Patents

Literature

124results about How to "Meet flatness requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

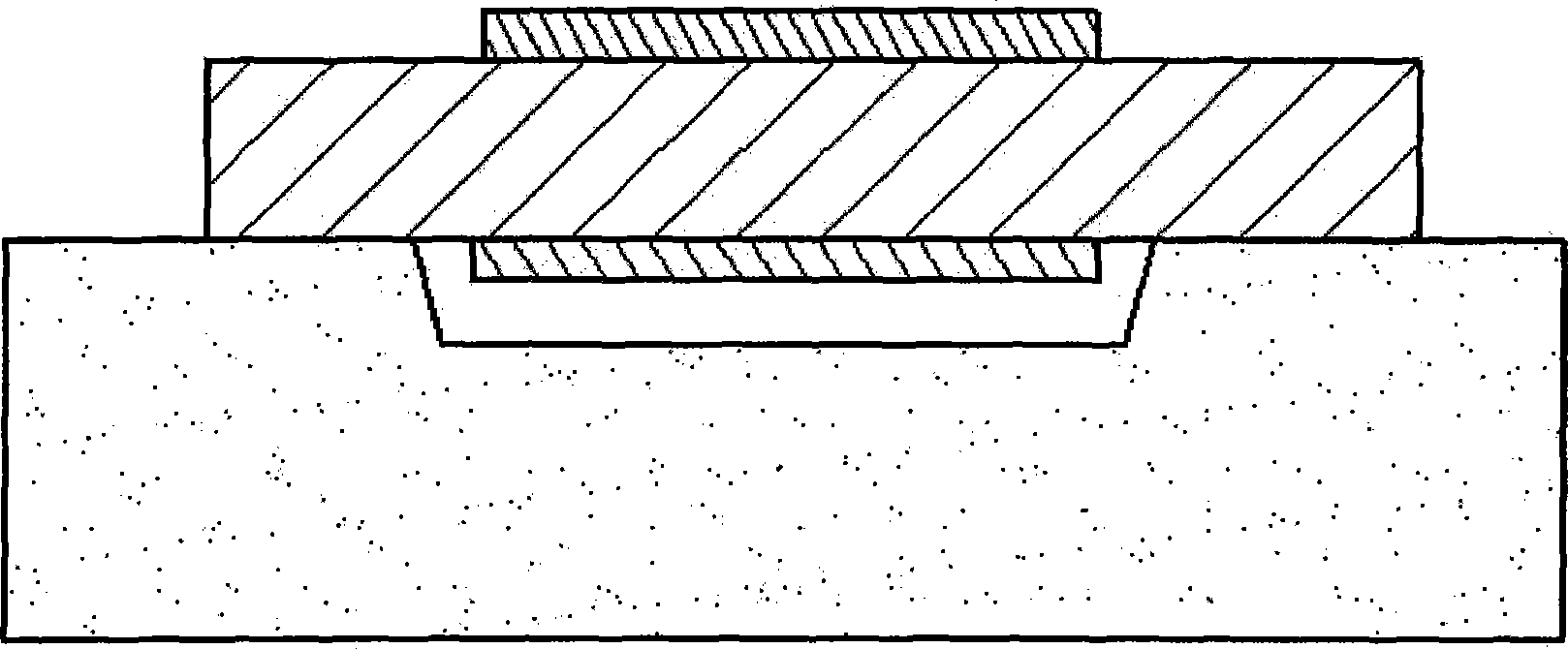

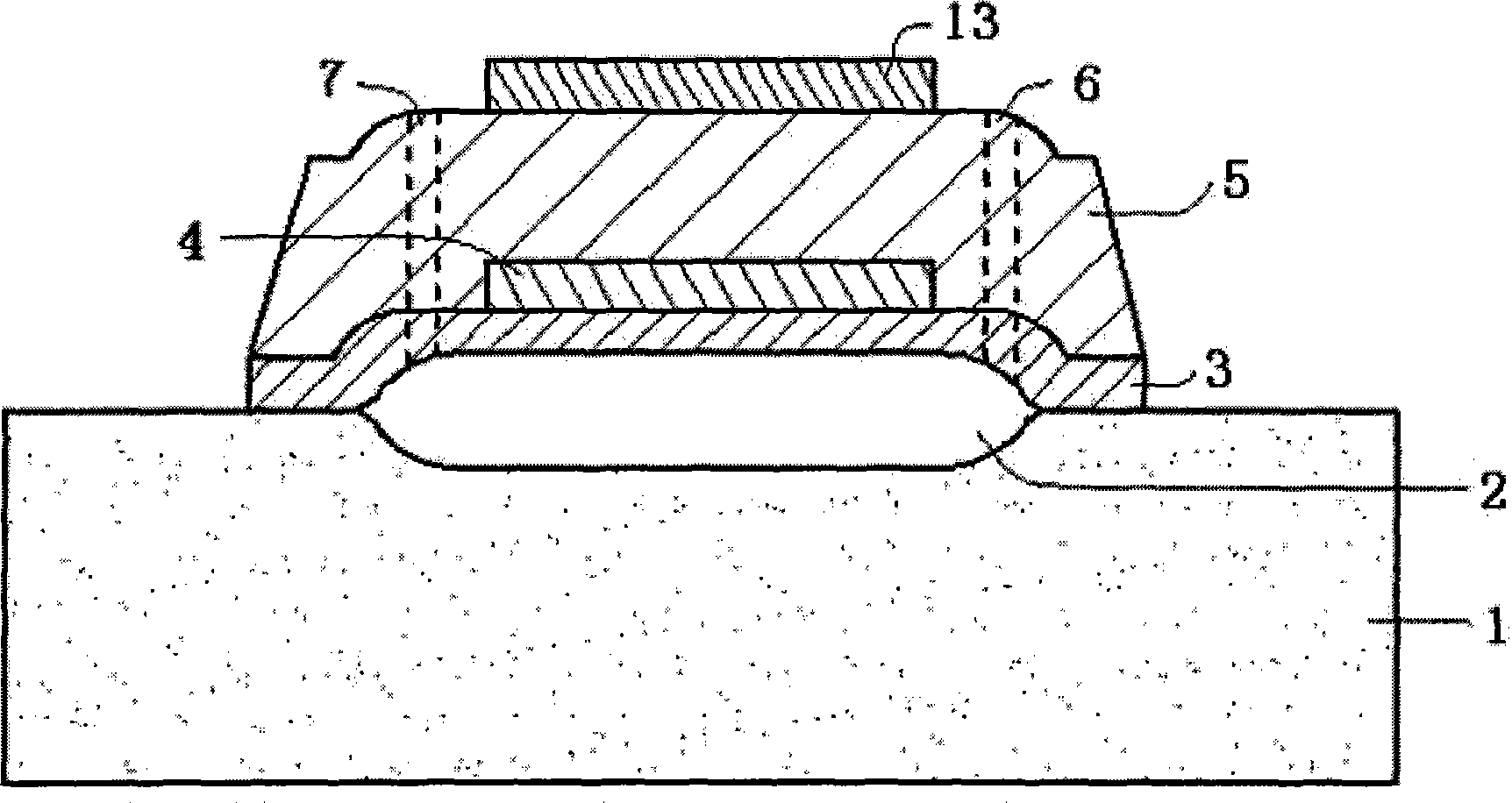

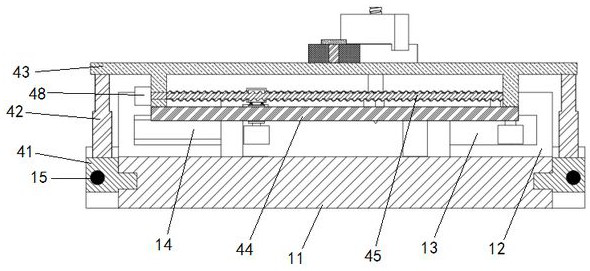

Film bulk acoustic wave resonator and preparation method thereof

InactiveCN101465628AHigh application frequencyReduce the requirements of the manufacturing process for equipmentImpedence networksThin-film bulk acoustic resonatorBulk acoustic wave

The invention discloses a thin film bulk acoustic wave resonator which comprises a substrate, a buffer layer, a piezoelectric layer and electrodes, and is characterized in that 1. A smooth concave groove and the buffer layer are arranged on the upper end surface of the substrate; the buffer layer crosses the concave groove and forms an air gap provided with a smooth upper convex edge with the substrate, and completely covers the air gap; the height of the lower top surface of the air gap is less than that of the substrate, and the air gap has flat surface and even change edge; 2. The edge of the buffer layer, which is contacted with the air gap and is close to the substrate is in smooth and outer-convex shape; the piezoelectric layer is arranged on the buffer layer; the electrodes include a bottom electrode and a top electrode; the bottom electrode is arranged in the piezoelectric layer on the buffer layer; the top electrode is arranged on the piezoelectric layer. The thin film bulk acoustic wave resonator has ingenious structure; a FBAR with stable structure and low loss can be fabricated on the substrate through the method, and the CMP process is avoided, so the thin film bulk acoustic wave resonator can be integrated into a CMOS chip conveniently.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

