Automatic tension control device of non-woven fabric dividing and cutting machine

An automatic control device and slitting machine technology, which is applied in the directions of transportation and packaging, winding strips, thin material processing, etc., can solve the problem that the trimming width cannot be adjusted according to needs, and achieve a high degree of automation and reduce waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

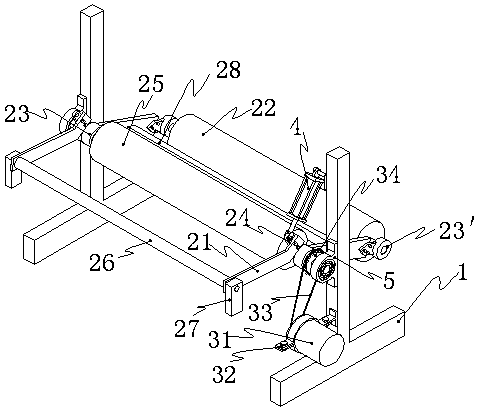

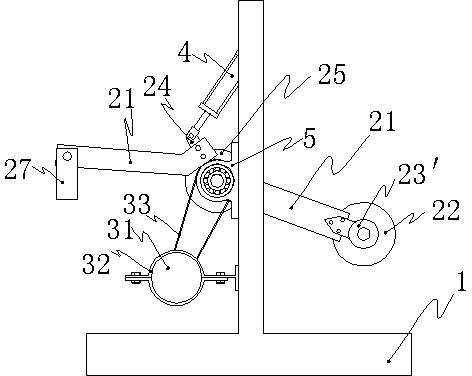

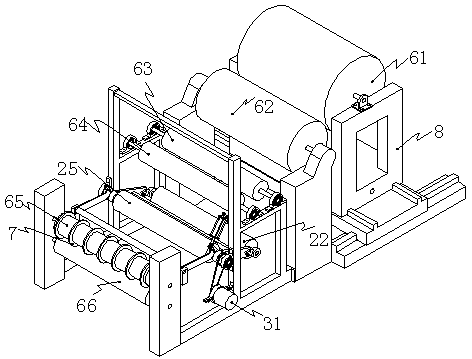

[0024] Such as Figure 1 to Figure 5 Shown, the present invention comprises support 1, rocking arm 21, tension roller 22, axle sleeve 23, support roller 25, counterweight shaft 26, encoder 31, chain 33, large chain wheel 34 and cylinder 4. The present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] Such as figure 1 As shown, the bracket 1 includes two metal parts with a "⊥"-shaped structure arranged opposite to each other, and each metal part with a "⊥"-shaped structure can be welded vertically by two square steels; the bracket 1 is used to install other components and support them Function, its shape can also be a frame structure. One side of the upper part of the support 1 is fixed with a pair of opposite bearing seats 5, and a support roller 25 is installed between the two bearing seats 5 through bearings. A shaft sleeve 23 is respectively movable on the support roller shafts at both ends, and a rocker arm 21 is respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com