Quick preparation method of die of transparent adhesive tape-carved micro-fluidic chip

A technology of microfluidic chip and scotch tape is applied in the field of rapid preparation of microfluidic chip mold, which can solve the problems of cumbersome process, long processing cycle, inability to modify, etc., and achieve the effect of convenient use and convenient production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

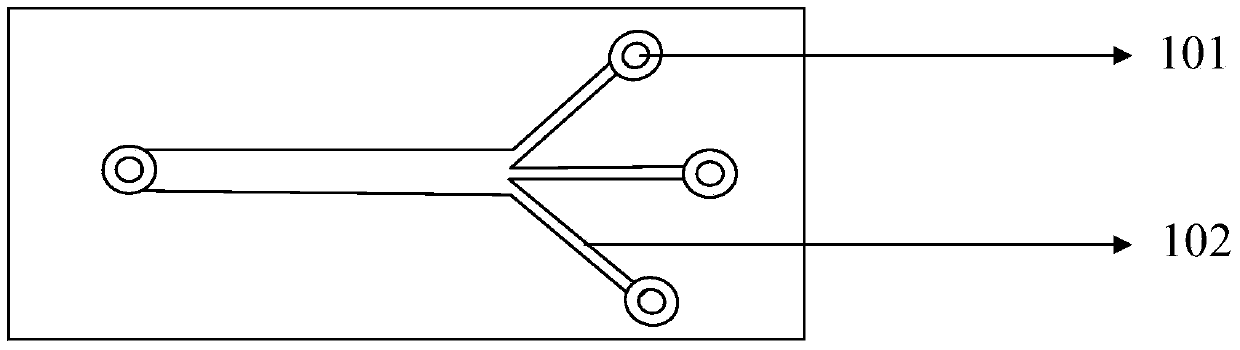

[0059] (1), hand-painted or drawn with computer graphics software such as figure 1 The mold channel pattern shown, the channel width is 1000 μm, the shape is a three-channel bifurcation, and printed;

[0060] (2), clean the surface of the slide glass with a plasma cleaner;

