Anaesthetic mask adopting air bag manufactured by unique method as air cushion and manufacturing method thereof

A technology of anesthesia mask and air cushion, which is applied in the field of medical equipment, can solve the problems of lack of flexibility of the air cushion and limit the good sealing of the face, and achieve the effects of high production efficiency, low material cost, and easy bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

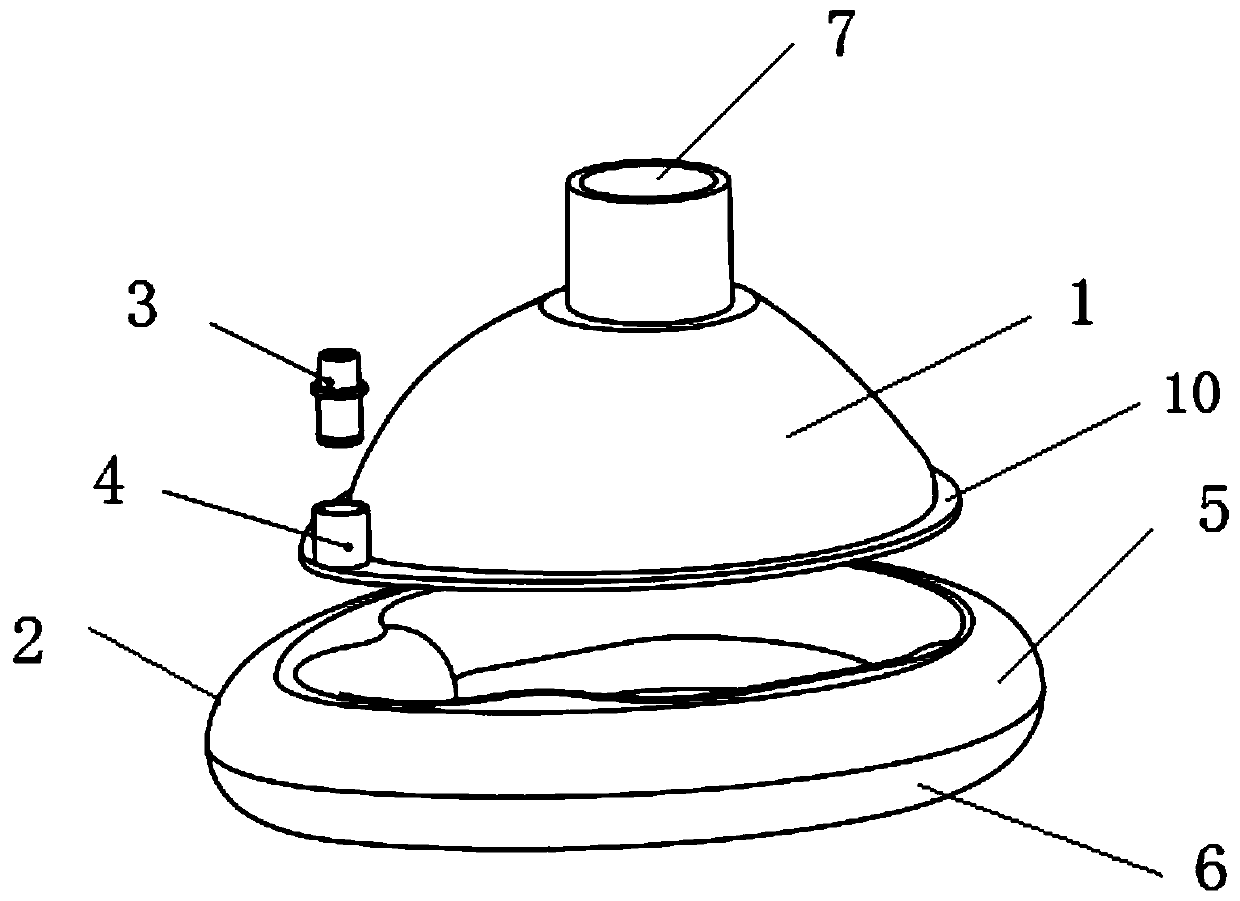

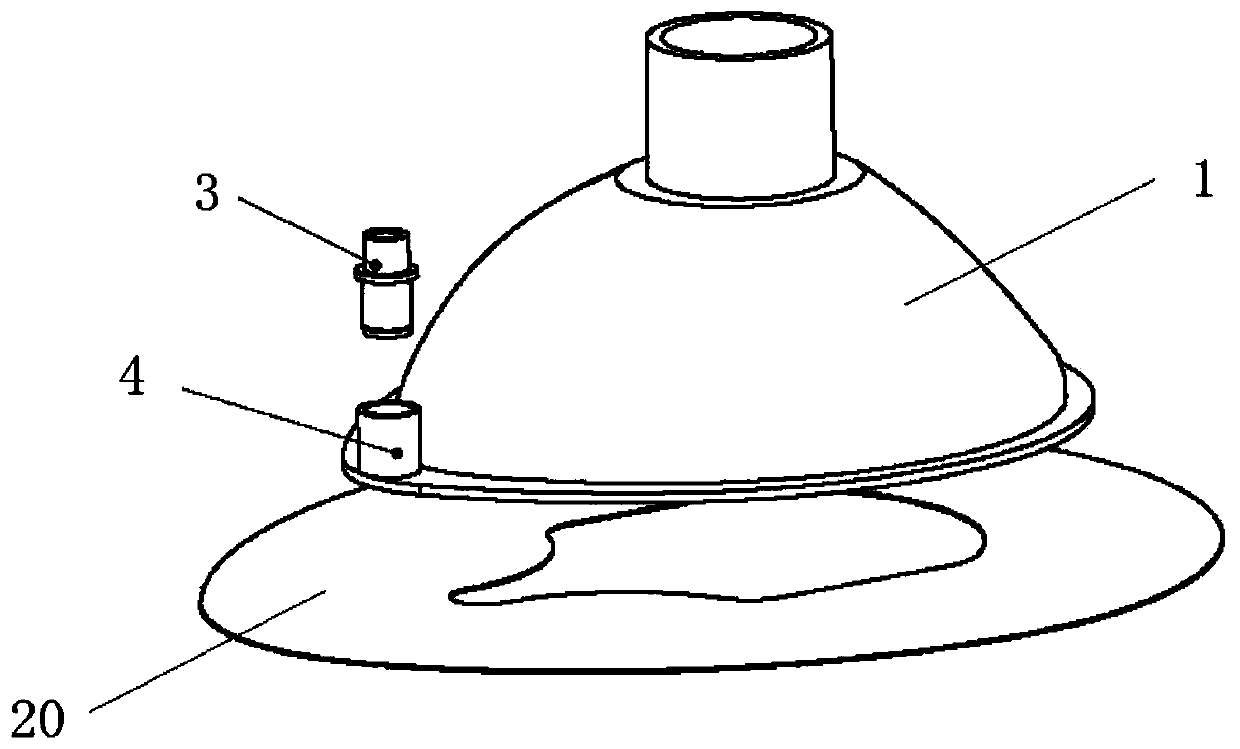

