Tangential turbine runner

A type of water turbine and runner technology, applied in impact engines, mechanical equipment, hydroelectric power generation, etc., can solve the problems of reducing the efficiency and output of runners, and achieve the effect of increasing output and reducing hydraulic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is specifically described below through the embodiment, and the present embodiment is only used to further illustrate the present invention, but can not be interpreted as the limitation of protection scope of the present invention, those skilled in the art can make some non-compliance according to the above-mentioned content of the present invention Essential improvements and adjustments belong to the protection scope of the present invention.

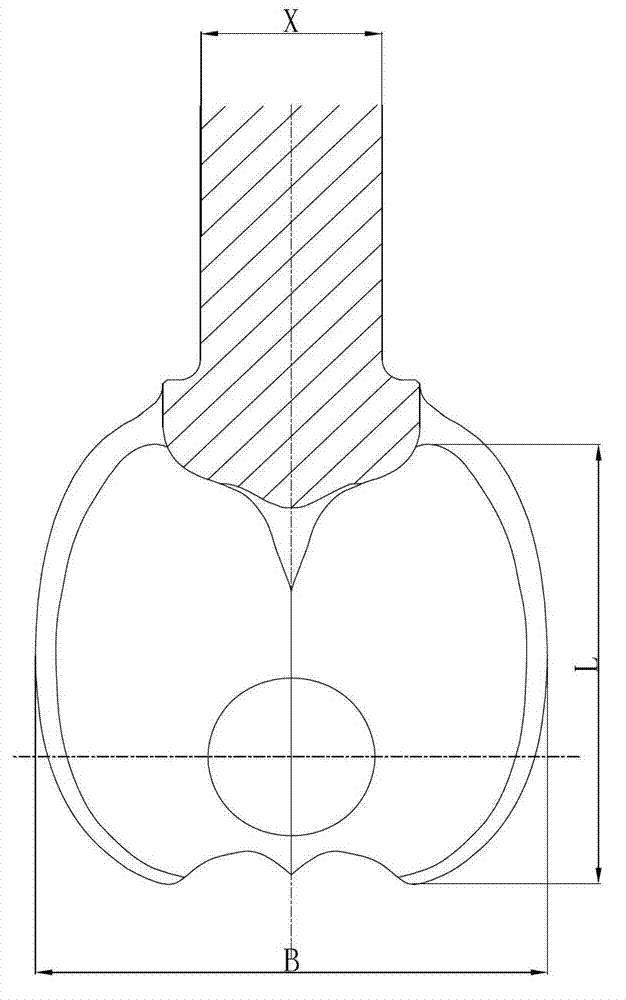

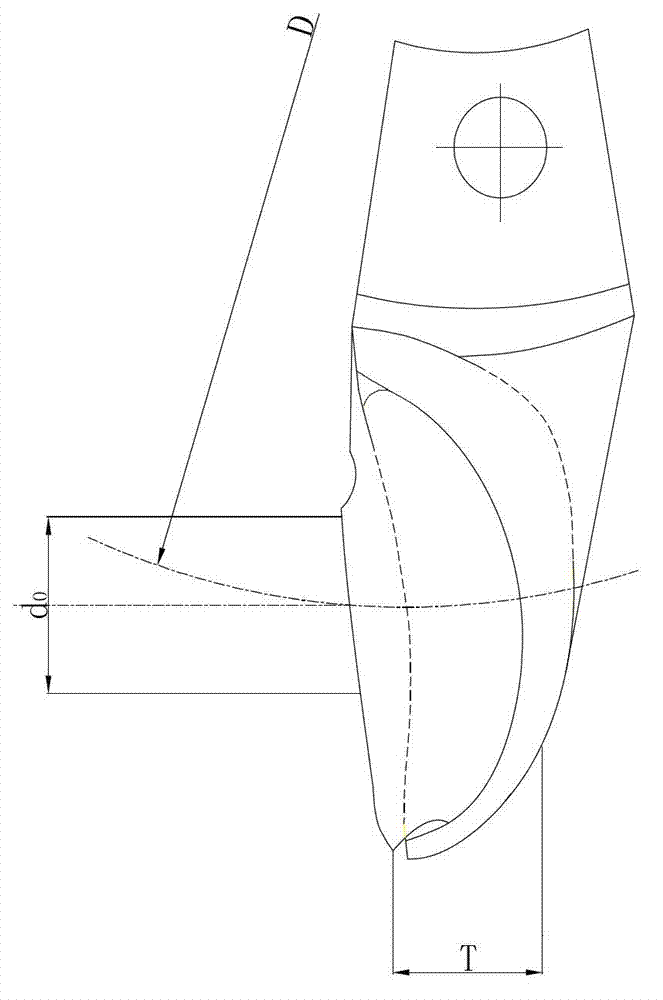

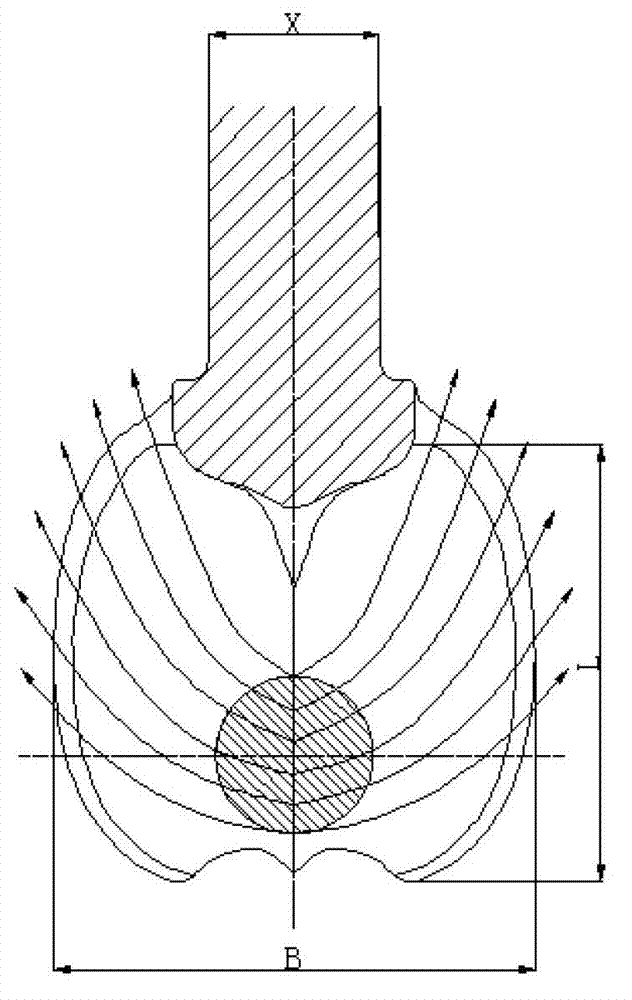

[0030] combine Figure 1 to Figure 4 .

[0031] The bucket blade number Z on the runner shaft circumference of the present invention is:

[0032]

[0033] Among them, k u is the peripheral velocity coefficient, is the jet velocity coefficient, r is the nominal radius of the runner, R is the radius of the notch of the runner, d 0 is the jet diameter;

[0034] The radial length of the bucket blade L=(2.2-2.5)d 0 ;

[0035] The width B=(2.8-3.2)d of the bucket blade 0 ;

[0036] The depth T=(0.95-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com