Grooving machine

A slotting machine and casing technology, applied in the field of building decoration tools, can solve problems such as damage to the walls on both sides of the groove, reduce the flatness of the groove, and damage the wall, so as to save production costs and use costs, and improve Flatness, damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

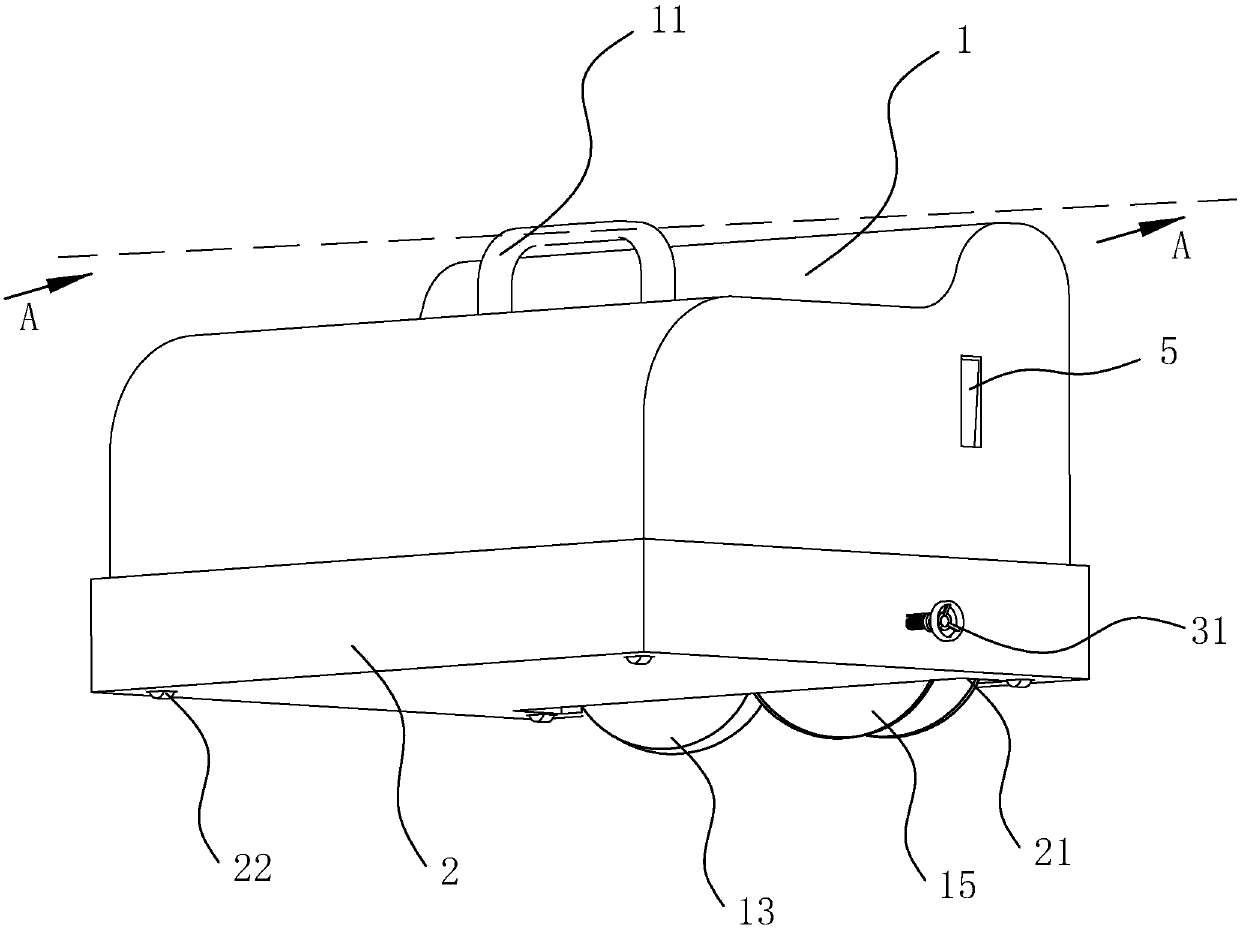

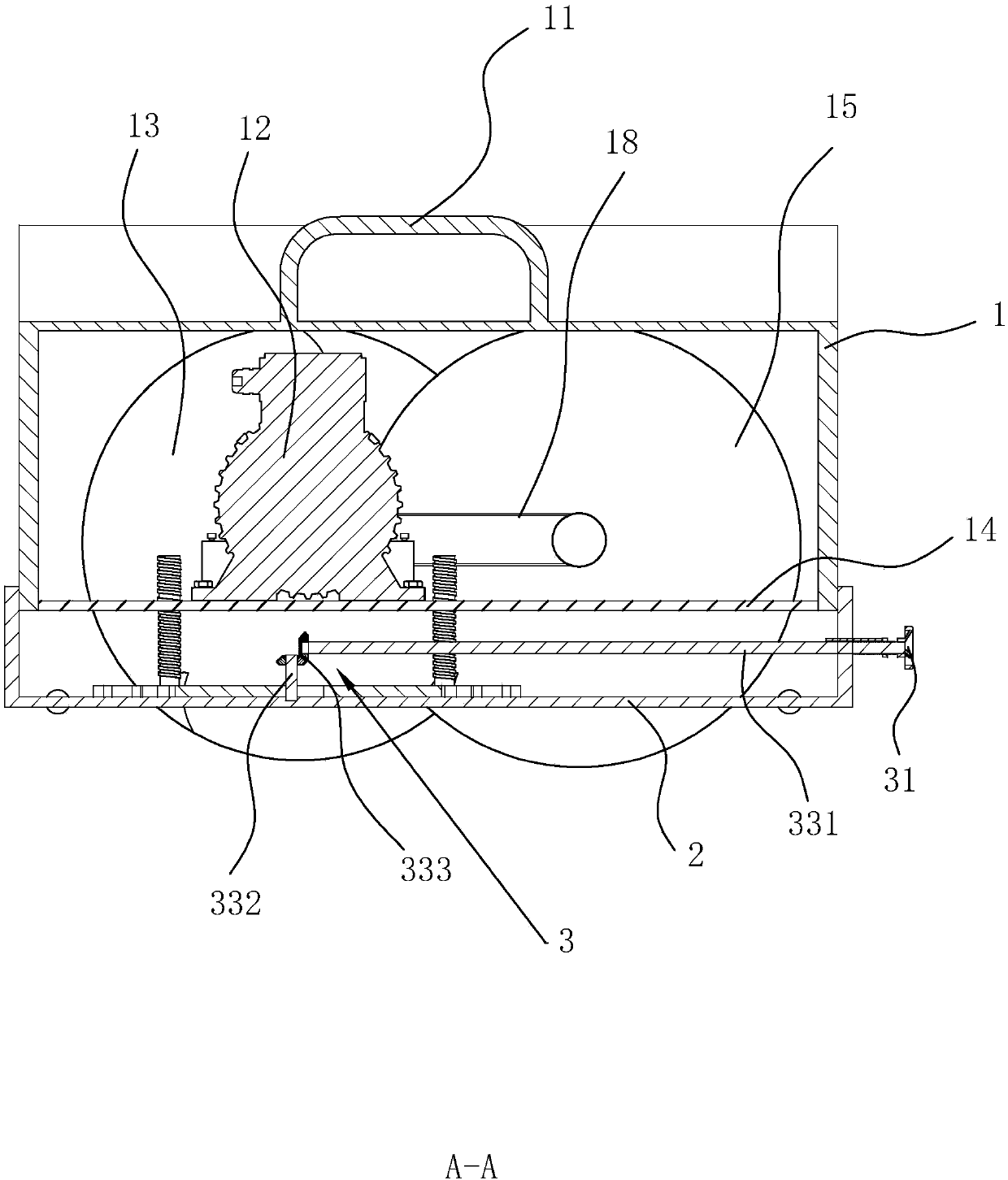

[0040] A slotting machine, refer to figure 1 and figure 2, comprising a casing 1 and a handle 11 connected to the outside of the casing 1, a driving motor 12 is installed in the casing 1, and a circular slotting knife 13 is installed at the end of the rotating shaft of the motor 12, and the rotating direction of the slotting knife 13 is consistent with the rotating shaft of the motor Vertical, and part of the groove knife 13 protrudes from the bottom plate 14 of the casing 1 . When carrying out the slotting operation, the operator holds the handle 11 to make the bottom plate 14 of the casing 1 fit the wall, the part of the slotting knife 13 protruding from the casing 1 cuts off the wall, and the slotting machine moves along the slotting direction on the wall. Move, so that slot cutter 13 excavates the slot on the wall smoothly.