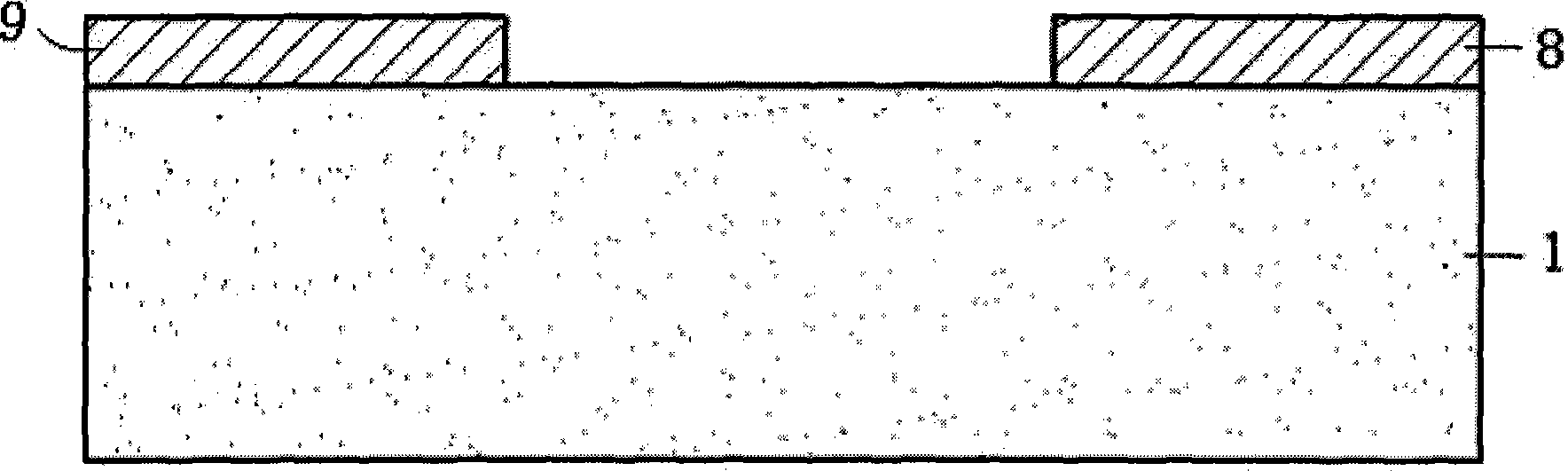

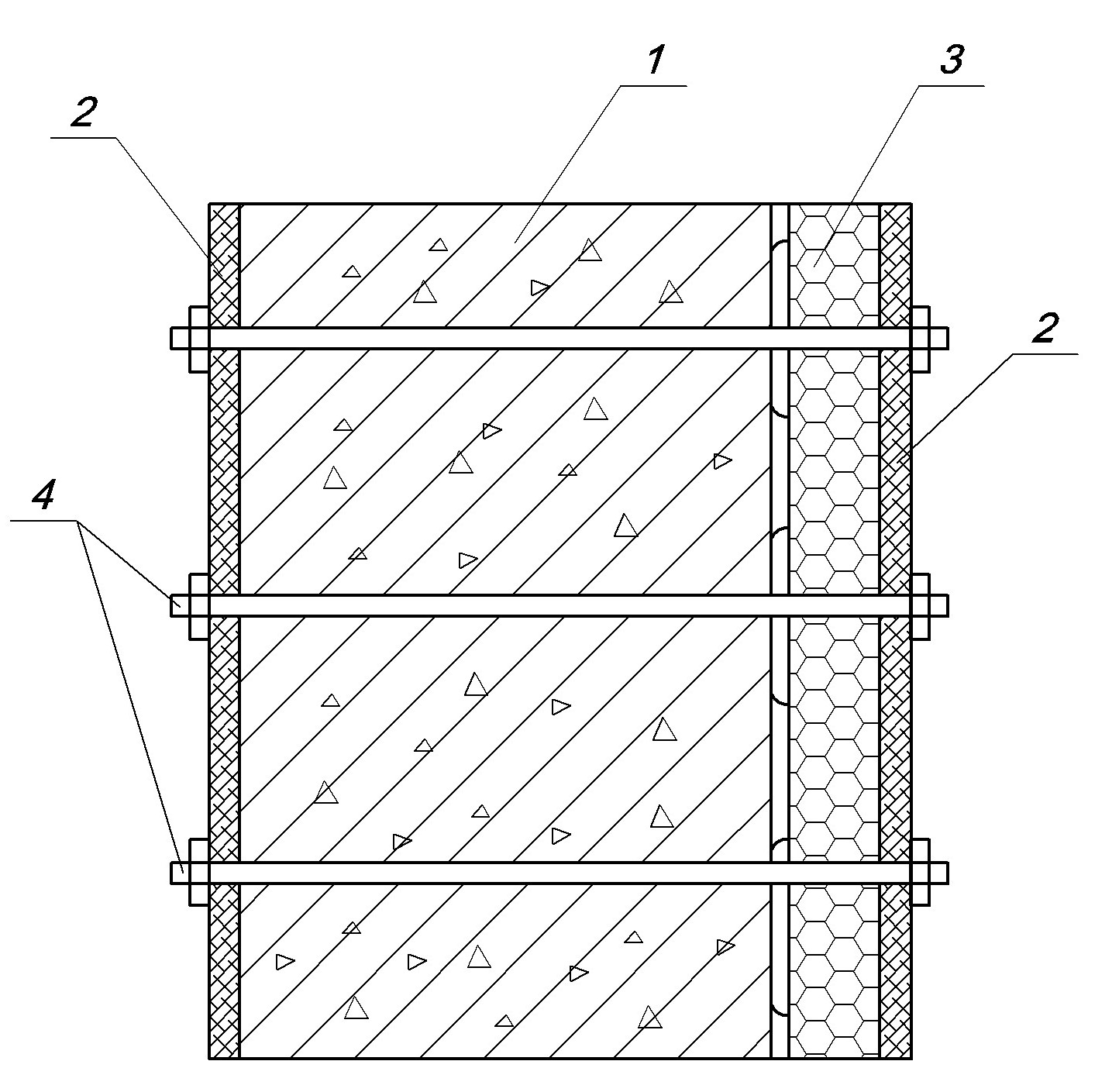

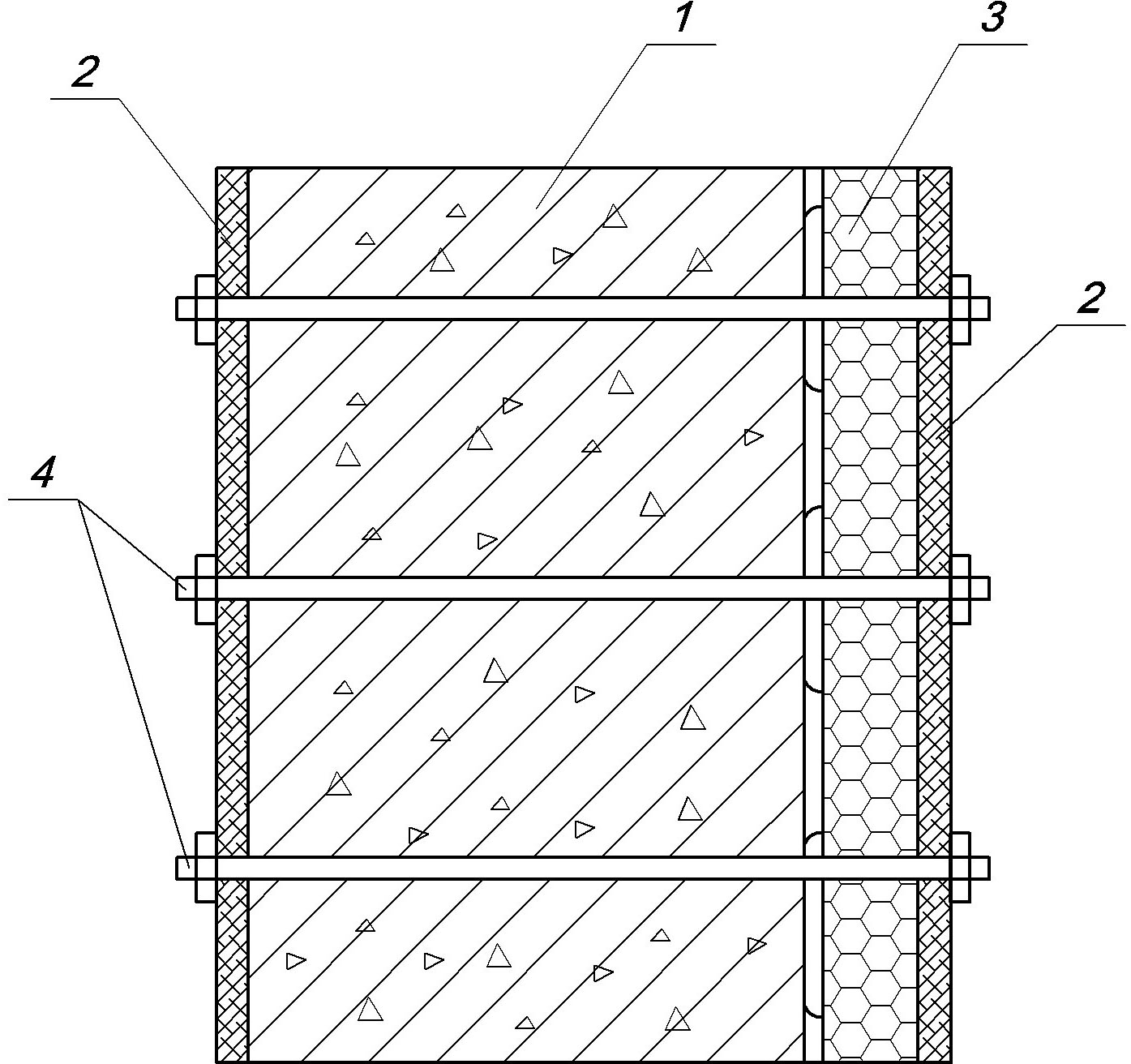

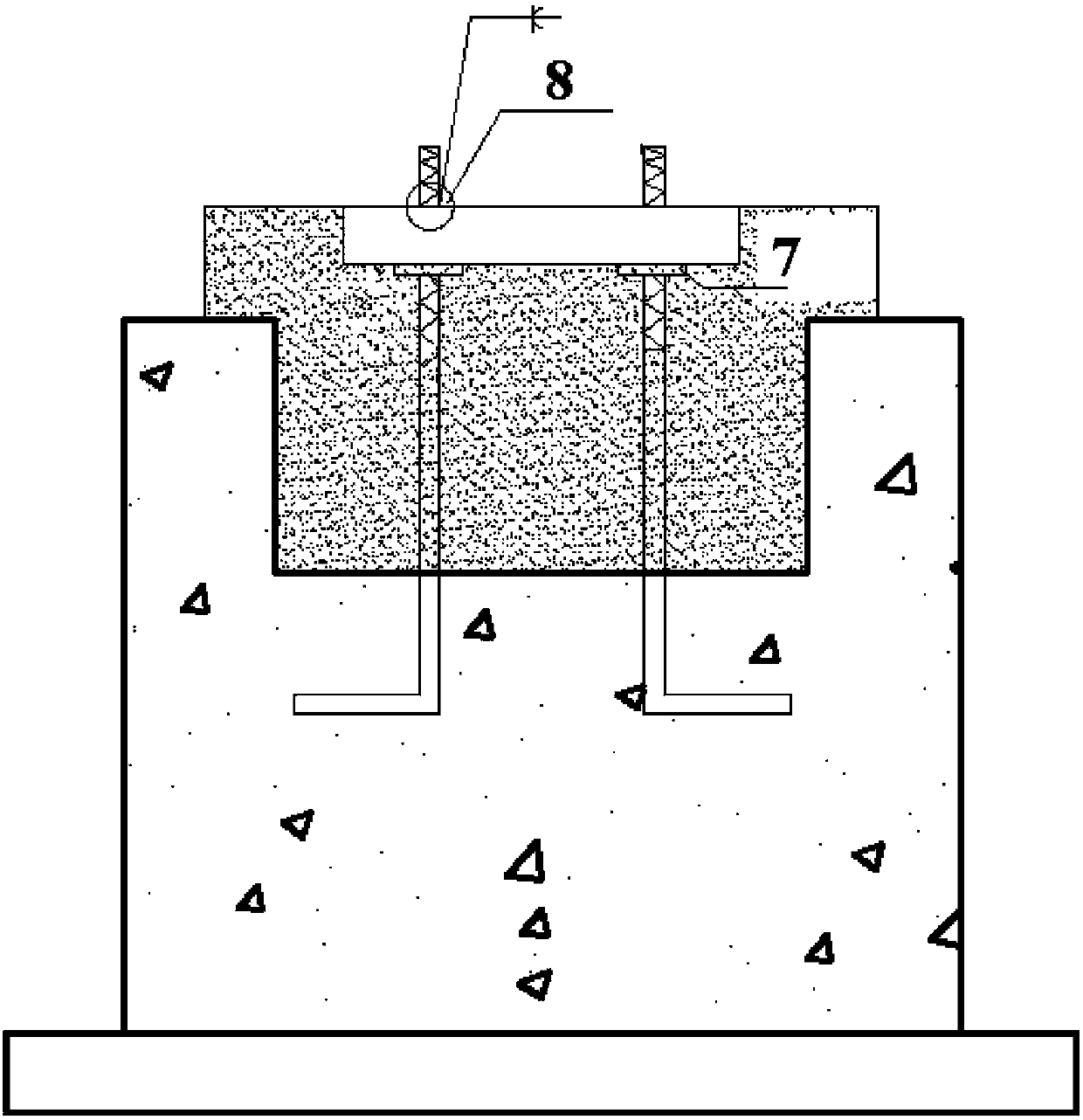

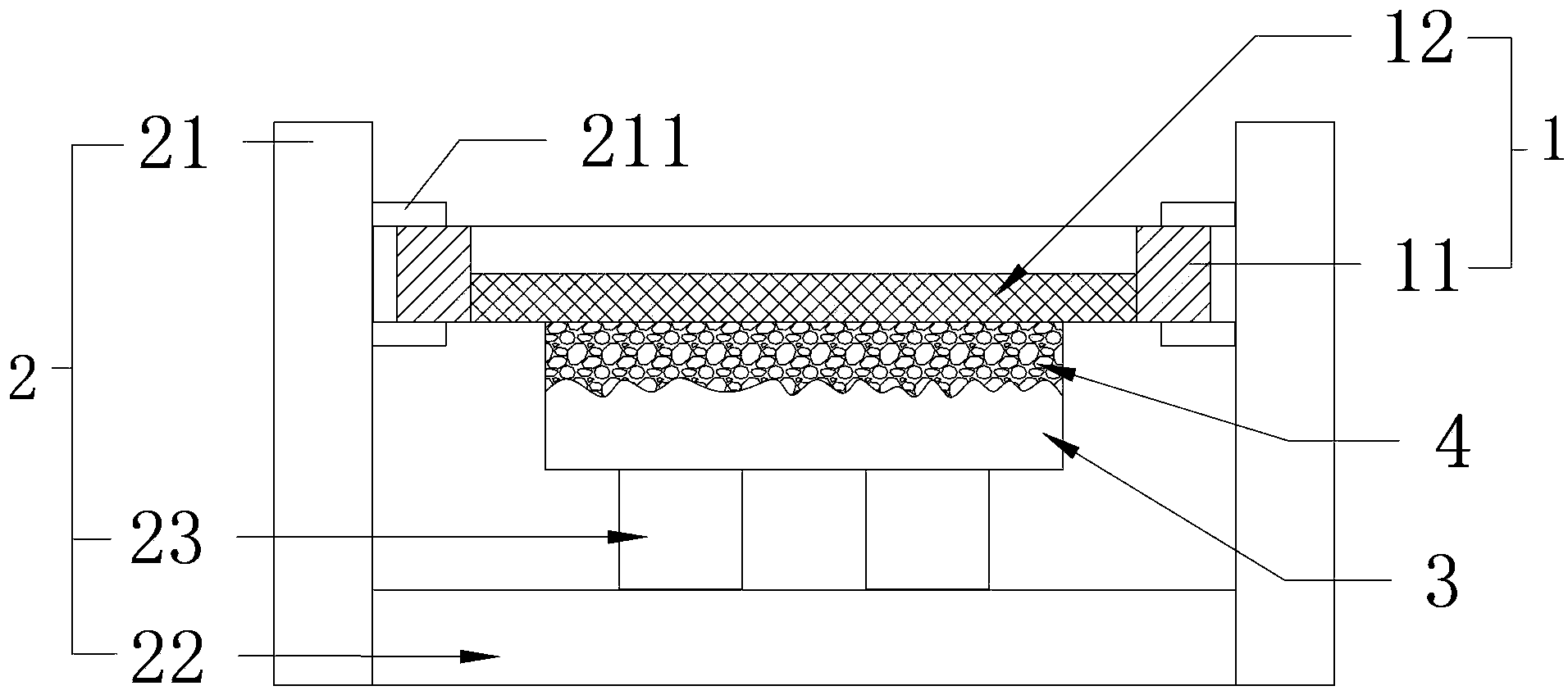

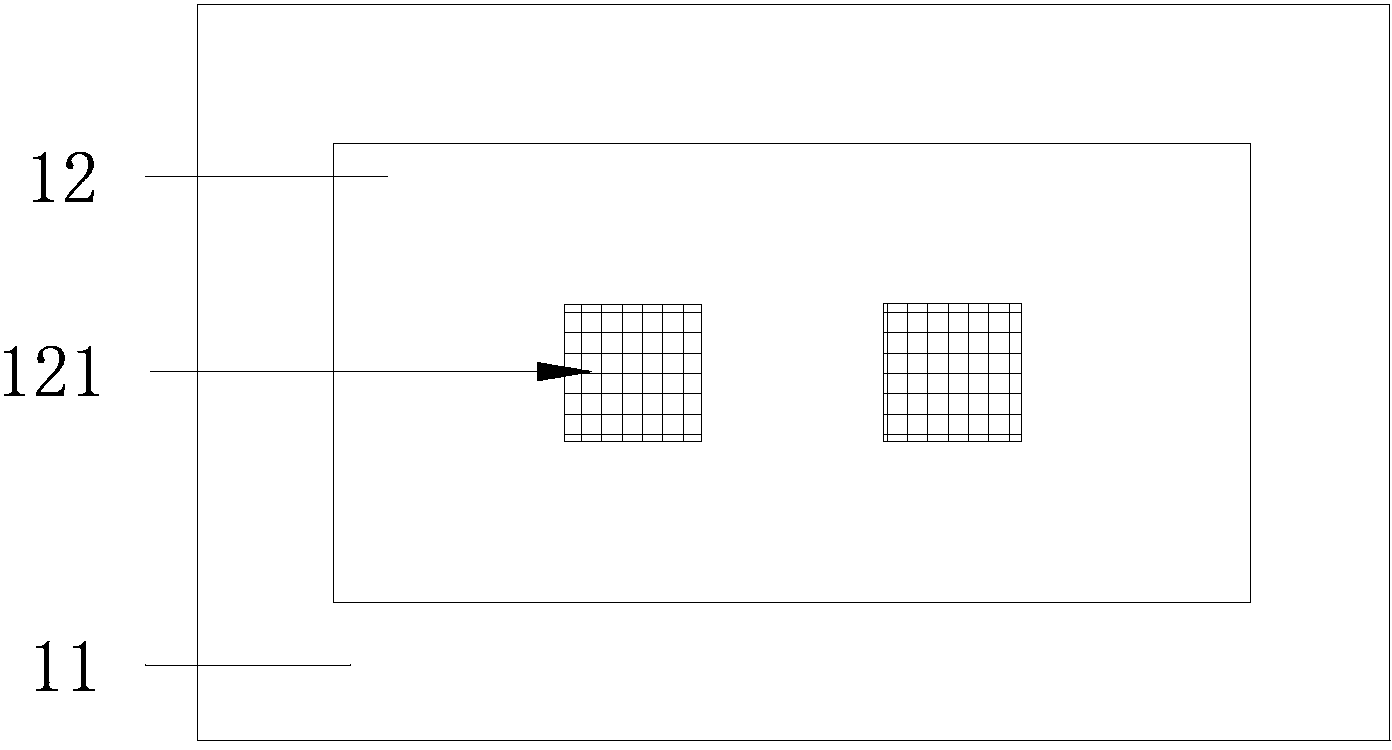

Fiber-reinforced plaster-free dismantle-free integrated heat-preservation template and exterior wall heat-preservation construction process

InactiveCN102071797AMeet flatness requirementsReduce thicknessWallsBuilding material handlingInsulation layerReinforced concrete

The invention relates to a fiber-reinforced plaster-free dismantle-free integrated heat-preservation template and an exterior wall heat-preservation construction process. The heat-preservation template is formed by compounding an expandable polystyrene (EPS) aggregate layer on the surface on one side of a fiber concrete plate. The process comprises the following steps that: a fiber concrete template and a fiber concrete composite heat-preservation template are vertically fixed on the two sides of the position of a pre-built wall body respectively, wherein the fiber concrete template and the fiber concrete composite heat-preservation template are fixed together through pull bolts; and reinforcements are arranged and concrete is poured between the fiber concrete template and the fiber concrete composite heat-preservation template, so that a reinforced concrete bearing wall body is formed. The integrated permanent dismantle-free heat-preservation template meets the requirements on heat preservation of an exterior wall and flatness of a plaster layer in place of the exterior wall template, an outer heat-preservation layer and the plaster layer. In the process, the template is not required to be removed, the heat preservation, heat insulation and water proofing performance are good, the thickness of the wall body is reduced, a great amount of materials and labor are saved, the construction period can be shortened, and the energy conservation requirement and the requirements on adhesion between the permanent template and a basic layer and flatness of a surface layer can be met. The template is suitable for high-rise and small high-rise buildings; the dwelling environment can be improved; the building function quality is improved; the building development benefit is improved; and the template has a wide application prospect.

Owner:ZHENGZHOU UNIV +2

Extruded-sheet external-wall external heat insulation construction method

InactiveCN101654932AGuaranteed flatnessNot easy to fall offCovering/liningsClimate change adaptationInsulation layerSurface layer

The invention relates to a building external-wall heat insulation construction method, in particular to an extruded-sheet external-wall external heat insulation construction method comprising the following steps: treating the basal layer of the wall surface, sticking extruded sheets, fixing the extruded sheets, installing gridding cloth, coating polymer mortar on the finishing layer, installing U-shaped fasteners and constructing the decorative layer. The construction of the decorative layer comprises the following steps: knife-coating soft water-resistant putty, brushing special alkali-resistant primer, spray-coating stone paint and spray-coating coating varnish. The method can ensure the flatness of the heat insulation layer, increase the thickness of the mortar layer especially by usingthe U-shaped fasteners and control the error within 5 mm, but the traditional construction process can not easily control the error. The surface layer does not easily fall off, and the thickness of the anti-cracking mortar needs to be controlled within 2-3 mm according to the specification requirement, otherwise, the surface layer can easily fall off. The traditional construction can not meet theflatness requirement for the same thickness; but after the method uses the U-shaped fasteners, the thickness of the anti-cracking mortar can be properly adjusted so as to meet the flatness requirement and ensure that the surface layer does not easily fall off.

Owner:河北省烟草公司唐山市公司

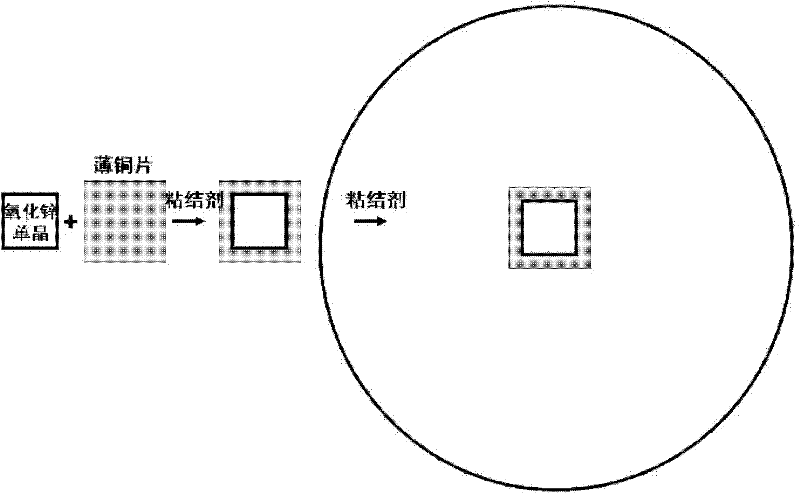

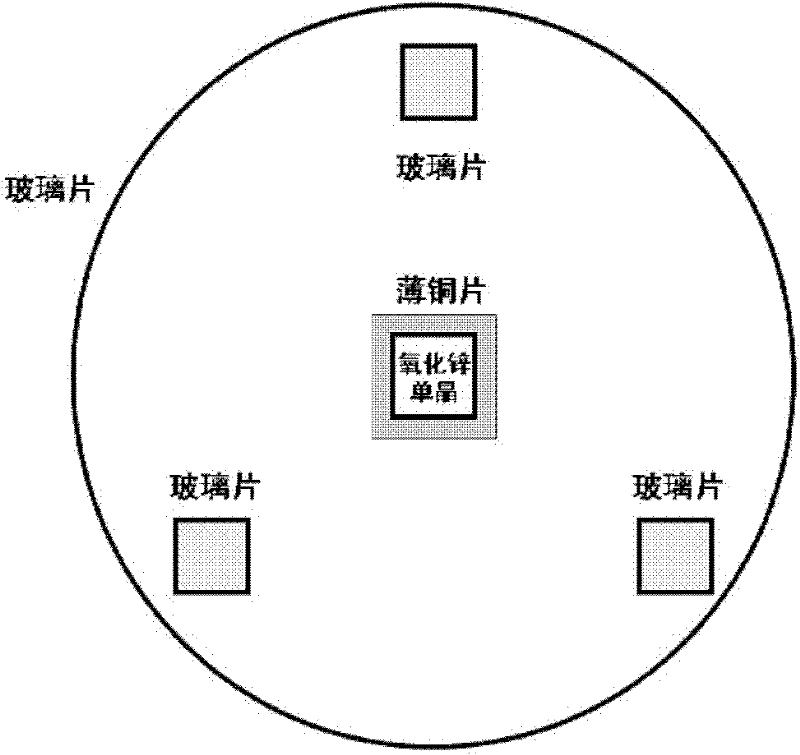

Zinc oxide single crystal polishing technology for substrate of photoelectric device

InactiveCN102240967AMeet flatness requirementsLapping machinesSingle crystal substrateSingle crystal

The invention provides a polishing technology of a zinc oxide single crystal substrate, which can meet the requirements for the epitaxial growth of a photoelectric device. The zinc oxide single crystal substrate with the surface RMS (root mean square) roughness of less than 1nm within a surface range of 10 mu m*10 mu m can be obtained through the steps of rough grinding of a single crystal, bonding, loading on a disc, mechanical rough grinding, mechanical fine grinding, mechanical rough polishing, chemical mechanical fine polishing, cleaning and packaging. The polishing technology relates to a bonding agent, a bonding technology and a technology of unloading from the disc used in the bonding process of the zinc oxide single crystal substrate, as well as grinding fluid, polishing fluid and a grinding thickness control technology used in the grinding process and the polishing process. The obtained zinc oxide single crystal substrate can be used for the epitaxial growth of a semiconductor photoelectric device.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

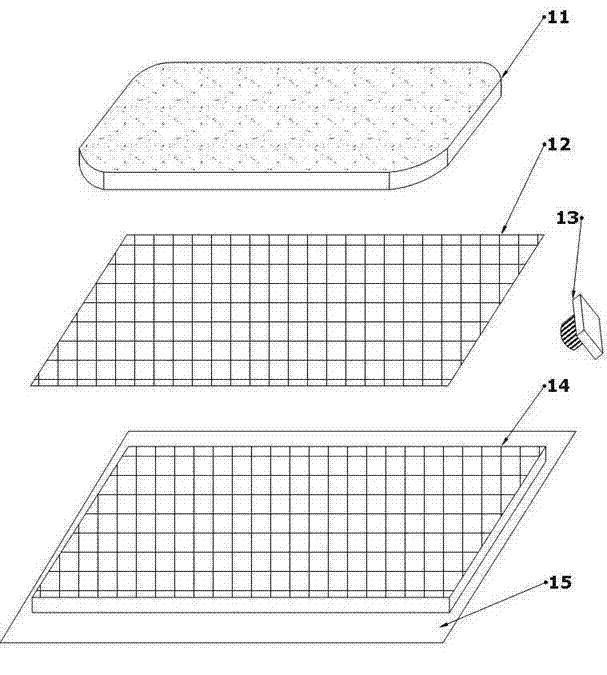

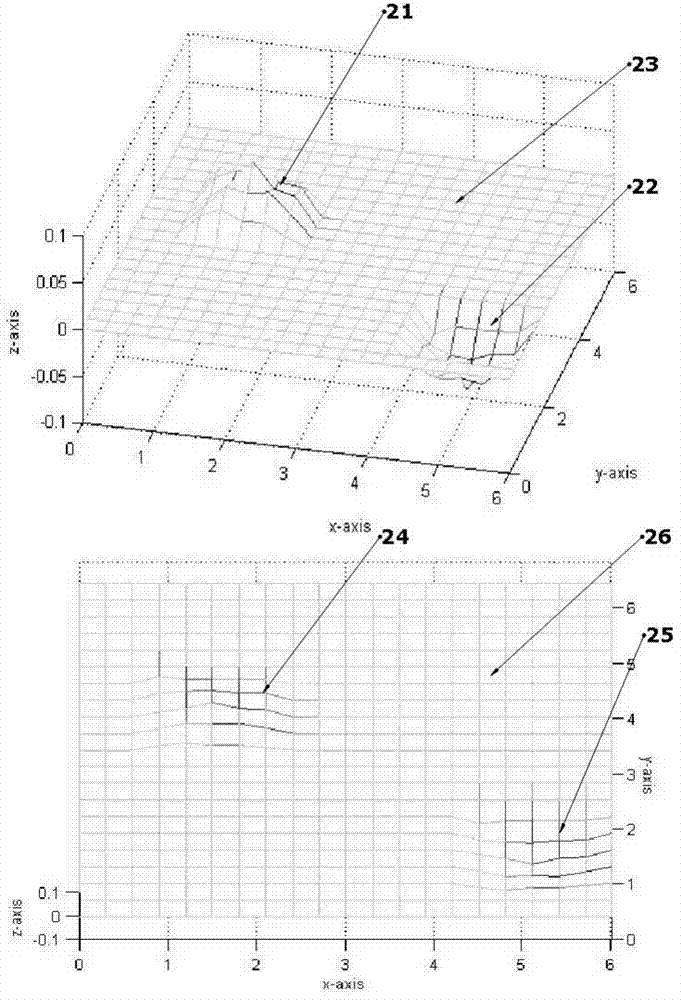

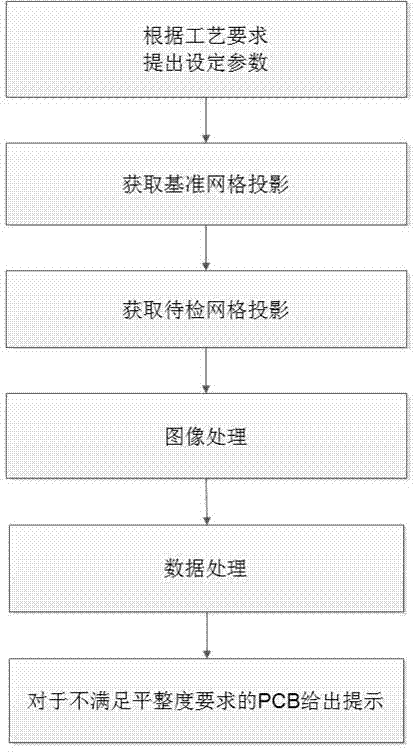

Method for detecting planeness of PCB based on network projection

InactiveCN103673934AOvercome the disadvantage of large errorOvercome subjectivityUsing optical meansComputer graphics (images)Image processing

The invention provides a method for detecting the planeness of a PCB based on a network projection. The method comprises the steps that the PCB is put on a horizontal operating platform; a light source over a dam board, and the dam board are installed over the PCB; a camera is installed in an included angle of 60 degrees formed between a side and the horizontal operating platform; the light source projects the shadow of a standard grid on the dam board on the PCB by the dam board; the camera takes a picture of the shadow of the grid on the PCB from the included angle of 60 degrees. An analysis device comprising a picture processing device and a data processing device analyses the picture taken by the camera so as to decide whether the PCB meets the requirement of the planeness. The method provided by the invention simply and accurately realizes the detection of the planeness of the PCB.

Owner:CHINA UNIV OF MINING & TECH

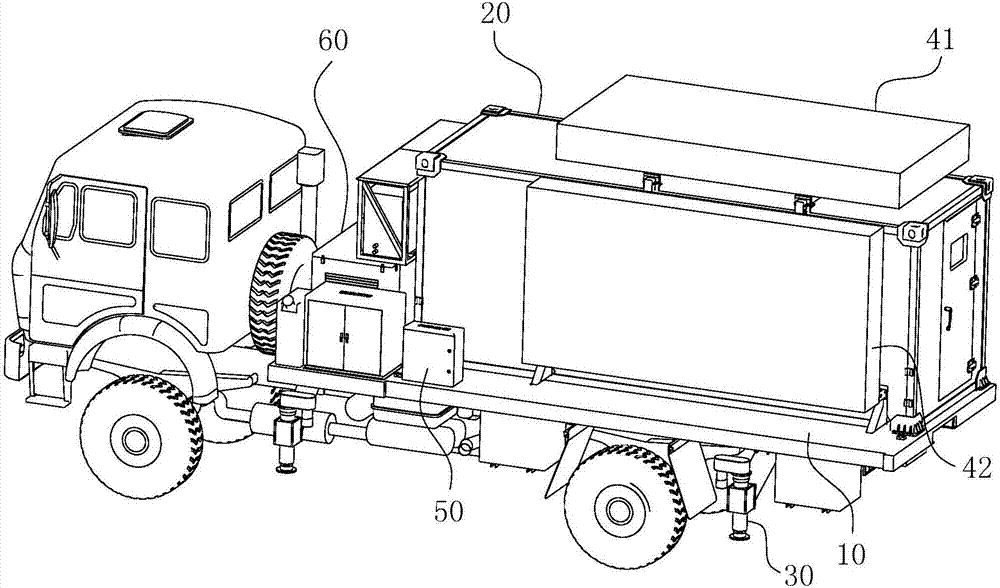

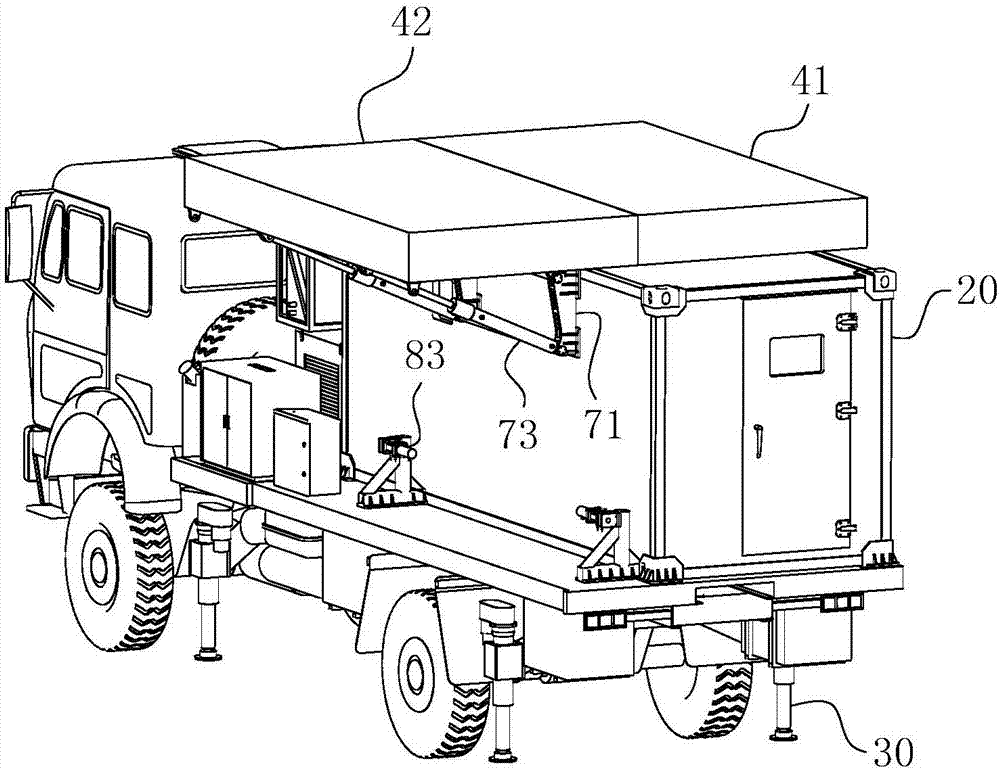

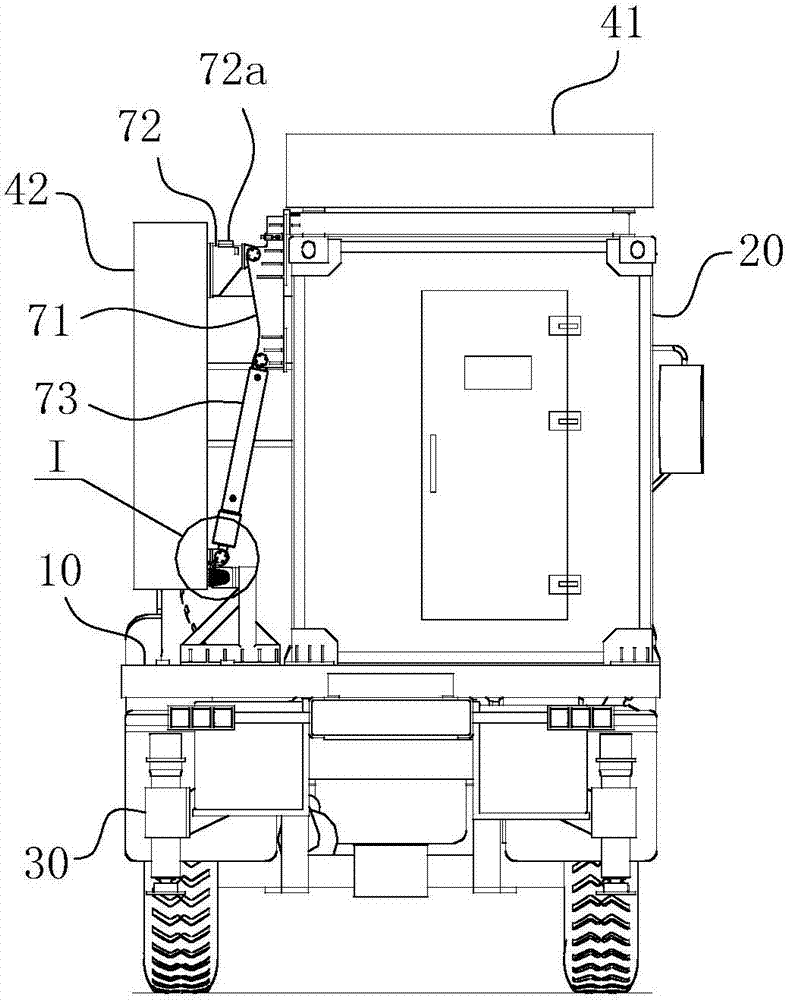

High-mobility large-scale radar vehicle

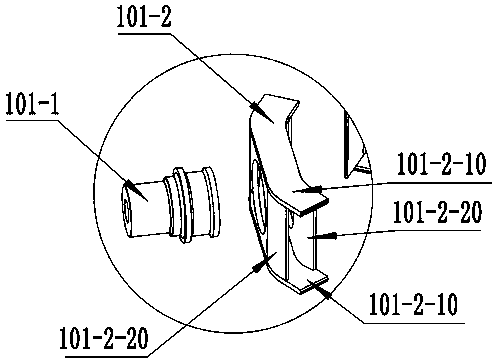

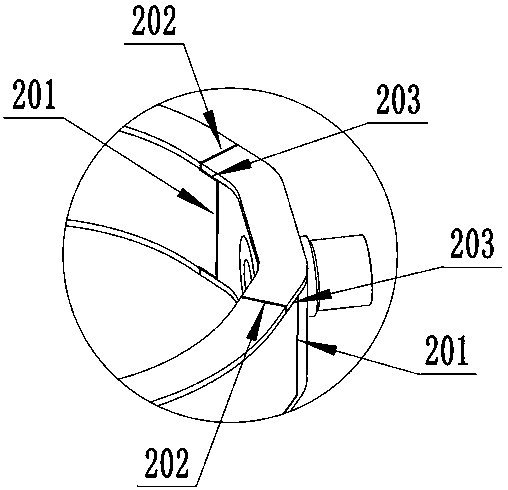

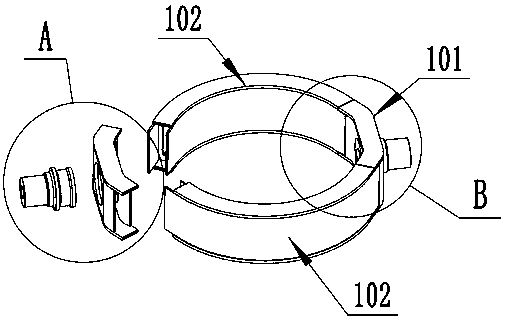

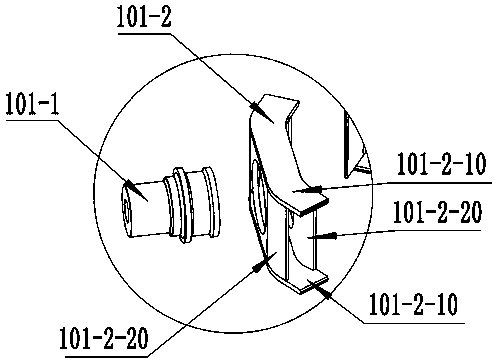

ActiveCN107097706AImprove mobilityGuaranteed mobilityCollapsable antennas meansWave based measurement systemsRadar antennasGround vehicles

