Patents

Literature

36results about How to "Guaranteed coaxiality accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

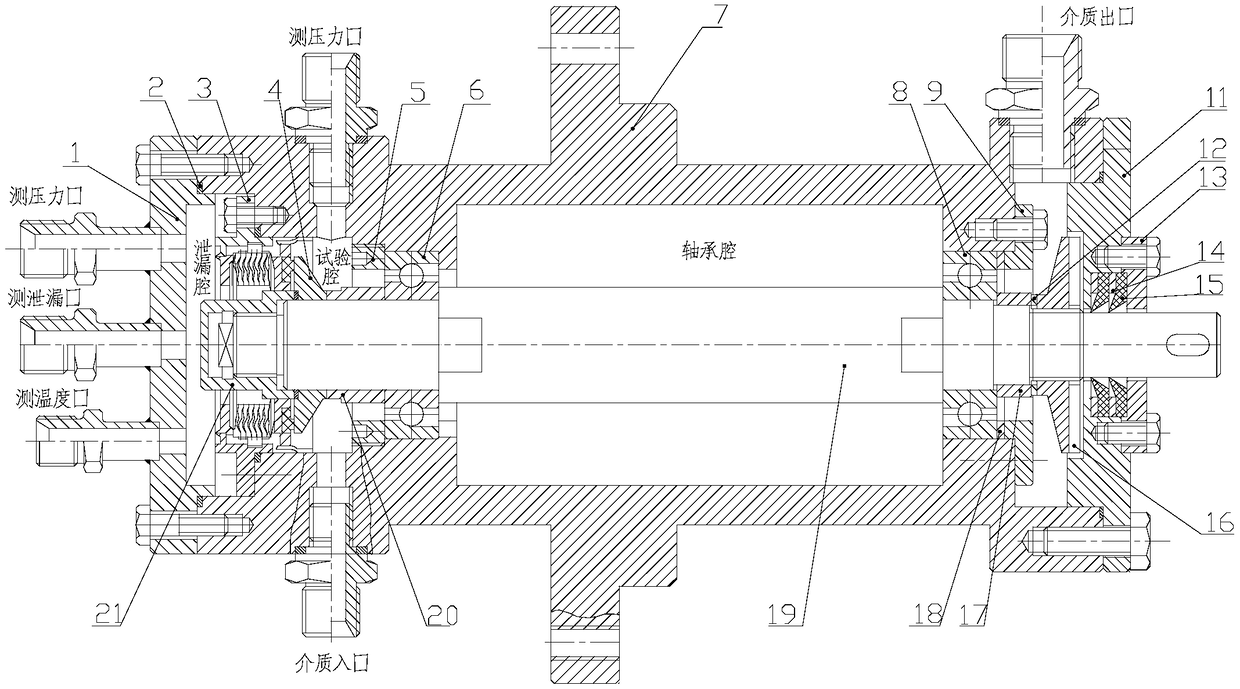

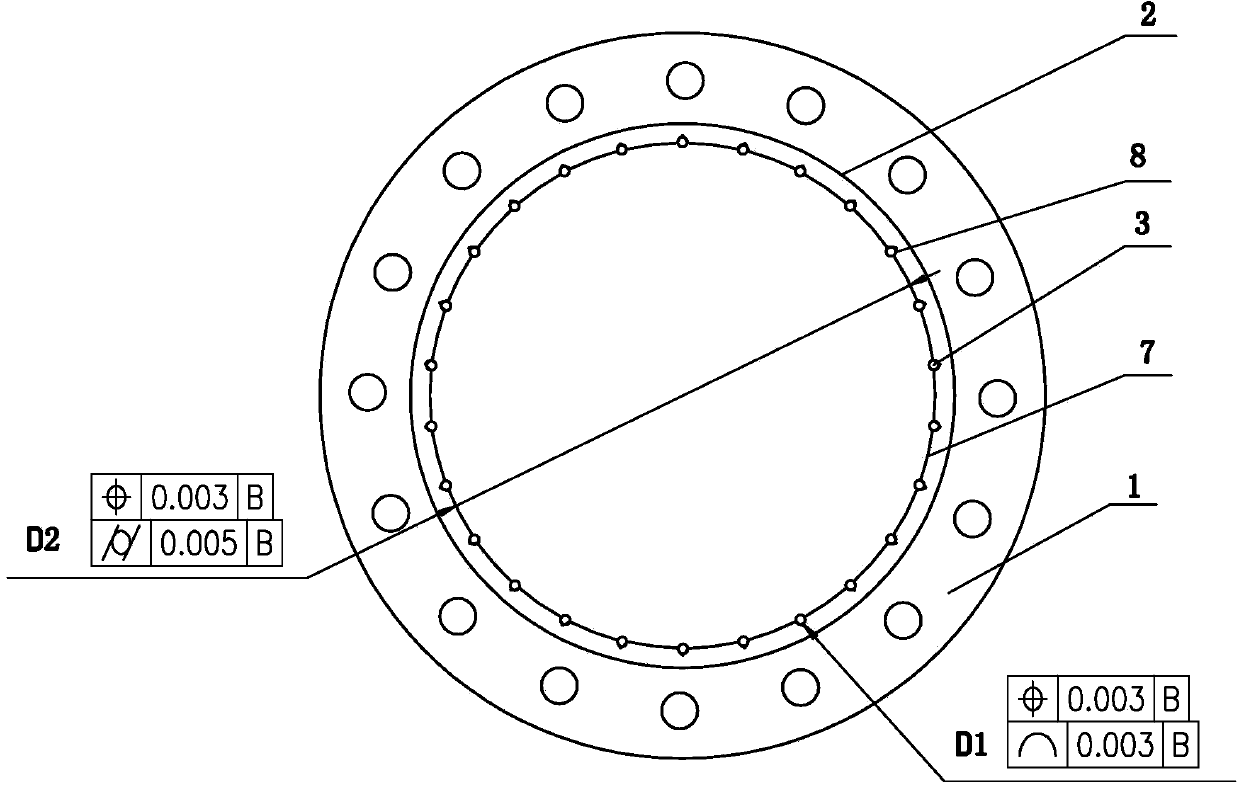

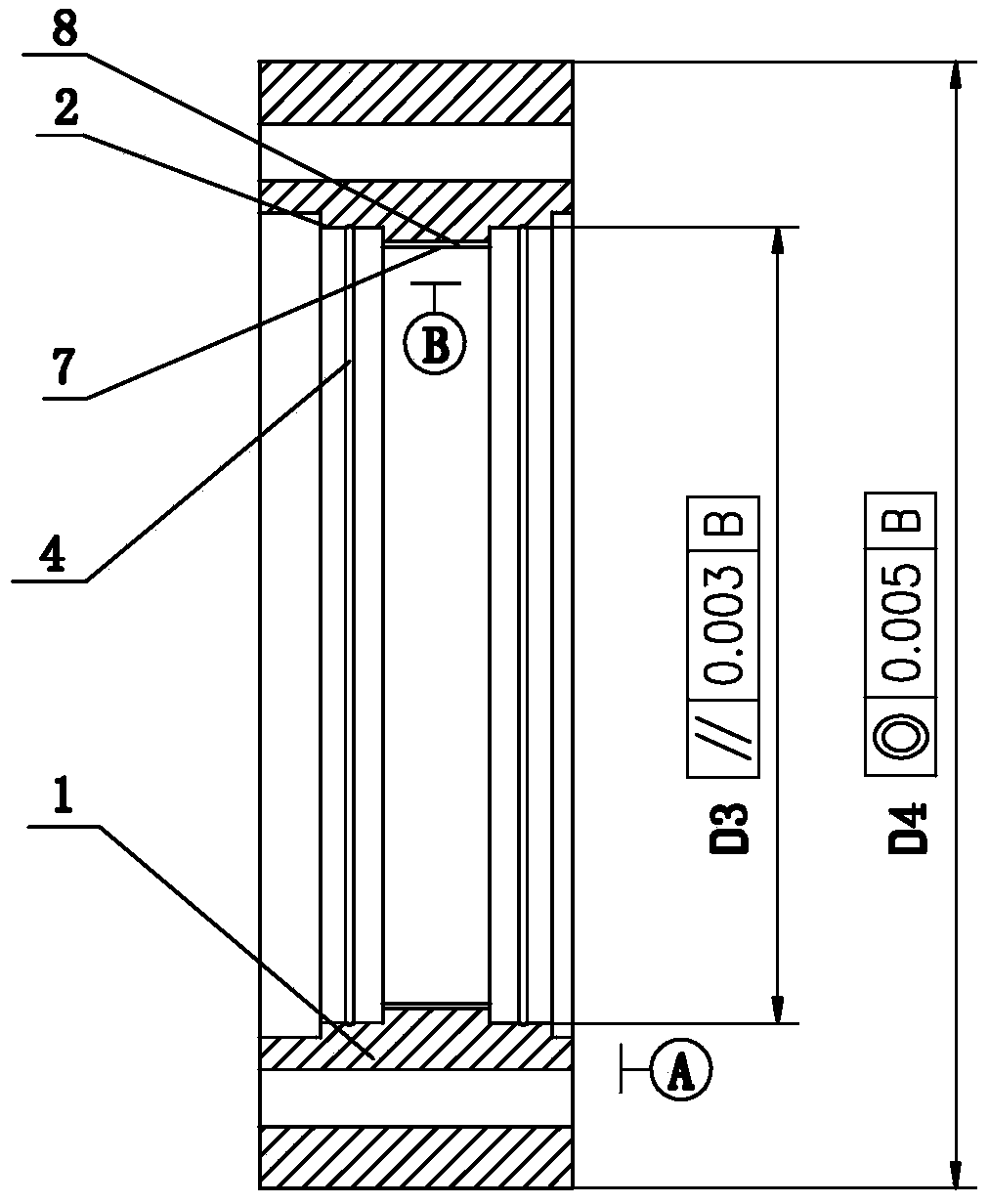

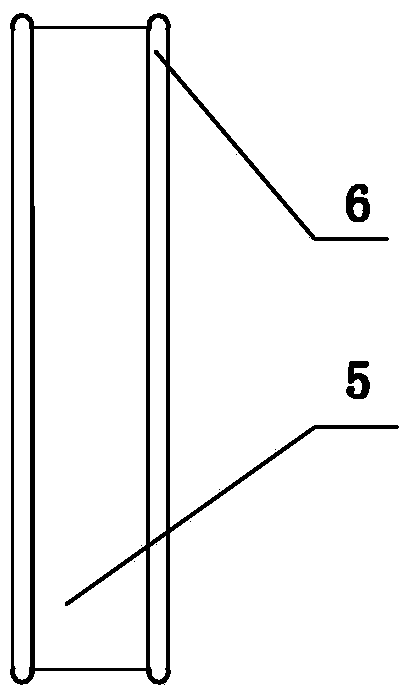

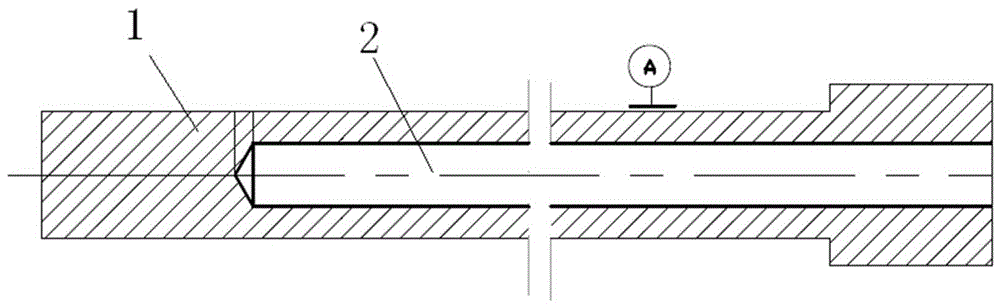

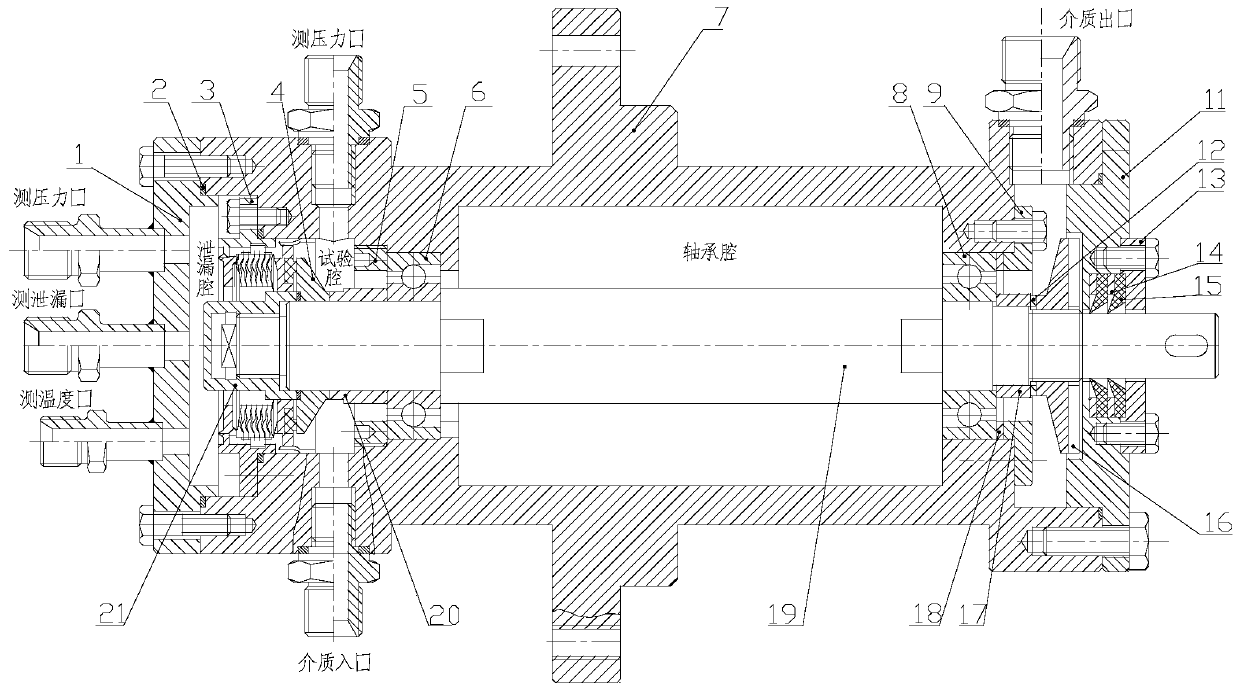

End face sealing test device for liquid rocket engine turbine pump under low-temperature and high-speed

The invention discloses an end face sealing test device for a liquid rocket engine turbine pump under a low-temperature and a high-speed. The device is applied to a sampling test of an end face sealing assembly of a rocket engine of a liquid hydrogen liquid oxygen propellant, in a running-in test and a research performance test, an end face sealing assembly product ( such as an engine static ringassembly and an engine moving ring ) is assembled in the test device of the invention, a working environment of the engine turbine pump is simulated, the sealing performance and the structural rationality of the sealing assembly product are checked, and the sealing performance of the sealing assembly product can be quantitatively detected. According to the device, the test device does not contractand deform under a low-temperature environment, and runs stably at a high speed, the device provides an important basis for improving various problems in the design of the end face sealing assembly product.

Owner:BEIJING AEROSPACE PROPULSION INST

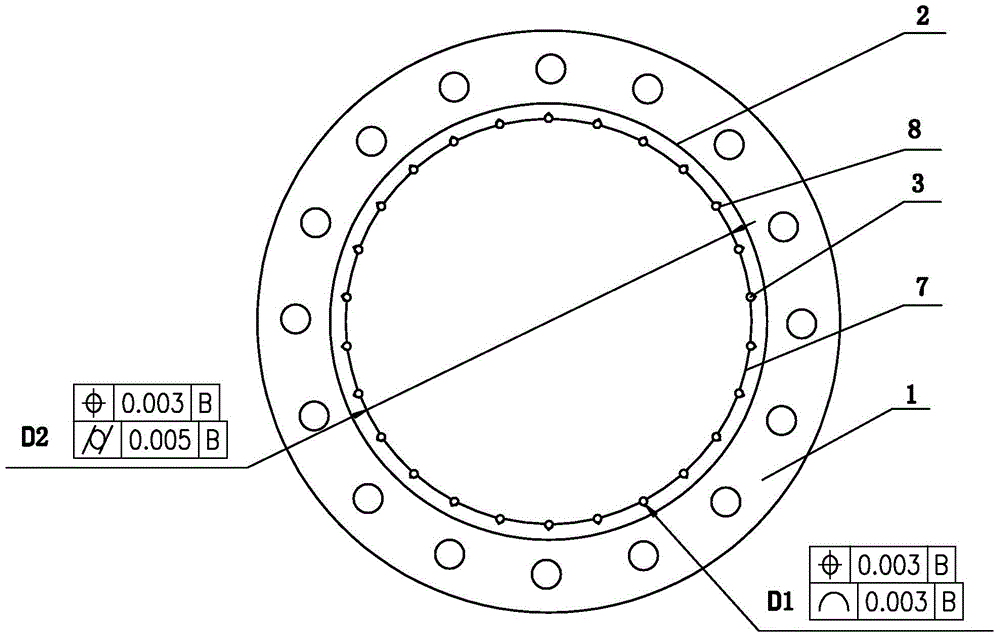

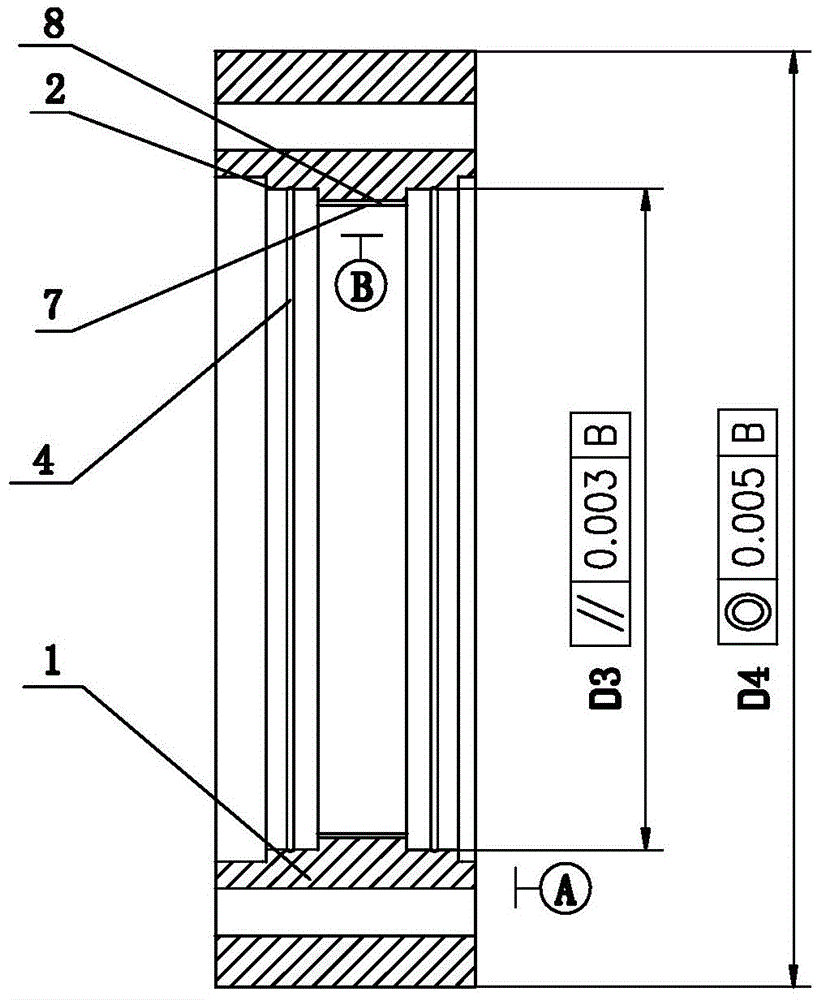

Processing technology of robot RV speed reducer needle gear shell

The invention discloses a processing technology of a robot RV speed reducer needle gear shell, and belongs to the technical field of robot RV speed reducer processing. The processing technology includes the steps that precise casting or forging is carried out on a needle gear shell blank; the needle gear shell blank is clamped after the surface of the needle gear shell blank is machined, and the rotation center of the needle gear shell blank is taken as a positioning reference; the end face of the needle gear shell blank, a bearing position of a roller pin bearing and bearing positions of two main bearings are machined; finish machining is carried out on the inner surface of the roller pin bearing according to the positioning reference; finish machining is carried out on a roller pin groove in line contact with a roller pin of the roller pin bearing according to the positioning reference; inner grooves are simultaneously machined in the bearing positions of the two main bearings in a finish machining mode according to the positioning reference; finish machining is carried out on the outer surface of the needle gear blank. The needle gear shell machined according to the steps improves machining precision and the parallelism degree of the bearing positions of the main bearings, guarantees coaxiality, the position degree and cylindricity of the main bearings after installation, achieves one-time clamping, can meet requirements of multiple process parameters, improves machining precision and installation precision of the needle gear shell, reduces accumulated errors, meets the high-precision requirements, and prolongs service life.

Owner:SHANDONG SHKE MACHINERY MFG

Integrated machining method of planet carrier of robot RV reducer

The invention discloses an integrated machining method of a planet carrier of a robot RV reducer, and belongs to the technical field of robot RV reducer machining. The method comprises the steps as follows: forging a first casing and a second casing, and performing hot extrusion on the first casing and the second casing respectively; performing thermal refining; performing tempering; performing finish machining on end surfaces respectively; connecting the first casing with the second casing to be clamped to a clamp, and performing finish machining on inner holes formed in the first casing and the second casing with a center of gyration serving as a locating basis; performing finish machining on outer surface with the locating basis; directly machining inner rings of rolling bearings on the first casing and the second casing; accurately grinding an outer track on each inner ring simultaneously; and performing finish machining bearing positions of three tapered roller bearings on the first casing and the second casing with the location reference, and directly machining outer rings of the tapered roller bearings. With the adoption of the method, the mounting accuracy, the manufacturing accuracy and the transmission accuracy are ensured, the requirement for high accuracy is met, the service life is prolonged, machining and assembling errors and accumulative errors are reduced, the output torque is increased, and the machining cost is effectively reduced.

