Meter-level large-aperture optical components co 2 Laser polishing device and polishing method

A technology for optical components and laser polishing, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve problems that affect the service life of optical components, easily induce defects, and pollute the environment, so as to improve the repair effect and improve polishing The effect of precision and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

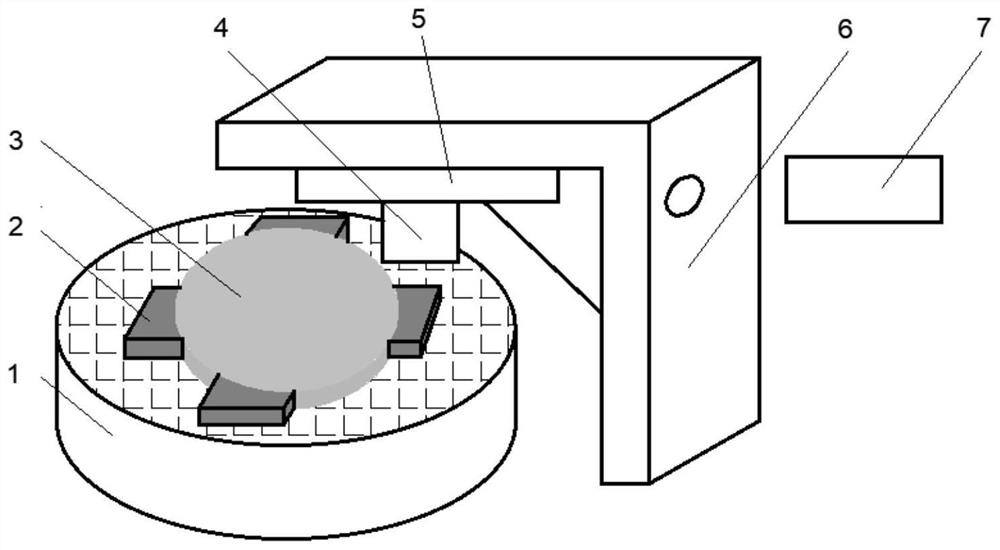

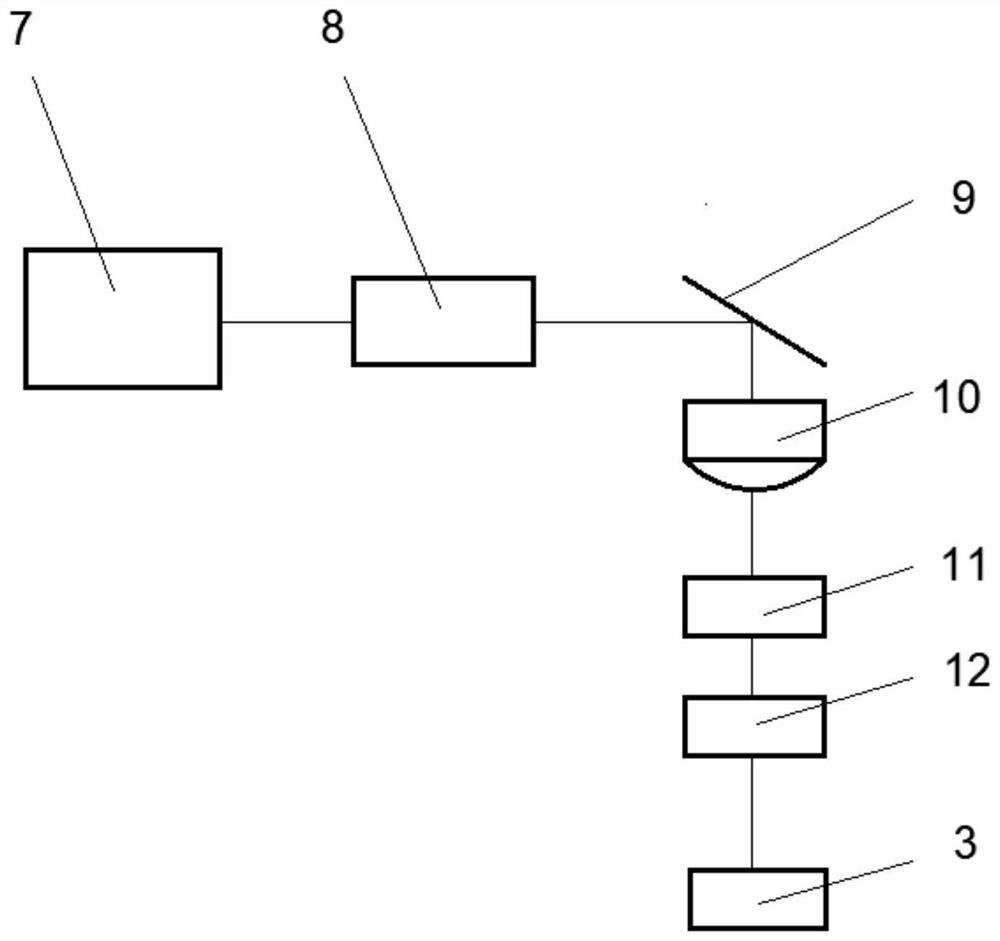

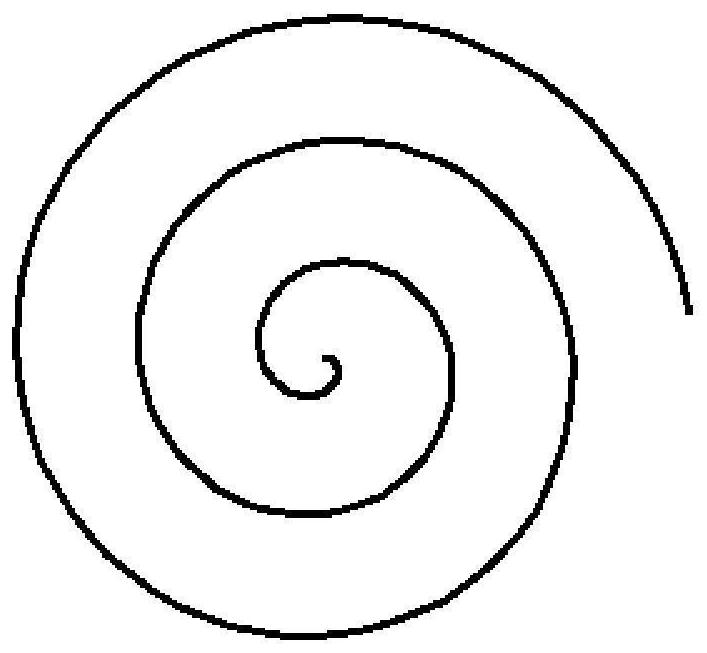

[0032] CO for meter-scale large-aperture optical components 2 Laser polished, the base material is round fused silica glass. The experiment was carried out in a class 10,000 clean room. First, the optical components are cleaned and dried for pretreatment. Then the optical element 3 is fixed on the workbench 1 through the electromagnetic clamp 2, and the optical element 3 faces the laser beam. Adjust laser parameters: laser power 60W, repetition frequency 1kHz, pulse width 10μs, focal length 20mm, spot diameter 2mm, galvanometer scanning speed 100mm / s, track interval 1mm, track exceeding fused silica size by 1%. The speed of workbench 1 is 1rad / s, the speed of the feed mechanism is 5mm / s, and the attachment image 3 Scanning in a spiral trajectory. After scanning the entire surface of the optical element, reduce the laser power by 5-10W each time, reduce the speed of the feed mechanism by 5-10mm / s, and keep the other parameters unchanged. Repeat multiple scans until the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com