The invention belongs to the technical field of vehicle-borne radars, and particularly relates to a high-mobility large-scale radar vehicle. The radar vehicle comprises an assembling platform and an electronic equipment cabin, wherein leveling supporting legs are arranged on the lower plate surface of the assembling platform; a fixed antenna and a folded antenna are arranged at the electronic equipment cabin; the folded antenna is driven by a hydraulic driving assembly, so that two position conditions of withdrawing and unfolding are generated along a vertical surface; when the folded antenna is under a withdrawing condition, the antenna plate surface of the folded antenna is vertically arranged, when the folded antenna is under an unfolding condition, the antenna plate surface of the folded antenna is horizontally arranged, and the antenna plate surface of the folded antenna and the antenna plate surface of the fixed antenna are in the same plane; and the radar vehicle also comprises a servo control system and an electric generating system. According to the high-mobility large-scale radar vehicle disclosed by the invention, the situation that the width and the height are not exceeded during the transporting of radar antennas can be guaranteed, functions of quick erecting and quick removing of an antenna array surface can also be realized, and finally, the high mobility of the ground vehicle-borne radar is guaranteed.

Owner:ANHUI SUN CREATE ELECTRONICS

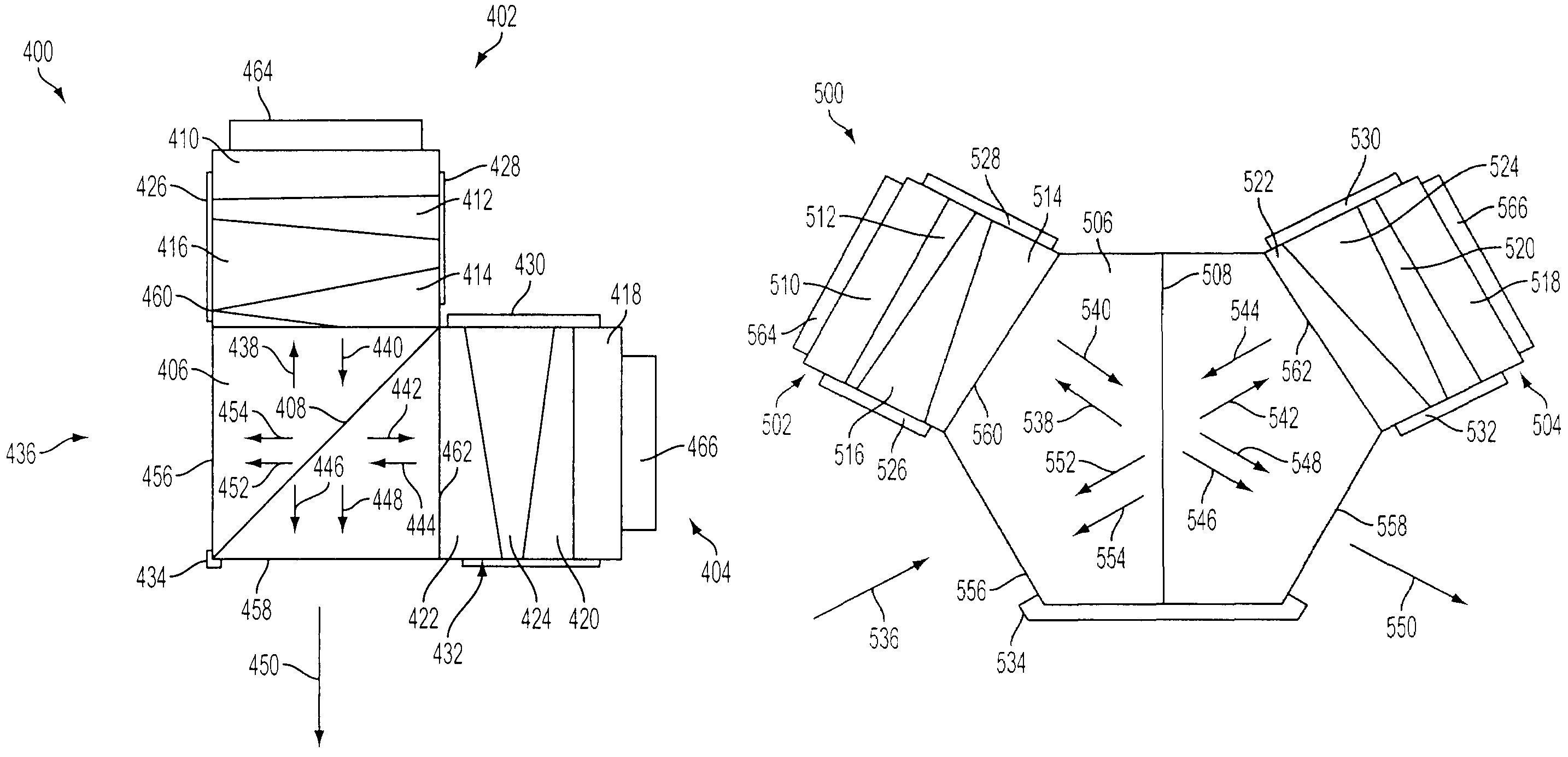

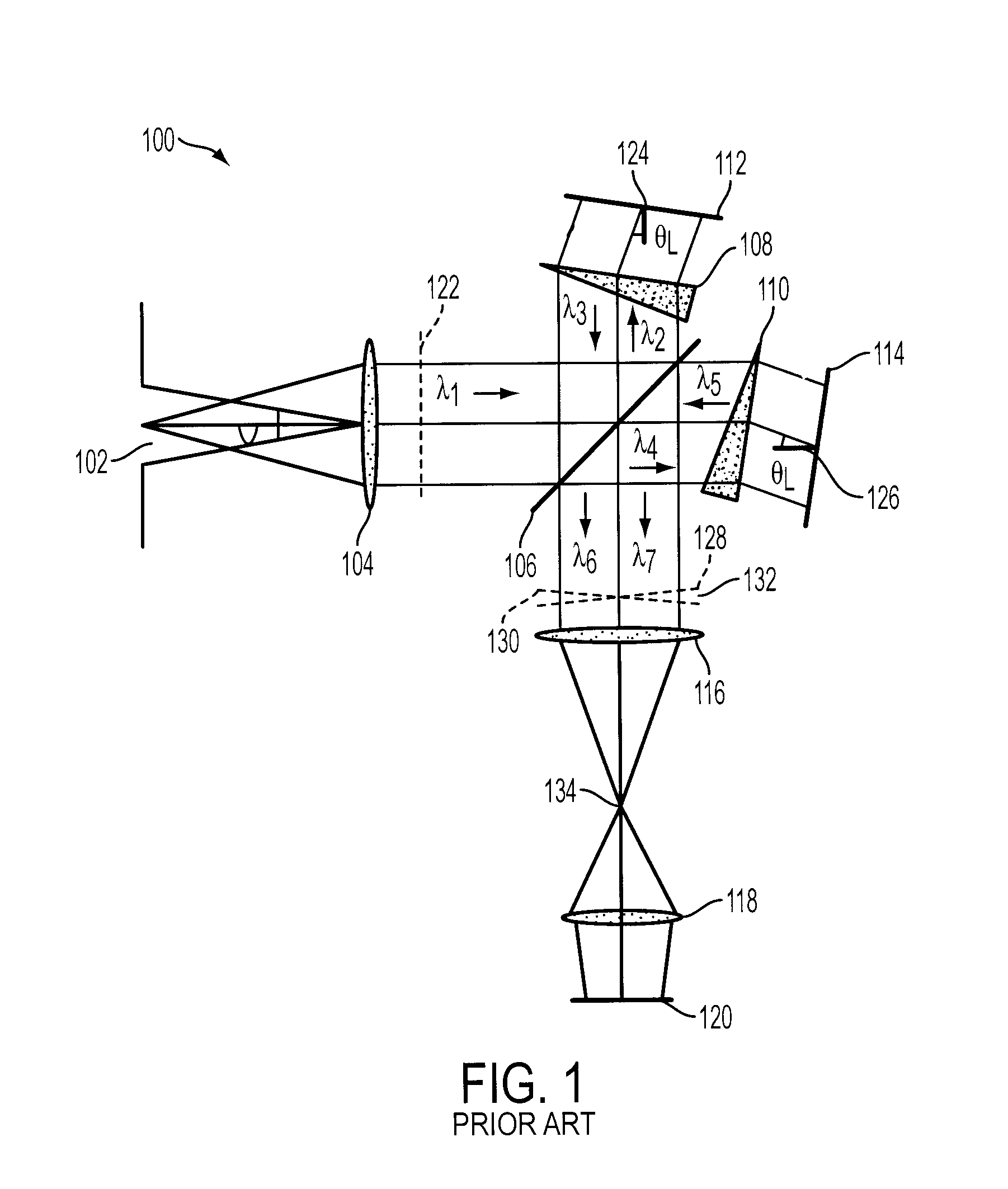

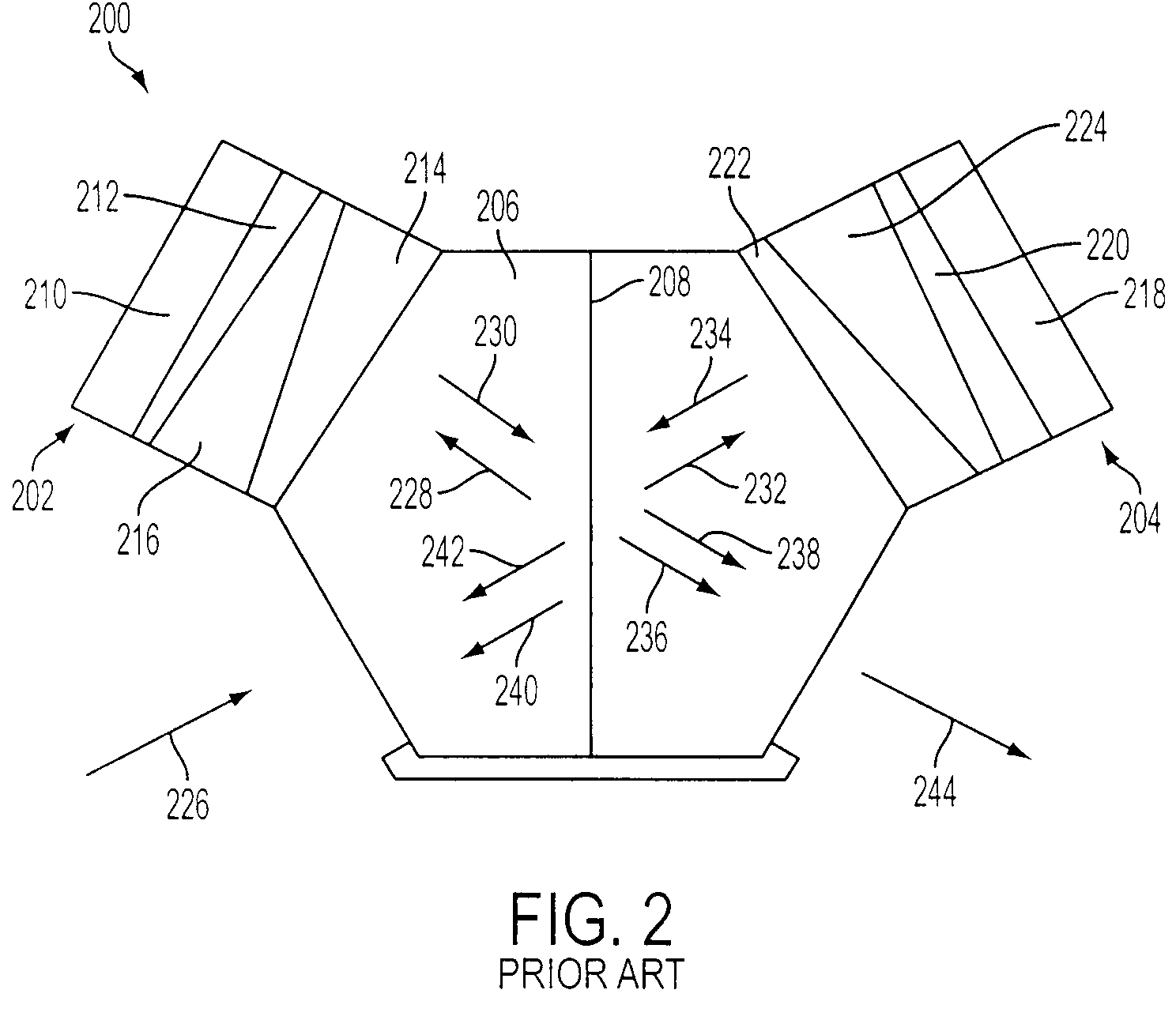

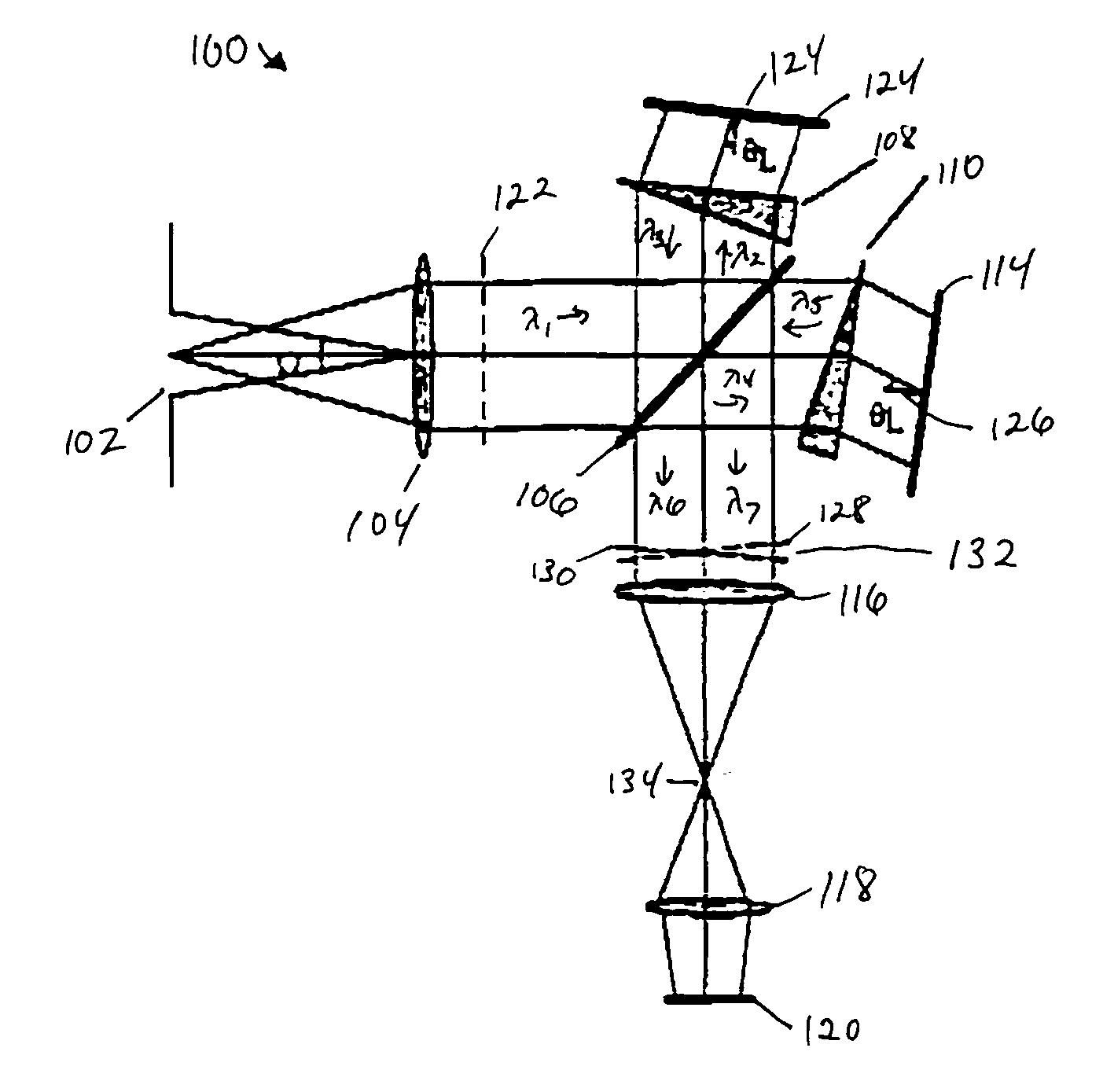

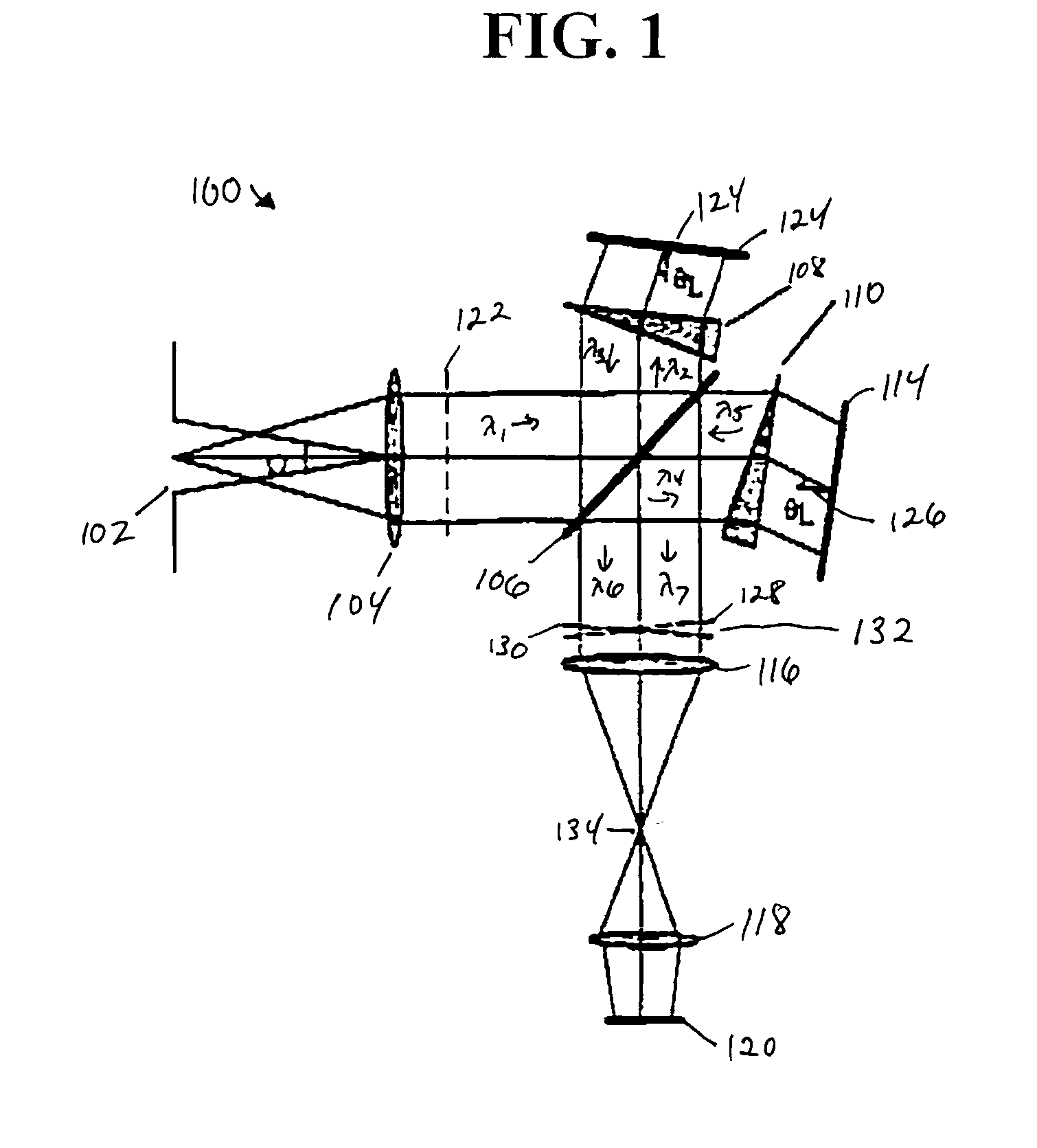

Compression assembly of spatial heterodyne spectrometer (SHS)

InactiveUS7535572B2Simplifies production and assembly and alignmentMaintain robustnessRadiation pyrometryInterferometric spectrometrySpectroscopySpectrometer

The present invention provides an economically feasible robust spatial heterodyne spectroscopy (SHS) interferometer. A first type prior art monolithic SHS interferometer is exceedingly expensive, whereas a second type of prior art SHS interferometer is extremely large and has many components, which need to be tuned. The present invention is much less expensive than the first type of prior art SHS interferometer and is much smaller that the second type of prior art SHS interferometer.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