Owner:SHANDONG SHKE MACHINERY MFG

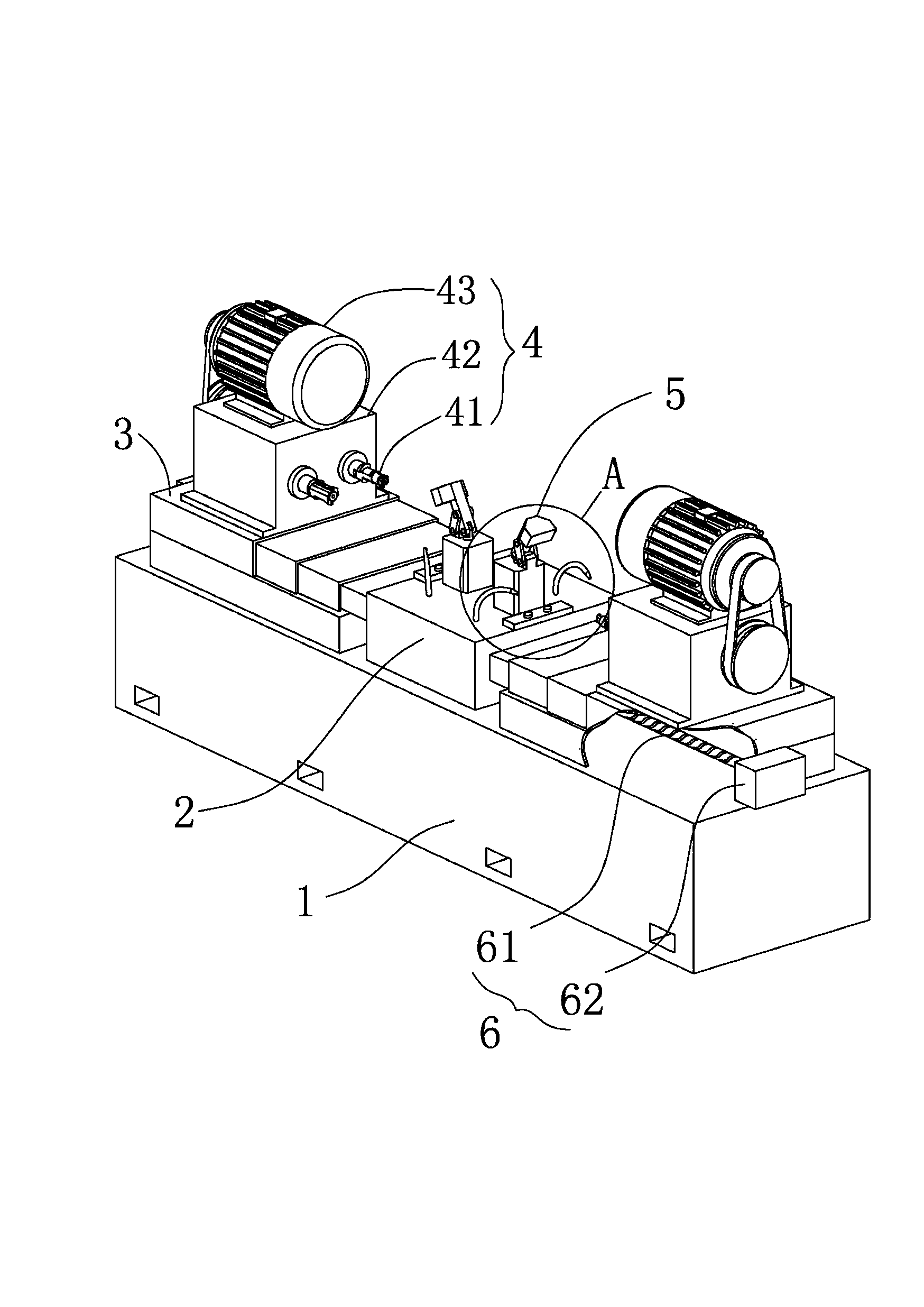

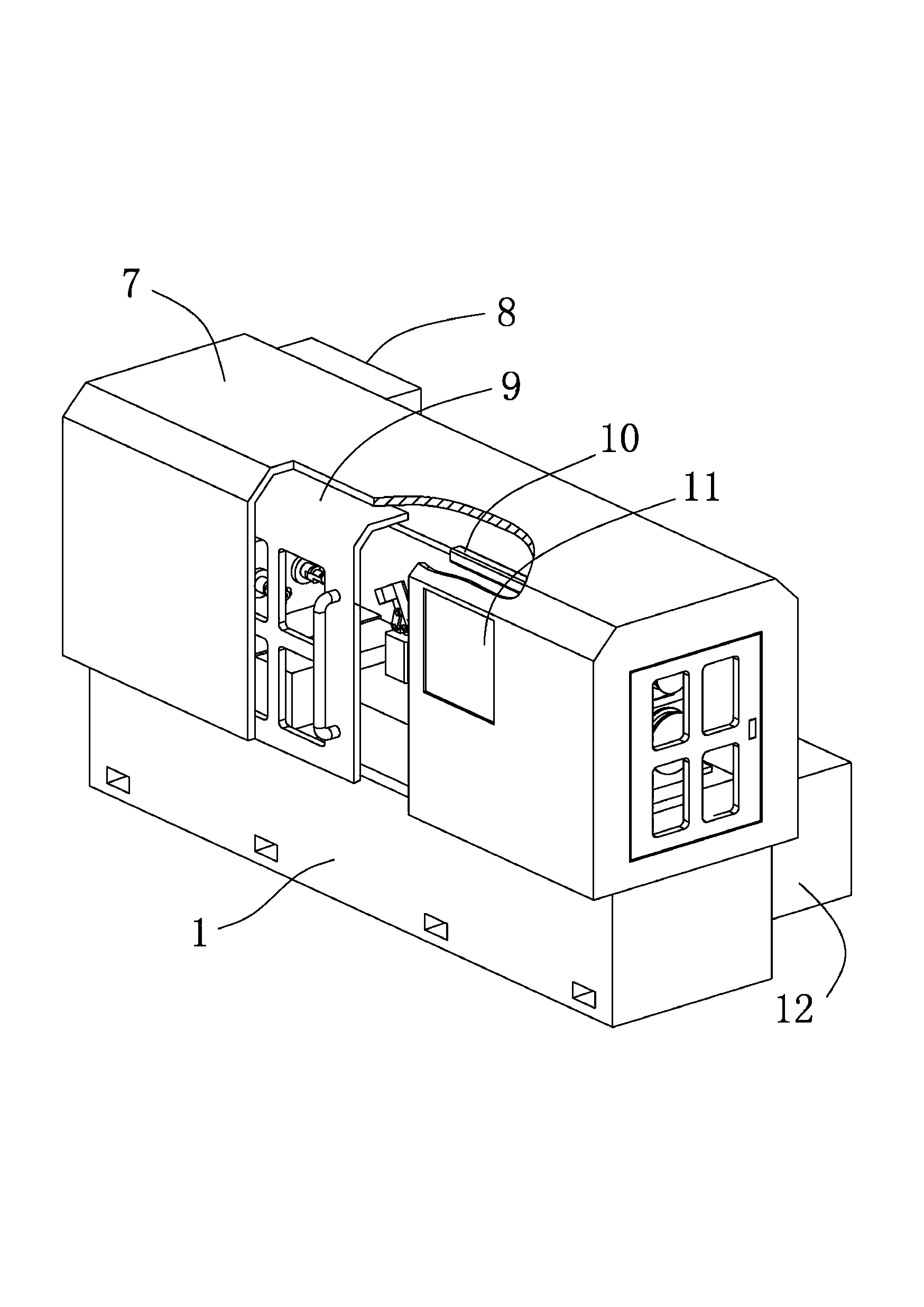

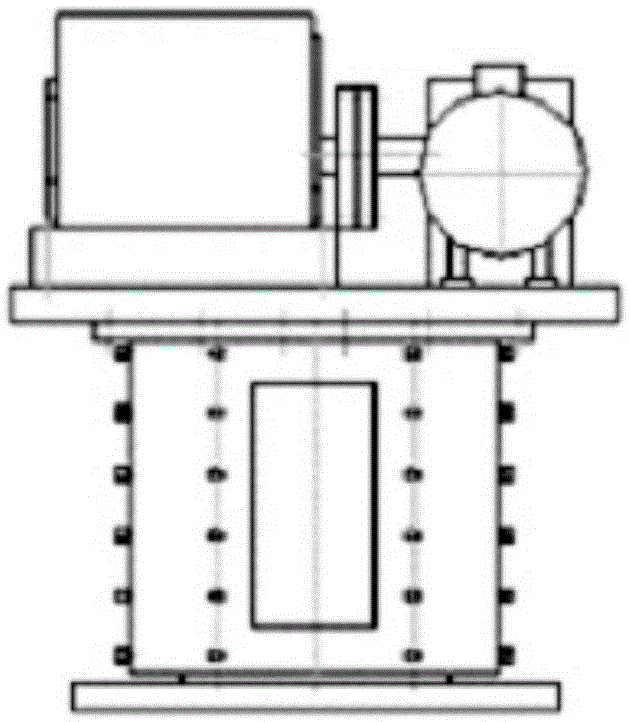

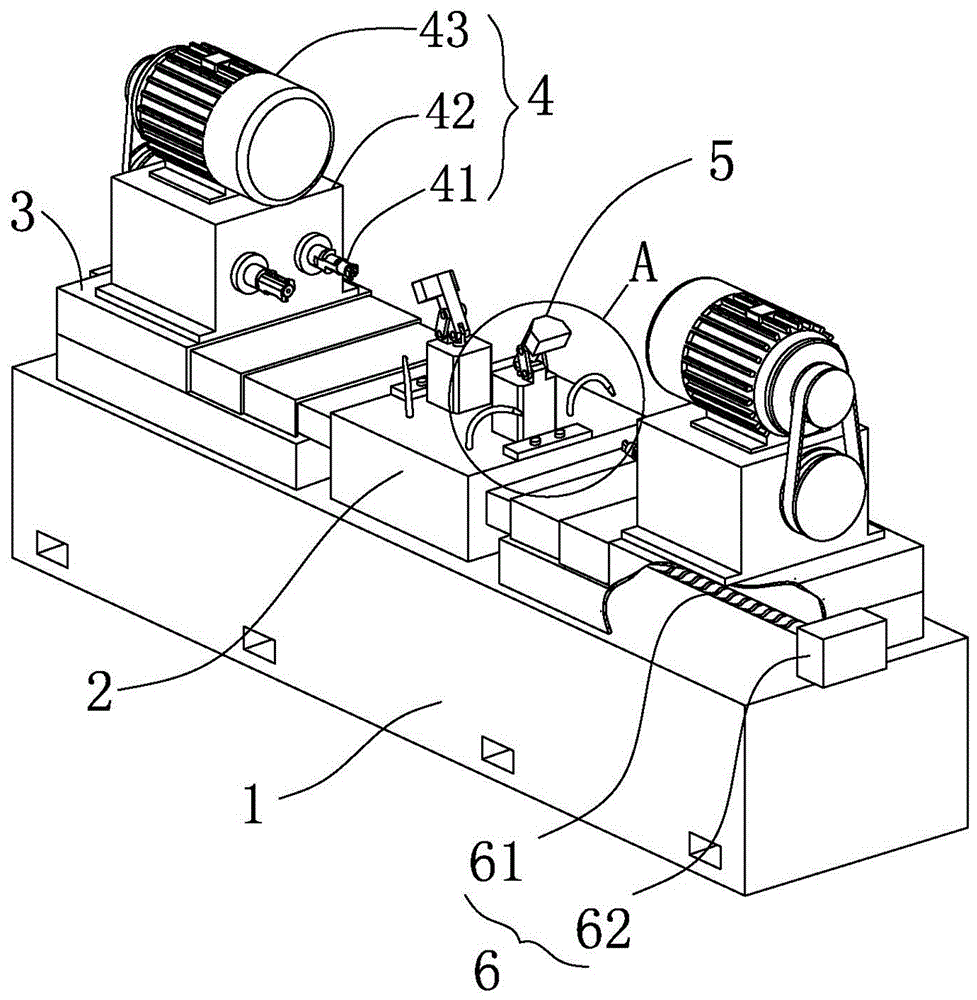

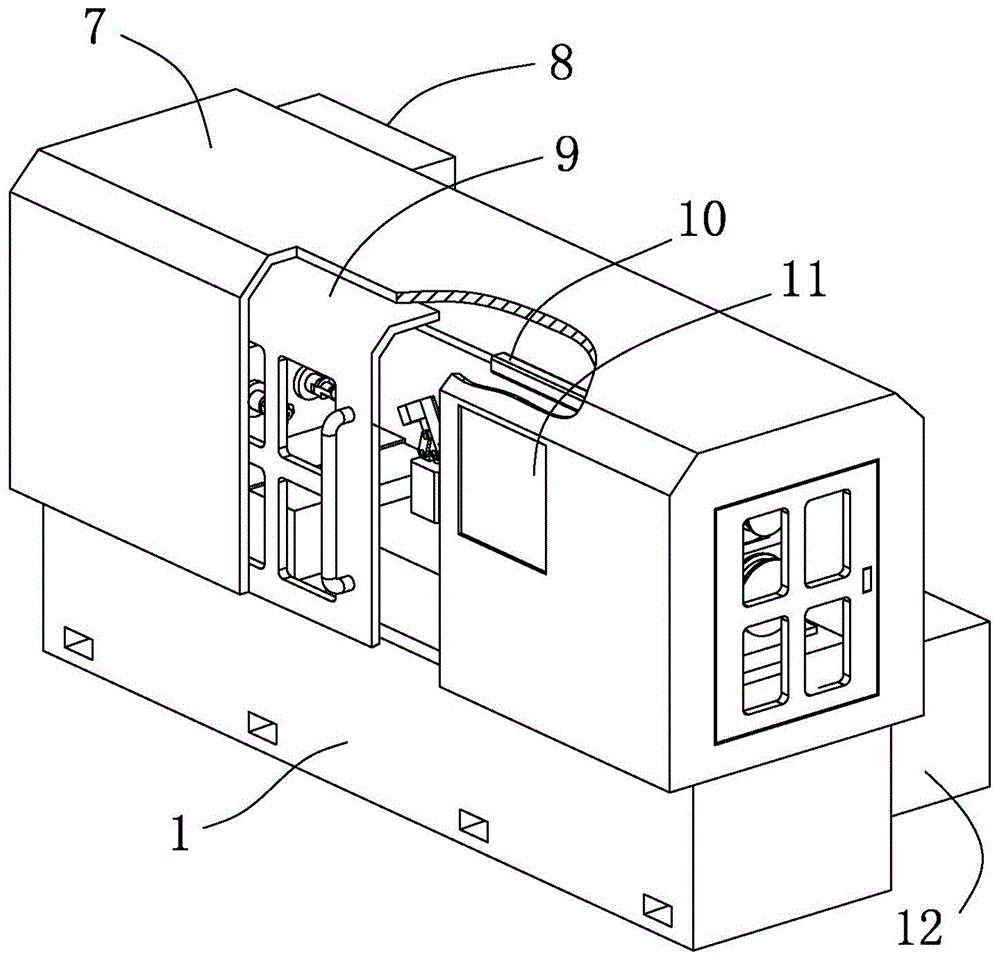

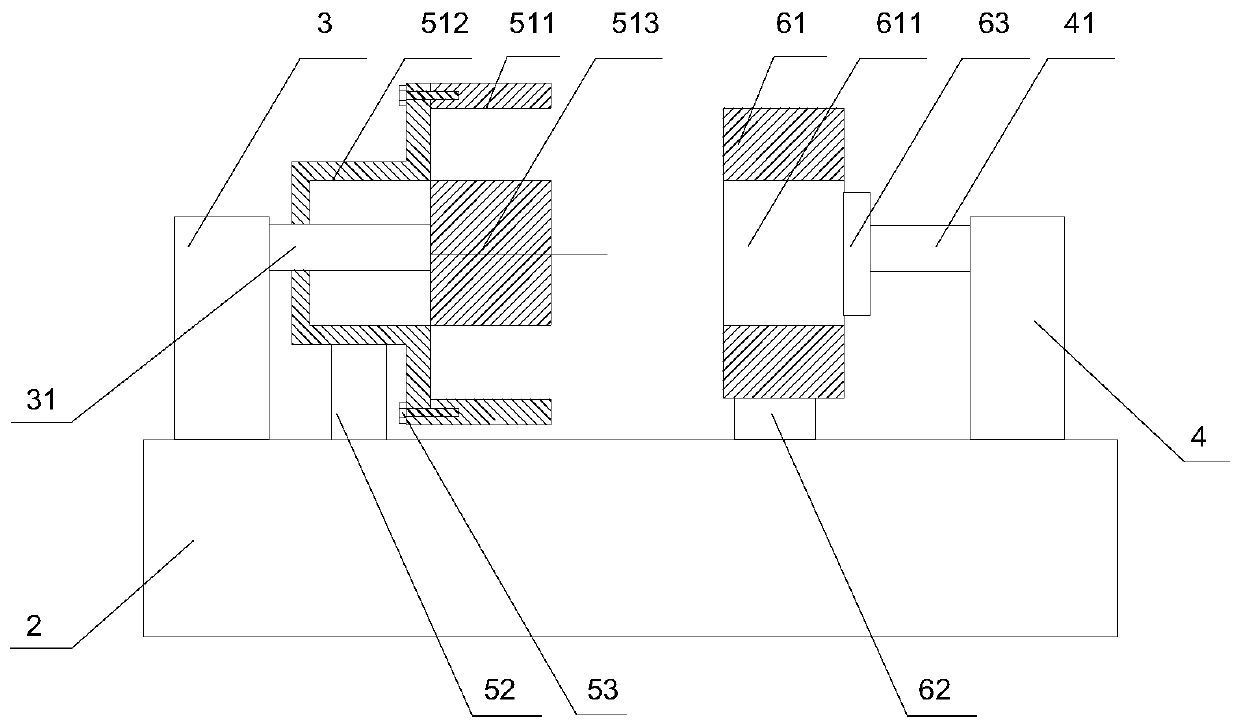

Special double-spindle numerical-control boring machine

InactiveCN103286341AGuaranteed coaxiality accuracyImprove processing efficiencyTurning toolsPositioning apparatusTool bitNumerical control

The invention provides a special double-spindle numerical-control boring machine high in precision and efficiency. The special double-spindle numerical-control boring machine comprises a body. A bench is disposed in the middle of the body, carriages are disposed on left and right sides of the body respectively, positioning clamping devices are symmetrically mounted at left and right ends of the top of the bench respectively, a boring power head is mounted above each carriage, two boring tools are mounted on each boring power head, each carriage is connected to the body through a driving device, a guard covering the whole body is disposed above the body, the middle of the guard is provided with a sliding door driven by an air cylinder, each boring tool is provided with at least one group of tool bits, and an automatic scrap discharger, an air pump device, an oil pump device and a cooling pump device are rested on the back of the body. The special double-spindle numerical-control boring machine is provided with the two boring power heads in bilateral symmetry for machining two workpieces simultaneously, each boring power head is provided with two boring tools for machining two holes of each workpiece simultaneously, and the efficiency of the special double-spindle numerical-control boring machine is ten times of that of the common boring machine. The special double-spindle numerical-control boring machine is provided with the guard and the automatic scrap discharger, the whole machining process is under control of a control cabinet, and the machining environment is closed and neat.

Owner:苏佳和

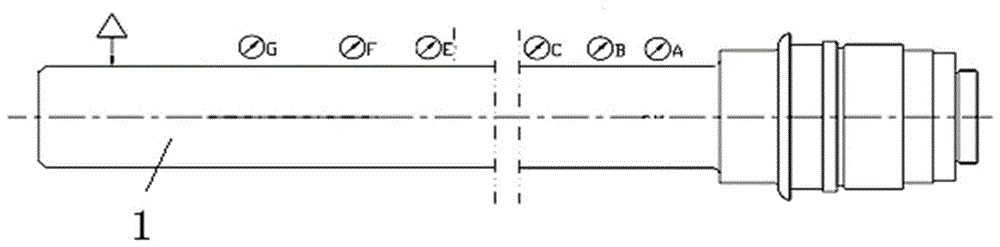

Travel shell of blind-hole rod of control rod drive mechanism in pressurized water reactor and method of machining travel shell

InactiveCN106826138AGuaranteed positionGuaranteed coaxiality accuracyConnecting rodsPressurized water reactorDiameter ratio

The invention relates to the technical field of methods of machining parts of pressurized water reactor equipment and discloses a method of machining a travel shell of a blind-hole rod of a control rod drive mechanism in a pressurized water reactor; the outer diameter of the blind-hole rod is less than 100 mm and length-diameter ratio of the blind-hole rod is greater than 54; the method comprises the steps of (1) roughly machining rough outside of a small end of a slender rod; (2) roughly drilling a blind hole; (3) correcting segment by segment, roughly machining the outside of the small end of the slender rod to ensure the coaxiality and positionality of the blind hole and outside; (4) machining the blind hole to preset size; (5) finely turning the outside segment by segment to arrive at a positioning reference; (6) machining the outside of the small end of the slender rod segment by segment for forming purpose in order to ensure the coaxiality or positionality of the blind hole and outside; (7) machining the outside, screw thread and weld groove of the large end of the slender rod. By using the method, the problems in the technique of machining the travel shell of the blind-hole rod of a slender rod in the control rod drive mechanism in the pressurized water reactor are solved; product precision is ensured, the dimensions meet the requirements of drawings.

Owner:上海第一机床厂有限公司

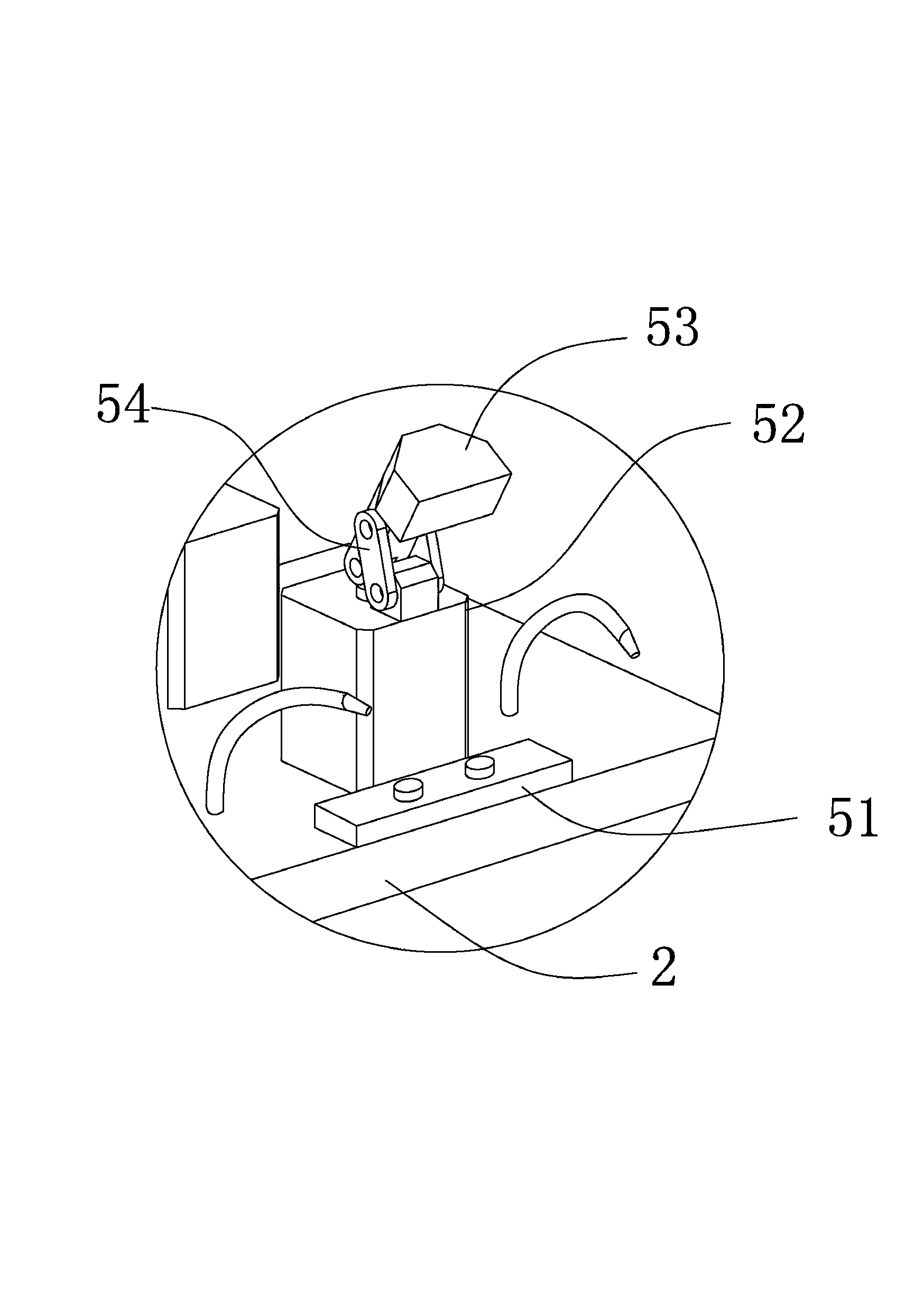

Outside-furnace welding device and method for auxiliary electrodes of vacuum arc furnace

ActiveCN106312265ACentering accuracy is easy to controlGuaranteed coaxiality accuracyWelding/cutting auxillary devicesAuxillary welding devicesElectric arc furnaceAuxiliary electrode

The invention provides an outside-furnace welding device and method for auxiliary electrodes of a vacuum arc furnace. The outside-furnace welding device and method are used for welding between the auxiliary electrodes of the vacuum arc furnace and consumable electrodes. A consumable electrode positioning device comprises a first center frame regulation device, a second center frame regulation device and a third center frame regulation device, wherein the first center frame regulation device, the second center frame regulation device and the third center frame regulation device are arranged in a manner of spacing a certain interval and are of the same structure. An auxiliary electrode positioning device comprises a fixed shear type regulation device, a movable shear type regulation device, a guide rail, a sighting device positioning mechanism and a scale mechanism. An electrode lifting and rotating drive device comprises a first lifting type rotation device, a second lifting type rotation device and a third lifting type rotation device. The second lifting type rotation device actively rotates (is provided with a drive mechanism), and the first lifting type rotation device and the third lifting type rotation device passively rotate (are not provided with drive mechanisms except a drive roller). By means of the outside-furnace welding device and method, the cylindrical auxiliary electrodes of different specifications and cylindrical consumable electrodes of different specifications can be welded outside the vacuum arc furnace according to a certain coaxiality requirement so that the original manner for conducting welding inside the vacuum arc furnace can be replaced.

