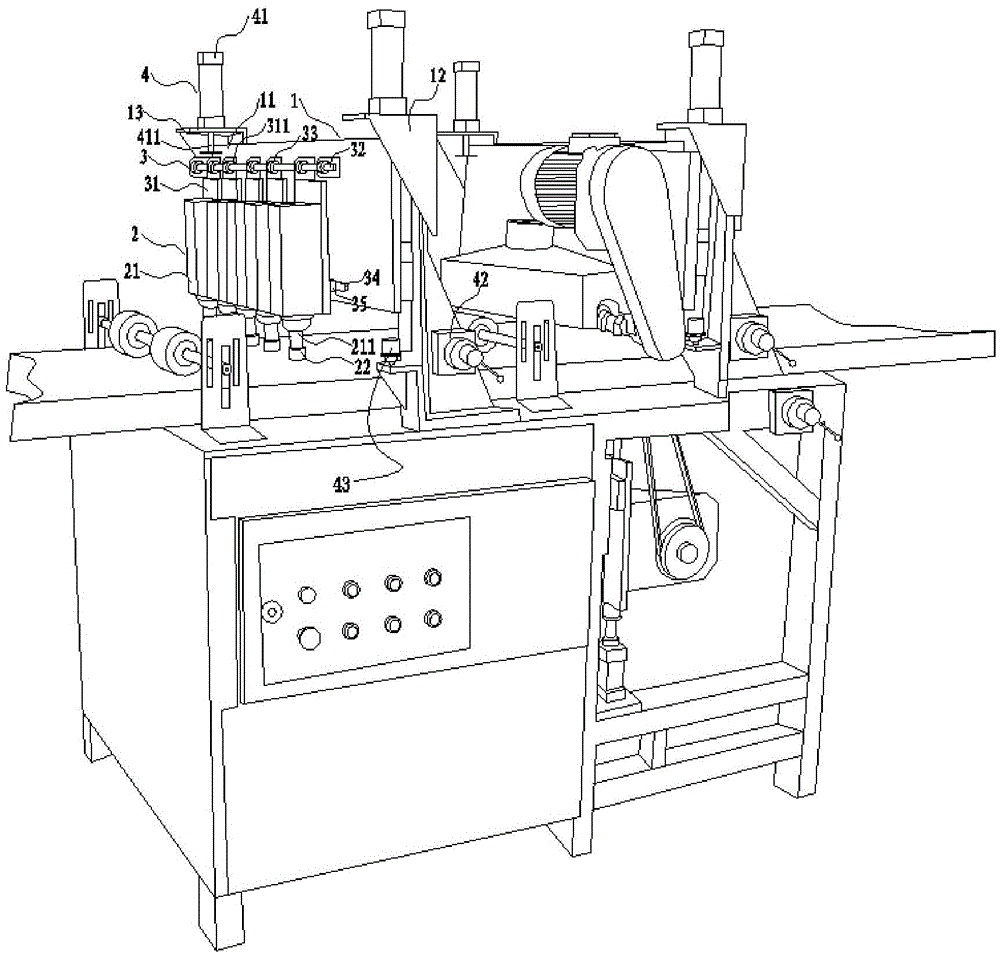

A kind of slotting equipment for sheet metal

ActiveCN106827123BChange spacingHigh precisionWood mortising machinesWood slotting machinesMechanical engineeringWood panel

The invention discloses plate grooving equipment, and relates to the field of furniture production equipment. The plate grooving equipment comprises a frame, a worktable, a clamping device and a grooving device; the grooving device includes a grooving knife, a lead screw driving mechanism and a first motor; the first motor can driven the grooving knife to move on the worktable through the lead screw driving mechanism; the grooving knife includes a base body, a knife frame, a first knife shaft, a second knife shaft, rotating knives, pull knives and a second motor; the knife frame is connected to the base body; the second motor is fixed on the knife frame; the first knife shaft is rotationally connected to the knife frame, and can be driven to rotate by the second motor; a rotating knife key is connected to the first knife shaft; a first pressure spring is arranged between the rotating knives; a first adjusting nut is arranged at one end of the first knife shaft; the second knife shaft is fixedly connected to the knife frame; a pull knife key is connected to the second knife shaft; a second pressure spring is arranged between the pull knives; and a second adjusting nut is arranged at one end part of the second knife shaft. The device can machine through grooves with different widths in plates without replacing knives.

