Sectional variable-section screw rotor

A segmented, variable cross-section technology, applied in the direction of rotary piston pumps, rotary piston machines, machines/engines, etc., can solve problems such as insufficient interstage sealing performance, insufficient suction volume, and reduced ultimate vacuum degree , to achieve the effect of broadening the application range and field and improving the internal volume ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

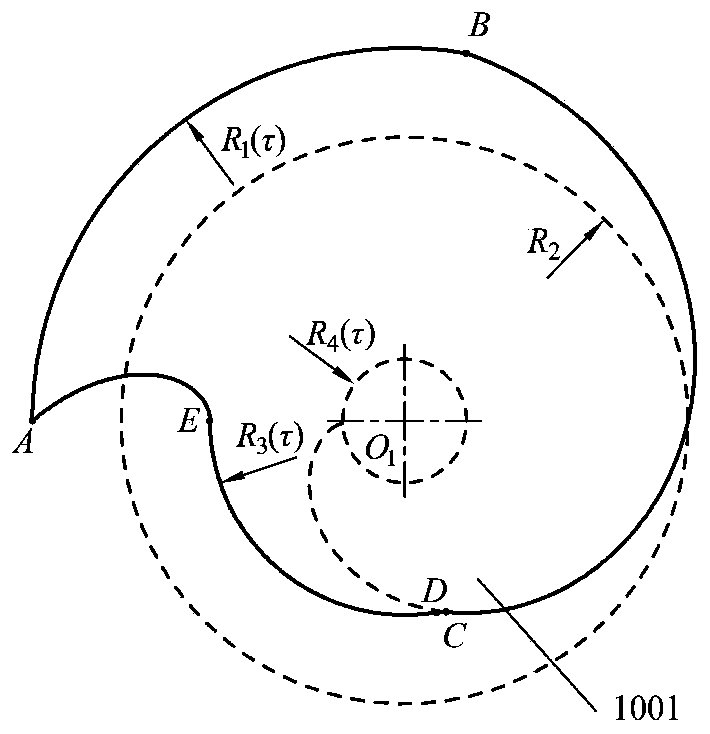

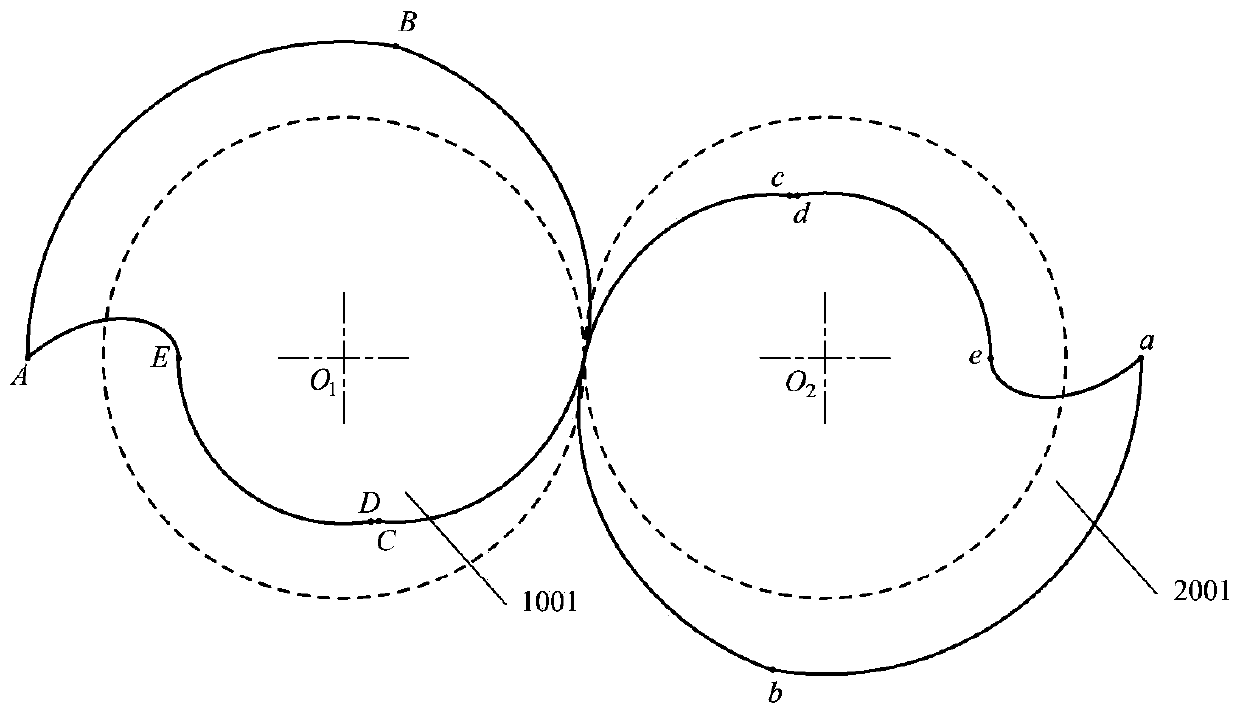

[0062] Such as figure 1 Shown is a left-handed cross-sectional profile line (1001) composition graph of the left-handed screw rotor (100). The left-handed section profile (1001) of the left-handed