Owner:宝武特种冶金有限公司

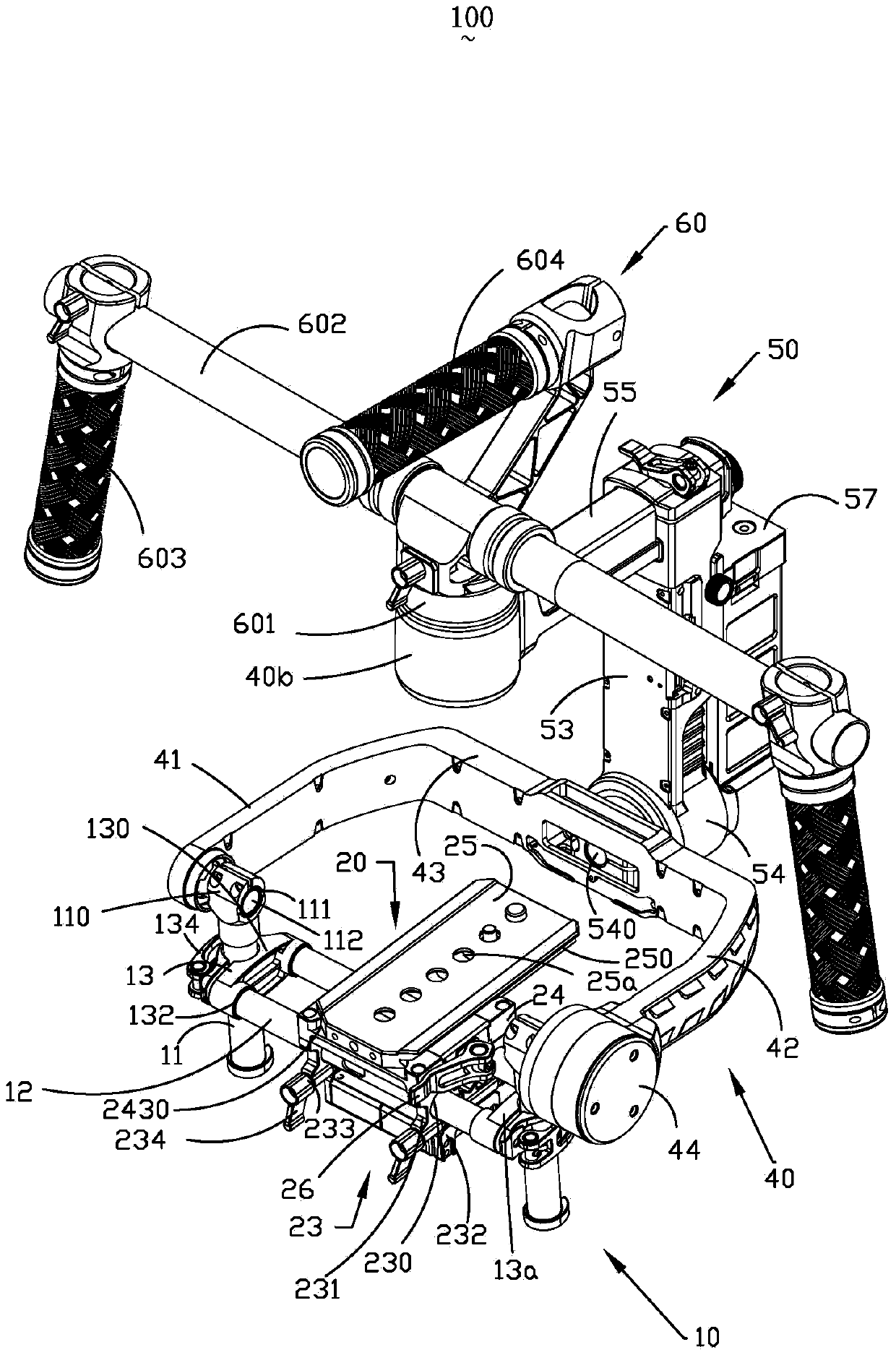

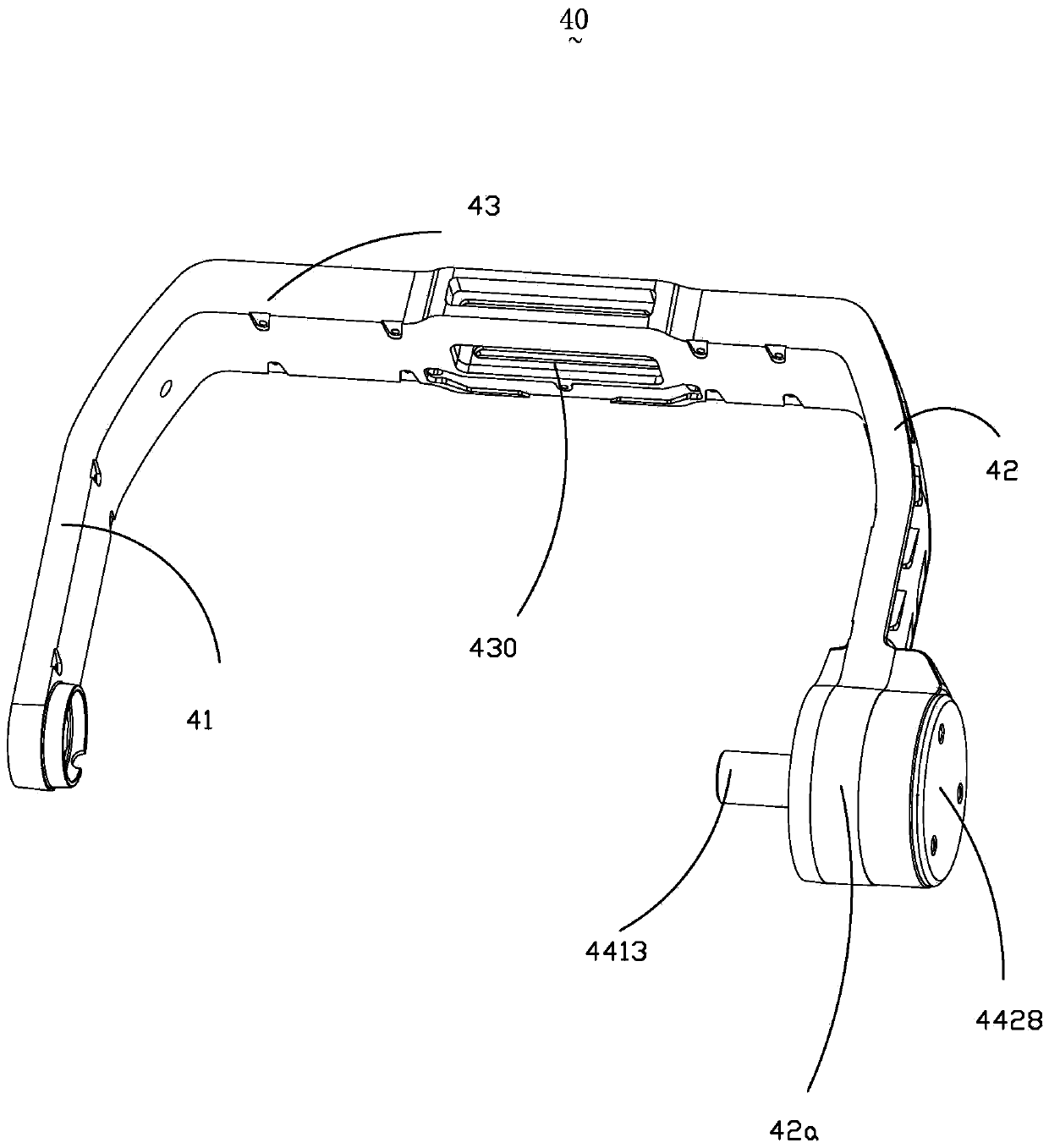

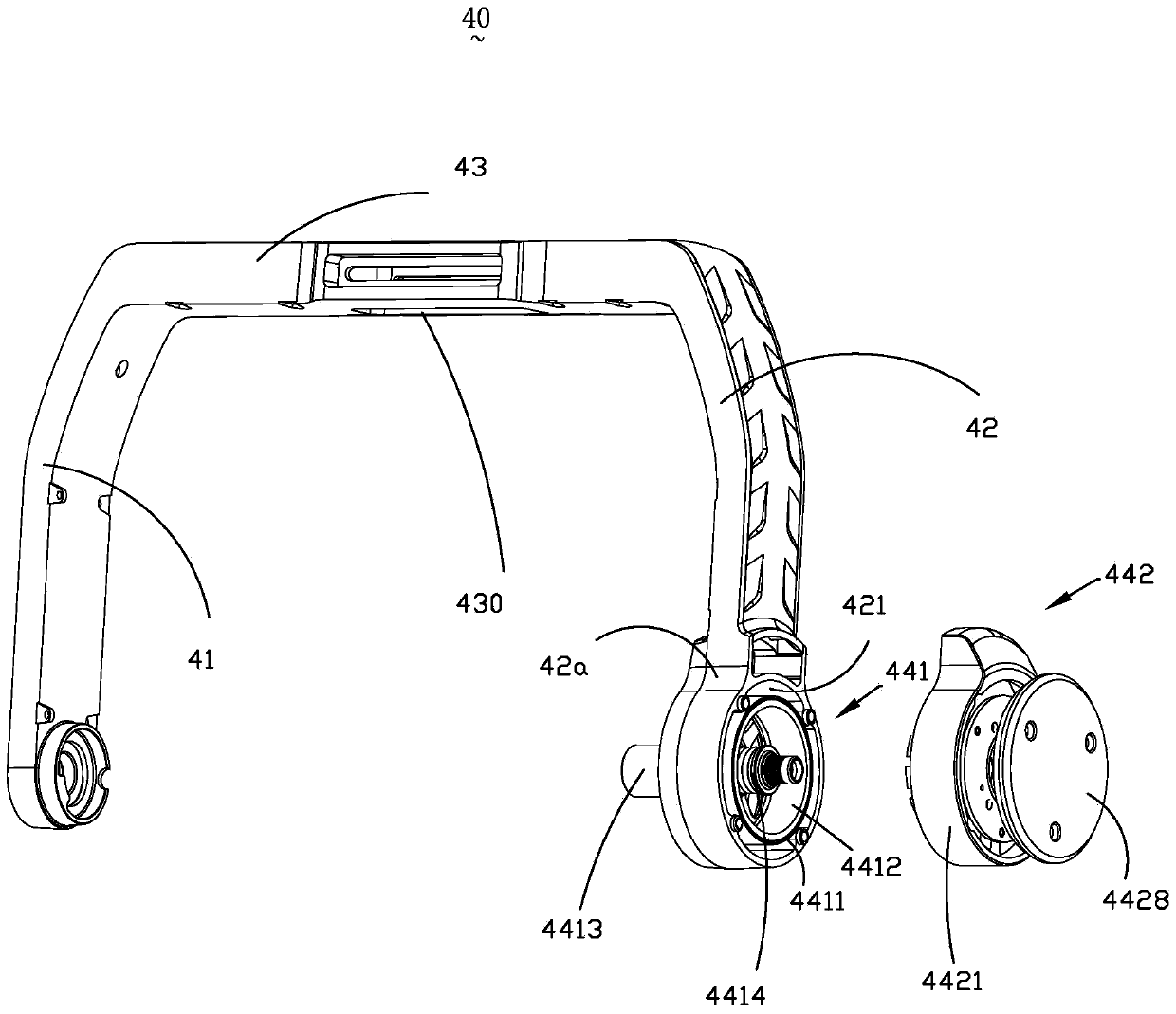

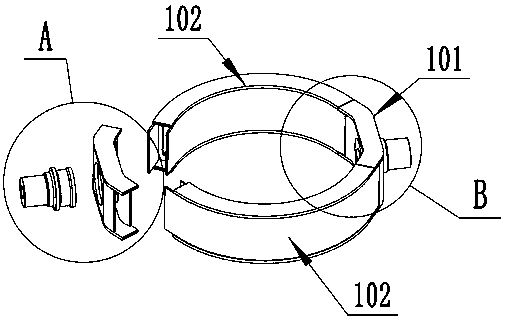

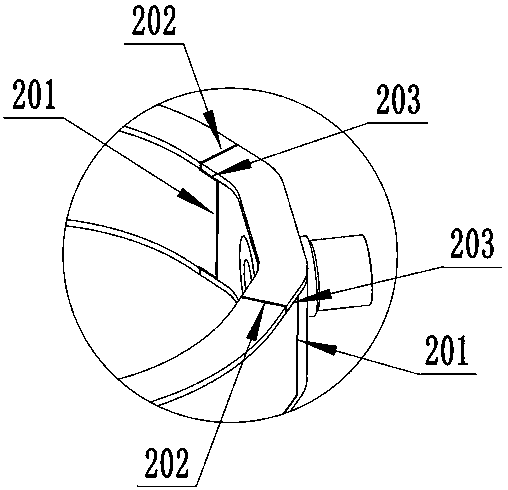

Cross rolling shaft assembly and cradle head using same

InactiveCN105518370AGuaranteed coaxiality accuracyReduce the numberStands/trestlesMechanical energy handlingMechanical engineeringStator

A rotating shaft assembly (40) and a cradle head (100) using the rotating shaft assembly (40). The rotating shaft assembly (40) comprises: a first supporting arm (41); a second supporting arm (42) disposed symmetrical to the first supporting arm (41); a connecting arm (43) connecting the first supporting arm (41) to the second supporting arm (42); and a first driving apparatus (44). A first bearing hole (410) is formed in the first supporting arm (41). A connecting seat (42a) is disposed at one end of the second supporting arm (42) away from the connecting arm (43). A second bearing hole (420) and an accommodating groove (421) are formed in the connecting seat (42a). The second bearing hole (420) is in communicated with the accommodating groove (421). The first driving apparatus (44) comprises a rotor assembly (441) and a stator assembly (442). The first supporting arm (41), the connecting arm (43) and the second supporting arm (42) are integrally formed. The rotor assembly (441) is directly accommodated in the accommodating groove (421).

