Ultrasonic wave vibration device for aluminum alloy casting

A vibration device and ultrasonic vibration technology, applied in the field of casting, can solve problems such as poor effect and complex structure, and achieve good forming effect, improved processing efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

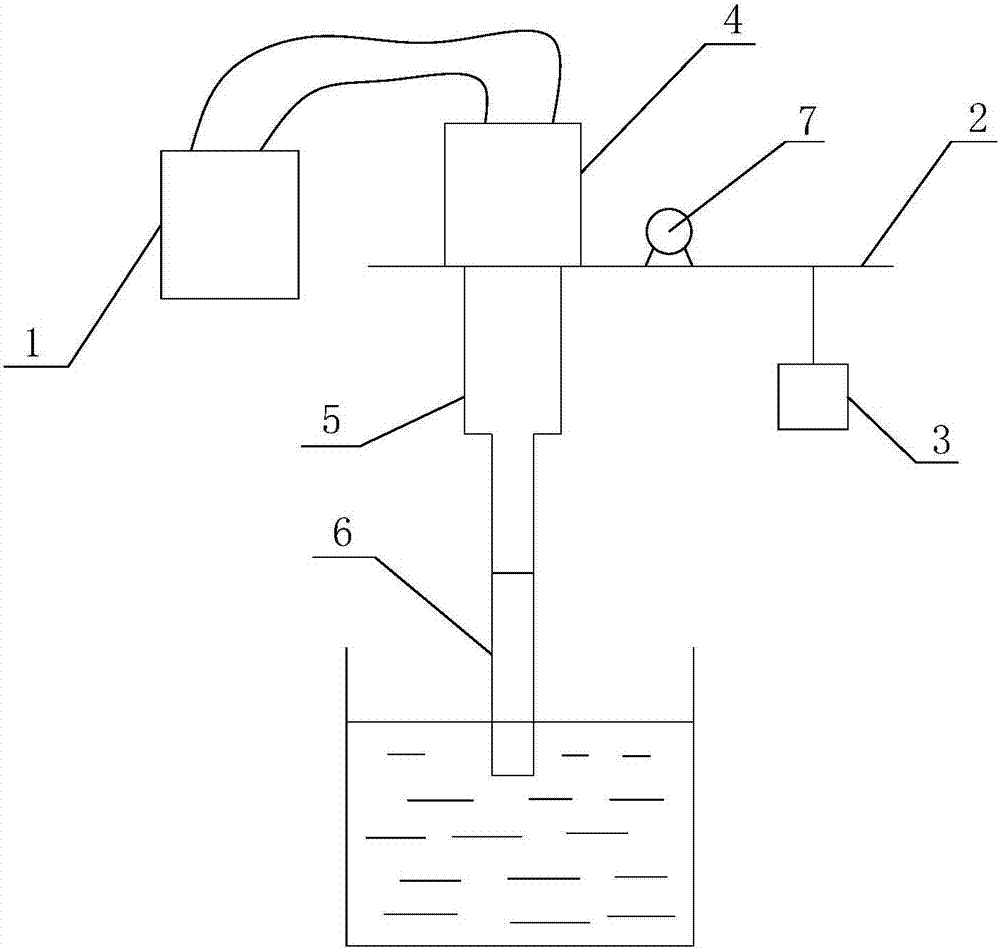

[0015] Such as figure 1 As shown, an ultrasonic vibration device for aluminum alloy casting provided by the present invention includes an ultrasonic generator 1, a mobile control platform 2, a power unit 3, and an ultrasonic vibration system, and the ultrasonic vibration system includes ultrasonic transducers connected in sequence 4. Ultrasonic horn 5 and tool bar 6, the ultrasonic generator 1 is connected to the ultrasonic transducer 4, and the ultrasonic transducer 4 is used to convert the input electric power into mechanical power and then transmit it out, while its own consumption is very little The ultrasonic transducer 4 is preferably a sandwich piezoelectric ceramic transducer. The sandwich piezoelectric ceramic transducer has the advantages of high efficiency, large amplitude and good heat resistance, and is very suitable for use in this devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com