Rotary type displacement compressor

A compressor and rotary technology, applied in the direction of rotary piston machinery, rotary piston pump, mechanical equipment, etc., can solve the problems of difficult processing of helical space tooth surface, difficult processing, high noise, and achieve flexible and diverse rotor combination schemes. No unbalanced inertial force, avoiding the effect of mutual friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

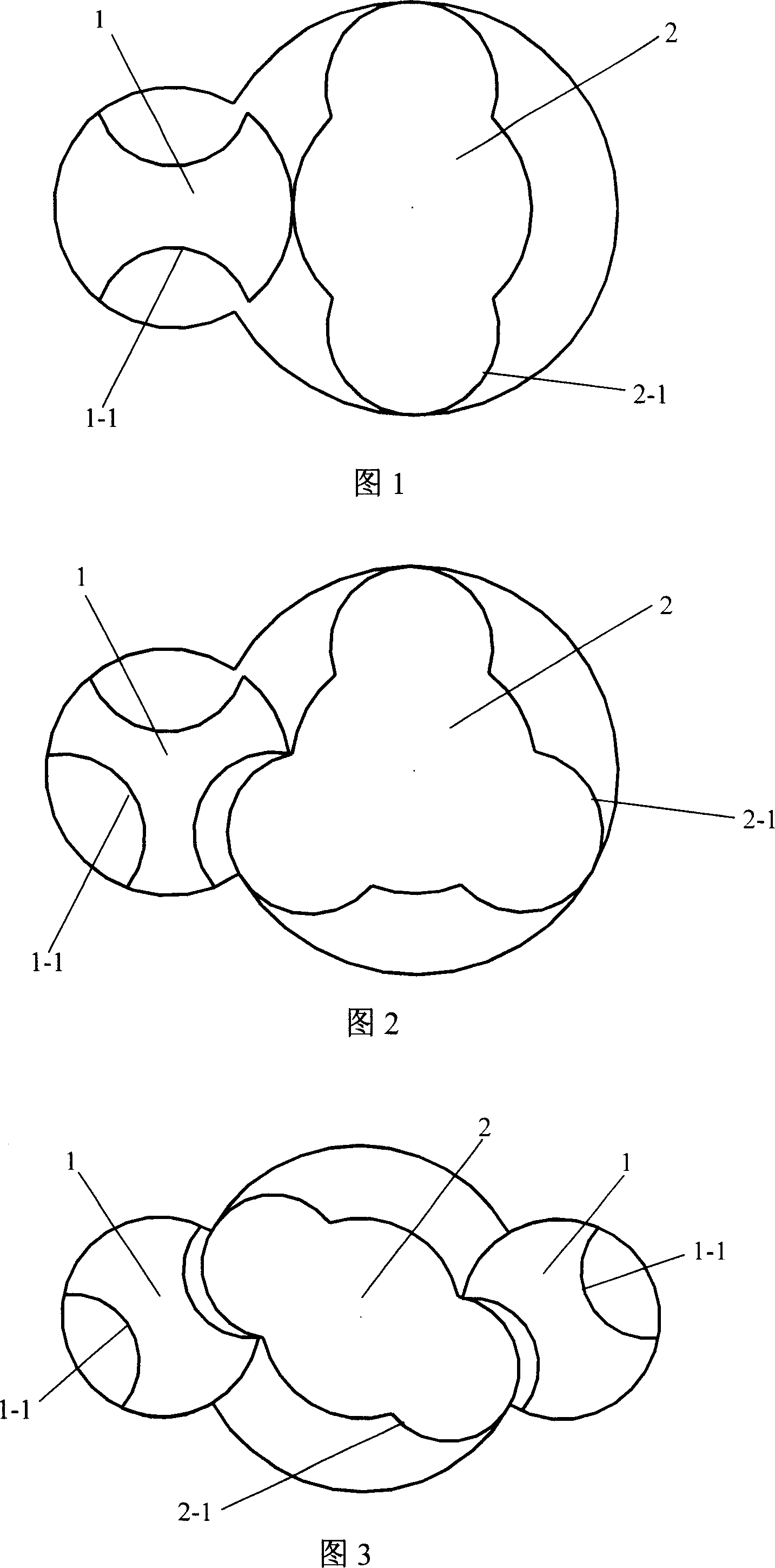

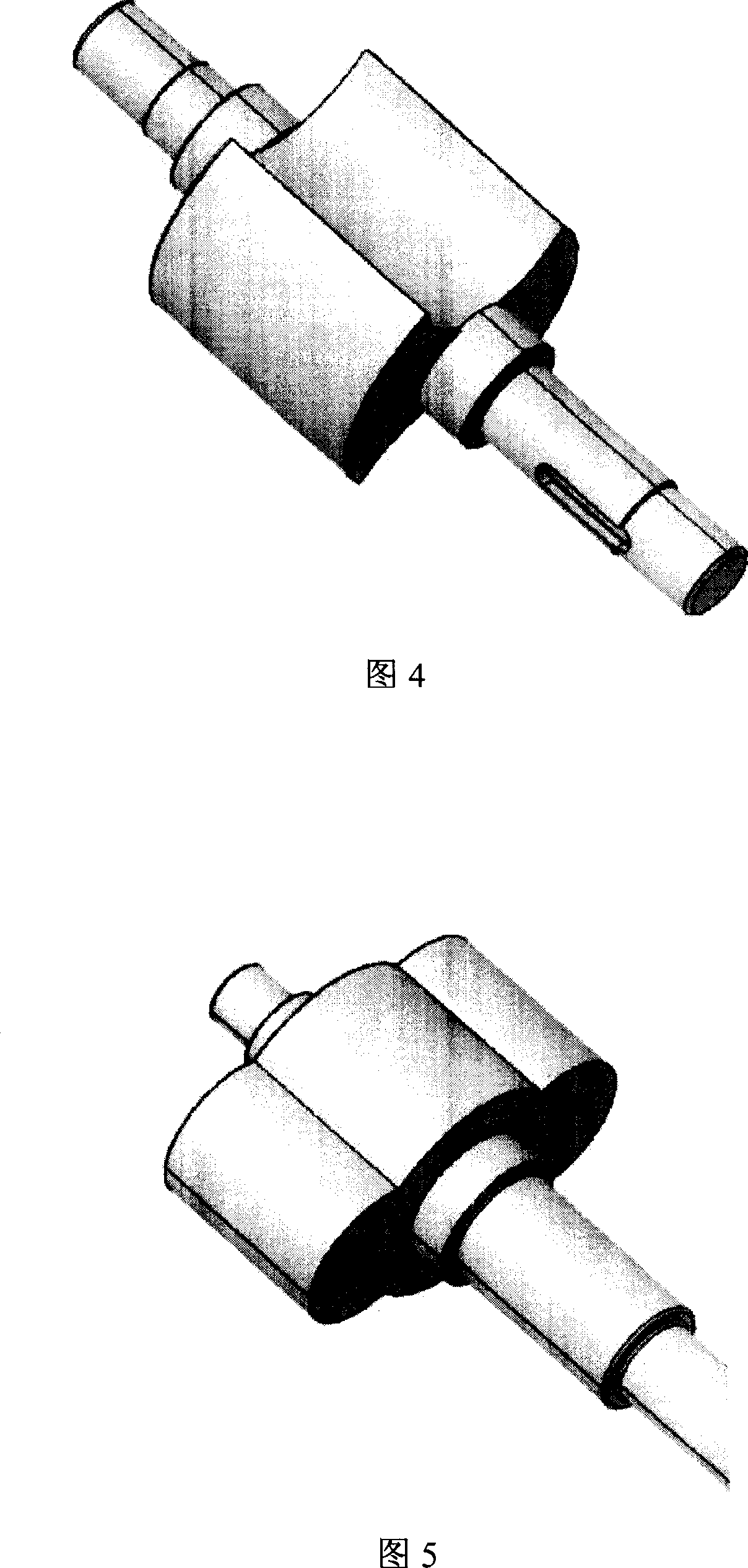

[0016] According to the technical solution of the present invention, when the female and male rotors are provided with grooved profiles and ribbed profiles parallel to the axial direction of the female and male rotors according to the conjugate profile that satisfies the meshing law, and through the synchronous gear When the ∞-shaped cylinder meshes and rotates according to the fixed transmission ratio consistent with the pitch circle diameter ratio of the female and male rotors, the beneficial effects of the present invention will be realized. Therefore, in theory, the realization of the technical solution of the present invention can have a variety of rotor combination schemes, but in practical applications, because the design arrangement of the fluid inlet and outlet positions and the requirements of exhaust or delivery pressure should be considered, so Usually, the ratio of the number of ribs on the male rotor to the number of grooves on the female rotor is 2 / 2, 2 / 3, 3 / 3, 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com