Dynamic control method and apparatus for sewage disposal

A dynamic control and sewage treatment technology, applied in water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve wasteful energy consumption, accurate control, low-load sludge bulking, etc. problems, to achieve the effect of reducing labor intensity, reducing control steps, and reducing operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

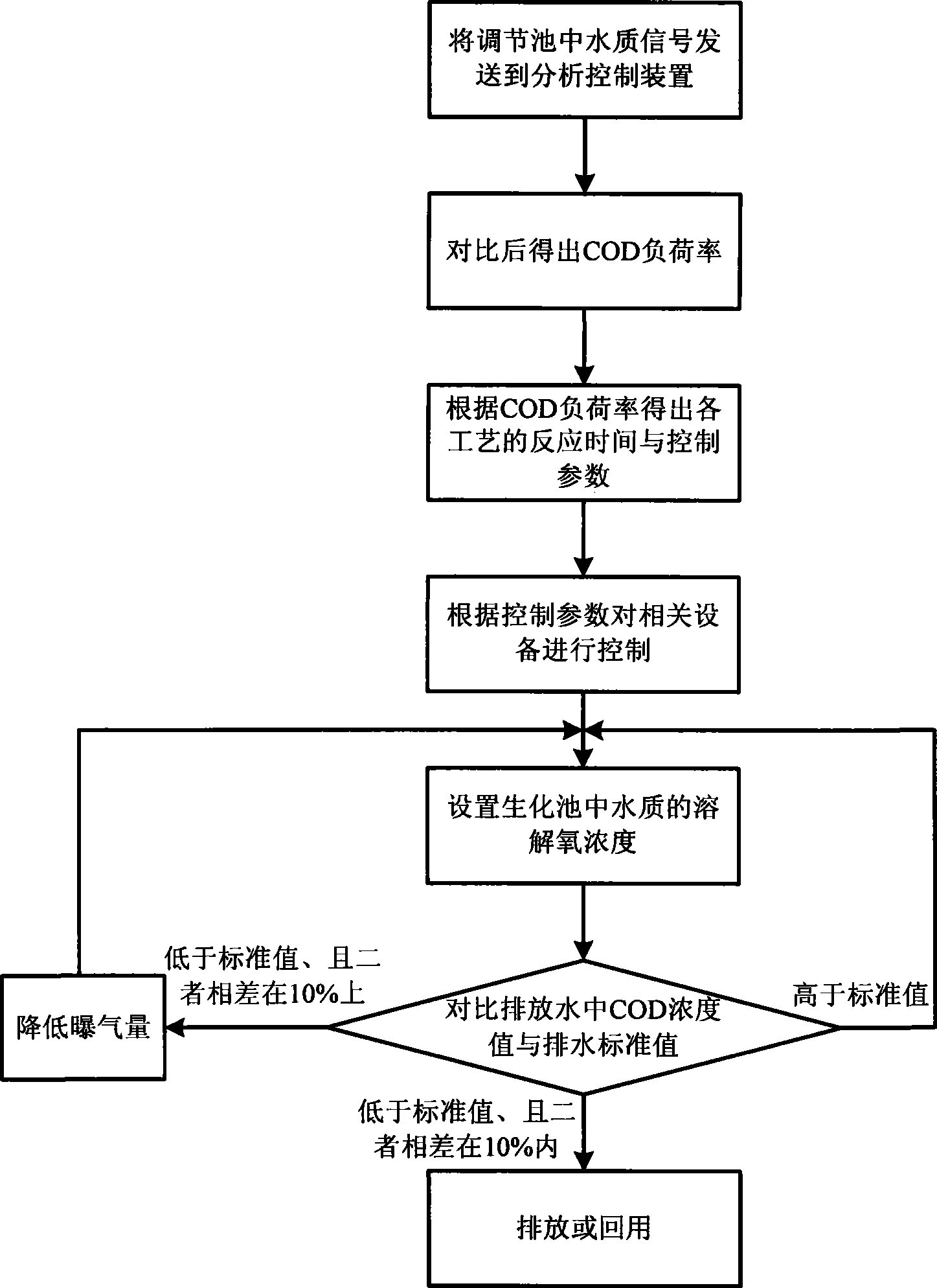

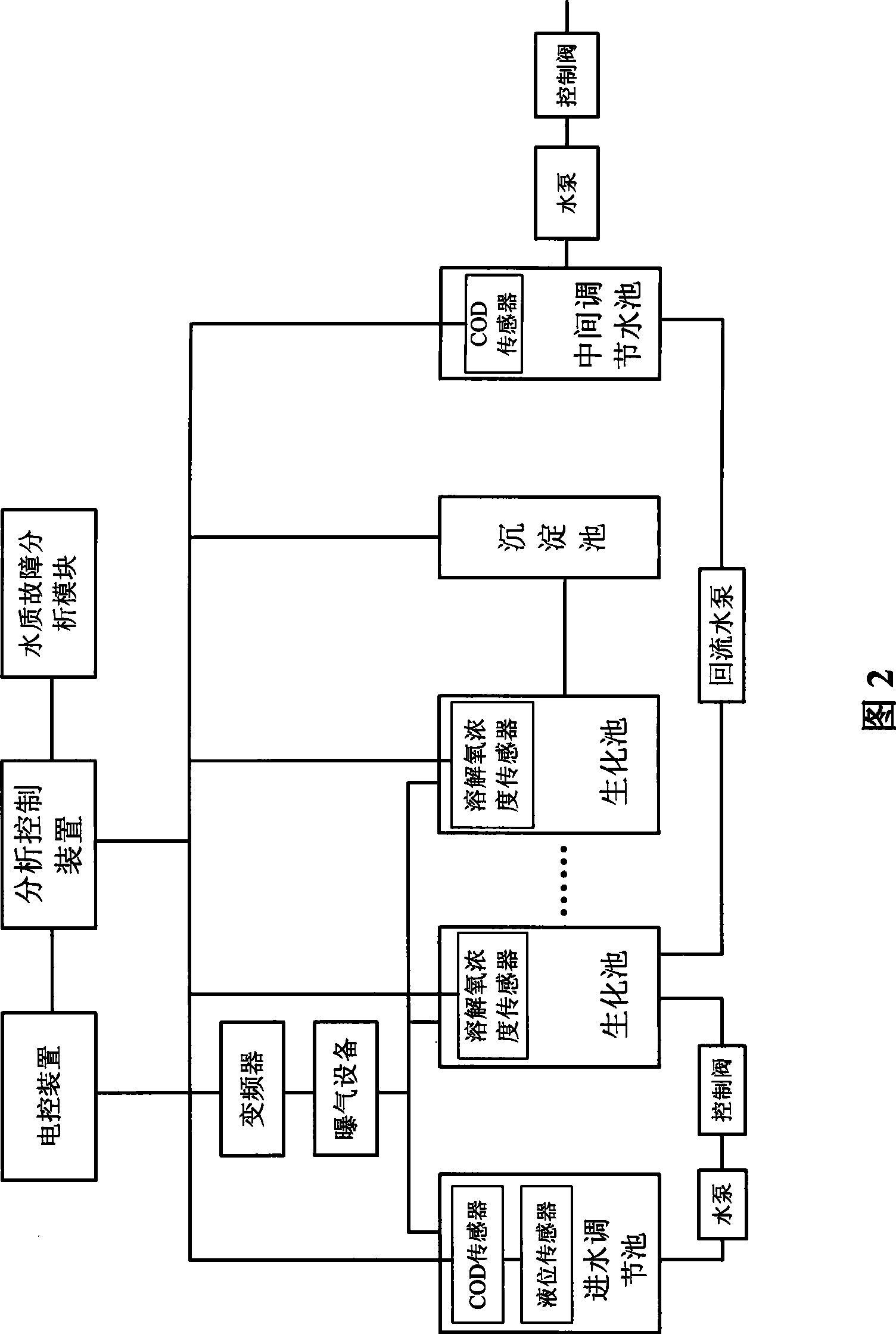

[0033] A dynamic control method for sewage treatment provided by the present invention includes a water inlet adjustment pool, a plurality of biochemical pools and an intermediate adjustment pool. The method includes the following steps:

[0034] (1) After the sewage is injected into the water inlet adjustment tank, the COD signal and liquid level signal data are input into the analysis control device through the COD concentration sensor and the liquid level sensor;

[0035] (2) The COD load rate is obtained after comparing with the required value of terminal effluent;

[0036] (3) According to the COD load rate obtained in the step (2), the water quality treatment capacity, the aeration rate and the response time and control parameters of each process in the unit time of the sewage treatment system are calculated;

[0037] (4) According to the control parameter obtained in the step (3), the sewage in the water inlet regulating tank is introduced in the biochemical tank by a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com