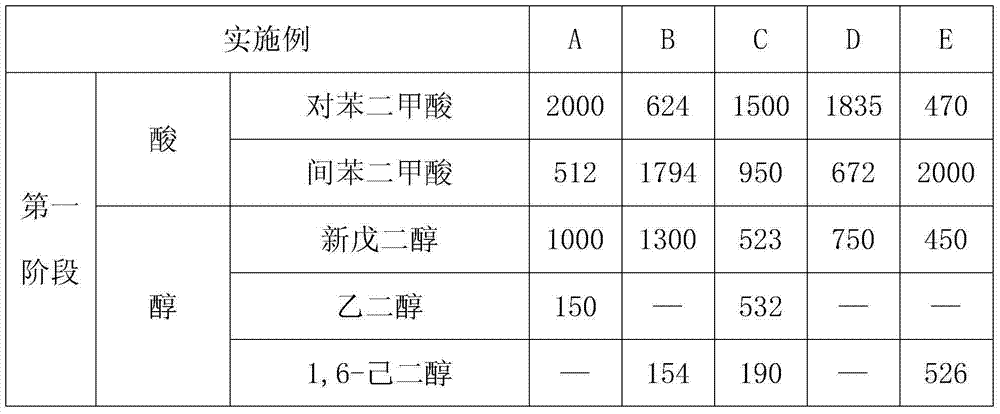

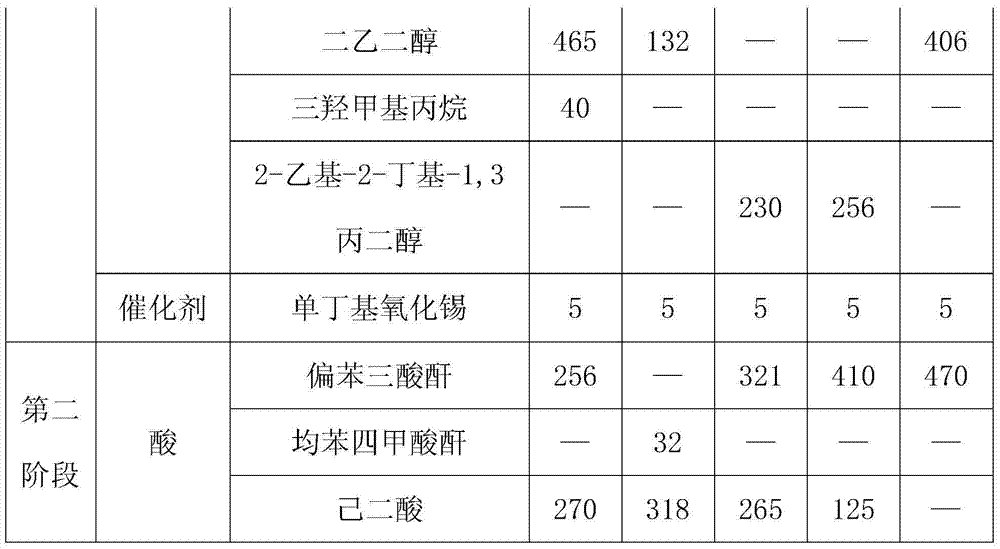

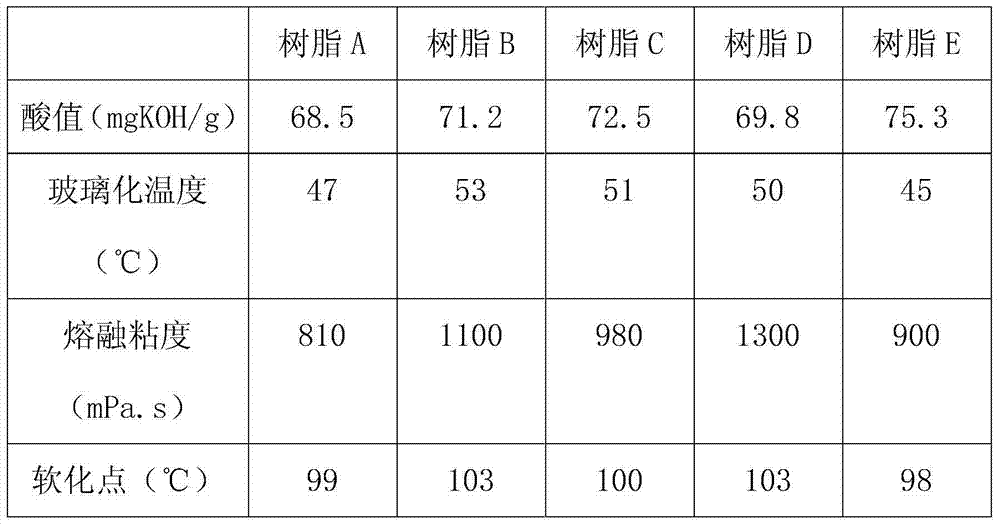

Preparation method and application of polyester resin applied to thermo-sensitive base material powder coating

ActiveCN103755940AMeet coating requirementsMeet flatness requirementsPowdery paintsPolyester coatingsAlcoholThree stage

The invention discloses a preparation method of polyester resin applied to a thermo-sensitive base material powder coating. The preparation method includes three stages, wherein the first stage comprises the steps of: putting a formula amount of alcohol into a reaction kettle, heating, stirring after the alcohol is completely melted, then adding the formula amount of an acid and an esterification catalyst, heating to 170-180 degrees centigrade, then heating to 245-250 degrees centigrade, and maintaining the reaction until reactants are clear; the second stage comprises the steps of: adding the acid, keeping the temperature at 210-220 degrees centigrade until the reactants are clear, sampling and measuring acid value; the third stage comprises the steps of vacuumizing at a vacuum degree from -0.095 to -0.097 MPa for 1.5-2 hours, and measuring the acid value. The invention further discloses application of the polyester resin to the thermo-sensitive base material powder coating. Polyester prepared by the method disclosed by the invention has a good hardness and a good adhesive force to a base material, simultaneously a coating has a good appearance and good chemical resistance, the coating requirement of the thermo-sensitive base material is satisfied, and the smoothness requirement of the thermo-sensitive base material is satisfied as well.

Owner:ANHUI SHENJIAN NEW MATERIALS

Compression assembly of spatial heterodyne spectrometer (SHS)

InactiveUS20070159634A1Simplifies production and assembly and alignmentMaintain robustnessRadiation pyrometryInterferometric spectrometrySpectroscopySpectrometer

The present invention provides an economically feasible robust spatial heterodyne spectroscopy (SHS) interferometer. A first type prior art monolithic SHS interferometer is exceedingly expensive, whereas a second type of prior art SHS interferometer is extremely large and has many components, which need to be tuned. The present invention is much less expensive than the first type of prior art SHS interferometer and is much smaller that the second type of prior art SHS interferometer.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

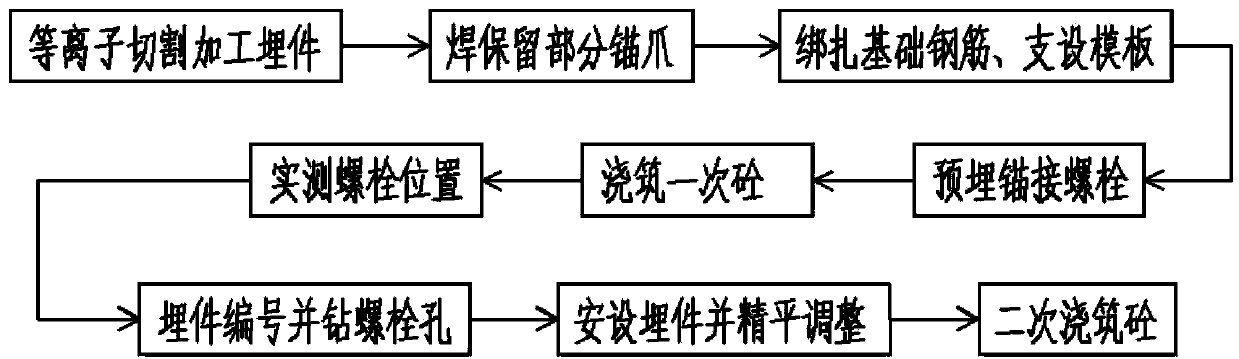

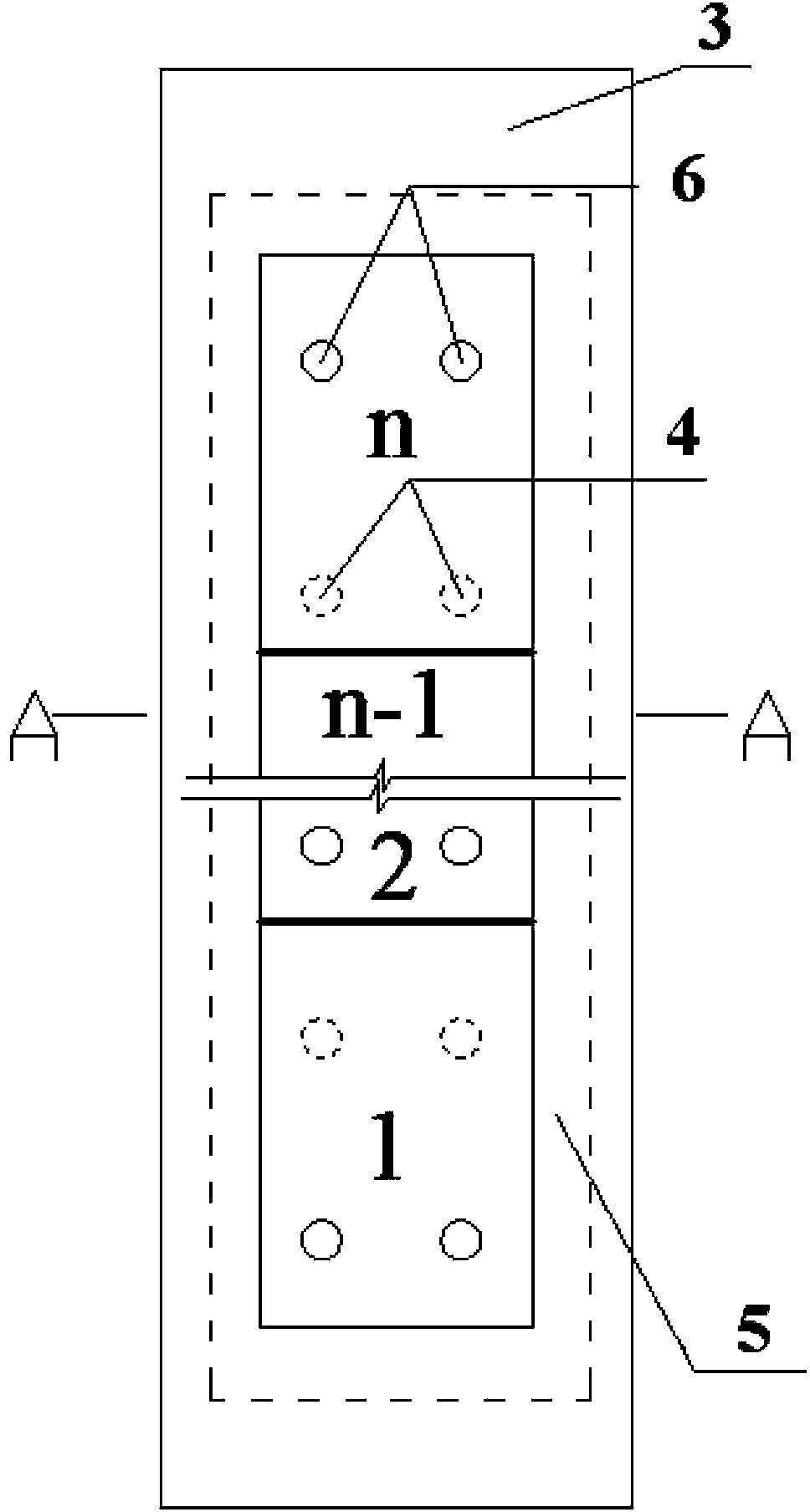

Super-long and large horizontal embedded part reverse construction method

InactiveCN103388343AReduce investmentImprove construction progressFoundation engineeringMaterials scienceCasting

The invention discloses a super-long and large horizontal embedded part reverse construction method. The method comprises the following steps: constructing a concrete equipment foundation; reserving an anchoring junction and a secondary casting layer in a corresponding range; embedding an embedded part; and performing secondary casting after leveling. According to the method, since repeated reinforcement, calibration and fixation work at the early stage are saved, the secondary casting can be performed by only arranging the embedded part after completion of primary casting; and thus, the investment in engineering resources such as labor and measure materials can be greatly saved, and the construction progress can be improved by 30-40 percent.

Owner:TIANJIN 20 CONSTR

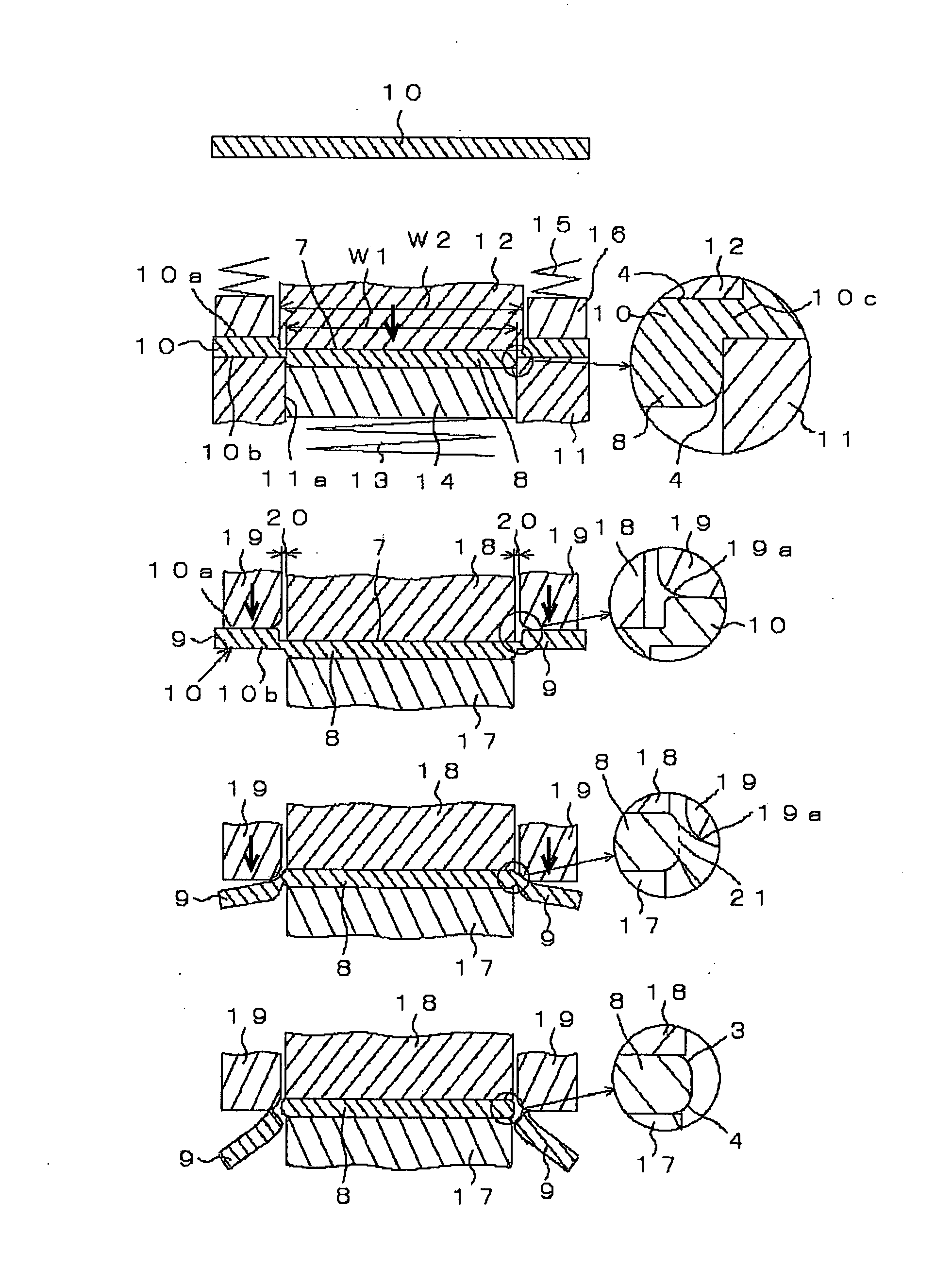

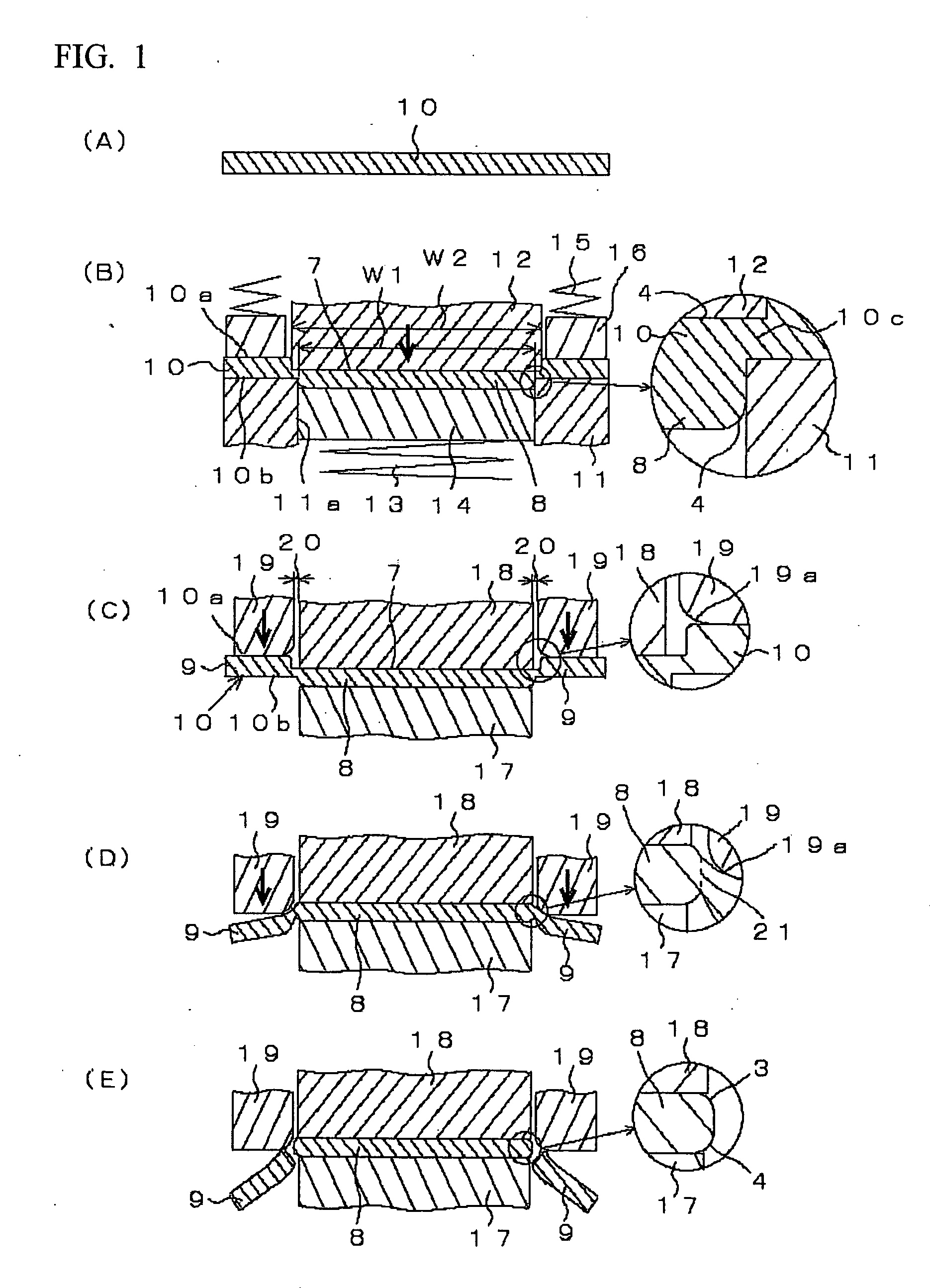

Shearing method for thin plate

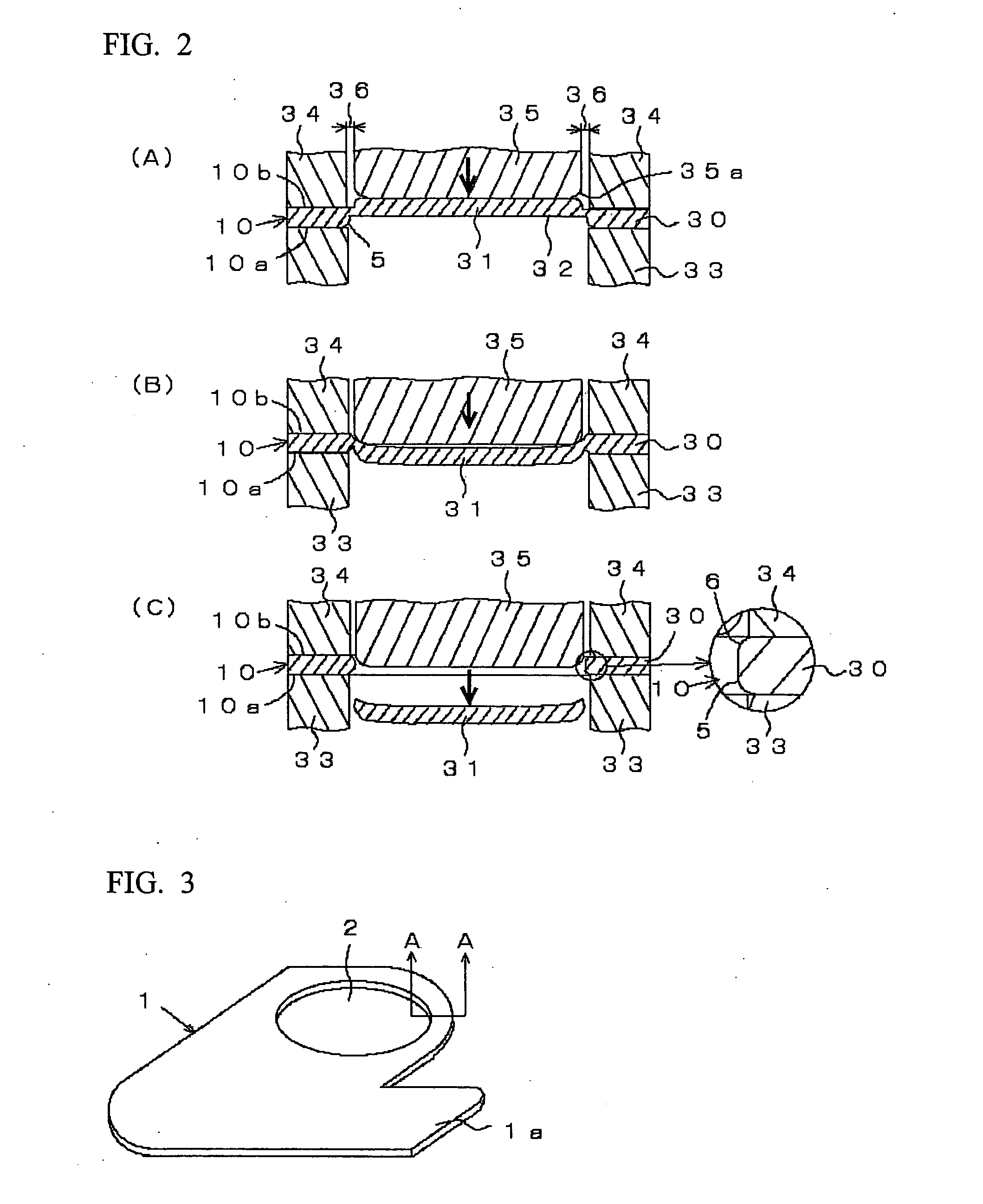

InactiveUS20060277961A1Low costReduce manufacturing stepsMetal working apparatusEngineeringProduct Part

A shearing method for a thin plate including forming a protruded product part having a first sagging part when the thin plate with a thickness of up to approximately 5mm is performed with a half die cutting by pressing the half die cutting punch slightly larger than the half die cutting hole to form a shallow recessed part, fixing the product part by a fixing member, forming a second sagging part at an edge portion of the thin plate by pressurizing a scrap part by moving a pressure punch which is provided with a gap between the fixing member and the pressure punch and by being bent between the scrap part and the product part, and then separating the scrap part from the product part.

