A damping slide rail with gear structure

A gear structure and damping technology, applied to furniture parts, household utensils, drawers, etc., can solve the problems of laborious pulling, reduced service life, wear of slide rails, etc., to improve balance and stability, increase internal volume ratio, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

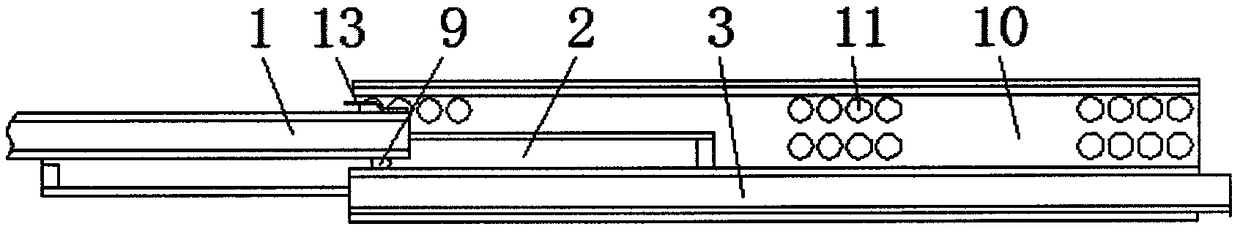

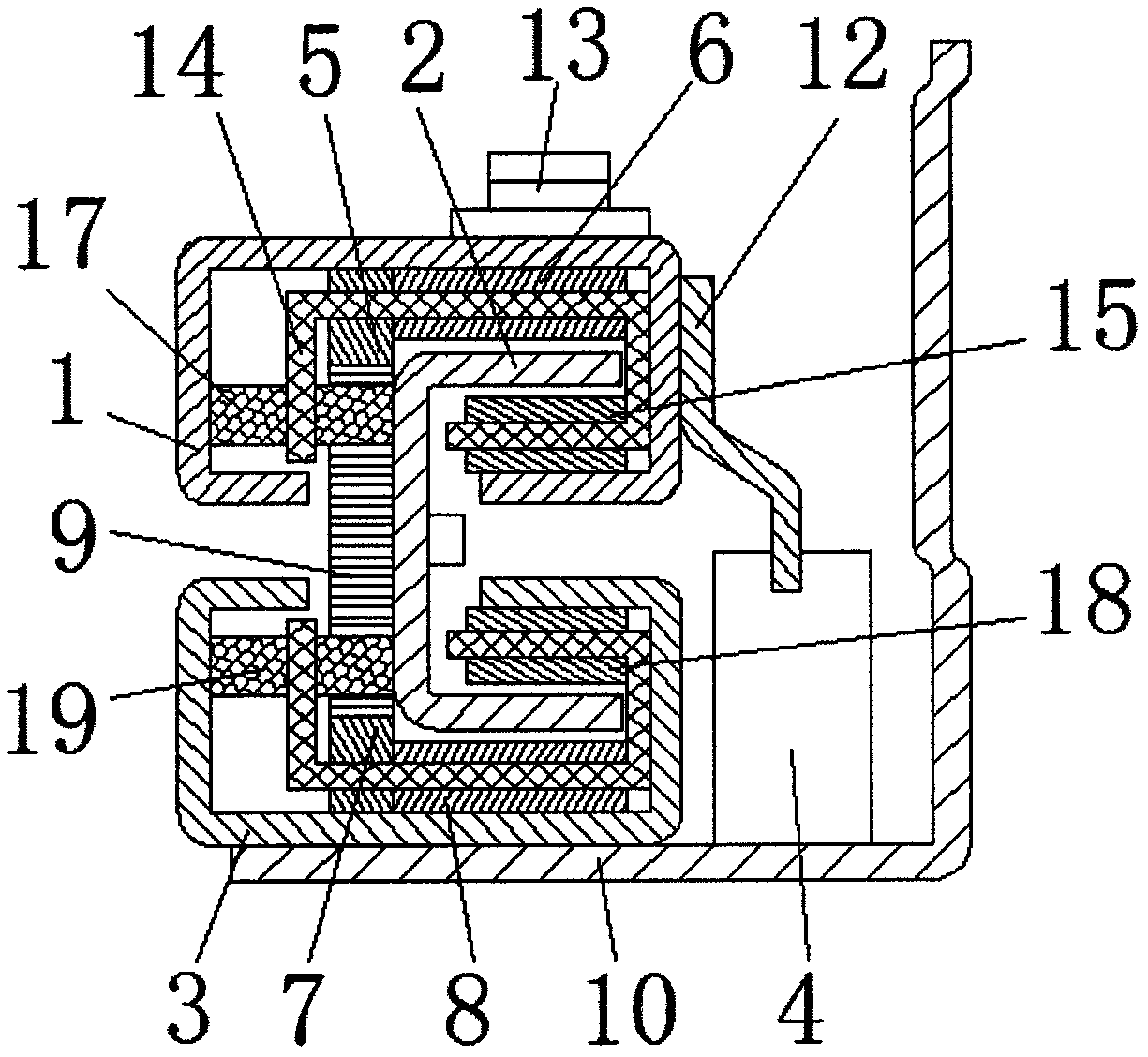

[0019] refer to Figure 1-2 , with gear damping slide rails, including two sets of guide rails, each set of guide rail upper rail 1, middle rail 2, lower rail 3 and damping mechanism 4, upper rail 1, middle rail 2 and lower rail 3 are made of stainless steel, and The surface is coated with a wear-resistant material layer, which can improve the wear resistance of the slide rail surface. Both the upper rail 1 and the lower rail 3 have a single-sided open cavity structure, and the middle rail 2 is a side-standing U-shaped structure, and the middle rail 2 runs through it. The opening position between the upper rail 1 and the lower rail 3, and the fully enclos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com