Owner:枣庄高新建设集团有限公司

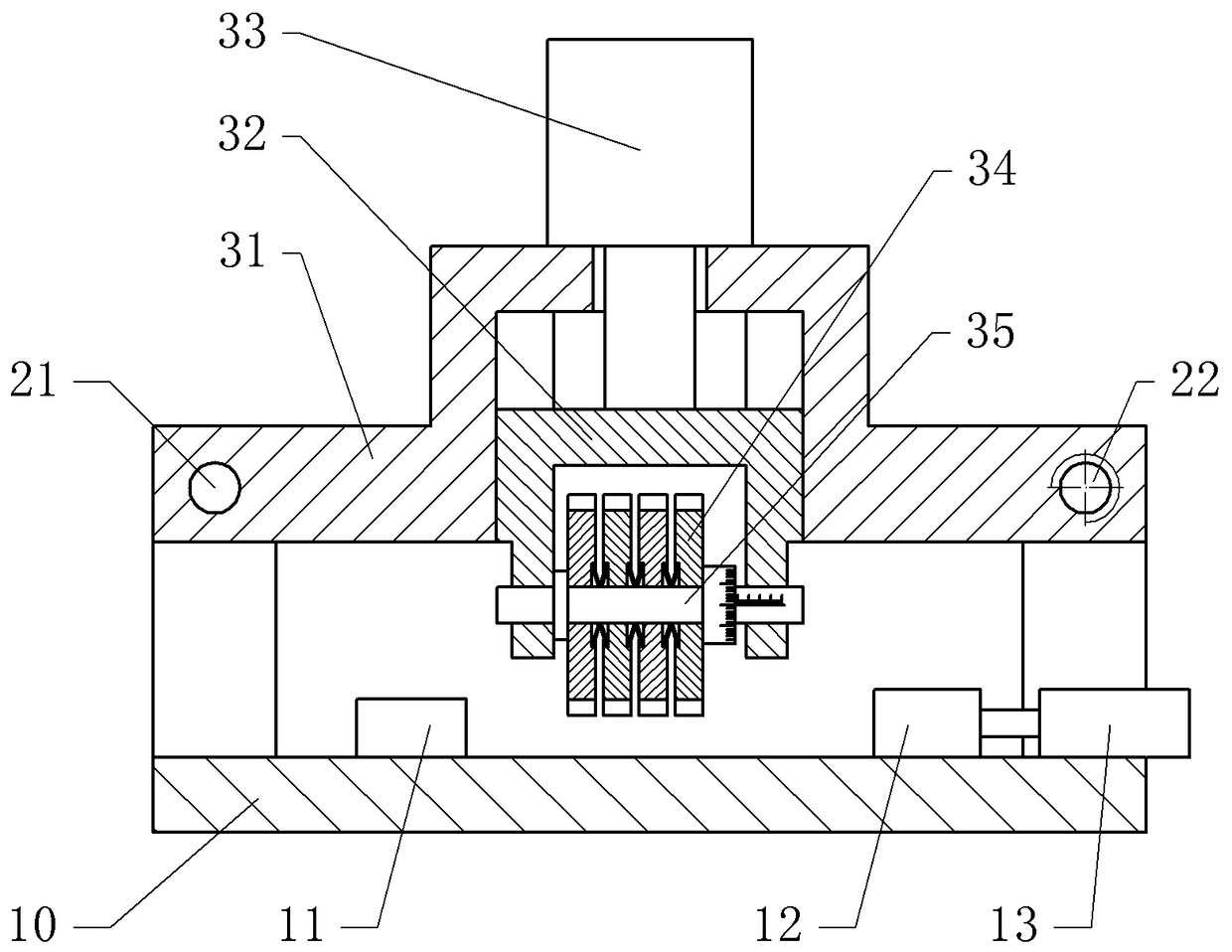

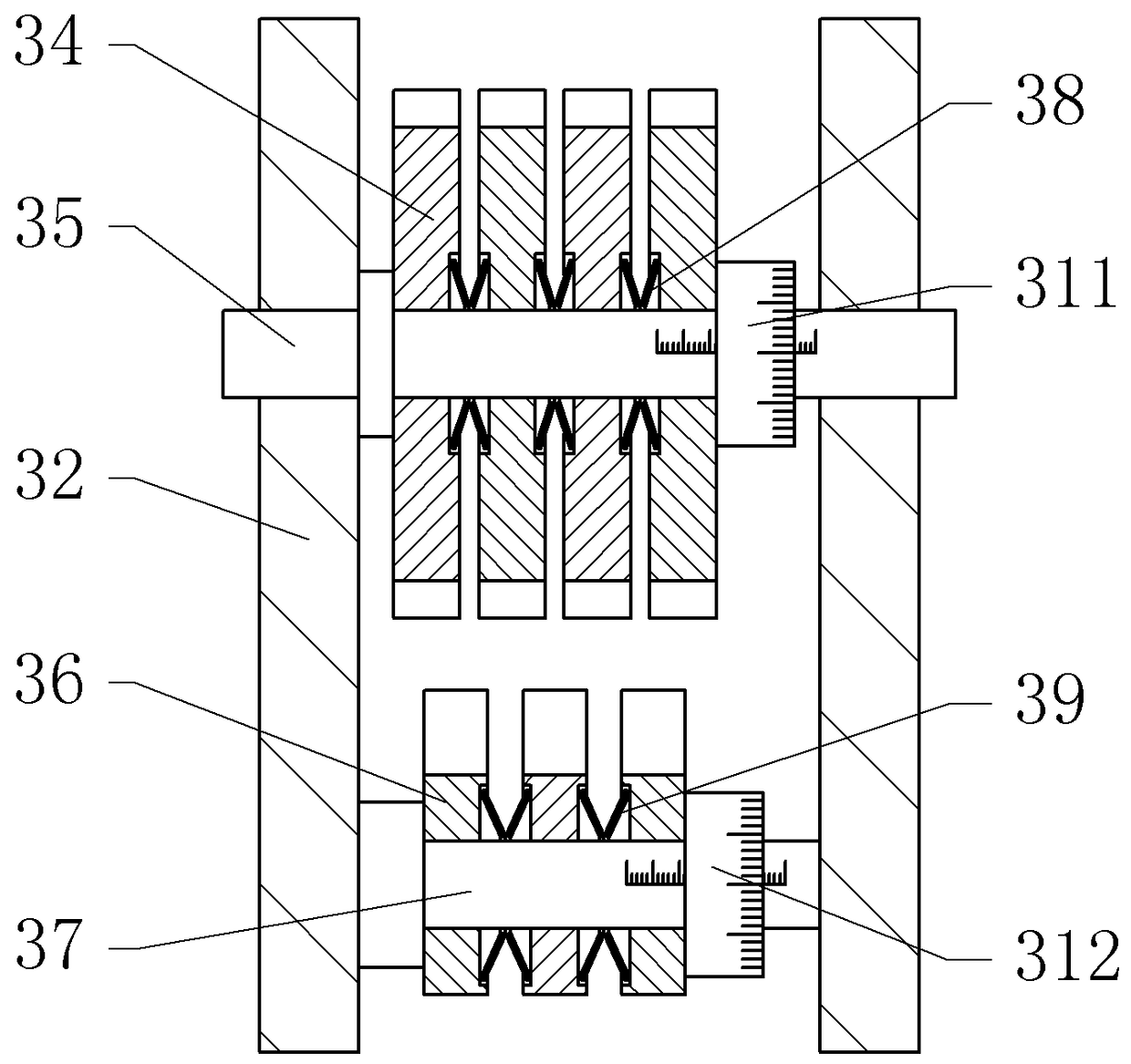

Grooving machine and routing device

The invention provides a grooving machine and a routing device. The grooving machine comprises a support, a plurality of grooving units and a plurality of positioning units. The positioning units are all arranged on the support used for supporting and installing the grooving machine, and the grooving units are all arranged on the support through the corresponding positioning units. The positioning units comprise first positioning parts and second positioning parts, the first positioning parts are connected with the support and used for adjusting the horizontal distance between every two adjacent grooving units, and the grooving units are arranged on the first portioning parts through the second positioning parts used for adjusting the height of the grooving units. The routing device comprises a pre-milling machine, a plurality of pressing mechanisms, a rack and the grooving machine. The pre-milling machine, the pressing mechanisms and the grooving machine are all arranged on the rack, and the pre-milling machine and the grooving machine are arranged in sequence in the plate moving direction. The grooving machine solves the technical problems that in the prior art, the groove type of grooves formed by a grooving machine is fixed, and the depth and groove pitch of the grooves are difficult to adjust.