Owner:NAKAMURA IND MFG CO LTD

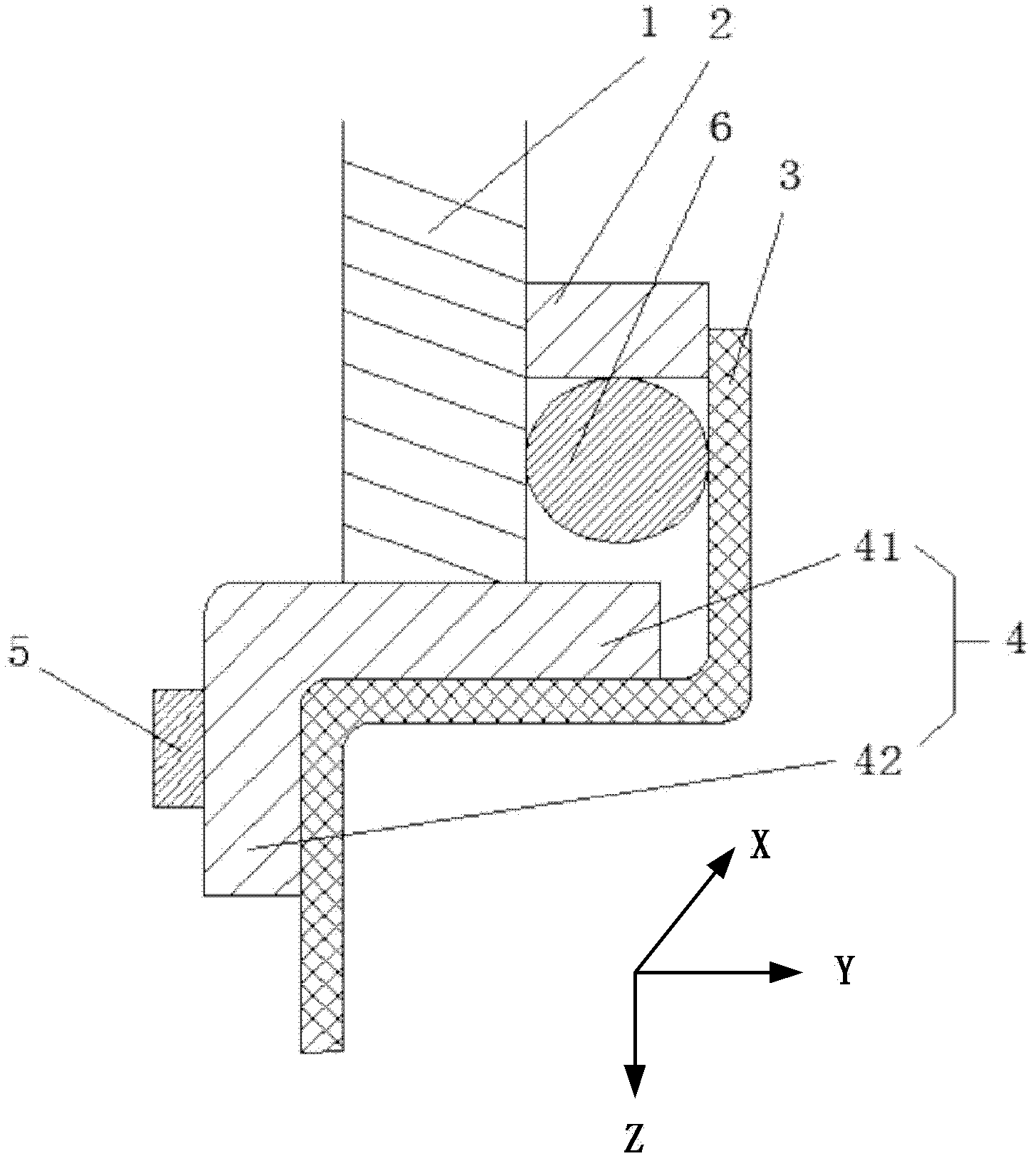

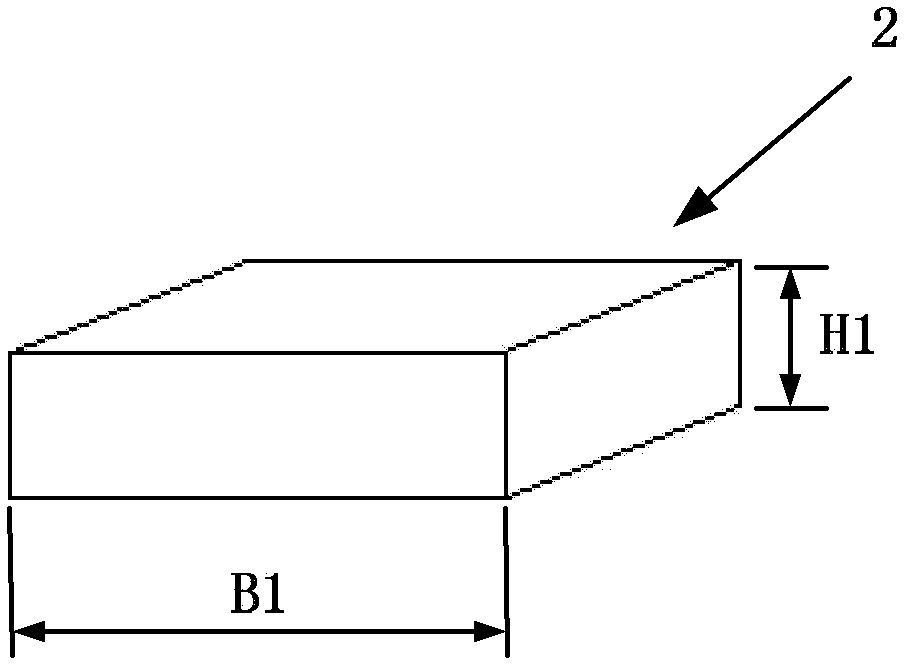

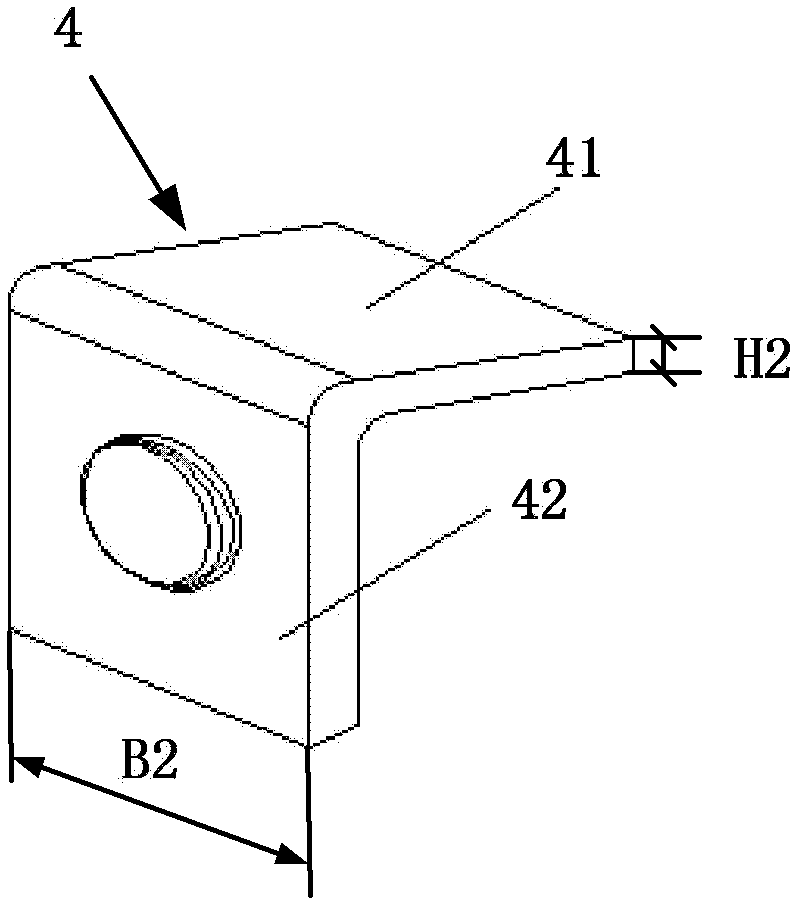

Special assistive device for glass installation

InactiveCN102616298AMeet flatness requirementsEasy to operateVehiclesMetallic materialsGoodness of fit

The invention discloses a special assistive device for glass installation, which is used for installing glass in a metal glass installation frame. The special assistive device comprises a first cushion block, a second cushion block and a fastener, wherein the first cushion block is installed between a lateral part of the glass and the glass installation frame and used for limiting a Y-direction position of the glass; the second cushion block is arranged between the bottom of the glass and the glass installation frame and used for limiting a Z-direction position of the glass; the fastener is arranged on the second cushion block; the second cushion block is fixed with the glass installation frame via the fastener; and both the first cushion block and the second cushion block are made of nonmetallic materials. The special assistive device for glass installation disclosed by the embodiment of the invention can not only meet the requirement of flatness of each windshield and the requirements of gap and goodness of fit among a plurality of windshields, but also has the advantages of simplicity in operation, convenience for use, reduced repair rate, decreased installation time and reduced manufacturing cost. Moreover, the gap can be accurately ensured as the device has high assembly reliability so that the potential safety hazard of spontaneous explosion of the glass is avoided.

Owner:CHERY AUTOMOBILE CO LTD

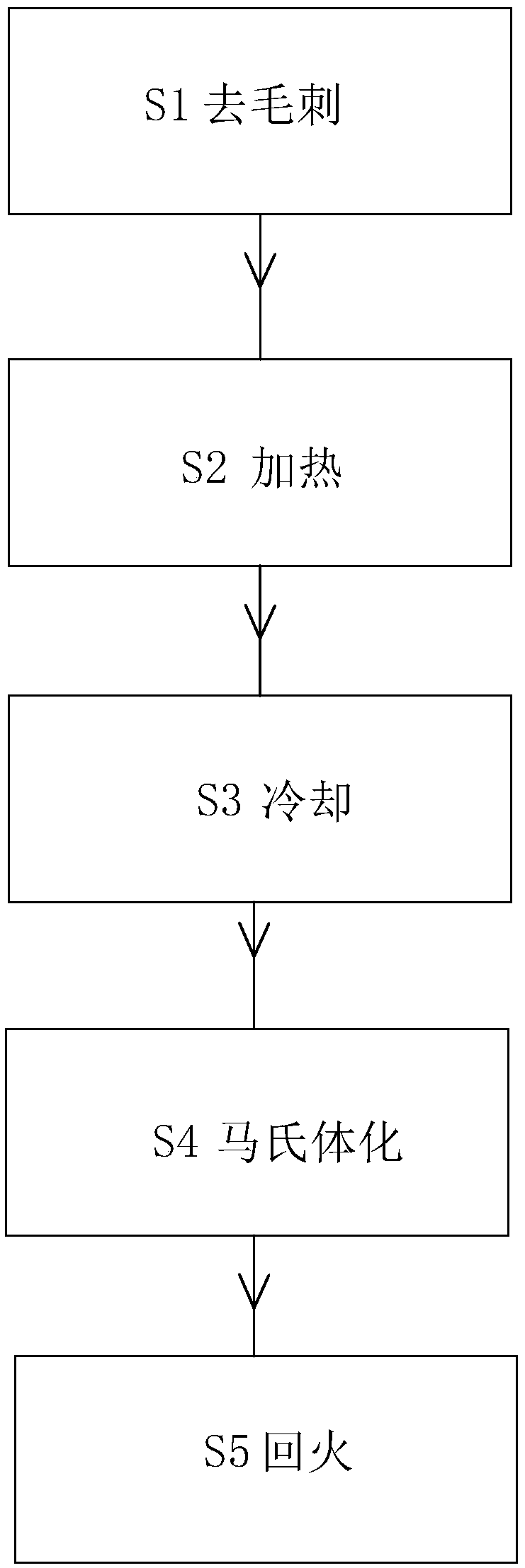

Thermal treatment process for saw web

ActiveCN108251609AImprove flatnessMeet flatness requirementsFurnace typesQuenching agentsThermal treatmentMartensite

The invention discloses a thermal treatment process for a saw web, relating to the technical field of thermal treatment. As the saw web is easy to be greatly deformed in the quenching stage of an existing thermal treatment process for the saw web, the use quality of the saw web is directly influenced. According to the technical scheme, the thermal treatment process comprises the following steps: (S1) deburring; (S2) preheating the saw web, and continuously heating the saw web to 830+ / -10 DEG C; (S3) cooling the saw web in quench liquid to a temperature range from an MS point to a temperature 10 DEG C higher than the MS point, and then taking out the saw web; (S4) planishing and shaping the saw web, and simultaneously carrying out formation of martensite; and (S5) carrying out tempering onthe saw web. By virtue of the process, the flatness of the saw web can be controlled in the quenching state, so that the deformation amount of the saw web is reduced, and the saw web can meet the requirements on the flatness of high-grade saw webs.

