Automatic adjustment method for smoothness of cutting path of roller of coal cutter in real time

A coal mining machine drum and automatic adjustment technology, applied in the direction of use feedback control, etc., can solve problems such as casualties, hydraulic support support is not in place, production interruption, etc., to improve coal mining accuracy and production efficiency, and maintain operation mode and stability, the effect of meeting the requirements of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

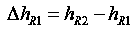

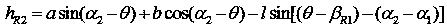

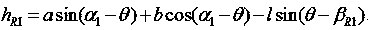

[0040] Taking the rear drum of a coal shearer as an example, taking the situation when the inclination parameter value of the dynamic running coordinate system is less than or equal to the inclination parameter value of the static reference coordinate system, that is, |α|≤|θ|, as the analysis object, the change of the body inclination angle α The effect on the cutting path and the adjustment process of the drum height.

[0041] During the cutting process of the shearer, the inclination angle α of the fuselage changes with the inclination angle of the coal seam. Due to the hinged relationship between the rocker arm and the fuselage, the cutting height of the drum also changes when the rocker arm is adjusted. When the inclination angle of the shearer body is α 1 when, such as figure 2 As shown, the inclination angle of the rocker arm of the shearer is β R1 , then the height h from the center of the shearer drum to the horizontal plane of the static reference coordinate system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com