Preparation method of magnetic core-shell alginate microsphere adsorbent

An alginate and microsphere adsorption technology, which is applied in the field of biomass resource utilization and biomass adsorption materials, can solve the problems of complex synthesis process, high temperature requirements, narrow application range, etc., and achieve simple operation, high adsorption efficiency, small size The effect of controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

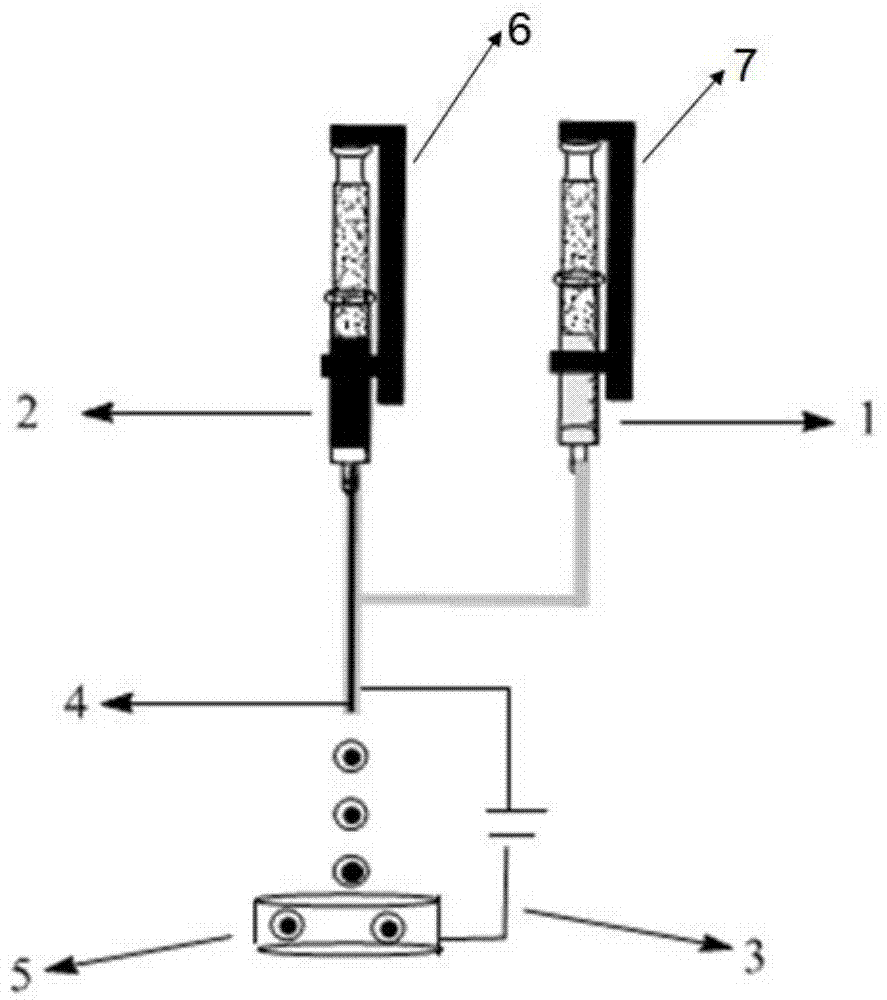

Method used

Image

Examples

Embodiment 1

[0042] Step 1. Add two parts of sodium alginate into distilled water respectively, stir fully, and prepare two parts of sodium alginate solutions with a concentration of 2wt%, one part is the shell solution; Dichloromethane and nano ferric oxide were added into the sodium aqueous solution, fully stirred and mixed uniformly to obtain a nuclear layer solution, the concentration of dichloromethane in the nuclear layer solution was 6wt%, and the nanometer ferric oxide in the nuclear layer solution The concentration is 1wt%;

[0043] Step 2: Using high-voltage electrospinning equipment, input the shell solution and the core solution into the outer layer and the inner layer of the stainless steel coaxial needle respectively. The size of the stainless steel coaxial needle is No. 4 inner needle and No. 8 outer needle , set the high-voltage electrostatic spraying conditions as follows: the ambient temperature is 30°C, the output voltage of the high-voltage power supply is 5kv, the dist...

Embodiment 2

[0046] Step 1. Add two parts of sodium alginate into distilled water respectively, stir fully, and prepare sodium alginate solutions with a concentration of 1wt% and 2wt%, and the 1wt% sodium alginate solution is the shell solution; Add dichloromethane and nano-ferric oxide to the sodium alginate aqueous solution, stir and mix evenly to obtain a nuclear layer solution, the concentration of dichloromethane in the nuclear layer solution is 2wt%, and the nano-ferric oxide in the nuclear layer solution The concentration of three irons is 0.5wt%;

[0047] Step 2. Using high-voltage electrospinning equipment, input the shell solution and the core solution into the outer layer and the inner layer of the stainless steel coaxial needle respectively. The size of the stainless steel coaxial needle is No. 6 inner needle and No. 12 outer needle , set the high-voltage electrostatic spraying conditions as follows: the ambient temperature is 35°C, the output voltage of the high-voltage power ...

Embodiment 3

[0050] Step 1. Add two parts of sodium alginate into distilled water respectively, stir fully, and prepare sodium alginate solutions with a concentration of 3wt% and 4wt%, and the 3wt% sodium alginate solution is the shell solution; Add dichloromethane and nano-ferric oxide to the sodium alginate aqueous solution, fully stir and mix uniformly to obtain a nuclear layer solution, the concentration of dichloromethane in the nuclear layer solution is 4wt%, and the nano-ferric oxide in the nuclear layer solution The concentration of three irons is 0.7wt%;

[0051] Step 2. Using high-voltage electrospinning equipment, input the shell solution and the core solution into the outer layer and the inner layer of the stainless steel coaxial needle respectively. The size of the stainless steel coaxial needle is No. 5 inner needle and No. 10 outer needle , the high-voltage electrostatic spraying conditions were set as follows: the ambient temperature was 40°C, the output voltage of the high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com