Owner:SZ DJI OSMO TECH CO LTD

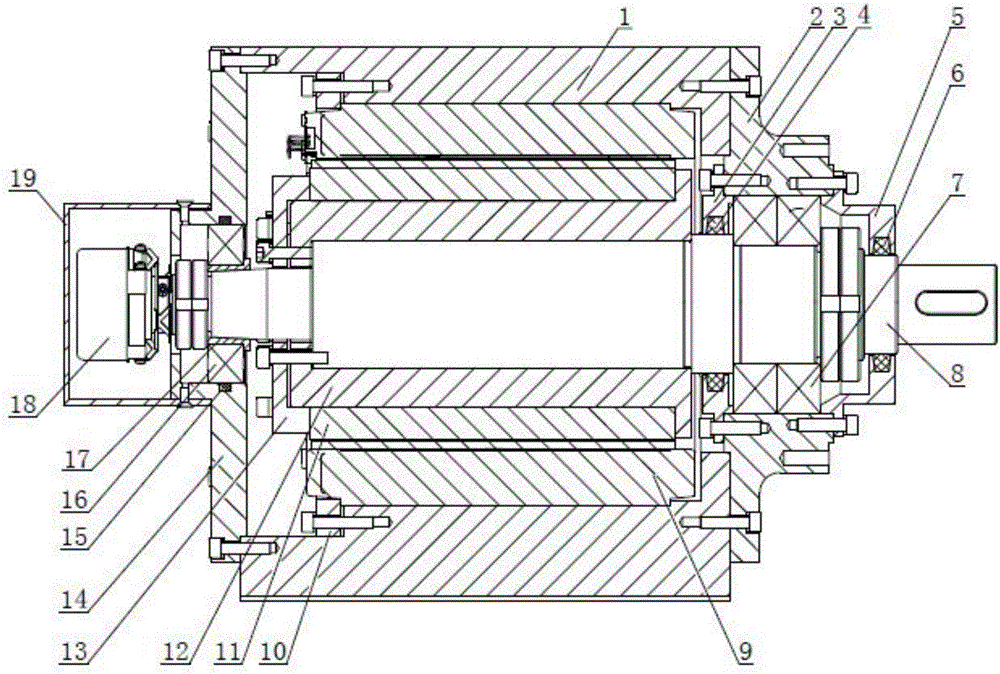

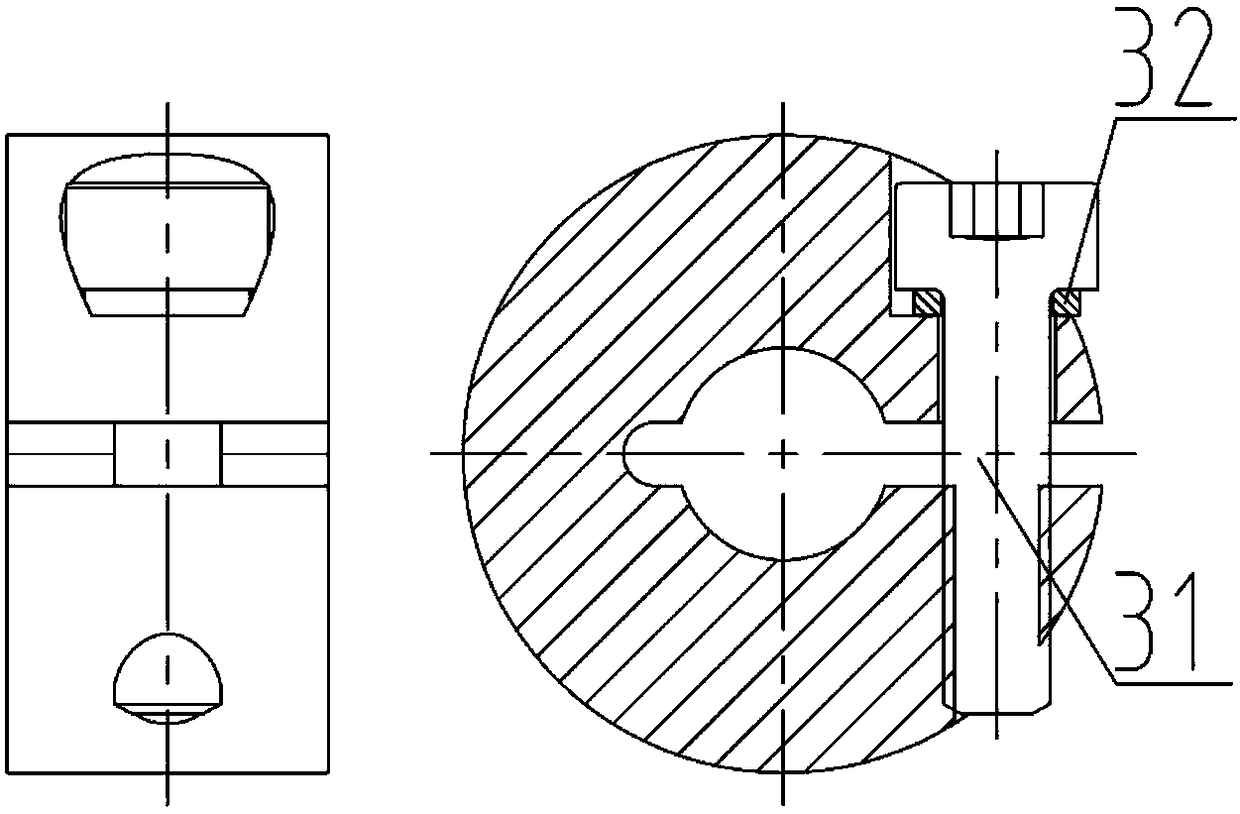

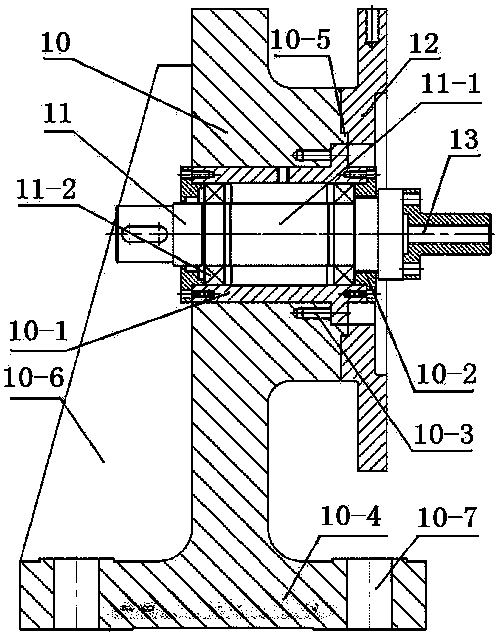

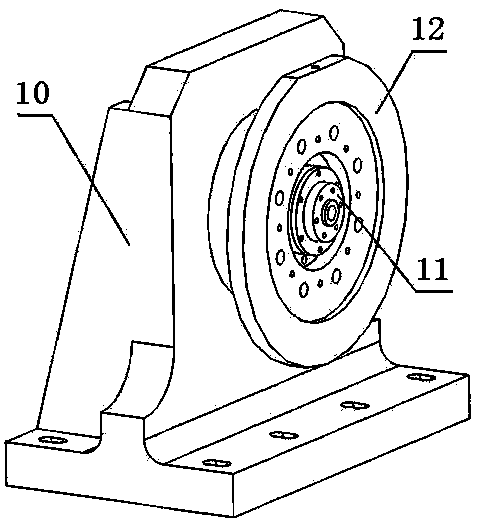

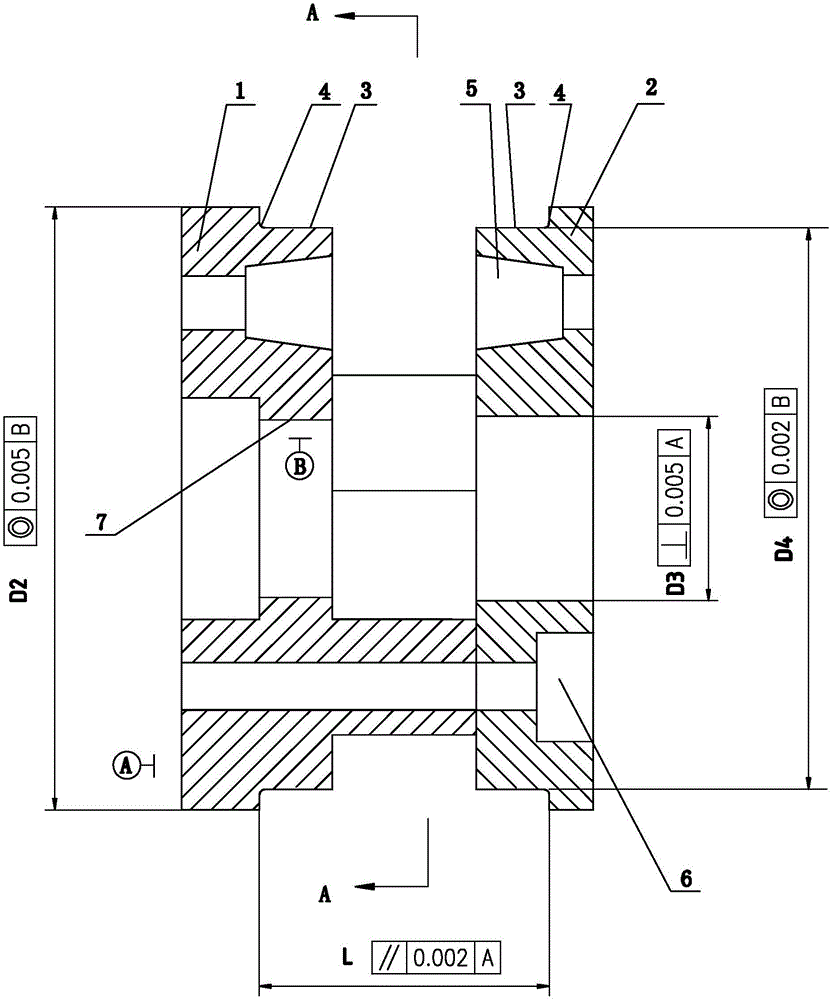

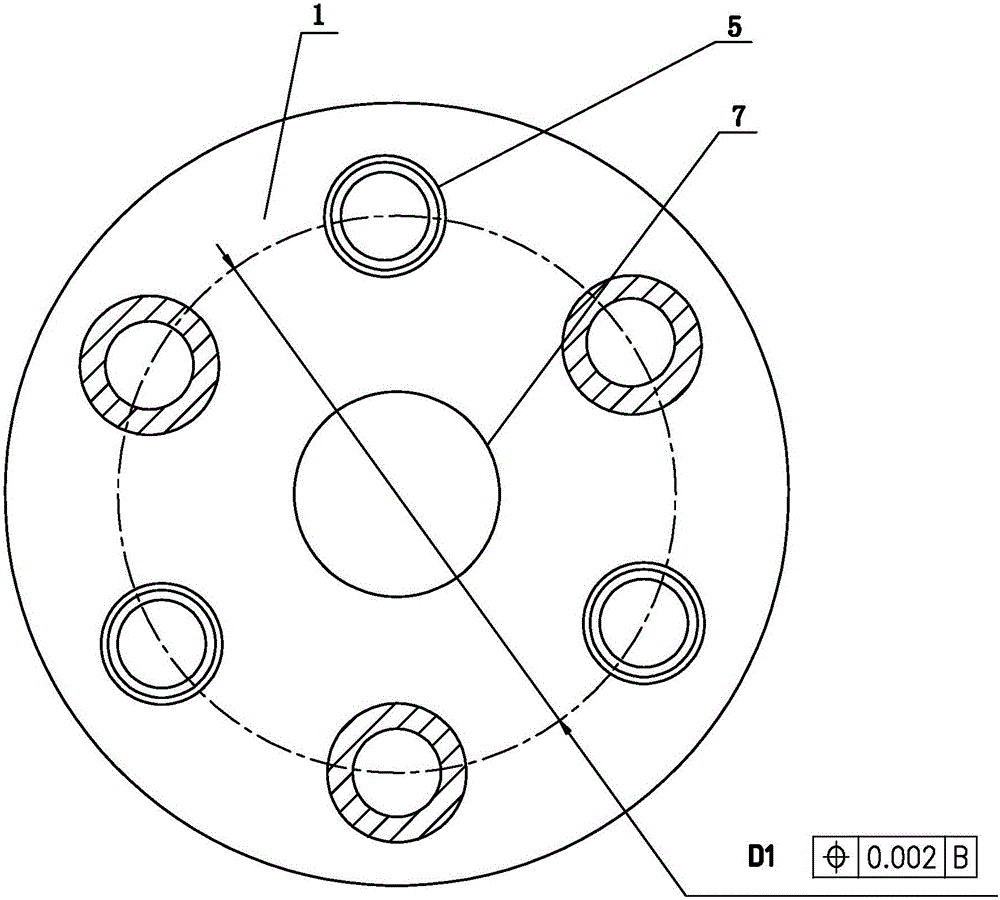

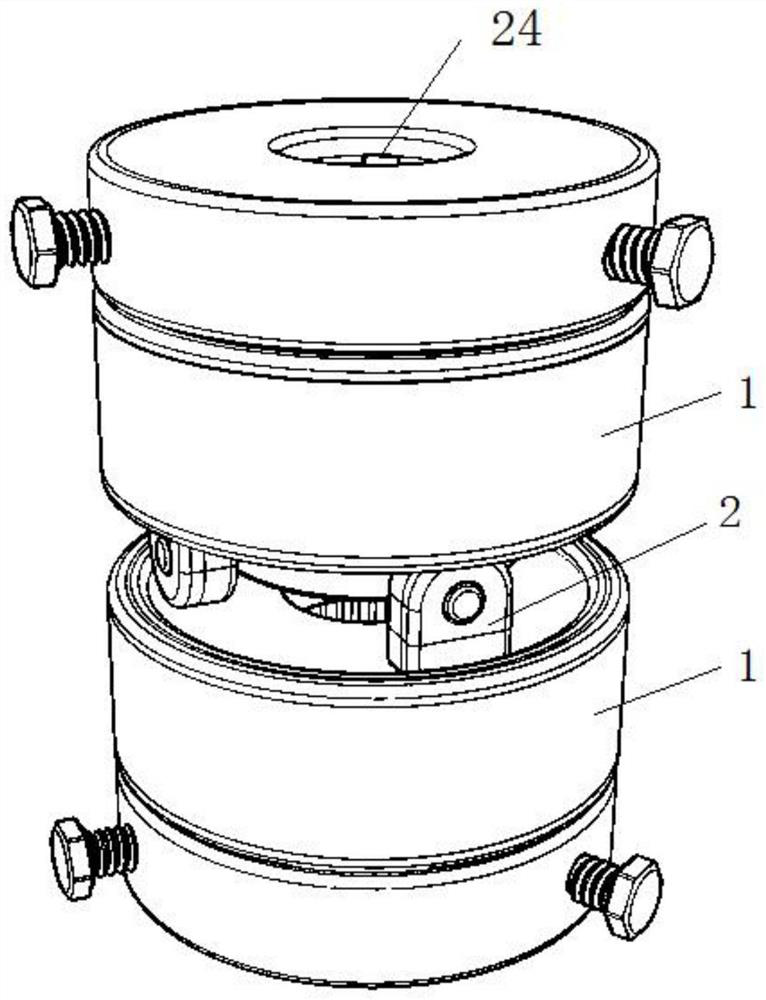

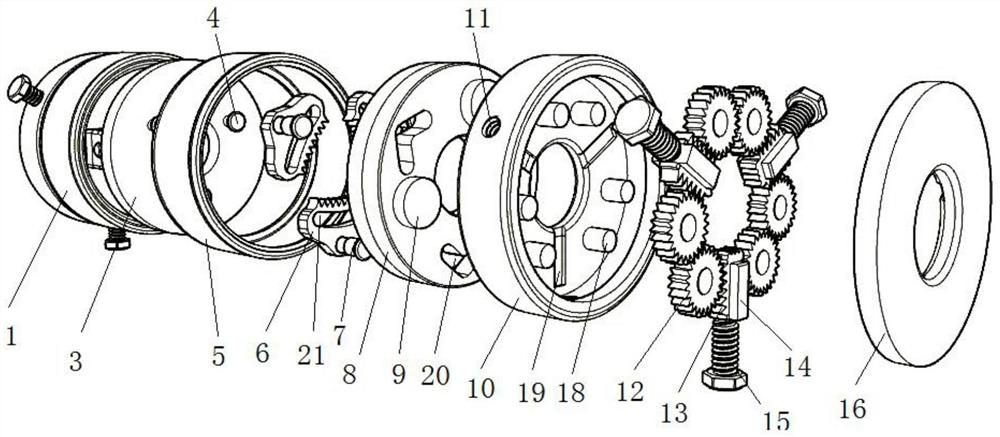

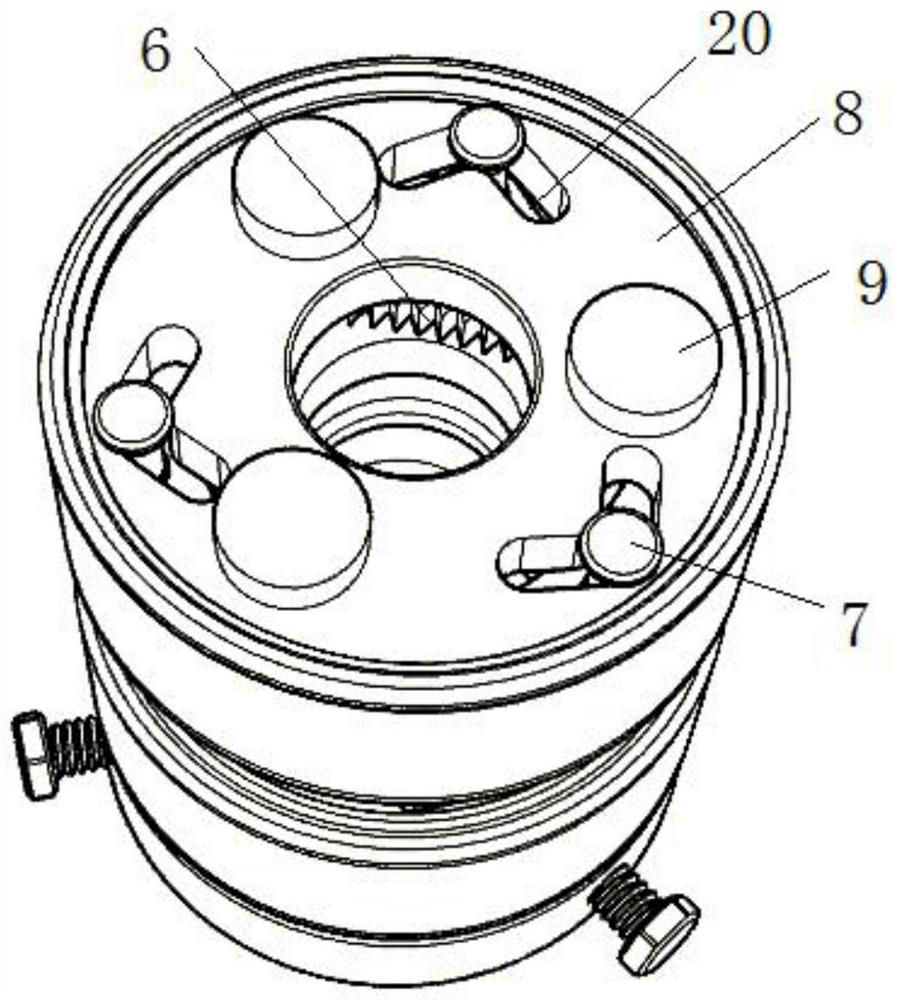

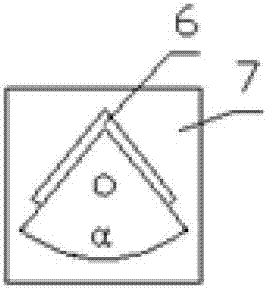

Moment motor structure

PendingCN106655592AGuaranteed coaxiality accuracyGuaranteed axial positioning accuracyStructural associationSupports/enclosures/casingsRubber ringBall bearing

The invention provides a moment motor structure. The structure comprises an outer shell, a motor shaft, a motor stator and a motor rotor. A front end surface of the outer shell is installed with a bearing pedestal. A rear end surface of the outer shell is installed with a bearing support seat. The structure is characterized in that a bottom of the bearing pedestal is installed with a group of angular contact ball bearings; the motor stator is fixed into the outer shell through a stator end cap; the motor shaft is installed with the motor rotor, a rotor fixing sleeve and a rotor fixing end cap; a deep groove ball bearing is installed in an inner hole of the bearing support seat; the inner hole of the bearing support seat is provided with a circular groove and a rubber ring is installed in the groove; an inner ring of the deep groove ball bearing is provided with a taper sleeve; and an outer section of the bearing support seat is fixedly installed with an encoder. In the invention, from aspects of a moment motor structure design and selection of a standard component, the structure is simple and reliable, the motor structure can be assembled without a special technology and a tooling and the structure is suitable for single one production and a small quantity of motor production.

