Hydrodynamic clutch

A technology of hydraulic coupling and coupling, applied in the direction of clutch, clutch, fluid clutch, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

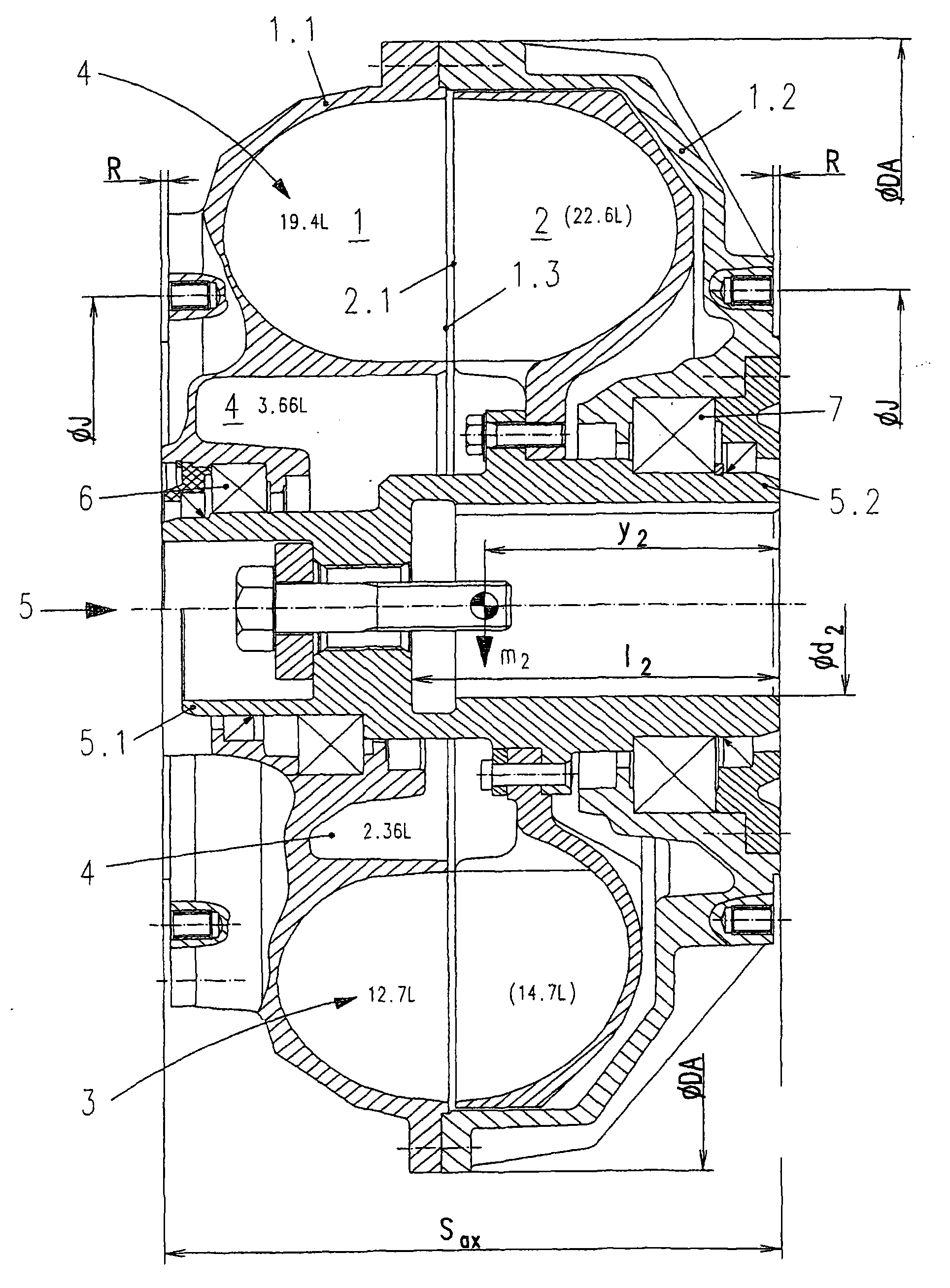

[0021] As is immediately apparent, the installation dimensions of the improved fluid coupling according to the invention correspond to those of conventional fluid couplings.

[0022] The pump impeller 1 and the turbine wheel 2 can be seen here, which together form the working chamber 3 . Furthermore, a storage chamber 4 can also be seen, which serves as a collection chamber for working medium that is not required in the working chamber. The storage chamber extends completely radially within the working chamber 3 in the axial direction of the hydrodynamic coupling. Specifically, seen in the axial direction, the storage chamber 4 extends from the middle of the turbine wheel 2 over the extent of the working chamber 3 arranged in the pump impeller 1 until there is a The defined distance, which is for example 10 mm, is generally between 5 and 20 mm, particularly advantageously between 8 and 12 mm.

[0023] The pump impeller 1 surrounds the turbine 2 together with the casing 1.2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com