Method for contactless capacitive thickness measurements

A thickness measurement, non-contact technology, applied in the direction of electric/magnetic thickness measurement, electromagnetic measurement device, measurement device, etc., can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

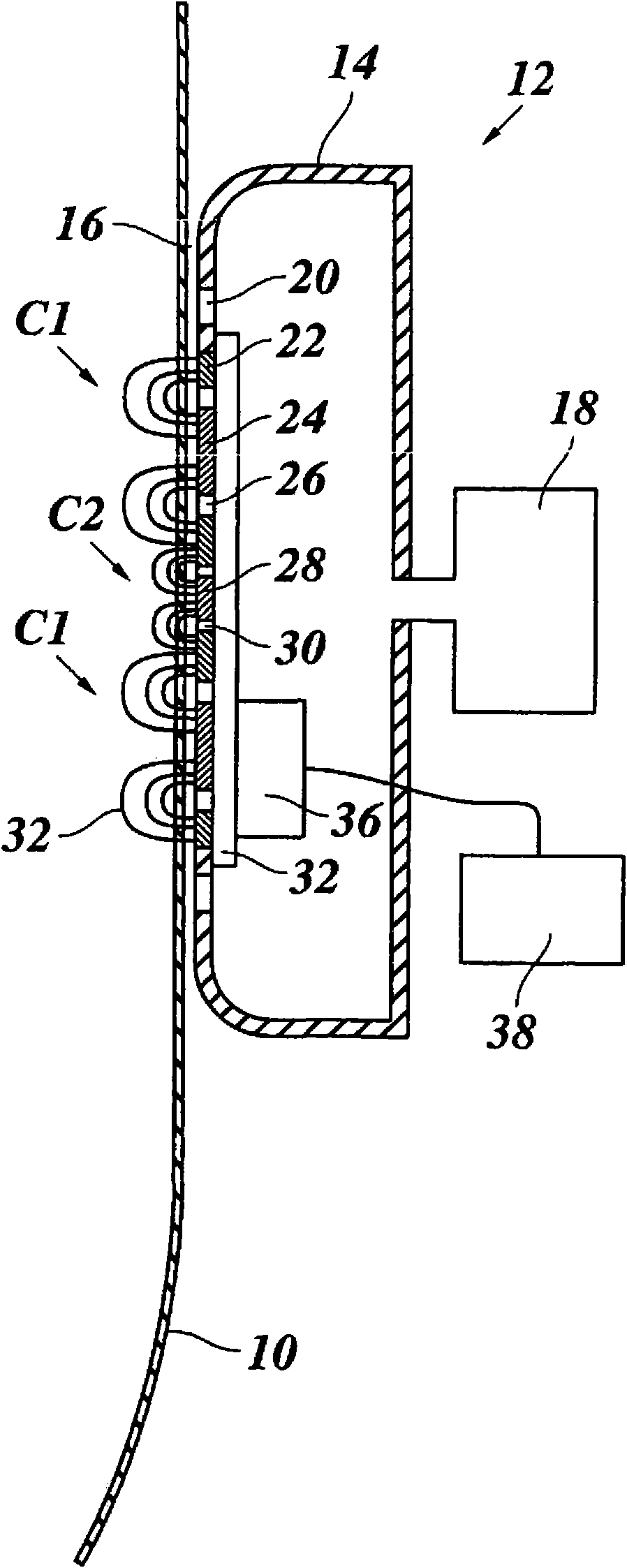

[0022] figure 1 A portion of a film 10, such as a bubble, is shown in schematic cross-section, extruded by a bubble extruder. The thickness of the film 10 will be measured non-contact by means of a capacitive measuring device 12 . For this purpose, the measuring head 14 of the measuring device is arranged on the periphery of the bubble in such a way that a narrow air gap 16 is formed with the constantly upwardly moving film. To stabilize the air gap 16 , the measuring head 14 is connected to a blower 18 , by means of which air is blown out of the measuring head 14 through the opening 20 in the direction of the film 10 . The measuring head can be slightly offset from the membrane so that the membrane will "suspend" on a cushion of air.

