Brace rod sliding groove type hydraulic flat digging grab bucket

A hydraulic and level excavation technology, applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of uneven surface, can not meet the requirements of seabed or riverbed flatness, etc., to achieve convenient change, popularization and application value, The effect of meeting the requirements of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

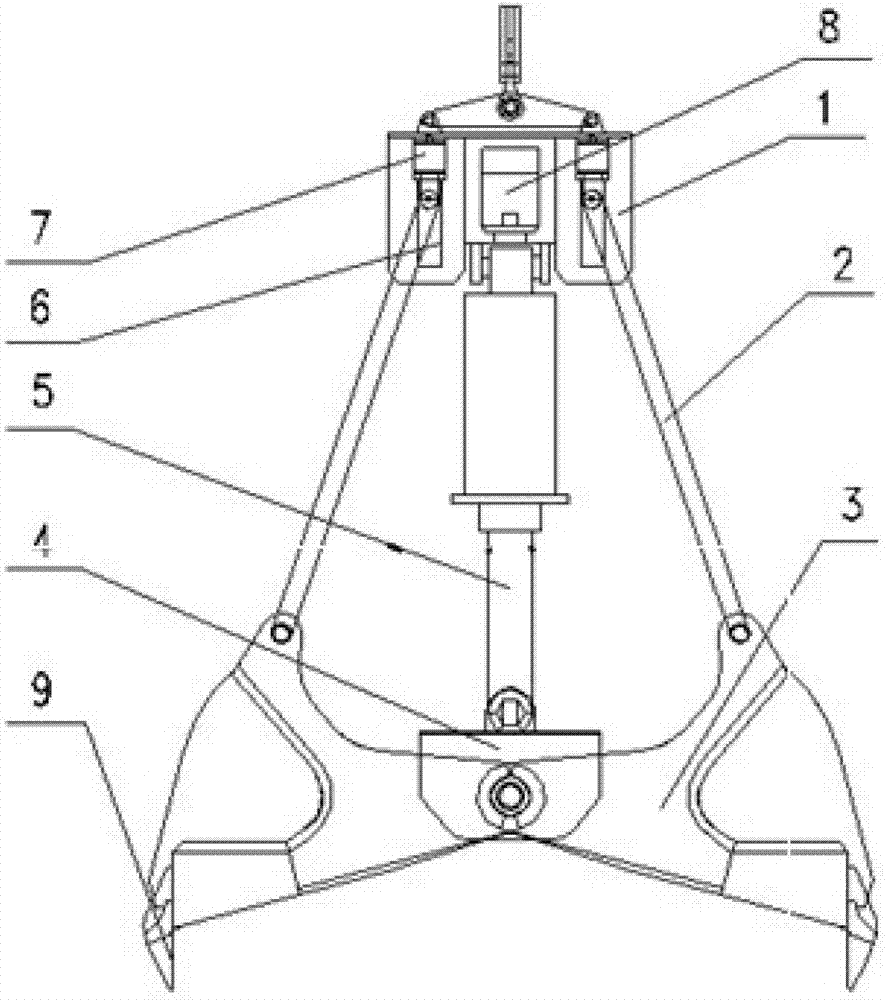

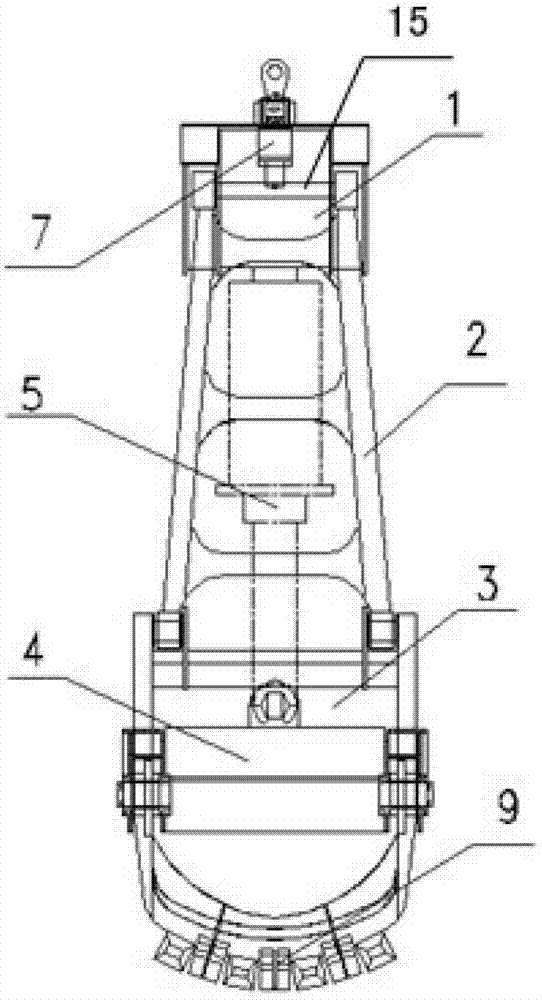

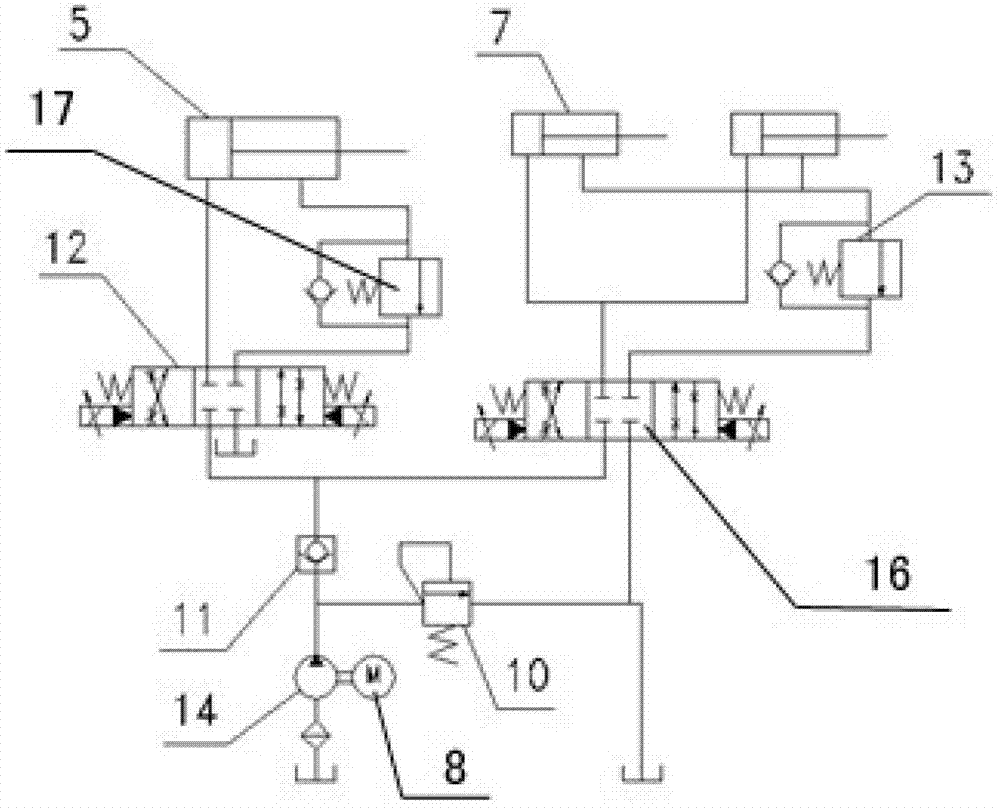

[0019] Such as Figure 1 to Figure 3 As shown, a strut chute type hydraulic horizontal excavation grab includes an upper bolster 1, a bucket body 3, a lower bolster 4 and a hydraulic control device, the upper bolster 1 and the lower bolster 4 Connected by the opening and closing bucket oil cylinder 5, the bucket body 3 is hinged to the lower bolster 4; the two sides of the upper bolster 1 are respectively provided with a strut sliding unit, and the strut sliding unit includes 2 struts Sliding oil cylinder 7 and strut 2, one end of 2 struts 2 is respectively hinged with both sides of bucket body 3; The other end of 2 struts 2 is hinged with strut sliding cylinder 7 through connecting rod 15; The hydraulic control device includes a hydraulic pump 14, a proportional reversing valve 12 for opening and closing buckets, a proportional reversing valve 16 for a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com