Owner:北京摩诘创新科技股份有限公司

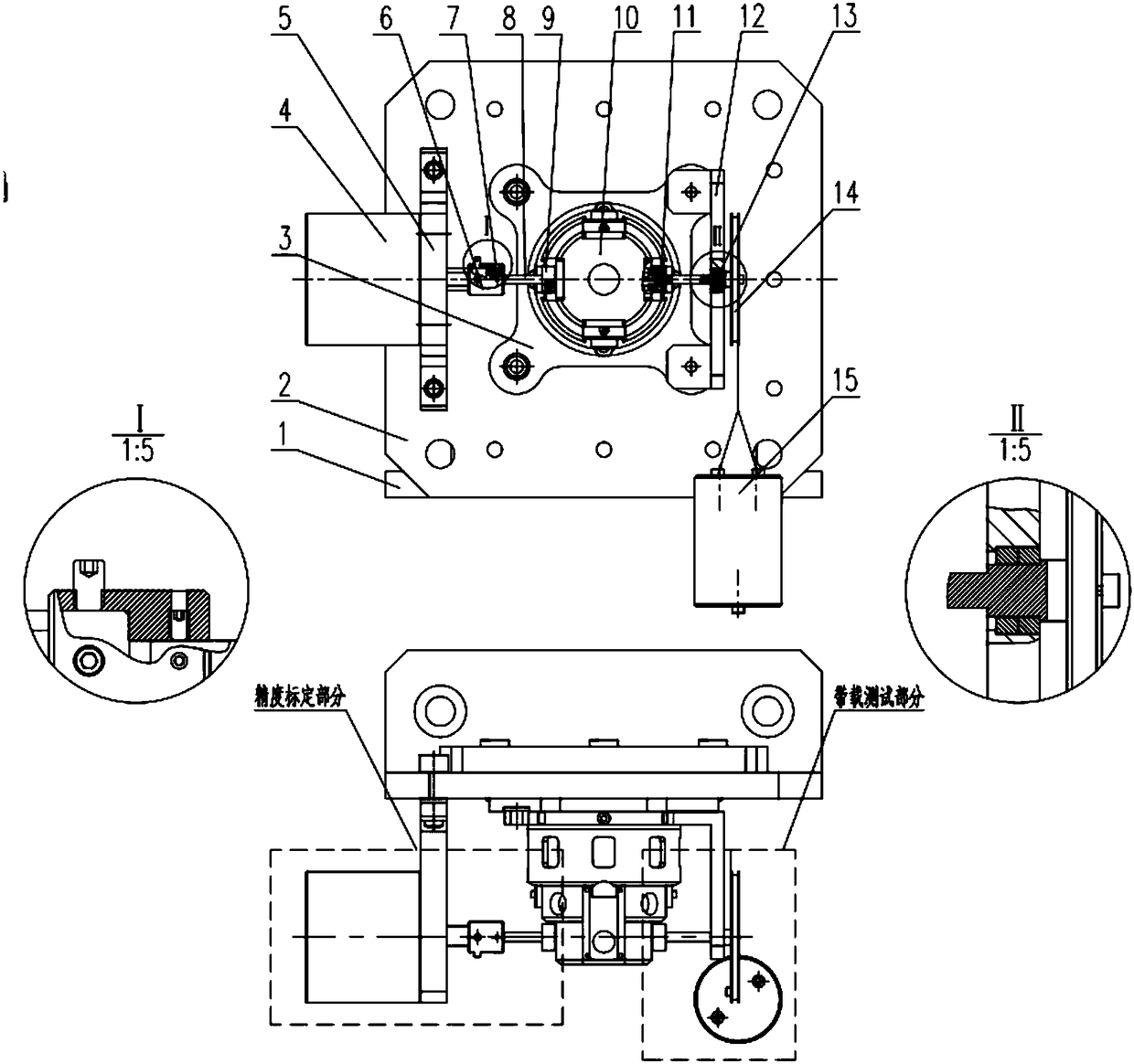

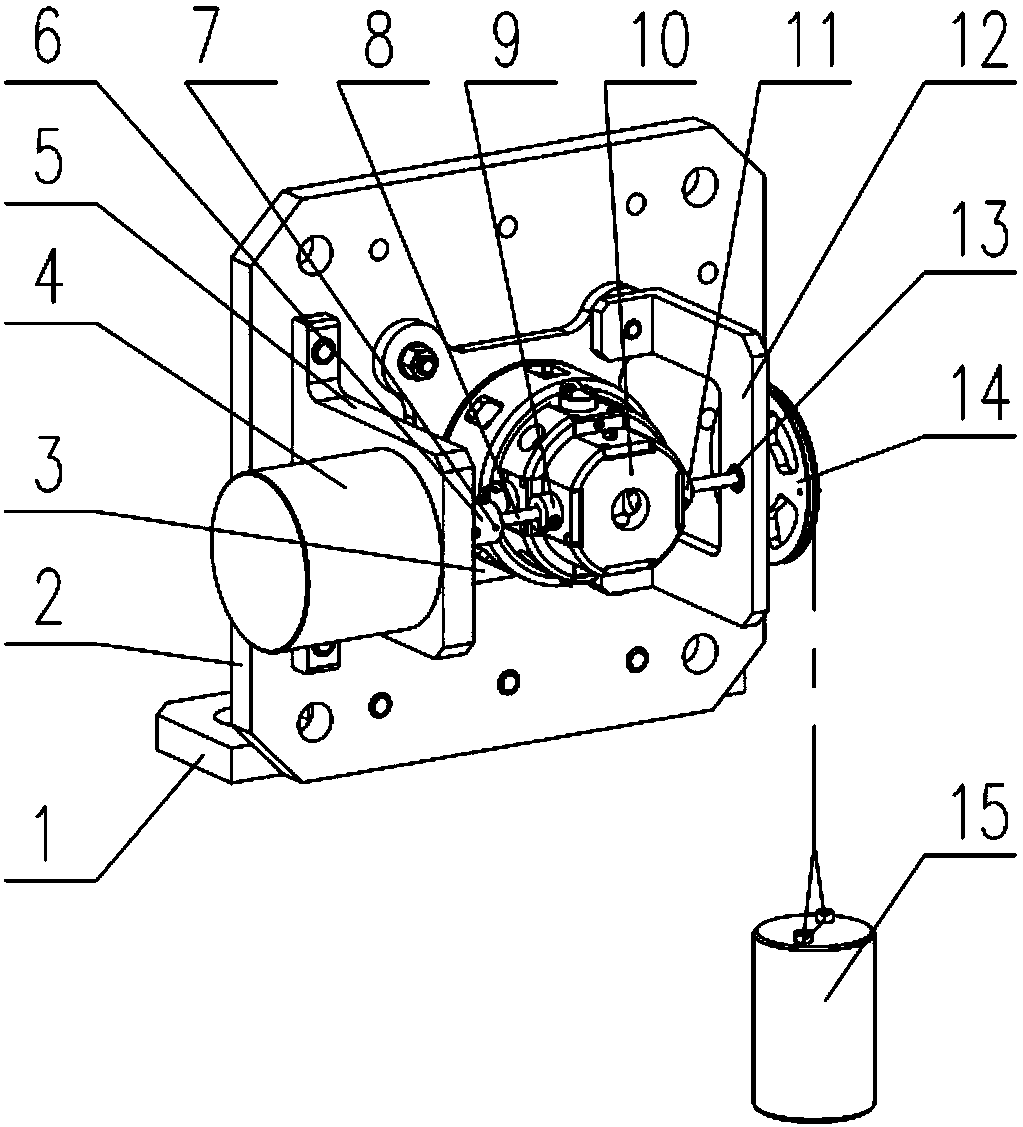

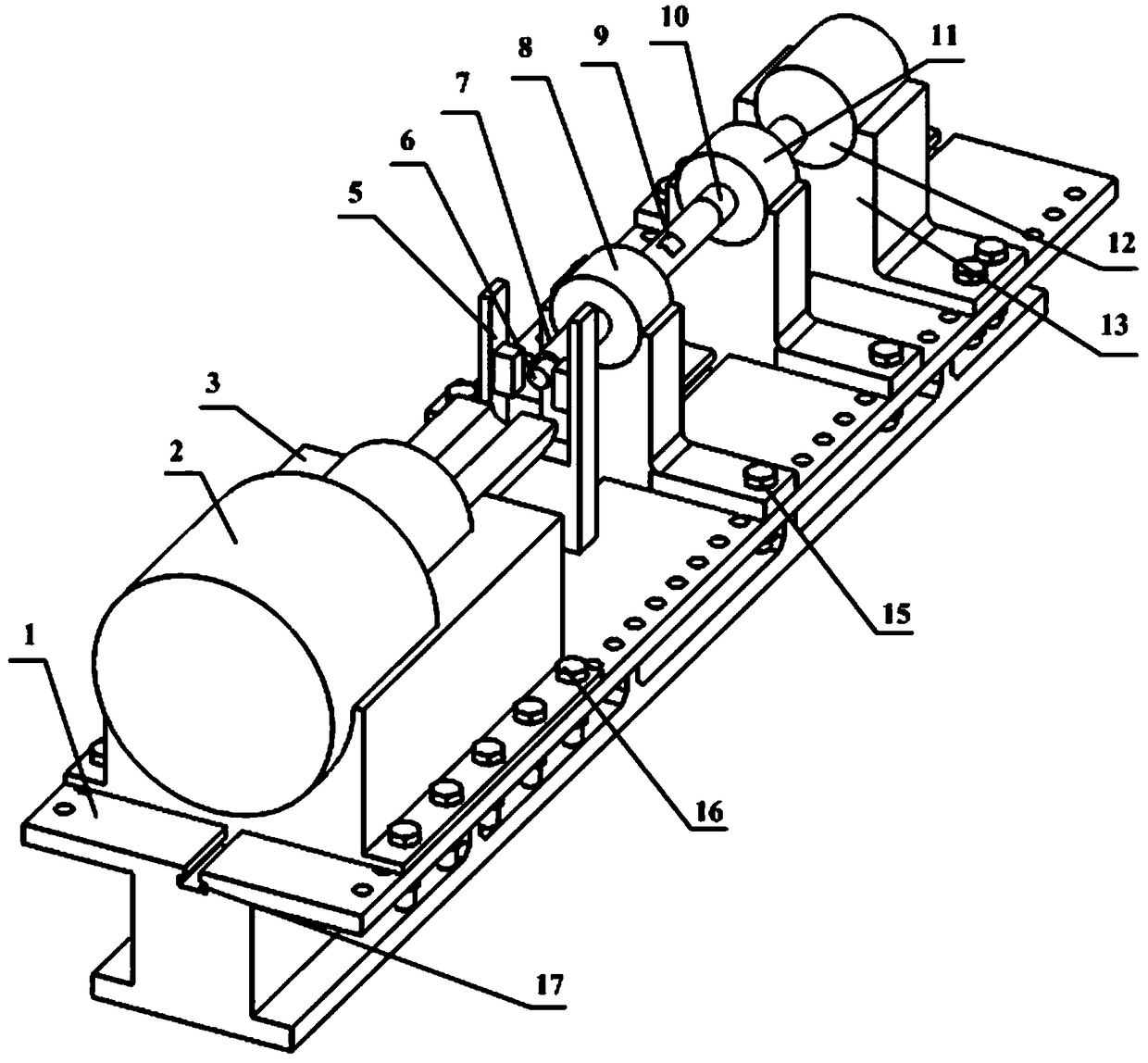

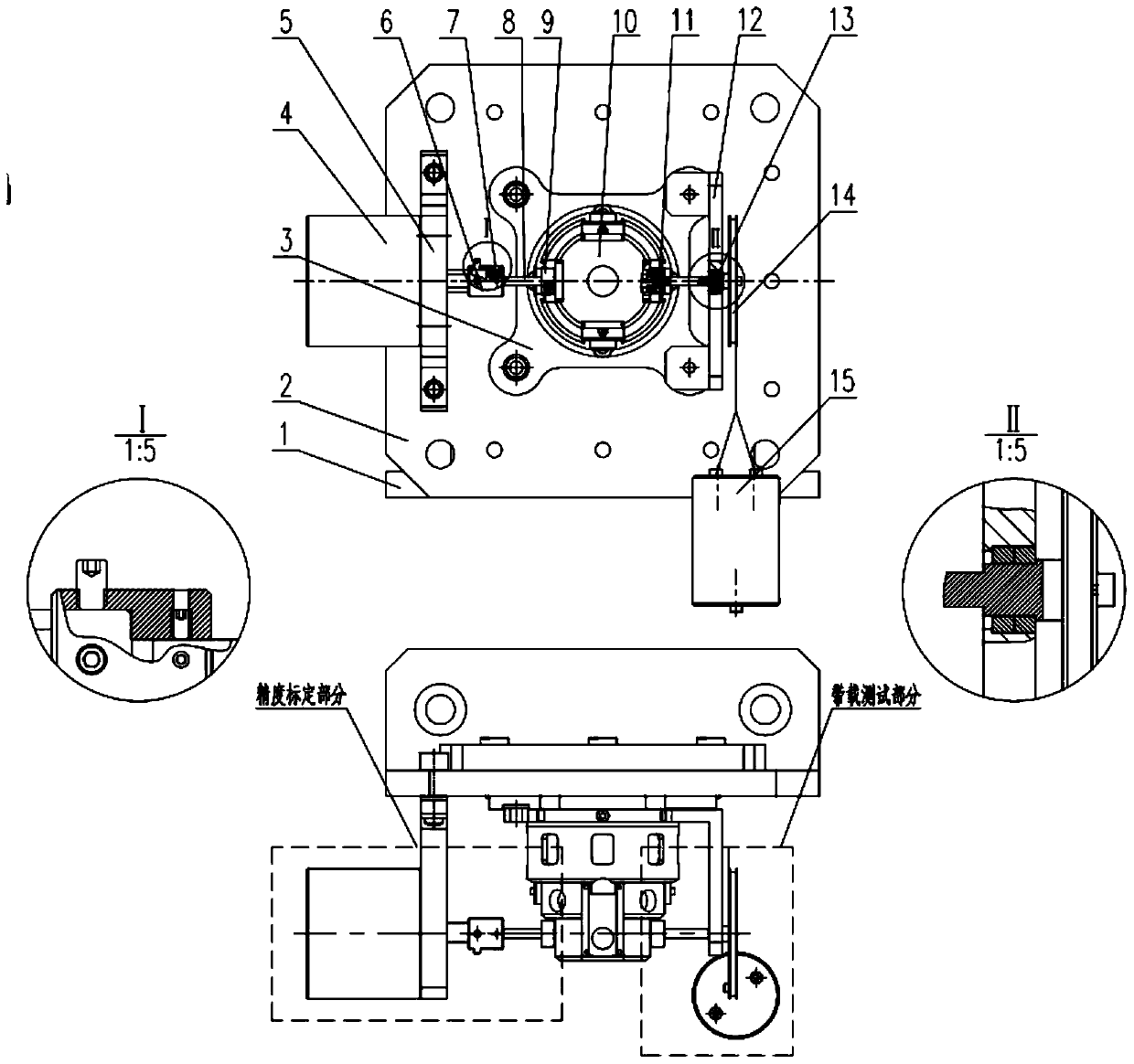

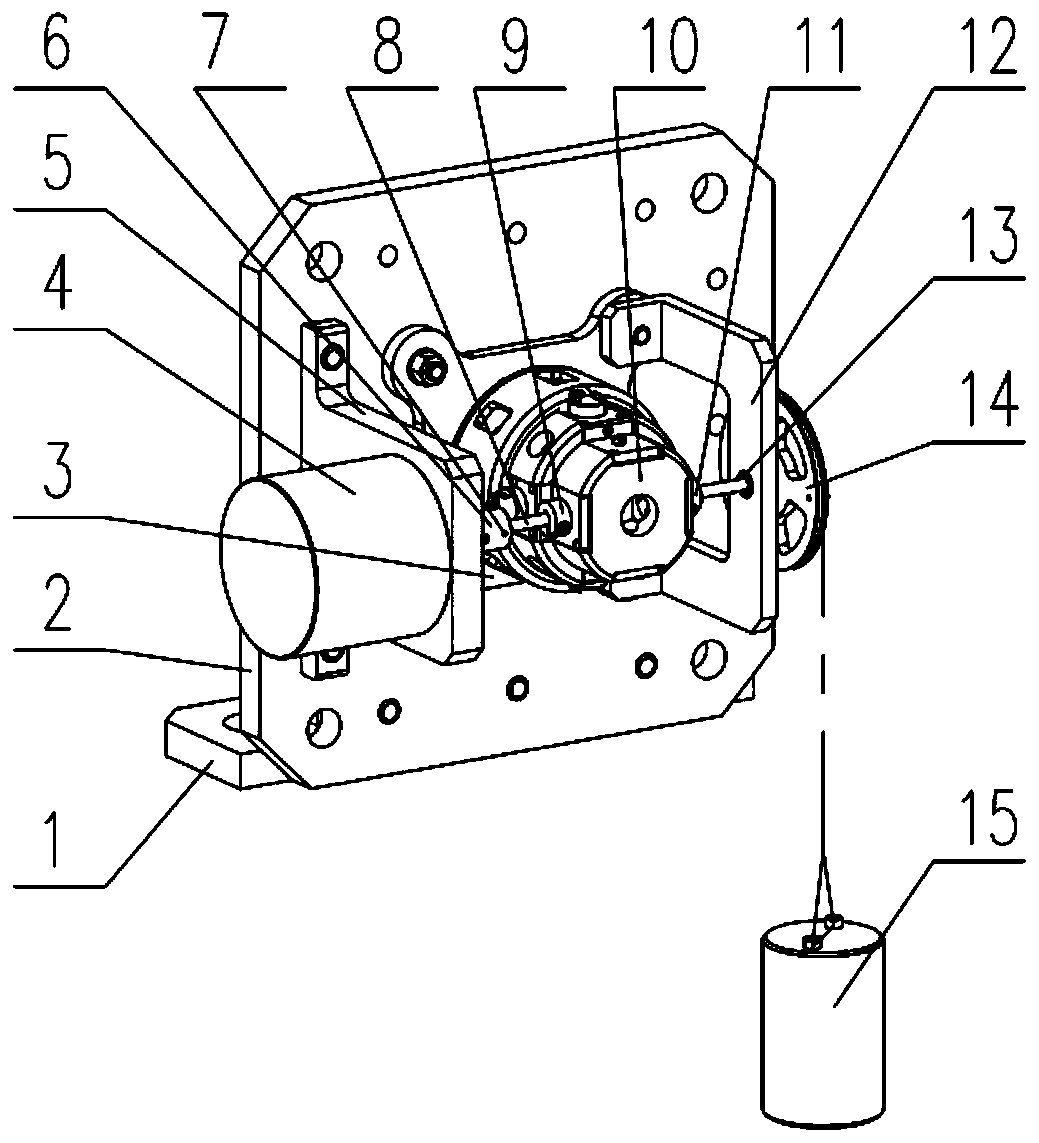

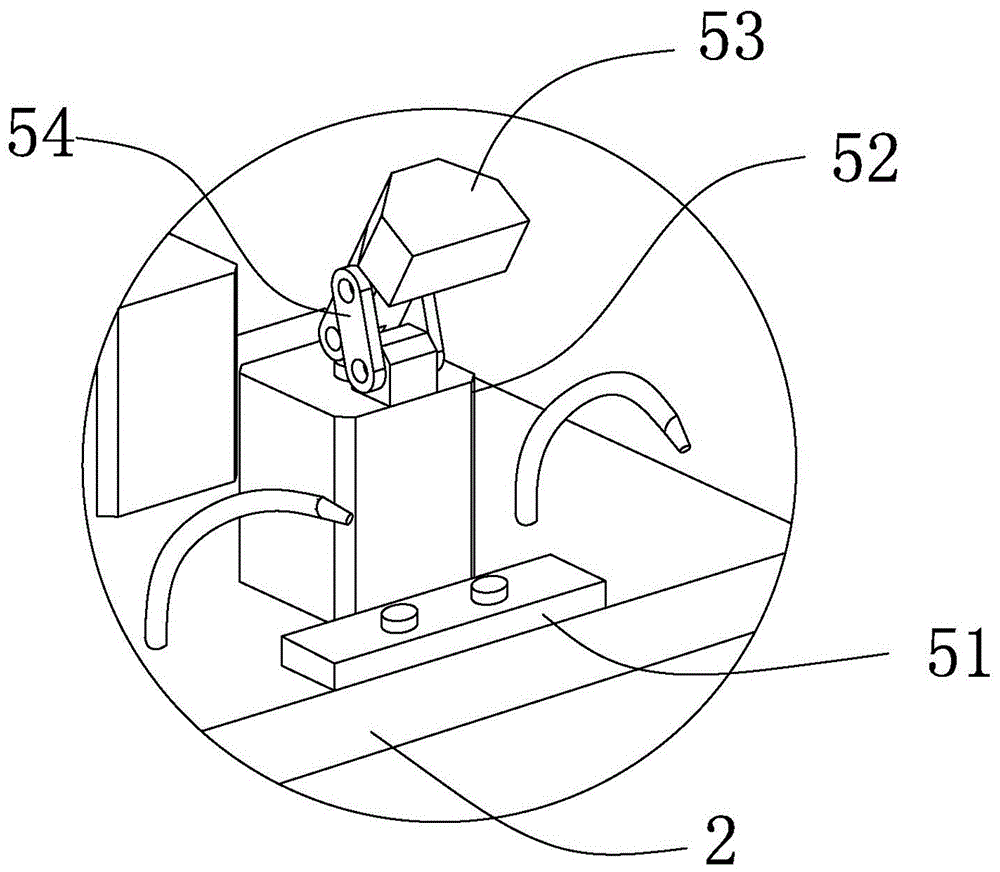

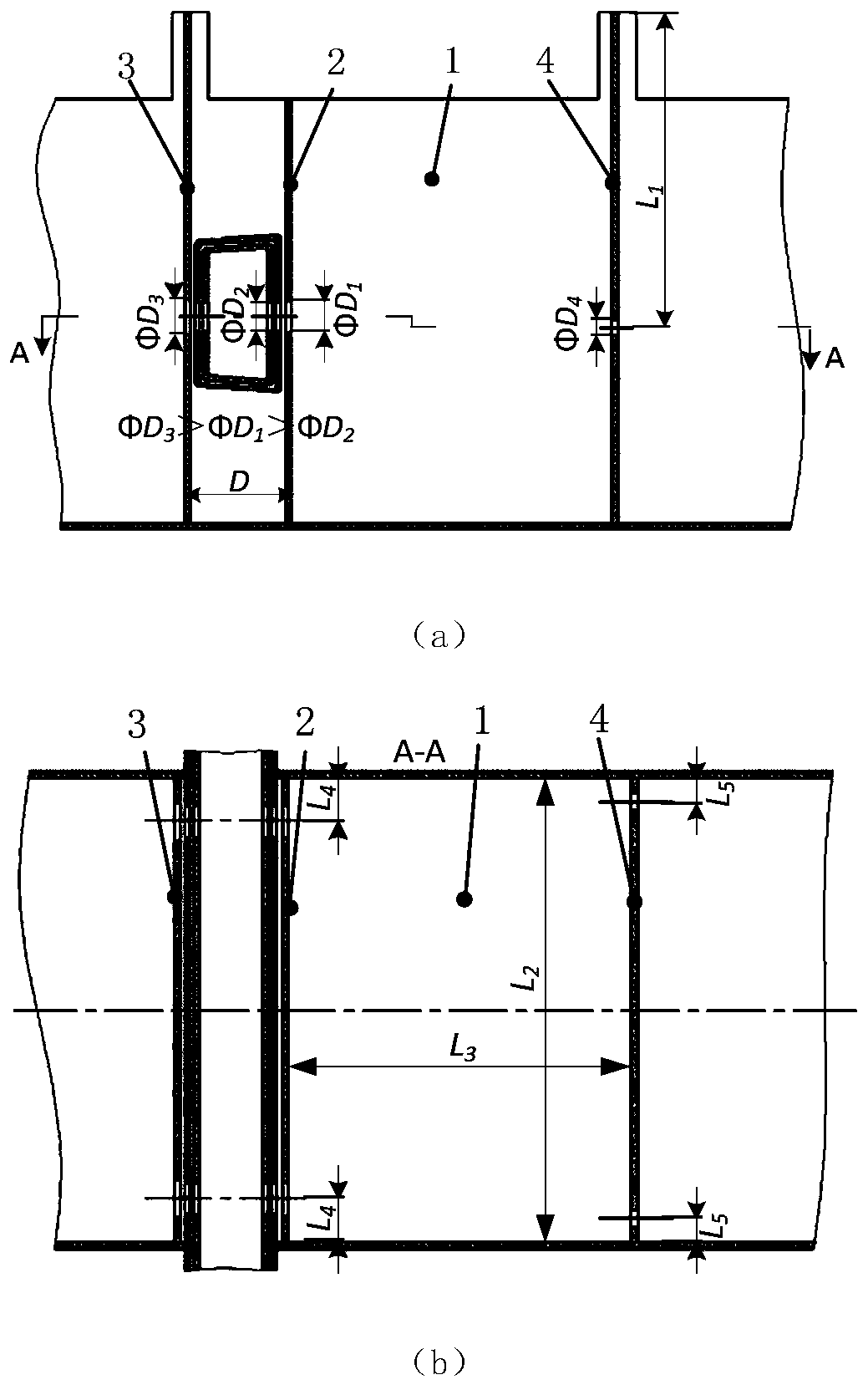

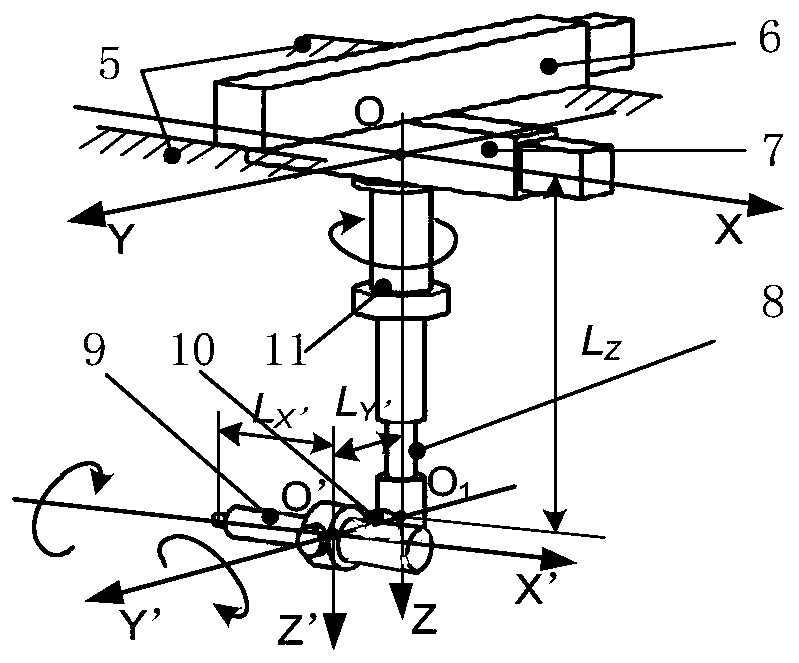

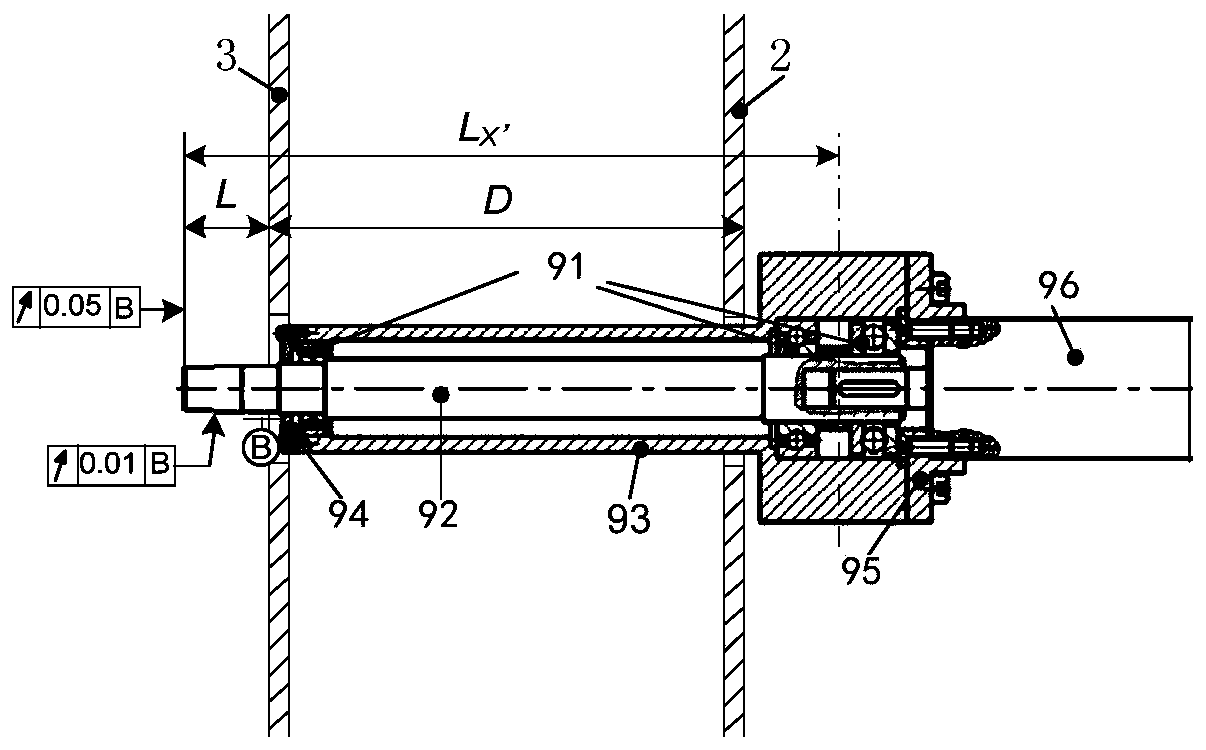

Device for on-load testing and precision calibration of steering engine component

ActiveCN108562452AAccuracy Calibration ImplementationHigh coaxial precisionStructural/machines measurementEngine testingControl theory

The invention relates to a device for on-load testing and accuracy calibration of steering engine component, and belongs to the technical field of high-precision steering engine testing. On the basisof the steering engine component and a substrate, the on-load testing part is coaxially connected with the output shaft of the one-way steering engine to test the rated load of the steering engine successfully; the precision calibration part is coaxially connected with the output shaft of the side one-way steering engine and achieves high coaxial precision, high-precision transmission angle and torque, so that the precision calibration of the steering engine is realized; the whole device can simultaneously realize the on-load testing and precision calibration of the steering engine component,has the advantages of simple structure, high integration level and convenient operation.

Owner:BEIJING AEROSPACE GUANGHUA ELECTRONIC TECH CO LTD

Process method for controlling welding deformation with high precision

InactiveCN111014994AGuaranteed coaxialityGuaranteed coaxiality accuracyWelding apparatusMarking outWeld seam

The invention discloses a process method for controlling welding deformation with high precision. The process method is embodied in effective control of form and location tolerance in a welding structure, and comprises a preparation stage, a positioning stage and a welding stage. In the preparation stage, a trunnion block combination and a fan-shaped block are machined and assembled respectively,and a weld groove is machined; in the positioning stage, a position of a trunnion is aligned, and then a marking device is arranged, so that the offset condition of the trunnion is conveniently detected in the welding stage; in the welding stage, welding is conducted in a symmetrical and synchronous mode, deformation conditions are monitored by means of marks and a dial indicator, and welding parameters are adjusted in real time. The process method changes the conventional process, finish machining of the two trunnion parts is firstly completed, then assembling and welding are conducted on thesame, the welding stress is made to be in a relatively low and symmetrical balance state by adopting a high-precision detection control method, a reasonable welding sequence and a flexible control means, and therefore the purposes of controlling connection deformation and guaranteeing the workpiece precision are achieved.

Owner:YANTAI GUOYE METALLURGICAL WATER COOLED EQUIP CO LTD

Process for high precision control of welding deformation

InactiveCN110421284AGuaranteed coaxialityGuaranteed coaxiality accuracyWelding/cutting auxillary devicesAuxillary welding devicesPosition toleranceEngineering

The present invention discloses a process for high precision control of welding deformation, the process is embodied in the effective control of the form and position tolerances in a welding structure, and the process comprises a preparation stage, a positioning stage and a welding stage. The preparation stage comprises: performing the processing and assembling respectively for a trunnion block assembly and a fan-shaped block, and processing weld grooves; the positioning stage comprises: aligning the position of a trunnion in a positioning stage, and arranging a marking device in order to check the deviation of the trunnion in a welding stage; and the welding stage comprises: conducting welding in a symmetric and synchronous manner, monitoring the deformation by use of marks and a dial indicator and adjusting the welding parameters in real time. The present invention changes conventional processes: firstly fine finishing is completed for two trunnion parts, then assembling and weldingare performed; by use of a high-precision detection control method, a reasonable welding sequence and flexible control measures, welding stress is kept relatively low and symmetrical, and thus the purposes of controlling welding deformation and ensuring the workpiece accuracy are achieved.

Owner:烟台众扬冶金设备有限公司

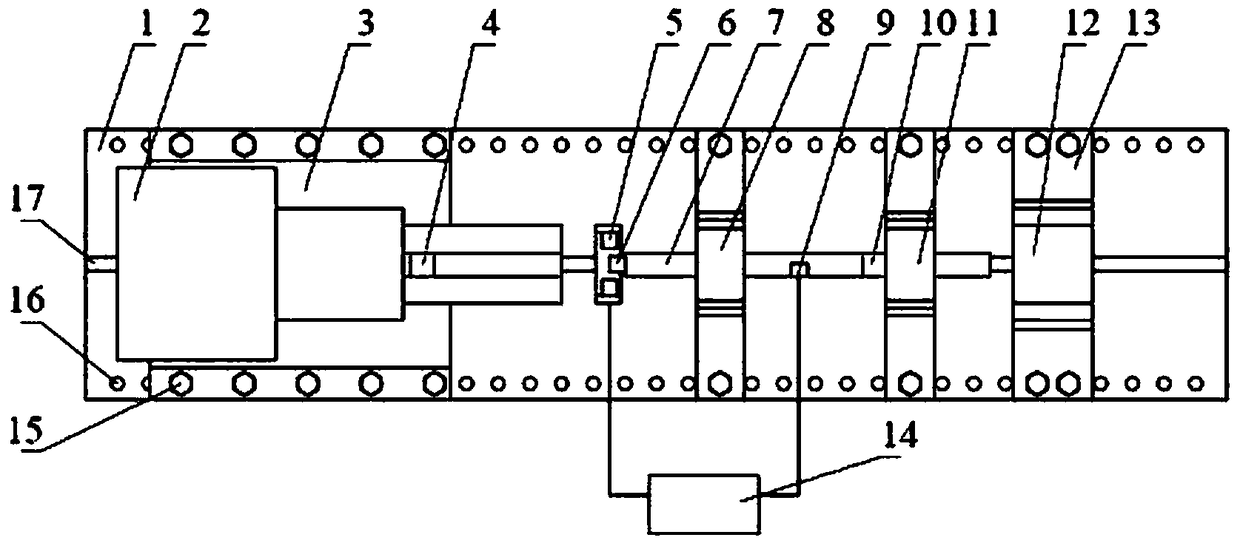

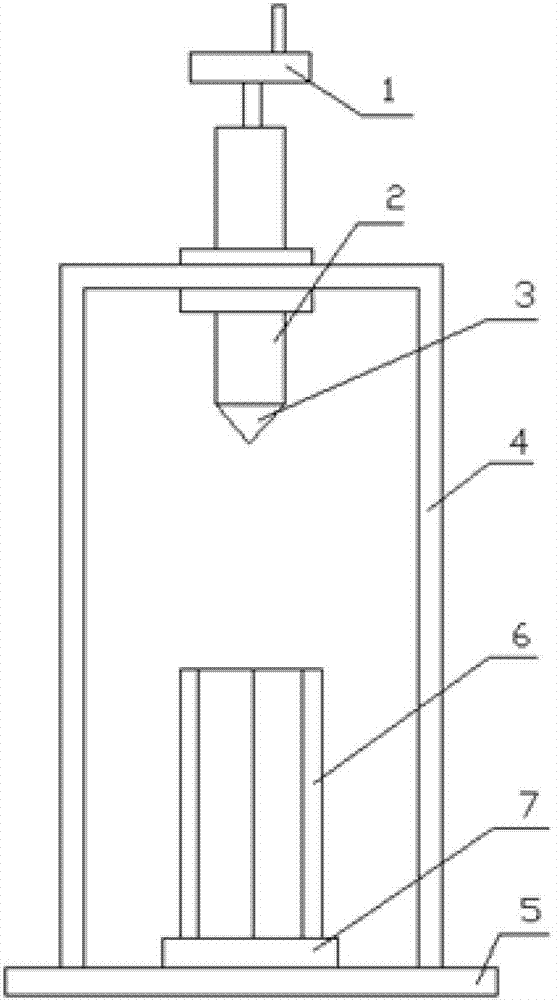

SHPB device and method for achieving ultra-high controllable strain rate impact

The invention discloses an SHPB device and method for achieving ultra-high controllable strain rate impact. The device comprises structures of a guiding rail with a T-shape groove, a light gas gun loading mechanism, a light gas gun base, a bullet, a magnetic electricity type particle velocity measuring device, a testing member, an output rod, an output rod fixing device, a strain piece, an absorbing rod, an absorbing rod fixing device, a damping device, a damping device fixing device, a data processing system and the like; the device is characterized in that the impacting on the testing memberof an incidence rod is replaced with the direct impacting on the testing member by the bullet, the particle velocity of the testing member at the incidence end is measured by the magnetic electricitytype particle velocity measuring device, the average stress, strain rate and strain of the testing member are obtained according to unidimensional stress wave assumption and uniform distribution assumption of the stress / strain of a short testing member along the length of the short testing member, and the coaxiality of the device is ensured by the T-shaped groove and bolt connection cooperative action. By means of the device and the method, controllable and ultra-high strain rate (107s<-1> scale) loading can be achieved within a larger range (104-107s<-1> scale), the debugging efficiency canbe improved, the structure is simple, and the dynamic mechanical performance of a material under the ultra-high strain rate is obtained conveniently and rapidly.

