an optical component 2 Laser remelting and gasification composite polishing method

An optical element, laser remelting technology, applied in laser welding equipment, metal processing equipment, welding equipment and other directions, can solve the problems of difficult to determine the laser incident angle, difficult to remove ablation vapors, low melting and polishing efficiency, etc., to avoid The effect of secondary pollution, convenient operation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

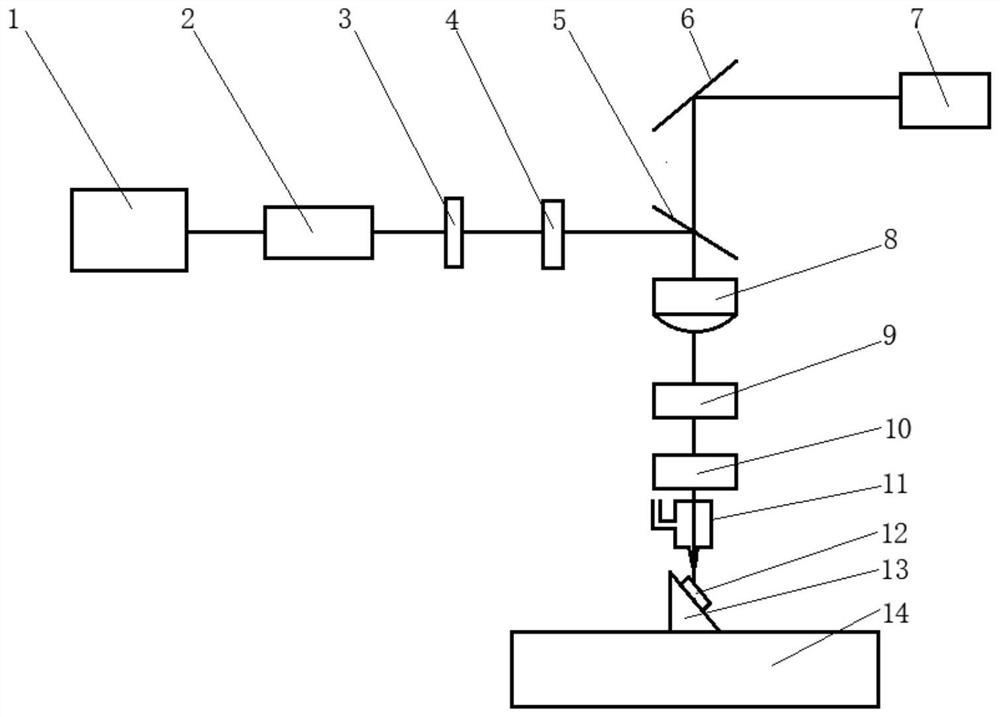

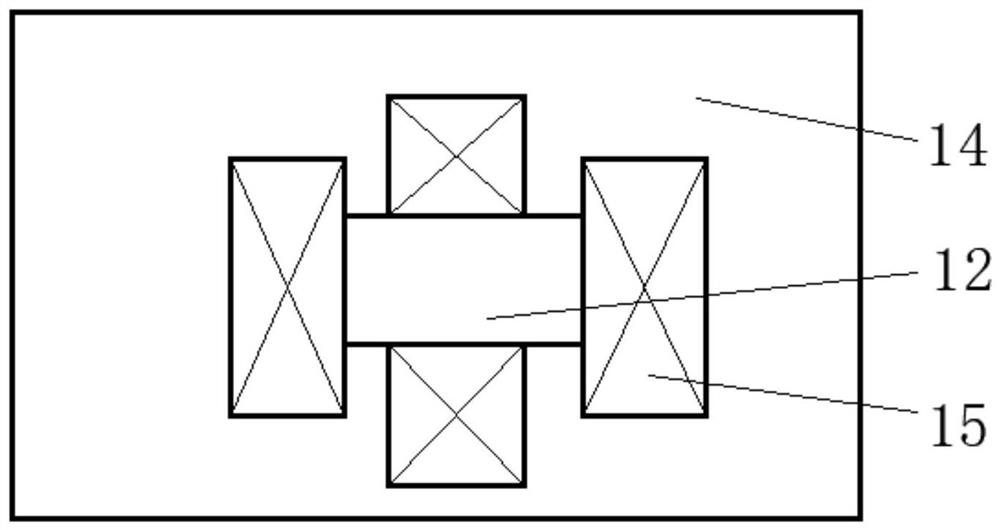

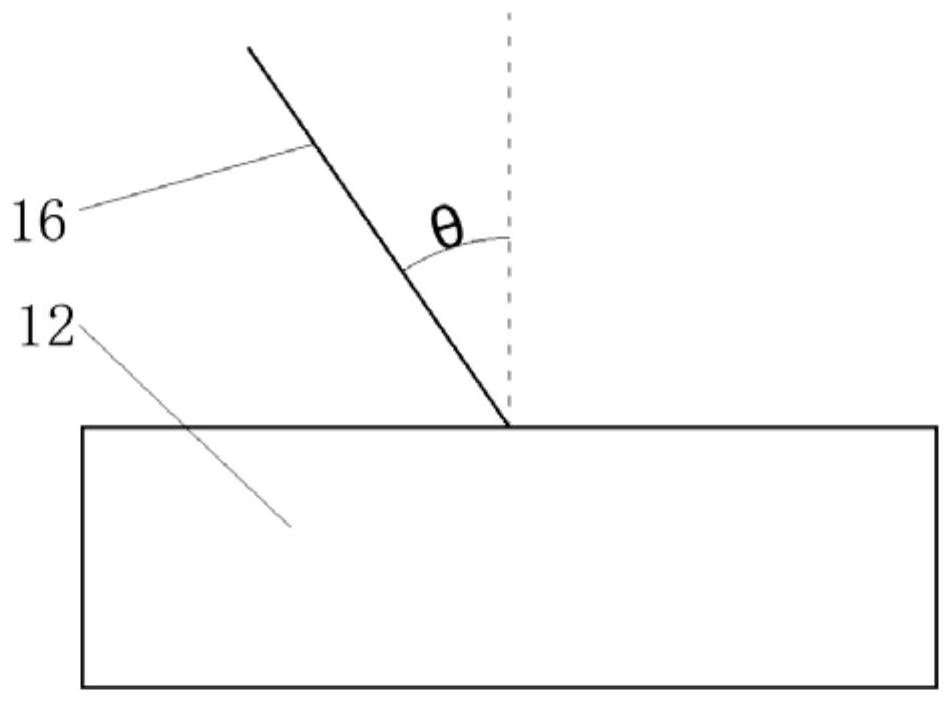

[0037]CO for optical components2Laser remelting and gasification composite polishing, the matrix material is a melted stone. The experiment is installed with CO2Tensile cleansing between laser polishing devices. First, the surface of the optical element is cleaned by the ultrasonic cleaner, and then dry the optical element with a hairdryer in the normal temperature mode, and the sample 12 is placed infigure 1 The displayed electric shifting table 14, and adoptedfigure 2 The method shown is fixed, turned on the laser 1, adjusts the laser parameters: the laser power is 40W, the frequency is 10 kHz, the duty ratio is 4mm, the spot is 10mm, the deguscad is 0.08 mm, the scan speed is 40mm. / S, drawimage 3 The parallel trajectory shown, introduces a laser system, and determines the set laser parameters, and positions the workpiece to the initial machining position and the optical element is remelted and polished by the CCD observation system. After the polishing is completed, the sample ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com