Owner:杭州双江工具制造有限公司

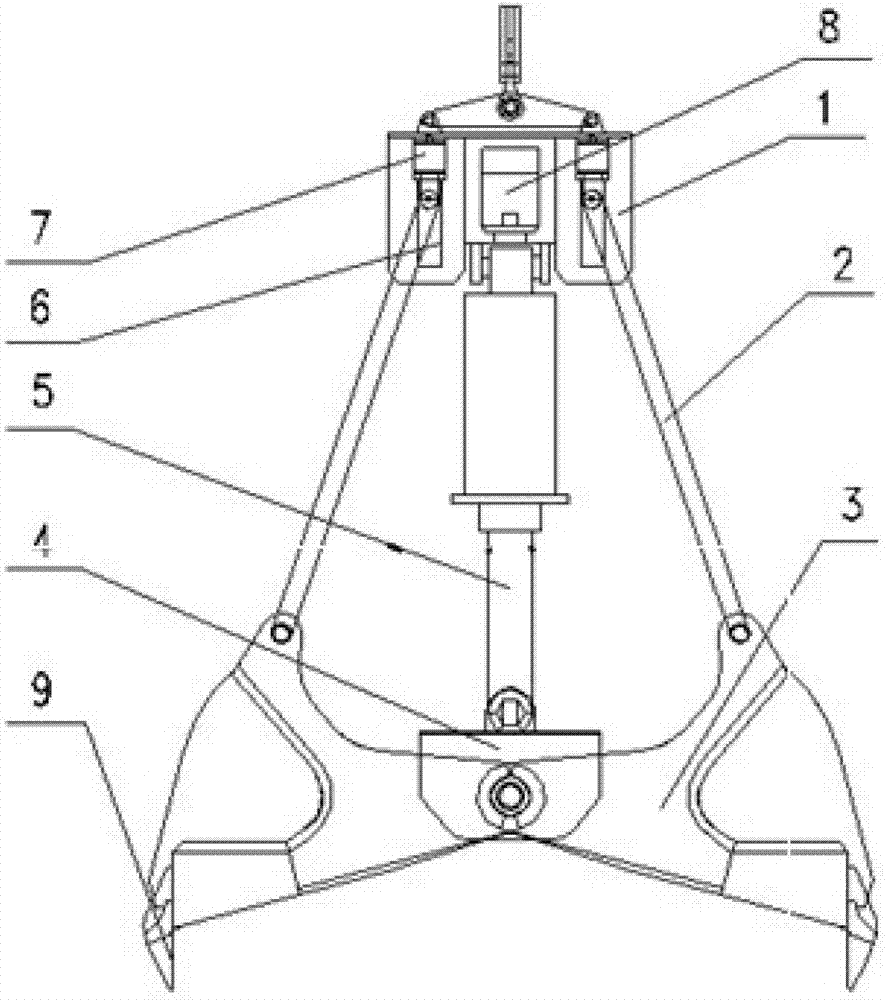

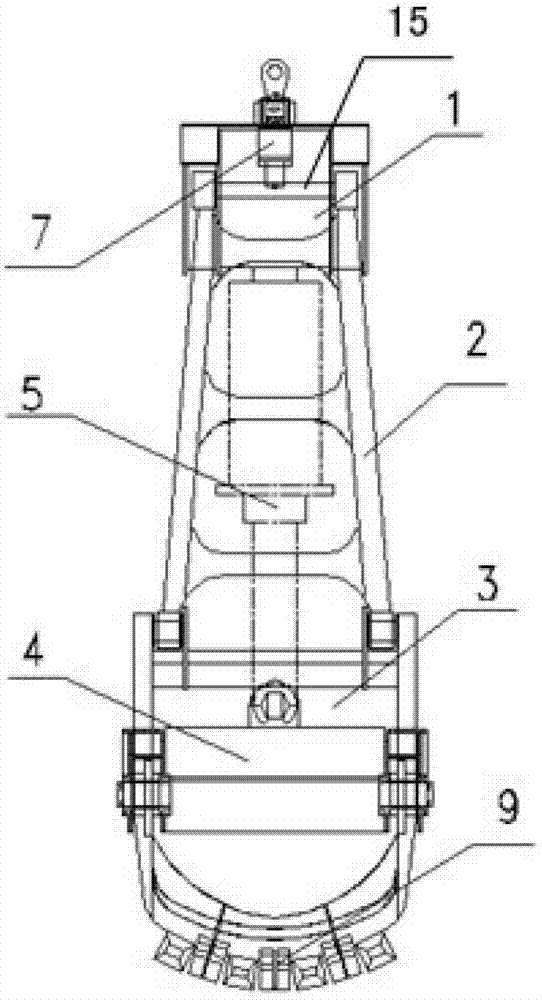

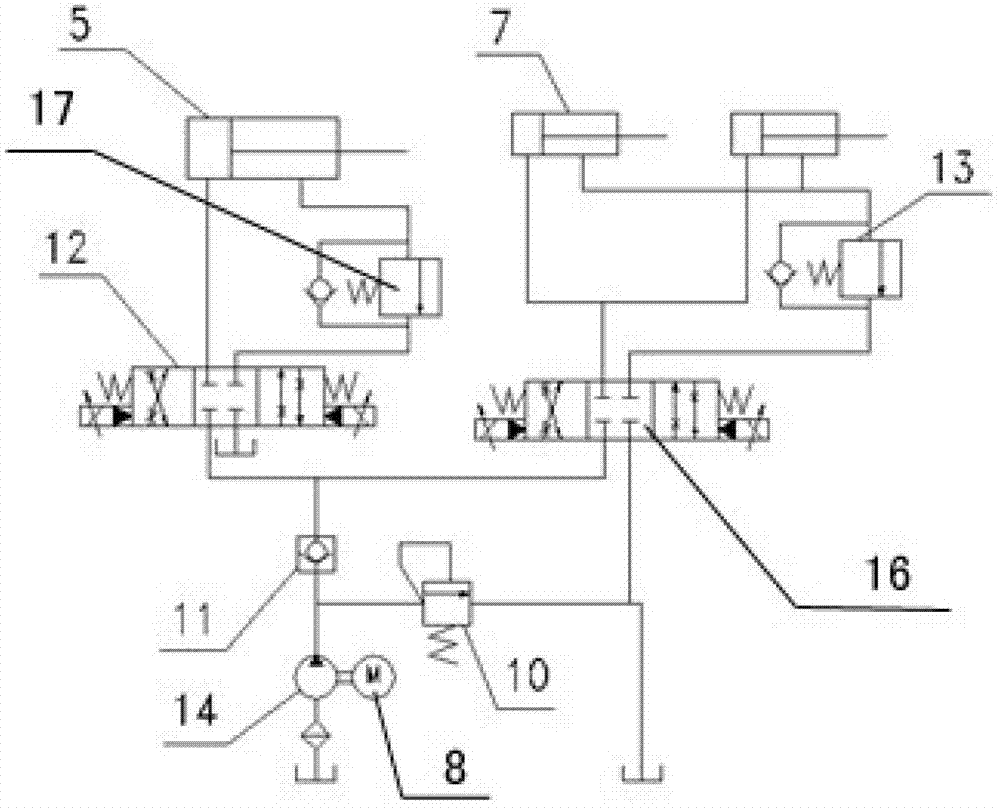

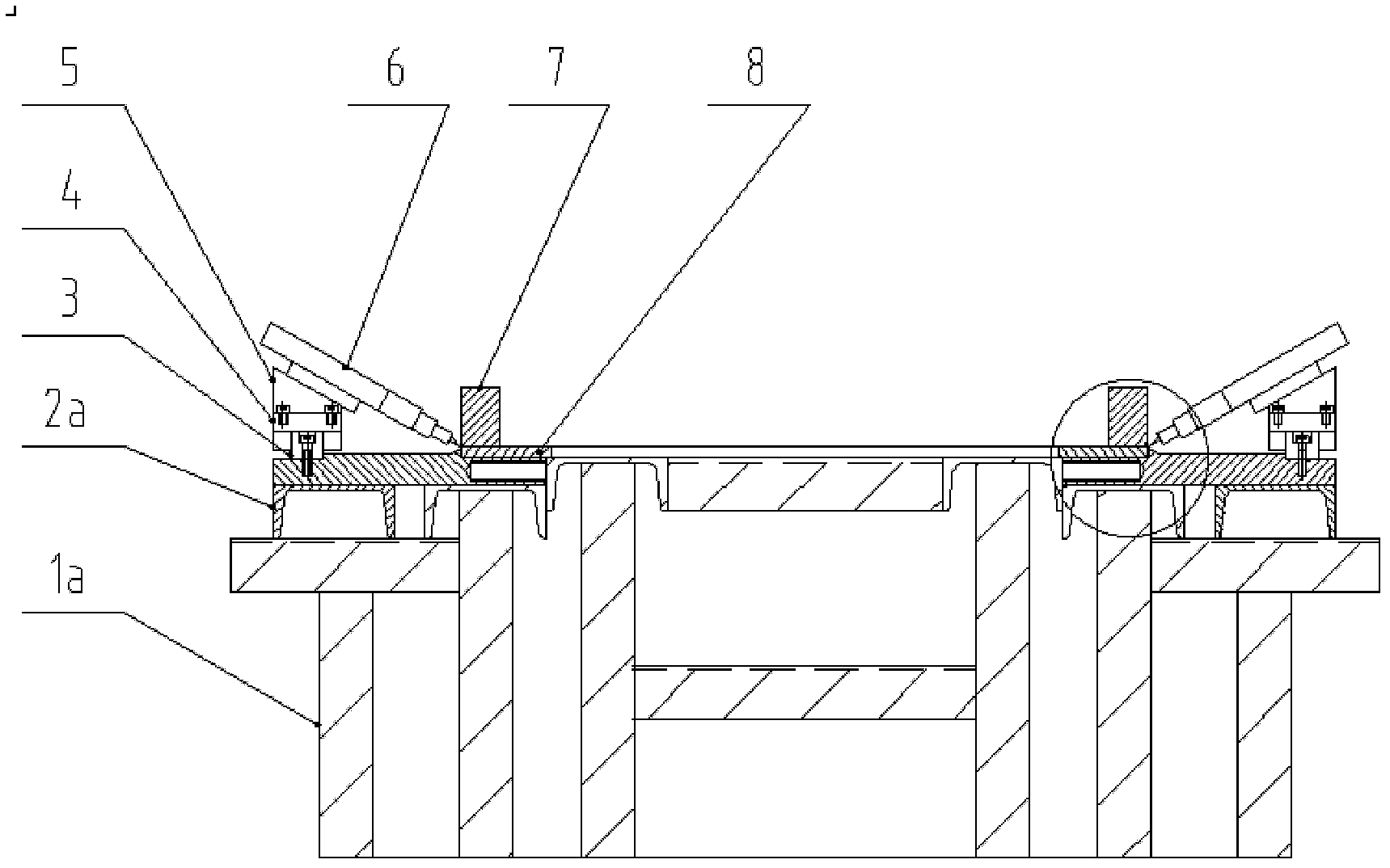

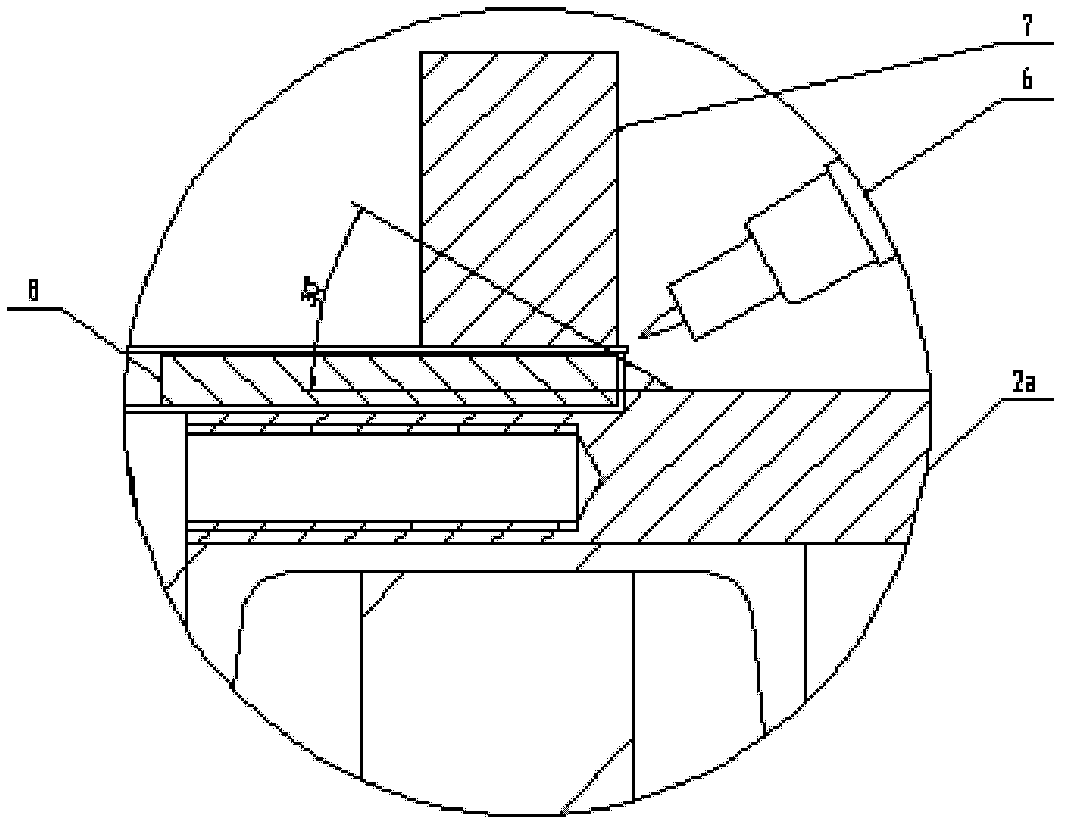

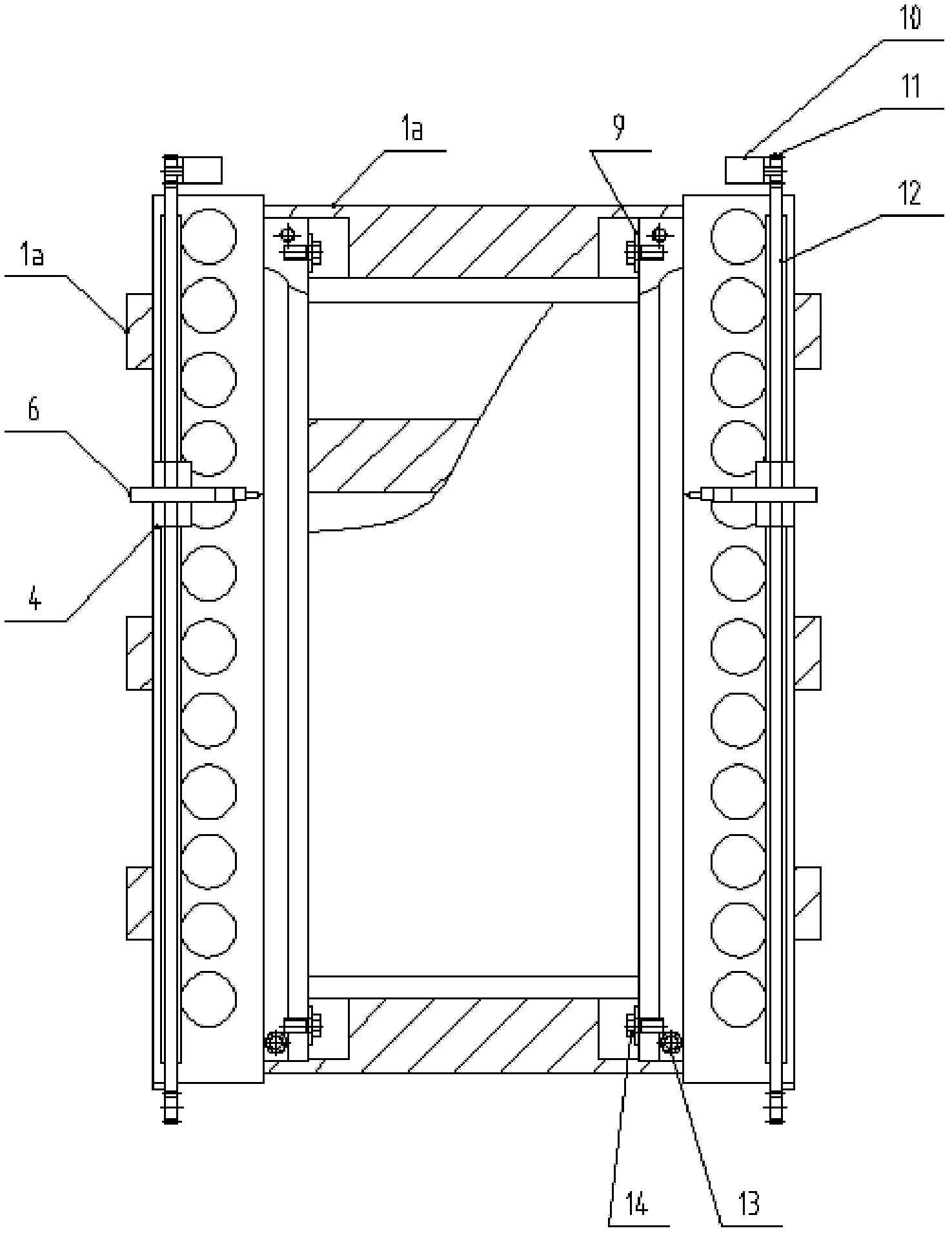

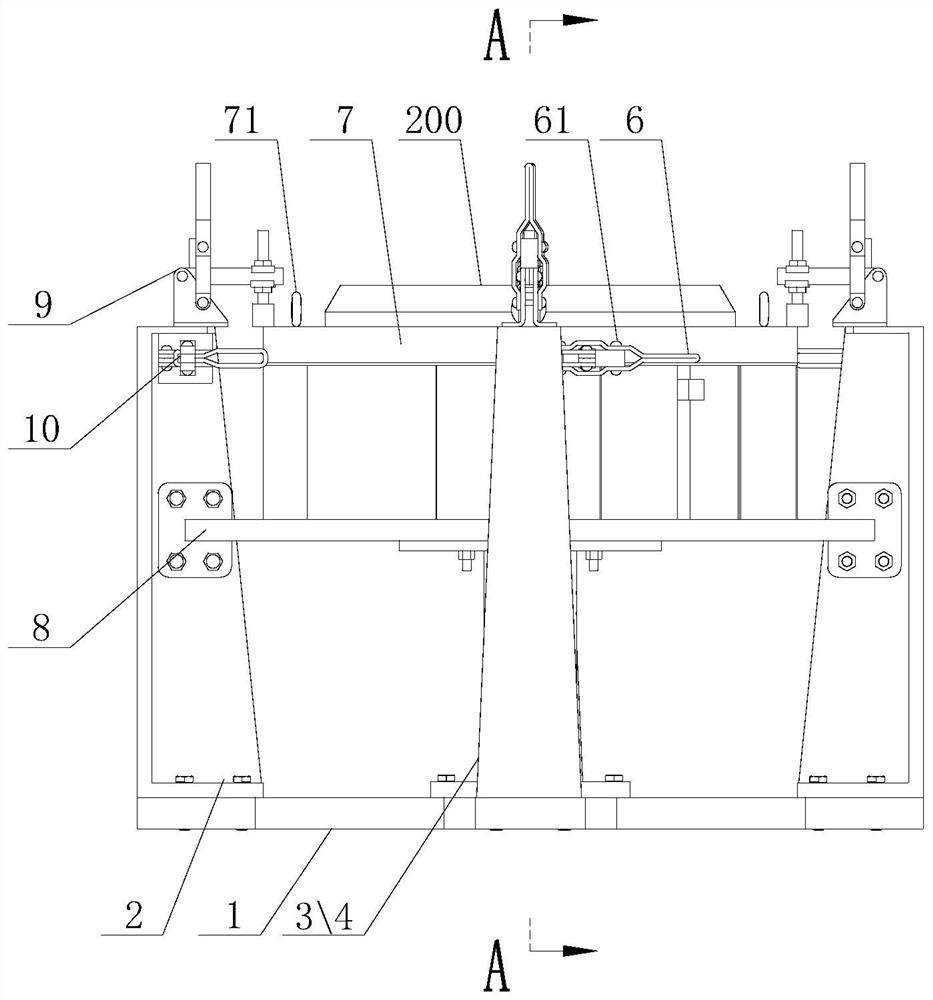

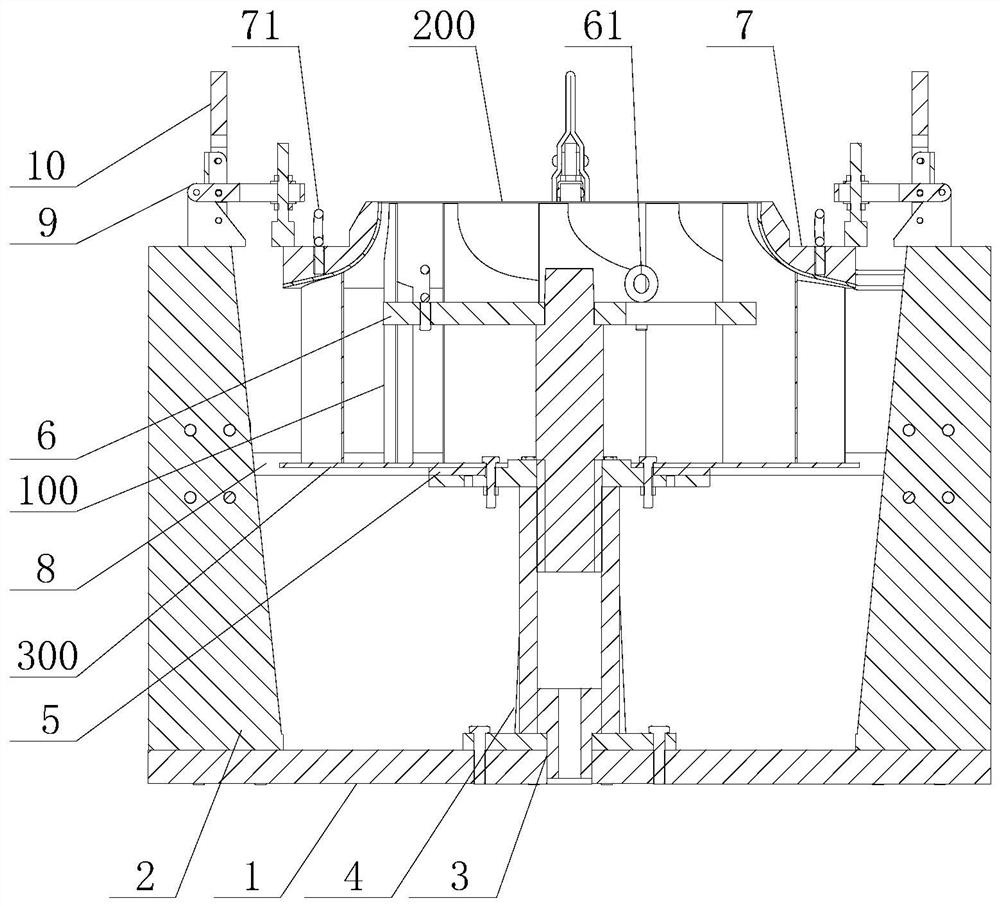

Brace rod sliding groove type hydraulic flat digging grab bucket

The invention relates to a brace rod sliding groove type hydraulic flat digging grab bucket which comprises an upper bearing beam, a lower bearing beam and a bucket body. The upper bearing beam is connected with the lower bearing beam through an open and closed bucket oil cylinder, the bucket body is hinged to the lower bearing beam, the upper bearing beam is provided with a brace rod sliding unit, the brace rod sliding unit comprises a brace rod sliding oil cylinder and a brace rod, one end of the brace rod is hinged to the bucket body, and the other end of the brace rod is connected with the brace rod sliding oil cylinder. The brace rod sliding groove type hydraulic flat digging grab bucket further comprises a hydraulic control device, and the hydraulic control device controls work of the open and closed bucket oil cylinder and the brace rod sliding oil cylinder. The brace rod sliding groove type hydraulic flat digging grab bucket has the advantages that the brace rod sliding groove type hydraulic flat digging grab bucket is simple in structure and convenient to operate, an excavated seabed or river bed can be flattened so as to meet the flatness requirements in engineering operation, the maximum opening and the maximum excavating depth of the grab bucket can be changed conveniently, the operation requirements of different working conditions can be met, and popularization and application values are large.

Owner:WUHAN UNIV OF TECH

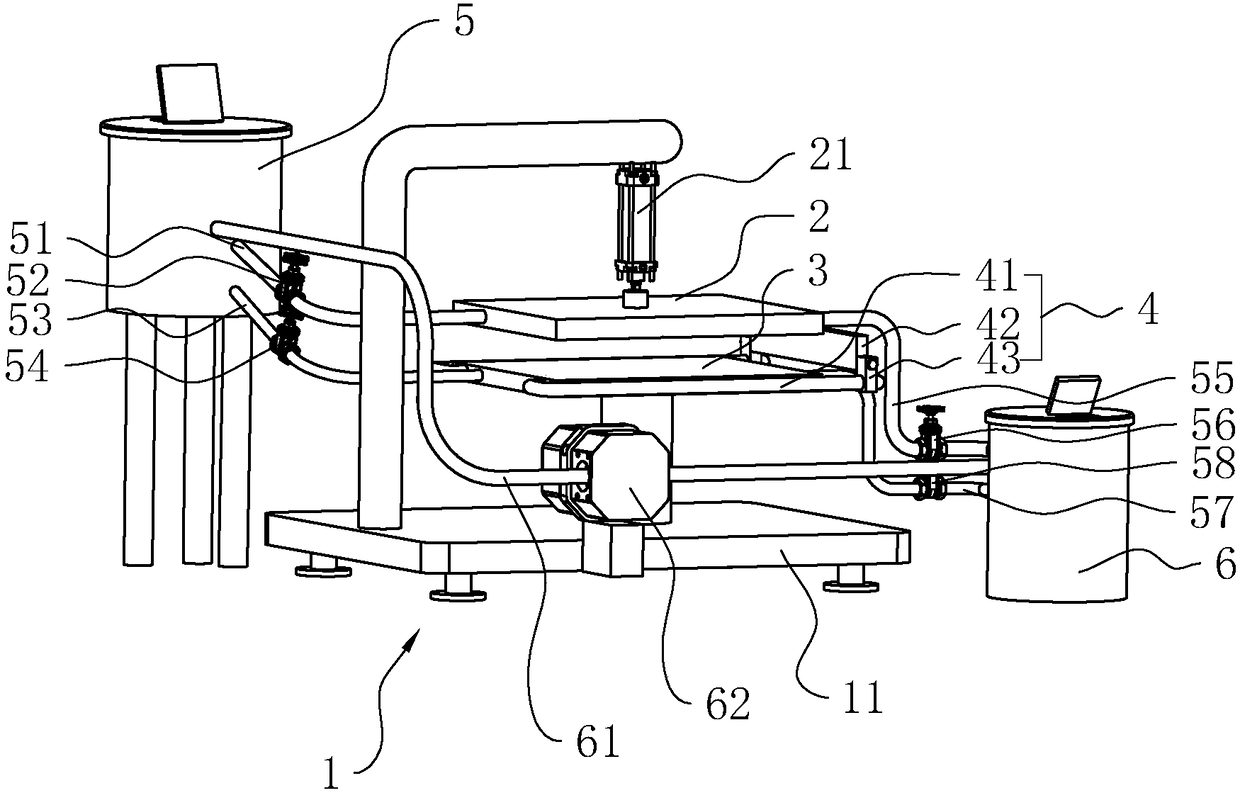

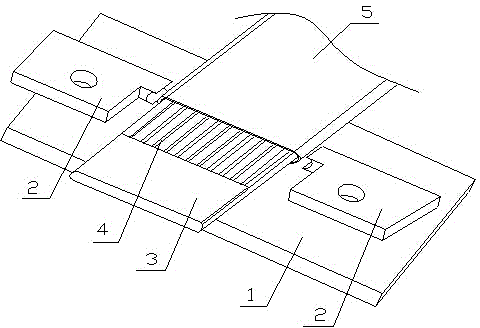

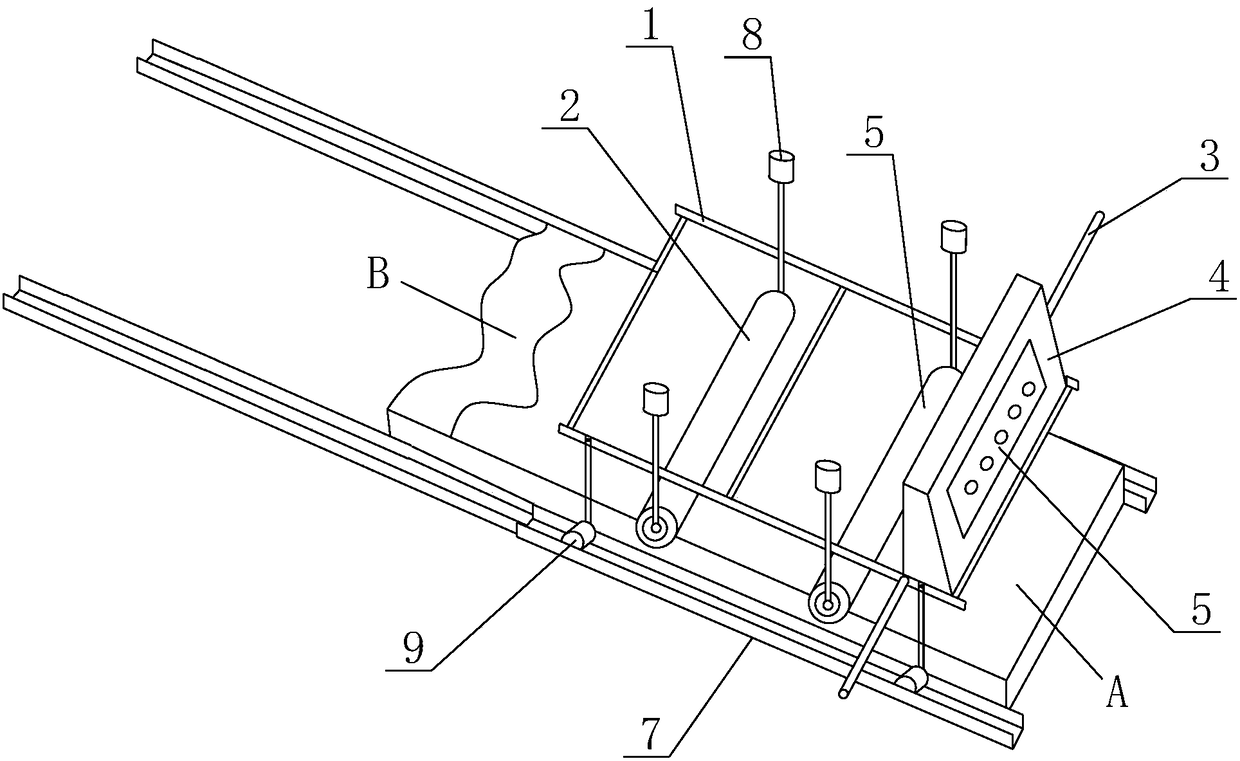

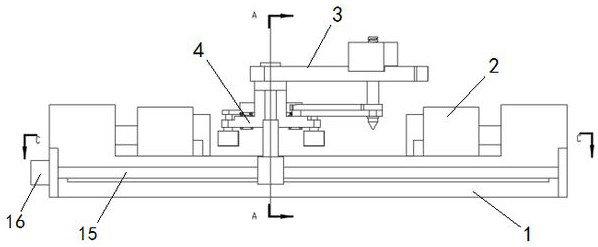

Automatic welding equipment for fillet weld of sheets

ActiveCN102430845AEasy loading and unloadingMeet strength requirementsWelding/cutting auxillary devicesArc welding apparatusFillet weldWeld seam

The invention relates to automatic welding equipment for a fillet weld of sheets, which is used for welding two structures with an included angle of 90 degrees. The automatic welding equipment is characterized in that in a fillet long-side structure I, a base plate is fixed on the horizontal plane of a support, a motor, a sliding rail, a slide block and a regulating mechanism for connection are installed on the base plate, a 30-degree gradient contact line is formed between a welding gun aslant installed on the regulating mechanism and a weldment heat exchange sheet on a middle horizontal plane, a weldment assembly supports the space to be welded of the heat exchange sheet, the base plate and two long ends of a press plate are clamped by nuts, the entire weldment assembly is laterally fixed by a lining board bolt, and the motor and an argon arc welding gun are started to automatically complete welding operation. A fillet wide-side structure II is characterized in that: a support for fillet wide-side welding is separated from a weldment base, the high side of a triangular support is fixed with the vertical face of an outer frame, and a bedplate is additionally arranged. The automatic welding equipment provided by the invention has the advantages that: the requirements on the strength and appearance quality of the welded seam and the flatness and verticality of the sheets can besatisfied; the characteristics of excellent formed welded seam, time / labor-saving performance, low labor intensity and high welding efficiency are achieved; and the operation is simple and convenientand the reliability is high.

Owner:沈阳汇博热能设备有限公司

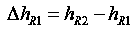

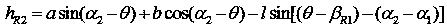

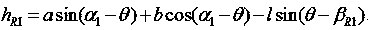

Automatic adjustment method for smoothness of cutting path of roller of coal cutter in real time

ActiveCN103399581AMeet the requirements of flatnessEasy to moveControl using feedbackAutomatic controlOriginal data

The invention discloses an automatic adjustment method for smoothness of a cutting path of a roller of a coal cutter in real time. The method comprises the following steps of establishing a static reference coordinate system according to original data of a dip angle of a coal cutter body; and during an operation process of the coal cutter, taking the static reference coordinate system as a reference standard, establishing a dynamic operation coordinate system, and automatically controlling a rocker arm of the coal cutter in real time according to a derivative control principle, so that the roller of the coal cutter is subjected to automatic height-adjustment continuously, and the roller is ensured to be operated continuously and stably. According to the method, a derivative control system is adopted, so that the cutting path of the coal cutter can be kept to be operated in a smooth path, the pushing and the waling of other equipment are favored, the continuousness and the production efficiency of coal cutting are improved, favorable operation mode and smoothness of coal cutting equipment are maintained, the risk of accident occurrence is reduced, and the method is simple and easy to implement, and can meet the requirements of smoothness of the cutting path of the coal cutter under the condition of different coal beds.