Owner:TIANJIN CHENBAO ELECTROMECHANICAL TECH CO LTD

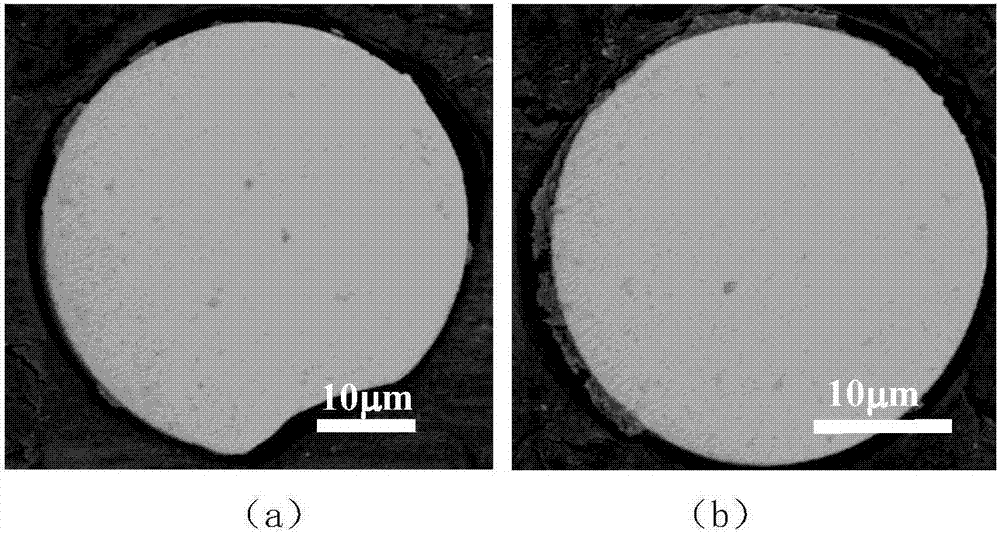

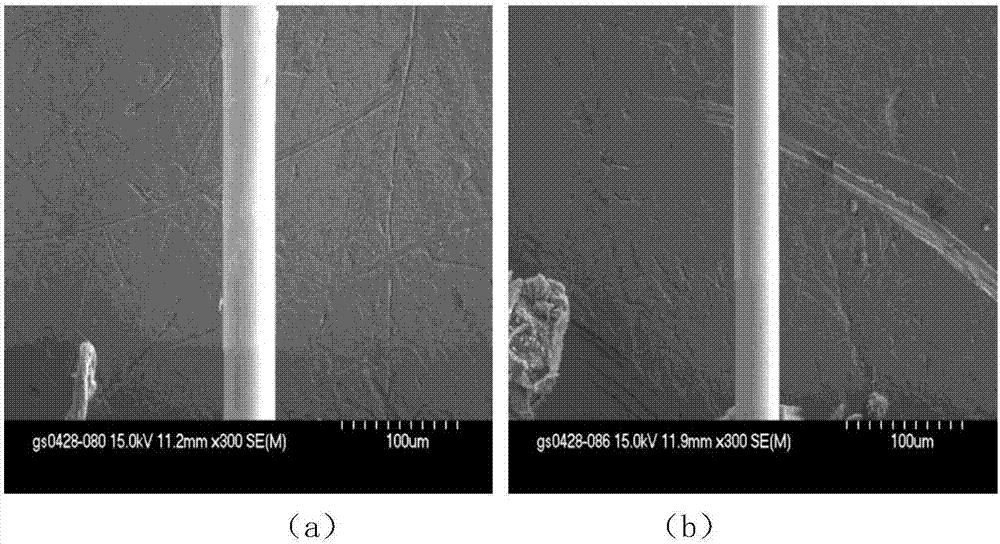

Modulation method for improving giant magneto-impedance (GMI) effect of melt extraction amorphous microwires

A modulation method for improving the giant magneto-impedance effect of melt-drawn amorphous microwires. The method is to electrolytically polish the melt-drawn amorphous microwires. The process parameters are: cathode current density of 100A / dm2 to 150A / dm2 , the electrolytic polishing time is 360s-600s, the electrolyte temperature is 45°C, and the magnetic impedance output stability test is carried out on the treated amorphous microwire. The method has the advantages of simple process, low cost, strong operability and high efficiency, and can significantly improve the giant magneto-impedance characteristics of melt-drawn amorphous microwires. The surface rounding treatment of the wire is realized, and the cross-section roundness and surface roughness of the melt-drawn amorphous microwire are improved, especially suitable for sensors with high sensitivity to weak magnetic field detection.

Owner:BOHAI UNIV

Building wall groove digging device

InactiveCN110258696AChange depthChange sizeSoil-shifting machines/dredgersBulkheads/pilesScrew threadPetroleum engineering

The invention discloses a building wall groove digging device and relates to the technical field of engineering machinery. The building wall groove digging device comprises a supporting frame, a transverse and longitudinal adjusting mechanism, a rotary driving part, a center hole drilling part, a main digging cutter disc and an inner wall grinding assembly. The building wall groove digging device has the beneficial technical effects that digging is performed from the lower portion, broken wall is automatically discharged downwards under the action of gravity, the process of conveying out the broken wall from inside to outside if digging is performed from top to bottom is omitted, the center hole drilling part is lifted upwards while the inner wall grinding assembly extends outwards, and the device is suitable for hard walls. The transverse and longitudinal adjusting mechanism is connected to the supporting frame, the rotary driving part is in clearance fit with the transverse and longitudinal adjusting mechanism, the rotary driving part is in transmission connection with the transverse and longitudinal adjusting mechanism through a belt; the center hole drilling part is connected into the rotary driving part in a sliding fit mode; the center hole drilling part is matched and connected with the rotary driving part through screw threads; the main digging cutter disc is fixedly connected to the upper end of the rotary driving part; and the upper end of the inner wall grinding assembly is fixedly connected to the rotary driving part.

Owner:安徽天驰建工集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com