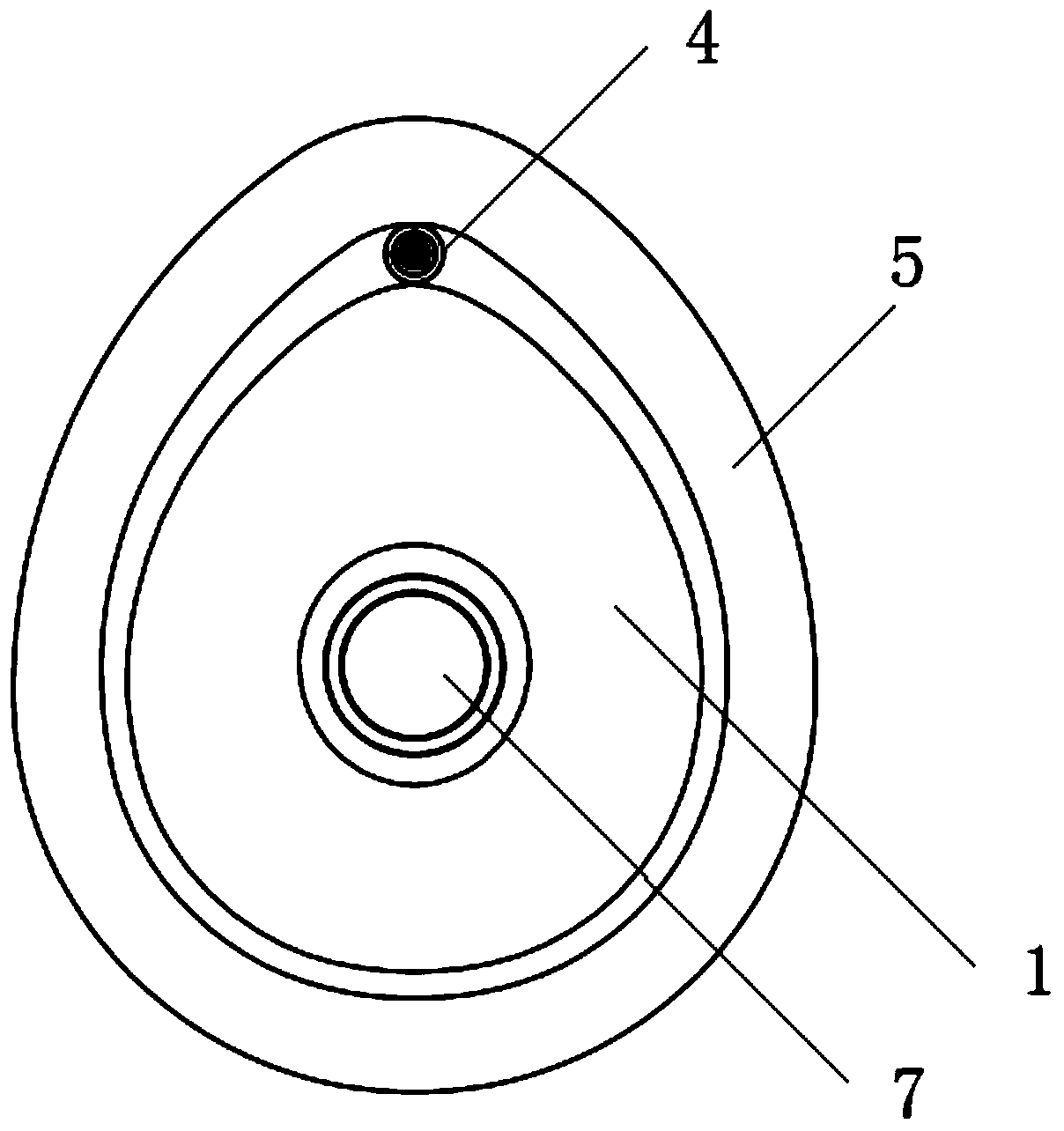

[0050] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 7 , Figure 8 Shown, the present invention adopts the anesthesia face mask that a kind of air bag made with unique method is used as air cushion, and this anesthesia mask is made up of loam cake 1, air cushion 2, air valve 3; Air cushion 2 has the required feature of anesthesia mask, and solved The problem of prior art, air cushion 2 is made of A sheet film 5, B sheet film 6, and it is the thin and soft plastic film base material (A sheet film base material, B sheet film base material) that is processed by two blow molding processes. Substrates) are superimposed together, and the irregular circular ring (such as Figure 5 Shown) the air cushion mold (metal hot-cutting mold or high-frequency mold, ultrasonic mold, etc.), using hot-melt stamping process or high-frequency welding process or ultrasonic welding process, the inner and outer edges of the A film and the B film are welded together ( The edge of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com