Adhesive tape pasting and folding device for insulation paper and pasting and folding method thereof

A folding device and insulating paper technology, which is applied in the direction of cardboard items, folding thin materials, transportation and packaging, etc., can solve the problems that the folding and cutting of insulating paper cannot be well realized, and the actual production needs of motors cannot be effectively met. Achieve the effect of preventing lateral offset and improving insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

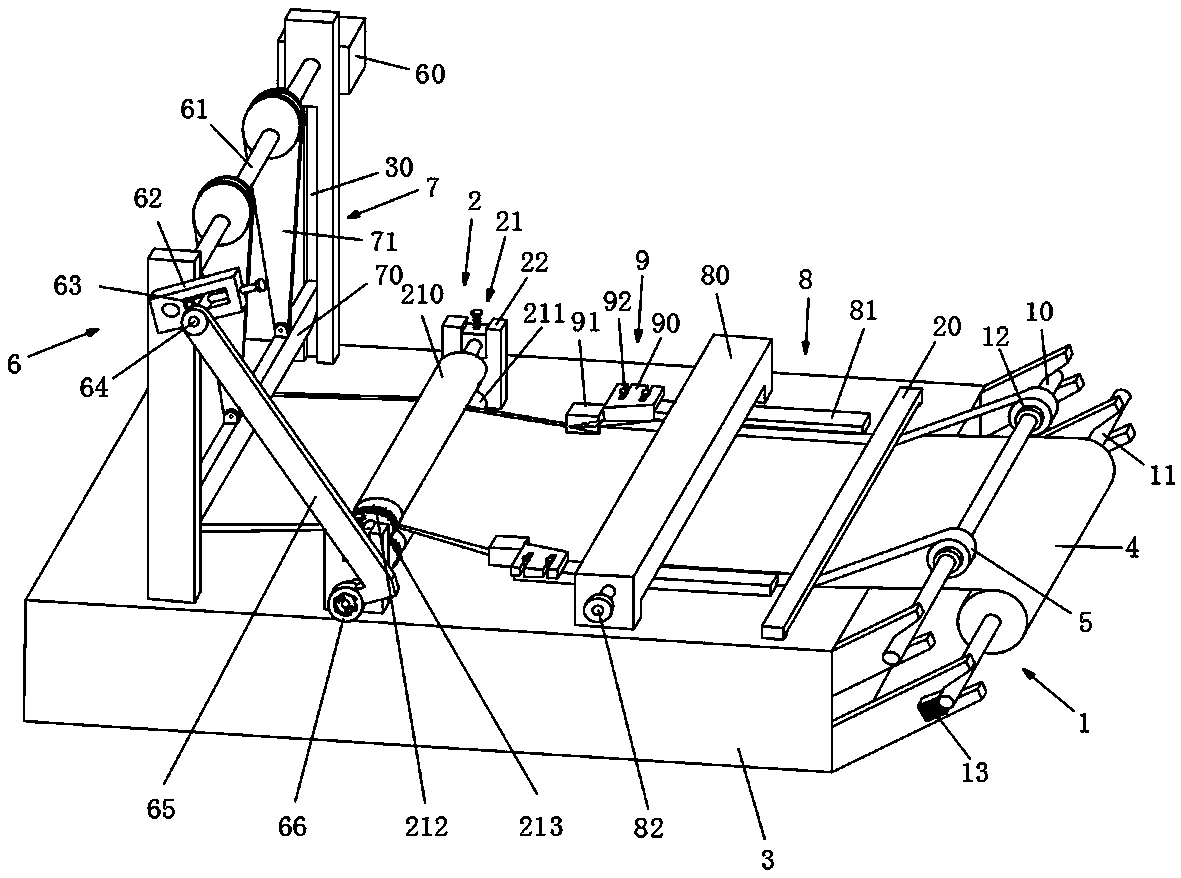

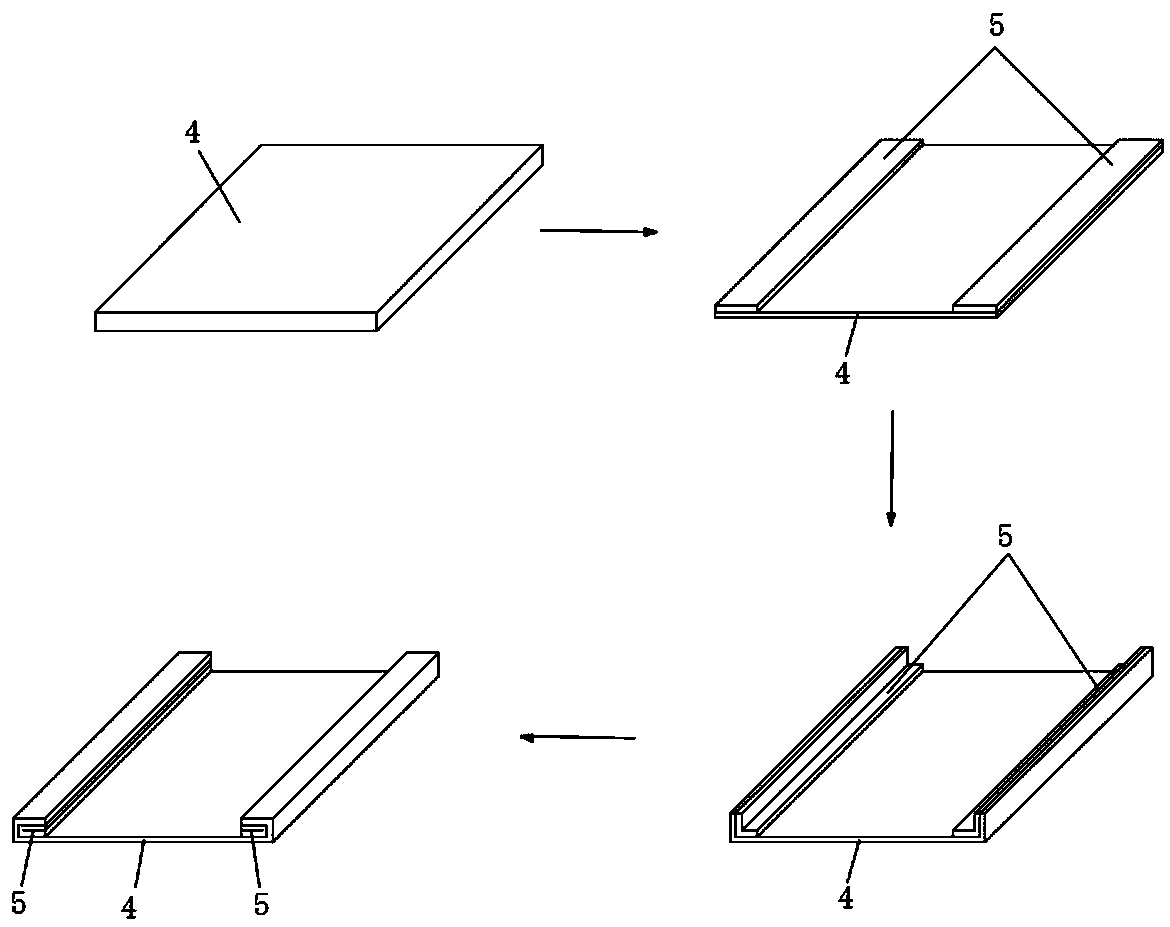

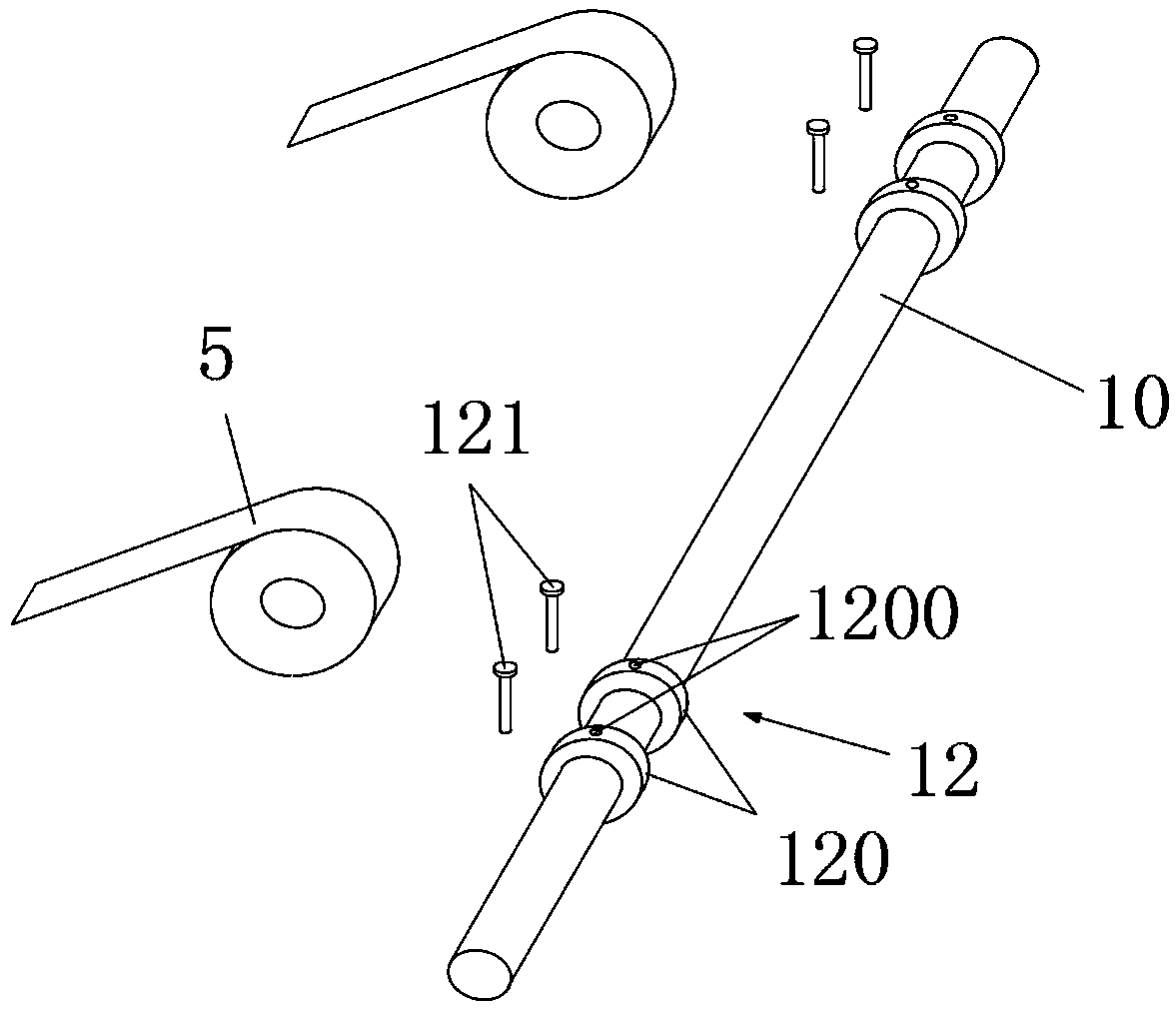

[0045] see Figure 1 to Figure 13 , a kind of insulating paper tape pasting hemming device, comprising a lead-out mechanism 1, a sticking main body 2 and a frame 3; the lead-out mechanism 1 includes an upper shaft 10 and a lower shaft 11 arranged up and down and connected to the frame 3 in rotation; the described The lower rotating shaft 11 is covered with roll-shaped insulating paper 4; the upper rotating shaft 10 is covered with two roll-shaped adhesive tapes 5, and the two adhesive tapes 5 are located above the two sides of the insulating paper 4; the sticking body 2 It includes pre-compressing rods 20 and counter-pressing rollers 21 arranged in sequence along the feeding direction of insulating paper 4; Paste the tape 5 on the insulating paper 4; the pressure roller 21 includes an upper pressure roller 210 and a lower pressure roller 211...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com