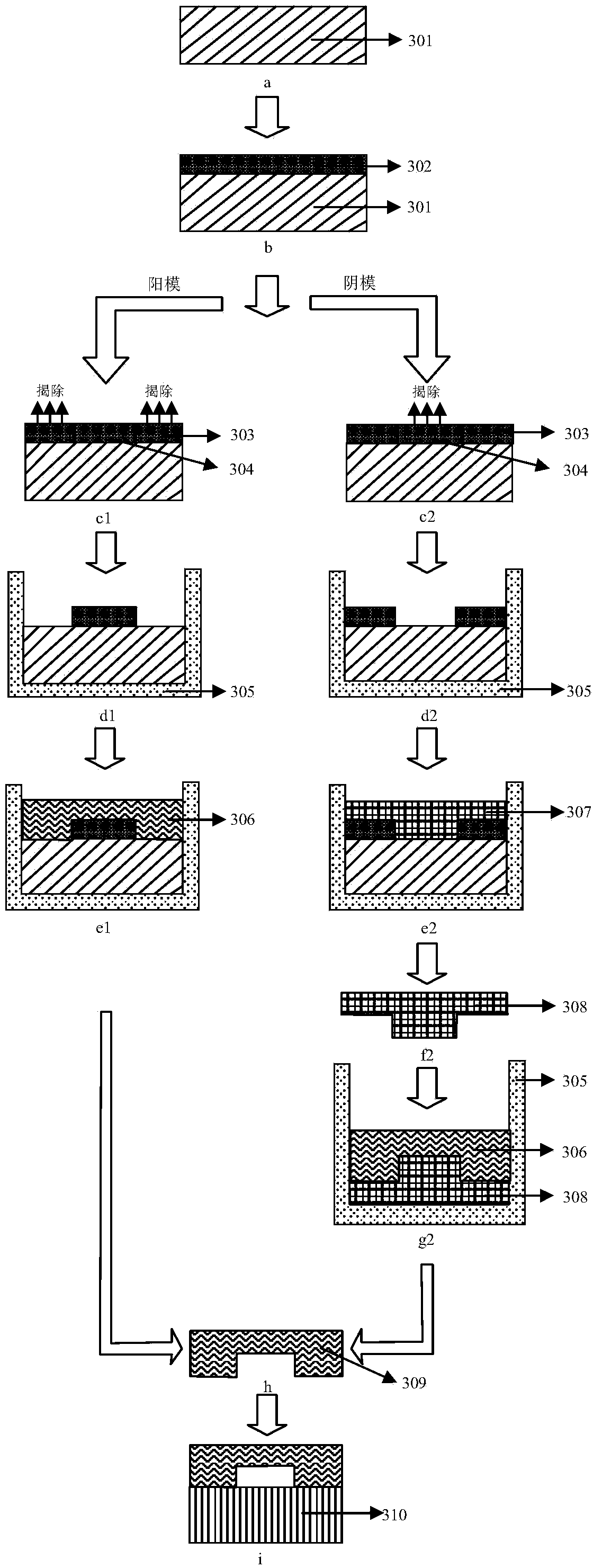

[0061] (3), take a cleaned glass slide (301), and attach two layers of scotch tape (302) with a single layer thickness of 50 μm on it, that is, the required channel depth is 100 μm, such as image 3 -b;

[0062] (4) Place the glass slide with scotch tape on a 70°C electric heating plate for 2 minutes;

[0063] (5) Place the printed mold channel pattern directly under the glass slide that has been attached with scotch tape, and stick it to the lower part of the glass slide so that it cannot be moved;

[0064] (6), use a scalpel to engrave the shape of the channel on the scotch tape along the drawn pattern, such as image 3 -c1;

[0065] (7), the scotch tape (303) around the channel is removed to obtain...

Embodiment 2

[0070] (1), with example 1 step (1), channel width is 50 μ m, and shape is " cross " shape;

[0071] (2), with example 1 step (2);

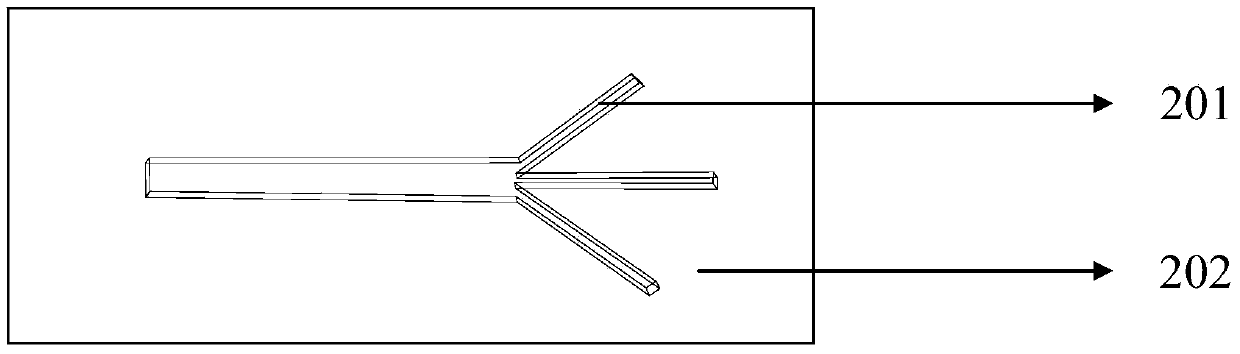

[0072] (3), with the example 1 step (3), attach one layer of scotch tape on it, that is, the required channel depth is 50 μm, such as figure 2 shown;

[0073] (4), with example 1 step (4);

[0074] (5), with example 1 step (5);

[0075] (6), with example 1 step (6);

[0076] (7), the scotch tape of channel shape is removed (304), then obtain negative mold, as image 3 -d2 shown;

[0077] (8), with example 1 step (8);

[0078] (9), vacuumize the epoxy resin (307) and pour it into the casting mold, place it on a 65°C electric heating plate for 2 hours to solidify;

[0079] (10), tinfoil paper and cured epoxy resin mold (308) tool are peeled off, can obtain required mold that can be used repeatedly, as image 3 -f2 shown;

[0080] (11), with example 1 step (8);

[0081] (12), with example 1 step (9), as image 3 -g2 shown;

[0082] (13)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com