Owner:UNIV OF JINAN

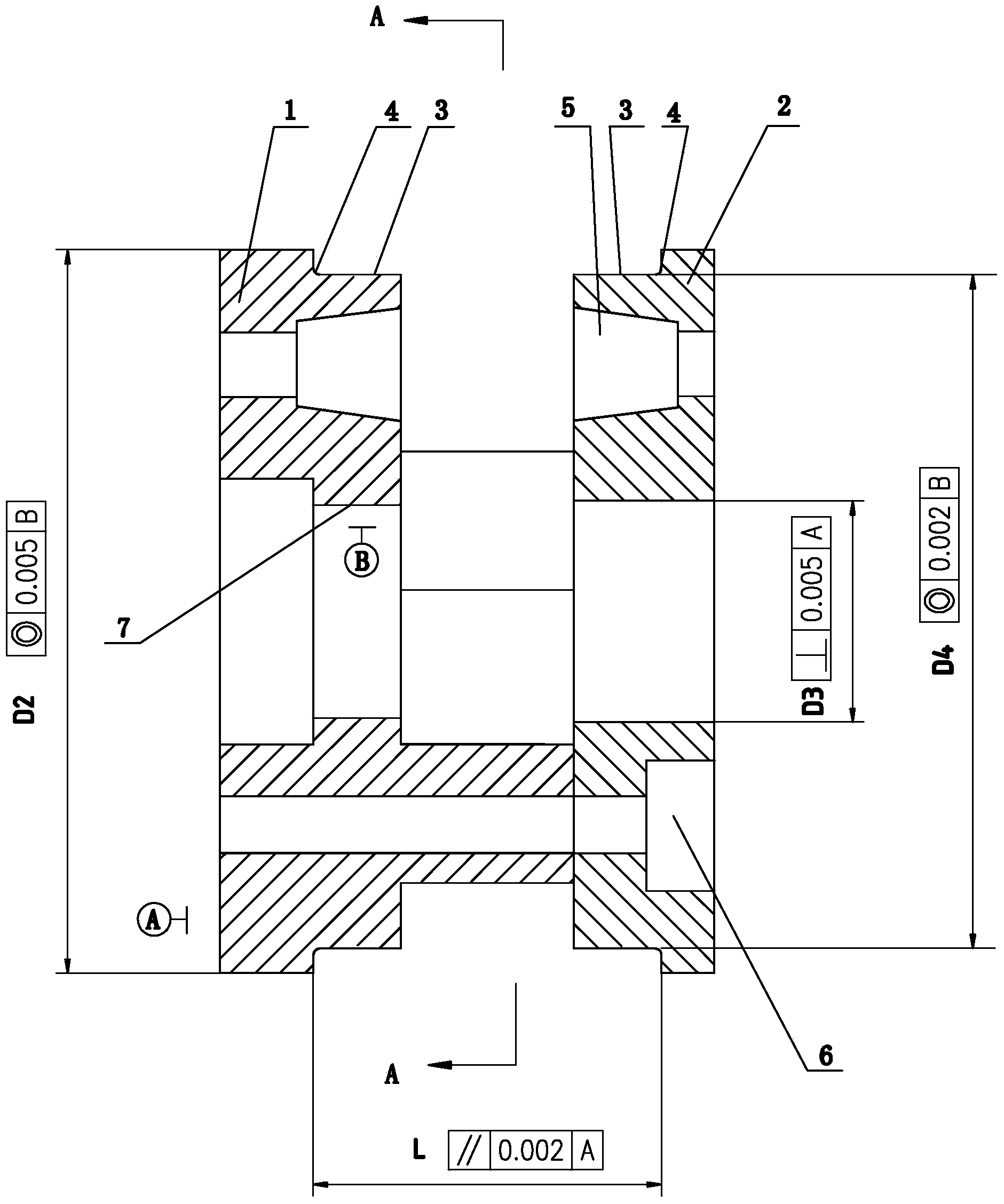

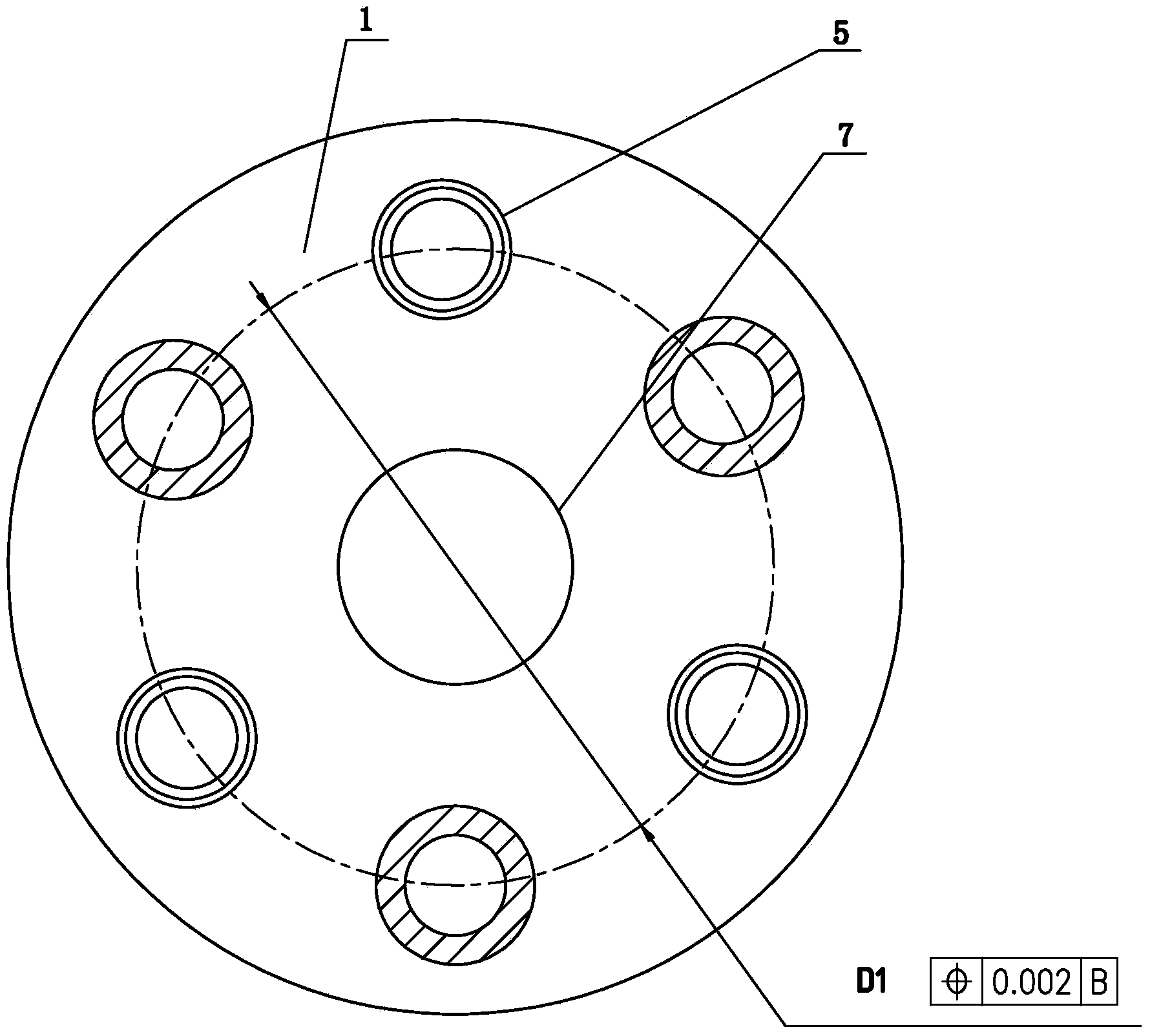

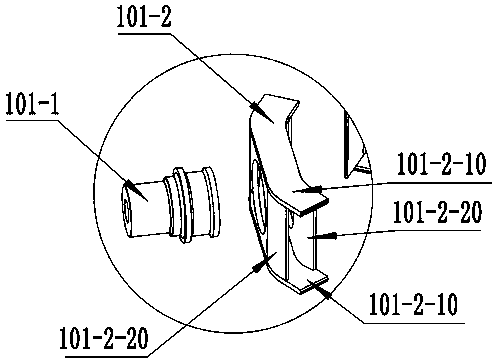

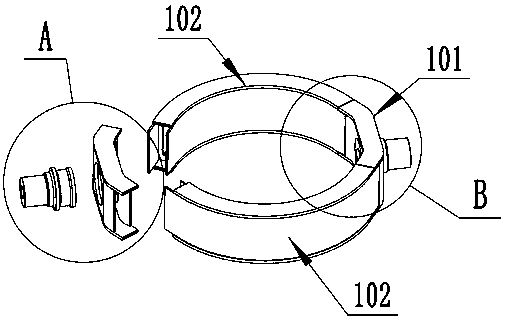

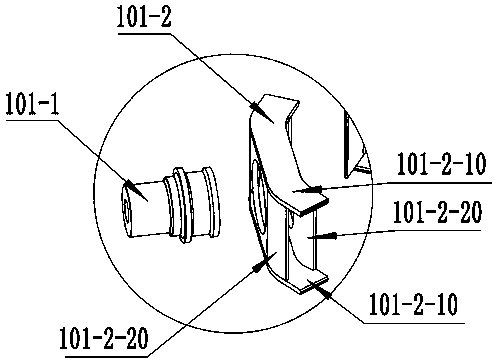

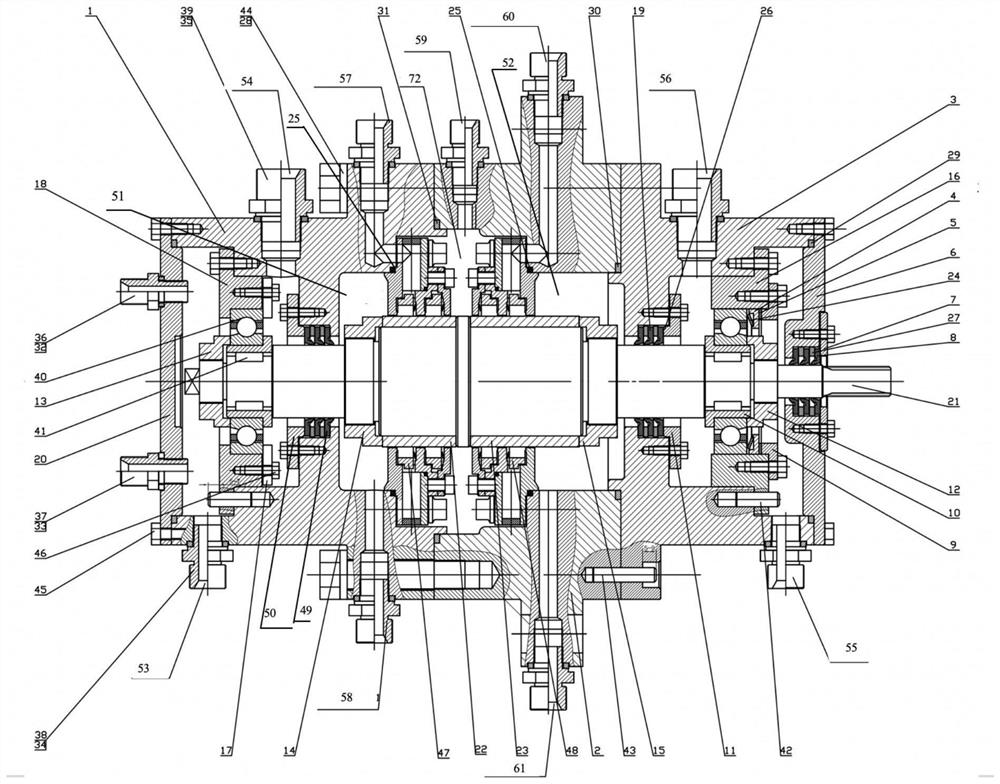

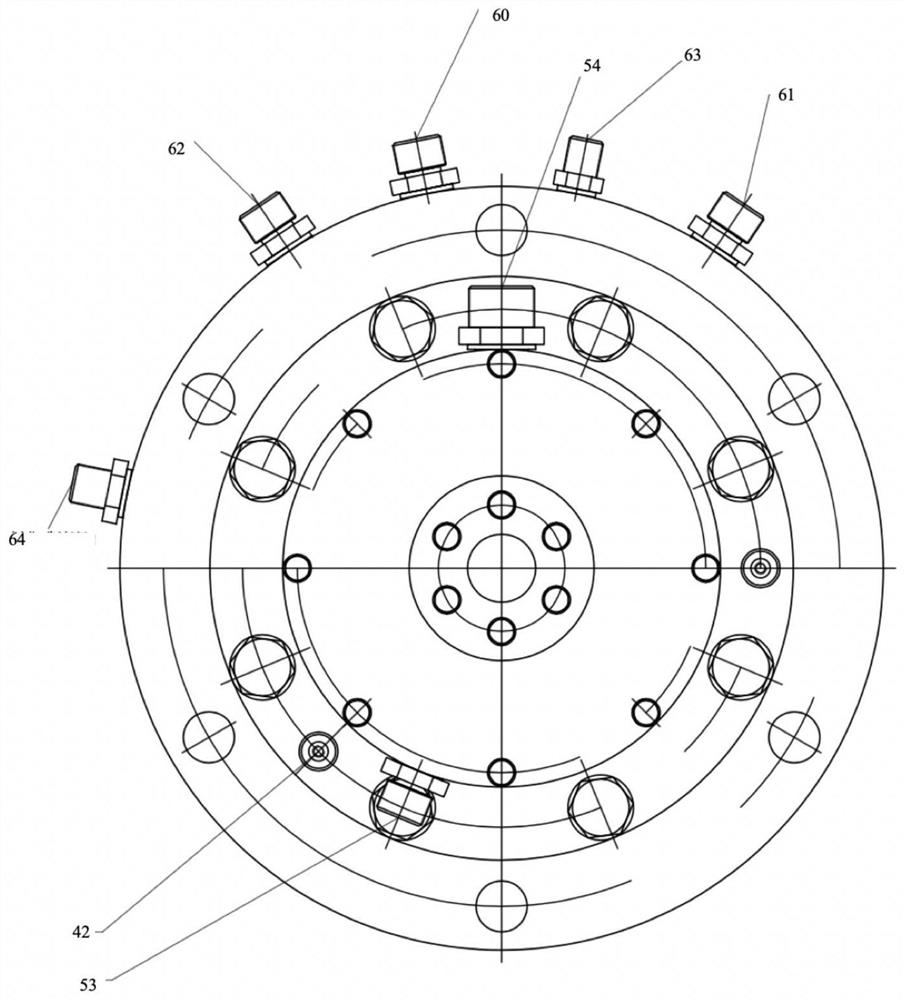

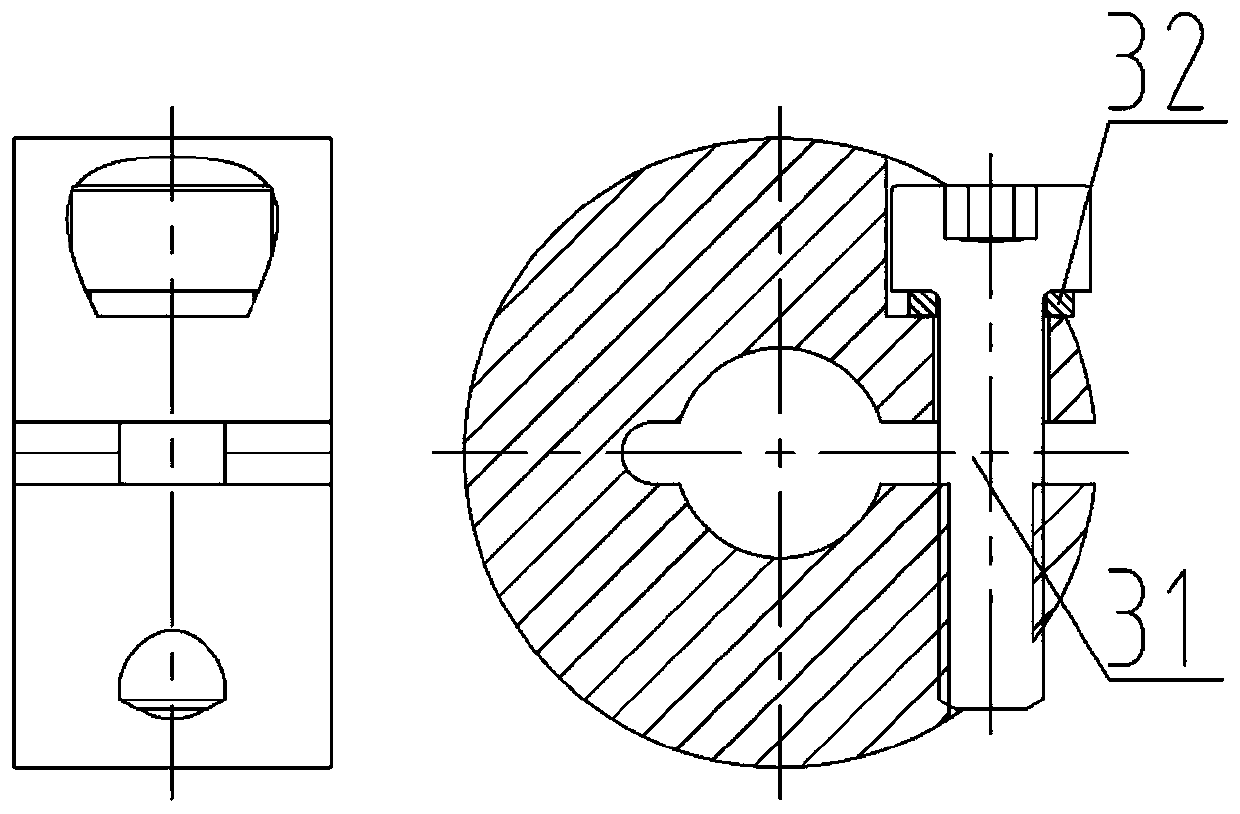

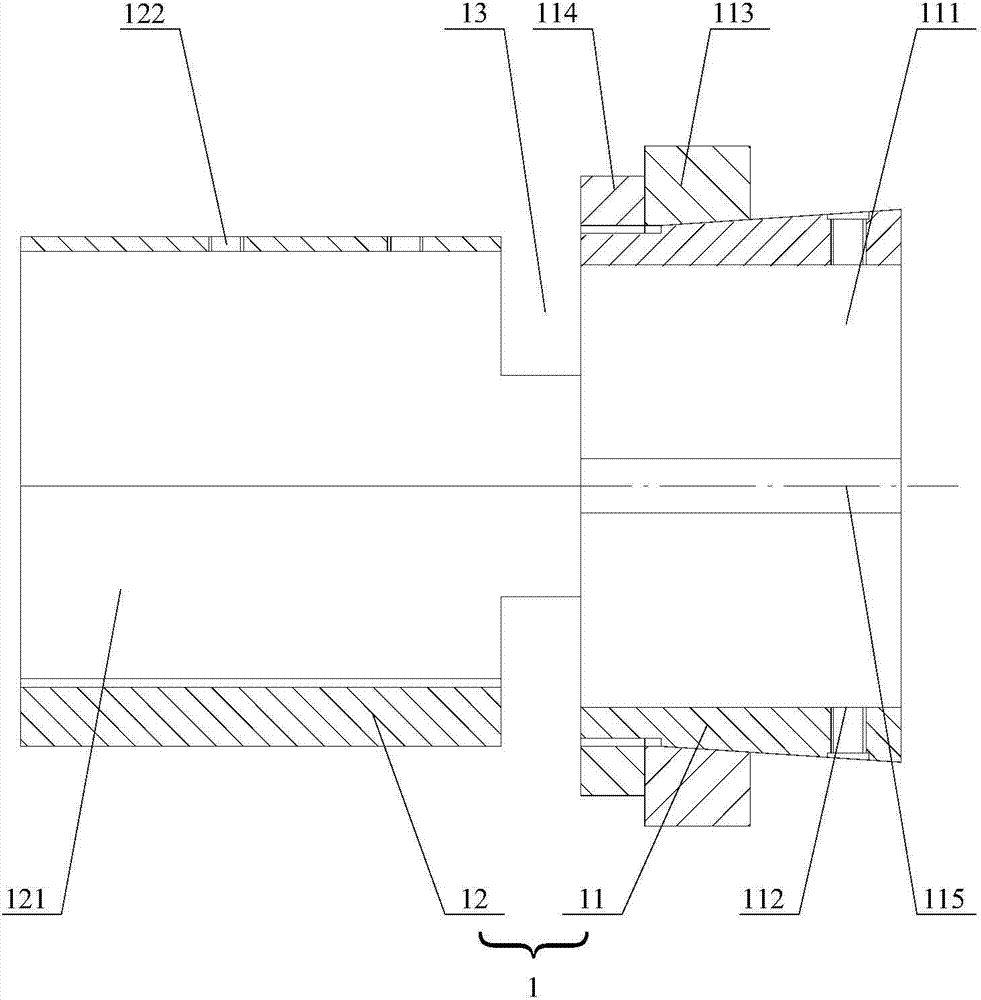

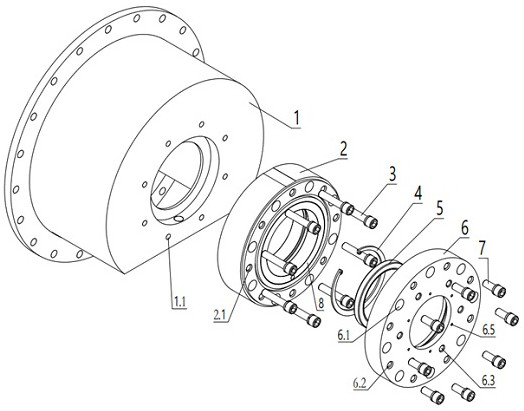

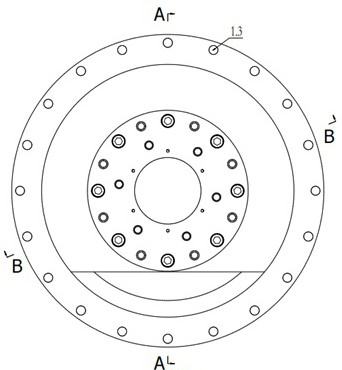

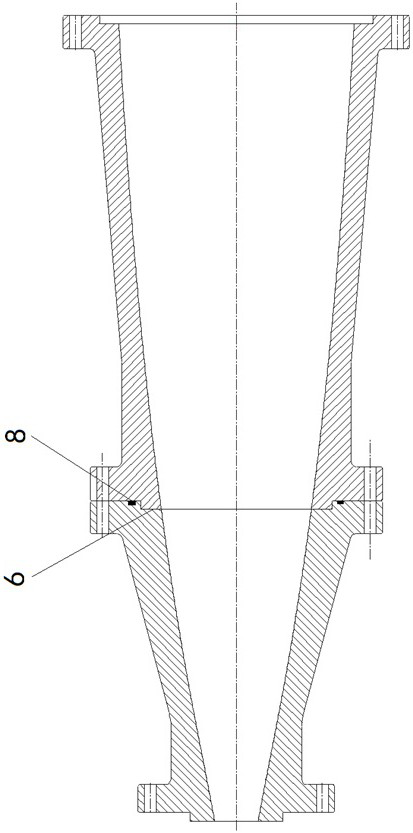

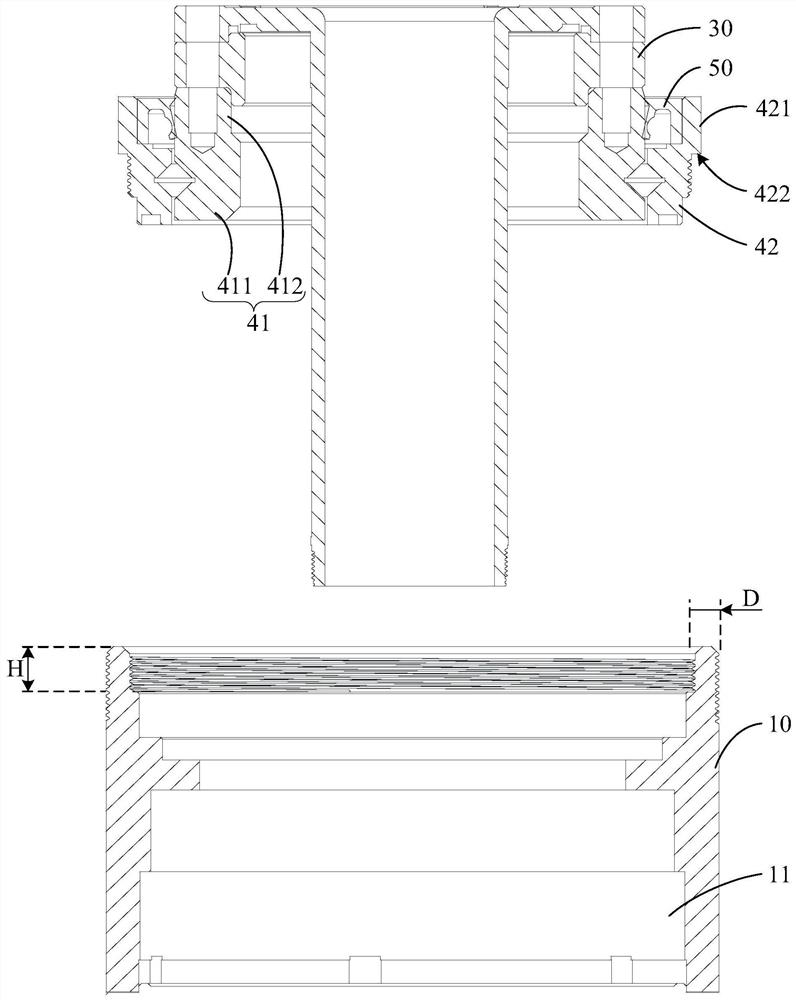

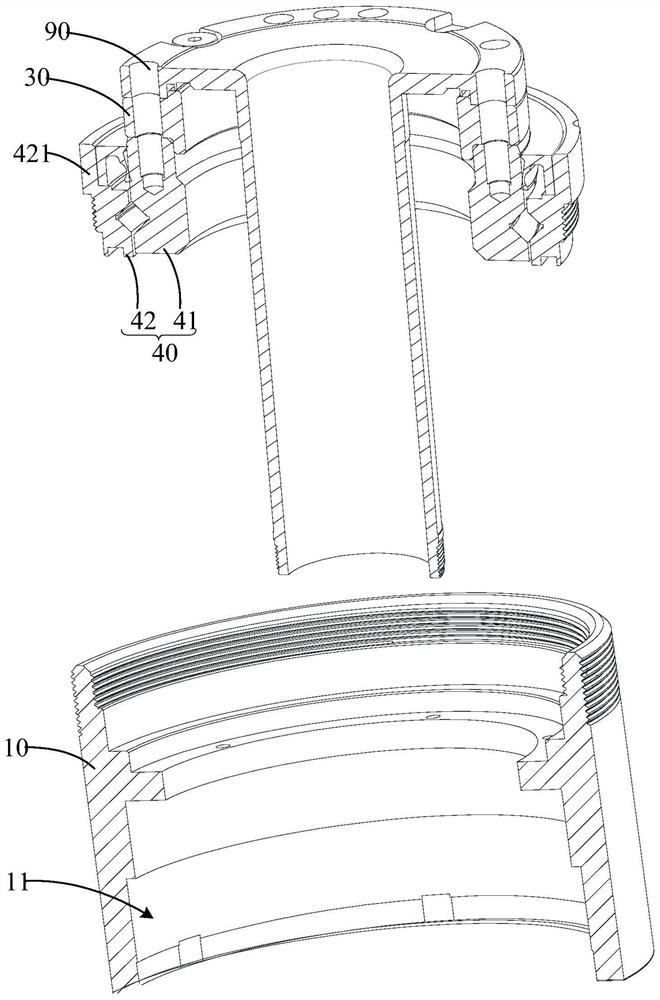

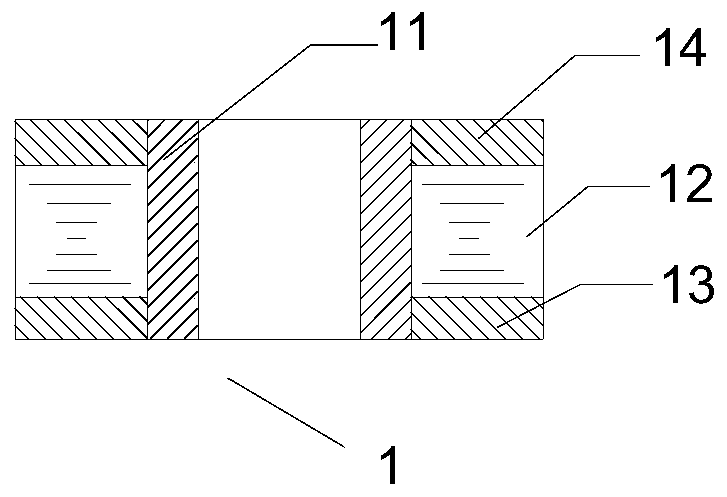

A low-temperature high-speed end-face sealing test device for a liquid rocket engine turbo pump

The invention discloses an end face sealing test device for a liquid rocket engine turbine pump under a low-temperature and a high-speed. The device is applied to a sampling test of an end face sealing assembly of a rocket engine of a liquid hydrogen liquid oxygen propellant, in a running-in test and a research performance test, an end face sealing assembly product ( such as an engine static ringassembly and an engine moving ring ) is assembled in the test device of the invention, a working environment of the engine turbine pump is simulated, the sealing performance and the structural rationality of the sealing assembly product are checked, and the sealing performance of the sealing assembly product can be quantitatively detected. According to the device, the test device does not contractand deform under a low-temperature environment, and runs stably at a high speed, the device provides an important basis for improving various problems in the design of the end face sealing assembly product.

Owner:BEIJING AEROSPACE PROPULSION INST

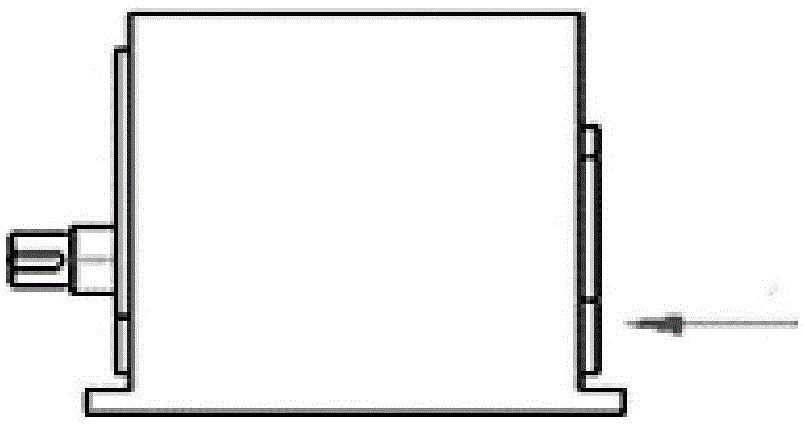

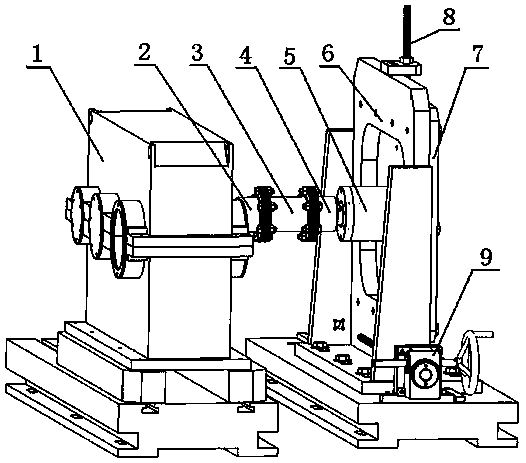

Automobile transmission assembly fatigue life test bench

The invention discloses an automobile transmission assembly fatigue life test bench, which relates to the technical field of automobile part manufacturing. The automobile transmission assembly fatiguelife test bench comprises a speed-up box, a speed-up box output end flange, a coupling, a cylinder input end flange, a cylinder assembly and a support assembly, wherein the support assembly comprisesa support body; the support body is provided with a horizontal through hole; the horizontal through hole is internally provided with a sleeve; the sleeve is fixed in the support body through screws;the right end surface of the support body is provided with a cylindrical boss; the boss is connected with a mounting plate with a groove matched with the boss; the cylinder assembly is provided with astepped shaft; and the stepped shaft is fixed in the horizontal through hole through the bearing. The problem of a long bench debugging process at an early stage of the current automobile transmission assembly fatigue life test can be solved.

Owner:柳州上汽汽车变速器有限公司

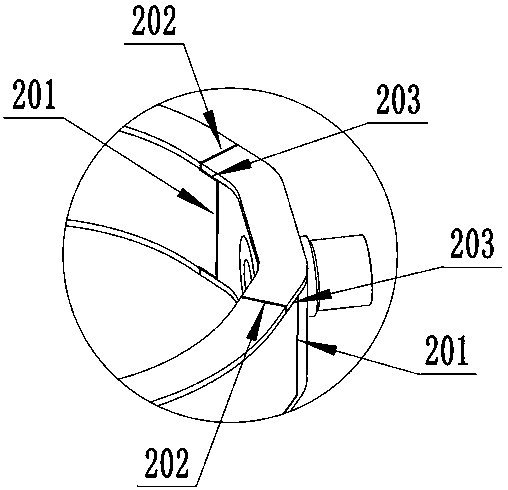

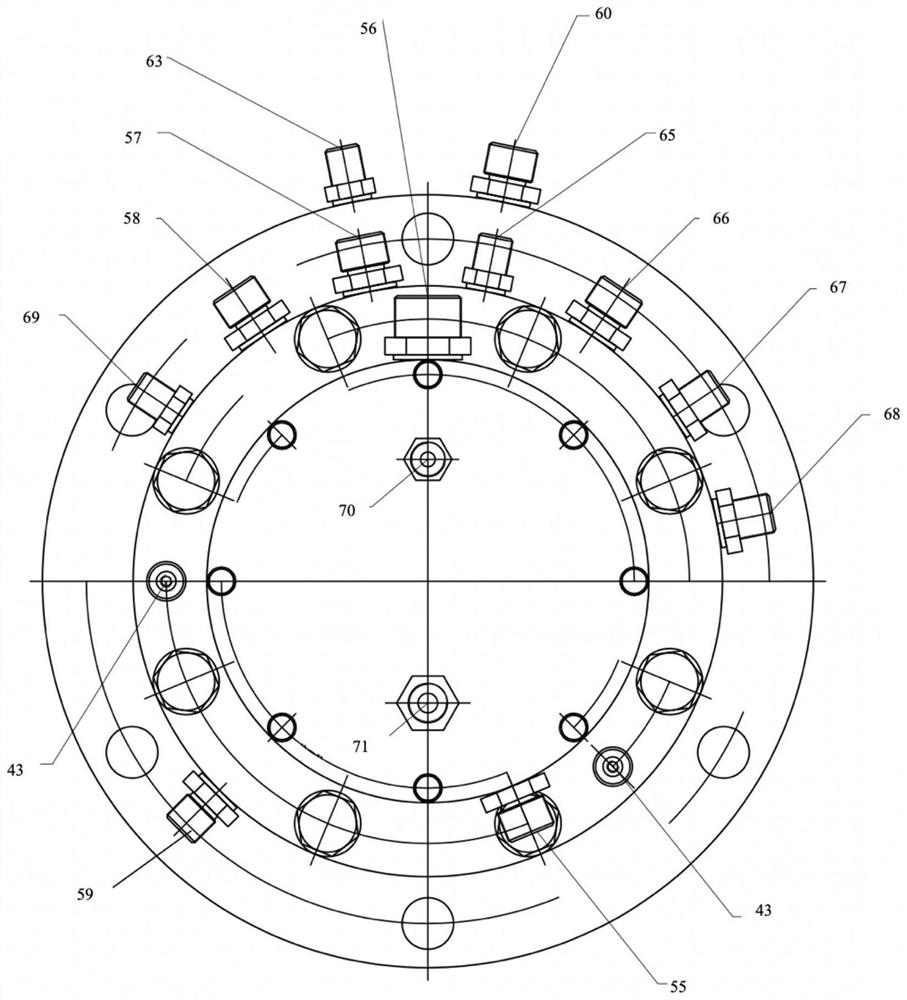

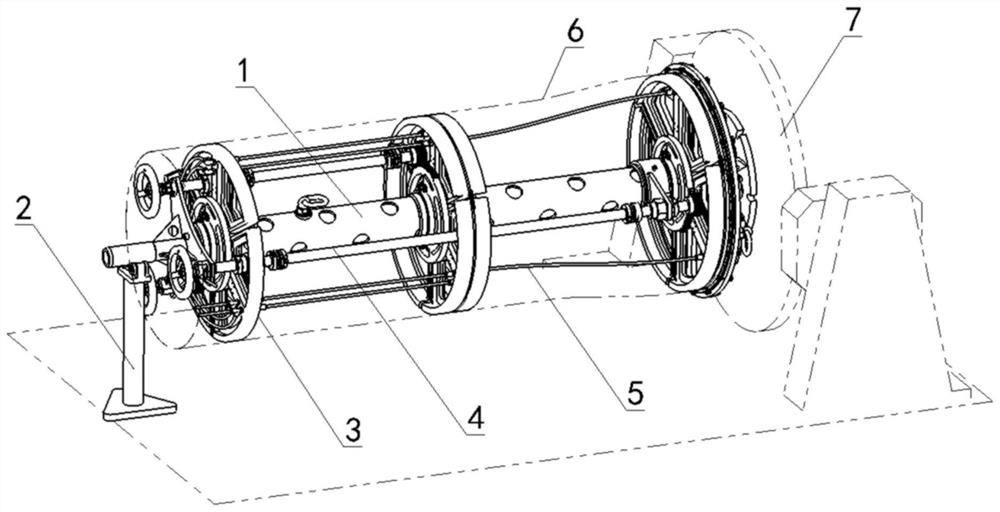

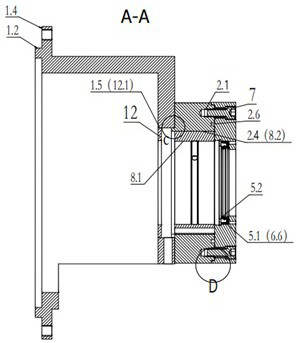

A low-temperature high-speed floating ring sealing test device for rocket engines

The invention provides a low-temperature and high-speed floating ring sealing test device for a rocket engine, which includes a casing, which includes a casing I, a casing II and a casing III; a stepped main shaft arranged inside the casing; The front floating ring seal assembly and the rear floating ring seal assembly; the front floating ring seal assembly and the rear floating ring seal assembly form a test chamber in the housing II. The low-temperature and high-speed floating ring sealing test device for a rocket engine according to the present invention has strong functionality, good compatibility, good performance at low temperature and high speed, and can carry out various low-temperature sealing tests of floating rings, which can verify the integrity of the floating ring assembly. The sealing performance can also be used to assess the rationality of the floating ring structure.

Owner:LANDSPACE TECH HUZHOU CO LTD

Aircraft engine exhaust funnel circular seam laser welding clamp and welding method

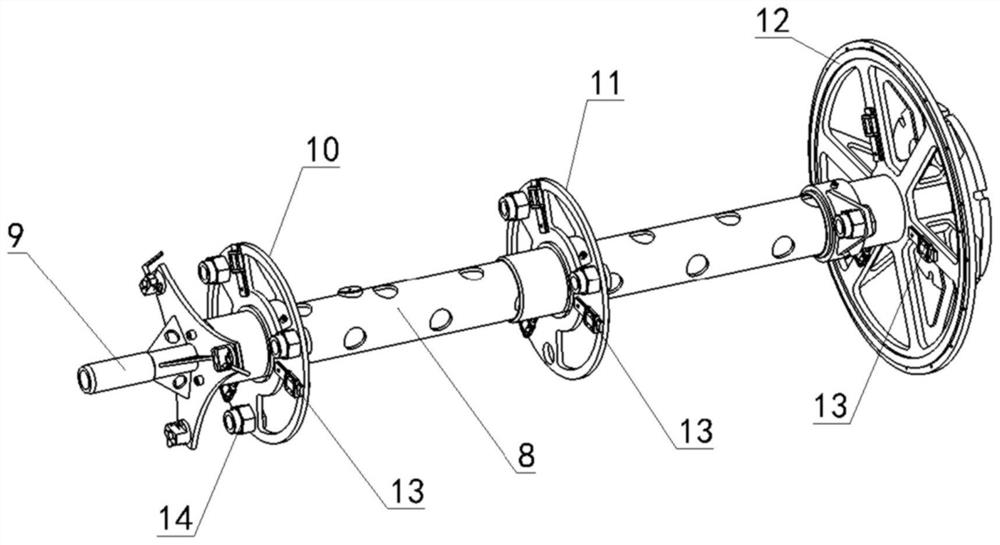

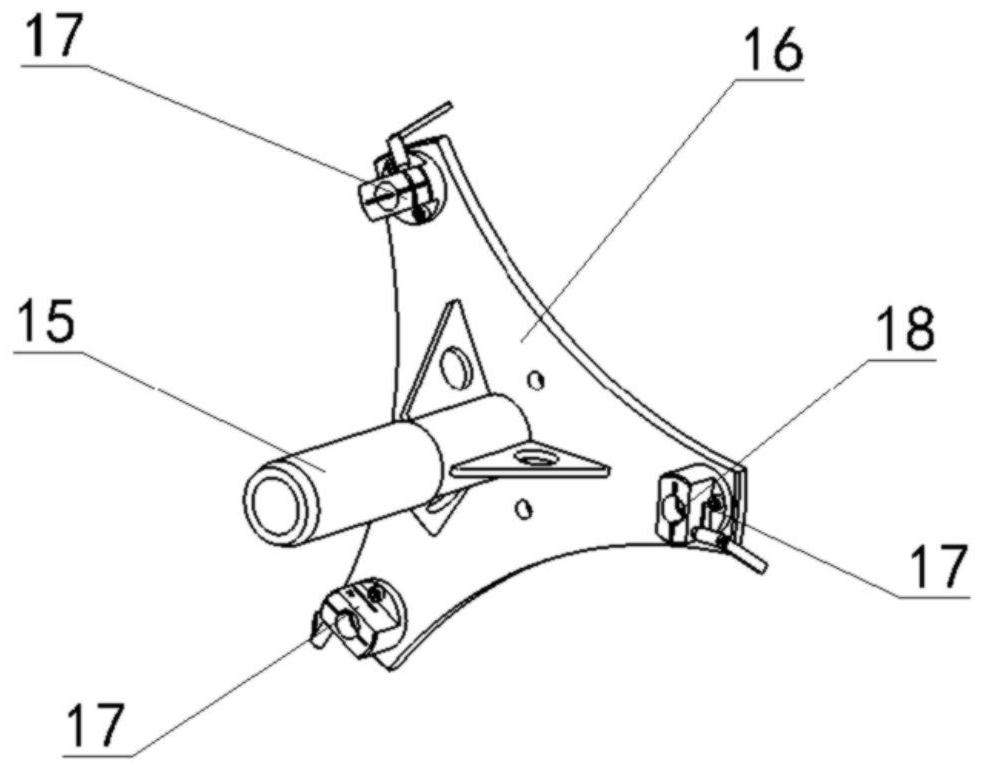

ActiveCN113579630AReliable positioning supportGuaranteed coaxiality accuracyWelding/cutting auxillary devicesAuxillary welding devicesWeld seamLaser soldering

