Method and device for realizing laser cleaning based on light beam peripheral scanning

A circular scanning and laser cleaning technology, applied in cleaning methods and utensils, chemical instruments and methods, optics, etc., can solve the problems of difficult change of scanning range, unfavorable uniform beam irradiation, high production process requirements, and low performance requirements. Low cost and uniform scanning results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 A method of laser cleaning based on beam circular scanning

[0045] The present invention provides a method for realizing laser cleaning based on beam circular scanning, comprising the following steps:

[0046] Step 1: Beam shaping, the laser emitted from the optical fiber becomes an approximately parallel beam after passing through the beam shaping system;

[0047] Step 2: irradiate the approximately parallel light beam on the rotating reflective mirror 2, and ensure that the approximately parallel light beam can be irradiated on the mirror surface during the rotation process of the rotating reflective mirror 2;

[0048] Step 3: The rotating mirror 2 irradiates the reflected light on the field mirror 4, and the field mirror 4 focuses the light beam reflected by the rotating mirror 2. When the motor rotates, the focal spot forms a scanning track 5 to realize circular scanning.

[0049] Specifically, the laser emitted by the optical fiber is transformed int...

Embodiment 2

[0050] Embodiment 2 A device for laser cleaning based on beam circular scanning

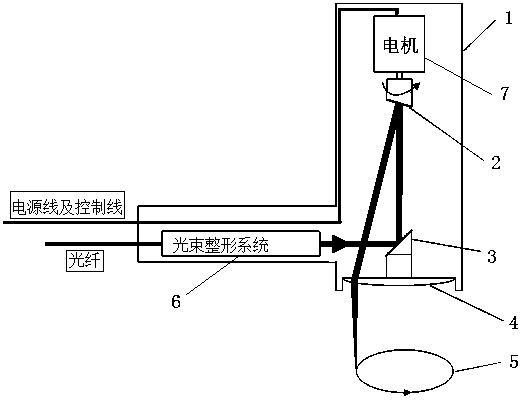

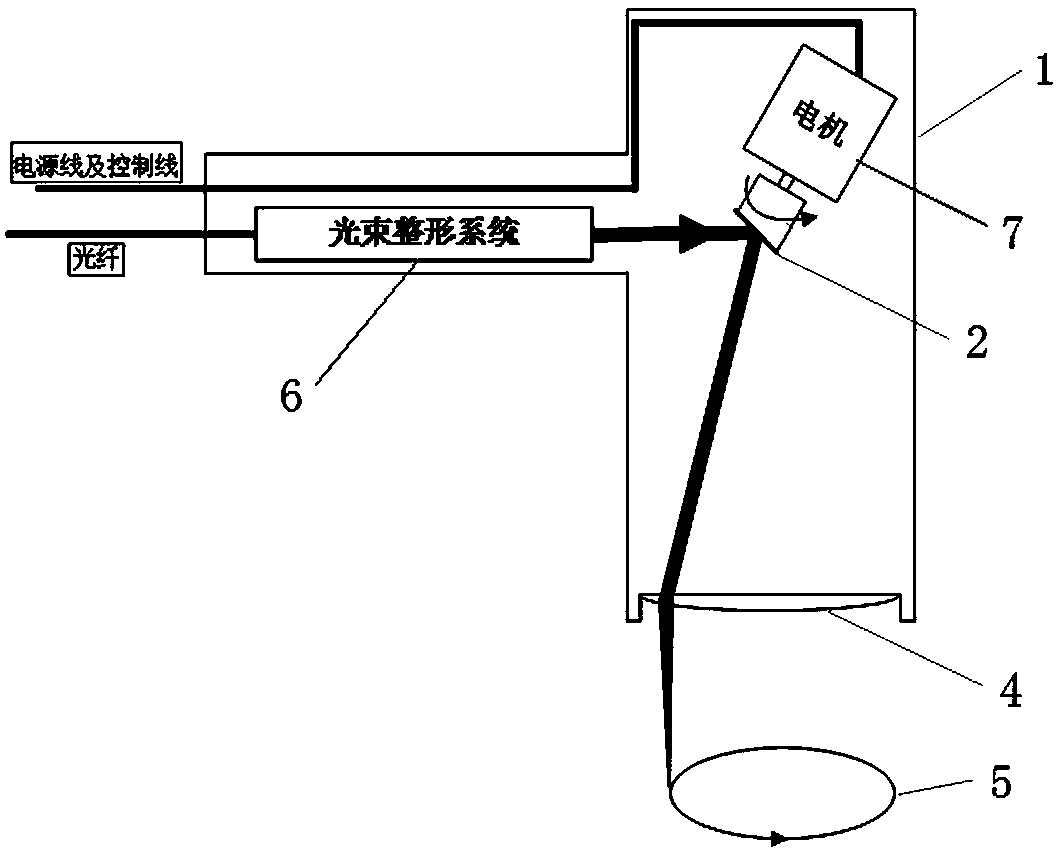

[0051] Such as figure 2 As shown, the present invention provides a laser cleaning device based on beam circular scanning, including a housing 1 , a bracket, a beam shaping system 6 , a motor 7 , a rotating mirror 2 , and a field mirror 4 .

[0052] A motor 7 is fixedly arranged on the top of the housing 1, and the motor 7 is electrically connected to a power line and a control line.

[0053] The motor 7 is fixed on the top or side wall of the housing 1 through a bracket, and the lower end of the motor 7 is connected with a rotatable rotating mirror 2, and the rotating mirror 2 can rotate clockwise or counterclockwise. The rotating mirror 2 has the function of adjusting the rotation speed, and the rotation speed is adjustable, because the laser irradiation time required by different cleaning objects will be different.

[0054] The rotating mirror 2 is a plane mirror.

[0055] The bottom of the...

Embodiment 3

[0059] Embodiment 3 A method of laser cleaning based on beam circular scanning

[0060] The present invention also provides a method for realizing laser cleaning based on beam circular scanning, comprising the following steps:

[0061] Step 1: Beam shaping, the laser emitted from the optical fiber becomes an approximately parallel beam after passing through the beam shaping system;

[0062] Step 2: irradiate the approximately parallel light beam on the fixed reflective lens 3, and the fixed reflective lens 3 irradiates the reflected light on the rotating reflective lens 2; the rotating reflective lens 2 ensures that the approximately parallel light beam can be irradiated on the mirror surface during the rotation process;

[0063] Step 3: The rotating mirror 2 irradiates the reflected light on the field mirror 4, and the field mirror 4 focuses the reflected beam of the rotating mirror 2. When the motor rotates, the focal spot forms a scanning track 5 to realize circular scannin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com