Modulation method for improving giant magneto-impedance (GMI) effect of melt extraction amorphous microwires

An amorphous microwire and melt pulling technology is applied in the field of improving the modulation of the giant magneto-impedance effect of the melt-drawing amorphous microwire, which can solve problems such as the surface performance modulation of the amorphous microwire, and overcome the solder connection method. The shortcomings and limitations of the equipment, the simple process of the equipment, the effect of eliminating residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

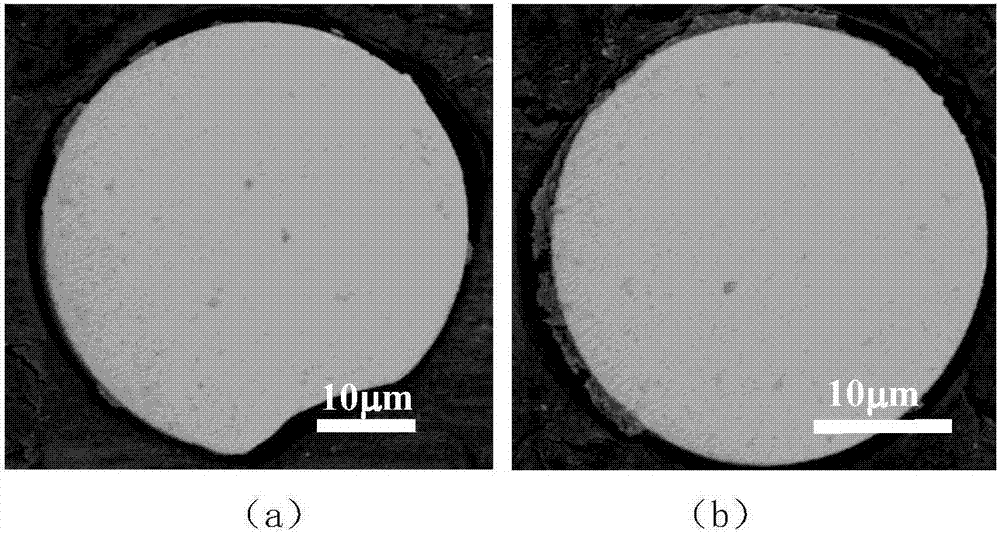

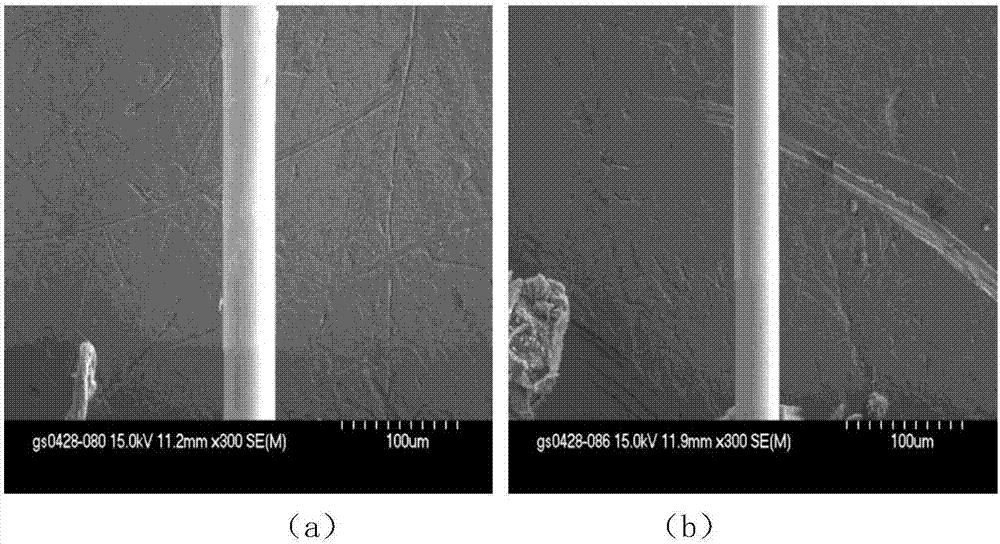

[0020] Select the melt to draw Co 68.15 Fe 4.35 Si 12.25 B 13.75 Nb 1 Cu 0.5 Amorphous microwires, one end of the amorphous microwires is fixed on a flat copper fixture, and the other end is immersed in an electrolyte solution for electrolytic polishing, wherein, the proportion of the electrolyte solution is: phosphoric acid 369g (ρ=1.8434g / mL), CrO 3 101.25g, 12.5g of deionized water; the anode material is the amorphous microwire, the cathode material is 99.99% pure copper sheet, and the current density is 100A / dm 2 , the electropolishing time was 600s, and the electrolyte temperature was 45°C; the magnetic impedance performance test was performed on the treated amorphous microwire in a zero magnetic shielding space.

Embodiment 2

[0022] Select the melt to draw Co 68.15 Fe 4.35 Si 12.25 B 13.75 Nb 1 Cu 0.5 Amorphous microwires, one end of the amorphous microwires is fixed on a flat copper fixture, and the other end is immersed in an electrolyte solution for electrolytic polishing, wherein, the proportion of the electrolyte solution is: phosphoric acid 369g (ρ=1.8434g / ml), CrO 3 101.25g, 12.5g of deionized water; the anode material is the amorphous microwire, the cathode material is 99.99% pure copper sheet, and the current density is 150A / dm 2 , the electrolytic polishing time was 360s, and the electrolyte temperature was 45°C; the magnetic impedance performance test was performed on the treated amorphous microwire in a zero magnetic shielding space.

Embodiment 3

[0024] Select the melt to draw Co 68.15 Fe 4.35 Si 12.25 B 13.75 Nb 1 Cu 0.5 Amorphous microwires, one end of the amorphous microwires is fixed on a flat copper fixture, and the other end is immersed in an electrolyte solution for electrolytic polishing, wherein, the proportion of the electrolyte solution is: phosphoric acid 369g (ρ=1.8434g / ml), CrO 3 101.25g, 12.5g of deionized water; the anode material is the amorphous microwire, the cathode material is 99.99% pure copper sheet, and the current density is 150A / dm 2 , the electropolishing time was 600s, and the electrolyte temperature was 45°C; the magnetic impedance performance test was performed on the treated amorphous microwire in a zero magnetic shielding space.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com