Owner:CHINA UNIV OF MINING & TECH +2

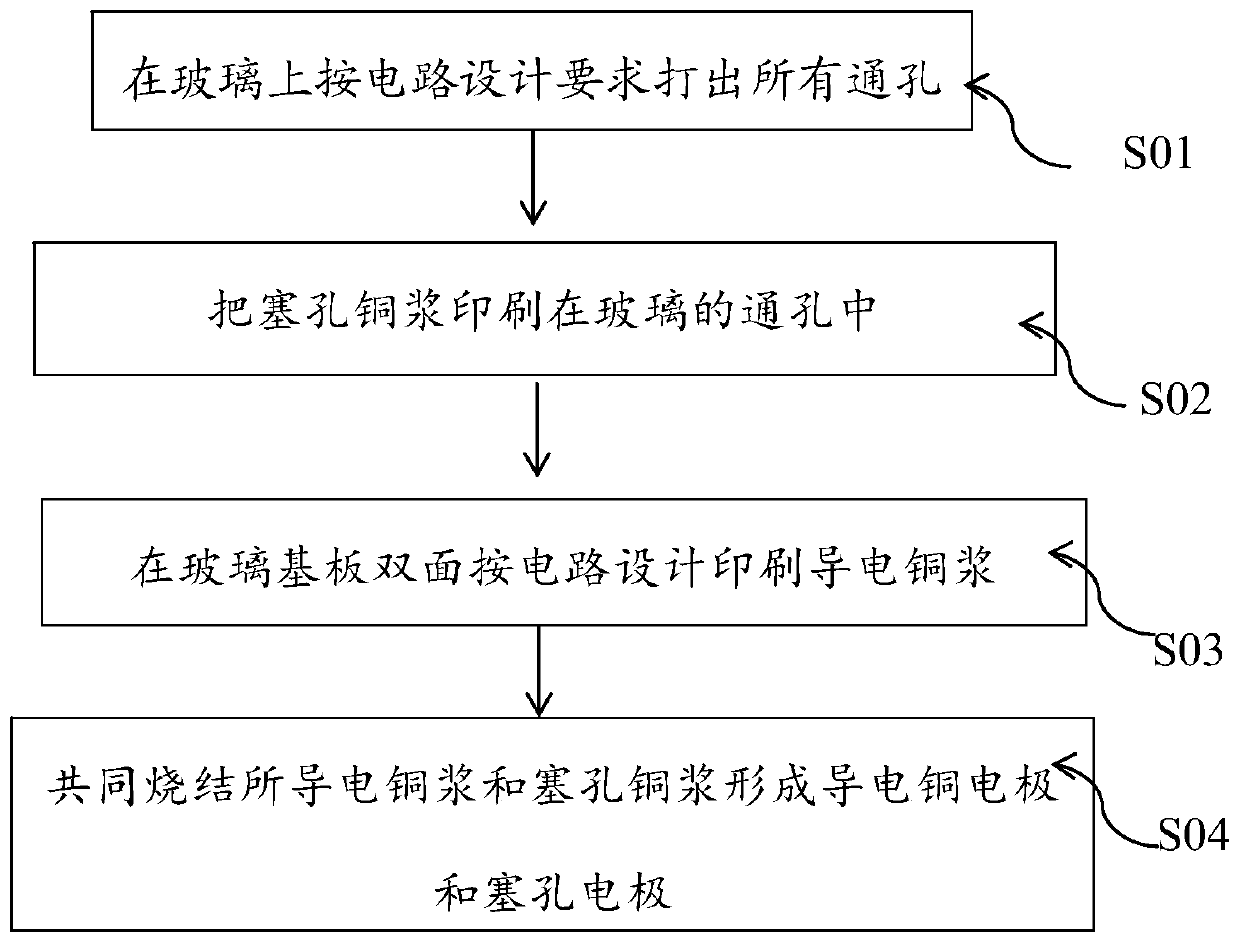

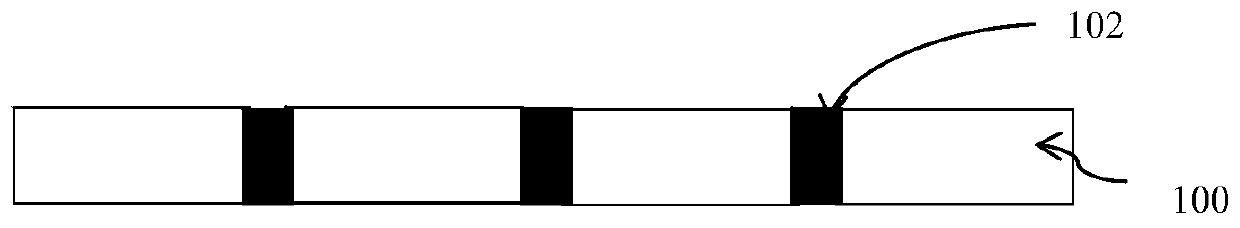

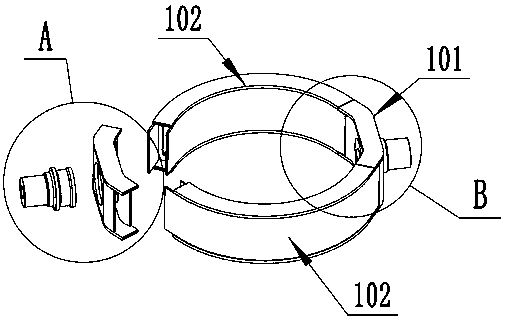

Method for additive manufacturing of glass substrate PCB and LED display

PendingCN111328192ALow costImprove reliabilityPrinted circuit assemblingMetallic pattern materialsElectrically conductiveDisplay device

The invention discloses a method for additive manufacturing of a glass substrate PCB and an LED display. The method comprises the steps of printing conductive copper paste on a glass substrate according to the circuit design requirements, and forming a conductive circuit with the controllable line width. According to additive manufacturing of the glass substrate PCB, copper paste can be preciselyprinted on glass through the silk-screen printing technology to form a copper conductive circuit, the characteristic of high heat conduction of the glass substrate can be brought into play. Meanwhile,a conductive circuit with the line width of 50 micrometers or below can be printed, and the paste contains extremely low organic residues after sintering, and good adhesive force (greater than 2N / mm)is achieved.

Owner:SHENZHEN BAROY NEW MATERIAL TECH CO LTD

Process method for controlling welding deformation with high precision

InactiveCN111014994AGuaranteed coaxialityGuaranteed coaxiality accuracyWelding apparatusMarking outWeld seam

The invention discloses a process method for controlling welding deformation with high precision. The process method is embodied in effective control of form and location tolerance in a welding structure, and comprises a preparation stage, a positioning stage and a welding stage. In the preparation stage, a trunnion block combination and a fan-shaped block are machined and assembled respectively,and a weld groove is machined; in the positioning stage, a position of a trunnion is aligned, and then a marking device is arranged, so that the offset condition of the trunnion is conveniently detected in the welding stage; in the welding stage, welding is conducted in a symmetrical and synchronous mode, deformation conditions are monitored by means of marks and a dial indicator, and welding parameters are adjusted in real time. The process method changes the conventional process, finish machining of the two trunnion parts is firstly completed, then assembling and welding are conducted on thesame, the welding stress is made to be in a relatively low and symmetrical balance state by adopting a high-precision detection control method, a reasonable welding sequence and a flexible control means, and therefore the purposes of controlling connection deformation and guaranteeing the workpiece precision are achieved.

Owner:YANTAI GUOYE METALLURGICAL WATER COOLED EQUIP CO LTD

Preparation method for intelligent trademark cloth base material applicable to RFID technology

ActiveCN107938380AIncrease coverageImprove flatnessHeating/cooling textile fabricsRecord carriers used with machinesPolyesterYarn

The invention discloses a preparation method for an intelligent trademark cloth base material applicable to an RFID technology, wherein the preparation method includes weaving of greige cloth, desizing and water washing, heat setting treatment, coating, and rewinding and slitting. Composite yarns formed by wrapping polyester with chinlon are used as greige cloth yarns. The chinlon component is slightly dissolved in a methanol-calcium chloride nylon system and is bonded with nylon resin in a coating glue. The coating glue and the greige cloth are combined firmly, and the washable performance isgood. The greige cloth subjected to pretreatment and polyamide coating layer finishing can be well bonded with an RFID chip. Modified kaolin subjected to high temperature calcination and hydrophobictreatment is used as a filler of a coating layer, the whiteness is increased, the mechanical properties are improved, the coating layer is prevented from absorbing moisture, the failure of the RFID chip is prevented, and a large number of microporous networks of the modified kaolin make the coating layer have excellent printing adaptability. The intelligent trademark cloth base material is suitable for both thermal transfer printing and RFID technology, so as to facilitate logistics management of trademark logos and products attached with the trademark logos.

Owner:HUZHOU SINY LABEL MATERIAL

Process for high precision control of welding deformation

InactiveCN110421284AGuaranteed coaxialityGuaranteed coaxiality accuracyWelding/cutting auxillary devicesAuxillary welding devicesPosition toleranceEngineering

The present invention discloses a process for high precision control of welding deformation, the process is embodied in the effective control of the form and position tolerances in a welding structure, and the process comprises a preparation stage, a positioning stage and a welding stage. The preparation stage comprises: performing the processing and assembling respectively for a trunnion block assembly and a fan-shaped block, and processing weld grooves; the positioning stage comprises: aligning the position of a trunnion in a positioning stage, and arranging a marking device in order to check the deviation of the trunnion in a welding stage; and the welding stage comprises: conducting welding in a symmetric and synchronous manner, monitoring the deformation by use of marks and a dial indicator and adjusting the welding parameters in real time. The present invention changes conventional processes: firstly fine finishing is completed for two trunnion parts, then assembling and weldingare performed; by use of a high-precision detection control method, a reasonable welding sequence and flexible control measures, welding stress is kept relatively low and symmetrical, and thus the purposes of controlling welding deformation and ensuring the workpiece accuracy are achieved.

Owner:烟台众扬冶金设备有限公司

Vehicle explosion-proof keyboard lock control device

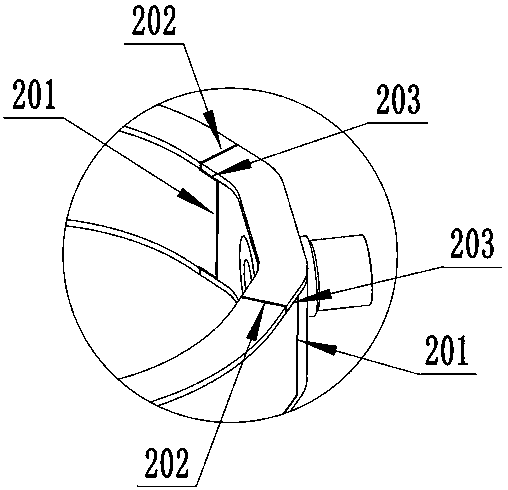

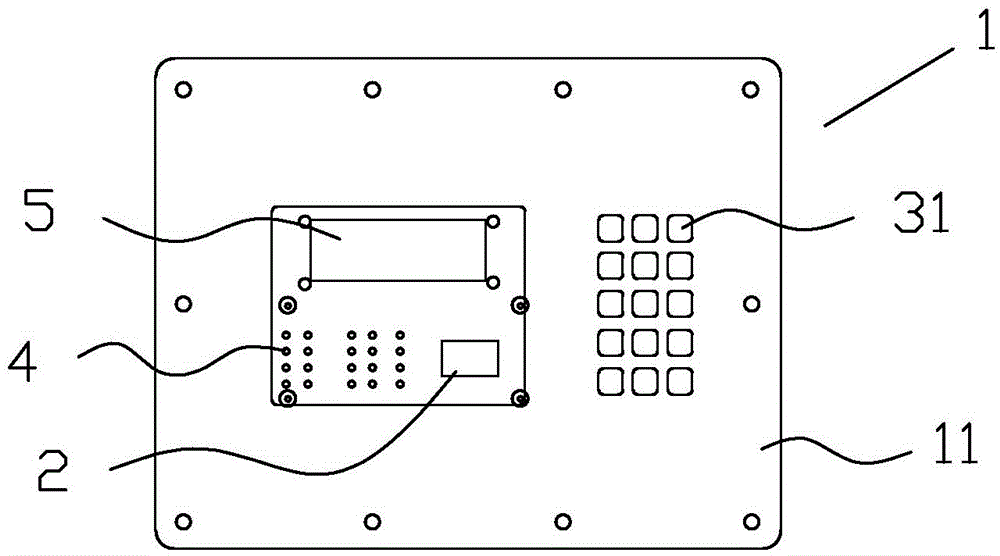

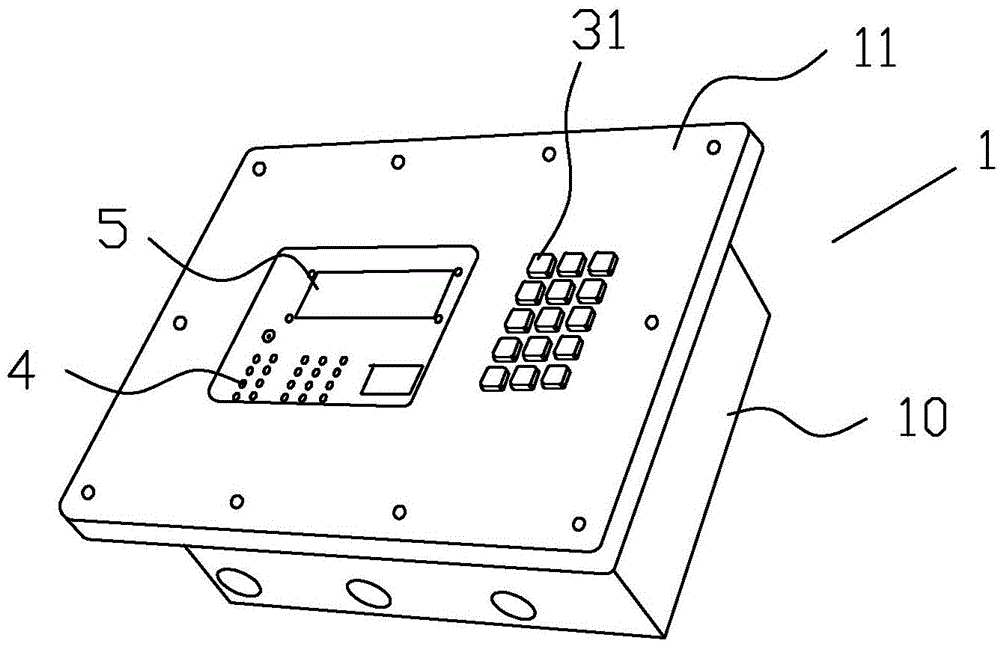

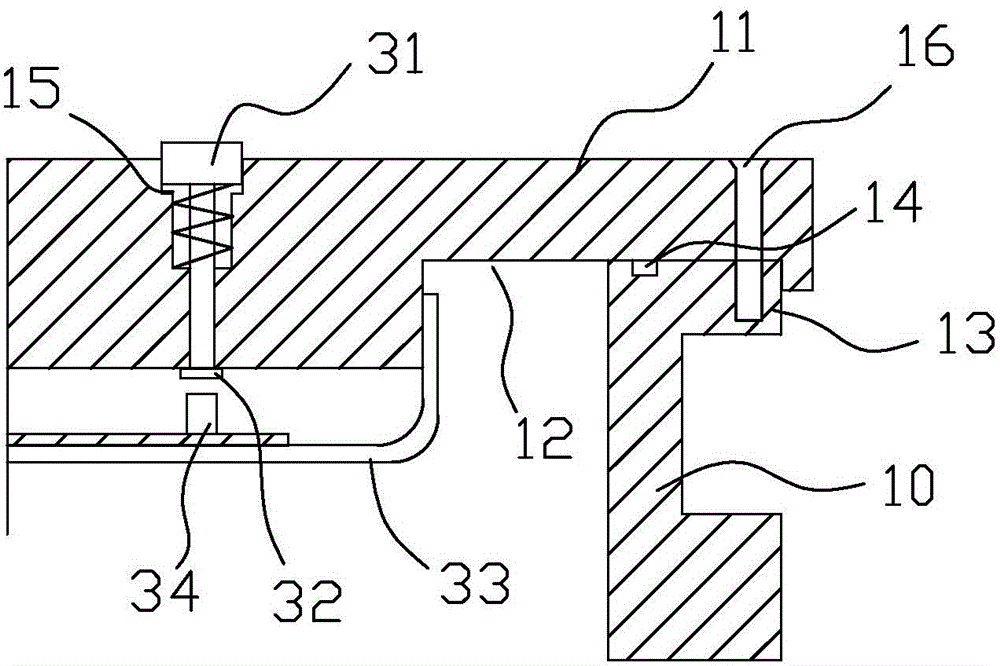

ActiveCN104537732AReasonable layoutNovel shapeIndividual entry/exit registersFuel tankMonitoring system

The invention relates to a vehicle explosion-proof keyboard lock control device. The vehicle explosion-proof keyboard lock control device comprises an explosion-proof case body arranged on an oil tank of an oil tank truck; the explosion-proof case body is composed of a housing and a front end cover, wherein one end of the housing is provided with an opening, the front end cover is arranged on the opening, and the housing and the front end cover are connected via sealing connection; a keyboard panel, a main control panel, and connecting wire are arranged in the explosion-proof case body; the keyboard panel is arranged on the front end cover, and an information output terminal of the keyboard panel is connected with the main control panel; the main control panel is connected with an oil outlet clock of the oil tank truck, and is used for controlling the oil outlet clock to open or close; and digital code is inputted into the keyboard panel, and is transferred to the main control panel so as to control the oil outlet lock for unlocking operation. A novel safe unlocking method is provided for an oil tank trunk monitoring system; the vehicle explosion-proof keyboard lock control device can be used when network breaks or a radio frequency card is lost, and opening of the oil outlet is in urgency; effective on-site operation is realized; and the vehicle explosion-proof keyboard lock control device is of great significance on solution of emergent events and ensuring vehicle and personnel safety.

Owner:BEIJING WANJIAXIN TECH

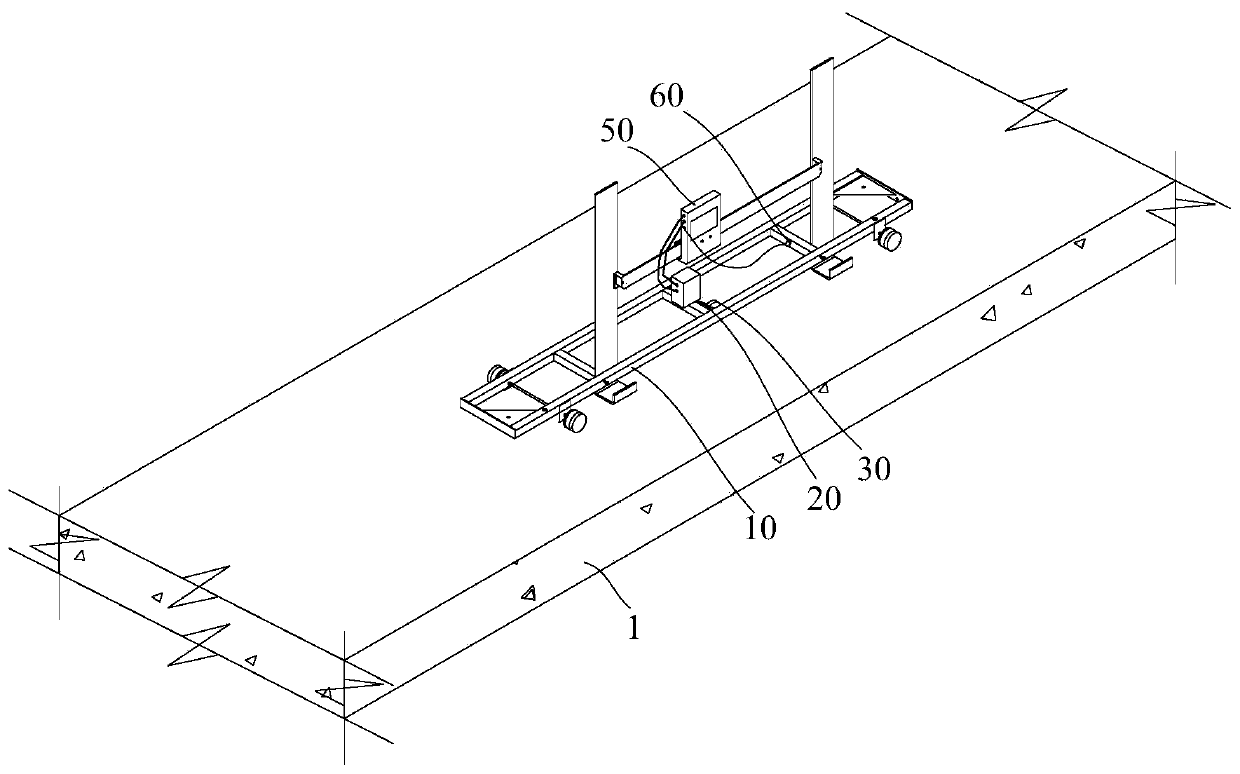

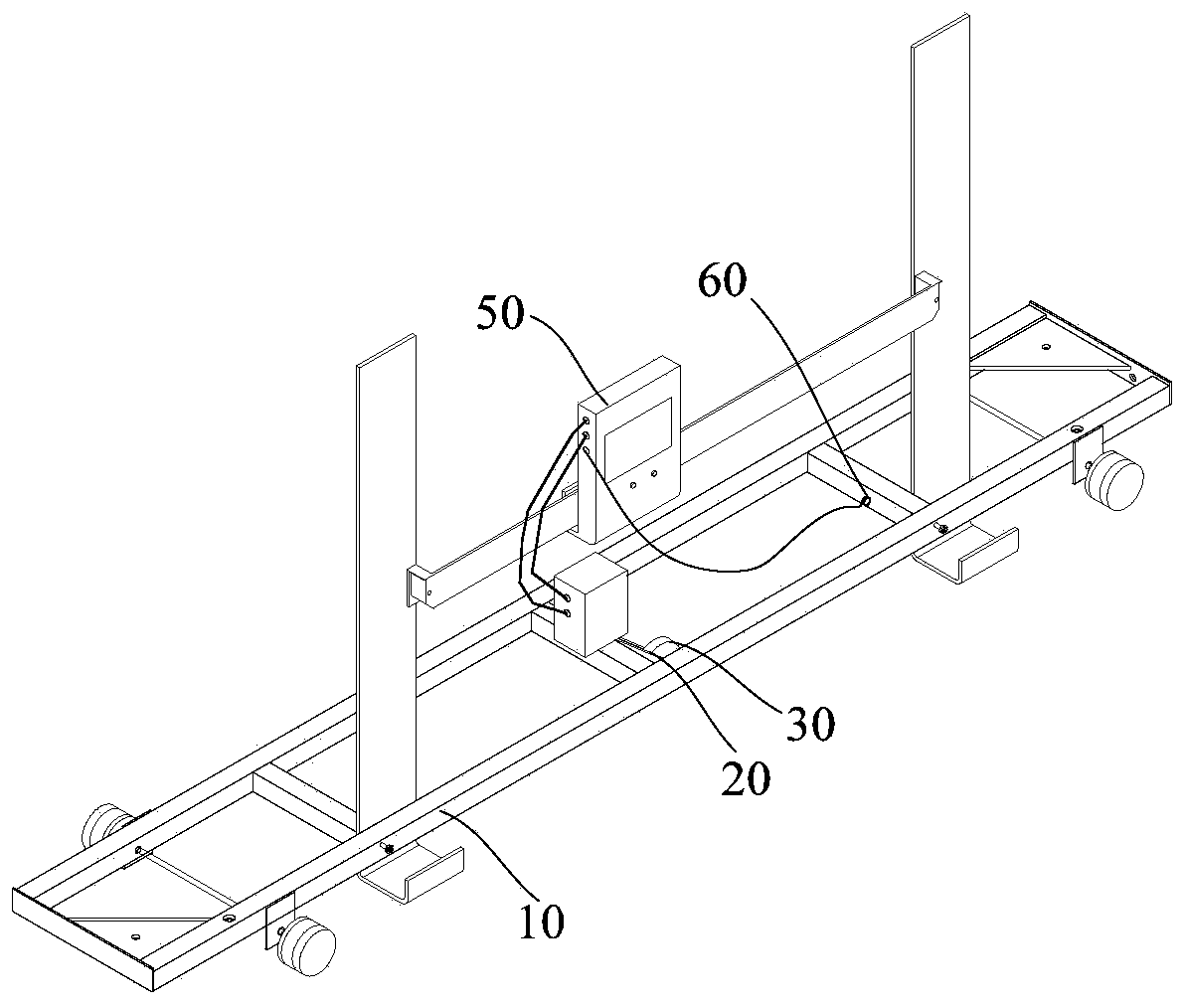

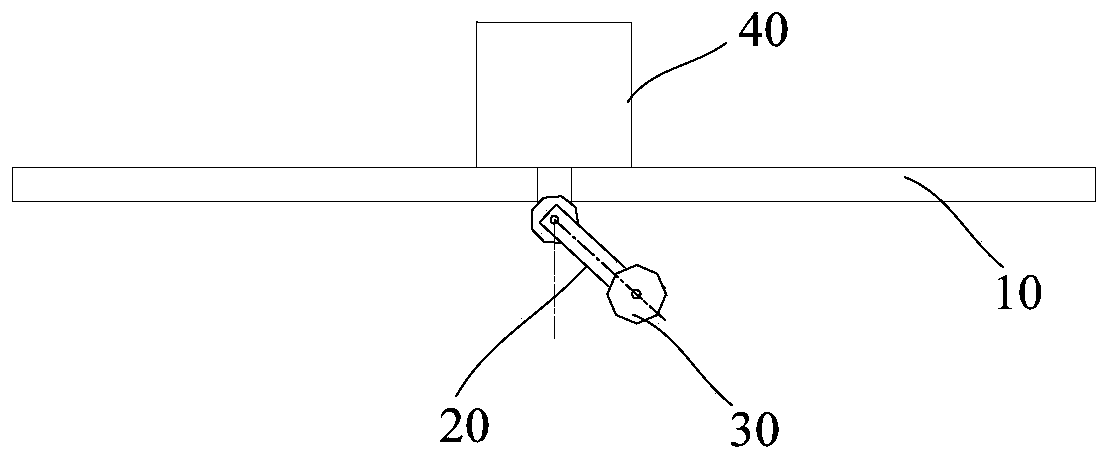

Pavement flatness monitoring device and detection method thereof

PendingCN110409267AMeet flatness requirementsEasy to detectRoads maintainenceAngular degreesRoad surface