screw rotor (100) is composed of left-handed addendum arc AB, left-handed circular involute BC, left-handed first cycloid CD, left-handed dedendum arc DE and left-handed second cycloid EA .

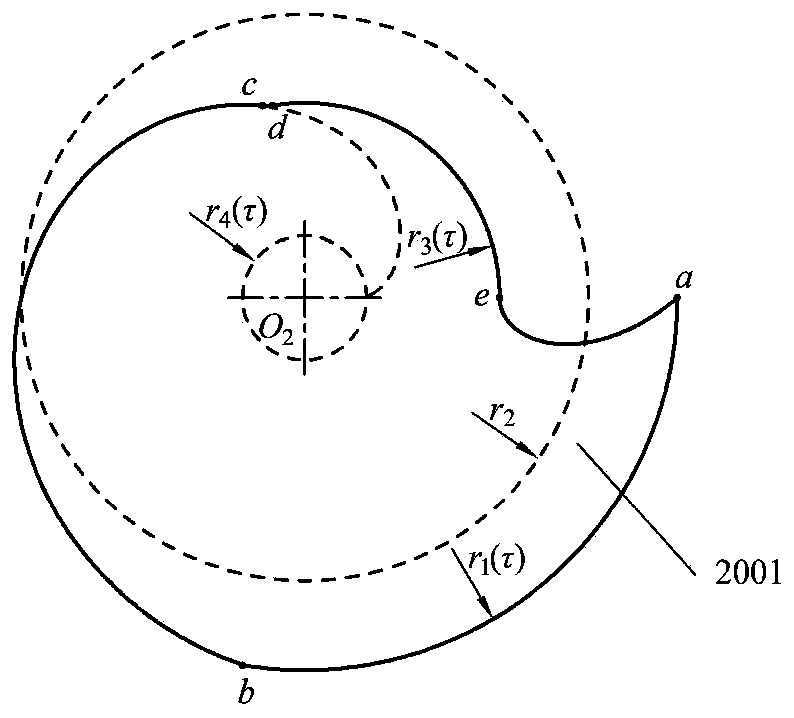

[0063] Such as figure 2 As shown, it is a composition curve diagram of the right-handed section profile (2001) of the right-handed screw rotor (200). The right-handed section profile (2001) of the right-handed screw rotor (200) consists of right-handed addendum arc ab, right-handed circular involute bc, right-handed first cycloid cd, right-handed root arc de and right-handed It is composed of the second cycloid ea.

[0064] At the same axial position, the radius r o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com