The invention discloses an aircraft engine exhaust funnel circular seam laser welding clamp and a welding method. The welding clamp comprises a main shaft structure, an adjustable support, a positioning disc structure, a positioning disc driving mechanism and a gas protection device, one end of the main shaft structure is connected with a machine tool working rotary table, the main shaft structure is driven by a machine tool to rotate, and the other end of the main shaft structure is connected with the adjustable support; the positioning disc structure is axially sleeved on the main shaft structure and is radially connected with the main shaft structure through a sliding rail and a sliding block; the positioning disc driving mechanism is installed on the main shaft structure and drives the positioning discs of different diameters on the positioning disc structure to stretch out and draw back in the radial direction; and the gas protection device is installed on the positioning disc structure and connected with the main shaft structure, inert gas protection is provided for backs of different welding seams, and an aircraft engine exhaust funnel is sleeved and positioned on the positioning disc structure for welding. Welding of an annular welding seam is achieved through rotation of the clamp and a welded workpiece, and the formed welding seam is optimal in quality and has universality.

Owner:XI'AN AIRCRAFT INTERNATIONAL

A device for on-load testing and precision calibration of steering gear components

ActiveCN108562452BAccuracy Calibration ImplementationHigh coaxial precisionStructural/machines measurementEngine testingEngineering

The invention relates to a device for on-load testing and accuracy calibration of steering engine component, and belongs to the technical field of high-precision steering engine testing. On the basisof the steering engine component and a substrate, the on-load testing part is coaxially connected with the output shaft of the one-way steering engine to test the rated load of the steering engine successfully; the precision calibration part is coaxially connected with the output shaft of the side one-way steering engine and achieves high coaxial precision, high-precision transmission angle and torque, so that the precision calibration of the steering engine is realized; the whole device can simultaneously realize the on-load testing and precision calibration of the steering engine component,has the advantages of simple structure, high integration level and convenient operation.

Owner:BEIJING AEROSPACE GUANGHUA ELECTRONIC TECH CO LTD

The processing method of the integrated planet carrier of the rv reducer of the robot

The invention discloses an integrated machining method of a planet carrier of a robot RV reducer, and belongs to the technical field of robot RV reducer machining. The method comprises the steps as follows: forging a first casing and a second casing, and performing hot extrusion on the first casing and the second casing respectively; performing thermal refining; performing tempering; performing finish machining on end surfaces respectively; connecting the first casing with the second casing to be clamped to a clamp, and performing finish machining on inner holes formed in the first casing and the second casing with a center of gyration serving as a locating basis; performing finish machining on outer surface with the locating basis; directly machining inner rings of rolling bearings on the first casing and the second casing; accurately grinding an outer track on each inner ring simultaneously; and performing finish machining bearing positions of three tapered roller bearings on the first casing and the second casing with the location reference, and directly machining outer rings of the tapered roller bearings. With the adoption of the method, the mounting accuracy, the manufacturing accuracy and the transmission accuracy are ensured, the requirement for high accuracy is met, the service life is prolonged, machining and assembling errors and accumulative errors are reduced, the output torque is increased, and the machining cost is effectively reduced.

Owner:SHANDONG SHKE MACHINERY MFG

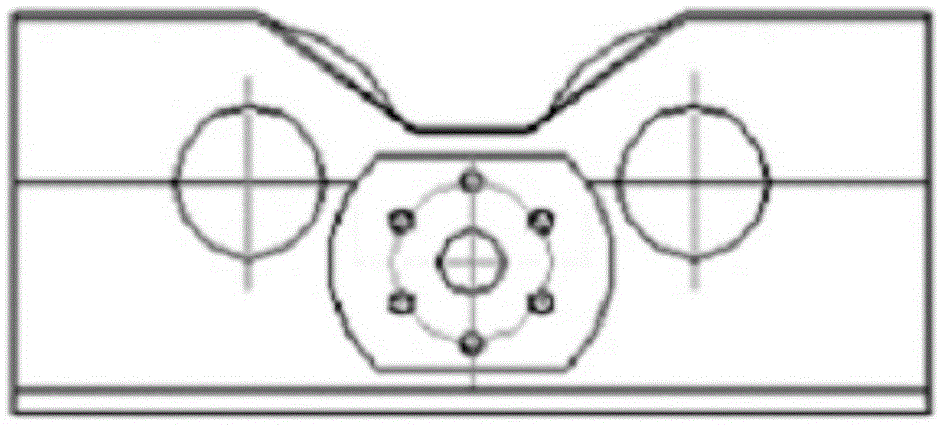

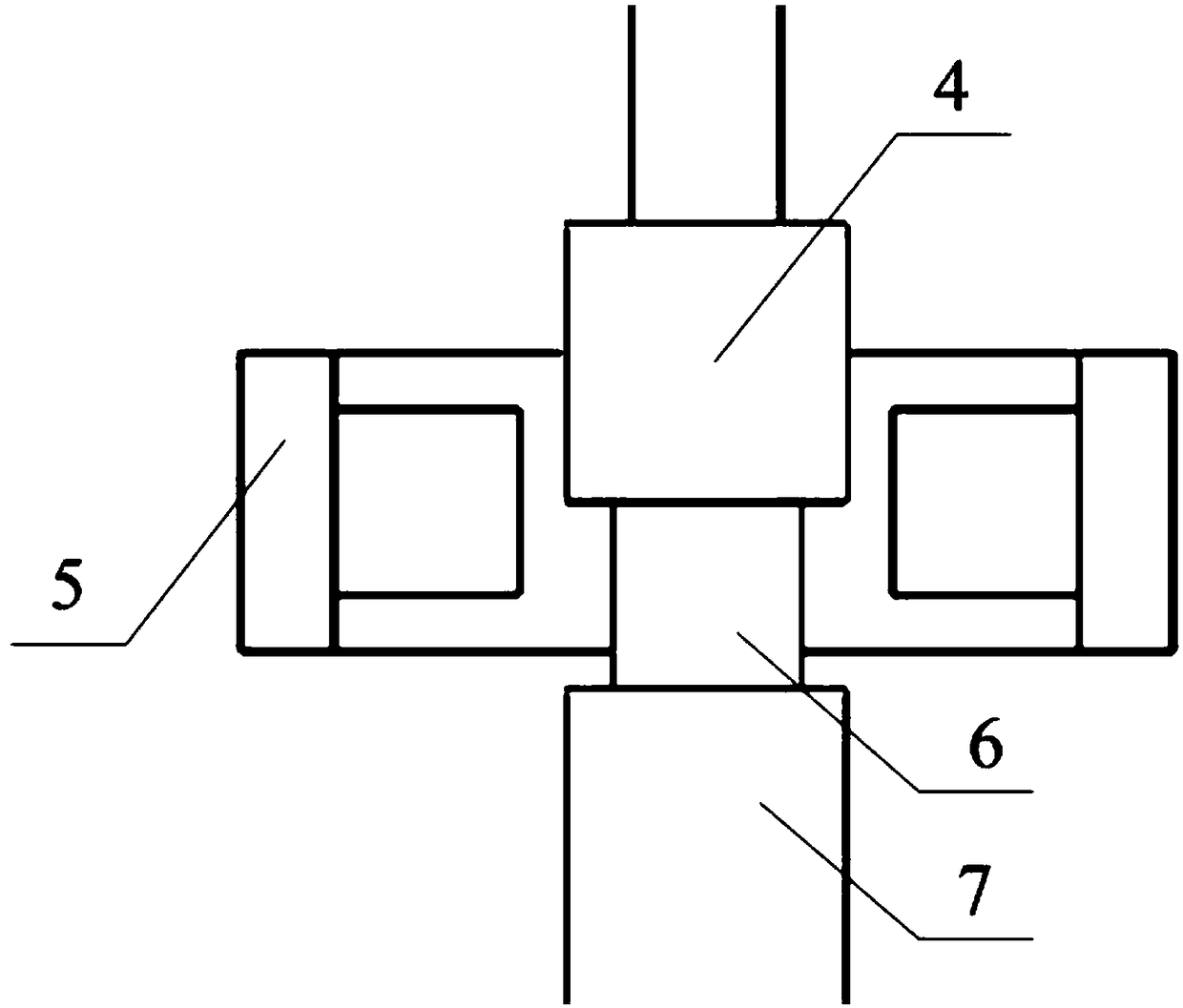

Coaxial welding positioning device

ActiveCN104722998AGuaranteed coaxiality accuracyGuaranteed positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesStructural reliabilityMechanical engineering

The invention discloses a coaxial welding positioning device. The coaxial welding positioning device comprises a body, a plurality of welding holes penetrate through the middle of the body in the radial direction of the body, the two ends of the body are a main hole end and an auxiliary hole end respectively, a main hole adapting to a main welding part penetrates through the main hole end in the axial direction of the body, and an auxiliary hole adapting to an auxiliary welding part penetrates through the auxiliary hole end in the axial direction of the body. A set bolt hole penetrates through the sidewall of the main hole end in the radial direction of the body, a set bolt matched with the main welding part is assembled in the set bolt hole, a lock screw hole penetrates through the sidewall of the auxiliary hole end in the radial direction of the body, and a lock screw matched with the auxiliary welding part is assembled in the lock screw hole. The coaxial welding positioning device can effectively guarantee the coaxiality of a shaft in an online welding process and improve structural reliability of the welded shaft.