The invention relates to a pavement flatness monitoring device and a detection method thereof. The device comprises a bracket, a supporting arm, a pulley and an angle sensor, wherein the bracket is arranged on the pavement and can move; the supporting arm is hinged to the bracket; the pulley is connected to the bottom end of the supporting arm and is arranged on the pavement in a sliding way; through the pulley, the supporting arm is driven to rotate around a hinging position; the angle sensor is connected to the supporting arm; through the angle sensor, the inclination angle value of the supporting arm when the bracket moves on the pavement is measured; and through the angle value, the displacement of the pulley in a vertical direction can be obtained to realize the detection of the pavement flatness. By use of the angle sensor, the inclination angle value of the supporting arm is firstly measured through the angle sensor, then, the displacement of the pulley in the vertical directionis calculated, so that whether bulges and pits are in the presence on the pavement or not can be judged, whether a flatness requirement is met or not is judged, and the device is convenient in detection.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

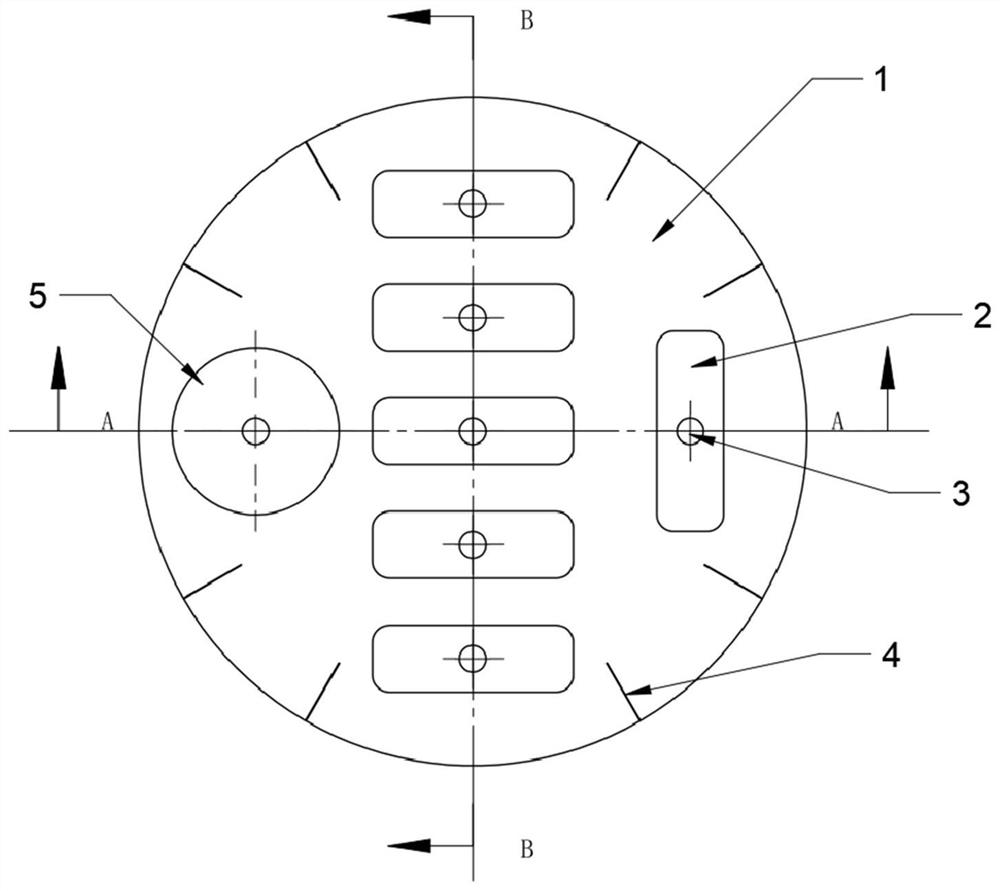

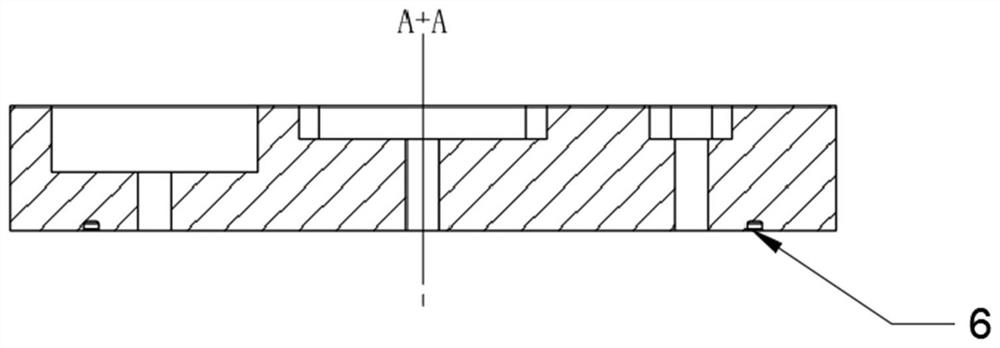

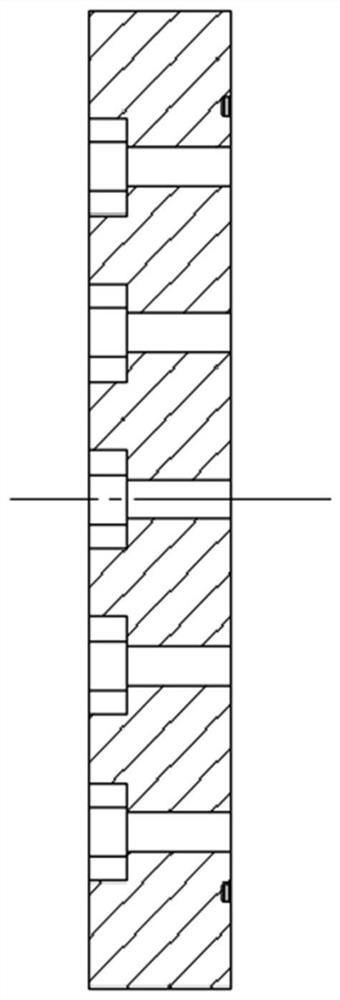

Assembly type base plate for powder bed melting additive manufacturing and using method thereof

PendingCN114082991AImprove assembly accuracyLow costAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgyMetal powder

The invention relates to the field of metal powder bed melting additive manufacturing, in particular to an assembly type base plate for powder bed melting additive manufacturing and a using method thereof. The assembly type base plate comprises a standard substrate, at least one assembly groove is formed in the standard substrate, and a through hole is formed in the bottom of the assembly groove; and the base plate also includes small substrates that are in one-to-one correspondence with the assembly grooves, the small substrates are embedded in the assembly grooves in the standard substrate, and the small substrates are detachably mounted on the standard substrate. According to the invention, the product and the small substrate can be conveniently taken down from the main substrate; the standard substrate does not need to be leveled after one-time printing is completed, so that the production preparation time is greatly shortened, the production efficiency is improved, and the processing cost is reduced; and after the products are formed and manufactured, the small forming substrates can be detached from the standard substrate, so that the products can be independently treated according to detection requirements, and the utilization rate of equipment is improved.

Owner:BEIJING UNIV OF TECH

Flat tube necking machine

The invention discloses a flat tube necking machine. The flat tube necking machine comprises a machine table and necking puncher pins arranged on the machine table. The machine table is further provided with a steel supporting needle. One end, provided with supporting needles, of the steel supporting needle is arranged between the necking puncher pins. The structure is simple, a flat tube which is cut in the fixed length is placed on the necking machine, the supporting needles of the steel supporting needle are inserted into micro holes of the flat tube, and width necking is carried out. In this way, in the punching necking process, due to the limitation on the pipe wall of the supporting needles, inward collapse cannot be carried out, the outer side is a cold punching forming mold, and only heading can be carried out. The flat necking surface is obtained, and the flatness requirement for brazing can be met.

Owner:ANHUI JINSANHUAN METAL SCI & TECH

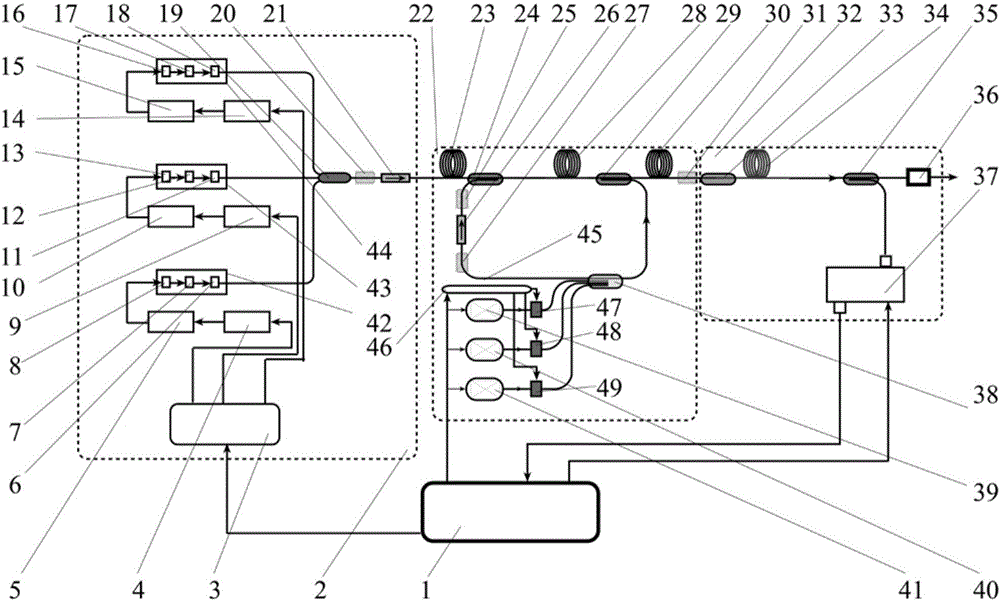

Intermediate infrared super-continuum spectrum laser device for outputting flat spectra

ActiveCN105762649AImprove flatnessImprove stabilitySemiconductor laser arrangementsExcitation process/apparatusInfraredSpectrograph

The invention discloses an intermediate infrared super-continuum spectrum laser device for outputting flat spectra.The intermediate infrared super-continuum spectrum laser device consists of a main controller, a pumping source module, an annular laser device module and a super-continuum spectrum generating and monitoring module.The main controller sends out an instruction to start three semiconductor laser units and a wide-spectrum spectrograph.A power controller is used for power adjustment of power amplifiers of the three semiconductor laser units.A frequency controller is used for adjusting the working frequencies of a first pulse generator, a second pulse generator and a third pulse generator.Spectrum widening of three-wavelength ultra-short femtosecond laser pulses is performed by a ZBLAN optical fiber, then the wide-spectrum spectrograph performs flatness analysis, and an analysis result is sent to the main controller for analysis.The intermediate infrared super-continuum spectrum laser device has the advantages of being capable of outputting intermediate infrared flat super-continuum spectra and meeting the demands on the aspects of accurate and quantitative wide-spectrum analysis and the like.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

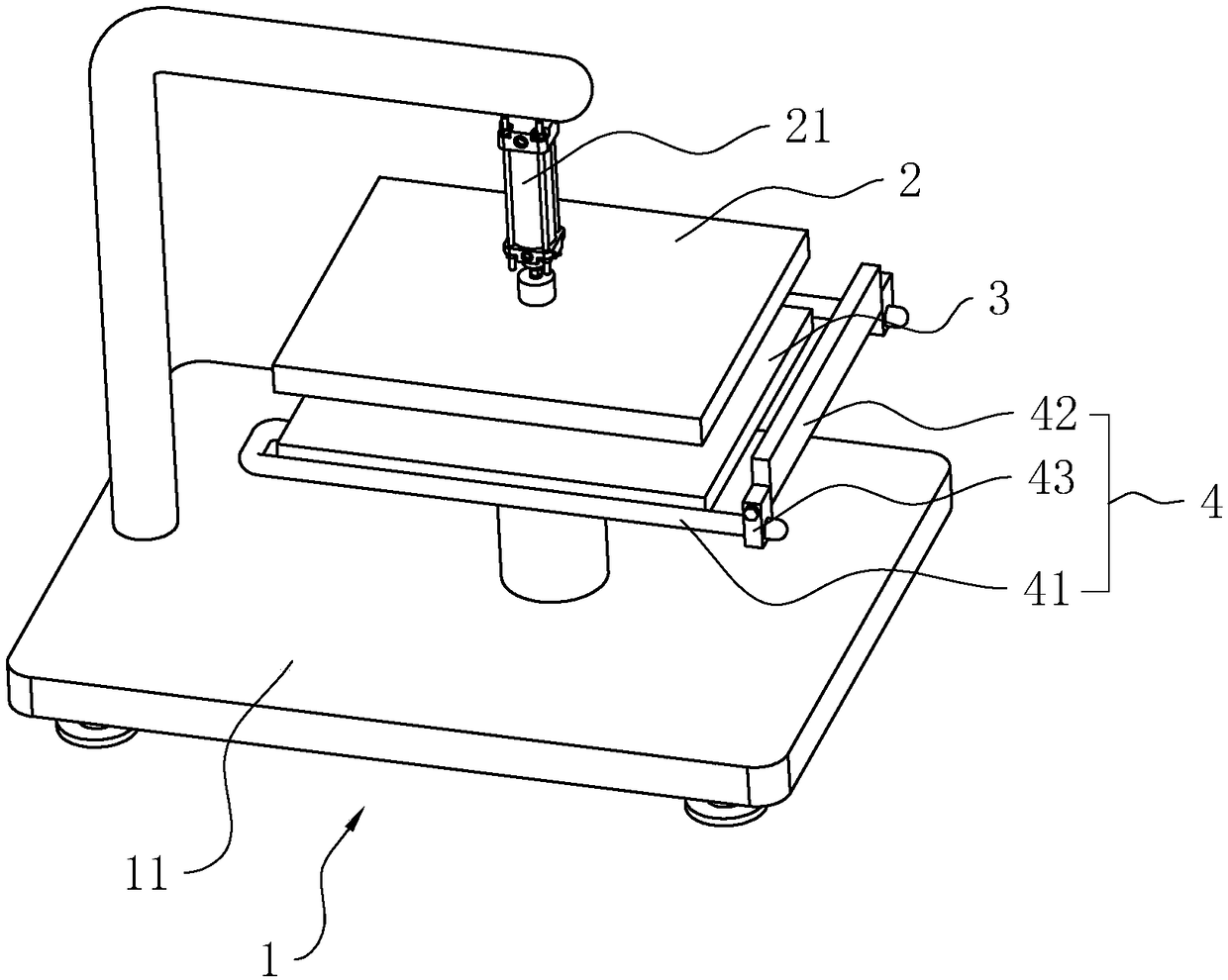

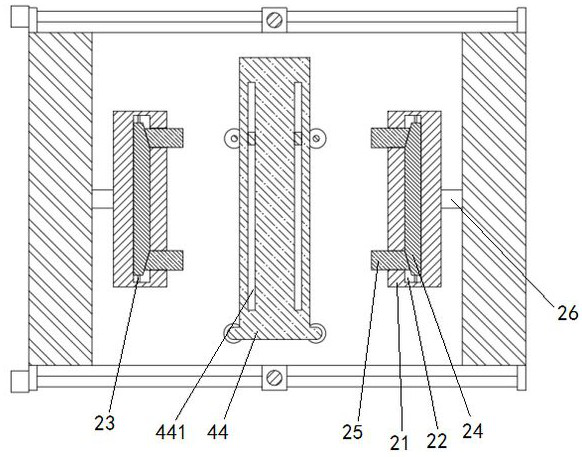

Thermally or electrically conductive paste smearing device and smearing method

InactiveCN103406240AMeet flatness requirementsImprove adjustabilityLiquid surface applicatorsCoatingsEngineeringElectrically conductive

The invention discloses a thermally or electrically conductive paste smearing device and a smearing method. The device comprises a control surface device and a positioning device. The control surface device comprises a mesh surface with a smearing pattern, and a mesh frame fixing the mesh surface. The positioning device comprises a positioning rack used for fixing the control surface device on the positioning device, a positioning plate arranged on the bottom of the positioning rack, and a positioning block arranged on the positioning plate and used for fixing an object to be smeared. The invention also discloses a thermally or electrically conductive paste smearing method adopting the smearing device. The object to be smeared is fixed in the smearing device and is positioned under the mesh surface; a proper amount of the thermally or electrically conductive paste is arranged on the mesh surface; and the paste is evened by smearing. With the smearing device and method provided by the invention, paste levelness, uniformity, thickness, and smearing area can be controlled, such that electronic device conductivity can be ensured, and product reliability and consistency can be improved.

Owner:COMBA TELECOM SYST CHINA LTD

Novel processing method for sealing strip with characteristics of fire resistance, smoke resistance and sound isolation

The present invention relates to a novel processing method for a sealing strip with characteristics of fire resistance, smoke resistance and sound isolation. The method comprises: preparing raw material particles used for two parts, and forming a mixing material I and a mixing material II, wherein the two parts are a hard bottom plate and a soft wing; cooling by using conical twin screw granulation equipment, and processing into particles respectively at a temperature of 150 DEG C and under 20 Mpa; and preparing two single screw extrusion equipment, respectively adding the particles of the two parts, connecting the mold, and preparing the finished product through the mold. The method of the present invention has the following beneficial effects that: the firm adhesion of the bottom and the soft wing can be ensured, the efficiency is high, the product quality is good, the structure of the produced product is stable, and the new shape structure which can not be produced by the traditional process method can be produced.

Owner:上海加尔福防火密封材料有限公司

Concrete pavement overall vibrating device and method

PendingCN108286216AMeet the crushMeet flatness requirementsRoads maintainenceEngineeringRoad surface

Owner:CHINA THIRD METALLURGICAL GRP

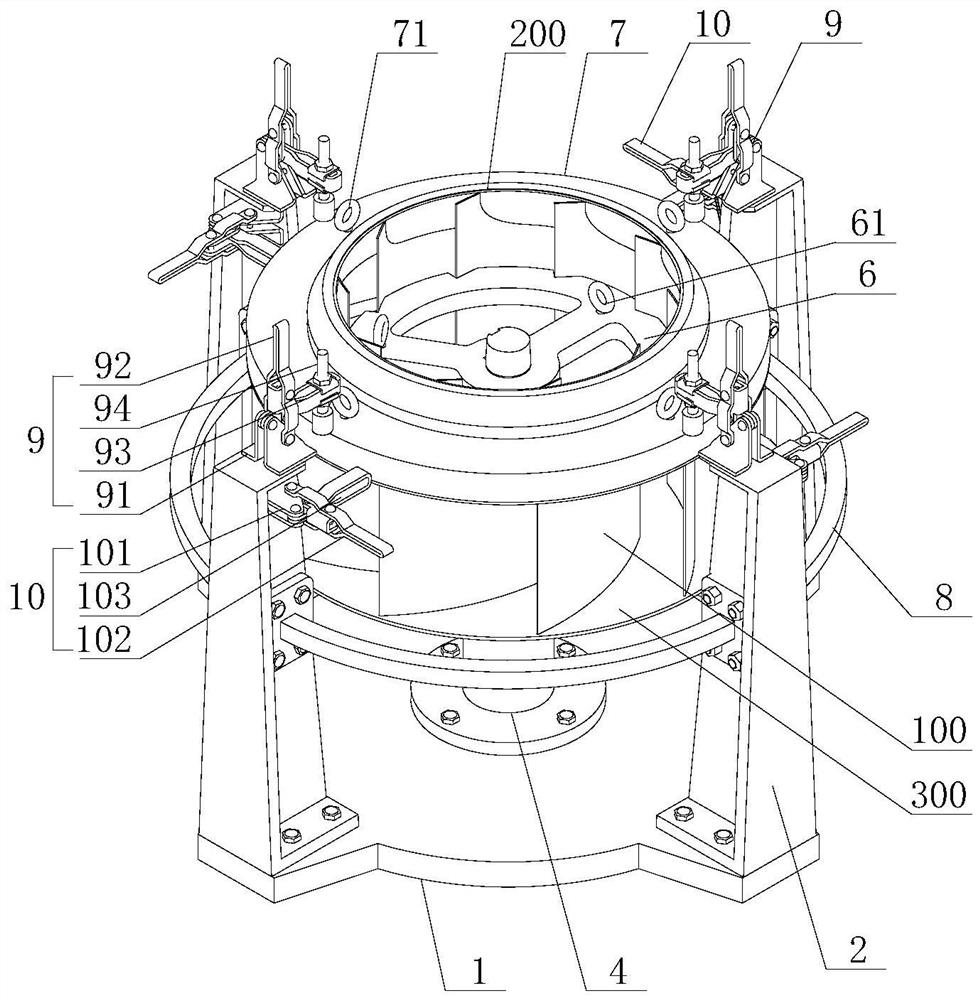

Welding positioning clamp for double-air-inlet impeller and positioning method of welding positioning clamp

InactiveCN113458694AImprove welding qualitySatisfy the requirement of coaxialityWelding/cutting auxillary devicesAuxillary welding devicesImpellerEngineering

The invention belongs to the technical field of fan impeller welding, and particularly discloses a welding positioning clamp for a double-air-inlet impeller. The welding positioning clamp comprises a bottom plate, a plurality of upright posts fixed to the edge of the bottom plate, and a central shaft fixed to the central position of the bottom plate, wherein a shaft support, a gasket used for accommodating a middle disc, an index plate used for accommodating blades and a pressing ring are sequentially and fixedly installed on the center shaft from bottom to top; and a locking mechanism used for limiting the position of the pressing ring and capable of pressing the pressing ring is arranged at the top of the stand column. All clamp body parts of the double-air-inlet impeller welding clamp are detachably installed on the impeller welding clamp, so that high fault tolerance in use is achieved, high-precision positioning welding of a to-be-machined double-air-inlet impeller is achieved with the bottom plate as a first positioning reference and the pressing ring as a second positioning reference, the machining efficiency is improved; the welding quality and the welding efficiency of the blades, a front disc and the middle disc are improved, and the stability of subsequent use of the double-air-inlet impeller is enhanced.

Owner:GUANGDONG ZHAOQING DETON

Clamping and positioning treatment equipment for plate machining

ActiveCN112405032AEasy to operateMeet uneven requirementsWork clamping meansPositioning apparatusControl engineeringProcess engineering

The invention discloses clamping and positioning treatment equipment for plate machining. The clamping and positioning treatment equipment for plate machining comprises a position adjusting mechanism,end face clamping mechanisms, a drilling machining mechanism and a center positioning mechanism; the end face clamping mechanisms are respectively mounted at the two ends of the position adjusting mechanism; the center positioning mechanism is mounted on the position adjusting mechanism in a sliding mode; and the drilling machining mechanism is mounted on the center positioning mechanism, and theposition of the drilling machining mechanism is adjusted through the center positioning mechanism. According to the clamping and positioning treatment equipment for plate machining, by means of sliding fit between the balance adjusting blocks and the dynamic adjusting plates, contact between the two dynamic adjusting plates and the end faces of the plates is dynamically adjusted, so that the clamping and fixing requirements for different end face flatness are met, and the clamping accuracy and firmness are improved; and a second transmission lead screw drives the center position adjusting plate to move so as to adjust the position of the center position adjusting plate, the position of the drilling machining mechanism can be adjusted according to the width of the plate, the drilling machining mechanism can drill the position of the central axis of the plate, and therefore, the drilling stability and accuracy are improved.

Owner:济南井泉精密锻造股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com