SHPB device and method for achieving ultra-high controllable strain rate impact

A strain rate and fixing device technology, applied in the field of material dynamic mechanical properties research, can solve the problems of repeated calibration, low debugging work efficiency, and difficult to determine the corresponding relationship, so as to reduce device cost and processing difficulty, improve debugging work efficiency, The effect of ensuring the coaxiality of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

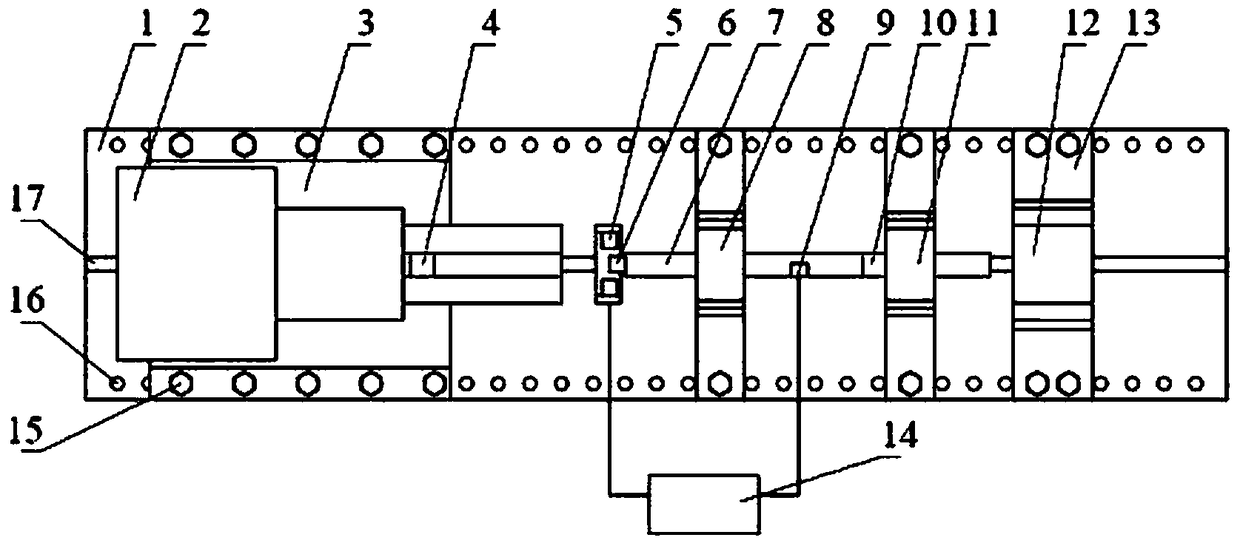

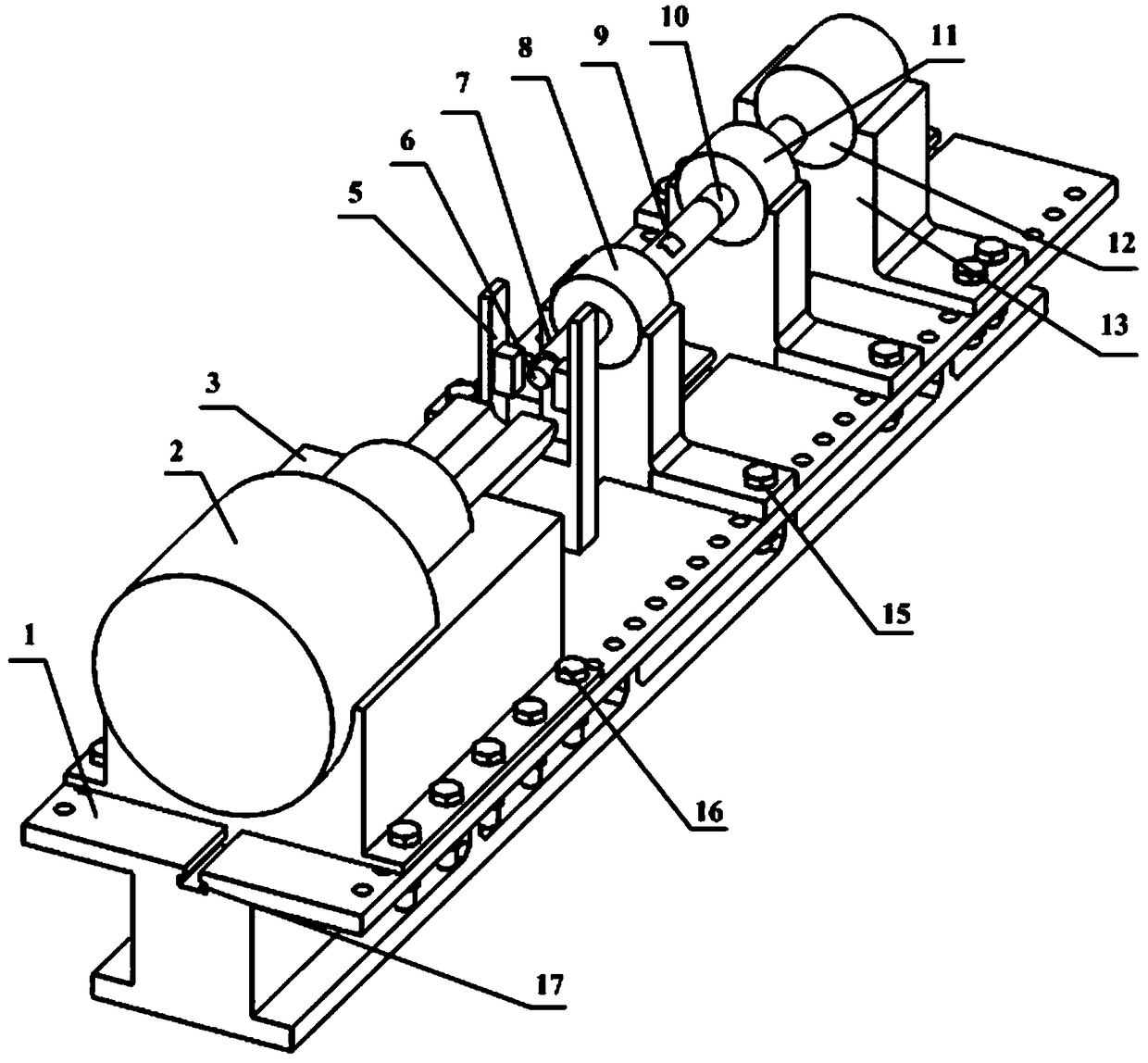

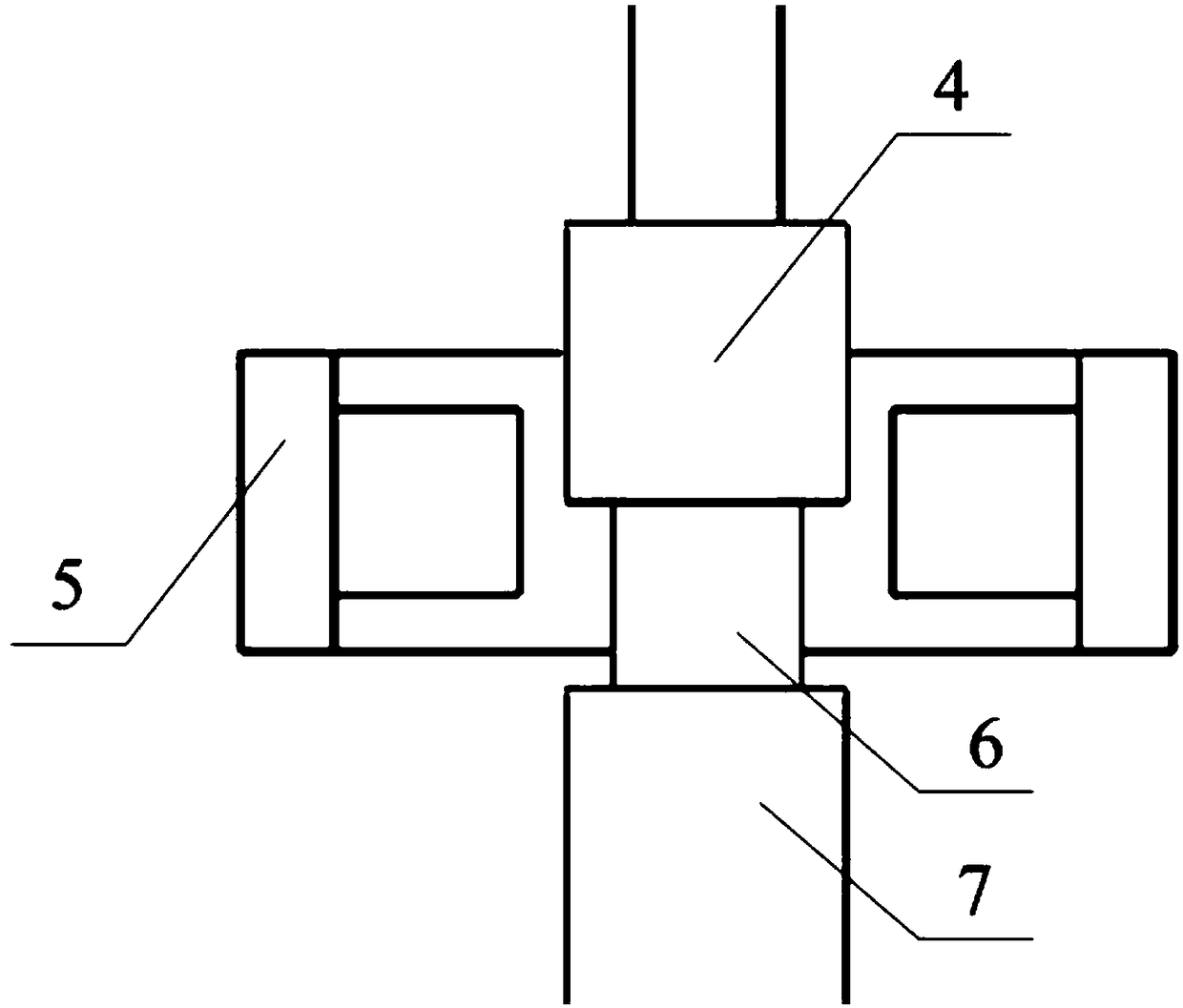

[0018] The present invention is a SHPB device and method for realizing ultra-high controllable strain rate impact, comprising a guide rail 1 with a T-shaped groove, a light gas cannon loading mechanism 2, a light gas cannon base 3, a marble 4, and a magnetoelectric particle velocity Measuring device 5, test piece 6, output rod 7, output rod fixing device 8, strain gauge 9, absorbing rod 10, absorbing rod fixing device 11, damper 12, damper fixing device 13, data processing system 14 and other structures, among which , light gas gun base 3, marble 4, magnetoelectric particle velocity measuring device 5, test piece 6, output rod 7, output rod fixing device 8, strain gauge 9, absorbing rod 10, absorbing rod fixing device 11, damper 12 , The damper fixing devices 13 are distributed sequentially along the axis.

[0019] The magnetoelectric particle velocity measuring device 5 is located between the test piece and the light gas cannon loading mechanism 3. When the marble 4 hits the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com