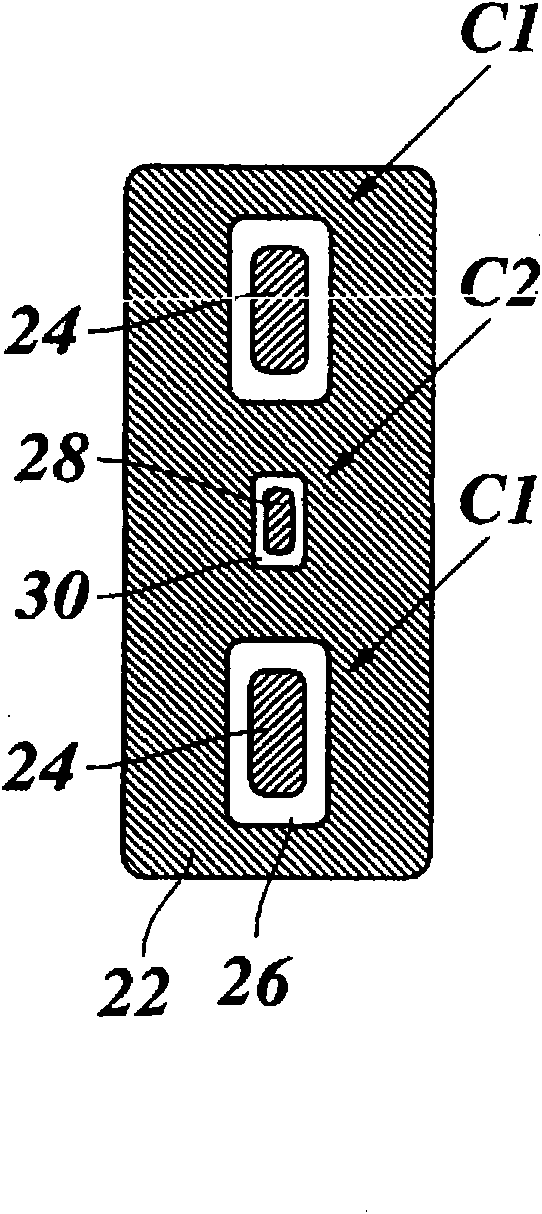

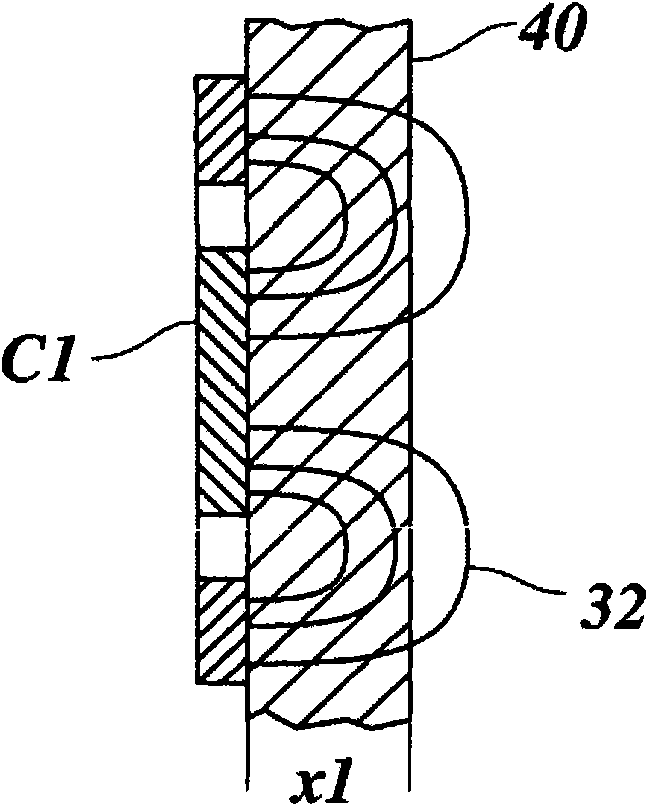

[0023] Integrated in the wall of the measuring head 14 facing the membrane 10 is a capacitor array forming two capacitors C1 and C2. The capacitor array has been shown in the figure 2 front view in . For reasons of symmetry, capacitor C1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com