Owner:LAIWU IRON & STEEL GRP

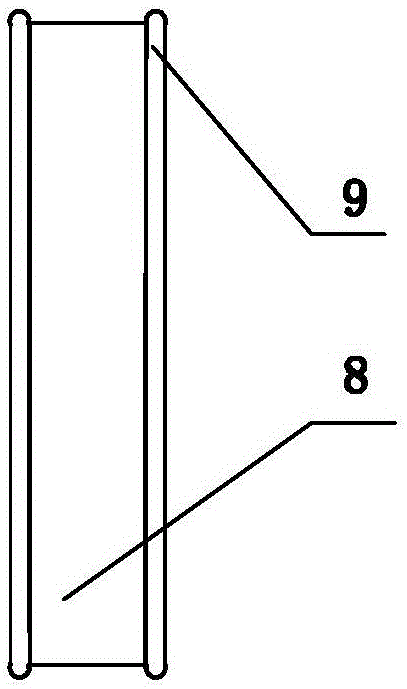

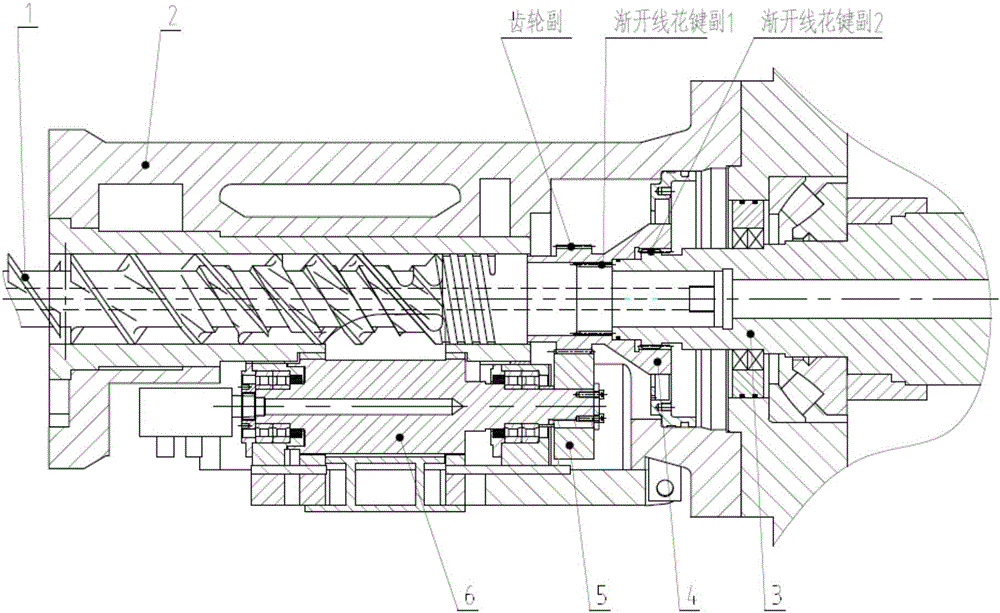

Screw rod transmission sleeve for single screw rod rubber extruder

PendingCN106239859AEasy loading and unloadingGuaranteed coaxiality accuracyInvolute gearMechanical equipment

The invention belongs to the rubber machining mechanical equipment field and relates to a screw rod transmission sleeve for a single screw rod rubber extruder. An inner involute spline at the rear portion of the transmission sleeve is matched with an outer involute spline of an reduction box hollow output shaft; an inner involute spline in the middle of the transmission sleeve is matched with an outer involute spline of an screw rod tail portion shaft neck, an outer involute gear in the front of the transmission sleeve and a feeding roll gear form a feeding roll gear pair. The transmission sleeve can achieve a direct transmission on the screw rod and the feeding roll.

Owner:QINGDAO UNIV OF SCI & TECH

The processing technology of the pin gear housing of robot rv reducer

InactiveCN103433705BSmooth runningGuaranteed coaxiality accuracyNeedle roller bearingReduction drive

The invention discloses a processing technology of a robot RV speed reducer needle gear shell, and belongs to the technical field of robot RV speed reducer processing. The processing technology includes the steps that precise casting or forging is carried out on a needle gear shell blank; the needle gear shell blank is clamped after the surface of the needle gear shell blank is machined, and the rotation center of the needle gear shell blank is taken as a positioning reference; the end face of the needle gear shell blank, a bearing position of a roller pin bearing and bearing positions of two main bearings are machined; finish machining is carried out on the inner surface of the roller pin bearing according to the positioning reference; finish machining is carried out on a roller pin groove in line contact with a roller pin of the roller pin bearing according to the positioning reference; inner grooves are simultaneously machined in the bearing positions of the two main bearings in a finish machining mode according to the positioning reference; finish machining is carried out on the outer surface of the needle gear blank. The needle gear shell machined according to the steps improves machining precision and the parallelism degree of the bearing positions of the main bearings, guarantees coaxiality, the position degree and cylindricity of the main bearings after installation, achieves one-time clamping, can meet requirements of multiple process parameters, improves machining precision and installation precision of the needle gear shell, reduces accumulated errors, meets the high-precision requirements, and prolongs service life.

Owner:SHANDONG SHKE MACHINERY MFG

Two-axis CNC boring machine

InactiveCN103286341BGuaranteed coaxiality accuracyImprove processing efficiencyTurning toolsPositioning apparatusNumerical controlTool bit

The invention provides a special double-spindle numerical-control boring machine high in precision and efficiency. The special double-spindle numerical-control boring machine comprises a body. A bench is disposed in the middle of the body, carriages are disposed on left and right sides of the body respectively, positioning clamping devices are symmetrically mounted at left and right ends of the top of the bench respectively, a boring power head is mounted above each carriage, two boring tools are mounted on each boring power head, each carriage is connected to the body through a driving device, a guard covering the whole body is disposed above the body, the middle of the guard is provided with a sliding door driven by an air cylinder, each boring tool is provided with at least one group of tool bits, and an automatic scrap discharger, an air pump device, an oil pump device and a cooling pump device are rested on the back of the body. The special double-spindle numerical-control boring machine is provided with the two boring power heads in bilateral symmetry for machining two workpieces simultaneously, each boring power head is provided with two boring tools for machining two holes of each workpiece simultaneously, and the efficiency of the special double-spindle numerical-control boring machine is ten times of that of the common boring machine. The special double-spindle numerical-control boring machine is provided with the guard and the automatic scrap discharger, the whole machining process is under control of a control cabinet, and the machining environment is closed and neat.

Owner:苏佳和

Reciprocating pump facilitating maintenance of motor shaft auxiliary supporting sliding bearing and sealing structure

PendingCN113915092AGuaranteed dimensional accuracyGuaranteed coaxiality accuracyEngine sealsPositive displacement pump componentsSlider bearingGear wheel

The invention discloses a reciprocating pump facilitating maintenance of a motor shaft auxiliary supporting sliding bearing and a sealing structure, and relates to the field of petroleum engineering equipment. The reciprocating pump specifically comprises a motor shaft auxiliary supporting seat, a sliding bearing seat, M12 screw washer sets, an elastic check ring for a hole, an inner wrapping framework rotating lip-shaped sealing ring, a sealing seat, the sliding bearing, cylinders, M16 bolts, a small sealing cover plate assembly, M12 screw holes, a positioning outer circle, a partition groove and the like. With the adoption of the structure, a gear shield and an inclined bull gear are not required to be disassembled, so that not only are the sliding bearing of an auxiliary support of a motor shaft and the inner wrapping framework rotating lip-shaped sealing ring convenient to maintain, but also the original precision of the sliding bearing and the inner wrapping framework rotating lip-shaped sealing ring is not changed after maintenance, and the service life of the sliding bearing and the service life of the inner wrapping framework rotating lip-shaped sealing ring are prolonged.

Owner:黄秀芳

Self-meshing coupling and using method thereof

ActiveCN114738393AGuaranteed coaxiality accuracyThe same amount of movementCouplings for rigid shaftsSurface toothCoupling

The invention provides a self-meshing coupling and a using method thereof.The self-meshing coupling comprises two half couplings connected through a universal fork head, and each half coupling comprises a meshing shaft assembly and a positioning shaft assembly; the biting shaft assembly comprises a transmission disc connected with the universal fork head, and the transmission disc is connected with a rotating shell. The transmission disc is connected with a lever shaft; cambered surface teeth are arranged in the rotary shell and are provided with arc-shaped grooves corresponding to the lever shafts; the cambered surface tooth is also connected with a swing shaft; the rotary shell is connected with a swing tooth sliding rail, a swing tooth groove corresponding to the swing shaft is formed in the swing tooth sliding rail, and the swing tooth groove is in a V shape. The positioning shaft assembly comprises a positioning shaft box body and a top cover which are connected with the swinging tooth sliding rail; six linkage gears are rotationally connected into the positioning shaft box body; every two linkage gears are meshed to form three meshed gear sets; a double-sided rack is meshed between any two adjacent meshing gear sets; and the side wall of the positioning shaft box body is connected with a top tooth screw. According to the invention, the coaxiality precision can be ensured, and quick connection can be realized.

Owner:潍坊水发供水集团有限公司

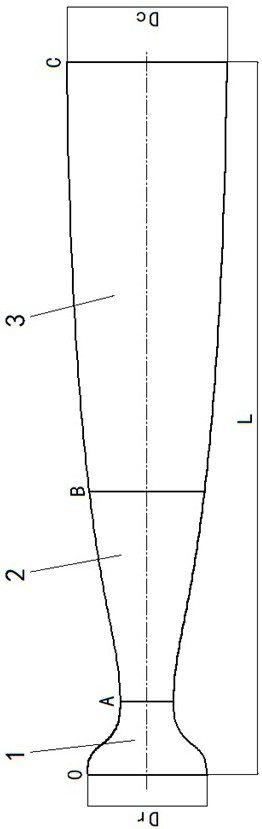

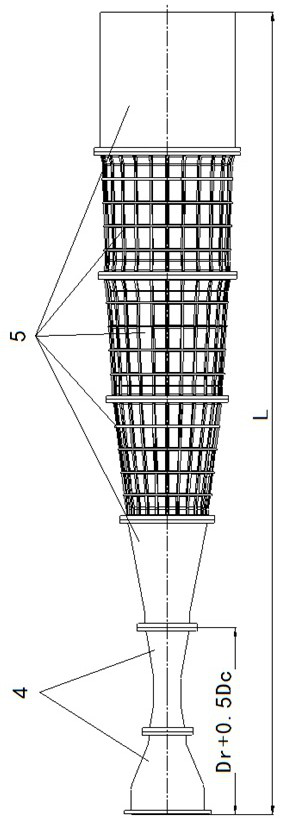

A Structural Design Method for Axisymmetric Nozzles in Hypersonic Wind Tunnels

ActiveCN114282326BReduce processing difficultyReduce manufacturing costGeometric CADAerodynamic testingClassical mechanicsMaterial selection

The invention belongs to the technical field of hypersonic wind tunnel equipment design, and discloses a structural design method for an axisymmetric nozzle of a hypersonic wind tunnel. The structural design method includes the following steps: aerodynamic segmental design, structural segmental design, processing segmental design, mechanical analysis of each segment, material selection of each segment, machining accuracy, coaxiality, step difference, roughness and gap accuracy of each segment Indicators, the cooling method of each section and the nozzle are sealed with the test section. The structural design method is a structural design method that can ensure that the axisymmetric nozzle of the hypersonic wind tunnel meets the quality requirements of the velocity field of the hypersonic wind tunnel nozzle in the national military standard; it can reduce the risk of design and processing. This structural design method has been applied in the design of axisymmetric nozzles in hypersonic wind tunnels of Ф0.5m, Ф1m and Ф2m levels, and the obtained maximum Mach number deviations in the uniform velocity field of the nozzles are all less than 1 %, meeting the requirements of the national military standard.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

Processing device and processing method for assembly hole at root of inner cavity side wall of composite material component

ActiveCN108115532BReduce volumeIncrease speedGrinding drivesGrinding machinesDegrees of freedomCantilever

Owner:沈阳大工先进技术发展有限公司

A special positioning fixture for assembling sapphire crystal rods

ActiveCN102965737BImprove smoothnessGuaranteed coaxialityAfter-treatment detailsEngineeringMachining

The invention provides a special positioning fixture for assembling a sapphire crystalbar, which comprises a grip, a screw rod, a positioning apex, a bracket, a platform, an axial positioning base and a crystalbar excircle radial positioning angle plate, wherein the crystalbar excircle radial positioning angle plate implements positioning connection by inserting two positioning pins into two positioning holes in the axial positioning base. The invention has the characteristic of high crystalbar assembling coaxiality and the like, can reduce the required reserved machining allowance to ensure the machining accuracy, and can obviously enhance the subsequent machining efficiency.

Owner:哈尔滨秋冠光电科技有限公司

Assembly method of joint module and joint robot

PendingCN114654501AImprove installation reliabilityGuaranteed coaxiality accuracyJointsReduction driveControl engineering

The invention discloses a joint module assembly method and a joint robot, and the joint module comprises a motor assembly which comprises a shell, a motor stator and a motor rotor, and the shell is provided with a mounting cavity with an opening in one end; the speed reducer is mounted at the open end of the motor assembly; the supporting bearing comprises an inner ring and an outer ring which are rotationally matched, and the outer ring is fixedly matched with the opening end of the shell through threads; the speed reducer further comprises a flexible bearing and a flexible transmission wheel. One end of the flexible transmission wheel extends into the mounting cavity and is folded outwards in the radial direction to form an outer flange. A supporting step is arranged in the mounting cavity and abuts against the outer flanging. The assembly method of the joint module comprises the steps that the current pressure between the supporting step and the turned-over edge is obtained; comparing the current pressure with a preset pressure range; and determining that the current pressure exceeds a preset pressure range, and adjusting the axial relative position of the outer ring and the shell so as to enable the current pressure between the supporting step and the outer flange to be within the preset pressure range. According to the joint module, the transmission reliability of the joint module can be improved.

Owner:深圳市零差云控科技有限公司

Assembling tool and method for magnetic suspension bearing rotor

PendingCN110277884AThe process is simple and convenientHigh rotor coaxiality and position accuracyManufacturing stator/rotor bodiesPetroleum engineering

The invention belongs to the technical field of magnetic suspension bearings, and particularly discloses an assembling tool and method for a magnetic suspension bearing rotor. The assembling tool comprises a support seat, a first oil cylinder and a second oil cylinder. The first oil cylinder is connected with a rotor assembly structure, and the second oil cylinder is connected with a sleeve pushing structure. The rotor assembly structure comprises a positioning sleeve used for assembling a rotor. A positioning cylinder which is the same as the sleeve in shape and size is arranged at the axis of the positioning sleeve. A first telescopic rod of the first oil cylinder is fixed with the positioning cylinder through a small-diameter part. The sleeve pushing structure comprises a cylindrical sleeve fixing part for pushing the sleeve to a large-diameter part, and a fixing hole matched with the sleeve in shape is formed in the axis of the sleeve fixing part. A push block capable of moving in the axial direction of the fixing hole is arranged at the outer side of the sleeve fixing part; and the push block is fixedly connected with a second telescopic rod on the second oil cylinder. There is no need of heating for rotor assembly, the process is simple and convenient, the coaxiality and the position precision of an installed rotor are high, and the stripping is convenient.

Owner:TIANJIN TIANGU MECHANICAL MFG

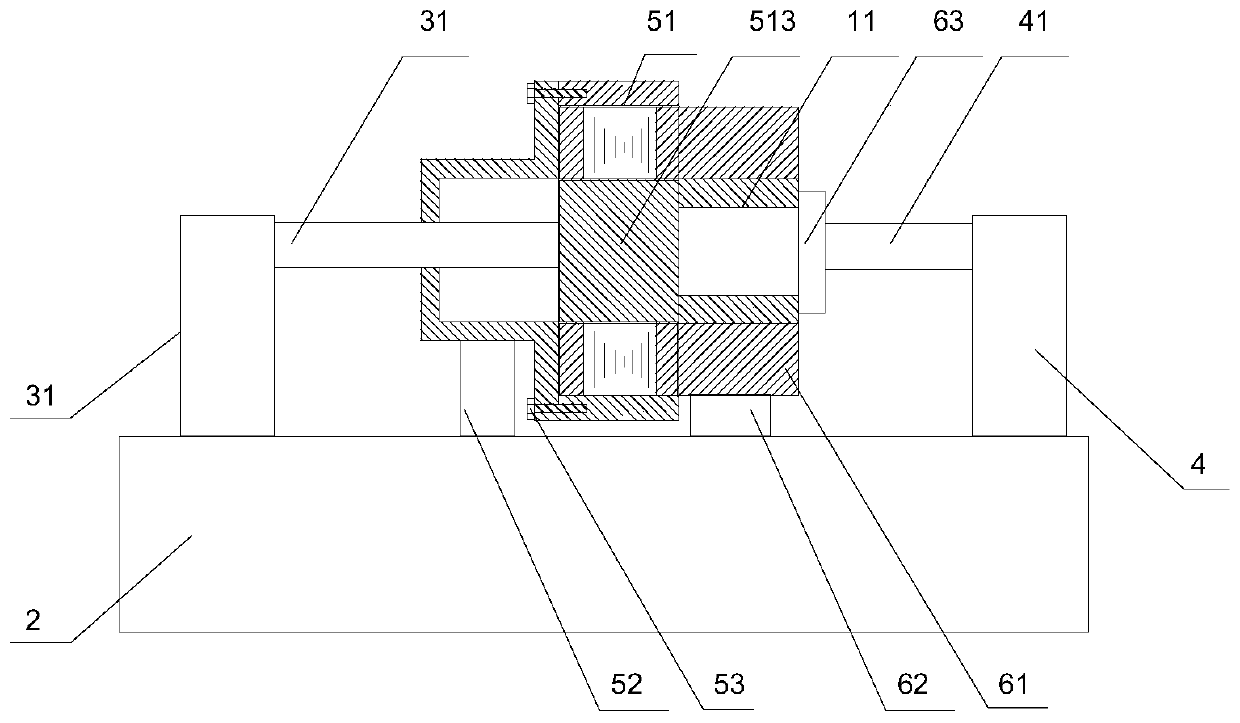

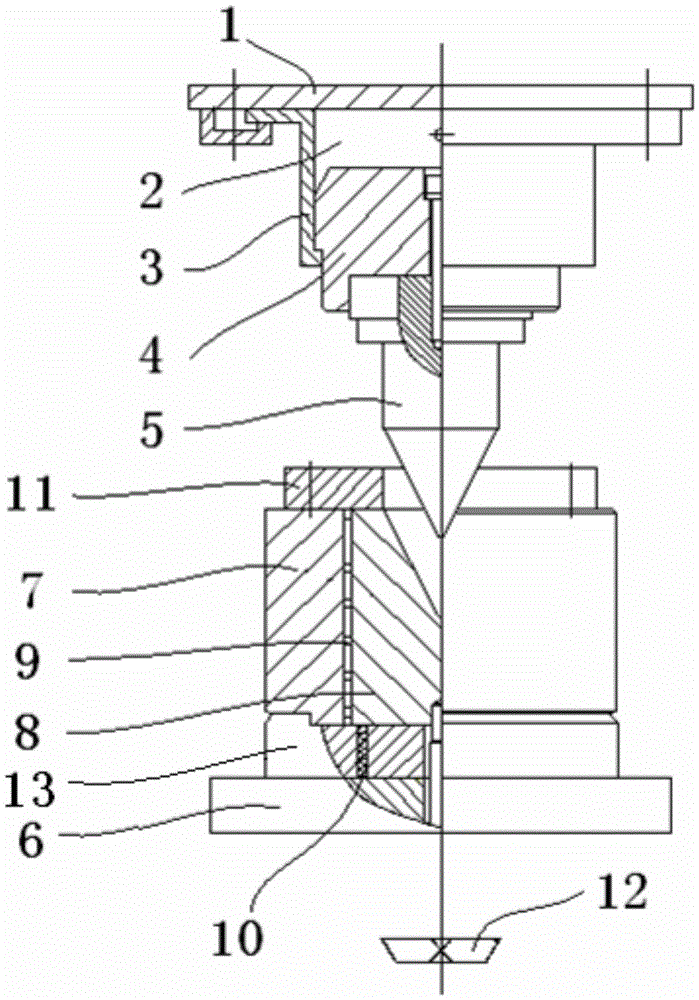

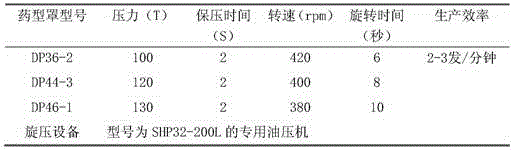

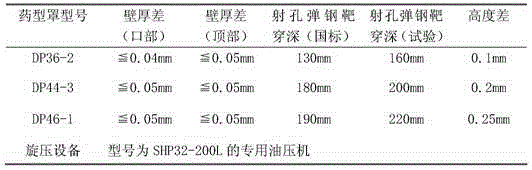

A kind of spinning forming device of powder drug type cap

The invention relates to a spin-forming device for a powder liner. The device comprises an upper module and a lower module, wherein the upper module comprises an upper template and a male die; the lower module comprises a lower template and a female die; the male die is arranged on the upper template through a floating device; the female die is arranged on the lower template through a low-spin friction device. According to the device, floating male die and adjustable air cushion structures are adopted, so that an original powder charging state can be changed, and powder can be uniformly distributed according to die cavities of the dies; a ball bushing and an elastic support device are adopted for the female die, so that the spinning resistance of the female die is greatly reduced, higher dynamic positioning accuracy and spinning stability are ensured, the flowability of metal powder can be improved, and the uniformity of circumferential density of the liner can be improved; in addition, the working accuracy of the dies is ensured, and requirements on key technical indexes of the liner are met.

Owner:NORTH SCHLUMBERGER OILFIELD TECH XIAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com