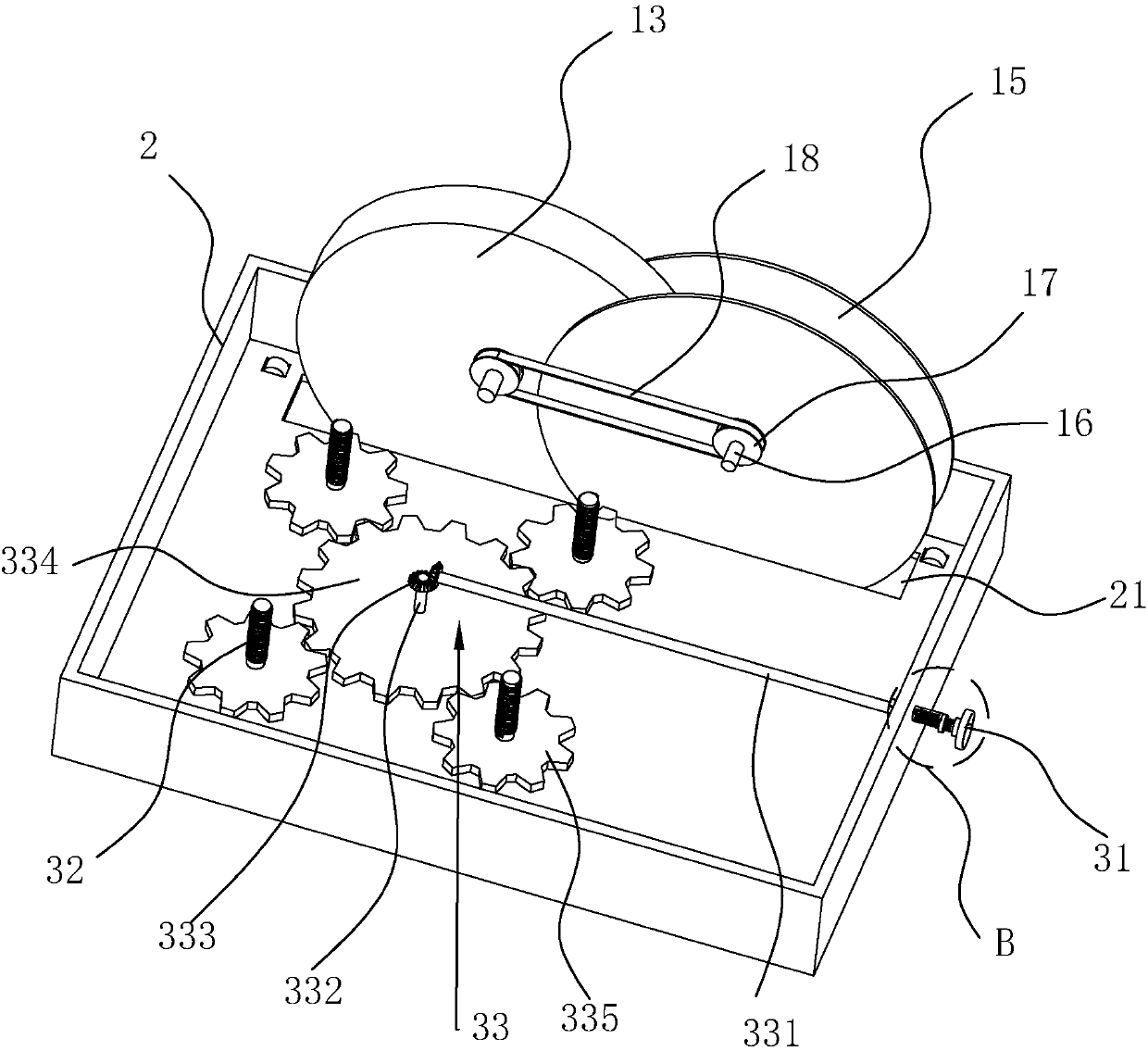

[0041] refer to figure 2 and image 3 Slotted saw blades 15 are attached to the slotted knives 13 on both sides of the slotted knife 13, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com